#hdipcb

Explore tagged Tumblr posts

Text

Discover the benefits of HDI PCB technology and its impact on modern electronics. This guide explains what HDI PCBs are, their advantages over traditional PCBs, and their applications in high-performance devices. Learn how HDI PCBs enhance functionality and design flexibility. For more details: https://www.lioncircuits.com/

0 notes

Text

#MacDermid Alpha Electronics Solutions#thermalmanagement#5G#automotive#computingapplications#HDIPCBS#Electronics#PCBManufacturing#Semiconductors#electronicsnews#technologynews

0 notes

Text

🚀 PCB üretiminde kalite tesadüf değildir! Elektronikte başarının temeli, yüksek kaliteli ve güvenilir PCB çözümleridir. Qtech olarak; katmanlı yapıların hassas üretiminden, BGA & SMT montajına, empedans kontrollü sinyal iletiminden, sertifikalı kalite süreçlerine kadar her adımda mükemmelliği hedefliyoruz. 📌 Peki, “Yüksek kaliteli PCB üretimi nasıl olmalı?” ✔️ PCBA nedir? ✔️ Hangi testler kaliteyi garantiler? ✔️ Hangi malzemeler tercih edilmeli? ✔️ Fiyat/kalite dengesi nasıl kurulmalı? 👉 Tüm bu soruların yanıtlarını ve çok daha fazlasını detaylıca anlattığımız rehber niteliğindeki makalemizi buradan okuyabilirsiniz: 🔗 https://qtech-us.com 📞 Daha fazla bilgi ve iş birliği için: 📧 [email protected] #pcbüretimi #pcbnedir #pcbanedir #qtechpcb #elektroniküretim #yüksekkalite #baskılıdevrekartı #hdipcb #smtmontaj #bga #empedanskontrolü #kalitekontrol #rohsuyumlu #iso9001 #çevredostüretim #teknolojidekalite #endüstriyelelektronik #güvenilirpcb #arge #elektronikmühendisliği

#çevre dostu üretim#baskılı devre kartı#bga montajı#elektronik üretim#elektronik montaj#empedans kontrollü pcb#güvenilir pcb üreticisi#hdi pcb#iso belgeli üretim#pcb üretimi#pcb kalite kontrol#pcb malzeme seçimi#pcb nedir#pcb prototipleme#PCB tasarımı#pcb test süreçleri#pcba nedir#qtech pcb#SMT montaj#yüksek kaliteli pcb

0 notes

Text

Laser Direct Imaging Equipment Market

The global Laser Direct Imaging (LDI) Equipment market was valued at 678.44 Million USD in 2021 and will grow with a CAGR of 2.4% from 2021 to 2027.

Get Free Research Report Sample PDF: https://cutt.ly/k0wxUTK

#imagingequipment#imagingequipmentmarket#laser#laserdirectimagingequipment#polygonmirror#dmd#hdipcb#icsubstrate#multilayerpcb#marektresearch#marketresearchreport#marketresearches#lifesciences#lifesciencesmarket#equipment#statsmarketresearch

0 notes

Link

What are Staggered, Stacked and Skipped #Microvias in #hdipcb? https://madpcb.com/microvia/ #microvia #μVia #laservia #laserablatedvia #MADPCB #pcb #printedcircuitboard

#microvia#μVia#Laser Ablated Via#Laser Via#MADPCB#PCB#printed circuit board#hdi pcb#microvias#micro via#staggered microvias#stacked microvias#skipped microvias

0 notes

Text

What is Blind microvia

Increase The Integration Density of PCB by filling blind microvia and through holes using electrolytic copper deposition.

The progressive miniaturization of electronic circuits increasingly requires the use of HDI circuit boards with copper-filled blind microvias. A newly developed copper electrolyte, which is currently being tested under production-related conditions, enables defect-free filling of blind microvias with a small copper layer thickness on the circuit board surface. A copper electrolyte currently in development should also enable the reliable filling of through holes in the future – the current development work is already showing promising results.

Filling of Blind Microvia and Through-holes

Increasing the Packaging Density of PCBs by Filling of Blind Micro-vias and Through-holes by Electrodeposition of Copper.

The increasing miniaturization of electronic circuits makes the use of HDI PCB (HDI printed circuit boards) with copper-filled blind micro-vias, increasingly desirable. A newly-developed copper electrolyte, currently under test in simulated production conditions, will enable defect-free filling of blind micro-vias while at the same time allowing reduced copper deposit thickness on the board surface. This brings with it a more efficient use of materials her and thus a reduction in the cost of PCB manufacture. Another copper electrolyte now under development promises to allow a reliable filling of through-holes.

1 Introduction

In microelectronics, there is still a trend towards miniaturization, that is, towards smaller and more powerful systems that are also supposed to be less expensive than previous systems. The best-known examples of this are smartphones and tablet PCs, the performance of which – in spite of the same or even smaller device size – has increased significantly in recent years.

HDI printed circuit boards (HDI: High Density Interconnect) make a significant contribution to miniaturization. For the electrical connection of individual PCB layers, space-saving blind holes (blind microvias) are used instead of through holes. The integration density can be further increased by filling the blind microvias with electrolytically deposited copper (blind microvia filling). In the meantime, the use of HDI circuit boards is no longer restricted to mobile electronics, but is also increasingly being used in other applications, for example in the automotive sector.

A newly developed electrolyte, which in the Blind Microvia Filling only deposits a very small layer thickness of copper compared to the previous generation of electrolytes, enables the resource, energy and cost-efficient production of HDI printed circuit boards.

Since the integration density of HDI printed circuit boards can be increased even further by using very thin core materials, the development of electrolytes for filling through holes (English: Through Hole Filling) is currently being strengthened. Results of the development work in this area are presented.

2 Miniaturization in the field of microelectronics

The best known representatives of the progressive miniaturization in microelectronics are the very powerful mobile devices such as smartphones and tablets. The high and constantly growing sales figures reflect the great attractiveness of these devices. In 2013, more than 1 billion smartphones were sold for the first time, sales of around 1.2 billion are expected in 2014 and around 1.8 billion in 2017 [2]. In the area of tablet PCs, sales of 271 million devices are predicted for 2014, which corresponds to an increase of almost 40% compared to the previous year [3].

These are installed in processors with very small housing sizes and a very large number of increasingly grid-like connections. The underside of the processor has 976 connections on an area of just under 2 cm², this corresponds to around five connections per square millimeter. The pitch of the connections is only 400 µm.

3 Miniaturization in the area of printed circuit boards

Printed circuit boards with a correspondingly high integration density are required for space-saving and reliable electrical connection of processors with extremely high connection densities. The classic multilayer printed circuit board is unsuitable for this, however, since it uses through holes for the electrical connection of individual printed circuit board layers. These have relatively large diameters and, since they are drilled only after the individual layers have been pressed, they extend over the entire circuit board thickness. The consequence of this is that even when directly adjacent layers are connected, the space above and below the actual connection is lost and therefore cannot be used for other structures, for example, conductor tracks. The resulting low integration density of multilayer circuit boards is not sufficient for the requirements described above.

A few years ago, a new, highly integrated generation of printed circuit boards, the so-called HDI circuit board, was therefore developed, which was initially used primarily for the production of mobile phones. When manufacturing HDI printed circuit boards, the individual printed circuit board layers are built up successively (SBU, Sequential Build Up). The electrical connection of adjacent assembly positions is realized using laser-drilled blind microvias. Figure 2 shows schematically the structure of a 2-4-2 HDI circuit board, i.e. the circuit board consists of a four-layer multilayer core and two layers on each side.

4 Blind microvia

Compared to through holes, blind microvias have smaller diameters in the range from 50 µm to 150 µm and they only extend in the z-direction over the thickness of a mounting position (typically 50 µm to 150 µm). They only take up as much space as is actually required for the actual connection. HDI printed circuit boards thus have a much higher integration density than multilayer printed circuit boards and are therefore suitable for the signal unbundling of highly functional electronic components in the smallest space.

4.1 Filling blind microvia

A further increase in the integration density enables stacked blind microvias (stacked blind microvias). If electrolytically deposited copper is used for filling instead of conductive paste, this leads to the following further advantages:

Increased reliability (the blind microvias only contain copper, there is no additional interface) better heat management (heat loss can be dissipated via the highly heat-conductive, copper-filled blind microvias) Further increase in integration density (no additional pads (pads) are required on the circuit board surface for contacting components) The main process steps in the manufacture of HDI circuit boards with copper-filled blind microvias are shown schematically in Figure 4. If a further layer is to be built up, the process sequence must be run through again starting with process step 2.

Stacking copper-filled blind microvias on top of each other means that even non-adjacent assembly positions can be connected in an electrically conductive manner with minimal space requirements (Fig. 5). The use of pad-in-via or via-in-pad designs leads to a further increase in the integration density, since component connections can be soldered directly onto the copper-filled blind microvias, so that no additional connection surfaces are necessary (Fig. 6).

4.2 Previous electrolytes for blind microvia filling

Typically, electrolytes for blind microvia filling contain a relatively high concentration of copper ions in the range from 40 g / l to 60 g / l in combination with a low sulfuric acid concentration in the range from 10 ml / l to 50 ml / l as well as chloride ions. The organic electrolyte additives required to control the coating properties differ from specialist company to specialist company, but mostly the following three components are contained in the electrolyte additives:

Basic additive (inhibitor) Grain Refiner (Activator) Leveler (inhibitor) In addition, the methods of the different providers can also differ in the following features:

System technology (standard vertical system, vertical continuous system, horizontal continuous system) Anode type (copper anode, insoluble anode) Current form (direct current, pulse current, reverse pulse current) applicable current density

The methods previously offered by Schlötter for blind microvia filling work exclusively with direct current in standard vertical systems or vertical continuous systems.

In the early years of blind microvia filling, there were essentially the following additional requirements in addition to the standard requirements for electrolytically deposited copper coatings for printed circuit boards (e.g. ductility, reliability):

defect-free filling of the blind microvias without electrolyte inclusions Minimum filling level or the maximum allowed deepening (dent.

During the filling process, 93 µm copper (B) was deposited in the blind microvia, while the layer thickness on the surface is only 22 µm (C), resulting in the following key figures:

Indentation (A-B): 30.4 µm

Degree of filling (B / A): 75%

Metal distribution (B / C): 426%

It is primarily due to the mode of action of the leveler, by means of which the copper is not deposited on the surface but rather in the blind microvias, i.e. in the areas of low current density and low electrolyte exchange.

To achieve a good filling result, the electrolyte additives must be very well coordinated. Figure 8a shows a blind microvia before the filling process as well as different results, which can only occur through variation of the electrolyte additives – with otherwise the same separation parameters (Fig. 8b – e).

4.3 New electrolyte for blind microvia filling

The integration density of the circuit boards can be increased even further by reducing the track width and spacing. For the etching of such fine conductors, however, the copper layer thickness on the surface must be low, since otherwise severe undercutting and problems with the conductor cross-section can occur.

As shown in Figure 4, the copper layer thickness can be reduced after filling with – possibly repeated – copper thinning, but additional process steps and systems are necessary for this. In addition, copper thinning of copper that was previously deposited is partially removed, which has a negative impact on resource, energy and cost efficiency in the manufacture of printed circuit boards. To completely avoid – or at least to reduce – the copper thinning, in addition to the requirements already mentioned, the requirement to deposit the smallest possible copper layer thickness during the filling process has been added in recent years.

50-70 mg / l chloride

3–10 ml / l additional slotocoup SF 31

0.2–1.0 ml / l additional slotocoup SF 32

0.2–2.0 ml / l additional slotocoup SF 33

The electrolyte is operated at current densities of maximum 2 A / dm² in the temperature range between 18 ° C and 22 ° C.

Compared to the previous generation of electrolytes, the copper layer thickness deposited on the surface could be extremely reduced. This is shown by the metal distribution, which in the laboratory test shown has an extremely high value of over 2000% (Fig. 9b).

Slotocoup SF 30 is currently being tested in cooperation with the Taiwanese Schlötter partner AGES in the PCB Development Center in Taipei opened in 2012 under production-related conditions in a 7200-liter vertical continuous system (Fig. 10).

Deepening: 7.0 µm

Degree of filling: 91%

Metal distribution: 740%

Figure 11b shows another copper-filled Blind Microvia, which comes from the same circuit board as the Blind Microvia in Figure 11a. It is noteworthy that, despite the non-optimal BMV geometry, the filling result is very good.

Slotocup SF 30 also enables defect-free filling of closely spaced blind microvias with a low layer thickness of the copper surfaces.Fig. 12: Slotocoup SF 30 test results when filling closely spaced blind microvias

Very flat blind microvias, which result when extremely thin dielectrics are used, can also be filled defect-free with the new electrolyte, but this results in somewhat higher copper layer thicknesses (Fig. 13).

5 Through Hole Filling

A further increase in the integration density of HDI printed circuit boards can be achieved by replacing the relatively thick multilayer cores that have been used up to now with significantly thinner cores with thicknesses between 100 µm and 200 µm.

Very thin cores can also have through holes instead of blind microvias. Previously, these through holes were first filled with paste after the first copper plating and then copper-plated again to produce the pads. In addition, the use of the paste can lead to reliability problems.

5.1 New electrolytes for through hole filling

Initially, attempts were made to use the copper electrolytes that had already been tried and tested in blind microvia filling in the area of through hole filling. However, it was shown that these electrolytes are not suitable for this application so that further development work was necessary. Some laboratory results from the current development work are shown in Figure 16.

By modifying the electrolyte composition, it was possible to significantly improve the filling of through holes (approx. 85 µm borehole diameter / approx. 110 µm borehole depth). All four depositions shown in Figure 16 were each carried out with direct current with the same deposition time and current density. In addition, only one electrolyte was deposited during the entire deposition period, i.e. there was no electrolyte change in the course of the deposition.

With increasing aspect ratio, i.e. decreasing borehole diameter and/or increasing borehole depth, the mass transport and thus the subsequent delivery of copper ions is made more difficult. As a result, defect-free filling of the through holes without electrolyte inclusions is becoming increasingly difficult. Figure 17 shows two filling results of non-preamplified through holes (approx. 50 µm borehole diameter / approx. 160 µm borehole depth).

The electrolyte enclosed in the defect (Fig. 17a) expands when the HDI circuit board is heated and can therefore already lead to a crack in this connection during the soldering of components or when the temperature is subsequently increased, which can lead to a system failure. The focus of the current development work is, therefore, the reliably defect-free filling of through holes with different aspect ratios (Fig. 17b).

6 Inconclusion

Due to their high integration density, HDI printed circuit boards enable reliable unbundling of the high connection densities of these microprocessors in the smallest space.

By filling blind microvias with electrolytically deposited copper, the integration density of HDI printed circuit boards can be further increased. The newly developed electrolyte Slotocoup SF 30, which is currently being tested in Taiwan under production-related conditions, enables defect-free filling with a low copper layer thickness. This leads to a further increase in the integration density and to a more resource, energy and cost-efficient production of HDI printed circuit boards. The first installation at a customer is scheduled for the second quarter of 2014.

The integration density can be increased even further by means of so-called coreless structures, which consist of very thin core materials. Results of current development work show that direct current deposition of copper makes it possible in principle to fill the through holes in these cores. Since the filling result and thus the quality of the connection depends on the aspect ratio of the through-holes, the realization of a reliable defect-free filling with different aspect ratios is currently in the foreground of the development work.

For further info about Blind microvia, you can also visit https://www.mokotechnology.com/blind-microvia/

0 notes

Link

0 notes

Text

AKEN profile.china pcb manufacturer

AKEN zhang

International PCB Board senior Sales Manager

graduated from Sun Yat-Sen UniversityShenzhen City, Guangdong, China

1--normal pcb boards with through hole; 2--special pcb board(HDIpcb/bury/blind hole pcb); 3--2-20L pcb board/metal pcb/others material pcb boards; what ability AKEN have ? 1--good communication; 2--details of sales oriented; 3--high knowledge of PCB and importing&exporting knowledge; 4--be familiar with international importing law; 5--fast response(quotation never exceed 4hours reply to you) discuss with AKEN, 1--you will get the better price; 2--you will be guide how to save more cost which purchase pcb from China; 3--you never need to worry about quality control,lead time control,after-sales guarantee; 4--you never worry about how i get the goods from China; 5--you will get free sample policy from AKEN; However,we only focus on long term cooperation!

0 notes

Text

China PCB market share keeps rising

HDIPCB supply of China accounts for 26% of total supply of 10,200 million dollars in the world. Taiwan circuit board association (TPCA) Investigation data display,create to last 2,660 million dollars China HDIPCB market 2008, last 15.4% compared with the same period of last year, and is expected in 2009 it is worth 11,200 million dollars that the global HDIPCB market will created. Though the gliding of global economy causes the step of this trade to slow down, the market share of China will keep the situation of rising.

With the constant enlargement of China PCB products application area, HDIPCB is expected to realize the growth of most high supply in all PCB products, the active market of mobile phone will promote this to only account for the industry of 1/4 of the proportions of China PCB trade to develop rapidly. Nearly 90% of the mobile phones in the world adopt HDIPCB, among them the majority comes from China, so China HDIPCB industry is expected to expand rapidly in a short time.

Besides the telecommunication products, HDIPCB can also be applied to the computer, consumption electron and car products extensively, the adoption rate of the medical treatment, industry and military field is rising continuously. Chinese enterprises will throw in more attention the high profit application when the market of mobile phone slump in demand.

In order to satisfy the miniaturization trend of the electronic product, HDIPCB researches and develops and is directed primarily to the precision, density which improves the products, reduces the line thickness / distance. It is Φ 0.1mm that the large-scale manufacturer plans to expand the aperture, it is in measured line spacing for 2mil, interlaminar tolerance in alignment for 3mil and impedance control limit in + /- tri-layer more than of the production of HDIPCBs two-sideds within 5%.

Chinese manufacturer can offer 1+N +1, 2+N +2 and 3+N +3HDIPCB, among them 2+N +2HDIPCB is a mainstream, 3+N +3HDIPCB used mainly in 3G mobile and other advanced electronic products. Ultrasonic printed plate Company of Shantou (ChinaCircuitTechnology (Shantou) Corp) , general forest circuit Co., Ltd. (TianjinPrintronicsCircuitCorp) of Tianjin And up right and foursquare circuit board (FounderPCB) Wait for a gleam of company but +1, the intersection of 2+N and +2 and 3+N +3HDIPCB, 1+N of quantity production. The small-scale manufacturer mainly produces major 1+N +1HDIPCB, some medium-sized manufacturers can offer 2+N +2HDIPCB.

0 notes

Text

Türkiye’nin hızla gelişen elektronik sektöründe pcb üretimi kritik bir rol oynuyor. Qtech Technology, pcb türkiye alanında yüksek kaliteli malzeme seçimi ve ileri teknoloji kullanımıyla fark yaratıyor. Bu kapsamlı makalemizde, PCB üretiminde kullanılan malzemeler ve yenilikçi teknolojileri detaylarıyla ele aldık. Siz de üretim süreçlerinizi güçlendirmek ve rekabet avantajı yakalamak istiyorsanız, Qtech Technology ile işbirliği yapmanın tam zamanı! 🔗 Detaylı bilgi ve işbirliği için makalemizi okuyun ve geleceğin teknolojisine birlikte yön verelim. #pcb #pcbÜretimi #pcbTürkiye #elektronik #teknoloji #qtechtechnology #üretim #yenilikçi #ArGe #elektroniktasarım #elektroniksektör #PCBFabrikası #çokkatmanlıpcb #esnekpcb #HDIpcb #elektronikmontaj #kalitekontrol #teknolojigelişimi #yeniüretimteknolojileri #işbirliği

#çok katmanlı pcb#baskılı devre kartı#elektronik üretim#elektronik devre#esnek pcb#hdi pcb#PCB#pcb arge#pcb üretimi#pcb fabrikası#pcb imalatı#pcb kalite kontrol#pcb malzemeleri#pcb montaj#pcb sektör#PCB tasarımı#pcb türkiye#pcb teknolojileri#pcb test

0 notes

Text

📢 PCB teknolojisi her geçen gün evriliyor! Yeni makalemde, pcb üretiminde yeni malzeme trendleri, yüksek yoğunluklu bağlantılar, ısı yönetimi, flex yapılar, ve Türkiye’nin yükselen üretim kapasitesi hakkında detaylı bilgiler verdim. Elektronikte geleceği yakalamak isteyen tüm üretici ve tasarımcılar için rehber niteliğinde! 📌 Okuyun, paylaşın, dönüşümde yerinizi alın: #PCB #PCBA #QtechTechnology #ElektronikÜretim #FlexPCB #HDIPCB #Endüstri40 #PCBÜretimi

#aoi#flexible pcb#hdi pcb#PCB#pcb üretimi#pcb nedir#pcb türkiye#pcba#pcba üretimi#pcba türkiye#Qtech Technology#SMT#termal yönetim#yüksek frekanslı devre#yeni nesil pcb

0 notes

Text

What is HDI PCB?

Do you remember IBM Simon? You can consider it the father of smartphones. The Simon phone has 38 mm thickness and almost 510g weight. So it was impossible to place in the pocket. On the other hand, look at today’s smartphone. You can easily put them in your pocket. And the reduction in the size of a smartphone is due to the HDI PCB. The purpose of HDI technology is to make devices smaller, thinner, and lighter as well.

So do you want to learn HDI PCB? This article gives you a clear idea about what is HDI circuit boards. So we will cover its features, benefits, and applications, etc. After completing this article, you will be adept in the HDI PCBs.

What is HDI PCB

HDI PCB stands for High-Density Interconnector Printed Circuit Board. It is one of the significant enhancement in the world of PCB electronics. Moreover, its advanced multiple via processes minimizes the number of layers. So it provides smaller yet most powerful circuitry.

Features of HDI PCB

HDI PCB fabrication uses the latest multilayer technology that allows you to integrate multiple layers with high density. This technology has significant dominance over other traditional PCBs. Here are some key features of this technology:

High-density interconnector uses laser drilling technology. So this technology precludes different drawbacks that occurred during traditional mechanical drilling technology. Therefore, it reduces your difficulties.

These boards contain high wiring density per unit surface area as compared to regular PCBs.

HDI boards most often come with apertures having a range of 3.0 to 6.0 mil. Moreover, the line width is between 3.0 and 4.0 mil. So by using these features, you can minimize the pad size significantly.

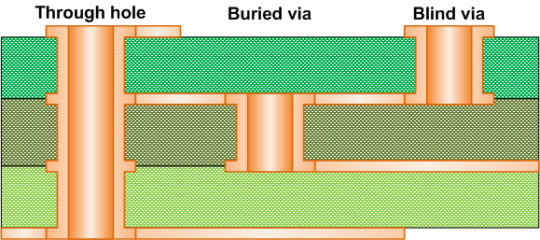

Another most popular feature of these boards is vias. There are different types of vias such as buried, blind and micro vias. The size of the vias can be lesser than 0.0006 mm in diameter. So these small size vias help you to save more space on the boards. So you can create a more compact design.

The effectiveness of these boards assists as a substitute to use of high-layer laminated boards. Moreover, these boards are expensive as well.

Different characteristics such as lightweight and high frequency. Plus, high electrical speed makes it the ideal option for various applications.

Different stack-ups for HDI PCBs

According to the IPC-2315 standard from the IPC, there are 6 basic types of stack-ups. These stack-ups types include I, II, III, IV, V and VI. However, the last three types are more expensive and have minimum use. So we will only discuss the first three types of vias. Moreover, the standard differentiates HDI stack-ups on the basis of the vias type. Such as micro, buried, blind and plated through vias.

HDI Type I: These types have a structure of a laminated core having at least just a single layer of micro vias. These vias can exist on one or both sides of the circuit. Type I HDI use blind and PTH vias. However, it doesn’t use buried vias.

HDI Type II: This type includes different blind and buried vias on a laminated core. Fabricators can stagger different micro vias and stack them relative to buried vias.

HDI Type III: To construct this type, the manufacturer uses micro vias, buried and blind vias on a laminated core. Moreover, this type includes at least two layers of micro vias on one side of the board or both. You can stagger micro vias over other micro vias. Furthermore, you can stack them over other buried vias.

Materials of HDI PCB Fabrication

Do you want to know about the different materials used in HDI PCB manufacturing? You should know about the different materials for various reasons. For example, if you know about the material, you can choose the right material for your HDI board. Let’s have a look at the most important material used for HDI:

Copper: This is the primary material for all PCBs.

Core: It is a skeleton of the board. It is a copper-clad board. You can use it for the double-panel production of the inner layer.

Surface treatment materials: It includes nickel-gold alloy, lead-tin alloy, OSP, silver, etc.

RCC: The specification of RCC includes 60T12, 60T18, 65T12, etc.

FR4 (LDP): The specifications of FR4 include 1080 and 106.

If you want your PCB to perform well, you will have to choose adequate dielectric and resin material. The properties of these materials include decomposition temperature and glass transition. It further includes thermal expansion coefficient and delamination time.

For example, most of the people go with FR4 materials. You can use it for those applications that need a few GHz frequencies. In addition to this, if you want to pick materials used in microwave/ RF applications. You need materials that are capable to maintain impressive signal integrity. So choose a material that can is good for up to 20 GHz.

And other material includes BT epoxy, polyamide, and enhanced epoxy. You can pick any of them according to your needs!

Benefits of using HDI PCB Board

Using HDI circuit boards in your application has a lot of advantages. Due to these benefits, most manufacturers prefer HDI over other types of circuit boards. Have a look at the benefits of using HDI PCB in your applications:

1. Reduce heat transferring

Traditional PCBs burn due to a lack of heat transferring. So this technology has an edge over traditional circuitry such that it reduces heat transfer. Why? It is because the heat has to travel for a short distance before leaving the HDI PCB.

The design of this circuity makes it capable to go through a high thermal expansion. So it increases the lifespan of the circuit boards.

2. Manage thermal conductivity

The availability of different types of vias makes sure the current transmission between the components. So it is up to you to fill these vias with either conductive or non-conductive materials. You can further enhance the functionalities by using the blind vias and via in pad components together.

Furthermore, the HDI boards have a compact structure. So it reduces the transmission distance between different components. It further reduces transmission times and crossing delays as well. So as a result, you will have a strong signal for your circuit.

3. Minimal power usage

HDI PCBs consume less battery power as compared to traditional ones. This is because of advanced manufacturing technology. This technology binds the electrical components resulting in minimizes loss of energy.

HDI circuits use vias instead of through holes that also reduce power usage. This effect increases the lifespan of your battery.

4. Smaller form factors

It is an ideal choice for saving space. You can easily minimize the total number of layers on HDI PCB desingning. For example, you can replace the 8-layer through holes by using a 4-layer via in pad solution. As a result, you will have a small PCB. Some vias will not visible to the people and increase performance as well.

5. Incorporation of components

You can’t only minimize the space but also incorporate your boards as well. It means you can put as many details as you want on the HDI board. Furthermore, you can populate both sides of the board to incorporate the components. So this depends on the design and the need for the application.

6. Different designs

By using the high-density interconnector technology, you can create different designs of the boards. So you can use these circuit boards in all applications as you want. Such as you can have rigid, flexible and combination of both.

How does HDI PCB change your lives?

HDI PCB is the fastest-growing part of different industries. Nowadays, devices are getting smarter and more portable. Furthermore, components insides the devices are smaller and lightweight. On the other hand, performance is getting higher and higher. In addition to this, performance works in smaller areas as well.

So all this happening just because of HDI circuits and other technologies similar to this. These circuits provide higher density per unit as compared to traditional circuit boards. This technology use buried, blind, and micro vias to uplift the performance. Besides, these vias provide high-quality results when combined with laser direct imaging and laser drilling machines.

Application of HDI PCBs

So far you have learned a lot of things about this amazing technology. However, you might be thinking that where you can apply these incredible circuit boards. So it is a fact that there are countless applications where you can use this board. Therefore, you can use this circuitry from simple to mega-complex applications. Here are some significant applications for HDI PCBs:

1. Consumer electronics

This term refers to all basic devices you find in your daily life usage. Such as laptops, smartphones, and cameras. Moreover, it also includes the majority of home appliances and entertainment systems.

All these gadgets need circuit boards having lighter weight. Moreover, these appliances also need flexibility. Thus, HDI circuitry meets the qualities of these gadgets.

2. Medical equipment

There are numerous electronics playing a key role in the wellbeing of our health. So the medical industry wants to ensure the high-quality circuits that meet their standards. So all medical equipment should be effective and play a major role in the safety of the patient.

So there are several devices where you will find HDI printed circuit boards. Such as monitors and scanners. It further includes heart pacemakers, scientific instruments and control systems.

3. Industrial applications

You can find this circuitry in the high-powered industrial applications. Due to its effectiveness and robust nature. Moreover, it consumes less energy and ensures maximum output.

Even these circuit boards are capable to perform in a harsh environment. So most boards use thick copper that helps in faster battery charging. Moreover, it also helps in high current applications as well.

So you can find this circuitry in various applications. Such as electric drills and different measuring equipment. Besides this, they exist in power equipment such as generators and solar power panels.

4. Automotive

Most automotive rely on different electronic parts to work properly. So you can use this technology in these applications. You can use high-frequency signals of RF and HDI PCBs combined with sensor applications. This is common in automotive.

Different technologies such as radar technology are clearing their way in the automobile industry. All such technologies rely on HDI circuitry.

In addition to this, some common applications such as engine management systems use this technology. It further includes navigation devices, video, and audio devices.

5. Aerospace applications

The precision and durability make HDI an ideal choice for aerospace applications. Moreover, HDI circuits can resist vibration effects. Airplane and jets need circuity that can withstand in harsh environments.

So HDI circuit boards ensure the security of aerospace applications. These apps include monitoring equipment such as pressure sensors. Plus, accelerometer.

Conclusion

The high-density interconnector circuit board is the most robust technology. You can use this technology in a wide number of applications. If you want to order high-quality PCB, you must be familiar with the basics of this technology.

So if you are looking for a reliable PCB, you can consult MOKO Technology. We utilize the latest technologies to create high-quality circuit boards.

0 notes