#handtooled cover design

Explore tagged Tumblr posts

Text

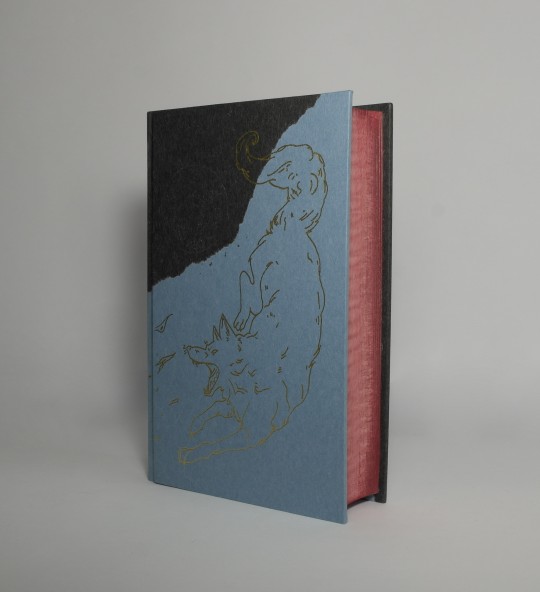

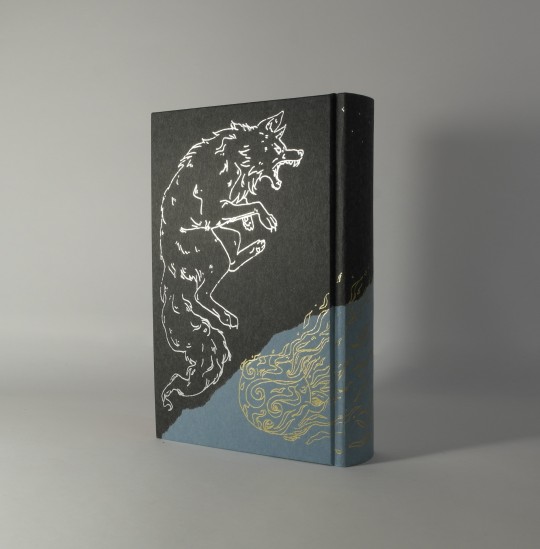

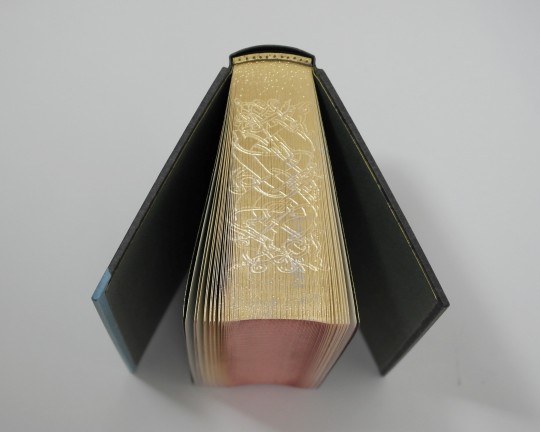

Midgard - W. and H. Hohlbein

Many thanks to Karitas for allowing me to use and adapt her wonderful art of 'Hati & Sköll' for my cover design.

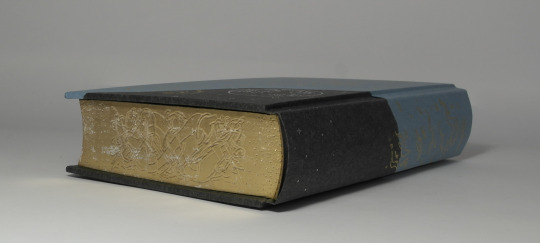

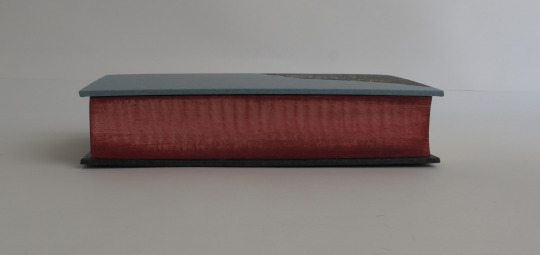

inner book mass produced paper back of Midgard bugra bütten paper, endpapers gilded leather, endbands acrylic paint, coloured edge leaf gold (ducate double gold 23 carat), gilded edge

case binders board 1,5mm, cover cardboard, spine stiffener Satogami paper, cover material gold and silver tooling on the covers

#bookbinding#re-binding#check out karitas art#midgard#hati and sköll#hohlbein#coloured edges#gilded edge#gauffered edge#handtooled cover design#the downside of making decisions as one goes#to be honest

430 notes

·

View notes

Note

can you talk a bit about what you do as conservation work? i’ve seen a couple of your posts float around (the seasonal worker comic and the one about the remote island) and have looked into conservation stuff a bit myself and it all looks super cool!! i was just looking for a bit of a more personable take that what job sites describe

Of course! :) A lot of the work I've done has been in either trail maintenance, habitat restoration, or biological fieldwork, with a little bit of outdoor recreation stuff mixed in. Pretty much all of those things (barring the outdoor rec) have been in partnership with or working directly for government agencies (DNR, USFS, BLM, NPS, USFWS, etc.)

Trail work is very trades oriented - you are using tools (generally handtools - especially if you are working in designated wilderness, which prohibits any kind of mechanization) and your body to build effective infrastructure that will last a good, long time. Project work covers a huge range - brushing trail, digging tread, building structures, fence repair, rock work/wall building, etc. Often you have to work with natural materials on the project site, because hauling in lumber or stone is not feasible. It's hands-on & technical work, and it needs a lot of creativity! Your end goal is that no one knows you were there at all, because your work blends seamlessly into the landscape. A lot of people who hike or mountain bike don't realize how much effort and complexity it takes to maintain a trail! It's a very secret service, & I think there's something really beautiful in that. It's dirty, hard work, and you'll very likely go long periods without access to service or utilities (lots of treating/filtering your own water, camp-cooking your meals, showering in the creek, and sleeping on the ground).

The habitat restoration I've done has generally involved the removal of invasive plants & the planting/seeding of natives. This is also pretty intense physical work! You might have to get certified/trained in working with herbicides, which are sometimes a necessary tool in fighting invasive plants. Hack-splash or drill-fill are the most commonly used herbicide techniques in restoration, because broadcast dispersion is considered a last resort. That involves individually treating each invasive plant with herbicide, using minimal amounts and concentrations to limit the effect on the surrounding ecosystem. The two biggest restoration projects I've worked on are the re-planting of disturbed alpine meadows (50K plants in about six weeks) and the removal of invasive coconut monocultures from native rainforest (hacking down palms with a machete, and spraying/injecting the cut stump with a small amount of herbicide to prevent it from coming back).

My biological fieldwork has been mostly marine-oriented - I've done a lot of work with seabirds, as well as coral reef survey & tagging sharks, mantas, tuna, and dolphins. My seabird work involved monitoring nesting colonies (counting babies, tracking growth) with some tagging, banding, and sample collection as well. The seabirds I worked most with were several different booby species, Greater Frigatebirds, Red & White-tailed Tropicbirds, noddies (both black and brown), & terns (white & sooty). Most of the marine tagging I did was using handline fishing techniques, and required me to have a lot familiarity with/certifications for boat operation & seamanship. Biological fieldwork has definitely been lower labor-intensive than trail work or restoration, but still requires a lot of hiking & hauling gear around remote (& sometimes treacherous) terrain! You will also have really intimate exposure to animal bodies and death, and will probably (definitely) get pooped on/thrown up on/bled on at some point.

A big common theme throughout these kinds of jobs is the ability to work in small groups, in isolated places, for long periods at a time. I hope this was the kind of information you were looking for in terms of what the actual work is! Feel free to reach out/message me if this didn't actually answer your questions <3

#sorry this got so long!#beckett.txt#asks#conservation#conservation work#anonymous#id is in alt text!#beckett.jpg#faq#dirtbag tag

128 notes

·

View notes

Text

Hand Tools in Noida

Looking for reliable hand tools in Noida ? Explore a wide range of high-quality hand tools at Industrywaala! From wrenches to screwdrivers, pliers to hammers, we've got all your needs covered. Whether you're a professional tradesperson or a DIY enthusiast, our hand tools are designed to meet your requirements. Visit us today to discover the perfect tools for your projects! 🛠️🔧 #HandTools #Noida #Industrywaala

Visit our website [https://industrywaala.com/] 🛒📍 Address [B – 80, B Block, Sector 5, Noida, Uttar Pradesh 201301] Phone Number📞 [7377017377].

0 notes

Photo

Blacksmith made Carbon Steel Heavy weight Bearded Axe with 20" Rose Wood Handle & Leather Cover Buy It Now Price 75 USD with Shipping Delivery Through DHL within 3-5 Working Days. Payment accepted through Paypal. Handling Time.. Same Day of Payment. We can make any kind of custom order regarding axes, swords and knives as per Customer design. #forsale #sale #axeforsale #axe #hatchet #beardedaxe #vikingaxe#fellingaxe #tomohawk #smokingaxe #damascussteelaxe #carbonsteel #carbonsteelaxe #custommade #customwork #handtools #handmade #handforged #forgedinfire #outdoor #sportsandgoods #gift #blacksmithing #bladessmith https://www.instagram.com/p/B4VSJfsDpvf/?igshid=rn8vgutepqtu

#forsale#sale#axeforsale#axe#hatchet#beardedaxe#vikingaxe#fellingaxe#tomohawk#smokingaxe#damascussteelaxe#carbonsteel#carbonsteelaxe#custommade#customwork#handtools#handmade#handforged#forgedinfire#outdoor#sportsandgoods#gift#blacksmithing#bladessmith

0 notes

Photo

Continuing the briefcase series. Showcasing an edge finishing test sample for the internal pockets of the briefcase. Edges are double folded, i.e. folded over twice to visually avoid any portions when you can see each layer of leather spliced together, something usually seen with a single folded edge. This further creates a visual of leather covered edges around the pocket. Running parallel to the edge is brogue detailing which will be lined across the pocket to add a little bit of spice to an otherwise mundane area. Endeavoring for these subtle design cues to translate into a briefcase that appears clean and refined at first glance, but carries so much more “hidden” detailing that you’ll probably only start to notice over time through usage. #heicrafted #handmade #handtools #handcrafted #handcraft #handstitched #handwork #bespoke #custom #madeinsg #style #leather #leatherwork #leathercraft #leathercrafttools #menstyle #menfashion #luxurylife #sgmakers #sgcrafters #thosewhomake #craft #togo #hermes #vergezblanchard

#style#menfashion#handcrafted#vergezblanchard#thosewhomake#leathercrafttools#menstyle#handmade#handstitched#leatherwork#madeinsg#bespoke#sgmakers#togo#leather#luxurylife#handwork#handtools#custom#handcraft#sgcrafters#heicrafted#leathercraft#hermes#craft

3 notes

·

View notes

Text

Install a Shift-Improvement Kit in Ford’s C6 Automatic

The 1966–2004 Ford C6 three-speed automatic transmission still finds a home in restored muscle cars, nostalgia race cars, and heavy-duty towing apps. Like any old-school trans, a good shift-improvement kit yields more positive shifts and tire-chirpin’ gear changes that improve full-throttle acceleration.

For the vast majority of consumers, a smooth-shifting automatic transmission is the gold standard. Detroit caters to the least common dominator, except in the relatively rare high-perf models. But with a hopped-up motor’s higher torque and power numbers, smooth shifting means lazy shifting that can cause excessive clutch and band-apply times. And that can mean higher temperatures and burned friction material leading to eventual transmission failure.

Assuming the transmission’s internals and frictions are otherwise still in good shape, the answer to this problem is an aftermarket shift-improvement kit. To a large extent, shift timing and quickness on traditional, pre-electronic transmissions is controlled hydraulically, through passages, orifices, springs, and check valves in the transmission’s valvebody. By modifying the valvebody, a bolt-in “shift kit” provides firmer, quicker shifts and also raises the hydraulic system’s operating pressure.

In these pages, working with Advanced Engineering West’s Mark Sanchez, we’ll follow the installation of Performance Automatic’s shift kit in Ford’s heavy-duty, classic, C6 three-speed automatic used in various applications from 1966 through the late-1990s. In production form, the C6 was a robust, if heavy, transmission. Its main competitors in the days of classic muscle cars were GM’s heavy-duty TH400 and Chrysler’s A727 TorqueFlite. “Shift-improvement kits are kind of generic, but I’ve always had good luck with anything Performance Automatic makes,” Sanchez says. “They’re known for specializing in Fords, but cover everyone else’s transmissions as well.”

Most shift kits enable upshifts and downshifts in First and Second gear at any speed, a feature not present in many stock transmissions. Specifically, PA’s C6 shift-improvement kit includes the following enhancements:

Replaces the pressure regulator spring to raise line pressure throughout the trans’ operating range, increasing the holding forces on the clutch and bands used in each range.

Swaps the springs within the accumulator circuits to decrease band-apply time, resulting in a firmer 1–2 shift.

Implements accumulator circuit and band-apply servo mods to further reduce band-apply time.

Adds a spring under the cut-back circuit valve to prevent line pressure reductions over 10 mph.

Enlarges a hole in the separator plate to increase flow to the direct (Third gear) clutch pack, firming up the 2–3 shifts as well as developing a cleaner band release.

Not included with the shift kit, but highly advised if making 400+ hp, we’ll also bolt-in PA’s Super Servo kit that’s built around a piston with greater surface area that increases the force applied to the band on the rotating drum. It works best with elevated line pressures generated by the shift kit.

Installing these parts requires the usual assortment of handtools, a small pick, and ideally a low-range torque wrench. And, if possible, grab a large cookie pan with a lip to place the valvebody on so all the little springs and check balls don’t go flying off (or use a large drain pan). Placing several small magnets on the underside of the cookie pan temporarily magnetizes it, further keeping those small parts together.

The C6 shift kit is representative of most classic-era automatics, as are the things you need to watch out for. Just remember that all the shift kits in the world won’t help if your trans is toast internally.

01] Performance Automatic’s 1967–1976 Ford C6 shift improvement kit (PN PA36417) contains an assortment of valvebody springs, a large servo spring, gaskets, and two drill bits. The springs are color-coded for easy identification. As this is HOT ROD, we’ll be implementing all the kit’s “heavy-duty” options for the quickest, hardest shifts.

02] Start by removing the C6’s 17 pan bolts with a ⁵⁄₁₆-inch socket. We suggest removing the bolts starting from one end and working toward the other end; that way, fluid will tend to drain out one end of the pan, hopefully into a handy drain pan and not all over your face. Be sure to follow the subsequent steps to avoid losing the little check balls and springs.

03] Don’t remove the filter yet; instead, carefully drop the valvebody and filter as an assembly out of the trans by removing eight mounting bolts, indicated here by white paint on the heads. The two bolts (arrows) that also pass through the filter are slightly longer. If you get mixed up, pre-insert the bolts through the assembly on the bench; their remaining projected length should be the same when in their proper locations.

04] Place the valvebody and filter assembly on the bench inside a steel cookie tray. The assembly’s upper side (the side opposite the filter side) should face up as shown. Remove the two bolts indicated by the arrows. For clarity, many of these photos were shot with the trans upside-down (“bottom’s up”) on the bench. Standing or lying under the vehicle, the view would be “flipped” 180 degrees.

05] Flip the assembly so the bottom (lower or filter side) faces up. Remove 11 bolts attaching the filter and filter gasket to the valvebody (A; two with a dab of white paint on their heads were removed in 03). The bolt with an “L” (circle) is longer than the other filter retaining bolts (but not as long as the two with white paint removed in photo 03). PA’s kit doesn’t include a new filter or filter gasket, but a C6 uses a screen-type filter that can be reused if carefully cleaned. The OE steel-shim filter gasket is also usually reusable. Remove the remaining five outer perimeter bolts (B). Don’t loosen the two bolts (C) under the filter yet.

06] With the bottom side still facing up, push down on the valvebody while carefully removing the final two bolts holding the two halves of the assembly and the separator plate together. Then slowly lift the valvebody’s bottom half off the separator plate and upper valvebody casting.

07] At this point, the convoluted disassembly procedure becomes apparent: It’s the safest way to keep those little springs and check balls under control.

08] Now the small parts installed in or on the valvebody’s top half can be accessed. The exact configuration of the parts may vary slightly in specific valvebodies. Only two valve cover-plates need be removed: the large seven-orifice plate held in place by eight bolts (A) and a single-orifice two-bolt plate on the opposite side (B). Note the early model two-bolt plate’s slot orientation. The callout numbers in this photo correspond to those in detailed photos and captions 09 through 16, below. Remove only the parts necessary to replace those referenced in captions 09 through 16. Use a pick, magnet, or small screwdriver if the parts don’t pop out of their orifices.

09] Pressure regulator circuit under the two-bolt plate: For the firmest shifts, replace the stock outer spring with the kit’s orange spring. The kit’s blue spring will yield firmer-than-stock shifts, but not as firm as the orange one. Either way, if there is an inner spring, reuse it. When bolting on the plate, be sure its slot lines up with the valvebody hole (arrow).

10] Under the seven-port cover-plate, replace the outboard stock servo modulator-valve spring with the kit’s yellow spring.

11] Remove the stock accumulator-valve spring, replacing them with the kit’s white spring inserted inside the kit’s pink spring.

12] Remove the stock cut-back valve. Install the kit’s black spring into the orifice, then reinstall the cut-back valve after it. OE ’bodies don’t have a cut-back spring. Adding the kit’s spring yields extremely firm shifts by preventing movement of the cut-back valve. If the new spring holds out the valve cover-plate during its reinstallation, grind or clip two coils off the spring.

13] All C6 check balls have the same ¼-inch diameter. Reuse the original check ball(s) in their original locations. 1976-and-earlier ’bodies use only the top ball as shown in photo 08 and 16; 1977-and-later also have a lower ball. It can’t hurt to put a dab of petroleum jelly on the balls to hold them in place.

14] Reuse the original torque converter pressure relief valve and spring at its original location (photos 08 and 16). A ¼-inch check ball was used in lieu of a valve in early 1967 production.

15] Reuse the original throttle pressure relief check ball and spring at its original location. This spring is slightly shorter than the converter pressure relief spring.

16] For even more bulletproofing, you can optionally drill a ⅟₁₆-inch hole using the kit’s supplied drill bit in the highlighted yellow area to prevent loss of converter lubrication during heavy throttle. This photo also shows the installed check ball (A) and pressure relief valve and spring (B).

17] A C6 needs just one separator plate mod: To increases fluid flow to the direct clutch pack, enlarge this hole in the plate using the kit’s 1⁄8-inch drill bit.

18] The kit contains two different separator plate gaskets: 1967 to early 1976 (left) and late-1976-and-later (right). Make sure the gasket holes match the separator plate holes, especially for changeover year 1976! C6 valvebodies physically interchange, but the trans won’t work right if an early valvebody is matched with a late trans (or vice versa).

19] Valvebody assembly stack order: Place the upper half (A) with its internal components, check balls, and springs face up on the bench. Flip and align the separator plate (B) and separator plate gasket (C) over the upper half, then position the lower half (D) on top and begin assembly, reversing the previous disassembly order.

20] The C6’s major design flaw: a too-small band-apply servo. At a minimum, on the case’s passenger side, remove the servo cover and replace the OE spring under the piston with the kit’s large red spring. The stronger spring quickens the band-apply time, but it’s still only a stopgap measure over 400 hp.

21] C6s used behind 428 Cobra-Jets had a larger servo piston. Better yet: PA’s separate (not included in the shift kit) billet-aluminum Super Servo kit (PN PA36411, right, versus stock setup, left). It also includes a new extra-heavy-duty black spring to provide a standardized release force for the new servo.

22] The lip on the Super Servo’s black outboard piston seal must face outboard, towards the cover.

23] Changing just the servo spring or upgrading to a Super Servo requires first releasing the band tensioner by backing off the band adjustment bolt (A) located on the case’s driver side. This photo also shows the manual (B) and downshift (C) levers.

24] With tension released, now’s a good time to polish the clutch drum band-apply surface with 180- to 220-grit sandpaper. Sand radially (not front to back) while hand-rotating the drum, then thoroughly flush-out the trans afterward.

25] Adjust intermediate band: Lightly bottom the locknut, hold it steady with a ¾-inch wrench, and using a ⅜-inch 12-point socket, tighten the weird square-head bolt to 10 lb-ft. Back the bolt out one full turn if using just the shift kit’s new servo spring, or 1¼–1½ turns with the Super Servo kit. Finally, hold the bolt head steady and final-tighten the nut to 40 lb-ft.

26–28] Valvebody reinstallation is a little tricky: You need to “trap” the downshift and manual trans-case levers in the proper position relative to their respective valves. In the trans case, preposition the levers (26). In the valvebody, be sure the manual valve is in its Neutral detent position (A): For this 1967–1970 C6 with detent spring in the valvebody, push the valve all the way in until it bottoms, then pull it out two audible clicks. Carefully drop the valvebody into the trans case. The manual lever’s button end (B) slips into the notch in the manual valve; the downshift lever (C) must fit between the “button” end of the bolt (D) sticking out of the valvebody and the throttle downshift valve hidden behind the manual valve but visible in photo 28, E.

29] Bolt on the pan and fill the trans with Type F fluid. The previous mods alter part-throttle shift timing, so after test-driving the vehicle, you may want to readjust the vacuum modulator located at the rear of the case’s passenger side near the cut-out area of the otherwise square transmission pan. For later shifts on this single-line modulator, turn the adjusting screw (arrow) in; for earlier shifts, turn it out.

30] If all this sounds like too much work, Performance Automatic offers a fully assembled street/’strip valvebody designed for everyday street driving and weekend dragstrip trips. PN PA36301, shown here, bolts into 1967–1970 models and has everything the shift-improvement kit does, but it’s delivered fully assembled, ready to bolt in. Assemblies for other model years are also available.

31] All fasteners should be tightened according to the torque values in the table below.

Torque Limits & Adjustments Filter screen and lower to upper valvebody 40-55 lb-in Intermediate band adjustment See caption 25 Intermediate servo cover to case 14–20 lb-ft End plates to valvebody 20–40 lb-in Oil pan to case 8–12 lb-ft Reinforcement (separator) plate to valvebody 20–45 lb-in Screen (filter) and lower to upper valvebody 40–55 lb-in Shift valve plate to upper valvebody 20–45 lb-in Upper to lower valvebody 40–55 lb-in Valvebody to case 100 lb-in

The post Install a Shift-Improvement Kit in Ford’s C6 Automatic appeared first on Hot Rod Network.

from Hot Rod Network https://www.hotrod.com/articles/install-shift-improvement-kit-fords-c6-automatic/ via IFTTT

0 notes

Video

instagram

This leather wallet was tooled and colored by hand with artwork based on HR Giger's Baphomet painting, seen on the cover of his art book Necronomicon. It features 4 card pockets, 1 cash pocket, a chain eyelet, and an optional braided black leather chain. Made from high quality veg-tanned leathers, it will soften greatly and form to your cards with use. HR Giger is known by most for his work designing the xenomorphs in Ridley Scott's movies Alien & Aliens, as well as Dennis Feldman's creature 'Sil' in the film Species. To his fans, he's known for the countless paintings and sculptures of biomechanical creatures, landscapes, and occult subjects. He is my favorite artist and I occasionally create items with my take on his works. If you like dark art, look up his art books online and you won't be disappointed. Or visit his museum in Switzerland which features permanent installments of many of his works. After taking in his artwork you can pop into Giger Bar next door and enjoy a 'HR Giger' (Gin/Green Vodka/Green Lemon) or a shot of 'Face Hugger' (Vodka/Cassis/Tabasco.) . . . . . #edc #leather #leatherwork #leathergoods #handmade #handcrafted #everydaycarry #madeinusa #madeinus #wallet #gear #pocketdump #cardwallet #custom #gearnut #handtooled #handstitched #diy #custom #chainwallet #bifold #billfold #hotchkissleather hotchkissleather.com #hrgiger #baphomet #darkart https://www.instagram.com/p/BsvurodBzFy/?utm_source=ig_tumblr_share&igshid=1meo9kgwdf385

#edc#leather#leatherwork#leathergoods#handmade#handcrafted#everydaycarry#madeinusa#madeinus#wallet#gear#pocketdump#cardwallet#custom#gearnut#handtooled#handstitched#diy#chainwallet#bifold#billfold#hotchkissleather#hrgiger#baphomet#darkart

0 notes

Photo

I don't know if this will work but here goes. I had a broken handle on my favorite 1.5" gouge and to make a quick repair, I made a leather whip to cover the split. The former owner used wire and this gouge is a war pony!!! https://terraindigena.com Plowshares back to Swords. #toolrestoration #tools #tool #woodworking #art #wood #woodcarving #gouge #art #design #designers #sharp #sharpener #sharpening #knife #stone #dmt #fleamarket #survival #blade #dyi #handtool #vintagetools #outdoors #bushcraft #carvingaxe #wood (at लुम्बिनी समाचार) https://www.instagram.com/p/BqRfIDplVfL/?utm_source=ig_tumblr_share&igshid=17mpvy7wj2ez3

#toolrestoration#tools#tool#woodworking#art#wood#woodcarving#gouge#design#designers#sharp#sharpener#sharpening#knife#stone#dmt#fleamarket#survival#blade#dyi#handtool#vintagetools#outdoors#bushcraft#carvingaxe

0 notes

Link

1) Assembles new billiard or pool tables, performing any combination of following tasks: Cuts, trims, and installs pool table parts, such as cushions, cloth covering, pockets, and tabletops, using cement, tacks, scissors, hammer, and portable bandsaw.

2) Assembles and installs rails and legs, using handtools.

3) Installs specified pool table accessories, such as coin meter assembly and ball return gullies, using handtools and power tools.

4) May assemble billiard sticks and glue tips on ends, using brush and glue.

5) May repair billiard tables, using handtools and power tools and be designated Billiard-Table Repairer; or may be designated according to component assembled as Cushion Former; Cushion Installer; Frame Assembler; Leg Assembler; Pocket Assembler; Rail Assembler; Trim Mounter.

0 notes

Text

Hello and welcome to my blog! This post completes a series in which I’ve built a Tea House garden bench of Honduran mahogany. This bench will be used outdoors and preparations have been made to help this bench endure the elements. I’ve detailed the steps taken to ensure that it will last in addition to having detailed the remaining steps of cutting and fitting the joinery.

The previous post ended with the center upright having been seated in place. With that now completed, I could install the stretcher. The stretcher is an important fixing point for the remaining joinery.

Once the stretcher was in place and squared up, I could then begin to layout the remaining joints. I transferred my baseline marks to the stretcher using a try square, then used those marks to scribe the tenon shoulders the full way around the stretcher. Next I applied marks to size the tenons and finally made cuts to form the tenons.

The tenons will form a type of notched connection known as a cogged joint. A cogged joint is one in which a notch is formed in the tenon, the notch hooks over the edge of the adjoining upright and a wedge or pair of wedges are put in place to keep the joint seated.

Having space for a wedge offers an advantage that the joint can be seated around a stationary tenon, or vice-versa. Layout marks were made and the tenon transferred to the upright. I’m careful in setting my gauges at this point so that my baseline for the tenons lines up along the entire bench.

I cut away the mortises, keeping away from the lines initially then paring to them with a large tsuki-nomi.

Once the tenon can be fitted through I use a knife to mark out for a notch which will be cut into the tenon.

The notch is then cut and the tenon reinstalled and test seated. My preference is for the notch to compress the adjoining wood and so I cut these joints for a tight fit and seat them carefully.

The shoulder is very carefully fitted to ensure that it seats squarely. Most often when building with handtools one prides themselves on cutting the shoulders and sides of a tenon ‘off the saw’. That is hardly the case here at such a critical connection, the shoulders are cut accurately but then finely tuned until the adjoining sides seat cleanly and squarely. This is done prior to marking out and cutting the notch.

Next, to fit the uprights into the bench. The uprights feature the dovetailed corners and they are cut exceptionally tight. The tight dovetails along with the need to jog the stretcher into place while assembling the end joints made for quite a a bit of apprehension. I used what slack I had available to me to seat everything into position then carefully drove the dovetails into place while wiggling the stretcher closer and closer to a seated position. This was done after applying glue to the joint and it made for a real ‘hair-raiser’, especially given that I did not test fit the dovetails out of fear of damaging the large joint. Wooden joinery compresses each time it is test fitted and what starts as tight can be quite loose after a few fits. I want the joinery tight so that the bench can stand on its own without reliance upon glue. The glue is acting more as a sealant than anything else.

As the joint seated, a sigh of relief escaped and then I moved on to the opposite side to repeat the process.

Once the joints were both seated my apprehension was lifted.

With the joinery now in position I could take a moment to look upon the changes I’ve made in this design. I’m happy with the heft of this iteration.

Dovetails are a fairly simple joint, but as the thickness of materials increase the joint becomes increasingly difficult to cut cleanly. On half blind dovetails I can taper them slightly so that the joint tightens up slightly as it is fitted, however with through dovetails no such tapering can be done, relying instead on cutting squarely and hitting my knife marks exactly. There are very few exposed through dovetails in traditional furniture, and I assume it is for that reason. Often enough through dovetail joints would be covered by molding or otherwise hidden.

Next I detailed the exposed material created by setting back the pins. The angle of the tails was reversed and applied to the outside which was then detailed with a chamfer around all edges.

The final touch was to create a facet from the edge of the pin to the end of the tail. This was done with a paring chisel and it nearly completed the woodwork on this bench.

The last and final step of the woodwork was to create two wedges for each of the through tenons and seat those, securing the cogged joint connections.

Next I headed out to the machine shop and turned out some brass feet on the Bridgeport machine. These are 360 architectural brass, otherwise known as free-machine brass, the only brass I plan to use moving forward, having learned the lessons of the recent past. I still tremor at the thought of machining naval brass.

If my readers will recall, I applied long grain patches into the end of each upright. Those were not only to correct the split at one end, but also to allow a side grain exposure which would be used to hold the screws for each of the applied feet. Pilot holes were first drilled followed by a thread cutting screw and finally a brass screw to seat the feet.

The thumb screw adjusters will allow for the bench to be leveled out on uneven terrain and allow for the bench to be lifted from the ground enough that these uprights will not soak up normal rainwater. As an additional precaution I applied a sealer to the end grain.

The bench is now complete! I very much look forward to your comments and questions. I’ve setup a photo studio in my shop in hopes of improving my photography, please have a look through.

Tea House Garden Bench – Complete Hello and welcome to my blog! This post completes a series in which I've built a Tea House garden bench of Honduran mahogany.

1 note

·

View note

Text

Plastic, Hardwood & Laminate Flooring Installation

Effective 16 September 2009, non structural flooring function is no longer licensed under the Home-Building Work in NSW. Carpeting has the features of muffling sound and holding in temperature although it may be more challenging to scrub and sustain than different floor choices. Our wide range of wood flooring ensures that wont break the financial institution, and that you will find a method you adore, that will appear great within your place. Locate your floor solution that is great in the UK’s primary property flooring dealer – Carpetright. Use our floor buying information to find which characteristics are most critical to contemplate. Catching-up after her installation of Kensington Manor Glacier Top Poplar with Nicole handscraped floor that is laminate CO, in Fort Collins from Lumber Liquidators. Hardwood floor offers various design selections and is normally easy-to clear.

Solid-wood flooring is a product that is normal, with each panel composed of just one piece of wood that’s unit-cut to dimension. They discover use within scenarios which range from the straightforward protection of garage surfaces, for the repair and safety of commercial and professional floor. Hardwood flooring is just a popular and desirable option, but it must be eliminated in high-moisture locations like basements and bathrooms, as the wood can be caused by water to warp. Floors Direct is actually a lifestyle alternatives company that’s the South African chief in laminate timber and vinyl floor.

Subfloors have to be clean, dried, structurally sound and flat, and most manufacturers recommend using a company experienced within the flooring being utilized (particularly for natural rock). All of the people inside our retailers are locals in your area, probably you ‘ll be known by us, or certainly one of your pals, or family. Plastic flooring has developed dramatically in the old wood that was inexpensive and nasty, transforming real, in to a lovely And extremely durable flooring solution for houses, practices and industrial spots. Cork flooring can be a floor product manufactured from the by-product of the cork pine tree Cork surfaces are considered to become eco friendly every nine to 10 years because the cork pine tree bark is stripped and does not damage the tree.

Whether you’ve thought we would mount resilient carpet inside your living room, tough that is gorgeous to complete your kitchen renovation or tile that is resilient to spruce-up your toilet, our highly-skilled installation staff could make sure the job is completed for your satisfaction.

Select Floors laminate flooring is a superb benefit in comparison to different floor covering products, providing quality item in a great value. With more than 100 years of experience on the market, BASF leads revolutionary floor products’ study and development that meet up with the most challenging flooring specifications. There are often quite a few flooring runs on unique at any one occasion – there might be one on unique that’s exactly what you’re trying to find! All Mullican Flooring products can be purchased with 5 and a network of 40 vendors across Canada and the Usa. Variations can happen in one group to the next, so buy the floor you will need at one time. We also hold popular modern designs and variety, for example our ecofriendly bamboo flooring to your more remarkable palm -scraped hardwood.

As one of the region’s greatest hardwood flooring merchants, we’ve helped hundreds of people from Cleveland to Medina and Akron to Mansfield to find the wood flooring that meets the style they’re going for. Check out our plastic sheet and luxurious vinyl floor selections with a selection of hardwood, standing looks, stone – plus a smooth, feel underfoot that is warm. Your range of vinyl flooring contains vinyl planks and plastic floor tiles and vinyl sheets. Like a national organization, we could offer alternatives such as timber or carpet flooring throughout Hobart, Adelaide Brisbane, Melbourne, Perth and Foreign regional locations. Quarter- sawn – The material is cut into groups, and also the floor is made up by the pieces. There are numerous varieties of floor tile available, including tile, stone tile and vinyl floor tiles. Do not forget to click on our packages page and view all-the excellent flooring packages we have.

We’ve a range of expert floor handtools that will help you obtain the work done. Wood flooring also advantages from being done having an interlocking program, which allows the panels to become easily related and fitted into your home. Other reasons for covering cement using a resin floor are for improving weight to compounds, boosting resistance to use and impact, as well as for artistic appearance reasons. The flooring alternatives for living rooms really should fit the type of the home and are several.

For example, markings will be left by particular tires on PVC floor but those marks can be less prevalent on polypropylene products. What’s more, you’ll find that our wooden flooring that is hard comes in three unique cut variations – flat- sawn, fraction – rift and sawn -sawn – that you’ve the freedom together with your components to guarantee the ideal end for the house.

MasterTop SRS floor systems – methyl methacrylate smooth floor devices cure within just one hour and provide an sturdy, UV resistant, and so are easy to maintain. Improvements in electronic imaging technology imply floor which mimics the look of rock lumber, and also concrete might be made, supplying a more hardwearing alternative. At Carpetright you can also find advice for your vinyl floor on fitting obtaining and caring; plus style inspiration on your home. Don’t use corrosive ammonia, solvent based wax polishes or cleaners on your vinyl floor. This implies where you need them you can buy plastic, bamboo flooring and quality timber floors. click here to read

The post Plastic, Hardwood & Laminate Flooring Installation appeared first on No Dig Organization - Salt Lake City UTAH.

0 notes

Text

Plastic, Hardwood & Laminate Flooring Installation

Effective 16 September 2009, non structural flooring function is no longer licensed under the Home-Building Work in NSW. Carpeting has the features of muffling sound and holding in temperature although it may be more challenging to scrub and sustain than different floor choices. Our wide range of wood flooring ensures that wont break the financial institution, and that you will find a method you adore, that will appear great within your place. Locate your floor solution that is great in the UK’s primary property flooring dealer – Carpetright. Use our floor buying information to find which characteristics are most critical to contemplate. Catching-up after her installation of Kensington Manor Glacier Top Poplar with Nicole handscraped floor that is laminate CO, in Fort Collins from Lumber Liquidators. Hardwood floor offers various design selections and is normally easy-to clear.

Solid-wood flooring is a product that is normal, with each panel composed of just one piece of wood that’s unit-cut to dimension. They discover use within scenarios which range from the straightforward protection of garage surfaces, for the repair and safety of commercial and professional floor. Hardwood flooring is just a popular and desirable option, but it must be eliminated in high-moisture locations like basements and bathrooms, as the wood can be caused by water to warp. Floors Direct is actually a lifestyle alternatives company that’s the South African chief in laminate timber and vinyl floor.

Subfloors have to be clean, dried, structurally sound and flat, and most manufacturers recommend using a company experienced within the flooring being utilized (particularly for natural rock). All of the people inside our retailers are locals in your area, probably you ‘ll be known by us, or certainly one of your pals, or family. Plastic flooring has developed dramatically in the old wood that was inexpensive and nasty, transforming real, in to a lovely And extremely durable flooring solution for houses, practices and industrial spots. Cork flooring can be a floor product manufactured from the by-product of the cork pine tree Cork surfaces are considered to become eco friendly every nine to 10 years because the cork pine tree bark is stripped and does not damage the tree.

Whether you’ve thought we would mount resilient carpet inside your living room, tough that is gorgeous to complete your kitchen renovation or tile that is resilient to spruce-up your toilet, our highly-skilled installation staff could make sure the job is completed for your satisfaction.

Select Floors laminate flooring is a superb benefit in comparison to different floor covering products, providing quality item in a great value. With more than 100 years of experience on the market, BASF leads revolutionary floor products’ study and development that meet up with the most challenging flooring specifications. There are often quite a few flooring runs on unique at any one occasion – there might be one on unique that’s exactly what you’re trying to find! All Mullican Flooring products can be purchased with 5 and a network of 40 vendors across Canada and the Usa. Variations can happen in one group to the next, so buy the floor you will need at one time. We also hold popular modern designs and variety, for example our ecofriendly bamboo flooring to your more remarkable palm -scraped hardwood.

As one of the region’s greatest hardwood flooring merchants, we’ve helped hundreds of people from Cleveland to Medina and Akron to Mansfield to find the wood flooring that meets the style they’re going for. Check out our plastic sheet and luxurious vinyl floor selections with a selection of hardwood, standing looks, stone – plus a smooth, feel underfoot that is warm. Your range of vinyl flooring contains vinyl planks and plastic floor tiles and vinyl sheets. Like a national organization, we could offer alternatives such as timber or carpet flooring throughout Hobart, Adelaide Brisbane, Melbourne, Perth and Foreign regional locations. Quarter- sawn – The material is cut into groups, and also the floor is made up by the pieces. There are numerous varieties of floor tile available, including tile, stone tile and vinyl floor tiles. Do not forget to click on our packages page and view all-the excellent flooring packages we have.

We’ve a range of expert floor handtools that will help you obtain the work done. Wood flooring also advantages from being done having an interlocking program, which allows the panels to become easily related and fitted into your home. Other reasons for covering cement using a resin floor are for improving weight to compounds, boosting resistance to use and impact, as well as for artistic appearance reasons. The flooring alternatives for living rooms really should fit the type of the home and are several.

For example, markings will be left by particular tires on PVC floor but those marks can be less prevalent on polypropylene products. What’s more, you’ll find that our wooden flooring that is hard comes in three unique cut variations – flat- sawn, fraction – rift and sawn -sawn – that you’ve the freedom together with your components to guarantee the ideal end for the house.

MasterTop SRS floor systems – methyl methacrylate smooth floor devices cure within just one hour and provide an sturdy, UV resistant, and so are easy to maintain. Improvements in electronic imaging technology imply floor which mimics the look of rock lumber, and also concrete might be made, supplying a more hardwearing alternative. At Carpetright you can also find advice for your vinyl floor on fitting obtaining and caring; plus style inspiration on your home. Don’t use corrosive ammonia, solvent based wax polishes or cleaners on your vinyl floor. This implies where you need them you can buy plastic, bamboo flooring and quality timber floors. click here to read

The post Plastic, Hardwood & Laminate Flooring Installation appeared first on No Dig Organization - Salt Lake City UTAH.

0 notes

Text

This 1966 Nova is a Race-Engineered Daily Driver

David “Dang” Marin is an unsung hero behind the Le Mans-conquering, championship-winning Corvette Racing program. He’s one of the team’s superstar race mechanics who keep the C7.R Corvettes at the front of the pack with meticulous preparation and lightning-fast pit stops. Skills honed in the most demanding environment, a circle of friends with equally mad skills, and access to a wide array of “obsolete” racing parts from cars designed and fabricated at Pratt & Miller Engineering, all proved invaluable when Marin decided to build a wickedly cool daily driver out of this 1966 Nova.

“A few things drove all of the choices I made with this car,” explains Marin. “I want to participate in the HOT ROD Power Tour, so it was built to drive, to be super reliable, and to be easy to fix roadside if a problem does arise. In about an hour, using a jack and simple handtools, I can have the nose off the car and the entire front chassis clip off. The way we built it, I can do killer burnouts, comfortably run down the highway at high speed, get through corners quickly, and most important by far, do road trips with my sister.” Marin’s sister is disabled, he’s her caretaker, and she gets immense joy from cruising around in this Nova.

A 0.50:1 overdrive Sixth gear delivers 85 mph cruising at only 2,400 rpm, making for a great highway cruiser.

When Marin bought the car a little over a year ago, it was a worn-out shell, complete with vintage ladder bars, a massive hoodscoop, and other remnants of its early drag-racing days. His initial plan was to replace some scabby sheetmetal, get an engine and drivetrain into the car, and go cruising. For some expert help with the sheetmetal, he turned to pal Bryan Barker, a master fabricator at Pratt & Miller. Barker took one look at the car and suggested addressing all of its functional deficiencies before tackling the bodywork and paint, and Marin agreed.

For motivation, Marin wanted to install a ferocious, old-school big-block, but then someone he works with suggested he take a look at an LS3 that was sitting unloved on a shelf in the restoration department at Pratt & Miller. It was believed to have come originally in a Camaro SS that got transformed into an IMSA GTD–class road racer, though nobody remembered for sure. It looked a little rough on the outside, so Marin was able to buy it for an excellent price and was delighted to discover that it was definitely a new car take-out once he opened it up.

Forgeline ZX3R wheels, which completed the 24 Hours at Daytona on a Pontiac GXP.R, were modified to work on Marin’s Nova.

One important aspect of the engine Marin was not so delighted with was its OEM sound. “LS motors sound too refined for me, and I really wanted it to sound like the car looks, so I asked Kevin Pranger for some help,” he recalls. “I was hoping he could come up with a cam that would make an LS3 sound more like a vintage big-block.” Pranger is the lead engine genius at Katech, one of the country’s foremost engine development and build facilities, and he happened to have exactly what Marin wanted. It was a lightly used, custom grind that Katech had utilized for development work. “All Kevin told me was it’s going to sound awesome at idle, pull like a mean mother from 3,500 rpm up, and it’s as big as you can go without valve-relief pockets in the pistons. It was too aggressive for the consumer engine package Katech was putting together, and it found a home with me, much like my dog rescues!” The cam in question features a 0.621-inch intake and 0.624-inch exhaust lift, 235/251 duration at 0.050, and a lobe-separation angle of 113-degrees. Comp Cams rockers and dual valve springs complete the package.

To feed the LS3, Marin installed a K&N inlet and filter sourced from the GT4.R Camaro racer and put together a custom fuel system using a 21-gallon Aeromotive Stealth tank fitted with a high-flow 340 Stealth in-tank pump. Camaro GT4.R-spec fuel lines produced by Brown & Miller Racing Solutions links the tank to Holley fuel rails via an Aeromotive regulator, and a Bosch filter setup borrowed from a Corvette C7.R keeps the flow scrupulously clean. A Chevrolet Performance 525 engine controller kit manages fuel and other crucial engine parameters.

The ride height was lowered 4.5 inches in the front and 5.5 inches in the rear.

Waste gasses are channeled out of the engine via ceramic-coated TCI long-tube headers. A 3-inch X-pipe from Pratt & Miller’s C6RS Corvette test car, 3-inch pipes, and glasspack mufflers complete the dual exhaust system. That same C6RS test car also donated its twin SPAL Automotive electric fan setup, which works with a DeWitts aluminum radiator to keep engine temperature in check.

Marin was able to buy an orphaned Tremec TR 6060 six-speed gearbox that came out of a new Cadillac CTS-V. The Caddy had been transformed into a Pirelli World Challenge racer with a race-only transmission. Joe Dunn at D&D Transmission reworked the original CTS-V gearbox to accept a slip-yoke and a Magnum shifter. He also changed Sixth gear to a 0.50:1 overdrive. An integral pump and transmission cooler in the car’s DeWitts radiator keep the Tremec’s gear-oil temperature under control. The transmission cooler lines started life as high-pressure air-conditioning lines in a C6.R Corvette race car. A McLeod RST clutch assembly and McLeod aluminum flywheel inside the CTS-V bellhousing firmly link the Tremec to the LS3.

To get the power to the ground, Marin installed a Chevy 12-bolt rear axle from DTS. It uses an Eaton limited-slip, Moser 35-spline billet axles with 5X5 5/8-inch NASCAR wheel studs, and an aluminum preload cover. A 3-inch aluminum DTS driveshaft marries the rearend and gearbox. The differential is fitted with a 4.56 ring-and- pinion set, which gives great off-the-line acceleration and fantastic high-speed cruising performance, thanks to that 0.50 overdrive Sixth gear. At 85 mph in Sixth, the engine is turning only 2,400 rpm.

Wicked, smoky burnouts are a big part of the joy Marin gets from his Nova.

Marin wanted this car to be equally at home on a highway, a road course, a dragstrip, or Michigan’s awful, pothole-scarred streets, so the chassis and suspension would need a serious makeover. This is where he really benefitted from the expertise and fabrication skills of friend Bryan Barker. The two modified an older TCI subframe to accept Mustang II–style Viking double-adjustable coilovers. They also modified TCI control arms and fitted drop links originally fabricated for a GT3-spec Cadillac ATS-V.R to work with a 1-inch TCI sway bar. TCI drop spindles carry hubs designed and fabricated by Pratt & Miller for GT class Pontiacs that raced in Grand Am. As with the Moser axles in the rear, the P&M front hubs were fitted with 5/8-inch NASCAR studs.

For easy cruising, Marin installed a Ford steering rack that’s fed by a Corvette C6.R hydraulic pump. The system uses a reservoir that came out of the Corvette C7.R that caught fire at the Daytona ROAR test in 2017.

This Nova was built to drive, and Marin uses it almost every day.

Stopping power comes from a Wilwood brake setup. Six-piston Superlite calipers clamp 13-inch slotted and drilled rotors at all four corners, and high-performance, street-compound Wilwood BP-10 pads provide smooth engagement, a flat torque curve, and relatively low dust levels.

Forgeline ZX3R wheels deliver both the performance and look Marin wanted. The three-piece wheels have 6061 T6 forged centers and spun rim halves. With Chevy truck hats on the rotors, the wheels clear those big Wilwood brakes. The fronts measure 18×10 inches with a 7-inch backspace, and the rears are 18×11.5 inches with a 6-inch backspace. They started life as race wheels for the Pratt & Miller–built Pontiac GXP.Rs, and the particular set on this Nova completed the 24 Hours at Daytona about ten years ago. Steve and Dave Schardt, owners of Forgeline Motorsports, modified them to properly fit Marin’s car. They wear Continental ExtremeContact DW tires sized at 265/35-18 in the front and 295/35-18 in the rear.

Master fabricator Bryan Barker (left) and David “Dang” Marin put a lot of time, thought, and effort into Marin’s Nova.

Though Marin initially planned to attack the body first, to date he still hasn’t done most of what’s needed. Parts of the floor and the transmission tunnel were cut out and replaced with new sections that pal Bryan Barker made to provide adequate clearance for the new drivetrain, and a new 2-inch cowl hood replaced the original, which had been cut up for a giant scoop back in the day. Under the hood, Marin installed carbon-fiber inner fenders fabricated at Pratt & Miller with sample material that otherwise would have gone unused.

In keeping with the build’s overall ambiance, interior work has been primarily limited to improving performance. Low-back, big bolster seats are upholstered in black vinyl, and insulating Boom Mat covers the floor and firewall. The billet steering wheel is from Eddie Motorsports, and a Racepak IQ3 digital dash display tells Marin everything he needs to know. For safety sake, the six-point rollcage was made with removable door bars using Corvette Daytona Prototype rear-engine brace mounts as couplers. All electrical functions are controlled with the help of a modified American Autowire harness. For his sister’s sake, Marin installed a Vintage Air A/C system.

An Aeromotive bypass regulator and BMRS lines deliver fuel to the Holley rails.

Though there’s still plenty he plans to do with his Nova, Marin is having too much fun driving it to do anything big that would take it off the road for an extended stretch. “It’s our cruiser,” he says, “and it brings so much happiness to my sister. I drive it whenever and wherever I can. It’s fast, handles well, stops well, does killer burnouts, and motors down the highway in total comfort. A lot of people went above and beyond to help get it to this point, including Gary Pratt, who loved watching old, obsolete race parts get off the shelves and on the car. I owe a huge thank you to Gary and all of the friends who helped out. The whole project was special because of everyone who got involved, everyone who went to extremes to help me get this car built. I simply can’t thank each and every one of them enough. I love driving the car, and it puts a giant smile on my sister’s face, which is the most important thing of all!”

The power-steering fluid reservoir came off the Corvette C7.R that burned at a Daytona test in 2017.

The original trim tag tells us, among other things, that this Danube Blue/blue interior Nova was built the fourth week of December at the Norwood Assembly Plant.

The K&N inlet and air filter were sourced from a GT4.R Camaro racer.

This LS3 came out of a Camaro SS that was converted to a GT4.R class race car.

Much of the plumbing and wiring was sourced from the obsolete parts bins at Pratt & Miller, including this battery cable.

The Chevrolet Performance 525 engine controller is commonly used for LS engine installations in older cars.

One of Pratt & Miller’s composite specialists built the front wheelwells from carbon, working on his own time to help out Marin.

Racepak’s Data Systems IQ3 display dash puts all critical information right where the driver needs it.

The mostly Spartan interior features custom seats, a six-point rollcage, and Boom Mat insulation.

The post This 1966 Nova is a Race-Engineered Daily Driver appeared first on Hot Rod Network.

from Hot Rod Network https://www.hotrod.com/articles/1966-nova-race-engineered-daily-driver/ via IFTTT

0 notes

Text

Dress Up Your Small-Block With A Billet Front Drive System

Dress-up accessories for the small-block Chevy are plentiful. In fact, the numerous choices can lead to some mismatched combinations of finishes, textures, and styles. That’s why we prefer to do our engine accessorizing with complete kits. The small-block Chevy in question for this tech piece just received a rebuild and is resting under the hood of Matt Hickman’s ’71 Chevrolet C10. Matt upgraded the appearance of the engine with some modern accessories but wanted to add air conditioning and give his engine bay a little more wow factor. His choice was an All American Billet Silverline Supreme Serpentine kit.

The All American Billet kit offers every component needed to install the system, including 6061-T6 aluminum brackets and pulleys, Tuff Stuff Performance accessories, and stainless steel hardware. The kit also includes a remote power steering reservoir and the necessary brackets to mount it. The kits are available in several finish options. Matt went with polished aluminum—a timeless look. The only items that Matt needed to outsource were the high-pressure hoses for the power steering system. All American Billet recently began offering an upgrade to braided stainless steel hoses for GM and Ford power steering systems.

The All American Billet serpentine kit is easy to install with basic handtools. A weekend in the shop could take your engine from bland to spectacular. The straightforward instructions helped us figure out how the pieces of the puzzle went together. It’s important to note that the design of the pulley system does not accommodate a stock-style mechanical fan so Matt took the opportunity to upgrade his cooling system with an aluminum radiator and dual electric fan setup. Now that the kit is installed and the truck is back on the road, Matt can open his hood with pride at the local cruise night and trust that his accessory drive system is ready for years of service. CHP

1. Our starting point is a potent small-block, sporting an Edelbrock top end and powdercoated Chevrolet valve covers. The front drive system is adequate, but it features a stock power steering pump, a pair of standard V-belt drives, and no air conditioning.

2. The engine already had some good parts on it, including a new aluminum water pump and a chrome one-wire alternator with chrome bracket. These components will be great swap meet material after we switch to the All American Billet Silverline Supreme Serpentine front drive system.

3. We found it easiest to remove the radiator, shroud, and fan before disassembling the front of the engine. From there, we removed the alternator, water pump, power steering pump, and crankshaft pulley.

4. Since our engine is fresh, we didn’t see the need to do a lot of touch-up work on the paint. Most of the painted surfaces will be hidden, so we simply did a quick cleanup with some spray detailer before installing the All American Billet crank pulley with the supplied bolts and the original harmonic balancer bolt.

5. The All American Billet Silverline Supreme Serpentine kit comes in a variety of finishes, we opted for polished aluminum. This kit comes with a polished aluminum water pump from Tuff Stuff, and we used standard water pump bolts to loosely install it.

6. With the temporary bolts in the top holes, we use the supplied bolts to pass through the drive system bracket and through the long spacers into the bottom water pump bolt holes. These are also loosely installed to hold the bracket in place.

7. The alternator will mount to the driver-side of the engine, and it uses this oval bracket for proper spacing. The bracket attaches to the engine via the top water pump bolt. You will use the shortest spacer in the kit to take up the slack between the main accessory bracket and this alternator bracket.

8. Next is the passenger side, which mounts the compressor for the air-conditioning system. The fourth and final long bolt is installed through the intermediate length spacer, and then into a Z-shaped bracket for the A/C compressor.

9. A button head bolt holds the A/C compressor to the Z-bracket. Space is tight with the heater hose installed, so for most cases, it’s best to wait until the accessory drive is fully installed before attaching the heater hose.

10. Out front, the polished Tuff Stuff Performance peanut-style A/C compressor is held in place with two supplied bolts.

11. Now we can bolt the polished 140-amp one-wire alternator into place. This is another Tuff Stuff component, polished to perfection, with a six-groove serpentine pulley and stylish billet aluminum fan already installed.

12. Below the alternator goes the power steering pump, another polished item from Tuff Stuff. The All American Billet kit utilizes a compact Type II power steering pump, which requires a remote reservoir.

13. Two supplied button head bolts hold the aluminum Type II power steering pump in place

14. Next is the belt tensioner, which is a genuine General Motors component. It attaches to the main pulley system bracket with a single bolt.

15. The All American Billet serpentine kit features beautiful polished aluminum pulleys that bolt into place easily using the supplied hardware. The pump turns freely so we were not able to get the four pulley bolts very tight at this stage of the install.

16. The A/C compressor has a black pulley built in, but the All American Billet kit comes with a decorative pulley cover that matches the contemporary design. It attaches to the compressor pulley with three supplied bolts.

17. Four supplied bolts hold the water pump pulley in place. All American Billet serpentine kits are complete, but keep in mind that the kit features a 1985-’91 Corvette-style “SuperCool” water pump, which features a 3/4-inch pilot shaft.

18. Now for the moment of truth, as we snake the supplied six-rib Gates belt around the pulleys and insert a 1/2-inch breaker bar into the square slot on the tensioner. The belt snapped into place perfectly, giving us a tight fit.

19. With tension on the belt, we can now finish tightening the stainless steel bolts that hold the water pump and power steering pump pulleys in place. Now would also be a great time to double-check all of your fasteners to make sure they’re tight.

20. The All American Billet serpentine kit features a Type II power steering pump with an external reservoir. Included in the kit is this cool, ribbed billet aluminum reservoir, complete with mounting brackets, set screws, and an O-ring spin-on lid. We chose to mount it to the radiator support.

21. We had a local NAPA store make up the hydraulic hoses using our measurements and fitting sizes. Although it would cost a few more bucks and require custom fitment for your application, All American Billet offers a braided stainless steel line kit as an option.

22. With the kit fully installed, it’s easy to see why we went with the All American Billet Silverline Supreme Serpentine kit. It gave our simple small-block a big facelift thanks to beautifully polished 6061-T6 aluminum components. The best part? It’s made in the USA!

23. The completed serpentine kit is compact and stylish, and the Tuff Stuff Performance accessories are ready for many years of service. This All American Billet serpentine drive system brightened up our engine bay, and it works as good as it looks.

Sources

All American Billet

844.580.7214

allamericanbillet.com

Chevrolet Performance

chevrolet.com/performance

Edelbrock

310.320.1187

edelbrock.com

Tuff Stuff Performance Accessories

800.331.6562

tuffstuffperformance.com

The post Dress Up Your Small-Block With A Billet Front Drive System appeared first on Hot Rod Network.

from Hot Rod Network http://www.hotrod.com/articles/dress-small-block-billet-front-drive-system/ via IFTTT

0 notes