#gritblast

Explore tagged Tumblr posts

Text

The Ultimate Guide to Sandblasting: Everything You Need to Know

Sandblasting is a powerful and versatile technique used in various industries for cleaning, resurfacing, and preparing materials. Whether you're a professional contractor or a DIY enthusiast, understanding how sandblasting works can help you achieve high-quality results. In this guide, we’ll cover everything you need to know about sandblasting, including its applications, benefits, types, and safety precautions.

What is Sandblasting?

Sandblasting, also known as abrasive blasting, is the process of using high-pressure air to propel abrasive materials against a surface. This technique effectively removes rust, paint, corrosion, and other contaminants, leaving the surface clean and ready for finishing.

Applications of Sandblasting

Sandblasting is widely used in multiple industries, including:

Automotive – Removing rust and old paint from car bodies.

Construction – Preparing concrete surfaces for coatings.

Metalworking – Cleaning and polishing metal parts.

Marine – Stripping paint and contaminants from ship hulls.

Woodworking – Creating textured wood surfaces for aesthetic purposes.

Types of Sandblasting

There are several types of sandblasting methods, each with its unique advantages:

Dry Sandblasting – Uses high-pressure air to blast abrasive materials onto surfaces.

Wet Sandblasting – Mixes water with abrasives to reduce dust and static buildup.

Soda Blasting – Uses baking soda as an abrasive for delicate surfaces.

Bead Blasting – Uses glass beads for a smoother finish on metals.

Shot Blasting – Involves steel shots to clean and strengthen metal surfaces.

Benefits of Sandblasting

Efficient Cleaning – Removes rust, paint, and contaminants quickly.

Surface Preparation – Ensures proper adhesion of coatings and paints.

Versatility – Works on a wide range of materials, including metal, wood, and concrete.

Eco-Friendly Options – Many modern abrasives are biodegradable and safe for the environment.

Safety Precautions

Sandblasting can be hazardous if not done correctly. Here are some key safety tips:

Always wear protective gear, including gloves, goggles, and respirators.

Work in a well-ventilated area or use dust collection systems.

Use the right abrasive material to avoid damaging the surface.

Follow proper equipment handling procedures to prevent injuries.

Conclusion

Sandblasting is an invaluable technique for cleaning and preparing surfaces efficiently. Whether you’re restoring an old car, prepping a concrete floor, or maintaining industrial equipment, understanding the different methods and safety precautions will help you achieve the best results. With the right tools and knowledge, sandblasting can be a game-changer for your projects.

#sandblastingservices#abrasiveblasting#surfacepreparation#industrialcoatings#metalcleaning#rustremoval#gritblasting#shotblasting#paintremoval#corrosionprotection#steelblasting#surfacefinishing#metalrestoration#industrialmaintenance#coatingpreparation

2 notes

·

View notes

Text

Enhancing Performance and Durability with Thermal Spray Aluminum Coating

Introduction

In the realm of industrial coatings, Thermal Spray Aluminum (TSA) emerges as a remarkable solution, offering a plethora of benefits ranging from corrosion resistance to increased lifespan. This innovative technique involves the application of aluminum coatings onto various surfaces using a high-velocity thermal spray process. In this article, we will delve into the world of Thermal Spray Aluminum coating, exploring its applications, advantages, and the impact it has on industries worldwide.

The Process of Thermal Spray Aluminum Coating

Thermal Spray Aluminum coating is a process that involves the melting of aluminum particles and propelling them at high speeds onto a substrate using a specialized gun. The melted aluminum solidifies upon impact, creating a uniform and dense coating. This process ensures excellent adhesion and minimal porosity, which are crucial factors in achieving a highly effective protective barrier.

Applications of Thermal Spray Aluminum Coating

Corrosion Protection: One of the most significant advantages of TSA coating is its exceptional corrosion resistance. Aluminum forms a naturally occurring oxide layer that acts as a protective barrier against environmental elements, making it ideal for offshore structures, pipelines, and industrial equipment that are exposed to harsh weather conditions.

Aerospace Industry: In the aerospace sector, weight reduction is paramount for fuel efficiency and performance. TSA coatings provide a lightweight solution with exceptional thermal and corrosion resistance properties. This makes it a popular choice for components like landing gear, engine parts, and airframes.

Oil and Gas Industry: In an industry where equipment is subjected to extreme conditions, such as high temperatures, corrosive substances, and abrasive materials, TSA coatings play a crucial role. They are used on pipelines, valves, and other components to extend their operational lifespan.

Automotive Industry: TSA coatings find extensive application in the automotive sector for components like exhaust systems, mufflers, and other parts exposed to high temperatures and corrosive environments. The coating enhances durability and ensures optimal performance.

Infrastructure and Marine Applications: Bridges, offshore platforms, and marine vessels are constantly exposed to corrosive elements like salt water and harsh weather conditions. TSA coatings provide a cost-effective and durable solution to protect these vital structures.

Advantages of Thermal Spray Aluminum Coating

Corrosion Resistance: The primary advantage of TSA coatings is their exceptional resistance to corrosion. The protective oxide layer formed on the surface of the aluminum provides an effective barrier against environmental elements.

Uniform Coverage: The thermal spray process ensures a uniform and dense coating, eliminating the risk of pinholes or gaps that can compromise protection.

High Adhesion Strength: The high-velocity impact of aluminum particles ensures excellent adhesion to the substrate, resulting in a long-lasting and durable coating.

High-Temperature Resistance: TSA coatings are capable of withstanding high temperatures, making them suitable for applications where heat resistance is essential.

Cost-Effectiveness: Compared to alternatives like galvanizing or painting, TSA coatings offer a cost-effective solution with superior longevity, reducing the need for frequent maintenance or replacement.

Environmentally Friendly: TSA coatings are free from hazardous solvents or chemicals, making them an environmentally sustainable choice.

Conclusion

Thermal Spray Aluminum coating has revolutionized the way industries approach corrosion protection and durability enhancement. Its remarkable properties, including corrosion resistance, uniform coverage, and high adhesion strength, make it an invaluable solution across various sectors, from aerospace to automotive and beyond.

As industries continue to seek sustainable and cost-effective alternatives to traditional coating methods, TSA coatings stand out as a reliable choice. Their ability to prolong the lifespan of critical components, reduce maintenance costs, and improve overall performance makes them a cornerstone of modern engineering and manufacturing practices.

In an era where efficiency and sustainability are paramount, Thermal Spray Aluminum coating represents a significant step forward in ensuring the longevity and reliability of industrial equipment and infrastructure around the world.

To know more about thermal spray aluminum coating contact us

http://madhumetallizing.com

0 notes

Text

Sand Blasting Machine - Sand Blasting Machine for Sale - Gritblast

Sand Blasting Machine - Sand blasting machine manufacturer in India (Jodhpur, Rajasthan). Get shot blasting machine, grit blasting machine & sand blasting machine price in India. Contact us today. Buy now latest sand blasting machine in India at a reliable price. Gritblast is the best sand blasting machine exporter, manufacturer and supplier in Jodhpur, Rajasthan, India. We offer automactic sand blasting machine at a low price. Sand blasting machine for sale at a reliableprice in India, Kuwait, New York, Singapure, Shrilanka, Oman, USA, Dubai and other country. Call us today at : +91-7728877775 OR Visit our website - https://www.gritblast.co.in/ for sand blasting machine.

#sand blasting machine#sand blasting machine manufacturer#sand blasting machine for sale#sand blasting machine india#sand blasting machine price#gritblast

0 notes

Text

In India, Surface International is one of the top producers and suppliers of Vacuum Grit Blasting Machine. For the removal of dust, sand, or paint from manufactured components, vacuum grit blasting equipment is very helpful. with each workstation receiving good performance. To learn more, get in touch with us.

#VacuumGritBlastingMachine#vacuum#GritBlastingMachine#vacuumcleaner#GritBlasting#BlastingMachine#vacuumtubes#vacuumbottle#vacuumchamber#vacuumservice#SurfaceInternational#Jodhpur#Rajasthan#India

0 notes

Text

Grit Blasting

Grit blasting is a surface preparation technique that uses a stream of abrasive particles to clean, smooth, or texture a surface. The abrasive particles are propelled at high pressure, typically using compressed air or water, and can range in size from fine sand to large steel shot.

Grit blasting is a versatile process that can be used on a wide variety of materials, including metal, wood, concrete, and plastics. It is often used to remove rust, paint, or other coatings, to prepare surfaces for painting or welding, or to create a specific surface texture.

The benefits of grit blasting include:

It is a very effective way to remove contaminants from surfaces.

It can create a variety of surface textures, which can be useful for aesthetic or functional purposes.

It is a relatively fast and efficient process.

The drawbacks of grit blasting include:

It can be a dusty and messy process.

It can create hazardous dust and fumes, which can be harmful to health.

It can damage delicate surfaces.

Grit blasting is a safe and effective process when it is performed by a trained professional. However, it is important to take precautions to protect the health of the operator and to prevent damage to the surface being blasted.

Here are some of the safety precautions that should be taken when grit blasting:

Wear protective clothing, including a dust mask, goggles, and gloves.

Use a blast cabinet or other enclosure to contain the dust and fumes.

Wet the surface being blasted to reduce dust.

Dispose of the abrasive material properly.

Grit blasting is a powerful tool that can be used to achieve a variety of surface preparation goals. However, it is important to use it safely and effectively.

Here are some additional details about grit blasting:

The type of abrasive material used will depend on the specific application. For example, fine sand is often used to remove rust, while larger steel shot is used to create a rough surface texture.

The pressure of the air or water stream will also affect the results of the grit blasting process. Higher pressure will create a more aggressive cleaning action, while lower pressure will be less aggressive.

The distance between the nozzle and the surface being blasted will also affect the results. A closer nozzle will create a more focused cleaning action, while a further nozzle will create a more diffuse cleaning action.

CONCLUSION

We Mythri Metalizing have Grit blasting is a versatile and effective surface preparation technique that can be used to achieve a variety of goals. However, it is important to use it safely and effectively to prevent damage to the surface being blasted and to protect the health of the operator.

www.mythrimetallizing.com

0 notes

Text

Waterproof cloth tape is designed for applications requiring additional strength and adhesion. Used for sealing, bundling, short term masking and protecting.Excellent for jointing polyethylene sheeting in asbestos removal applications. Suitable for double glazing unit sealing. For masking during sand & grit blasting.Call 9822619307 OR Get it here @ https://www.pioneertapes.com/contact-us

0 notes

Photo

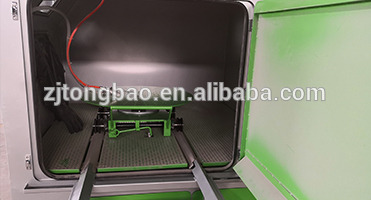

sandblast machine with turntable /Cart-type turntable sandblast machine/Blast cabinet

The characteristics and the scope of application:

The sandblasting heavy workpieces, such as various types of mold, tree, statue, castings, motor, and so on.

Specially designed manual carts (electric carts), can be cart add turntable sandblasting cabin, convenient and quick. Operation and maintenance easy to learn.

0 notes

Photo

Before and after. Moto Guzzi wheel blasted and keyed ready for paint. We have done these before but vapour blasted instead of grit blasted. Depends on whether you want a natural or paint finish. Call us for all your car or motorcycle parts cleaning and finishing. #motoguzzi #motorcycle #classicbike #classicmotorcycle #gritblast #vapourblasting #vaporblasting #ultrasonic #restoration #beforeandafter #icleenz #icleenzmacheenz #classiccar #vintagecar (at Penge)

#beforeandafter#vintagecar#motorcycle#restoration#gritblast#vapourblasting#icleenz#classiccar#motoguzzi#classicbike#vaporblasting#ultrasonic#classicmotorcycle#icleenzmacheenz

0 notes

Link

0 notes

Text

Grand Challenges in Metal Corrosion on Metal Surface and Methods of Protection

Introduction

Metal corrosion is a ubiquitous and costly phenomenon that affects various industries worldwide. From infrastructure to transportation, electronics, and manufacturing, metal corrosion presents significant challenges, leading to the deterioration of structures, loss of productivity, and substantial economic losses. As industries strive for technological advancements and sustainability, understanding and mitigating metal corrosion have become crucial grand challenges.

This article delves into the multifaceted issue of metal corrosion, exploring the underlying causes, its impact, and the grand challenges faced by scientists and engineers in developing effective corrosion protection strategies.

Understanding Metal Corrosion

Metal corrosion is the process of deterioration and degradation of metals caused by various environmental factors. The most common form of corrosion is electrochemical corrosion, wherein metal reacts with its surroundings to form an oxide or corrosion product. The corrosion process can be accelerated by factors like moisture, temperature, pH levels, contaminants, and atmospheric pollutants. While certain metals exhibit natural corrosion resistance, most are susceptible to various degrees of deterioration over time.

Metal Corrosion can be protected by doing sandblasting services and by other coatings like Zinc and Aluminum. So that metal will get protected with an increased lifespan.

Impact of Metal Corrosion

The consequences of metal corrosion are far-reaching and can impact safety, economic stability, and environmental sustainability. Some key implications include:

Infrastructure Damage: Bridges, pipelines, buildings, and other critical infrastructure face deterioration due to corrosion, leading to structural integrity issues and costly repairs.

Economic Losses: The direct and indirect costs associated with corrosion-related repairs and maintenance are substantial, affecting industries' productivity and competitiveness.

Environmental Impact: Corrosion can release harmful substances into the environment, contributing to pollution and ecological imbalances.

Safety Hazards: Corroded metal structures pose safety risks to human lives, as witnessed in accidents and failures in various industries.

Energy Efficiency: Corrosion on metal surfaces can decrease energy efficiency in equipment, machinery, and vehicles, leading to increased energy consumption.

Challenges in Metal Corrosion and Protection

Material Design and Selection: Developing novel materials with enhanced corrosion resistance is a crucial challenge. Scientists and engineers need to consider the environmental conditions, stressors, and operating temperatures to design materials that resist corrosion effectively.

Understanding Corrosion Mechanisms: Despite significant progress in corrosion research, understanding the intricate mechanisms underlying different corrosion types remains a challenge. Obtaining insights into localized corrosion, stress corrosion cracking, and corrosion under complex environments is essential for targeted protection strategies.

Eco-Friendly Corrosion Protection: Many traditional corrosion protection methods involve toxic chemicals, posing environmental risks. Developing eco-friendly and sustainable alternatives is vital for promoting environmentally responsible practices.

Real-Time Monitoring and Detection: Implementing real-time corrosion monitoring systems can help industries detect corrosion at its early stages and prevent catastrophic failures. The challenge lies in developing cost-effective and reliable sensors capable of operating in diverse conditions.

Coatings and Surface Treatments: Coatings and surface treatments play a crucial role in protecting metals from corrosion. Developing advanced and durable coatings that adhere well to metal surfaces and provide long-term protection is a significant challenge.

Corrosion in Extreme Environments: Industries operating in extreme conditions, such as deep-sea environments, extreme temperatures, or highly acidic or alkaline settings, face unique challenges in protecting metals from corrosion.

Corrosion in Advanced Alloys: As industries move towards utilizing advanced alloys with unique properties, understanding their corrosion behavior becomes vital. Investigating the compatibility of advanced alloys with traditional corrosion protection methods is a challenge.

Corrosion under Stress: Stress corrosion cracking is a severe issue affecting metals under tensile stress in corrosive environments. Addressing this challenge requires a comprehensive understanding of material behavior under stress and designing strategies to mitigate stress-related corrosion.

Prevention and Mitigation Strategies: Developing effective strategies to prevent and mitigate corrosion requires interdisciplinary collaborations and innovative approaches, such as using inhibitors, cathodic protection, or sacrificial anodes.

Long-Term Durability: Ensuring the long-term durability of corrosion protection measures is critical, particularly for infrastructure projects with extended lifespans. Developing methods to predict the aging and performance of protective coatings is essential.

Conclusion

Metal corrosion poses significant challenges to various industries, demanding innovative solutions for effective protection. As technology advances and the focus on sustainability grows, researchers, engineers, and policymakers must work together to address the grand challenges in metal corrosion and protection. By understanding the underlying mechanisms, developing eco-friendly solutions, and adopting advanced materials, we can pave the way for a corrosion-resistant future, reducing costs, enhancing safety, and promoting environmental responsibility.

To Protect your metal from corrosion Visit us

0 notes

Text

Shot Blasting Machine | Shot Blasting Machine for Sale : Gritblast

The shot blast machine is hardware that is used in an unusual way and is manufactured for the particular needs of the customers. Shot blasting machine is used for the cleaning of the steel of the structure that completely affects the first profiled steel parts to remove the surface rust, welding slag and scale, consumption restriction effect, and develops even more in the coating Shows quality with a similar metallic tone.

The firing blast hardware is made up of the rear blast chamber, roller transport component housing wheel contraption, dust collection structure, support schematics, and electrical control frame components.

SHOT BLASTING MACHINE PROCESS:

The rough harvester is lifted by the container elevator to the drum screen, there is a curved cutting edge inside and outside the drum screen. The curved sharp edge leaves huge chunks inside; After filtration, a combination of abrasive media, sand, and debris is pushed off the rotating edge which then frames a flow curtain.

Ruff can isolate himself completely by changing the heaviness of the situation. The two folding circles bolted together comprise the impeller body equipped with eight blades on the impeller body and a focus located at the center point of the blast wheel projected onto the one driven by the motor shaft.

The hood is fixed with a clock board that is installed in the packaging directly on the cylinder. The speed of the shot increases with the synchronized turning edge.

SHOT BLASTING MACHINE USE:

• To clean metals such as iron, steel, forgings, non-cast parts and anything else.

• Preparation of surfaces for work such as composition, coatings, etc.

• For mechanical cleaning of MS sheets, ropes, bars, curls, etc. by means of steel pellets.

• Extension of protection against blast weakness to modify mechanical properties, such as springs, gears, etc.

• Shot blasting machine process provisions:

• High efficiency with an exceptional impeller structure.

• All major machining parts are finished with CNC focus to maintain exceptional precision and balance when turning is fast.

• The difference between the weight of each rim piece is less than 8 grams, giving the wheels consistent performance.

• Gives you a protective liner and fixation as the top cover has a solid, elastic wearable metal with two layers that secure and hold it in place.

• Less movement because the Blast wheel base has elastic padding that dampens vibrations.

• The Sprinter wheel is carburized and uses a full 400 Cr material. After handling this, the sprinter needs a reveal measure below balance.

• Uses two plate blast wheels that are compact and have a great throwing capacity.

SHOT BLASTING MACHINE FOR SALE

GRITBLAST is excellent among other in shot blast machine manufacturer in India. Their highly competent and experienced group ensures clients' compliance with transfers that require exceptional consideration during capacity and bundling. Shot Blasting Machine for Sale at a low price. They can help you get the most suitable and specific shot blast machine for the best results and performance.

We are also exporters of sand blasting machine, grit blasting machine, portable sand blasting machines, portable shot blasting machine, thermal spray gun, and shot blasting machines. Gritblast is one of the best blast machine supplier in India and offers the best quality at a reliable price.

#SHOT BLASTING MACHINE FOR SALE#SHOT BLASTING MACHINE#GRITBLAST#SHOT BLASTING MACHINE USE#SHOT BLASTING MACHINE PROCESS

0 notes

Link

The Grit Blasting process is one of the most effective blasting techniques available. With the help of a variety of abrasive, it manages to clean and weld all types of surface and machines.

0 notes

Text

https://www.mythrimetallizing.com/sand-blasting-4

Mythri Metallizing India Pvt Ltd provides, the best sandblasting services in Bangalore

#sandblasting#gritblasting#surface preparation#copper slag blasting#sandblasting services#sandblasting services in bangalore

0 notes

Text

Corrosion Protection Techniques: Sand, Grit, Copper Slag Blasting, and Spray Painting.

Introduction

Corrosion, the gradual deterioration of materials due to environmental factors, is a persistent problem in various industries. To combat this issue and prolong the lifespan of structures and equipment, engineers and maintenance teams rely on various corrosion protection techniques. Among the most effective methods are grit blasting, copper slag blasting, sandblasting services, and spray painting. In this article, we will explore each of these techniques and their contributions to safeguarding metal surfaces from corrosion.

Sand Blasting:

Sandblasting is a widely-used corrosion protection method that involves propelling fine sand particles at high speeds to clean and prepare metal surfaces. The process efficiently removes rust, old paint, and other contaminants, leaving the surface clean and roughened. This rough texture enhances the adhesion of subsequent coatings, such as paints or protective layers, and significantly reduces the risk of corrosion. Sandblasting is especially suitable for large industrial applications like bridges, oil rigs, and ship hulls. However, it has some limitations as well. The process can produce a significant amount of dust, which may pose health hazards if not properly controlled. Moreover, sand used in the process can cause silicosis, a lung disease, if inhaled. To address these concerns, alternative materials like steel grit or aluminum oxide are sometimes used for blasting.

Grit Blasting:

Grit blasting is a similar technique to sandblasting, but it employs abrasive materials other than sand. Commonly used abrasives include steel grit, aluminum oxide, and crushed glass. The selection of the abrasive depends on the specific requirements of the project, as each material has its unique properties.

Grit blasting is particularly effective for removing heavy corrosion and mill scale from metal surfaces. The process prepares the surface for protective coatings and ensures long-term corrosion resistance. Unlike sandblasting, it generates less dust, making it a safer option for certain applications.

Copper Slag Blasting:

Copper slag blasting is an innovative and eco-friendly corrosion protection method that has gained popularity in recent years. Copper slag, a byproduct of copper smelting, is used as an abrasive in the blasting process. It offers several advantages, such as low dust generation, high cleaning efficiency, and lower cost compared to some traditional abrasives.

Additionally, copper slag blasting creates a surface profile that enhances coating adhesion, thereby improving overall corrosion protection. The process is suitable for various applications, including shipbuilding, oil and gas facilities, and structural steel components.

Spray Painting:

Spray painting, or protective coating application, is a widely adopted corrosion protection technique that involves applying a protective layer on metal surfaces using spray equipment. Various types of protective coatings are available, including epoxy, polyurethane, and zinc-rich coatings.

The primary purpose of spray painting is to provide a physical barrier between the metal surface and the corrosive environment. These coatings are specially formulated to withstand harsh conditions, such as exposure to saltwater, chemicals, and atmospheric elements. Proper surface preparation, such as sand or grit blasting, is essential before applying the protective coating to ensure optimal adhesion and performance.

Conclusion

Corrosion protection is a critical aspect of maintaining the integrity and longevity of metal structures and equipment. Sandblasting, grit blasting, copper slag blasting, and spray painting are proven techniques that effectively mitigate the impact of corrosion. Each method serves a specific purpose, and their selection depends on the nature of the project, the extent of corrosion, and environmental considerations.

When properly executed, these corrosion protection techniques can extend the service life of metal components, reduce maintenance costs, and enhance safety. To ensure the success of any corrosion protection project, it is vital to engage trained professionals who can apply these methods with precision and adhere to industry best practices. By implementing these corrosion protection measures, industries can ensure the sustainable and efficient operation of their assets for years to come.

To know more about Corrosion protection services, Visit us

0 notes