#gantry crane components

Explore tagged Tumblr posts

Text

Worn Hopes and Armored Plated Dreams

The Scrapplemech had a stupid name, Katrina had decided. No quadmech, covered in salvage arms, fluid support systems, and lifting booms should be named “Scrapplemech”. She hated everything about the name. She hated that Tisha named it that. It was terrible that she got name it for it was her creation. What an awful machine.

And yet here it was, lifting her beloved’s decapitated Phoenix Hawk IIC onto a heavy recovery truck. The six Hammerheads of the trinary’s command star stood vigil over the salvage teams as they moved mechs onto recovery vehicles for towing back to the FOB. It didn’t matter if they were enemy or ally. Both would serve their purposes for what they would need in the coming days.

That did not stop the creeping feeling that crawled down her spine from watching eight of her own mechs get pulled back to the FOB.

______________________________________________________________

The Scrapplemech towered over the rest of the CSJ’s camp as it stood over the area in the middle they had cleared for refit and rearm. It looked like an ominous portent, all of its gantries and support structures extended out into the air, appearing like an industrial spider’s web intent on catching any pesky components. The Phoenix Hawk IIC had been laid out next to it, under one of the primary lift arms that could do major refit work.

Objectively speaking, the Phoenix Hawk IIC was not in bad condition. Katrina hated to think about it too hard, but this was fixable. And quickly as well. Quietly she muttered curses to herself as she hooked up lift gear to the damaged LB 10-X and prepared to lift it out of the torso module that it was seated in, stepping back a foot or so and throwing at thumbs up to Tisha so that she could engage the lift. The humming whine of the crane filled the air as its electric winch engaged, tugging the weapon up and out of its cradle.

The retractable blade that had damaged it had been removed prior, but the damage it left was clearly visible now that the cannon was out of the mech. The blade had mangled the breech and part of the feed mechanism. This gun would need significant rework if it was to be made operational again. For now it would get stuck in the rebuild pile.

Katrina sighed as she directed the boom, aiding Tisha in getting the 10 ton weapon where it needed to go. She had to think about what she was going to rebuild this with.

Maybe… maybe the Blakists needed a bit of a fright. She had some old refit plans floating around for the Phoenix Hawk IIC 7 for if they ever needed to do shock and awe ops. Perhaps those would suit. They had the RAC-2s available as well as the AP Gauss Rifles, and all of their spare parts had been flown down with the Scrapplemech.

Yeah. That idea would work. Maybe the Hammerheads too, if she could get the pilots on board. They likely would be. Disconnecting the lift harness from the landed LB 10-X, Katrina settled herself in for a hard day’s work.

@karriethemechtech

4 notes

·

View notes

Text

Understanding Cranes: A Comprehensive Guide for All Types of Cranes

Cranes are essential machinery in various industries, particularly in manufacturing and construction. They play a critical role in lifting, transporting, and arranging heavy objects and machinery. This guide will explore how cranes work, the different types available, and their specific applications, focusing on manufacturers of all types of cranes, including the cranes exclusively manufactured by Shri Bhagwati Machines Pvt. Ltd.

How Do Cranes Work?

Cranes operate on fundamental principles that allow them to lift heavy loads with ease. Here’s a breakdown of the basic operational principles:

1. Mechanical Advantage

Cranes utilize mechanical components such as levers and pulleys to gain a mechanical advantage. This reduces the amount of effort required to lift heavy objects, making it easier for operators to manage large loads.

2. Distribution of Loads

Cranes are designed to distribute weight evenly across their structure. This distribution minimizes structural stress and enhances stability during lifting operations. Key components such as the base, boom, and counterweights work together to maintain balance.

3. Control Systems

Modern cranes are equipped with sophisticated control systems that allow operators to maneuver loads precisely. These systems may include levers, joysticks, or remote controls, enabling smooth operation even in complex environments.

Types of Cranes and Their Purposes

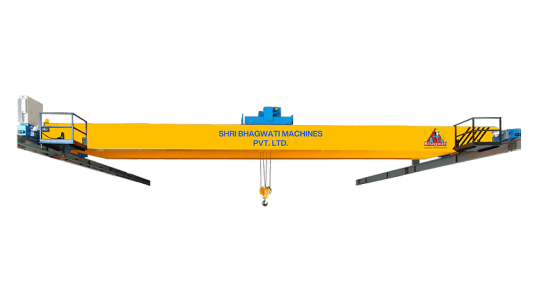

1. Overhead & Gantry Cranes

Shri Bhagwati Machines Pvt. Ltd. is a prominent manufacturer of Electric Overhead Traveling (EOT) cranes, known for their exceptional quality and reliability. EOT cranes are essential in various industrial applications, providing efficient solutions for lifting and transporting heavy loads with ease. Designed to operate on a fixed track, these cranes feature a robust construction that ensures stability and safety during operation. The EOT cranes manufactured by Shri Bhagwati Machines are equipped with advanced control systems, allowing for precise maneuverability and enhanced operational efficiency. Their design maximizes workspace utilization, making them ideal for factories, warehouses, and construction sites. With a commitment to excellence,SBMPL has established itself as a trusted name in the crane industry, delivering high-performance EOT cranes tailored to meet the diverse needs of clients across various sectors.

Visit : https://bhagwatimachines.com/eot-cranes.html

2. Wall Mounted Cranes

SBMPL specializes in manufacturing high-quality wall-mounted cranes, designed to optimize space and enhance efficiency in various industrial settings. These cranes are ideal for environments where floor space is limited, as they utilize overhead areas effectively, allowing for the lifting and moving of loads without occupying valuable ground space.

Visit : https://bhagwatimachines.com/wall-cranes.html

3. JIB Cranes

We are a leading manufacturer of high-quality jib cranes, designed to enhance efficiency and productivity in various industrial applications. Jib cranes are versatile lifting solutions that feature a horizontal arm (jib) mounted on a vertical mast, allowing for flexible load handling within a defined radius.

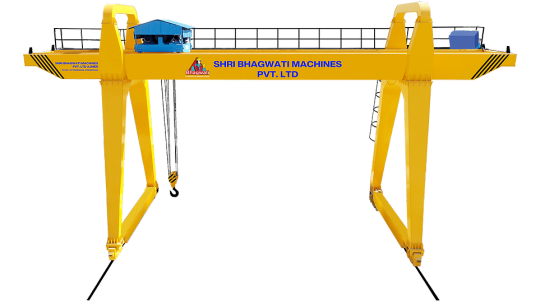

4. Gantry/Goliath Cranes

We manufacturer high-quality gantry and goliath cranes, designed to meet the diverse needs of various industries. These cranes are essential for lifting and transporting heavy loads, making them invaluable in manufacturing, construction, and logistics.

Visit : https://bhagwatimachines.com/gantry-cranes.html

4. Semi Gantry Cranes

We are a prominent manufacturer of semi-gantry cranes, designed to provide efficient lifting solutions in various industrial applications. These cranes are characterized by their unique design, featuring one leg that runs on a track while the other is fixed to a wall or column. This configuration allows for greater flexibility in confined spaces where traditional gantry cranes may not fit.

Visit : https://bhagwatimachines.com/semi-gantry-cranes.html

5. Additional Crane Types

Mobile Cranes: These cranes offer mobility on job sites and can be driven on highways.

Tower Cranes: Commonly used in urban construction projects due to their height and lifting capacity.

Rough Terrain Cranes: Designed for off-road use with enhanced stability on uneven surfaces.

Crawler Cranes: Feature tracks for mobility and can lift extremely heavy loads.

Floating Cranes: Used in maritime applications for loading and unloading cargo from ships.

Operational Procedures for Planning and Setup

Preoperative Planning: Engineers and operators assess the site, calculate load weights, and plan the lifting procedure to ensure efficiency and safety.

Tower Cranes: Commonly used in urban construction projects due to their height and lifting capacity.

Lifting Procedure: Operators use control systems to raise the load while counterweights help maintain balance

Weight Shifting: Once lifted, the operator carefully moves the load horizontally using the boom or gantry system while ensuring precise synchronization to avoid obstructions.

Positioning: The operator gently lowers the load into place, often guided by signals from ground crew members to ensure accuracy.

Frequently Asked Questions regarding types of manufacturing and construction cranes

How do cranes work? Cranes used in manufacturing and construction are essential for lifting, transporting, and arranging large objects and machinery.

What is the Basic Crane Operation Principles Mechanical Advantage ? Cranes have an edge when lifting large objects because they use mechanical components like hydraulic cylinders, levers, and pulleys. This lowers the amount of work required to move objects.

How cranes helps in Distribution of Loads ? Cranes disperse weight uniformly, reducing structural stress and guaranteeing stability. To balance loads, the base, boom, and counterweights cooperate.

What are System Of Control in Cranes ? Control systems installed on cranes enable operators to precisely move loads. Levers, joysticks and occasionally remote controllers that are manipulated by hand fall under this category.

What are Overhead Cranes ? These tracks-based cranes are commonly observed in production facilities and have the ability to lift and transport objects within a predetermined region. They are very handy when transferring large items between warehouses or assembly lines.

What are wall-mounted Cranes ? ? Wall-mounted cranes serve a specific and valuable purpose in the manufacturing and construction industries. Here’s a detailed overview of their functions and benefits: Wall-mounted cranes allow for lifting and moving loads in areas where floor space is limited. They utilize overhead space, leaving the floor clear for other activities.Their installation against walls helps free up valuable floor space, making them ideal for smaller workshops or factories.

What are JIB Cranes ? Jib cranes are adaptable lifting tools that are frequently utilized in a variety of sectors, such as building, manufacturing, and warehousing. Jib cranes can raise and move big loads both horizontally and vertically, which makes them appropriate for a variety of tasks, including handling commodities and moving industrial parts.

What are the Operating Procedures for Planning and Setup in Manufacturing and Construction ? Engineers and operators arrange the lifting procedure, calculate load weights, and evaluate the site before starting up. Efficiency and safety are guaranteed by a proper setup.

0 notes

Text

Lifting Equipment Offshore: Ensuring Safe and Efficient Operations

In offshore industries such as oil and gas, wind energy, and marine engineering, lifting equipment plays a crucial role in the daily transportation and handling of heavy loads. Whether it’s moving machinery, materials, or containers between platforms or from vessels to offshore installations, reliable lifting equipment ensures that these operations are carried out safely, efficiently, and in compliance with stringent industry standards.

Types of Offshore Lifting Equipment

Offshore lifting equipment comes in many forms, each designed for specific tasks and load capacities. Some of the most commonly used equipment includes:

Offshore Cranes Offshore cranes are one of the most essential pieces of lifting equipment on platforms. These cranes are mounted on vessels or rigs and are capable of lifting loads from supply vessels, moving large machinery, or positioning equipment on the platform. These cranes are typically designed to handle high wind speeds, rough sea conditions, and the constant motion of platforms and ships.

A-Frames and Gantry Cranes These are used for lifting large loads or conducting subsea operations. A-frames are commonly found on vessels and allow for the safe deployment of subsea equipment, such as ROVs (Remotely Operated Vehicles), directly into the ocean.

Davit Systems Davit systems are smaller lifting devices used for light to medium loads, such as lowering life-saving boats or small equipment onto vessels or platforms. They are compact but strong and versatile.

Hoists and Winches Used to lift or pull loads in vertical and horizontal directions, hoists and winches are critical for operations that require precision. They come in various forms, such as hydraulic, electric, or manual, depending on the weight and type of load they are handling.

Lifting Slings and Shackles These are essential accessories that assist in the connection of the load to the crane or hoist. Offshore lifting slings are usually made from durable materials like wire ropes, chains, or synthetic fibers and must meet safety standards to handle heavy loads. Shackles, hooks, and other rigging components are also used to secure the load and maintain safety during lifting operations.

Safety and Standards in Offshore Lifting

Offshore lifting operations are inherently risky due to challenging conditions such as high winds, rough seas, and platform instability. Ensuring safety in lifting operations is paramount, which is why offshore lifting equipment must adhere to international standards such as:

Lloyd’s Register of Shipping (LRS)

Det Norske Veritas (DNV GL)

International Maritime Organization (IMO)

These organizations set the guidelines for equipment design, load testing, and operational procedures. Equipment must undergo regular inspection, maintenance, and testing to maintain safety certification. Additionally, lifting operations are typically carried out by trained, certified personnel who understand the dynamics of lifting in offshore environments.

Importance of Lifting Equipment in Offshore Operations

Without reliable lifting equipment, offshore industries would face significant delays and safety risks. Heavy-duty cranes and hoists ensure that critical components, such as drilling equipment or turbine parts, can be transported safely between platforms and vessels. In emergency situations, lifting equipment is also essential for evacuations or moving life-saving gear.

In conclusion, lifting equipment is a backbone of offshore operations, ensuring that tasks are carried out efficiently while meeting strict safety standards. Investing in high-quality, well-maintained lifting systems and trained personnel is crucial to the success of any offshore project.

0 notes

Text

Keep Your Operations Running Smoothly with Expert EOT/Overhead Crane Repair & Maintenance

Our team of highly skilled engineers are committed to the task of repairing and servicing Gantry/Goliath cranes in order to ensure their reliability and minimize any chances of breaking down as well enhancing their operational efficiency.

Why Choose Us?

Our expert technicians team handles all your crane repair and maintenance needs.

Our scope of work extends from periodic checks to emergency fix-up services to help keep your machines running smoothly.

Our cranes ever stay in good shape as we use the best components while adhering strictly to industry standards.

Our Services Include:

Regular maintenance and inspections

Emergency repair services

Load testing and certification

Spare parts supply and replacement

Contact Us Today! 📞 +91-98-2413 5305 | ✉️ [email protected] | 🌐 www.endeavourweigh.com/mhe-spare-division-category/mhe-services/

Ensure your EOT/Overhead Cranes are always ready for action. Trust us for reliable repair and maintenance services.

#CraneMaintenance#EOTCraneRepair#OverheadCraneService#IndustrialMaintenance#EndeavourWeigh#ReliableService#HeavyDutyCranes#MaintenanceSolutions

0 notes

Text

Single Girder Crane

SAFE AND SMOOTH MATERIAL HANDLINGMoving Material Resources Safely With Care : Harsiddhi Crane Single Girder and Double Girder E.O.T. Cranes are designed and manufactured in accordance with IS/BS/DIN. Considering adequate factors of safety with respect to appropriate duty, the structural parts of the cranes are designed in accordance with IS/BS/DIN. Harsiddhi Crain also manufactures / utilises standard components and controls to ensure reliability

Span : 3 mtrs. to 20 mtrs.

Safe Working Load : 0.5 ton to 15.0 ton

Crane Control : From floor through Pendant Push Buttons, Optionally through Radio Remote Control / cabin with master control.

Power Supply System : To Hoist and Cross Travel through Trailling Cables / Drag Chain to Crane through Shrouded Bus Bars / Trailling Cable / MS Angle Iron Conductors / Bare Copper Conductors (depending on customer’s choice and application).

Motors : Squirrel Cage Slip Ring Motors based on application requirements, built-in separator electrically operated fail to safe brakes for all three motions. Motors with “F” class insulation provided in all motions

Single Girder Crane, Wire Rope Hoist Crane, Cranes, EOT Crane, Goliath Gantry Crane, Semi Gantry Crane, Under Slung Crane, Trolley Crane, Crane, Crain

#harsidhicrain#harsidhicrane#craneharsidhi#crane#singlegirdereotcrane#doublegirdereotcrane#goliathgantryeotcrane#semigantryeotcrane#underslungeotcrane#wireropehoistcrane#doublerailtrolleytypecrane#walltravellingjibcrane#eotcrane#hoistcrane#jibcrane#goodslift#crain

0 notes

Text

Suspended in Efficiency: The Advantages of Monorail Installations

In the realm of material handling and transportation, monorail installations soar as beacons of streamlined efficiency. Join us as we explore the advantages that elevate monorail systems, suspended in their ability to revolutionize various industries.

Space Optimization: Elevating Capacity Without the Footprint

Monorail installations are masters of space optimization.

Suspended overhead, mobile gantry crane efficiently transports materials without occupying valuable floor space. This enables businesses to maximize capacity without compromising on the overall layout of their operational areas.

Versatility in Layout: Crafting Customized Pathways

The flexibility of monorail layouts is a key advantage.

Tailored to the unique needs of each facility, monorail installations can navigate complex pathways, including curves and inclines, optimizing material flow and adapting seamlessly to the spatial dynamics of diverse environments.

Enhanced Safety: Minimizing Ground-Level Hazards

Safety takes center stage with monorail installations.

By keeping the transport system elevated, ground-level hazards are minimized. This ensures a safer work environment, reducing the risk of accidents and collisions commonly associated with floor-level material handling systems.

Efficient Material Flow: Continuous and Uninterrupted

Monorail systems excel in maintaining continuous material flow.

With the ability to transport materials without interruptions, businesses benefit from enhanced operational efficiency. This streamlined flow is especially advantageous in industries where a seamless production process is critical.

Customizable Load Capacities: Tailored to Material Requirements

Monorail installations offer customizable load capacities.

Whether transporting lightweight components or heavy machinery, the system can be designed to accommodate specific material requirements. This adaptability ensures optimal performance across a range of industries and applications.

Easy Maintenance: Accessibility for Upkeep

Maintenance becomes a straightforward task with monorail systems.

Accessible from below, the suspended track allows for easy inspection and maintenance. This accessibility minimizes downtime and facilitates prompt repairs or adjustments, contributing to the overall reliability of the material handling system.

As we explore the advantages of monorail installations, it becomes clear that they are not just transport systems; they are elevated pathways to a future where efficiency reigns supreme.

Source

0 notes

Text

Exploring the Versatility of Portable Gantry Cranes

Portable Gantry Cranes are a game-changer in the world of lifting and material handling. These versatile devices offer a wide range of benefits and applications across various industries. Let's delve into the key features and uses of portable gantry cranes.

Key Features of Portable Gantry Cranes

Portability As the name suggests, portable gantry cranes are designed for easy transportation and setup. They typically feature wheels or casters, allowing users to move them effortlessly from one location to another. This mobility makes them ideal for temporary lifting tasks or environments where a fixed crane is impractical.

Adjustability Most portable gantry cranes come with adjustable height and span options, providing flexibility to accommodate different lifting requirements. Users can adjust the crane's height and span to suit the dimensions of their workspace or the size of the load being lifted, enhancing versatility and efficiency.

Ease of Assembly Unlike traditional overhead cranes that require complex installation procedures, portable gantry cranes are relatively easy to assemble and disassemble. They often feature bolt-together components that can be quickly assembled using basic tools, allowing for rapid deployment and breakdown as needed.

Load Capacity Despite their portable design, these cranes are capable of lifting heavy loads with ease. Depending on the model and configuration, portable gantry cranes can typically handle loads ranging from a few hundred pounds to several tons, making them suitable for a wide range of lifting tasks in industrial, construction, and workshop settings.

Versatile Applications of Portable Gantry Cranes

Construction Sites Portable gantry cranes are commonly used in construction sites for lifting and moving heavy materials such as steel beams, concrete panels, and equipment. Their portability and adjustable height make them ideal for navigating uneven terrain and accessing hard-to-reach areas.

Workshops and Warehouses In workshops and warehouses, portable gantry cranes are invaluable for lifting and maneuvering machinery, parts, and other materials. Their versatility allows workers to easily reposition the crane to different workstations, maximizing productivity and efficiency.

Event Setup and Maintenance Portable gantry cranes are also used in event setup and maintenance tasks, such as lifting stage equipment, lighting rigs, and audiovisual components. Their portability and quick assembly make them ideal for temporary installations and teardowns at concert venues, trade shows, and outdoor events.

Marine and Shipping In marine and shipping environments, portable gantry cranes are utilized for loading and unloading cargo from ships and docks. Their ability to handle heavy loads combined with their portability makes them essential for efficient cargo handling operations in ports and harbors.

In summary, portable gantry cranes are versatile lifting solutions that offer portability, adjustability, ease of assembly, and robust load capacity. From construction sites to workshops, event venues to shipping yards, these cranes play a vital role in lifting and material handling operations across various industries. Their flexibility and efficiency make them a valuable asset for any workspace requiring reliable lifting capabilities.

More Info Contact Us

Website https://hescranes.com.au/

Ph: 1800 437 272

Mail id: [email protected]

Working Time: Monday to Friday 9.00am - 5.30 pm Saturday and Sunday Open 24 hours.

0 notes

Text

Streamlining Operations: The Role of Material Handling Equipment in Industrial Efficiency

In the realm of industrial operations, material handling equipment plays a pivotal role in optimizing efficiency, productivity, and safety. From warehouses and manufacturing facilities to distribution centers and logistics hubs, the strategic deployment of the equipment enables organizations to streamline workflows, minimize manual labor, and maximize throughput. In this comprehensive guide, we’ll explore the significance of equipment, examine its key categories and applications, and highlight its transformative impact on industrial operations.

Understanding Material Handling Equipment

Equipment to handle material encompasses a diverse range of tools, machinery, and systems designed to facilitate the movement, storage, protection, and control of materials and products within industrial environments. These equipment types are essential for handling raw materials, work-in-progress (WIP), finished goods, and other items throughout the supply chain, from receipt to distribution.

Key Categories of Material Handling Equipment

1. Conveyors

Conveyors are a fundamental component of material handling systems, enabling the efficient transportation of goods between various stages of production or storage areas. Types of conveyors include belt conveyors, roller conveyors, chain conveyors, and overhead conveyors, each suited for specific applications and material handling requirements.

2. Forklifts and Industrial Trucks

Forklifts and industrial trucks are versatile vehicles used for lifting, transporting, and stacking materials in warehouses, distribution centers, and manufacturing facilities. These vehicles come in various configurations, including counterbalance forklifts, reach trucks, pallet jacks, and order pickers, providing flexibility and adaptability for diverse material handling tasks.

3. Storage and Retrieval Systems

Storage and retrieval systems are designed to maximize space utilization and optimize inventory management within warehouses and distribution centers. These systems include pallet racks, shelving systems, mezzanines, and automated storage and retrieval systems (AS/RS), which use robotics and automation to store and retrieve items with speed and precision.

4. Automated Guided Vehicles (AGVs)

AGVs are autonomous mobile robots that transport materials and goods within industrial facilities, following predefined paths or navigation systems. AGVs can be used for a variety of material handling tasks, including transporting raw materials to production lines, moving finished products to storage areas, and replenishing inventory in distribution centers.

5. Cranes and Hoists

Cranes and hoists are used for lifting and positioning heavy loads in manufacturing plants, construction sites, and port terminals. These equipment types include overhead cranes, gantry cranes, jib cranes, and hoists, which provide the lifting capacity and precision needed for material handling operations in various industries.

Transformative Impact of Material Handling Equipment

1. Increased Efficiency and Productivity

Material handling equipment streamlines workflows reduces manual labor, and accelerates material flow, leading to increased efficiency and productivity in industrial operations. By automating repetitive tasks and optimizing resource utilization, organizations can achieve higher throughput and output levels while minimizing downtime and labor costs.

2. Enhanced Safety and Ergonomics

Material handling equipment improves workplace safety by reducing manual handling risks, minimizing the likelihood of accidents, and mitigating ergonomic hazards associated with heavy lifting and repetitive motion. By using equipment such as forklifts, conveyors, and lifting devices, organizations can create a safer and healthier work environment for employees.

3. Improved Accuracy and Quality

Automated material handling systems enhance accuracy and quality control by reducing errors, minimizing damage to goods, and ensuring consistent handling of materials throughout the production process. By leveraging robotics, sensors, and automation technologies, organizations can achieve higher levels of precision and reliability in material handling operations.

4. Scalability and Flexibility

Material handling equipment offers scalability and flexibility to adapt to changing demand patterns, production volumes, and operational requirements. Whether expanding operations, introducing new product lines, or reconfiguring warehouse layouts, organizations can easily scale their material handling systems to accommodate evolving business needs and market dynamics

5. Choosing the Right Equipment

When selecting material handling equipment, organizations should consider factors such as operational requirements, facility layout, throughput goals, budget constraints, and safety regulations. By conducting a thorough needs assessment and consulting with material handling experts, organizations can choose the right equipment types and configurations to optimize their material handling operations effectively.

Conclusion

Material handling equipment is the backbone of modern industrial operations, providing the tools and systems needed to efficiently transport, store, and manage materials and products throughout the supply chain. By leveraging conveyors, forklifts, storage systems, AGVs, and other equipment types, organizations can streamline workflows, enhance productivity, and achieve operational excellence in today’s competitive marketplace. As organizations continue to invest in technology and automation, the equipment will remain indispensable for driving efficiency, safety, and agility across a wide range of industries.

Also Read: Unleashing Agility: A Comprehensive Exploration of Flexible Manufacturing Systems

0 notes

Text

Powering Efficiency: Electric Chain Hoists Revolutionizing Material Handling Industries

In the bustling world of material handling, efficiency is key. Every operation, whether it’s in manufacturing, construction, or logistics, relies on the swift and safe movement of heavy loads. Traditionally, this has been achieved through manual labor or cumbersome mechanical systems. However, the advent of electric chain hoists has revolutionized the landscape, offering a powerful solution that enhances productivity, safety, and precision.

Electric chain hoists are compact yet robust devices designed to lift, lower, and maneuver heavy loads with ease. Unlike their manual counterparts, these hoists are powered by electricity, which provides consistent and reliable performance. This power source not only reduces the physical strain on workers but also enables precise control over lifting operations, leading to greater efficiency and accuracy.

One of the primary advantages of electric chain hoists is their versatility. These devices can be easily mounted onto various structures, including overhead beams, gantry cranes, and jib cranes, allowing them to adapt to different work environments seamlessly. Whether it’s lifting materials in a warehouse, positioning machinery in a factory, or erecting steel structures at a construction site, electric chain hoists offer unparalleled flexibility.

Safety is paramount in any material handling operation, and electric chain hoists are engineered with this in mind. These hoists are equipped with advanced safety features such as overload protection, emergency stop buttons, and limit switches to prevent accidents and protect both personnel and property. Furthermore, the precise control offered by electric hoists reduces the risk of load swinging or sudden movements, enhancing overall workplace safety.

Another significant benefit of electric chain hoists is their efficiency. By automating the lifting process, these hoists can significantly reduce the time and labor required to move heavy loads. This not only boosts productivity but also allows workers to focus on more skilled tasks, thereby optimizing resource utilization and driving down operational costs.

In addition to their efficiency, electric chain hoists are also highly durable and low maintenance. Constructed from high-quality materials and precision-engineered components, these hoists are built to withstand the rigors of daily use in demanding industrial environments. With proper care and maintenance, electric chain hoists can provide years of reliable service, making them a cost-effective investment for businesses of all sizes.

Furthermore, the advent of smart technologies has further enhanced the capabilities of electric chain hoists. Integrated sensors, remote monitoring systems, and connectivity features enable real-time tracking of performance metrics, predictive maintenance scheduling, and seamless integration with other automation systems. This not only improves operational efficiency but also provides valuable insights for optimizing workflows and enhancing decision-making processes.

In conclusion, electric chain hoists have emerged as a game-changer in the material handling industry, offering a potent combination of efficiency, safety, and versatility. By harnessing the power of electricity, these hoists have transformed the way heavy loads are handled, making operations smoother, safer, and more productive. As technology continues to advance, electric chain hoists are poised to play an even more significant role in shaping the future of material handling, driving innovation, and unlocking new possibilities for businesses around the globe.

0 notes

Text

The Most Popular Crane Types For Construction And Manufacturing

Because they can lift big objects and equipment to a safe and effective location, cranes are a vital component of the manufacturing and construction sectors. Selecting the ideal crane for your requirements can be made easier if you are aware of the different kinds that are available. The most popular kinds of cranes, such as wall-mounted cranes, jib cranes, semi-gantry cranes, Goliath cranes, EOT cranes, and gantry cranes, will all be covered in this blog.

1. Electric overhead traveling cranes, or EOT cranes

One of the most popular varieties of cranes in manufacturing and construction are EOT cranes. They are intended to run on a system of tracks that are mounted to a factory or workshop ceiling. With these cranes, loads are raised and lowered by a trolley that can move along a bridge that spans the width of the workspace.

Important Characterstics

Versatility: Fit for a range of uses, such as material handling and heavy lifting.

Space Efficiency: Because they run overhead, they maximize floor space.

Precision Control: Accurate and seamless movements are made possible by electric drives.

2. Gantry Cranes

Important Characterstics

Mobility: Able to relocate to new places with ease.

Height Adjustability: Lifting at different heights is possible thanks to adjustable legs.

Economical: Usually less costly than cranes overhead.

3. Goliath Cranes

Important Characterstics

High Load Capacity: Able to move very heavy objects.

Outside Use: Designed to endure outside environments.

Durability: A long service life is guaranteed by a sturdy structure.

4. Semi Gantry Cranes

Semi-gantry cranes are cranes that combine elements of EOT and gantry cranes. They walk on the ground with one leg and sprint along an overhead track with the other. Because to their special design, they can reach places that full gantry cranes cannot, which makes them especially helpful in spaces that are limited in size.

Important Characterstics

Compact Design: Ideal for spaces with little headroom.

Operation Flexibility: Suitable for a range of environments, such as warehouses and workshops.

Simple Installation: Compared to larger cranes, this one is easier to erect.

5. Wall Mounted Cranes

Important Characterstics

Space Efficiency: Preserves important floor area.

Easy to Use: They are easy to use and may be used for a variety of purposes.

Low Maintenance: Compared to larger cranes, these often require less maintenance.

6. JIB Cranes

Important Characterstics

Versatility: Adaptable to different settings (wall, floor, or portable).

Enhanced Reach: Offers a longer reach for activities involving lifting.

Economical Solution: Perfect for workshops or smaller companies.

In Summary

For maximum productivity and safety in your industrial or construction operation, use the appropriate crane. Every kind of crane has particular benefits and is appropriate for a given set of uses. Knowing your alternatives can help you make an informed choice, regardless matter whether you require the flexibility of a jib crane or the enormous lifting capacity of a Goliath crane. To make sure you choose the ideal crane for your purposes, always seek professional advice and bear in mind elements like weight capacity, workspace configuration, and operational requirements. Happy weightlifting! .

0 notes

Text

Enhancing Industrial Operations: Applications of Double Girder Gantry Cranes

In the dynamic landscape of industrial operations, efficiency, precision, and safety are paramount. Businesses across diverse sectors rely on advanced equipment to streamline processes and meet demanding production targets. Among the arsenal of industrial machinery, double girder gantry cranes stand out as versatile and indispensable assets. In this article, we explore the diverse applications of double girder gantry cranes and how they contribute to enhancing industrial operations across various sectors.

1. Manufacturing and Assembly:

In manufacturing facilities, where the assembly of heavy machinery and equipment is routine, double girder gantry cranes play a pivotal role. These cranes provide the lifting capacity and precision required to maneuver large components into place during assembly processes. Whether it's automotive, aerospace, or heavy equipment manufacturing, double girder gantry cranes ensure efficient production by facilitating the movement of materials and sub-assemblies with ease.

2. Construction and Infrastructure Development:

The construction industry relies on double girder gantry cranes for various tasks, ranging from lifting and placing construction materials to erecting structural components. These cranes are instrumental in projects involving the construction of bridges, buildings, and infrastructure, where the handling of heavy loads at height is essential. Their extended span and height capabilities make them ideal for navigating construction sites and executing lifting operations with precision.

3. Port and Logistics Operations:

Ports and logistics facilities handle vast volumes of cargo on a daily basis, requiring robust lifting solutions to expedite loading and unloading processes. Double girder gantry cranes(https://gantrycrane.kz/dvukhbalochnyy-kozlovoy-kran-30-tonn/) excel in this environment, offering the lifting capacity and reach necessary to handle containers, bulk goods, and oversized cargo efficiently. With their ability to span multiple lanes and stack containers at heights, these cranes optimize terminal throughput and streamline maritime logistics operations.

4. Warehousing and Distribution:

In warehousing and distribution centers, where inventory management and order fulfillment are critical, double girder gantry cranes provide essential support for material handling tasks. These cranes enable the efficient movement of pallets, crates, and heavy machinery within the facility, minimizing downtime and maximizing storage capacity. Whether it's loading and unloading trucks or organizing inventory in high-rise storage racks, double girder gantry cranes enhance operational efficiency in warehouse environments.

5. Steel and Metal Fabrication:

Industries involved in steel and metal fabrication rely on double girder gantry cranes for lifting and transporting raw materials, semi-finished products, and finished goods within manufacturing facilities. These cranes are essential for handling heavy coils, plates, and structural components with precision and safety. With their robust construction and advanced control systems, double girder gantry cranes streamline material flow and optimize production processes in metalworking industries.

In conclusion, the applications of double girder gantry cranes are diverse and far-reaching, spanning across various industries and sectors. From manufacturing and construction to port operations, warehousing, and metal fabrication, these versatile lifting solutions enhance efficiency, productivity, and safety in industrial operations. As technology continues to advance and industries evolve, double girder gantry cranes remain indispensable tools for businesses seeking to optimize their material handling processes and stay competitive in today's dynamic marketplace.

1 note

·

View note

Text

Elevate Efficiency with Double V Guide Wheel Bearings

In the fast-paced world of industrial machinery, efficiency and precision are paramount. To ensure optimal performance and longevity of your equipment, consider upgrading to Double V Guide Wheel Bearings. These specialized bearings offer unparalleled stability, accuracy, and durability, making them an indispensable component for various industrial applications.

Why Choose Double V Guide Wheel Bearings?

1. Enhanced Stability: Double V Guide Wheel Bearings are designed with a unique double V groove profile that provides exceptional stability and alignment. This ensures smooth and precise movement, even in high-speed and high-load conditions. 2. Improved Accuracy: With precision machining and tight tolerances, Double V Guide Wheel Bearings offer superior accuracy, allowing for precise positioning and repeatability. This is crucial for applications where precise motion control is essential. 3. Exceptional Durability: Constructed from high-quality materials such as stainless steel or carbon steel, Double V Guide Wheel Bearings are built to withstand harsh operating environments and heavy-duty usage. This results in extended service life and reduced maintenance requirements.

Applications of Double V Guide Wheel Bearings

Double V Guide Wheel Bearings find wide-ranging applications across various industries, including:

1. Automation and Robotics: In automated manufacturing processes and robotic systems, Double V Guide Wheel Bearings play a critical role in ensuring smooth and precise movement of components and machinery. 2. Material Handling: From conveyor systems to gantry cranes, Double V Guide Wheel Bearings are utilized in material handling equipment to facilitate efficient and reliable transportation of goods and materials. 3. Medical Devices: In medical equipment such as diagnostic machines and surgical robots, Double V Guide Wheel Bearings provide the accuracy and stability required for delicate and precise movements.

Factors to Consider When Choosing Double V Guide Wheel Bearings

When selecting Double V Guide Wheel Bearings for your machinery, consider the following factors:

1. Load Capacity: Ensure that the bearings can support the anticipated loads of your application without compromising performance or longevity. 2. Environmental Conditions: Take into account the operating environment, including temperature, humidity, and exposure to contaminants, to select bearings with suitable material and sealing options. 3. Compatibility: Verify compatibility with existing machinery and components to avoid compatibility issues and ensure seamless integration.

Installation and Maintenance Tips

Proper installation and maintenance are essential for maximizing the performance and lifespan of Double V Guide Wheel Bearings. Follow these tips for optimal results:

1. Precision Installation: Ensure that the bearings are installed correctly and securely, following manufacturer guidelines and recommended procedures. 2. Regular Lubrication: Keep the bearings properly lubricated with compatible lubricants to reduce friction, prevent wear, and prolong bearing life. 3. Periodic Inspection: Regularly inspect the bearings for signs of wear, damage, or contamination, and address any issues promptly to prevent further damage and downtime. Upgrade your machinery today with Double V Guide Wheel Bearings and experience enhanced stability, accuracy, and durability in your industrial operations.

Frequently Asked Questions

Q: What are the main advantages of Double V Guide Wheel Bearings over standard bearings?

A: Double V Guide Wheel Bearings offer enhanced stability, accuracy, and durability compared to standard bearings. Their unique double V groove design provides superior alignment and load distribution, resulting in smoother motion, higher precision, and longer service life.

Q: Are Double V Guide Wheel Bearings suitable for high-speed applications?

A: Yes, Double V Guide Wheel Bearings are designed to perform reliably in high-speed applications. Their precision machining and stable design ensure smooth and consistent motion even at high speeds, making them ideal for use in various industrial settings.

Q: How do I know if Double V Guide Wheel Bearings are the right choice for my application?

A: Consider factors such as load capacity, operating environment, and required precision when selecting bearings for your application. Double V Guide Wheel Bearings are well-suited for applications that require high stability, accuracy, and durability, making them suitable for a wide range of industrial machinery and equipment.

Q: Can Double V Guide Wheel Bearings be customized to meet specific requirements?

A: Yes, many manufacturers offer customization options for Double V Guide Wheel Bearings to meet specific application requirements. This may include variations in material, size, sealing options, and lubrication methods to ensure optimal performance and compatibility with your machinery.

Q: What maintenance is required for Double V Guide Wheel Bearings?

A: Proper installation, regular lubrication, and periodic inspection are essential for maintaining the performance and longevity of Double V Guide Wheel Bearings. Follow manufacturer guidelines and recommended maintenance procedures to ensure optimal performance and prevent premature wear or damage.

Conclusion

Upgrade your machinery today with Double V Guide Wheel Bearings and experience the benefits of enhanced stability, accuracy, and durability. With their unique design and superior performance, Double V Guide Wheel Bearings are the ideal choice for demanding industrial applications where precision and reliability are paramount.

Read Also…Track Roller LFR: Enhancing Efficiency and Performance

0 notes

Text

The Ultimate Guide to Choosing the Right Crane Duty Motor Dealer for Your Business

Crane duty motors are essential components in various industries, including construction, manufacturing, and logistics. These motors are designed to withstand the demanding conditions of crane operations, providing reliable performance and long service life. However, choosing the right crane duty motor dealer is crucial to ensure that you get the best products and services for your business needs. This guide will help you navigate the process of selecting the right crane duty motor dealer for your business.

Introduction to Crane Duty Motors

Crane duty motors are specially designed electric motors that are used in crane applications. These motors are built to withstand the high starting torque and frequent starts and stops that are typical in crane operations. Crane duty motors are available in various sizes and configurations to meet the specific requirements of different types of cranes, including overhead cranes, gantry cranes, and jib cranes.

Importance of Choosing the Right Crane Duty Motor Dealer

Choosing the right crane duty motor dealer is crucial for several reasons. First and foremost, the dealer's reputation and experience can greatly impact the quality of the products and services you receive. A reputable dealer with a proven track record of delivering high-quality products and excellent customer service is more likely to meet your expectations and provide you with the support you need.

Factors to Consider When Choosing a Crane Duty Motor Dealer

When choosing a crane duty motor dealer, there are several factors you should consider. These include:

Reputation and Experience: Look for a dealer with a solid reputation and a wealth of experience in the industry. A dealer with a long history of providing high-quality products and services is more likely to meet your needs.

Product Range and Quality: Choose a dealer that offers a wide range of crane duty motors from leading manufacturers. Ensure that the motors they offer are of high quality and meet the required specifications for your application.

Customer Service and Support: Look for a dealer that provides excellent customer service and support. They should be responsive to your inquiries and able to provide you with the assistance you need, whether it's technical support, product information, or after-sales service.

Pricing and Payment Terms: Consider the pricing and payment terms offered by the dealer. Compare the prices of different dealers to ensure that you are getting a competitive price. Also, consider the payment terms, including any discounts or financing options available.

How to Find Crane Duty Motor Dealers

There are several ways to find crane-duty motor dealers:

Online Search: Use search engines to find crane duty motor dealers in your area. Visit their websites to learn more about their products and services.

Industry Associations and Trade Shows: Attend industry associations and trade shows to meet crane duty motor dealers and learn more about their products and services.

Referrals and Recommendations: Ask for referrals and recommendations from colleagues, suppliers, or industry experts who have experience with crane duty motors.

Conclusion

Choosing the right crane duty motor dealer is essential for ensuring that you get the best products and services for your business needs. Consider factors such as reputation, experience, product range, customer service, and pricing when selecting a dealer. By taking the time to research and evaluate different dealers, you can find a reliable partner for your crane-duty motor needs.

0 notes

Text

Double Girder Crane

SAFE AND SMOOTH MATERIAL HANDLING

Moving Material Resources Safely With Care : Harsiddhi Crane Single Girder and Double Girder E.O.T. Cranes are designed and manufactured in accordance with IS/BS/DIN. Considering adequate factors of safety with respect to appropriate duty, the structural parts of the cranes are designed in accordance with IS/BS/DIN. Harsiddhi Crane also manufactures / utilises standard components and controls to ensure reliability.

Span : 3 mtrs. to 35 mtrs.

Safe Working Load : 0.5 ton to 100 ton

Drive System : Accordance with IS/BS/DIN Structural Parts and Other Class of Duty /

Standards : Equivalent to M3, M5, M7, M8 as per IS/BS/DIN Miscellaneous Parts with IS/BS/DIN

Speeds : Selected depending on client specifications / applications / shed dimensions

Double Girder Crane, Double Rail Trolley Type Crane, Hoist Crane, Cranes, EOT Crane, Goliath Gantry Crane, Semi Gantry Crane, Under Slung Crane, Crane

#harsidhicrain#harsidhicrane#craneharsidhi#crane#singlegirdereotcrane#doublegirdereotcrane#goliathgantryeotcrane#semigantryeotcrane#underslungeotcrane#wireropehoistcrane#doublerailtrolleytypecrane#walltravellingjibcrane#eotcrane#hoistcrane#jibcrane#goodslift#crain

0 notes

Text

Gantry Glory: Understanding the Basics of Crane Gantry Systems

In the realm of heavy lifting and material handling, crane gantry systems stand as robust and versatile solutions. These structures, often seen dominating industrial landscapes, play a pivotal role in various applications, from construction sites to shipping yards. Let's delve into the basics of crane gantry systems, exploring their design, functionalities, and the diverse industries that benefit from their impressive capabilities.

Anatomy of a Gantry Crane

Frame, Hoist, and Trolley

A gantry crane typically consists of a horizontal gantry frame supported by vertical legs at each end. The frame serves as the foundation for the crane's main components, including the hoist and trolley. The hoist is responsible for lifting and lowering heavy loads, while the trolley moves horizontally along the gantry beam, enabling precise positioning of the load.

Types of Gantry Cranes

Fixed, Adjustable, and Rubber-Tired

Gantry cranes come in various types, each tailored to specific applications. Fixed gantry cranes are stationary and suitable for lifting heavy loads in a fixed location. Adjustable gantry cranes offer flexibility by allowing the adjustment of the span and height to accommodate different load sizes. Rubber-tired gantry cranes, equipped with wheels, provide mobility and are commonly used in shipping terminals and container yards.

Applications in Construction

Efficient Material Handling

In the construction industry, gantry cranes play a vital role in efficiently moving heavy materials and equipment around the job site. Whether lifting steel beams, concrete panels, or machinery, gantry cranes provide the strength and precision needed for construction projects of varying scales.

Shipbuilding and Maritime Operations

Lifting and Assembling Ship Components

Shipyards rely on gantry cranes for lifting and assembling massive ship components, including hull sections and ship modules. The ability to handle substantial weights and navigate large working areas makes gantry cranes indispensable in the maritime industry, contributing to the construction and maintenance of ships.

As industries continue to evolve, gantry cranes remain at the forefront, embodying the marriage of power and precision in the realm of heavy lifting.

Source

0 notes