#formwork clips

Explore tagged Tumblr posts

Video

youtube

Formwork Clamp

#youtube#formwork#shoring#formwork clamps#formwork accessories#shoring accessories#formwork clips#formwork parts#wellmade scaffold#wellmade#china#manufacturer

0 notes

Note

🌧️ Share something angsty from your WIP?

I don't really have anything angsty written up for one of my more active WIPs, at the moment, but I do have this >:)

Just remember that you asked for it <3

If there is one thing Cody has been conditioned for as a CC—and one of Alpha-17’s in particular—it is to think on his feet in less than ideal conditions, to take negative situations and turn around and find ways to use them to the benefit of himself and his brothers. Even to extremes. Cody is neck-deep in formwork in the office he’s come to share with his general when they bring him the news. He knows something is wrong immediately when he sees that it’s Bones that’s been elected to tell him, but he is—wholly unprepared for how bad. He’s expecting an amendment to the casualty report from their last campaign, or some new ship-wide illness (he still shudders to think of their last brush with the flu), but he— —this— “How?” He hears himself ask tonelessly, his own voice seeming to come from somewhere far away. He can’t see Bones—his head hanging down somewhere near his knees at the moment while he tries to process what he’s being told—but he swears he can feel the face his CMO must be making. “Sniper on Coruscant,” Bones says after a moment, upfront but not unkind. He knows that’s what Cody needs right now. No bullshit. Straight to the point. “Looked like it was quick, if it’s any consolation. I saw the clip on the newsreel.”

#ask games#wip games#Codywan War Widow AU#this one lives mostly in my head for now but I do have a little bit of it#maybe I'll get back to it after I finish up with Foelu#asks

28 notes

·

View notes

Text

How and Why to use Rebar Safety Caps?

Rebar safety cap is a simple yet effective solution to alleviate the danger posed by protruding rebar, among the multitude of risks and potential dangers present in construction site environments.

However, not all rebar safety caps are made of the same size, and choosing the perfect size requires careful consideration of rebar size. This is where the expertise of, Swift Technoplast, becomes invaluable.

What is a Rebar Safety Cap?

Rebar safety cap is a protective devices designed to cover the ends of exposed reinforcement bars (rebar) on construction sites. These caps are typically made of plastic or rubber and come in various sizes to fit different rebar diameters. Their primary function is to avoid impalement injuries by covering sharp ends of protruding rebar.

Why Rebar Safety Caps Important at Construction Sites?

Rebar safety caps play a vital role in avoiding such accidents by covering and cushioning exposed rebar ends. They provide a protective barrier that reduces the risk of impalement and minimizes the severity of injuries in case of accidental contact. Additionally, rebar safety cap enhance visibility on construction sites, making it easier for workers to identify and avoid potential hazards.

What Benefits Do Rebar Safety Cap Offer?

1. Injury Prevention

The primary purpose of rebar safety cap is to avoid impalement injuries by covering the sharp ends of rebar. By barring exposed ends, safety caps significantly reduce the risk of accidents and injuries on construction sites.

2. Compliance with Regulations

Many safety regulations and standards mandate the use of rebar safety caps on construction sites to ensure worker safety. Clinging to these regulations not only protects workers but also helps construction companies avoid fines and legal liabilities.

3. Enhanced Visibility

Rebar safety caps are often available in bright colors such as orange or yellow, making them highly visible on construction sites. Enhanced visibility helps workers identify potential hazards and navigate the workspace safely.

4. Ease of Installation

Installing rebar safety caps is a straightforward process that requires minimal time and effort. Caps are typically designed to fit securely over the ends of rebar, providing instant protection without the need for additional tools or equipment.

5. Reusability

Many rebar safety caps are reusable, allowing them to be removed and reused on different rebar sections as demanded. This feature not only enhances cost-effectiveness but also promotes sustainable practices in construction.

6. Liability Mitigation

By proactively enforcing safety measures such as rebar safety caps, construction companies can alleviate their liability exposure in the event of workplace accidents. Demonstrating a proactive approach to safety can help protect against legal claims and reputational damage.

How To Use Rebar Safety Cap?

1. Assess the Work Area

Before installing rebar safety caps, conduct a thorough assessment of the work area to identify any exposed rebar ends. Pay close attention to areas where workers are actively engaged in tasks involving rebar, such as concrete pouring or formwork assembly.

2. Select the Appropriate Size

Rebar safety caps come in various sizes to accommodate different diameters of rebar. Choose caps that match the diameter of the rebar you need to cover. Using the correct size ensures a secure fit and maximum protection.

3. Clean and Prepare the Rebar

Remove any debris or obstructions from the exposed rebar ends. Ensure that the rebar is clean and free from rust or corrosion, as this can affect the effectiveness of the safety caps.

4. Install the Safety Caps

Place the rebar safety caps firmly over the exposed ends of the rebar, ensuring a snug fit. Press down on the caps to secure them in place. Some caps feature built-in clips or fasteners that users can attach to the rebar for added stability.

5. Check Regularly

Periodically inspect the rebar safety caps to insure they remain intact and properly secured. Replace any damaged or missing caps immediately to maintain a safe working environment.

Conclusion

Rebar safety caps are an indispensable safety measure in construction, serving to protect workers from impalement injuries and ensure compliance with safety regulations.

By understanding the importance of rebar safety caps, following proper installation procedures, and promoting a safety-conscious environment, construction companies can create safer work environments and avoid accidents on the job site.

Let Swift Technoplast be your partner in safeguarding your construction site, improving worker’s safety, and reducing injuries.

Visit our website and start getting solutions today. Our dedicated experts are ready to assist you in making the right choice for your business!

#swifttechnoplast#plastic industry#plasticmanufacturer#plasticproducts#safety products#rebar safety cap#rebar cap#rebar mushroom cap

0 notes

Text

What Are The Benefits Of Concrete Formwork?

Concrete formwork has become one of the integral parts of modern-day construction projects. From constructing durable, smooth, and strong beams, columns, walls, floors, and more, concrete formwork plays a critical role.

The best concrete formwork companies have also introduced insulated formworks which are now winning the world. However, concrete formwork has been a popular choice for a long time even when extremely advanced varieties were not available.

Here is a list of reasons why concrete forms have consistently remained essential for the construction industry at large.

Durable and Rigid

One of the primary reasons for the popularity of concrete formworks made of plastic, aluminum, etc., remains their durability. Compared to timber, the traditional variety of formwork materials, metals, alloys, and plastic withstand the test of time and weather more graciously.

Regardless of the climatic extremities like incessant rain, gushing wind, or scorching heat, plastic formworks do not undergo any wear and tear and help in the construction process optimally.

Additionally, the engineered build of these forms ensures that the form does not move an inch during concrete casting. Therefore, modern formworks are more convenient to work with and remain usable for a very long time.

Multiple Usages

Since the concrete formworks do not depreciate easily to show any sign of instability during the casting process, they remain ready for multiple usages. This means that once a construction house invests in a concrete formwork, it can use the same for multiple projects.

Especially the plastic forms that remain reusable for more than 100 times are perfect for long-term investments.

Additionally, plastic is lightweight and easy to move and store. Therefore, transporting the form from one site to another does not become a hectic task. This is another reason why most construction companies prefer using these formworks.

Enhances Construction Speed

Engineered concrete formwork construction ensures that construction companies do not have to experience any amount of hassle. Installation of these forms remains easy and involves pinning, screwing and clipping. Once installed, the forms remain ready to use.

Therefore, the construction work starts almost as soon as the forms reach the construction site. As a result, using concrete forms reduces the overall project time by several days. Therefore, modern construction projects find these forms particularly cost-effective and time-saving.

It’s Safe and Fire-Proof

The numerous clips, screws and pins make sure that the concrete form left unattended for several days to let the concrete dry does not fall or get displaced by any means. Even if a storm rages or heavy downpours arrive unannounced, these forms stand erect and do not let the drying concrete suffer the consequences.

Has High Resale Value

Another advantage of using concrete formworks remains its resale value. After using aluminum or plastic for 50 or 60 times, you can resale it at a good price. Therefore, investing in a form can be beneficial in more ways than one.

NovaFormWorks is one of the most reputed and reliable formwork manufacturers in India. As one of the most renowned concrete formwork companies, Nova manufactures the best quality plastic formworks, ideal for all modern-day construction requirements. Check the collection today to pick the best quality form at a reasonable price.

0 notes

Text

Sustainability in formworks - How Nova Formworks Contributes towards Sustainability?

Sustainability has become one of the major concerns of modern production processes. Even for the components, parts, and other products used in various sectors, sustainability remains an issue. As far as construction site waste generation is concerned, the use of modern formworks like plastic formworks can make the projects more eco-friendly.

The followings remain the few most popular formwork varieties that had found extensive application in a number of construction projects for decades. However, all these alternatives are not equally sustainable and often result in huge quantities of debris.

Timber Formwork: Timber formwork is probably the oldest and one of the most popular alternatives. However, this one is not suitable for harsh conditions such as areas with heavy rainfall or harsh winters with snowfall.

Also for underwater construction projects, timber remains a poor choice. Additionally, these are not ideal for multiple uses and require indiscriminate felling of trees. In short, timber is far from an ideal sustainable choice for formwork material.

Aluminium & Steel Formwork: Steel column formwork is also a popular choice for several construction projects. However, this metal alloy is also not a perfect option for the most sustainable formwork material. Even though steel looks aesthetically pleasing and exhibits qualities like anti-corrosion and weathering resistance, reusability remains an issue with this one.

Less flexible and customisable, this one is one of the traditional varieties of formworks that need to be more adaptable to the latest requirements of modern projects. Similarly, metal formworks like Aluminium formworks also offer several advantages but are not the best choice as a sustainable formwork.

Why The Plastic Formworks Stand Apart?

Plastic formworks have been the latest additions to the existing pool of formworks. NovaFormWorks is one of the most reliable manufacturers of plastic forms ideal for a wide variety of construction projects. The followings are a few features of these plastic forms that make them one of the most eco-friendly choices at present.

Economically More Viable: Reusability remains one of the primary issues with traditional formworks. On the other hand, plastic formworks can be used by multiple projects without much ado.

To be precise, one plastic form can find application in more than 100 construction projects. Therefore, plastic formworks are undeniably one of the most cost-effective alternatives for construction houses. This alternative makes every construction project more profitable and revenue-generating.

Environmental Benefits: For manufacturing plastic formworks, the felling of trees or indiscriminate mining of metals is not a prerequisite. Therefore, the entire process does not involve any environmental hazard. This is another reason why most construction projects are now replacing traditional formworks with the latest plastic ones.

Safety Benefits: Unlike Aluminium formworks, plastic formworks are lightweight and easy to relocate. Every part of these humongous structures remains perfectly riveted through clips. Therefore, handling plastic formworks remains an entirely safe task for all.

NovaFormWorks is inarguably one f the leading manufacturers of plastic formworks. Check its exhaustive collection of modular and customisable formworks to pick the best ones for your construction projects to minimise on-site waste generation.

1 note

·

View note

Text

Highlighted by Chernobyl. Part 1.

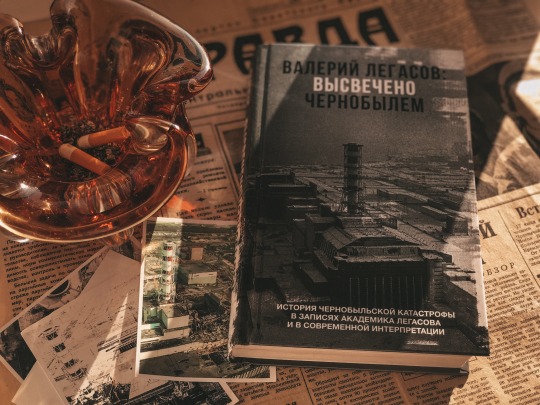

This article is my review on a book «Valery Legasov: Highlighted by Chernobyl. History of the Chernobyl disaster in the notes of academician Legasov and in modern interpretation».

First of all, I apologize for being a lazy ass, a very busy person, since I’ve been promising some of you to write this book review for ages.

Also, in a post about how I bought this book, I mistakenly called it only Legasov's printed notes, but this book does not consist only of them.

The book is in three parts. And the first part really is Legasov's notes about the first days of the accident and the subsequent work in Chernobyl, which he wrote shortly before his death. These notes can also be found in English. As we know, they were published by Gubarev in the PRAVDA newspaper in an short-hand form on May 20, 1988. I will not go into much detail on this part of the book.

Also, the first part contains three articles by Valery Legasov, published in his lifetime: “Through the prism of Chernobyl. Conversation with Academician V.A. Legasov "(Pravda, September 5, 1986), "Highlighted by Chernobyl "(Chemistry and Life, 1987)," Problems of the Safe Development of the Technosphere "(Communist, 1987) Articles in which he also talks about the causes and consequences of the the Chernobyl accident, and also expresses concern about the state of large technological facilities in the USSR, and what measures need to be taken to create a separate institute of safety.

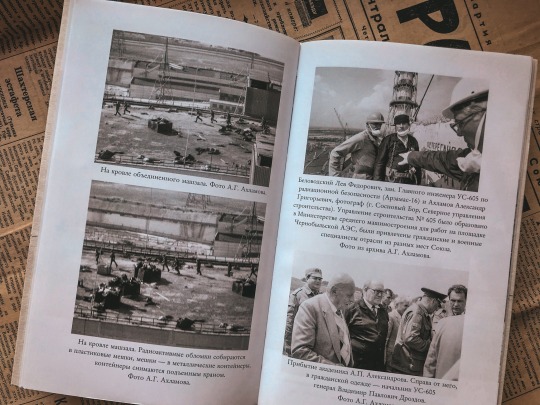

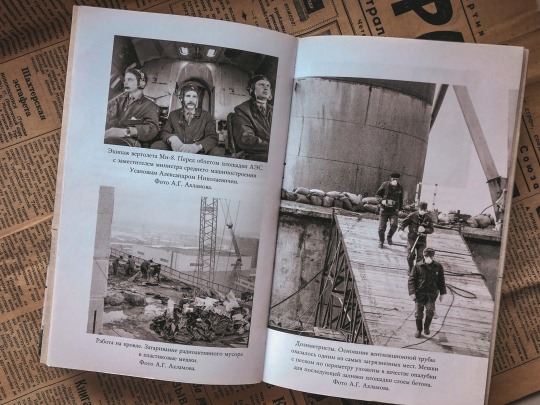

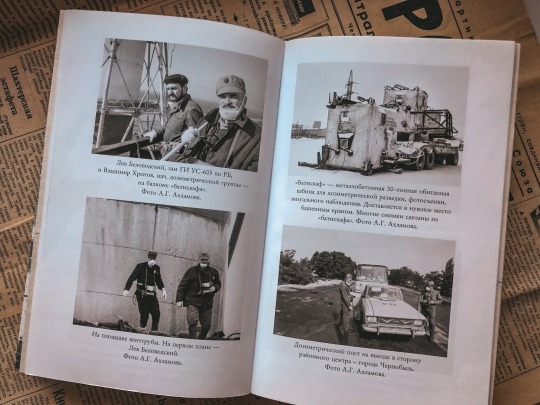

The book contains quite a lot of pictures that I haven't seen before, as well as photos of newspaper clippings that covered the events of the disaster and the progress of its elimination.

Through the prism of Chernobyl. Conversation with academician V.A. Legasov

General view of the destroyed Unit 4 of ChNPP. May, 1986

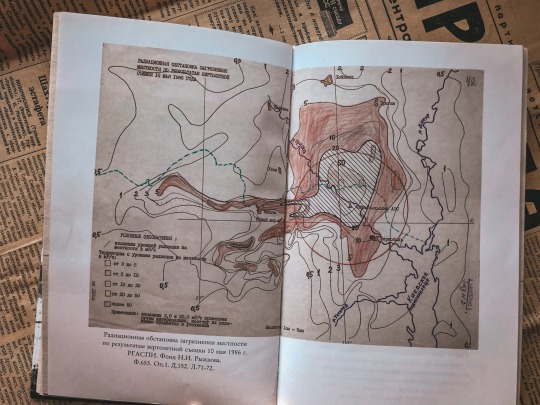

Radiation situation in a contaminated area based on helicopter survey results May 10, 1986

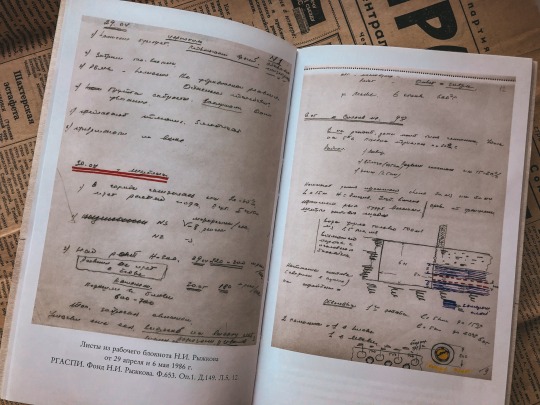

From N.I. Ryzhkov’s notebook from April 29 and May 6 1986

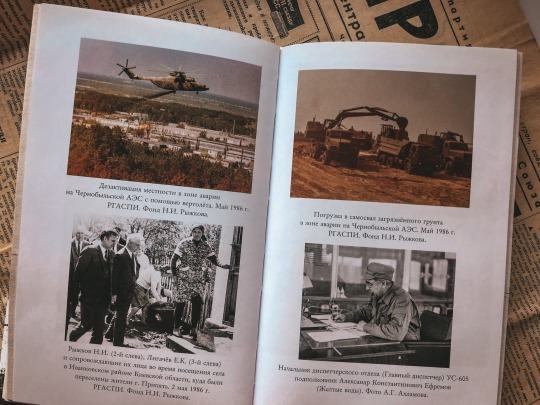

Deactivation of the area in the accident zone using a helicopter. May 1986

Ryzhkov N.I. (2-nd on the left), Ligachev E.K. (3-rd on the left) and their attendances during the visit to a village in the Ivankovsky district of Kiev region, where residents of Pripyat were resettled May 2, 1986

Loading contaminated soil into a dump truck in the accident zone of the ChNPP, May, 1986

Head of the dispatch department (Chief dispatcher) УС – 605 (Construction Department) lieutenant-colonel Aleksandr Konstantinovich Efremov

On the roof of the united turbine hall

On the roof of the turbine hall. Radioactive debris is collected in plastic bags, bags are placed in metal containers, containers are removed by a crane

Belovodskiy Lev Feodorovich, deputy of the Chief Engineer of УС-605 on radiological safety (Arzamas-16) and Akhlamov Aleksandr Grigorievich, a photographer ( the city of Sosnoviy Bor, North Construction Department). The Construction Department №605 was formed in the Minsredmash to carry out work on the site of the Chernobyl NPP, civil and military specialists were involved

Arrival of the academician A.P. Alexandrov. On his right, in civilian clothes – the Head of the Construction Department 605, General Vladimir Pavlovich Drozdov

The crew of the MI-8 helicopter. Before flying around the NPP site with Usanov Alexander Nikolaevich, the Deputy Minister of Medium Machine Building

Working on the roof. Packing radioactive waste in plastic bags

Dosimetrists. The base of the ventilation pipe turned out to be one of the most contaminated area. Sandbags along the perimeter are laid as formwork for subsequent pouring with a layer of concrete.

Lev Belovodskiy, deputy of the Chief Engineer of УС-605 on RS and Vladimir Khrenov, Chief of the dosimetric group – on a balcony of the « Bathyscaphe»

On the site of the vent pipe. In the front – Lev Belovodskiy.

«Bathyscaphe» - metal-concrete 30-ton manned cabin for dosimetric survey, photography, visual observation. Delivered to the destination by a tower crane. Many pictures were taken from the bathyscaphe.

Dosimetric monitoring station at the exit towards the regional center - the city of Chernobyl

The group of liquidators on the way from the pioneer camp «Golubie ozera» («Blue Lakes») to the NPP site. Time of getting up – 5 am

Main control room in the building of the reactor auxiliary systems

May 8, 1986. Eve of the Victory Day

Reactor auxiliary systems room. A.K. Efremov reports to the Deputy Minister of Minsredmash A.N. Usmanov

Government Commission after inspection of the cleaned and restored roof of the united turbine hall of the ChNPP Dosimetric control.

@elenatria @alyeen1 @litttlesilkworm @rbmk-ana @the-jewish-marxist @soviet-history-detective @owlboxes @borislegasov

#chernobyl npp#chernobyl disaster#chernobyl#ussr#soviet history#history talk#valery legasov#boris shcherbina#liquidator

61 notes

·

View notes

Photo

250000 pcs of spring clips shipped to Europe customers today. Length:60mm Diameter:12mm Made by RSF factory-Scaffolding and formwork materials manufacturer and supplier since 1993. [email protected](在 Rizhao Rricom Industrial Co.,Ltd) https://www.instagram.com/p/CKyKIlkBalP/?igshid=yxzwb8llu2yh

1 note

·

View note

Photo

Well hello from Victoria BC! This is probably the last I will see of my model for now...Too bad it never gets to come to its completion, maybe one day.

I managed to download Rhino on my laptop and retrieve my Task 8 file so I finished it up to the best I knew how and added some materiality to better show off how I imagine it to be. Unfortunately, the free V-ray trial I downloaded would let me add materials but would not actually Render for me it instead would show me a black screen, so all of these renders are just the basic Rhino “Rendered” view.

Now onto explaining my model as if there was not a worldwide virus pandemic stopping me from actually finishing it!

So first off, which model type I would have chosen (representational/scale model, sectional model, detail model) and why? It was back at the first pin-up that I decided I wanted to use a sectional model. Throughout discussions in my group of three, we collectively decided that would be the best way to showcase our models due to the fact that we intended to stack all three models on top of one another to represent the change from submerged to amphibious to land fairing. My model would have landed right in the center because it is the amphibious aquatic life research lab half in and half out of the water. The sectional model would have been able to neatly show how my model interacts with the water. I intended for the model to resemble the sectional perspective image pictured above.

Now to describe what kinds of components I would have digitally fabricated, which fabrication tools I was going to use, and why? So my plan was to first use the CNC milling machine to fabricate the land topography of my topographic model. That being the hill and the islands in my topography that were surrounded by water. For the water component, I was planning to use a blue epoxy resin in a wood formwork to create a cool water effect. I thought it would look super cool to pour the resin along the path of the waterfall to create a lifelike effect. For the actual capsule itself and the ruin in behind it, I was planning to 3D print a section of each of them by creating a clipping plane in Rhino and determining a center cut through both the capsule and the ruin. I wanted to use the 3D printer because I know it could pick up on the small details and nicely fabricate the curved edges of my capsule. To attach the capsule to the ruin I planned to hand model a suspension system out of string or some kind of wire to would attach to the ruin and the top of the capsule. This would leave my capsule suspended and floating half in air and half in the water

And lastly, I will talk about what digital models and/or drawings I would have had to create or were going to create in order to successfully fabricate my model. First off I would have had to create a CNC file on Rhino that I would use to fabricate my topography. That file would have been sized down to the 20x20x20cm size, on a rectangle the size of the CNC machine bed and would have needed to have no naked edges. I would have removed all the water components from the file because I planned to create those by hand. Once that was done I would have needed a separate file for 3D printing my capsule and ruins. The two pieces would be separate and like the CNC file, they also would have needed to have no naked edges. With both of those finished and sent to their respective fabrication machines, I would have then needed to create drawings from Rhino using the Make2D tool. I think the most important of those drawings would be the section because it will help to explain the model more clearly. But of course, I would have also included a plan, elevation, and perspective to try to explain the very cramped space inside of the 24 square meter research lab I created.

I think that's all for now! I hope everyone is staying home, staying safe and staying healthy! Thanks for an awesome semester!

1 note

·

View note

Photo

We are specialized in Steel Formwork, including Wall Formwork, Flat Formwork, Column Formwork, Angle Formwork, Internal & Outernal Formwork and accessories(U Clip).

1 note

·

View note

Text

Significance of formwork constructions in building structures

Construction organisations may now enhance their speed, effectiveness, and cost efficiency thanks to technological advancements. Modern technology has had a significant impact on the construction business, whether it is for residential homes, office buildings, bridges, tunnels, or roadways.

The materials used in building have evolved through time to become more robust, flexible, durable, and long-lasting. One of the reasons for the great quality of commercial concrete structures is the formwork constructions, which is an important part of the construction process.

# what is Formwork?

Formwork in construction is well-known around the world and is literally the cornerstone of construction, having been utilised for thousands of years to construct structures of various sizes and shapes. Many building companies employ various forms of formwork. Each style of formwork serves a different purpose, but they all have a mould where the concrete is poured. It also varies depending on the type of structure being constructed and the project's budget.

Here are few of the most commonly used formwork construction methods:

1. TIMBER FORMWORK

Timber formwork, commonly known as 'traditional formwork,' is one of the earliest types of building formwork. Formwork of this sort is often composed of wood or plywood. It can be easily manufactured and built on-site, but it has a short lifespan and is time-consuming to create. As a result, classical formwork is not suitable for large-scale projects. On the other hand, its adaptability may be the best option for complex building projects.

2. ENGINEERED FORMWORK SYSTEMS

Engineered formwork is made out of prefabricated modules that are held together by metal frames, which are often made of steel or aluminium. It may be swiftly built with pins, clips, and screws, unlike traditional formwork. Furthermore, because engineering formwork can be reused several times, many construction companies choose to employ it to save money.

3. CONCRETE FORMWORK

In many nations, including United Kingdom, this sort of formwork is considered one of the most sophisticated. Concrete formwork constructions are built of insulated polystyrene foam and assembled on-site to provide thermal, acoustic, fire and rodent resistance. Furthermore, many construction businesses prefer concrete formwork because of its energy efficiency, sustainability, minimal environmental imprint, and inexpensive costs.

# IMPORTANCE OF FORMWORK

In today's civilization, using formwork in building offers several advantages. Despite the fact that everything is changing, formwork is one aspect of the structure that no technology can replace. The concrete structure may be erected faster and for less money if formwork is used.

Formwork efficiently reduces the project's construction time and cost by minimising the floor-to-floor building cycle time. As a result, high-quality formwork is required to keep under budget. Project managers may ensure that formwork resources are mobilised and demobilised on schedule while employing formwork in construction, increasing efficiency and lowering costs.

The quality of the surface finishing is connected to the quality of the formwork used during construction. The smaller the formwork used, the finer the surface polish. In the construction sector, every worker's safety is crucial. In order to achieve the greatest possible formwork quality, formwork allows individuals to work more efficiently and effectively.

Get the right Formworks Construction

Many things have changed in the building sector throughout the years. Traditional Timber Formwork, Engineered Formwork System, and Concrete Formwork are some of the most prevalent forms of formwork constructions accessible in United Kingdom.

Depending on the project's goal and budget, each of these is employed. Formwork is a very important aspect of constructing an infrastructure for a variety of reasons. Do you need a reputable and dependable formwork company? HYB Constructions is one of Sydney's most reputable rebar suppliers and manufacturers. We can also help with formwork and concrete installation.

0 notes

Text

Which is a prominent plywood manufacturer in Yamunanagar?

Evergreen Plywood Industry is a prominent plywood manufacturer in Yamunanagar. We offer premium-grade wood products that include a wide range of plywoods such as shuttering plywood, commercial plywood, marine plywood etc.

All the steps from clipping wood to the complete manufacturing process of products and their embellishing are done with exceptional attention and beneath the guidance of qualified and well-trained designers.

You have to go over our list of products to comprehend what bounties we provide. You can esteem us without any doubt. For exceptional integration and client gratification, we produce high-grade products. We are not only plywood manufacturers; we are a peerless plywood supplier in Yamunanagar.

Plywood can be use for various purposes based upon the quality of the work.

Softwood Plywood

Floors, fences, and shelters in roof constructions

Wind strengthening boards

Transportation

Cement shuttering boards

Readily paint surfaces in buildings

Hardwood Plywood

Boards in cement formwork systems

Floorboards subdued to massive wear in many factories

Scaffolding supplies

Sports gear

Vocal instruments

Want To Enquire More? Contact Us Today!

Comprising 1 of the esteemed plywood manufacturer in Yamunanagar, we offer a variety of plywood’s attainable in premium quality, multiple sizes and other specifications that can accomplish customer demands to the best. If you have any queries related to the same, perpetually feel free to call us or drop an enquiry at evergreenply.com. We’d be fascinated to serve you.

Read More – http://www.evergreenply.com/plywood-yamunanagar.html

For Further Information

Please Contact

Evergreen Plywood Industry

Village Kami Mazra, Khajuri Road, Yamunanagar - 135001, Haryana, India

+91-9812008111

0 notes

Text

Build The Marvels Architecture With Brilliant Shuttering

The Shuttering’s history can be date back to the Roman Era. The arches, domes, and vaults of that period were supported by shuttering formwork built in the form of the final construction. With the increasing requirements of mass construction, shuttering needs to be efficient, modular, replicable, and fast to the mantle and dismantle. And the obvious way to do that was by making them molds in regular geometrical forms. This way shuttering has been one of the drivers of the modern geometric design aesthetic.

Shuttering molds come in many varieties:

Timber Shuttering:

Timber shuttering is the traditional way to make the concrete shape. Timber shuttering has very short lifespans. In the new age, we often use film-faced plywood as the scaffolding plank.

Engineered molds:

This is the modern way with the two main materials in use being – steel and aluminum (technically called Aluminum Formwork). These have the advantages of speed of setup (modular systems are quickly pinned, screwed, or clipped) and the longevity of metal.

Flexible Molds:

This lies at the cutting edge of shuttering technology. This involves shuttering made of flexible sheets of fabric that utilize concrete fluidity to create interesting new construction forms.

Shuttering for big projects can get very costly. To help the builders manage costs, innovative shuttering manufacturers are coming up with creative business models like providing shuttering on hire and offers to exchange old rusted shutter molds for brand new ones at lesser costs.

Shuttering is one of the foundations of the modern construction industry. It is imperative to choose only good shutter molds from a reputed manufacturer with a proven track record. Builders should refrain from compromising on their shuttering investments as good shutter molds can really help in hardening the concrete well, leading to strong and robust structures.

0 notes

Photo

250000 pcs of spring clips shipped to Europe customers today. Length:60mm Diameter:12mm Made by RSF factory-Scaffolding and formwork materials manufacturer and supplier since 1993. [email protected](在 Rizhao Rricom Industrial Co.,Ltd) https://www.instagram.com/p/CKyKh1hBpcY/?igshid=kbxfpk1ilt43

0 notes

Photo

Toko Online FORMWORK ACCESSORIES BEKISTING Pertama Di Indonesia . Dengan Senang Hati Kami Akan Membantu Anda .

Perusahaan Kami Bergerak Di Bidang Supplier Material Formwork Accessories Khusus Nya Pada Pekerjaan Civil Bekisting.

Dengan Bekal Pengalaman Yang Sangat Cukup Lama Dalam Bidang Formwork Accessories Bekisting Kami Hadir Dalam Menawarkan Material Berkwalitas Standar Nasional Indonesia Dan Material Import Yang Bersertifikat. Di Karenakan Pertumbuhan Pembangunan Pekerjaan Pekerjaan Proyek Yang Sangat Besar Di Wilayah Indonesia Dalam Segala Aspek, Maka Kami Hadir Dalam Melayani Kebutuhan Material Formwork Accessories Bekisting Kepada Proyek Proyek Yang Sedang Anda Hadapi Di Wilayah Indonesia Khusus Nya.

Kami Juga Jual Type Washer Kami Juga Jual Betton Decking

Dengan Pelayanan Marketing 24 Jam Nonstop Serta Di Dukung Dengan Technicial Yang Berpengalaman Maka Kami Siap Membantu Proyek Yang Sedang Anda Jalankan. Dengan Pelayanan Yang Mudah, Harga Kompetitif Serta Material Yang Berkwalitas Kami Siap Bersaing Dalam Memenuhi Kebutuhan Proyek Di Indonesia.

safety net untuk konstruksi jual safety net jual safetty net universal jual safety net untuk orang jual safety net di malang jual safety net malang safety net universal safety net untuk orang safety net untuk apa jual safety net murah jaring pengaman orang jatuh safety net penahan orang jaring safety net jual safety net proyek . hp 0812-8268-8006 jual safety net penahan orang jatuh di proyek daerah malang. distributor jaring pengaman gedung proyek bangunan murah. Jual Safety Net Proyek - jual jaring pengaman gedung, safety net untuk konstruksi, jual safetty net universal, jual safety net untuk orang, jual safety net di malang, jual safety net malang, safety net universal, safety net untuk orang, safety net untuk apa, jual safety net murah, jaring pengaman orang jatuh, safety net penahan orang

Tie Nut Steel Cone Formtie Plastic Cone Plastic Chamfer KT Jual Roof Drain Cast Iron Roof Drain Cast Iron Jual Manhole Cover Cast Iron Jual Kayu Bangunan Bekisting Proyek Jual U Clip Jual Scaffold Keeper Wall Tie Jual As Drat Breccing Kickers Dan Push Pull Jual Baji Kecil Baji Besar Jual L Anchor Jual As Drat Jual Three Type Rib Washer Tie Rod Bekisting Jual Swivel Clamp Jual Flat Rib Washer Jual Safety Net Proyek Jual Safety Net Proyek - jual jaring pengaman gedung proyek bangunan kontruksi Jual Beton Decking jual Pvc Cone Jual Water Stop Tie Rod Bekisting Jual Steel Cone Tie Rod Bekisting Jual Wing Nut 92 Jual Wing Nut 94 Jual Tie Rod Bekisting

https://cofeeboz.com/ https://2sahabatberdikari.com/ https://www.rizkylogamjaya.com/ https://poetrabudimanjaya.com/

0 notes

Photo

The elements of the moulds used for the formation of structural reinforced concrete members are separated in four categories: - Surface elements or planking. - Horizontal bearing elements or beams. - Scaffolds or staging. - Accessories like connectors, pins or clips etc. @engrandarch 👨🎓 👩🎓 #formwork #structure #reinforcedconcrete #surfaceelements #planking #bearing #beams #scaffolding #staging #scantling #tower #building #civilengineering #engineering #ingenieria #ingenieriacivil #arquitectura #architecture #arquitetura #moldaje #engineer #architect #architectural #construction #construcao #construccion #shearwall #column #slab #metalwork https://www.instagram.com/p/CE4aPtYBoTC/?igshid=1arprxrqzigkh

#formwork#structure#reinforcedconcrete#surfaceelements#planking#bearing#beams#scaffolding#staging#scantling#tower#building#civilengineering#engineering#ingenieria#ingenieriacivil#arquitectura#architecture#arquitetura#moldaje#engineer#architect#architectural#construction#construcao#construccion#shearwall#column#slab#metalwork

0 notes

Text

7 Things About concrete powder minecraft You'll Kick Yourself for Not Knowing

Poured concrete is permitted to established in formworks for specified time according to type of structural member to realize adequate energy.

Before you decide to Make your countertop, you must definitely produce a exam kind. We constructed two one x 2 foot forms with rebar and remesh to test pouring consistency, shade, approach etc.

The first thing you have to know is the fact not all of Concrete Genie’s Tale method is playable in VR. The truth is, the VR area of the sport is fully independent.

Just Really don't undervalue the significance of this move. It is possibly The key With regards to acquiring a easy concluded floor without voids. Also, much less voids usually means less prospective for cracking.

If you have more and more people out there at this move, a couple of is usually tapping the shape while others are working the concrete.

They ended up then attached to the form and the gray concrete was poured in excess of them. The top and sides had been then ground to expose the combination. The backsplash was developed utilizing plexiglas to curve the perimeters and it much too was floor to reveal the mixture. See additional photographs from this contractor >>

insert bundle All calculators to be used on one area. Please Call us For added pricing. Get this calculator for your site:

This web page will teach you the most effective method for eradicating cat (and Pet) urine smell from the concrete. Probably the most up to date facts information obtainable.

youtube

In such cases, we selected to go away the voids from the hand-packed cones unfilled. The full backsplash also has a unique aspect that frames imported tiles the homeowner brought back again from Italy. See additional pics from this contractor >>

The wire needs to be twisted round the rebar numerous instances then 1 close clipped off. The other close with the wire hooks on the aid screw and may be Lower following the the concrete is poured and the top is simply pushed down into your soaked concrete.

Being familiar with Egocentrism Piaget applied a number of Inventive and clever techniques to check the psychological talents of youngsters. Among the renowned tactics to demonstrate egocentrism associated using a 3-dimensional Display screen of a mountain scene.

Knowledge Conservation A further very well-known experiment requires demonstrating a child's knowledge of conservation. In a single conservation experiment, equivalent amounts of liquid are poured into two equivalent containers.

In this particular principle, Piaget also argues that children inside the concrete operational stage are significantly less egocentric in contrast to those in preceding stages. Consequently a child within the concrete operational stage has the opportunity to realize that other people may have a distinct impression from theirs. This means that a child in this stage is ready to recognize situations where by Other individuals existing differing views from what the kid thinks (Shaffer & Kipp, 2010).

The preoperational stage is the second stage in Piaget's concept of cognitive improvement. This stage starts all around age two, as youngsters begin to communicate, and lasts until eventually close to age seven.

0 notes