#forklift certification training

Explore tagged Tumblr posts

Text

Purpose Of OSHA Confined Space Certification

Business entities engaged in heavy lifting and/or manufacturing often have to use heavy vehicles to source and transport materials. The forklift is usually utilized to carry the required materials to and from different parts of the facility. Understanding the operation process is of the utmost importance, for skill is vital for a forklift operator. It is equally essential to undergo a forklift certification training course as advised by OSHA to ensure eligibility. It is advisable to inquire about and learn this training course's associated facts. It is interesting to know that the operators have the required aptitude and knowledge about the proper operation procedure, along with information about the necessary safety standards. Successfully completing the training can go a long way in preparing an operator for the specialized job. Prevention of physical injury and damage to the company property are motivations for obtaining the training.

Thankfully, the training period requires almost no time to complete. An operator or an aspiring one can do it within 1.5 hours. The operator must sit on the seat behind the controls and operate the forklift to lift and load the equipment as necessary. Unloading the materials at a designated site is also part of the responsibility. The topics addressed with preventive measures being discussed at length for a sit-down forklift operator usually include the following:-

· Job Safety Basics · Proper Clothing for operation · Personal Protective Equipment (PPE) · General discussion to improve Safety Awareness · Electrical Safety · Equipment Safety · Chemical Safety · Ladder Safety · Slips and Falls · How to Prevent Back Injuries · Fire Prevention techniques

Not all forklift vehicles allow the operator to sit down, though. Certain heavy forklifts require the operator to remain in control while standing up. The course topics are similar for stand-up operators, too. Such operators usually complete the training in an hour.

There are no prerequisites or eligibility standards for taking the safety training. The students must understand English, as the modules are usually prepared for the English-speaking populace.

Both training courses can be taken online from the privacy of one's home. What's more? Students may complete the training over a weekend, too. Appearing for the final test at the end of the training is mandatory to pass the course. A student must secure a minimum of 70% marks to be eligible to receive the certificate. Printing out the certificate ensures quick receipt, and the printed certificate is shared with the employer to provide evidence of being trained in safety procedures.

The certificate is good for continuing with the job of a forklift operator and does not come with a specific timeline. However, there may be employers who require their workforce, especially the forklift operators, to go through a refresher course once every 3-5 years.

People working in construction, oil and gas, and other general industry areas may be exposed to toxic and hazardous materials or face entrapment. Taking the OSHA confined space certification training course can help them remain safe at work.

0 notes

Text

Lmaooo so pretty much since I started, my work friend who works in the freezer/cooler sections has been trying to get me to come help over there (I actually cannot as I am not SAFE certified. He knows this but still it's just a running joke) and the other week I was working Health and Beauty and he was like "hey hey hey uh uh! You're supposed to help ME!" To which I said that only one person can ask a day and Bootleg already asked that day. So a couple days ago he was leaving the breakroom as I was coming in to clock in, as was our mutual work buddy who also works that area. He goes "ah ah ah you gotta help work the cooler today. See I asked before anyone else could!" To which I said "ah man, I'm not clocked in yet, doesn't count!" And went in to clock in as they left

So yesterday our mutual work buddy was like "so I heard you're coming to the cooler 👀" (again joking) and I just said "nope he's a liar. He's telling you lies man. But I heard YOU'RE coming to clothing."

We just laughed and went on with what we had been doing.

But TODAY I guess when RC came in to lunch, he was telling Homicidal Forklift Driver that I should move to the cooler. Like trying to get someone else to back them up that I should switch bc they see what a good job I do in clothing so I would be able to make the shelves look nice there too

RC was like oh hell no, I need her in clothing man. She's like the one person there who works!

To which they both said, "yeah and imagine how nice the cooler would look!"

She told them that I actually had mentioned yesterday that it didn't really sound like a bad deal, but that I'd 100% be moved back to clothing within a month bc no one but me can handle the kids section 😅

Felt nice though having people "fight" over me/praise my work sgdgdggdg getting that recognition for how well I do my job

I really dont think I'd mind working in the cooler, or fresh, but I hate having to check for close expiration dates and the boxes are so so heavy 😰

Plus I think the girl who recovers clothing second shift would kill me agsgdgdggd she'd like come in as a customer 8am on the dot and track me down to beg me to come back to clothing bc she can't handle the mess that is kids without me 😅

Anyways that made me laugh to hear

#marquilla#i mean 👀 it's a viable way out if NewLady pisses me off bad enough and they dont move her first agdggdgdgdh#ive seen the SAFE certification test before and it's mostly common sense food handling imo it's just that the specifics are what get you is#what ive heard like theres basically no room for error (which is good bc safe food handling SHOULD be that high a priority) and you need to#know 100% what the correct temps for the safe zone are ect ect (i did at one point know them i just dont remember)#anyway anyways thats funny that he's got HFD on board and he doesnt even work in that area 😭 he works recieving#which is another job ive thought ab tbh like if i ever get forklift certified i think i want to work back there bc they get to unload trucks#and sign for packages from what ive seen and they get to work the big door thats satisfying to open shdgdggd i got to do that once bc i was#over there and whoever is closest no matter your actual job is supposed to let them in and let a receiving person know and damn is that#door fun to watch open and close 👀 i ALMOST got to close it yesterday but they didnt leave before i was done :( shdhdhhdhd#i think unloading the trucks would be fun bc you drive the pallets around the store or just dump em in the dock if it's past 8am but then#you have to clear the dock if someone else filled it overnight 😒 but hey that might still be fun idk#and as far as I know the 4am recieving crew all like me a lot abdbbdbdgd so other than working with HFD it wouldn't be so bad#i think we should be allowed to shadow other areas like not specifically cross training but like i think working liquidations/claims would#be fun but it might not be idk only problem with that and recieving is that it's very loud in the back and idk if id be allowed those yellow#headphones or earplugs to dampen the sound or not#i think any of those jobs would be fun. id really like to work bakery but im allergic to too many common ingredients that id be#afraid that i might not be a great fit like yes gloves exist but still idk if thats a safe/good idea job wise...#ANYWAYS dhddhhdhd

3 notes

·

View notes

Photo

@guiltiest-gear

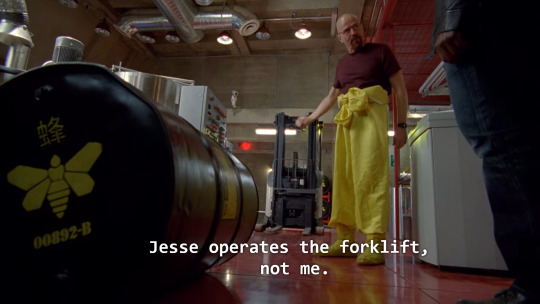

jesse pinkman canonically forklift certified

26K notes

·

View notes

Text

Importance of Forklift Certification & Training Classes for Workplace Safety and Efficiency

Superior Forklift Training, we are committed to providing top-tier forklift certification courses that prioritize safety, regulatory compliance, and hands-on expertise. Our training programs not only help businesses stay OSHA-compliant but also empower forklift operators with the skills they need to operate forklifts safely and effectively.

#online forklift training California#Online Forklift Training Course ca#forklift certification classes online ca

0 notes

Text

Forklift Training Schools Toronto - Forklift Driving School Toronto

Forklift Training Schools Toronto offers comprehensive training programs for individuals looking to become skilled forklift operators in the Toronto area. With a focus on safety and efficiency, our Forklift Driving School Toronto provides hands-on training and theoretical knowledge to equip students with the necessary skills to operate forklifts in various industrial settings.

Our experienced instructors guide students through practical exercises, teaching them how to maneuver forklifts, handle loads, and navigate different types of terrain. Additionally, our training programs cover important topics such as safety regulations, maintenance procedures, and emergency protocols to ensure that students are well-prepared for real-world scenarios. Whether you are a beginner or an experienced operator looking to enhance your skills, Forklift Training Schools Toronto is the ideal choice for comprehensive and professional forklift training.

#Forklift Training Academy Toronto#Professional Forklift Driver Training Toronto#Forklift Certificate Toronto#Forklift Driver Licence Toronto#Forklift Driving Courses Toronto

0 notes

Text

Elevate Your Career with Forklift Certification in Calgary.

0 notes

Text

As the premier Equipment Safety Training school in NJ, Fast Line Safety Training specializes in Mobile Elevated Work Platform, Scissor Lift, Boom Lift, and Dirt Moving Equipment Certification. We also offer Excavator, Skid Steer, Backhoe, Lull, Forklift, Warehouse Forklift, and Pallet Jack Certification. We provide comprehensive training solutions including WBE, DBE, ANSI A92, SST Worker, SST Supervisor, and OSHA 30 Construction training. Our courses also cover Fall Prevention, Scaffold, 4HR Scaffold, and First aid CPR/AED Training. Site Safety Audits are part of our offering. Your safety is our mission!

Contact Us: Fast Line Safety Training One Gateway Center, Suite 2600, Newark, NJ 07102, USA (201) 208-2203 https://fastlinesafetytraining.com/

#Boom lift certification Newark#Scissor lift certification Newark#Mobile elevated work platform Newark#Excavator certification Newark#Skid steer certification Newark#Forklift certification Newark#Forklift certification card Newark#Scaffolding training Newark#Heavy equipment training schools Newark#62 hour sst card Newark#Scissor lift training Newark#Scissor Lift Certification

1 note

·

View note

Text

Hands-On Learning: Inside Heavy Equipment Training Programs

In the realm of heavy machinery, knowledge and skill are the cornerstones of success. The towering cranes, earth-shaking bulldozers, and powerful excavators that shape our modern world require operators who are not just well-versed in theory but are also adept at hands-on control. This is where heavy equipment training programs come into play, immersing aspiring operators in a world of practical learning that bridges the gap between classroom instruction and real-world applications.

The Power of Hands-On Learning

Hands-on learning has long been recognized as one of the most effective methods of education, and heavy equipment training programs embody this principle. These programs understand that the intricate dance between an operator and their machine demands muscle memory, instinctive reactions, and the ability to adapt to changing conditions in real-time. Through hands-on experiences, students can internalize the art of operating heavy machinery, translating theoretical knowledge into practical prowess.

Simulating Real-World Environments

Central to hands-on learning in heavy equipment training is the use of realistic simulations. These simulations recreate authentic work environments, enabling students to practice their skills in a controlled setting before facing the challenges of a construction site. From maneuvering a bulldozer through tight spaces to lifting and placing loads with precision, simulations offer a safe space to make mistakes, learn from them, and develop confidence in their abilities.

Mentorship by Industry Experts

One of the defining features of quality heavy equipment training programs is the mentorship provided by seasoned industry experts. These instructors bring a wealth of experience to the classroom, sharing anecdotes, insights, and practical tips that textbooks simply can't convey. Learners benefit from this firsthand knowledge, gaining insights into best practices, safety protocols, and the nuances of different machines.

Mastering Machine Controls

At the heart of hands-on heavy equipment training lies the mastery of machine controls. Students learn to navigate control panels, levers, switches, and joysticks that govern the intricate movements of the machinery. Through guided practice, they develop an understanding of the cause-and-effect relationships between their actions and the machine's responses, fostering a deep connection between operator and equipment.

Safety as a Priority

Safety is paramount in heavy equipment operations, and hands-on training programs are committed to instilling a safety-first mindset in their students. Operating heavy machinery comes with inherent risks, and proper training ensures that operators are well-versed in safety protocols, emergency procedures, and risk assessment. Hands-on training allows students to experience these safety measures in action, making safety an instinctive part of their operating routines.

Building Confidence and Adaptability

The journey from novice to proficient heavy equipment operator is marked by the growth of confidence and adaptability. Hands-on learning plays a crucial role in this transformation. As students progress through their training, they encounter a range of scenarios, from routine tasks to unexpected challenges. Each experience contributes to the development of problem-solving skills, adaptability to different machines, and the ability to make split-second decisions under pressure.

Realizing Industry Relevance

The heavy equipment industry is in a constant state of evolution, with new technologies, techniques, and machinery continually reshaping the landscape. Hands-on training programs are designed to keep pace with these changes, equipping students with the skills and knowledge that are relevant to today's job market. Graduates of these programs emerge not only as operators but also as adaptable professionals ready to contribute to the industry's future.

Hands-On Learning in Action

Consider a scenario in a heavy equipment training program: a student sits in the cab of a hydraulic excavator, hands gripping the controls, and eyes focused on a pile of debris that needs to be moved. With guidance from their instructor, they deftly operate the excavator, scooping up the debris and depositing it into a designated area. This simple action is a culmination of classroom learning, safety instruction, and hours of hands-on practice.

As the training progresses, the student encounters more complex challenges. They might learn to use GPS systems for precise digging, simulate digging trenches for utility lines, or practice intricate maneuvers for delicate tasks like pipe laying. Each exercise hones their skills, building a foundation of competence and confidence that will serve them well in their future career.

The Essence of Hands-On Learning

Heavy equipment training programs focus on bridging the gap between theoretical knowledge and practical application. While classroom education is essential for imparting foundational concepts, the heart of mastery lies in hands-on learning. Students enrolled in these programs get a chance to step into the operator's seat, maneuver the controls, and feel the vibrations of the machinery beneath their fingertips. This tactile experience is invaluable, as it allows trainees to internalize the nuances of machine operation, develop muscle memory, and learn to make split-second decisions.

Simulated Realism

The training environment provided by these programs mirrors real-world conditions as closely as possible. Advanced simulators recreate scenarios that operators are likely to encounter on job sites. From navigating uneven terrain to lifting and placing heavy loads, trainees gain exposure to diverse challenges in a controlled setting. Simulated training not only builds technical proficiency but also hones problem-solving skills and enhances situational awareness.

Safety First

Safety is a paramount concern in heavy equipment operation. A significant portion of hands-on training is dedicated to instilling safety protocols and practices. Trainees learn how to perform pre-operational checks, assess potential hazards, and respond effectively in emergency situations. By incorporating safety into hands-on training, aspiring operators develop a safety-conscious mindset that stays with them throughout their careers, contributing to a culture of safety in the workplace.

Variety of Equipment

Heavy equipment training programs expose students to a variety of machines commonly used in the industry. This breadth of experience equips trainees with versatility, enabling them to adapt their skills to different equipment types. From compact loaders to towering cranes, each machine comes with its own set of challenges and intricacies. Hands-on exposure to a range of equipment prepares operators to tackle various tasks with confidence.

Expert Guidance

Experienced instructors are the linchpin of effective hands-on learning in heavy equipment training programs. These instructors are seasoned professionals who have spent years in the field, mastering the art of machine operation. Their guidance is invaluable as they share practical insights, offer real-world anecdotes, and provide personalized feedback to each trainee. The mentorship aspect of hands-on training not only enhances technical skills but also fosters a deep understanding of the machines' capabilities and limitations.

Progressive Skill Development

Heavy equipment training programs are designed to accommodate learners of all levels – from novices with no prior experience to experienced operators seeking to refine their skills. The curriculum often follows a progressive structure, starting with fundamental concepts and gradually advancing to complex maneuvers. This scaffolding approach ensures that each trainee builds a strong foundation before moving on to more intricate tasks. The gradual progression not only builds competence but also boosts trainees' confidence in their abilities.

Real Job Site Integration

While simulated environments are essential, the ultimate goal of heavy equipment training programs is to prepare operators for real job sites. Many programs incorporate field training, where trainees work under the supervision of experienced operators on actual construction projects. This integration provides a taste of the challenges and demands that operators face in the field. It also instills a sense of responsibility and accountability, as trainees contribute to ongoing projects.

Industry Certification

The successful completion of a reputable heavy equipment training program often leads to industry-recognized certification. This certification serves as a testament to the trainee's skills and competence as an operator. Many employers prioritize certified operators when hiring, recognizing that certified individuals have undergone rigorous training and possess the necessary expertise to operate heavy equipment safely and efficiently.

Building Careers

Beyond the technical skills, heavy equipment training programs contribute significantly to career development. The demand for skilled heavy equipment operators remains high, offering graduates a range of employment opportunities across various sectors. Whether it's in construction, mining, forestry, or logistics, the skills acquired through hands-on training are transferable and in constant demand. Moreover, with experience, operators can advance to supervisory roles or even transition to related careers such as equipment maintenance or safety management.

CONTACT US: Fast Line Safety Training 535 Broadhollow Rd STE B9, Melville, NY 11747, United States 631-393-6755 https://www.fastlinesafetytraining.com/

#Boom lift certification Long Island#Scissor lift certification Long Island#Mobile elevated work platform Long Island#Excavator certification Long Island#Skid steer certification Long Island#Forklift certification card Long Island#Scaffolding training Long Island#Heavy equipment training schools Long Island#62 hour sst card Long Island#Scissor lift training Long Island

0 notes

Text

Best Forklift Operator Training Course South Australia

Looking for the best forklift operator training course in South Australia? Look no further! Johnson Safety & Training offers top-notch training to help you become a skilled forklift operator. Enroll now!

0 notes

Text

Purpose of Taking The Fall Protection Training

Many areas require early intervention by skilled workers. Unfortunately, most workplaces are fraught with dangers and pose the risks of slipping and falling. It is customary to keep the workers protected from such risks. Knowing how to save oneself by training can minimize such incidents too. Several industries make fall protection training from OSHA a prerequisite for recruitment today. The old timers are asked to undergo the training as early as possible to ensure workplace safety. Statistics reveal that over a thousand workers across the USA sustain injuries from slips, falls, and tripping over hard edges. The “Occupational Safety and Health Administration (OSHA)” emphasizes training to reduce the risks and save lives. The company management and employers are advised to take the necessary action by providing training to their workforce. The training is necessary for the construction industry and the general industry with its employees working in hazardous conditions. Some of the areas more prone to the risks of accidental falls include the following:- · Construction · Utility & Public Sector · Health Care · Food & Hospitality · Oil & Gas The Fall Protection course The employees do not have to lose their wages for absenteeism, though. Instead, they can continue to fulfill their responsibilities and undergo the training without losing any working days. This is made possible by online training courses available at present. The trainees can choose a convenient time to take the training and get the certificate after successful completion. What is included in the training course? · Basics of fall protection with particular emphasis on the dos and don’ts · Review of the OSHA fall protection standards. It is interesting to know that several standards are meant for varied industries. · Knowing the fall protection components and analyzing each individually to gauge their efficiency · Use of stairways and OSHA-recommended ladders to prevent falls · Identifying the risk-prone spots and determining the right kind of protection The course complies with the OSHA standard of 29 CFR 1926, which is meant for construction industry workers. The training course designed for the general industry complies with 29 CFR 1910 standard and includes subsection 1910.28-30 of OSHA standard The trainees do not require any special qualification to take the course. Employing by any of the industries mentioned above makes one eligible for it. Furthermore, people with aspirations of being employed in any of these industries may achieve their objectives sooner when equipped with an OSHA fall protection certificate. The trainee must be able to understand English as the training is conducted in that language. While taking the course online saves time and money, one may take it late in the evening and over weekends at convenience. The entire course is completed in 2.5 hours, making it easy to find the time. The certificate can be printed directly once the final exam is passed. A professional forklift operator must take the forklift certification training course to be employed by a reputed company and/or at government sites

0 notes

Text

Training people is actually so fulfilling I see why people become teachers now

#training someone for forklift certification rn and theyre already doing so well im so proud 🥲#dont get me wrong i still dont think id be able to handle teaching kids#but teaching adults? easy peasy#this has turned my day around#anna says stuff

1 note

·

View note

Text

Tumblr is probably interested in the fact that my husband finished his forklift certification yesterday, with the hands-on training portion of the work.

16 notes

·

View notes

Note

leopardstar is girl boss blackstar is girl union etc etc

BB!Blackstar had to go through like 5 years of union training and earn his lives (forklift certifications) one by one until he got the final from Russetfur, who is like, the patron of unionized lesbians.

BB!Leopardstar was a small business owner

#fennelposting#Top 10 bones posts inscrutable to anyone else in the world#But its my blog and people come here for my mysterious nature and queer ways

72 notes

·

View notes

Text

Why Superior Forklift Training is Essential for Safety and Efficiency in the Workplace

In any industry that relies on material handling, forklift operations are a critical part of day-to-day operations. Whether in warehouses, distribution centers, or construction sites, forklifts are indispensable tools that allow businesses to move goods, equipment, and materials efficiently. However, improper use of forklifts can lead to workplace accidents, injuries, and costly damages. This is where professional forklift training becomes essential. Superior Forklift Training is dedicated to providing comprehensive and industry-leading forklift certification programs that ensure your team operates forklifts safely, efficiently, and in compliance with OSHA regulations.

The Importance of Forklift Training

Forklifts are powerful machines that can easily cause damage or injury if not operated correctly. According to the Occupational Safety and Health Administration (OSHA), forklift accidents are responsible for hundreds of fatalities and thousands of injuries each year. In fact, OSHA reports that improper operation, lack of proper training, and failure to adhere to safety regulations contribute significantly to these incidents.

To minimize risks, every forklift operator must undergo proper training. Superior Forklift Training offers specialized programs designed to teach operators not only the technical skills necessary to operate forklifts but also the importance of workplace safety, hazard identification, and best practices. This comprehensive approach ensures that operators are well-prepared to handle the responsibilities associated with forklift operation.

Why Choose Superior Forklift Training?

Superior Forklift Training stands out in the field for its commitment to safety, quality instruction, and real-world applicability. Here are several key reasons why businesses should choose their services:

1. Tailored Training Programs

Superior Forklift Training understands that each workplace is unique, with different operational needs and equipment. Their training programs are customizable to suit the specific requirements of your business, whether you’re training a few employees or a whole fleet of operators. They offer both in-person and online training options to accommodate different schedules and learning preferences.

2. Expert Trainers with Industry Experience

The instructors at Superior Forklift Training are highly experienced and knowledgeable. They bring years of practical experience in forklift operations, providing trainees with insights that go beyond textbook knowledge. Their trainers are skilled at teaching all types of learners, ensuring that even novice operators gain a full understanding of how to operate forklifts safely and effectively.

3. Comprehensive Safety Focus

Safety is at the core of everything Superior Forklift Training does. The training programs emphasize not only how to operate a forklift but also how to identify and mitigate potential hazards. Trainees learn how to conduct pre-operation checks, how to navigate various types of terrain safely, and how to respond to emergencies. The goal is to reduce workplace accidents and create a safer working environment for all employees.

4. OSHA Compliance

Superior Forklift Training ensures that all training programs are fully compliant with OSHA standards. Certification from an OSHA-compliant training provider is not only important for safety but also for legal and regulatory reasons. Employers can rest assured that their operators will be properly certified, helping to avoid costly fines and legal issues.

5. Enhanced Productivity

A well-trained forklift operator is not only safer but also more efficient. Superior Forklift Training helps workers learn how to operate forklifts more efficiently, which leads to better productivity and faster material handling. This boosts operational efficiency, reduces downtime, and helps businesses meet their targets.

Conclusion

Investing in professional forklift training is not just about compliance; it’s about creating a culture of safety and efficiency in the workplace. Superior Forklift Training offers high-quality training programs that provide both new and experienced operators with the skills they need to work safely and effectively. With their customizable programs, expert trainers, and focus on safety, Superior Forklift Training is the best choice for businesses looking to reduce risks, enhance productivity, and promote a safe working environment. For more information on their training services and to schedule a course, visit their website at superiorforklifttraining.com.

#Online Forklift Training Course ca#forklift training CA#Forklift Training Near Me california#Forklift Certification Training california

1 note

·

View note

Text

got some more forklift training in at work today. i think i'm starting to get a better grasp of how to handle the dang thing

forklift certification, here i come!

8 notes

·

View notes

Text

Truck Driving Schools Toronto | Truck Training Schools Toronto

The Importance of Choosing the Right Truck Driving Schools Toronto: When beginning on the journey to become a professional truck driver, the choice of the right truck driving school is pivotal. With numerous truck training schools in Toronto, it's essential to identify the one that aligns with your career goals and learning style.

#Truck Driving Schools Toronto#Truck Training Schools Toronto#Forklift Training Schools Toronto#Forklift Driving School Toronto#Forklift Training Academy Toronto#Professional Forklift Driver Training Toronto#Forklift Certificate Toronto#Forklift Driver Licence Toronto#Forklift Driving Courses Toronto#Forklift Driver Training Toronto

0 notes