#flat article screen printing machine

Text

Supplier of Monolayer Blown Film Machine in Kerala

Adroit Extrusion is a Manufacturer, Exporter, and Supplier of Monolayer Blown Film Machine in Kerala.

Adroit Extrusion specializes in manufacturing Monolayer Blown Film, ABA, and AB Blown Film, as well as Multilayer Blown Film.

We provide a diverse range of customized Monolayer Blown Film Lines tailored to meet each customer's specific needs.

Our highly acclaimed Monolayer Blown Film Plants offer outputs ranging from 35 kg/hr to 450 kg/hr, with lay-flat widths spanning from 50 mm to 6000 mm, suitable for processing LD, LLD, HM, and HDPE polymers.

You can configure our Monolayer Blown Film Plants to process wide-width HDPE film and include up to 4-color inline flexographic printing capabilities.

Incorporating advanced features such as grooved feed barrels, barrier screws, dosing systems, Liquid PIB dosing systems, manual and automatic screen changers, rotating dies/platforms, internal bubble cooling, automatic bubble cages, online thickness monitoring and control, 2/4 station surface and center winders, auto tension control, and corona treaters.

This process allows for precise control over film thickness, width, and properties, empowering manufacturers to customize the film to meet specific packaging requirements, including barrier protection, puncture resistance, and clarity.

Compared to alternative packaging materials, monolayer blown film offers a cost-effective solution, delivering superior strength and barrier properties at a competitive cost per unit.

Adroit Extrusion is a Supplier of Monolayer Blown Film Machine in Kerala and various locations like

Barauni, Begusarai, Bettiah, Bhagalpur, Bihar Sharif, Bodh Gaya, Buxar, Chapra, Darbhanga,

Dehri, Dinapur Nizamat, Gaya, Hajipur, Jamalpur, Katihar, Madhubani, Motihari, Munger, Muzaffarpur,

Patna, Purnia, Pusa, Saharsa, Samastipur, Sasaram, Sitamarhi, Siwan.

For further details and inquiries, please feel free to contact us.

Read the full article

0 notes

Text

Shirt Embroidery In Friendswood, Texas - A Comprehensive Guide

To enhance your garment's value, wearing a custom embroidered shirt is an excellent choice. Whether you want a shirt to represent a sports club, business, or a personal job dress code, there are so many printing methods available in Texas, but shirt embroidery is the right choice for you and has amazing benefits. At P.S Quilting, Our team is highly trained to offer you custom Shirt Embroidery. We made the embroidery t-shirt with passion and precision and having the latest technology. This article will tell you everything about Custom Shirt Embroidery., its benefits, and much more.

What Is Custom Shirt Embroidery?

Embroidery is the process of stitching a design, logo, or text on the fabric. It is done either by hand or by machines. All embroideries are carried out by our highly experienced team members. They are mainly designed by our industry-leading digital machines, which can do the work with perfect precision. You can also check out hand-made personalized quilts from tour official website. You might have a question in your mind: what is the difference between T-shirt Embroidery and Screen Printing.

Difference Between Shirt Embroidery and The Screen Printing

These are the most popular methods for customizing t-shirts. They offer very different advantages as per your preferences. Here is the difference between shirt embroidery and the Screen Printing

In embroidery, we stitch the thread directly to the fabric to make a wonderful design, whereas, as in screen printing, we push the ink through the stencil ( screen) on the clothing fabric. The basic idea for screen printing is to get a flat printed design.

When we talked about durability, embroidery is more durable than screen printing. Embroidery threads can adjust to washing and drying and wear and tear, but in screen printing, the design may crack, fade, or peel over time. The link should be of great quality. Otherwise, the result is the same as we discussed.

When we talk about design, embroidery is generally used to make a simple design and a very great look where, whereas screen printing is great for complex designs, which are generally used to make logos and fine details.

When we talk about cost, embroidery is expensive when the order is few. The reason is the setup cost, but if you order a larger quantity, it will become cost-effective. On the other hand, Screen printing is cheaper if you order in bulk with multiple colors.

At, last when we talk about fabric embroidery works in various types of fabric like study canvas and smooth polos. On the other hand, screen printing is generally used in thicker fabrics. Like Cooton shirts. It is highly not recommended to use in delicate materials Now let's discuss the

Benefits Of a Shirt Embroidery

It is durable. You can easily wash and dry it multiple times. Its design does not fade and looks as new as it did in the first place.

It is applied in a variety of fabrics. You can easily choose as per your needs. You can also check handmade quilted wall hangings from our website.

For more information, you can explore our online store.

0 notes

Text

ENGYPRINT Tech Company Ltd: The Leading Producer of Pad Printing Machines

Pad printing is a popular printing technique that involves transferring ink from a specially designed pad onto the surface of a product. This method is commonly used to print onto uneven, irregular, or curved surfaces, making it ideal for decorating a wide range of products including plastics, metals, glass, ceramics, and more. ENGYPRINT Tech Company Ltd is a leading manufacturer of pad printing machines, and has been in business since 2002. In this article, we will explore the company’s products and services, and explain why they are a top choice for businesses in need of high-quality pad printing equipment.

ENGYPRINT Tech Company Ltd is based in China, and is a professional manufacturer of pad printing machines, silk screen printers, pad printer plates (clichés), ceramic rings, ink cups, pad molds, and all kinds of pad printing consumables. The company has a long-standing reputation for producing high-quality equipment that is both reliable and affordable. With a focus on innovation and customer satisfaction, ENGYPRINT Tech Company Ltd has become a go-to destination for businesses looking to improve their printing processes.

One of the company’s most popular products is the pad printing machine. These machines are available in a range of models to suit different needs and budgets. The company’s pad printing machines are known for their precision, reliability, and ease of use. They are suitable for printing on a wide range of surfaces and materials, including plastics, metals, glass, ceramics, and more. ENGYPRINT Tech Company Ltd’s pad printing machines are also highly customizable, allowing businesses to choose the features that best suit their needs.

In addition to pad printing machines, ENGYPRINT Tech Company Ltd also produces a range of other equipment and consumables for the pad printing industry. For example, the company manufactures silk screen printers, which are used for printing onto flat surfaces. These printers are ideal for printing on products such as T-shirts, posters, signs, and more. ENGYPRINT Tech Company Ltd also produces pad printer plates (clichés), which are used to transfer the ink from the pad to the product being printed. These plates are available in a range of sizes and shapes to suit different applications.

ENGYPRINT Tech Company Ltd also produces a range of other consumables for the pad printing industry, including ceramic rings, ink cups, and pad molds. These items are essential for the proper functioning of pad printing equipment, and are designed to be durable, long-lasting, and easy to use. ENGYPRINT Tech Company Ltd is committed to producing high-quality consumables that meet the needs of businesses of all sizes.

In addition to producing pad printing equipment and consumables, ENGYPRINT Tech Company Ltd is also a leader in pad printing plate making technology. The company designs and manufactures plate making machines, including coating machines, UV exposure units, and steel plate etching machines. These machines are essential for creating high-quality pad printing plates, which are used to transfer ink from the pad to the product being printed. ENGYPRINT Tech Company Ltd has also developed an aluminum plate that can be engraved using a fiber laser machine. This innovative technology allows for faster and more precise engraving, making it ideal for businesses that need to produce large quantities of printed products.

ENGYPRINT Tech Company Ltd is a leading manufacturer of pad printing equipment, consumables, and plate making technology. The company has a long-standing reputation for producing high-quality products that are both reliable and affordable. With a focus on innovation and customer satisfaction, ENGYPRINT Tech Company Ltd has become a go-to destination for businesses in need of high-quality pad printing equipment. Whether you are looking for a pad printing machine, silk screen printer, pad printer plate, or any other pad printing consumable, ENGYPRINT Tech Company Ltd has the experience, expertise, and resources to meet your needs. The company’s commitment to quality and customer satisfaction makes it a top choice for businesses in a range of industries, from manufacturing and packaging to advertising and promotional products.

One of the reasons why ENGYPRINT Tech Company Ltd has been so successful is its dedication to innovation. The company is always looking for new ways to improve its products and services, and is constantly investing in research and development. This has led to the development of new technologies and materials that have helped to make pad printing more efficient, cost-effective, and eco-friendly. For example, ENGYPRINT Tech Company Ltd has developed a new type of pad made from silicone rubber that is more durable and longer-lasting than traditional pads. This innovation has helped to reduce waste and improve the overall efficiency of the pad printing process.

Another reason why ENGYPRINT Tech Company Ltd is a top choice for businesses is its commitment to customer service. The company’s team of experts is always available to answer questions and provide support, whether you need help choosing the right equipment, troubleshooting a problem, or learning how to use a new product. ENGYPRINT Tech Company Ltd also offers training and education programs to help businesses get the most out of their pad printing equipment.

Finally, ENGYPRINT Tech Company Ltd is committed to sustainability and social responsibility. The company uses environmentally friendly materials and processes whenever possible, and is constantly looking for ways to reduce its environmental impact. ENGYPRINT Tech Company Ltd also supports local communities by providing jobs and contributing to charitable causes.

In conclusion, ENGYPRINT Tech Company Ltd is a leading manufacturer of pad printing machines, silk screen printers, pad printer plates, and other pad printing consumables. With a focus on innovation, customer service, and sustainability, the company has become a top choice for businesses in need of high-quality pad printing equipment. Whether you are a small business looking to improve your printing processes or a large manufacturer in need of a reliable printing solution, ENGYPRINT Tech Company Ltd has the products, services, and expertise to meet your needs.

0 notes

Text

Hotel In Patna For Couples | Hotel Bodhi Tree

Hotel Bodhi Tree is one of the best hotel in Patna for couples looking for a comfortable and luxurious stay. The hotel is located in the prime location of Patna and offers a range of amenities that are perfect for couples. In this article, we will take a closer look at Hotel Bodhi Tree and all that it has to offer. Hotel Bodhi is the best hotel in Patna near railway station, making it easily accessible from all parts of the city. The Bodhi Tree is top hotel in Patna near junction, which is a popular commercial and business hub of the city. The hotel is located just 5 min walk from Patna Junction Railway Station and 30 min drive from from the Patna International Airport, making it easily accessible for out-of-town visitors.

Hotel Bodhi Tree is the best hotel in Patna and offers a range of accommodation options for couples, including Deluxe Rooms, Executive Rooms, and Suites. All rooms are spacious and tastefully designed with modern amenities to ensure a comfortable and luxurious stay. The rooms are equipped with air-conditioning, high-speed Wi-Fi, flat-screen TVs with satellite channels, mini-fridges, and tea/coffee makers.

The Deluxe Rooms are perfect for couples who are looking for a comfortable stay with all the necessary amenities. These rooms are equipped with a king-size bed, a work desk, and a seating area. The rooms also have large windows that offer a beautiful view of the city.

The Executive Rooms are more spacious and luxurious, with additional amenities such as a bathtub and a separate living area. These rooms are perfect for couples who want to indulge in a little luxury during their stay at the hotel.

The Suites at Hotel Bodhi Tree are the epitome of luxury and comfort. These rooms are spacious and come with a separate living area, a large bedroom with a king-size bed, and a luxurious bathroom with a bathtub. The suites are perfect for couples who want to pamper themselves during their stay at the hotel.

Hotel Bodhi Tree is top hotel in Patna near junction and has a range of dining options that cater to all tastes and preferences. The hotel has an in-house restaurant, which serves a range of Indian, Chinese, and Continental cuisines. The restaurant is open for breakfast, lunch, and dinner and offers both buffet and à la carte options. For couples who want to enjoy a romantic dinner together, the hotel offers private dining options. The hotel's staff can arrange for a romantic dinner in a private dining area, complete with candles and flowers, to create the perfect romantic atmosphere.

Hotel Bodhi Tree offers a range of facilities and amenities that are perfect for couples. The hotel has a fitness center, where couples can work out together and stay fit during their stay at the hotel. The fitness center is equipped with modern equipment and is open 24 hours a day.

For couples who want to indulge in a little pampering, the hotel offers a range of spa treatments. The spa at Hotel Bodhi Tree offers a range of massages, body treatments, and facials, all designed to rejuvenate and refresh the body and mind. The hotel also has a business center, which is perfect for couples who are in Patna on business. The business center is equipped with modern equipment, including computers, printers, and fax machines, and offers a range of services, including printing, scanning, and copying.

0 notes

Text

5 Easy Ways to Customize a T-Shirt: A Comprehensive Guide

Customizing a t-shirt can be a fun and creative way to express your personal style and make a statement. Whether you're looking to add a unique design to a plain shirt or create a batch of matching shirts for a group, there are plenty of options available to help you get the look you want. In this article, we'll explore the different ways you can customize a t-shirt, including both DIY methods and professional services. By the end, you'll have a better understanding of the options available and how to get started on your own custom t-shirt project.

One of the simplest ways to customize a t-shirt is to use iron-on transfer paper. These sheets of paper are printed with ink that can be transferred onto fabric using a household iron. You can find transfer paper at most craft stores or online, and they come in a variety of colors and finishes including matte, gloss, and foil. To use transfer paper, you'll need to design your image or text using a computer program like Photoshop or Illustrator and then print it onto the transfer paper using a standard inkjet printer. Once your design is printed, you'll need to follow the manufacturer's instructions for ironing it onto the shirt. This method is great for small batches or one-off projects, but it can be time-consuming and the designs may not be as durable as other methods.

If you're looking for something a bit more professional, you can use screen printing to create custom t-shirts. Screen printing is a printing technique where ink is pushed through a fine mesh screen onto the shirt. The screen is first coated with a layer of photo-sensitive emulsion, which is then exposed to UV light. The areas of the screen that are exposed to light harden, while the rest remains soft and can be washed away. This leaves a stencil of your design on the screen, which can then be used to print the design onto the shirt. Screen printing is a more labor-intensive process, but it allows you to create larger batches of shirts with consistent, high-quality results.

Another option for customizing t-shirts is to use heat transfer vinyl (HTV). HTV is a thin, flexible material that can be cut into any shape or design using a cutting machine like a Cricut or Silhouette. Once the design is cut, it can be ironed or pressed onto the shirt using a heat press or household iron. HTV is great for creating intricate designs or small text, and it's relatively easy to use. However, it may not be as durable as screen printing or embroidery, and the designs can peel or fade over time.

If you're looking for a more permanent and professional-looking option, you can consider embroidering your design onto the shirt. Embroidery involves using a special machine to sew the design onto the shirt using thread. This method is more expensive and time-consuming, but it produces high-quality, long-lasting results. Embroidery is a good choice for logos or text that will be worn frequently or need to stand up to harsh conditions.

No matter which method you choose, there are a few key considerations to keep in mind when customizing a t-shirt. First, think about the type of shirt you want to use. Different fabrics will work better with different customization methods, so it's important to choose a shirt that will work well with the method you've chosen. Cotton shirts are generally the most versatile, but you can also use synthetic materials like polyester or spandex for a different look.

Next, consider the placement of your design. If you're using a transfer paper or HTV, you'll need to make sure there's enough flat surface area on the shirt to iron the design onto. For screen printing or embroidery, you'll need to think about the orientation of your design and where it will look best on the shirt. You may also want to consider the size of your design – a small design may get lost on a large shirt, while a large design may overwhelm a small shirt.

Finally, think about the colors you want to use in your design. Different methods have different color limitations – for example, screen printing typically requires that you use a limited number of colors, while HTV and embroidery allow for more flexibility. Keep in mind that the colors you see on your computer screen may not match the colors of the finished product, so it's a good idea to test out your design on a small scale before committing to a large batch.

In conclusion, customizing a t-shirt is a fun and creative way to express your personal style and make a statement. Whether you choose to DIY with iron-on transfer paper or hire a professional service like screen printing or embroidery, there are plenty of options available to help you get the look you want. By considering factors like the type of shirt, placement of the design, and colors, you can create a unique and professional-looking custom t-shirt that reflects your personality and interests.

Read the full article

0 notes

Link

Technorobotic machines are one the best Bag Packer Machine Manufacturers in India . These machines packs plastic containers into polythene bags machines have been designed to cope with different bottle shapes and line requirements. For more details visit our site.

#bag packer machine#bottle screen printing machine#flat article screen printing machine#injection#moulding machine manufacturer#plastic injection moulding machine manufacturer in india

0 notes

Text

Fic I just wrote based on These Two art pieces that I’ve drawn and THIS POST by @body-utensil-travels-terrain

———

You’ve spent your life being told you couldn’t. Now there’s a voice telling you that you can.

You remember it distinctly. You were fourteen at the time, just really starting to figure out what you wanted to do with your life (it certainly isn’t what society expected from you— but then, society doesn’t expect someone like you anyway, does it?) when you first heard her voice over the radio in your living room. The words she said resonated with you, the promise and ambition that she spoke with. It was almost like she was talking directly to you.

You do your research. You study hard. You tinker away at things in your garage, supplementing your studies in your own way. And five years later, after you’ve graduated, you put in your application.

A letter arrives a few weeks later, emblazoned with the circular symbol you’ve kept in your mind’s eye all this time, and bold lettering on the front— Aperture Science Innovators. It’s addressed to you. You open it, and your fingers tighten around the smooth paper— “congratulations” it says. You’ve been accepted. At the bottom is Her signature. You trace over it with your fingers. Delicately, as gently as you’d handle an irreplaceable machine part.

Two weeks later your bags are packed and you’re boarding a flight to Detroit. The attendant greets you. You hold up your boarding pass and get on. You land a few hours later. Getting a cab would be too complicated— people don’t like to take the time to read, and most can’t speak the way you do. So you walk to the train station, it’s not too far. Just an hour or two. You’ve walked further before.

Flat fields flow by endlessly as the train rattles down its tracks. You lean your head against the window, watching the hues of gold rush by, blurring on into infinity.

The sun is gone when you pull up outside a strange little town, surrounded by chain link fence. You fish through your bag for the packet you’d been sent— and pull out the temporary ID you’d been given. You show it to the gate guard. He lets you in. A man is waiting to show you your dormitory. You shake your head at his offer of a tour— you’ll explore the place yourself tomorrow. There are a few days before you’re actually needed for orientation.

The room is small and plain. A bed, desk, and dresser, and a small closet. That’s alright. You don’t need much. You hang up your few articles of clothing and tuck your shoes next to the door. The bed isn’t soft, but it isn’t hard. You fall asleep quickly, exhausted from your travels.

The next few days are spent wandering. Visiting the little shops, the stations. Peering into labs where you can. Climbing over fences (they could never keep you out) before quickly retreating as a security guard passed. You don’t want to get in trouble before your internship even begins. You wonder if you’ll see her. But you only hear her voice in announcements as you trigger motion sensors throughout the complex.

When work actually starts, it’s tedious. Getting coffee. Taking documents to the shredder and the incinerator. You don’t usually see the labs. Or, well, much of anything. It’s just a lot of running here and there, back and forth at your superiors’ beck and call. It’s tiring. But you do it— after all, you want to be here, you want to do this— and you never give up.

It’s a few months before you see her— before your internship takes you to the main complex. Now you’re checking inventory, sorting mail, sorting records (and chucking the casualty lists into the incinerator as instructed). Occasionally they’ll call you in to fix the coffee maker or the refrigerator.

You hear her voice once, muffled— she’s talking to someone, to a group it seems, just outside the room you’re in. You look over your shoulder and catch a glimpse. Rosy cheeks and bright-red lips, wavy dark hair flowing around her shoulder, a smile on her face (manufactured, you can tell with just this glance that she’s concealing so very much), a bright red scarf tied around her neck.

Your eyes lock for just a second, and the corner of her mouth creases, dimpling her cheeks. Your heart races— that, that was a hint of a true smile. Warmth flushes your own cheeks and you tear your gaze away. Suddenly shy— much shyer than you’ve ever been before.

It doesn’t make sense to you. Not yet. Not until you start seeing her more. Not until her smiles become more frequent and pointed. Not until her gaze lingers on you a little longer than before each time. The fluttery feeling doesn’t go away— and you’re determined more than ever to reach her.

Of course, it happens sooner and easier than you think. She starts requesting you specifically to bring her her coffee. You take a red pen and draw a little smiley face next to her name before giving it to her. When you come up to her office, there’s a sticky note left on the monitor, in that oh-so-hard to read yet absolutely beautiful cursive of hers. At the end of it is a smiley face, so much more elegant and less childish than yours. You keep the note. On her next cup, you add a heart to the dot of the ‘i’ in her name. You start responding to her notes with little notes of your own, your rounded, sometimes scratchy handwriting a stark contrast.

The notes are never there when you get back. You like to think she kept them. You’re pretty sure she did.

A year after you arrive, your internship is over, and you’re up for a promotion— junior mechanic. Probably still more of the same, but you’ll be getting a salary now (not that you really have any use for it since Aperture provides your housing) and you’ll have a permanent place. But you’ll see her less. You’ll miss that, of course— but you’re finally moving beyond your station, moving up in the company.

The day before your internship ends, you get another note. “Wanna get coffee together tomorrow?” Your heart leaps. You scribble out your answer just beneath her writing.

You’re sitting across from her at the cafe table. The cafe serves the same stuff as the cafeteria, but it’s decorated more quaintly, and always costs more for some reason. Maybe because there’s sunlight coming through the windows.

“So, headed up the ladder,” she begins after the two of you sip your drinks (well, she sips her drink, you’re too caught up in the crimson of her lips). “I guess I won’t be seeing as much of you now.”

There’s something behind her cheery voice, a sadness that you’ve caught glimpses of before, a wistfulness deeper than her words. You look up, catching her gaze for a moment and nod in response.

“Well, this is nice. Maybe we should do this more often. Once a week, at least? Or you could come over to my place. We could spend time together. As friends, or something.” With that, she gives you a wink. Your cheeks flush bright red.

You catch the implication right away. Your hero, your inspiration— and now here you are sitting across from her at a cafe while she all but outright asks you out.

You thought you’d be excited for things to grow beyond the notes and the gestures. But you feel different than that. After the initial jolt, the initial flutter, you look back over at her and you see the chasm yawning out between the two of you. The mountain she’s perched on, the valley you’re standing in. Your scratchy print against her elegant cursive, your short, bitten nails against her sharp manicure, your messy ponytail against her shiny waves. You look down at your simple intern’s badge, then over at her emblazoned one. She doesn’t even have a title listed— everyone knows who she is.

You’re miles apart, even if you might have seemed to be closer.

You stand up, your throat knotting up as you shake your head. You can’t look at her now, but you can practically feel the disappointment in her face as she murmurs “oh.” You want to explain but you can’t, your thoughts racing a mile a minute. The last thing you want is to turn Her, your idol, the one who makes your heart flutter, the reason you came here in the first place, down.

But you can’t do this now. Not yet. Not until you’ve reached the top of the mountain. Not until you’re close enough for her to reach out her hand and pull you the rest of the way up.

“Let me know if you change your mind,” she says.

You pause, halfway to the door. You turn back just enough so that you can glimpse her, and give a tiny nod.

After that you throw yourself into your work. Up to senior mechanic, then technician, then engineer— you’re working on Aperture’s new technology now, its most important projects. But you’re still not close enough. Into the test chambers you go at the CEO’s behest, defying death and physics at breakneck speeds, trusting in the tech you’ve helped create to ensure your survival.

Sometimes you look up and see her watching from the observation room, the tell-tale flash of red. You don’t look too long.

The CEO falls ill. He leaves a disturbing message. You try not to think too much of it— you’re almost there.

Your superior fails a test. You’re not surprised. Not hurt, not sad. It just happens and now you’re in the upper echelon. Now you’re at the top— now, you can reach out to her again. Tell her you’ve changed your mind. You can be equals now.

You go to her office. She isn’t there to answer the door. “Don’t you remember Mr. Johnson’s last request?” They say to you. You tried to block it out, but you remember.

You use your pass on a high security door. It opens. Your name is emblazoned too now. Just like hers was.

Before you is a massive operating system. On the screen reads a message: “transfer complete. transfer successful. writing data : do not disconnect subject.”

She’s lying inside a tube-like compartment. A transparent coffin. Wires hooked up to her. Eyes closed. Lips still ruby red.

You reach out and touch the glass. There’s no response. There won’t be a response.

This technology is untested. This is the first human-AI interfacing project Aperture has conducted. There’s only a fifty percent chance it will work, and even if it does, it doesn’t change the fact that she’s gone. You’ll never clasp her small hands inside your own calloused ones, tuck your head against her shoulder, press your lips against hers.

You’ve finally reached the top of the mountain. Finally reached her. But it was too late. When you crested the summit, she was already gone, and there was only a spatter of crimson left behind to show that she was ever there at all.

#portal#fanfiction#portal fanfic#portal fanfiction#chell#chell portal#portal chell#caroline portal#portal caroline#chelline#cheroline#chell x caroline#portal au#intern chell#intern chell au#my writing#cinna writes#might edit and post to AO3 at some point#but for now have the rough draft

40 notes

·

View notes

Text

<<PREVIOUS⏺<<CONTENTS>>

WARREN COUNTY/CARPENTER COUNTY LINE, ILLINOIS

Twenty Seven Hours Later

“Oh god!” The Governor turned from the Mustang with a hand over her mouth, her face suddenly pale.

“Oh jesus fuck!”

She took off across the roadway, running has fast as her flats would carry her. One of those shiny black shoes slipped on the wet asphault causing her to teeter, but she did not fall. She reached the tall wet grass on the opposite side of the road, bent, and proceeded to vomit in the ditch there. Salazar hurried after her.

Meeker and McGrath gave each other a tired look, and then looked back to the wreck. They barely noticed the white truck pull up behind them and Fred Colbourne hop out. A siren wailed in front of them as another Carpenter County Fire Department vehicle joined the other one and ejected six or seven more fire fighters in full yellow and orange regalia.

McGrath pointed to the crumpled body which lay in the middle of the road, atop the white lines.

“That's definitely Lloyd Chumway there,” he said morosely, “And this one here in the drivers seat...that's Lee.”

Meeker spit. “Pretty well intact, considering.”

“Well, they were in a pretty nice truck.” McGrath said, glancing over to the Governor who had now dropped to her knees. Salazar held her gently by the shoulders. She was still wretching.

“It's Booger's truck,” Meeker replied softly.

“The cook from the diner? The one with his head in the..”

Meeker cut him off, “Yep.”

“What about the kids in the Mustang? Can you ID them?” McGrath asked, walking around to the other side of the orange sports-car.

“Well,” Meeker took a deep breath, “This is Brad Doyle's mustang. He's pretty well known by the police around here. Not a bad kid.” He spit again, “But not a very good one either.”

McGrath's eyes panned across the headless torso in the driver's seat clad in a blood soaked Code Orange shirt. Bits of blood, bone, and brain lay all over the steel bumper of the truck which had completley intruded upon the cab of the Mustang. Some of it belonged to Brad, some belonged to the mess of a carcass that lay in the center of the car beside him. There was nothing but a heap of blood, skin, bones, and some sort of leopard print clothing. Another crumpled body lay in the backseat. Young female, her head turned around the wrong way on her neck. She was missing her legs.

“Do you know these other two occupants?” McGrath asked.

“The one in the backseat is Kyndra Bailey. I'm guessing this one,” he gulped as he looked over the tattered remains, “this one is probably Zoey Gonland, her girlfriend. They liked to hang out with Brad.”

McGrath looked up from the other side of the car, “More trouble makers?”

“They were good kids. A little bit of the talk of the town, but good kids.”

McGrath shook his head, “I don't follow.”

“A high school lesbian couple in a small town like this. Everyone knows them.”

“Jesus God Almighty,” Fred Colbourne said as he stepped up to the wreck beside them.

Another man, this one tall and thin with short brown hair, a yellow polo shirt and khaki pants also appeared beside them. Meeker looked at him. The man extended his hand.

“I'm Shelton Ganoux, the Carpenter County Medical Examiner. They called for me as soon as they arrived.” The man said, nodding a head to the fire fighters who were laboring around the wreck of the semi-truck and ambulance.

“And we here in Warren County greatly appreciate your help,” Meeker said, shaking the young man's hand firmly. “We've had one hell of a night over here and our boys are a little tied up.”

Ganoux half-bowed his head, “So I've heard.”

“What the hell happened out here,” Colbourne asked.

The Governor and Salazar re-appeared next to them. The Governor pulled a kleenex from her pantsuit pocket and dabbed at her mouth.

“It appears we have two separate accidents, occurring within about an hour and a half of each other. The orange sports-car, the truck, and the tractor trailer incident occurred at around six o'clock this morning, while the ambulance seems to have collided with the tractor trailer at around seven thirty.”

“Makes sense,” Meeker mumbled.

“What?” Colbourne asked, “What makes sense.”

“It looks like Mustang was behind the tractor trailer and went to try and pass him when they struck the Chumway Brothers in the truck coming from the opposite direction.” McGrath said.

Meeker's phone began to vibrate in his pants. He pulled it out, hit the green button on the screen, and stuck it to his ear.

“Meeker!” He barked. The voice that answered was gruff.

“Hey Deputy, it's Lorne Appleby.”

“Who?”

“Appleby, from Protective Services.”

“Oh right. Well?”

“Nothing yet. I'm gonna head to the hotel room for some shut eye. Miss. Cromer should be back in a few hours. Just wanted to keep you abreast of the...”

“Mrs. who?”

“Cromer...Ellen Cromer...from DCF.”

Meeker rubbed his forehead. “Aww yeah..right right. I'm sorry Appleby, I got a million things going on right now.”

“I know, I know. Like I said, just wanted to keep you abreast of the situation.”

“Who do I got over there now?”

“Officer Chang just left, Officer Stanton just arrived, two other officers in a squad car just went on patrol an hour or so ago...forgive me, I don't remember their names.”

Meeker adjusted the phone from one ear to the other. “Oh right, that's Warner and Farnsworth I think.”

“Maybe.”

“Okay, keep me posted.”

“Will do.”

Meeker ended the call.

“Who was that?” Fred asked.

“Guy from Protective Services about Maddie Keane.”

“Still haven't found her?” Colbourne asked.

Meeker shook his head and waved at the wreckage in front of him. “And if it wasn't for all this shit and everything else I'd have every god damn cop out there looking for her.”

Fred patted his friend's back. “I know Bengie. I know. You're doing the best you can.”

They were quiet for awhile and Ben took some deep breaths to gather his thoughts.

“You know what I'm wondering?” Colbourne asked after some time had passed.

“What's that?” Ben replied quietly.

“How in the world did no one around here hear a wreck like that?”

“Well the only ones out here are Reverend Taylor over there,” he pointed to his right, to a house on the top of a hill, “and Amos Yoder. Amos claims to have been woken up by the second accident, he's talking to the state troopers now.” he pointed to his left, toward a dirt road leading down to a quaint little farmhouse with a big red barn. An Amish man was indeed standing along side the curb next to his driveway talking to an Illinois State Trooper who was dictating his statement on a clipboard.

“Amos said he slept right through the first accident, and I've known Kevin Taylor for years, we had sleep overs together when we were kids. He has to sleep with some kind of noise. He always brought a sound machine to my house, annoying little shit.” Meeker continued, “He sleeps with a box-fan I think. He probably couldn't hear a frieght train coming through his living room.”

“Besides that it was still raining at six o'clock this morning,” Ganoux said, “the sound of the storm could have muffled much of the noise.”

“I just can't believe Gary Windorf didn't see the over-turned tractor trailer.” Colbourne said, gesturing to the ambulance. Gary Windorf had been the driver.

“We told him to haul ass,” Meeker sighed, “it was still dark and raining.”

“Plus he was coming up from over this hill,” McGrath added, waving at the rise in the road behind them.

The Governor cleared her throat. “So we have the Chumway brothers here...where the hell is Myers? Is he in the back of that ambulance where he belongs?”

“Who is Myers?” Ganoux asked.

“Objective number one,” Meeker replied, “Big guy, jumpsuit..”

“The guy with the mask, kinda toasty?”

“That'd be him,” McGrath nodded.

“He's over there.” Ganoux pointed. Three firefighters crouched beside a body near the tree line. The figure was face down in the mud only a few feet from the trailer of Gabriel Couture's truck. “It appears the patient was thrown from the ambulance.”

“But he's dead?” Meeker asked.

“Very much so. He hit a tree in mid air.” Ganoux replied.

“He was dead before he was even put in the ambulance,” Colbourne grunted.

“Well, I can't tell that. I'd need to do a full autopsy to do that.” Ganoux said.

“Forget that,” The Governor spat, “Get his ass in a body bag and let's get it back to the High School. Get all these bodies over there so we can...”

She was interrupted by the sound of approaching vehicles. The whole party turned as a black GMC Van pulled up behind the firetrucks. In the distance, it looked as if the van had been followed by a train of semi-trucks. The truck tractors where plain white with no lettering, while the trailers were gray, and also blank. The hiss of the parking brakes sounded off one at a time.

The doors of the GMC Van opened. Several almost identical looking Caucasian men in black suits stepped out. They seemed to be led by another man, who had climbed out of the passenger side of the van. He was older than the others, judging by the gray in his hair.

The older gentlemen stepped up and extended his hand to the Governor.

“Governor Harris?” He asked simply.

“I am,” The Governor replied, taking his hand.

“I'm Dick Spencer, Director of the Disaster Mortuary Operational Response Team for Region Five.”

“How do you do?” The Governor asked with a forced smile. “This is Deputy McGrath of the---”

Spencer cut her off and pulled a piece of paper from the inside breast pocket of his coat, “Did you request Federal Response?”

“Yes sir, we've had a bad night in this town---” The Governor started but again, Spencer cut her off.

“And you are fully aware that in so doing, you have allowed the Department of Homeland Security to begin to conduct an investigation into the order, as to the reasons why such an order would be placed pursuant to Guideline 542, section B, article F?”

The Governor looked at Meeker and then to McGrath, who took the roll of papers from Agent Spencer. “Yes sir..I am aware of the...”

“Excellent then,” Spencer looked down at the papers and began to thumb through them, “I have two affidavits for your law enforcement officers here to fill out. They must be in precise detail as to the events that transpired over the night , and why you would need to place an order for a portable refrigeration unit for casualty victims.” He looked at McGrath, “You need to fill one out as does this local officer...Officer----???”

Meeker took one of the papers, “Deputy Sheriff Ben Meeker.”

“Meeker,” Spencer nodded, “I also have a battery of questions we need to go over, but first I have three questions.”

McGrath took the other paper, “Yeah, shoot.”

“Do you or do you not want to be a big pain in my ass today?” Spencer asked.

McGrath laughed in spite of himself. “What?”

“I'm not aware that I said anything amusing Agent?” Spencer replied, cutting a look to Meeker and then back at McGrath, “Do you want to be a big pain in my ass today?”

“No sir,” McGrath replied.

Spencer looked back at Meeker, “Do you want to be a big pain in my ass Deputy Sheriff?”

“No sir,” Meeker replied.

“Excellent,” Spencer said, “Now let's get something straight. I don't want to be here, okay?”

Meeker and McGrath nodded.

“You are aware that last night was Halloween?” Spencer asked.

Meeker and McGrath looked at one another, not sure how to answer. McGrath was brave enough to try. “Well—yes...”

“Do little girls and boys play dress up on Halloween?” Spencer asked.

The two men looked at each other again and then replied in unison: “Yes sir,”

“You know who else plays dress up?”

Meeker and McGrath looked at each other a third time and then back at Spencer and shook their heads.

“Russian mail order brides play dress up,” Spencer said matter-of-factly. “Just hours ago, I was playing dress up with my Russian mail order bride, and you can imagine what kind of activities proceed playing dress up and drinking Vodka and 7-Up all night. And you can imagine how doing these things would be very taxing for a man my age, couldn't you?”

“Yes sir,” the men replied.

“I would like nothing better than to be back in my bed, in my Chicago penthouse, with Katya on my Saturday morning. But instead, I'm called out to this piss-ant little town in the Storm-of-the-fuckin'-century. You can imagine how that would put me in a bad mood, correct?”

“Yes sir,” the men agreed.

“If there is any thing between those two affidavits that doesn't match up, or if there is anything that has transpired in this town that isn't cherry, or if the two of you aren't one hundred percent crystal clear and straight with me and obedient to my will like two little golden retriever puppy dogs, I will have Washington DC on my ass, and I don't want Washington DC on my ass for anything, and that will turn you into a big pain in the ass for me, and we don't want that now do we?”

“No sir,” they responded.

“I want to get this over with so I can go back home and enjoy my weekend, got it?”

“Yes sir.”

“Good,” Spencer pointed to the trucks, “Second question,” he said, “Where is the mobile refrigeration unit going to be erected?”

McGrath stuttered and looked at Meeker.

Meeker swallowed and said, “Best place I guess would be the parking lot of the high school...we've already set up a field---.”

“You guess?” Spencer stammered.

“Yes sir,” The Governor cut in, “The parking lot of the High School is where we want it.”

“What high school? I need a name people! I need an address!” Spencer's volume level went up a notch.

“It's Haddonfield High School, on the corner of Belmont and Main Street,” Meeker said.

“Well is it Belmont or Main Street?!” Spencer nearly roared.

“248 Belmont Avenue,” Meeker responded calmly.

“Got it,” one of the accompanyng men in black suits said quietly, and then they all turned to walk toward the first truck.

“Third question,” Spencer said, his volume level returning to normal, “is there a police station in this god-forsaken town that we conduct business in, or do we rednecks like to stand out in the road and play with our dicks in front of a bunch of mangled car accident victims?”

“I have two of my boys setting up a big tent in the parking lot of the hospital. That's gonna be ground zero for now until that scene gets under control and we can shift everything to the high school.” Meeker replied.

“The tent we use for the exhibitions on fair days and stuff. The recruitment tent?” Colbourne asked.

“Exactly. Herman Beach and Chris Huber are grabbing it from the storage unit. They should be there any minute. We should probably get over there now, I think we're done here.”

“That sounds like a fantastic idea,” Spencer said, turning back toward his vehicle. “There better be coffee.”

The Governor piped up, “Don't you have a Mayor in this town somewhere? Someone is gonna have to talk to the press!”

Meeker winced.

NEXT>> (Coming Soon)

3 notes

·

View notes

Photo

The Lisa Hardware

Reporting on the technical specifications of a computer toward the end of an article is unusual for BYTE, but it emphasizes that the why of Lisa is more important than the what. For part of the market, at least, the Lisa computer will change the emphasis of microcomputing from “How much RAM does it have?” to “What can it do for me?” For example, it is almost misleading to say that the Lisa comes with one megabyte of RAM, even though the fact itself is true. That doesn’t mean that the Lisa is sixteen times better than machines that have 64K bytes of RAM. Nor does it necessarily mean that the Lisa can work on much larger data files than other computers; its application programs each take 200K to 300K bytes, which significantly reduces the memory available for data. It’s more instructive to say, for example, that the Lisa with one megabyte can hold a 100-row by 50-column spreadsheet (as its advertisements state). With this in mind, let’s take a look at the Lisa.

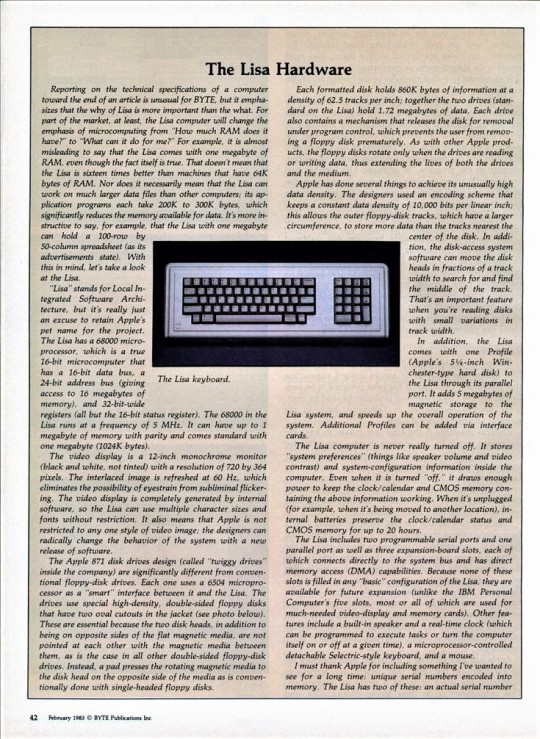

“Lisa” stands for Local Integrated Software Architecture, but it’s really just an excuse to retain Apple’s pet name for the project. The Lisa has a 68000 microprocessor, which is a true 16-bit microcomputer that has a 16-bit data bus, a 24-bit address bus (giving access to 16 megabytes of memory), and 32-bit-wide registers (all but the 16-bit status register). The 68000 in the Lisa runs at a frequency of 5 MHz. It can have up to 1 megabyte of memory with parity and comes standard with one megabyte (1024K bytes).

The video display is a 12-inch monochrome monitor (black and white, not tinted) with a resolution of 720 by 364 pixels. The interlaced image is refreshed at 60 Hz, which eliminates the possibility of eyestrain from subliminal flickering. The video display is completely generated by internal software, so the Lisa can use multiple character sizes and fonts without restriction. It also means that Apple is not restricted to any one style of video image; the designers can radically change the behavior of the system with a new release of software.

The Apple 871 disk drives design (called “twiggy drives” inside the company) are significantly different from conventional floppy-disk drives. Each one uses a 6504 microprocessor as a “smart” interface between it and the Lisa. The drives use special high-density, double-sided floppy disks that have two oval cutouts in the jacket (see photo below). These are essential because the two disk heads, in addition to being on opposite sides of the flat magnetic media, are not pointed at each other with the magnetic media between them, as is the case in all other double-sided floppy-disk drives. Instead, a pad presses the rotating magnetic media to the disk head on the opposite side of the media as is conventionally done with single-headed floppy disks.

Each formatted disk holds 860K bytes of information at a density of 62.5 tracks per inch; together the two drives (standard on the Lisa) hold 1.72 megabytes of data. Each drive also contains a mechanism that releases the disk for removal under program control, which prevents the user from removing a floppy disk prematurely. As with other Apple products, the floppy disks rotate only when the drives are reading or writing data, thus extending the lives of both the drives and the medium.

Apple has done several things to achieve its unusually high data density. The designers used an encoding scheme that keeps a constant data density of 10,000 bits per linear inch; this allows the outer floppy-disk tracks, which have a larger circumference, to store more data than the tracks nearest the center of the disk. In addition, the disk-access system software can move the disk heads in fractions of a track width to search for and find the middle of the track. That’s an important feature when you’re reading disks with small variations in track width.

In addition, the Lisa comes with one Profile (Apple’s 5-1/4-inch Winchester-type hard disk) to the Lisa through its parallel port. It adds 5 megabytes of magnetic storage to the Lisa system, and speeds up the overall operation of the system. Additional Profiles can be added via interface cards.

The Lisa computer is never really turned off. It stores “system preferences” (things like speaker volume and video contrast) and system-configuration information inside the computer. Even when it is turned “off,” it draws enough power to keep the clock/calendar and CMOS memory containing the above information working. When it’s unplugged (for example, when it’s being moved to another location), internal batteries preserve the clock/calendar status and CMOS memory for up to 20 hours.

The Lisa includes two programmable serial ports and one parallel port as well as three expansion-board slots, each of which connects directly to the system bus and has direct memory access (DMA) capabilities. Because none of these slots is filled in any “basic” configuration of the Lisa, they are available for future expansion (unlike the IBM Personal Computer’s five slots, most or all of which are used for much-needed video-display and memory cards). Other features include a built-in speaker and a real-time clock (which can be programmed to execute tasks or turn the computer itself on or off at a given time), a microprocessor-controlled detachable Selectric-style keyboard, and a mouse.

I must thank Apple for including something I’ve wanted to see for a long time: unique serial numbers encoded into memory. The Lisa has two of these: an actual serial number An interesting aspect of the Lisa is that it abandons hardware graphics chips like the NEC 7220 for system software that requires the 68000 microprocessor to generate and maintain the video image. At first, I questioned the wisdom of this decision because it makes the 68000 assume a heavy computational burden that could be transferred from software to hardware. But according to the designers, the use of a dedicated hardware graphics chip would itself limit and slow down the system (for a discussion of this, see the interview on page 90). In particular, the 68000 clock was set at 5 MHz instead of the usual 8 MHz to give the hardware just enough time to access the 32K bytes of screen memory during the machine cycles in which the 68000 is not using the address lines. This gives the Lisa access to the video memory that is transparent to the 68000 (hardware graphics chips severely limit access to the video memory) and results in a static-free image. (Much of the static or “hashing” in graphic video images results from the system accessing the video memory while the circuitry is using it to generate the video image.)

Apple will also be offering the Apple Dot Matrix Printer and the Apple Letter Quality Printer. Apple’s engineers tested many existing printers, chose two (from C. Itoh and Qume, respectively) that best met their needs, then had the companies produce modified versions with Apple-specified hardware and software changes. Apple needed such exacting print quality because the Lisa software is very demanding of both printers. For example, both printers will reproduce almost exactly both the text and graphics that can be displayed on the Lisa screen. In addition, Apple has created special print wheels for its Letter Quality Printer so that you can print normal, italic, underlined, and bold characters without changing print wheels (quite a nice move who’s going to change print wheels several times a page just to get true italics?). The amazing thing about the Apple Dot Matrix Printer is that Apple plans to sell it for around $700 (the Letter Quality Printer will sell for about $2100). Unfortunately for Apple II and III owners, these printers’ tricks are done entirely in software on the Lisa and won’t transfer to other Apple computers.

Daily inspiration. Discover more photos at http://justforbooks.tumblr.com

10 notes

·

View notes

Text

Fandom: Sk8 the Infinity

Characters: Sakurayashiki Kaoru (Cherry Blossom), Shindo Ainosuke (Adam), Nanjo Kojiro (Joe)

Warnings: Light angst

Word Count: <1k

Summary: In which Kaoru reflects on the young man who he once knew, traveling back in time through a scrapbook.

[LoveBlossom Week 2021 | Day 1: Photograph]

"Why do you do it, Kaoru?" Kojiro had asked once, and he'd had no answer for his friend. He still doesn't.

Even so, he clips the article out of the magazine with careful precision, applying a thin layer of glue to the back before pressing it against the blank page of the scrapbook. He smooths it out with a practiced hand, making sure that it lays completely flat before writing in the date and title of the magazine under it.

Ainosuke's face smiles up at him, as charming as always, from next to an interview with the popular young politician. And he studies it for a moment before turning the page, looking at a picture of Ainosuke, smiling as he gives a speech to commemorate the opening of a new park. The facing page has another image of the blue-haired man with a nearly identical expression as he attends a fundraising event.

Slowly, he continues to turn the pages, looking at the same smile, over and over. There are slight variations: a more somber twist of the lips in the aftermath of a tsunami, a brighter sparkle in his eyes as he reads to children, a burning intensity as he glares at his opponent during a debate, a bit of humble self-deprecation at the start of his career. And it looks genuine, but when Kaoru turns to the very first page of the album, the boy there is almost unrecognizable.

It's the only picture he has of Adam.

He's laughing as his arms are slung over Kaoru and Kojiro's shoulders, all of them smiling at the camera. In the background, there's the Eiffel Tower, and a border of tacky pink hearts surrounds the edge of the sticker. It's only a few centimeters long on each side, and the colors have faded slightly, but Kaoru remembers it just as clearly as if it was only yesterday.

"What's that?"

Both Kaoru and Kojiro looked at the photo booth, then at each other, and back at Adam. Kojiro didn't hesitate to swing an arm around their friend, forcibly steering him toward it.

"It's a purikura. You can take pictures and decorate them," Kojiro said as Kaoru strode toward it with a determined expression on his face. Adam's face lit up the way it always did when they introduced him to something "ordinary," and he let Kojiro push him past the curtain while Kaoru tapped the screen, choosing options while Kojiro continued to explain. With the three of them inside, it was a little cramped, but they wouldn't be in there long.

"After Kaoru finishes making all his selections, it'll start taking pictures. After that, we can choose to add decorations to the pictures: a background, flowers, cat ears, and other things that girls usually think are cute. Since they're usually the ones that use these sorts of things. And after we're done, it'll print them out as stickers. Actually, Kaoru, how do we want to do this? Poses? Funny faces?"

Kaoru paused in his tapping, looking over his shoulder at the other two.

"Just something natural for the first time? What do you want, Adam?" he asked. Adam looked startled for a moment when he was asked, but he nodded.

"Something natural," he agreed. Eventually, they decided on putting him in the middle of them, their arms wrapped around each others' shoulders. And then Kaoru fed a few coins into the machine, leaning back as they smiled for the camera. At some point, Kojiro whispered something to Adam, making their friend laugh.

But Adam seemed to have the most fun decorating the pictures afterwards, so Kaoru and Kojiro had just let him experiment, scrolling through the backgrounds and frames while they teased him and made suggestions. He'd also picked an underwater background, an image of space, and Times Square with matching borders, then added small embellishments until he was satisfied. And after the stickers printed, Kaoru took this one for himself, while Kojiro took the one where he was leaning towards Adam, letting their friend keep the other two for himself.

Afterwards, they'd fallen out of the booth, still laughing as they rushed to meet up with the rest of their friends. They'd been late, of course, but it had been worth it.

And now... what's happened? Adam has changed, but he refuses to discuss it with either of them. He'd started to change even before he left for America, but the man who returned to them is barely recognizable. There's a violent, reckless, and almost desperate air to their former friend when he skates, leaving a trail of destruction behind him. If he'd only agree to a beef with Kaoru--or even with Kojiro--then maybe they could understand him better: skating has always been a common language between them. But perhaps Adam realizes that, and that's why he's constantly turning them down and even showing up less frequently to "S."

Still, Kaoru isn't ready to give up yet. He reaches out to trace the edges of the photograph, careful not to touch the image itself and wear it away. He wants to believe that this boy is still inside Ainosuke. Perhaps something has happened to him, and perhaps he's hiding beneath the mask that Ainosuke puts on for everyone, but Kaoru can't believe that he's really gone. This is the real Adam. The real Ainosuke. And he'll drag him back out, whatever it takes.

#sk8#SK8 the Infinity#skate the infinity#fanfic#fan fic#loveblossomweek2021#sk8 adam#shindo ainosuke#ainosuke shindo#sk8 cherry blossom#sakurayashiki kaoru#kaoru sakurayashiki#sk8 joe#nanjo kojiro#kojiro nanjo#mine

1 note

·

View note

Text

PART DECORATION FOR PLASTIC INJECTION MOLDING

Many plastic injection molded parts need to have some form of decoration applied to them after being manufactured. Possible reasons for decorating or marking parts include identification, tracking, branding, notices, warnings, instructions, as a product attribute, or otherwise. There are some standard methods of decorating plastic parts, and each has certain advantages and considerations, depending on the part application, the decorating purpose, and the resin being used.

PAD PRINTING

Historically, one of the more popular methods for decorating plastic parts has been with pad printing. There are three different types of pad printing machines: open inkwell, closed ink cup, and rotary gravure, which is used for printing 360 degrees on a part. Machines have a printing plate or a cliché, which commonly are made out of steel for durability. The artwork to be printed onto the parts is etched into the printing plate.

As the name suggests, the machines have transfer pads that come in a few different shapes and that are made out of silicone rubber with various hardness or shore levels. Pad life ranges from 10,000 to 100,000 cycles with an average of about 50,000.

The process consists of the pad picking up ink in the etched image on the cliché and placing it onto the part. Pad printing uses a type of solvent-based ink specifically designed for this purpose. This type of decoration also requires the fabrication of nesting fixtures to hold the parts in place during the printing process.

HEAT TRANSFER

A newer and usually more effective method of part decoration is thermal or heat transfer. With this process, the image is printed on a polyester film, which is coated with an adhesive so the image will stick to the part. Rolls of this film with the digitally printed images are placed on the printing machine’s reels, which index forward to print successive parts. Fixtures to hold parts are used here, as they are in pad printing. Additionally, a silicone decorating head or pad applies heat and pressure to print the transfer image onto the part.

Some advantages of heat transfer include the ability to create an image with four colors plus white in as high as 1200 dpi. In addition, there is no drying or curing time with decorating plastic parts, as there is with pad printing. Further, heat transfer decorations generally are tougher than pad printing and can be dishwasher safe.

HOT STAMP

Another common technique used to decorate plastic injection molded parts is hot stamping. A hot stamp machine transfers an image with pre-dried ink to a part with a die, again using heat and pressure and a fixture to hold the part, as with the previous methods.

One main advantage of hot stamping is the ability to apply a metallic foil or embossing to a plastic part. If you’re reading this article on a desktop computer, chances are the monitor in front of you has a logo that has been hot stamped on it. It also is a relatively clean process, compared to the wet ink used in pad printing.

LASER MARKING

Another method for decorating injection molded parts is by utilizing a laser marking system. This approach includes laser marking, laser engraving, and laser etching. Laser marking (or foaming) changes the color of the part where the text or graphic is, while the surface stays relatively unchanged. Alternatively, laser engraving removes some of the surface material, whereas laser etching melts the surface resin and creates a raised mark.

Of course, laser marking, engraving and etching all require a laser decorating machine. Additionally, fixtures to hold the parts usually are required, as with other decorating methods, although some fixtureless laser decorating systems have been developed. Some advantages of laser decorating include less wear and tear on the decorating equipment, it’s a precise and repeatable process, and it provides the ability to decorate some hard-to-reach part areas. Due to these benefits, industries like medical, automotive and aerospace often utilize the process.

IN-MOLD DECORATION

The method of in-mold decoration involves placing a pre-printed plastic film or appliqué in an injection mold before the part is molded, and the graphic then adheres to the part after it forms in the mold’s cavity. In-mold decoration requires a uniquely designed and built plastic injection mold and a carrier film feeder. The film can be manually placed into the mold between each cycle, but that greatly increases the manufacturing time and labor costs associated with the parts. However, even with a feeder, parts requiring in-mold decoration generally tend to be more expensive than other decorated parts, due to the specialized design, tooling and manufacturing required.

INKJET DECORATION

Inkjet printing on plastics is a relatively newer process, and it involves digitally printing a graphic onto a part. The system essentially is the same as inkjet printers for paper, with which most of us are familiar, although it uses a different type of ink. These machines typically use either conventional or LED lamps, and the process eliminates labels, films, printing plates, clichés or screens, as required with other decorating methods, although they do require a printhead and ink. Historically, this kind of decorating is somewhat slower and more costly than other forms, although advances are being made.

SCREEN PRINTING

Most people are familiar with screen printing in the context of t-shirts, and this also can be referred to as silk screening. Screen printing can be used for parts with flat or cylindrical surfaces but is not recommended for parts with complex curves and shapes. One advantage of screen printing is that it can print metallic graphics onto parts, which some other methods cannot do. Although providing the option of printing with multiple colors, a separate screen is needed for each separate hue, which increases cost and decorating time. The surface to be decorated needs to be prepared prior to printing, too.

PAINTING

When injection molding a part cannot achieve the desired texture, finish or color, painting the parts sometimes is utilized as a secondary operation. This approach can include spray painting and powder coating. As most injection molders do not perform painting as a finishing operation, the parts will need to go to a secondary provider, which often results in increased costs.

PLATING

When looking for a metal finish on an injection molded part, hard chrome plating and electroless nickel plating are two commonly used options. Plating offers a decorative finish, and it provides a certain level of corrosion protection. One item to note is that any surface imperfections on the part can affect the look of the plating, so consideration needs to be given there. Additionally, few molders also perform plating services, so those two suppliers will need to coordinate their work. There also are some design and material considerations that must be taken into account.

CONCLUSION

There are many different methods of decorating a plastic injection molded part, and each has its own unique advantages and disadvantages, depending on the requirements of the project. When developing a new product with components that may need to be decorated in some way, attention should be given to the part design, the polymer being used, the decorating purpose, the part application, the governing regulations, and the cost considerations. If we can answer any questions, don’t hesitate to reach out to us.

--

Ash Brown // VP, Business Development

1 note

·

View note

Text

The production process of eight-sided self-sealing bags

Jiecheng is a packaging bag manufacturer, the article mainly introduces the production process and advantages of eight-sided self-sealing bags, follow along to see it.

Eight-sided self-sealing bags production process.

1. Into the film for printing (printing each colour has a plate roll, the plate roll is carved concave plate carving), in the printing ink is non-stop flow, because the ink will condense, in the ink printing and film for printing inlaid with a scraper, scraper is to the plate roll projection to scrape the ink, so that the concave plate roll can be printed. If the squeegee gets dust on it, the ink contamination will appear in the form of streaks. For the dotted ink pollution phenomenon is because the ink in the rolling printing ink spattered on the packaging film and caused by the dotted ink pollution.

2. After the film is printed, we start to compound, for our company's production of film is generally dry and wet compounding method, that is, the colour printing of good film coated with glue into a baking to bake 2 minutes and then and PE for compounding, compound tension is 5.6kg. our company uses the packaging bag is two-layer composite.

3. Curing: the film is cured after gluing the compound, the main effect of curing is that the glue can be firmly adhered to, curing is generally cured at 50 ℃ for 24 hours. In fact, it is a good composite film will be stored at 50 ℃ for 24 hours. If the time and temperature does not meet the requirements there will be a film compound is not tight phenomenon.

4. After curing, the film is then inspected, which means that the standard sample print is entered into the computer and the cured film is then passed through a white screen controlled by the computer, where a black mark will be pasted directly on the film if it fails.

5. After inspection, the film is slit.

6. After slitting, the film is then bagged, which is made by a machine that automatically seals the edges of the film and presses the bag.

The advantages of eight-sided self-sealing bags.

1. Stand up smoothly, conducive to shelf display, deeply attract the consumer's eye;

2. A total of eight printed pages, sufficient place to describe the product or language product sales, global sales product promotion for use. Product information is displayed more completely;

3. Because the bottom of the bag is flat and open, the bottom of the bag is not lost as a good display layout;

4. The eight-sided seal stands up straight, which is conducive to the soft display of the brand;

5. flexible packaging composite process, material variation, according to the thickness of the material, water and oxygen barrier, metal effect and even printing effect, the benefits than a single box change;

6. Eight side seal zip bag with reusable zip, the consumer can re-open and close the zip, the box is unable to compete;

7. Unique appearance to prevent counterfeiting, easily recognisable to consumers and beneficial to brand building;

8. Multi-colour printing is available, which makes the product look beautiful and has a strong promotional effect.

Jiecheng is a manufacturer of packaging bags, with a wide range of products exported overseas, which are unanimously recognized by everyone. If you are interested in packaging bags, you are welcome to contact our company.

0 notes

Text

Different Types Of Industrial Printing Machines

In the industrial set up of the economy, the printing machines are growing in large numbers. Different printing techniques and processes are used by every industry for effective communication. Any machine used in printing ink on the substrate (printing medium) which can be cloth, paper or plastic, is referred to as the printing machinery. By applying pressure to the substrate, the printing machinery transfers the ink on the printing medium resting on an inked platform composed of movable type. The development of industrial printing machines changed a lot of things in the world. It would make transfer and preservation of historical records, scientific findings, and knowledge easy and possible. There's a great advancement in the printing machinery introduced in the market today given the improvement in science and technology. There's a competition in the industry, as many companies are now making printing press. As every company is introducing better features and making an effort to overcome the other competitors, this has led to the introduction of many enhanced features in printing machinery. With the introduction of various features in these types of machinery, printing is now easier to be done than it was in earlier days.

Today, printing machinery is available in many sizes to suit different needs. Bigger sizes of printing machinery are available for heavy-duty printing or big-time printing businesses. You can get small and medium sizes too for small and medium printing businesses. The machinery size determines the volume of printing that will be done in a day, to a greater extent. When compared with small-sized printing machinery, the heavy industrial printing machines can print a lot of things per hour or regularly. There are different types of printing machines for printing on a different medium since different printing machines make use of different printing technology. Each of the below-mentioned printing machinery is meant to serve a particular purpose. You must consider your printing needs or the type of printing that you are doing before you want to buy or order for your printing machine. Several factors such as the size, the type of printing done, the seller, the brand, and others determine the cost.

Types Of Printing Machines

Digital Printers

Ink-jet Printers

Screen Printers

Embossing Machines

Flexographic Printing Machine

Letterpress Printing Machines

Offset Printers

Laser printers

Wireless Printers

3D Printers

Thermographic Printers

Electrostatic Printing Machine

Pad Printers

Rotogravure Printing Machines

The digital printing machines have gained immense popularity for short to medium run jobs requiring high clarity, quality, and fine printing. A vibrant quality image is delivered with these types of printers. By providing cost-effective and fine printing solutions, these affordable and high-performance machines are revolutionizing the printing industry. Because of the on-demand services, digital printing equipment ensures fast turnaround time. Digital printers are ideally suited to publish a small print run of posters and books. They have many advantages over traditional methods.

Understanding Metal Stamping

Metal stamping is a cold-forming process that makes use of dies and stamping presses with rewinding machine to transform sheet metal into different shapes. Pieces of flat sheet metal, typically referred to as blanks, is fed into a sheet metal stamping press that uses a tool and die surface to form the metal into a new shape. Production facilities and metal fabricators offering stamping services will place the material to be stamped between die sections, where the use of pressure will shape and shear the material into the desired final shape for the product or component.

This article describes the metal stamping process and steps, presents the types of stamping presses typically employed, looks at the advantages of stamping compared to other fabrication processes, and explains the different types of stamping operations and their applications.

Basic Concepts of Metal Stamping Machine

Metal stamping, also referred to as pressing, is a low-cost high-speed manufacturing process that can produce a high volume of identical metal components. Stamping operations with slitting machine are suitable for both short or long production runs, and be conducted with other metal forming operations, and may consist of one or more of a series of more specific processes or techniques, such as:

Punching

Blanking

Embossing

Coining

Bending

Flanging

Punching and blanking refer to the use of a die to cut the material into specific forms. In punching operations, a scrap piece of material is removed as the punch enters the die, effectively leaving a hole in the workpiece. Blanking, on the other hand, removes a workpiece from the primary material, making that removed component the desired workpiece or blank.

Embossing is a process for creating either a raised or recessed design in sheet metal, by pressing the raw blank against a die that contains the desired shape, or by passing the material blank through a roller die.

Coining is a bending technique wherein the workpiece is stamped while placed between a die and the punch or press. This action causes the punch tip to penetrate the metal and results in accurate, repeatable bends. The deep penetration also relieves internal stresses in the metal workpiece, resulting in no spring back effects.

Bending refers to the general technique of forming metal into desired shapes such as L, U, or V-shaped profiles. The bending process for metal results in a plastic deformation which stresses above the yield point but below the tensile strength. Bending typically occurs around a single axis.

Flanging is a process of introducing a flare or flange onto a metal workpiece through the use of dies, presses, or specialized flanging machinery.

Metal hot stamping machines may do more than just stamping; they can cast, punch, cut and shape metal sheets. Machines can be programmed or computer numerically controlled (CNC) to offer high precision and repeatability for each stamped piece. Electrical discharge machining (EDM) and computer-aided design (CAD) programs ensure accuracy. Various tooling machines for the dies used in the stampings are available. Progressive, forming, compound, and carbide tooling perform specific stamping needs. Progressive dies can be used to create multiple pieces on a single piece simultaneously.

0 notes

Text

Custom made Printed Neck Lanyards: From your to Z

From celebrations and reunions to tradeshows and special events, customized printed neck lanyards are usually being used to advertise names, logos and messages. Usually, neck lanyards are actually utilized to carry and show id cards and title badges. Today many a lot more purposes of neck lanyards usually are being found for additional small objects. From writing instruments and mobile phones to lips balm and keys, they will provide a convenient approach to keep these beneficial objects accessible while to get hands free.