#flame arrester

Explore tagged Tumblr posts

Text

0 notes

Text

0 notes

Text

#centrifugal pump supplier singapore#industrial equipment#bliss flow systems#safety relief valve#flame arrester#plate heat exchanger supplier in singapore

0 notes

Text

Types of Flame Arresters and Their Applications

Flame arresters play a crucial role in ensuring safety and preventing the propagation of flames and explosions in various industrial settings. These essential devices are used to mitigate the risks associated with flammable gases, vapors, and liquids. In this article, we will delve into the different types of flame arresters and explore their applications across industries.

Introduction to Flame Arresters

Flame arresters are vital safety devices used to control and prevent the propagation of flames in various industrial processes involving flammable substances. They are designed to allow the passage of gases or liquids while effectively extinguishing any flames present.

How Flame Arresters Work

Flame arresters operate based on the principles of quenching, heat dissipation, and flame inhibition. When a flammable mixture passes through the arrester, its propagation is disrupted, and the heat generated is dissipated, preventing ignition.

Deflagration vs. Detonation

Before delving into the types of flame arrestor, it's essential to differentiate between deflagration and detonation. Deflagration refers to a subsonic combustion process, while detonation is supersonic combustion accompanied by shock waves.

Types of Flame Arresters

Deflagration Flame Arresters

Deflagration flame arresters are designed to handle subsonic combustion processes. There are two primary types:

In-Line Deflagration Arresters

These are installed directly in the pipeline to prevent the propagation of flames within the pipe. They consist of a flame arrester element and housing designed to withstand the process conditions.

End-of-Line Deflagration Arresters

These are placed at the end of a pipeline or vent to prevent flames from escaping into the atmosphere. They are particularly effective in applications where the process material could potentially accumulate in the arrester.

Detonation Flame Arresters

Detonation flame arresters are meant for supersonic combustion processes. Similar to deflagration arresters, there are two main types:

In-Line Detonation Arresters

Installed within a pipeline, in-line detonation arresters prevent the high-speed flame front resulting from detonation.

End-of-Line Detonation Arresters

Positioned at the end of a pipeline, these arresters effectively quench and extinguish detonation flames before they can escape.

Choosing the Right Flame Arrestor

Selecting the appropriate flame arrestor depends on factors such as the type of process, flow rate, the composition of the gas or vapor, and the potential for deflagration or detonation.

Oil and Gas Industry

The oil and gas sector extensively employs flame arrestor to enhance safety during various stages of production, refining, and distribution.

Chemical Processing

Chemical plants use flame arresters to safeguard against explosions in processes involving volatile substances.

Storage Tanks

Flame arresters are crucial components in storage tanks containing flammable liquids or vapors, preventing external ignition sources from causing catastrophic incidents.

Vent Stacks and Pipes

Vent stacks and pipelines equipped with flame arresters prevent flame propagation and protect against external ignition sources.

Biofuel Production

The production of biofuels involves potentially flammable materials, making flame arresters essential for safe processing.

Wastewater Treatment

Flame arresters are employed in wastewater treatment facilities to manage the risks associated with flammable gases produced during the treatment process.

Pharmaceutical Manufacturing

Pharmaceutical companies utilize flame arrestor to ensure the safe handling and processing of volatile chemicals.

Maintenance and Testing of Flame Arresters

Regular inspection, maintenance, and testing of flame arresters are vital to ensure their proper functioning and continued safety.

Importance of Compliance and Safety Standards

Adhering to industry-specific safety standards and regulations is crucial when selecting, installing, and maintaining flame arresters.

Conclusion

A flame arrester is an indispensable safety device that plays a pivotal role in preventing the spread of flames and explosions in various industrial applications. By effectively quenching and inhibiting flame propagation, they contribute to a safer working environment and protect valuable assets.

FAQs (Frequently Asked Questions)

How do deflagration and detonation differ?

Deflagration is a subsonic combustion process, while detonation involves supersonic combustion accompanied by shock waves.

What are the main types of deflagration flame arresters?

The main types are in-line deflagration arresters and end-of-line deflagration arresters.

Where are detonation flame arresters typically installed?

Detonation flame arresters can be in-line or placed at the end of pipelines to prevent supersonic flame fronts.

0 notes

Text

How to Choose the Right Flame Arrester for Your Application

Choosing the right flame arrester for your application is crucial for safety and compliance. Consider factors like the type of flammable material, flow rate, temperature, and pressure.

Stay protected with FIDICON DEVICES INDIA's reliable flame

arresters.For more information visit our site: https://fidicondevices.com/how-to-choose-the-right-flame-arrester/

0 notes

Text

i can’t believe octavian died like… that. of all things in a middle grade kids books series. and everyone was chill about it. literally no one gaf octavian died so horrifically even if it was ‘just’ —and as the readers… we were chill with it too

#octavian pjo#pjo series#percy jackon and the olympians#percy jackson and the olympians#heroes of olympus#no but like ??? hello??? he CATAPULTED HIMSELF INTO A FLAMING METEOR DYING GODDESS??? AND EVERYONE (MIND YOU THEYRE LIKE 14 AND JUST WITNESS#ED THIS) AND LIKE THEYRE COOL WITH IT TOO NO ONE GAF — IN FACT NICO LITERALLY JUSTIFIED DOING THAT EVEN.#they could’ve like. arrested octavian.??? punched him in the face during his lament and K.O.’ing him#and they drag his unconscious body away and go on w their lives. LIKE WTF#there’s MORE RATIONAL ENDINGS TO THIS#have i mentioned octavian this guy i think he is FRESHLY turned eighteen. so maybe a senior in highschool with some issues in his noggin#(this is assuming rick even like. thought of anything of that and just needed a quick way to Wheee octavian out of the way cuz he didn’t#intend for him to be anything but a one dimensional bully that drives the B maybe C plot )#anyway#pjo hoo toa#nico di angelo#adjacent cause i’m talking him#will solace#also this reminds me they do a shitty job of bringing this back up in TSATS. don’t get me started on TSATS i’m sorry…..#octavian hoo#HE DOESNT EVEN HAVE A LAST NAME OH MY GOE#GOD#FUCKING HELL#he got the Celia (iykyk. fuck cc and hb) treatment#sorry i’ll shut up now#percy jackson

289 notes

·

View notes

Text

irt poverty/homelessness + alcohol use (esp with @butchfeygela‘s tags on my post)- people really underestimate the function that substance use/alcohol use can have for someone who is unhoused. being unhoused is boring, cold, painful, + lonely. substances can allow the 8 hours panhandling to get the $45 you need for a motel to fly by. alcohol reduces your perception of the cold + can knock you out whben you can’t sleep. substances can help you cope with the physical deterioration from malnutrition, constant stress, + sleeping outside. substances can provide social connection with others who you would otherwise not enjoy or help you cope with being alone.

not only that but- many unhoused people are stuck in a seemingly inescapable position. the pathway to financial stability or even housing is difficult or even impossible. in the wake of that hopelessness, the downsides of substance use start to seem insignificant. arrest? you’re getting arrested anyway for sleeping outside, peeing outside, standing in the wrong place, etc. physical danger? you’re already beat the fuck up, anyway, right? loss of relationships? you’ve lost most people already. inability to keep a job? nobody will hire you + you can’t stay employed, anyway, because you have no car + no shower.

perhaps for you or me, the cons of heroin use or binge drinking nightly greatly outweigh the pros. that isn’t the case for everyone. if we are really serious about ending overdose/addiction, we need to start looking at giving people lives worth recovering into instead of shaming them for their own hopelessness.

#i had a long talk with my dad once about how#my brother sank into so much financial despair#that he was never going to be able to find#a livable job or housing (eviction record#plus bad credit plus#arrest record ofc#he was going to be forced into poverty for the rest of his life#the only job prospects he had were menial shit jobs#he once worked at one of those chicken butchering places#it was the only place that paid him a living wage but he got fired for relapsing#his only options were to go to school part time + try to pass with his dyslexia which made him essentially unable to read#then work a horrible shitty job the rest of the time#while paying atlanta's outrageous rent prices#plus who is he gonna room with?? all his friends are opioid users!#while he paid back all the debt he accrued from going to rehab#then MAYBE after like 6 years of school he could get a decent job#but his credit would be in flames for years his eviction record there for years#his arrest record + lack of driver's license limiting his employment..#sorry but i would have probably given up at that point too#not to mention his interpersonal + familial relationships up in flames + the shame#of the things he did while using hanging over his head#the only family member who didn't think he was an irredeemable fuckup (me) living a thousand miles away + about as broke as him#substance use#harm reduction

309 notes

·

View notes

Text

The Arrest of Christ

Artist: Hans Holbein the Elder (German, 1460-1524)

Date: 1501

Medium: Oil on Spruce Wood

Collection: Städel Museum, Frankfurt, Germany

The Arrest of Christ

The arrest of Jesus is described in multiple Bible passages, including: Matthew 26:47-56: An armed crowd sent by the chief priests and elders arrests Jesus. Judas, one of Jesus's disciples, betrays him by kissing him.

John 18:1-12: Jewish police and Roman soldiers arrest Jesus in a garden. Jesus overpowers the forces with the name of God.

Luke 22:39-53: Jesus is arrested in Gethsemane. The arrest of Jesus is described in all four Gospels, but only Matthew and Mark name the location as Gethsemane

#religious art#arrest of christ#garden of gethsemane#the kiss of judas#biblical scene#new testament#soldiers#jesus christ#apostle peter#judas iscariot#john the evantelist#flame#torch#hans holbein the elder#painting#oil on wood#european art#german painting#16th century#sword#rope#helmet#kiss#gospels

23 notes

·

View notes

Text

okay. i caved

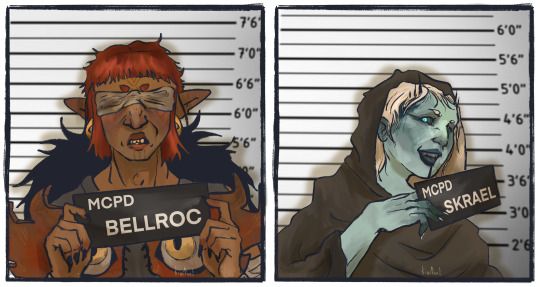

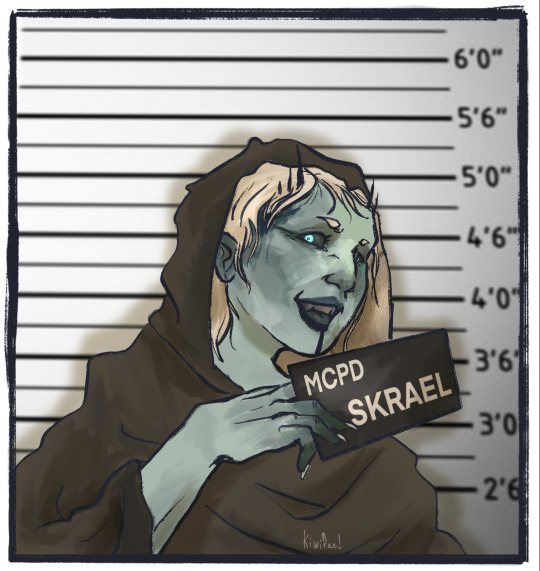

(individual versions under the cut!)

i had SO much fun rendering their skin tbh

#lowkey dropping my height hcs here 👀👀 (though skrael’s cloak and the angle is very kindly giving him an inch or two lol)#kiwifae draws#the arcane order#bellroc#skrael#tales of arcadia#wizards toa#bellroc keeper of the flame#trollhunters rott#skrael of the north wind#i imagine this happening post train scene where the order got arrested alongside the trollhunters skslskdk#i want to write this So Badly tbh 😭#bellroc absolutely gets into a fistfight w a police officer#barbie movie#barbie meme#honestly the only way i can see this forreal happening is if they literally couldn’t ditch immediately like in canon. so. au where#the (honestly probably not tested whatsoever) anti magic beam disconnects them from their magic longer term 👀

183 notes

·

View notes

Text

neither lumpus nor jane want to die alone and that's both such a massive part of the inner workings of their minds to me and yet what it spawns out of them is also exactly the reason why they shouldn't ever be together ��️ amen

#talk#camp lazlo#scoutmaster lumpus#jane doe#there's like so much room for them to paralell each other like ugh#my Themes...#but like to me it's either going to flames immediately or enabling the worst of them#cus frankly anything else also isn't very interesting to me#and don't get me wrong i love when lumpus is being a fucking idiot over her#but like What is there for jane? NOTHING#she deserves so much better#at least with slinkman he and lumpus have history y'know it's so much different when you're already life partners#but anyway it's funny to me because jane is slinkman's friend FIRST OF ALL and lumpus's Target of Affection SECOND#he's in the middle of them here#but if i had to see jane ''fix'' lumpus i would put my head into my hands and slink into the deep earth#the two of them getting married in canon is only excused and funny due to the fact that lumpus gets arrested literally a few episodes later

7 notes

·

View notes

Text

0 notes

Text

do you think the marines have sensitivity training. was there a debate over whether it was intolerant to crop ace’s chest out of his first wanted poster picture because he refused to get top surgery but plenty of other cis male pirates are shirtless and their pictures are posted as-is. do you think the navy’s medical branch will supply hrt

#riko.txt#ace#no op ace is a beloved hc of mine. partially because it makes me feel better abt my chest#but also bc after a point i don’t think he’d care#+ it’s funny to watch people decide how to react + if anyone has a problem with it. well. flame emperor 🔥‼️💥🔥🔥‼️💥💥#sidebar i once read a fic that featured a scene where a marine was desperately trying to arrest (an openly nb) luffy#and stumbling over which title to announce the arrest attempt with like pirate ki—quee—uh. pirate ruler monkey d luffy!#and mentioned trying to follow the pointers from sensitivity training. anyway i think about it all the time

26 notes

·

View notes

Text

#centrifugal pump supplier#industrial equipment#flame arrester#centrifugal pump singapore#centrifugal pump supplier uae#centrifugal pump supplier singapore#bliss flow system

0 notes

Text

Flame Arrester Manufacturer & Exporter in India

Fidicon Devices India is a company that manufactures various types of flame arresters. Flame arrestors are safety devices that are designed to prevent the propagation of flame from one area to another. There are Many Types Of Flame Arresters, In Ofline Flame Arrestor, End Ofline Flame Arrester, Drumvent Flame Arrestor We are a leading flame arrester manufacturer in India, you can buy flame arresters at the best price with all types, contact us now for flame arresters.

0 notes

Text

Flame Arresters and Rupture Discs: A Technical Comparison

Introduction

In industrial settings where flammable gases, vapors, and liquids are present, safety measures are of paramount importance. Flame arresters and rupture discs are two essential devices used to prevent and mitigate potential hazards. While they serve different purposes, both play critical roles in ensuring safety and protecting equipment from damage. In this article, we will delve into the technical aspects of flame arresters and rupture discs, comparing their functions, designs, and applications.

Flame Arresters

The purpose of flame arresters is to stop the spread of flames and explosions. They are frequently used in sectors like oil and gas, chemical manufacturing, and pharmaceuticals. The primary function of a flame arrester is to extinguish flames by disrupting the flame front and dissipating heat. This prevents the flame from reaching potentially flammable substances, thus preventing the occurrence of an explosion.

How do Flame Arresters work?

Flame arresters work on the principle of quenching flames through a combination of physical barriers and heat dissipation. The device consists of a series of metal plates or wire mesh that is arranged in a parallel configuration. When a flame propagates through the arrester, the heat is absorbed by the metal plates or mesh, causing a drop in temperature. This cooling effect prevents the flame from advancing further, effectively arresting its progress.

Applications of Flame Arresters

Flame arresters find application in various scenarios where there is a risk of flammable gases or vapors igniting and causing explosions. Some common applications include:

Storage tanks: Flame arresters are installed on storage tanks containing volatile substances to prevent external flames from entering and causing an explosion.

Vent lines: In systems where pressure relief valves release flammable gases or vapors, flame arresters are installed on vent lines to prevent flames from propagating backward into the system.

Process equipment: Flame arresters are also employed in process equipment such as pipelines, reactors, and distillation columns to mitigate the risk of explosions.

Rupture Discs

Rupture discs, also known as burst discs or pressure safety discs, are devices used to relieve excessive pressure in a system. They are intended to burst at a specific pressure, releasing extra pressure and avoiding catastrophic failures. Rupture discs are widely used in industries where pressure vessels and piping systems are involved, ensuring the safety of personnel and equipment.

How do Rupture Discs work?

Rupture discs are designed as thin, circular membranes that are made from materials capable of withstanding high pressures. These discs are installed within a pressure vessel or pipeline and act as a barrier to contain the pressure. When the pressure exceeds the predetermined limit, the rupture disc bursts, creating an opening for the excess pressure to escape. This controlled release prevents the equipment from undergoing structural failure.

Applications of Rupture Discs

Rupture disc is utilized in numerous industries where pressure relief is critical. Some common applications include:

Chemical processing: Rupture discs are extensively used in chemical plants to protect reactors, storage tanks, and pipelines from overpressure situations.

Oil and gas industry: In the oil and gas sector, rupture discs are employed in wellheads, pipelines, and offshore platforms to safeguard against pressure build-up.

Pharmaceutical manufacturing: Rupture discs play a vital role in ensuring the safety of equipment used in pharmaceutical production processes, where high pressures may be involved.

Conclusion

Flame arresters and rupture discs are indispensable safety devices in industries where the presence of flammable substances poses a significant risk. While flame arrester prevent the propagation of flames and explosions, rupture discs relieve excessive pressure to protect equipment and personnel. Understanding the technical aspects and applications of these devices is crucial for ensuring a safe working environment and preventing potential disasters.

0 notes

Text

Boys, it’s the first game of the season, you couldn’t have refrained from giving me a heart attack for at least another couple games??

In other news: FLAMES WINNNNNNN

2 notes

·

View notes