#extruded aluminium alloy round bar

Explore tagged Tumblr posts

Text

Unveiling The Brilliance Of Extruded Aluminium Alloy Round Bar - Mcalloys

In the realm of metallurgy, where precision meets innovation, the extruded aluminium alloy round bar emerges as a shining exemplar. This unassuming cylindrical form conceals within its structure a symphony of engineering brilliance and versatility.

The Extrusion Artistry

At its core, the extruded aluminium alloy round bar undergoes a meticulous manufacturing process known as extrusion. This method involves forcing a billet of aluminum alloy through a die, shaping it into the desired round profile. The result?A seamless and homogeneous structure with exceptional dimensional accuracy.

Unraveling the Alloy Magic

An intrinsic aspect of the extruded aluminium alloy round bar is the alloy blend itself. These bars are often crafted from high-strength aluminum alloys, meticulously chosen to imbue the final product with a myriad of advantageous properties. From enhanced corrosion resistance to commendable mechanical strength, the alloy composition is the silent architect of the bar's durability.

Navigating the Landscape of Large Diameter Aluminium Round Bar

When we talk about aluminum round bars, one cannot overlook the significance of diameter. The term "large diameter aluminium round bar" encapsulates a subclass of these metallic wonders, showcasing a grandeur that sets them apart in various applications.

In engineering feats demanding steadfast structural support, large diameter round bars become the unsung heroes. Their expansive circumference provides a robust backbone, making them indispensable in construction projects where resilience is non-negotiable.

Where Form Meets Function

Picture a scenario where architectural integrity meets the prowess of extruded aluminum alloy round bars. The amalgamation is nothing short of awe-inspiring. Large diameter bars, with their commanding presence, find their niche in applications ranging from aerospace engineering to maritime construction.

Embracing the Extruded Elegance

Beyond the sheer physicality, the extruded nature of these aluminum round bars imparts a distinct aesthetic appeal. The seamless finish, devoid of any welding marks or seams, adds a touch of sophistication to their utilitarian essence.

In the language of metallurgy, every extrusion is a narrative, and each round bar is a chapter waiting to be explored. The smooth, polished surface not only speaks of precision engineering but also beckons a tactile engagement that transcends the conventional.

Versatility in Every Revolution

The versatility of extruded aluminium alloy round bars is a testament to their adaptability. From intricate machined components in automotive engineering to pivotal structural elements in architectural masterpieces, these round bars gracefully navigate the intricate tapestry of industries.

The Future in the Hands of Aluminium

As industries evolve and technology propels us into uncharted territories, the role of extruded aluminium alloy round bars is poised to expand. Their lightweight nature, coupled with formidable strength, positions them as indispensable assets in the pursuit of sustainable engineering solutions.

In conclusion, the journey through the intricacies of extruded aluminium alloy round bars and the realm oflarge diameter aluminium round bars is a testament to the marriage of precision, durability, and aesthetic finesse. In the symphony of materials, these bars play a harmonious tune, echoing the relentless pursuit of excellence in modern metallurgy.

0 notes

Text

Overview of Round Bars: Types, Applications and Advantages

Rajkrupa Metal Industries is a top Round Bars Manufacturers in India. We've established ourselves as one of the leading names in the Round Bars industry. Because of its strong commercial and technical staff capabilities, Rajkrupa Metal Industries has purposefully positioned itself as a leading Round Bar manufacturer.

What Are Round Bars?

Round bars are long, cylindrical pieces of metal that are produced through various manufacturing processes such as rolling, drawing, or extruding. They come in a variety of sizes, materials, and finishes, making them suitable for an extensive range of applications. The diameter of round bars can vary significantly, from a few millimeters to several inches, depending on their intended use.

Types of Round Bars

Round bars can be classified based on the material they are made from. Here are some of the most common types:

Stainless Steel Round Bars:

Highly resistant to corrosion and staining

Used in environments where hygiene and durability are critical

Carbon Steel Round Bars:

Known for their strength and hardness

Widely used in construction and manufacturing

Alloy Steel Round Bars:

Enhanced mechanical properties due to alloying elements

Ideal for applications requiring higher strength and toughness

Aluminum Round Bars:

Lightweight and corrosion-resistant

Commonly used in aerospace, automotive, and marine industries

Brass Round Bars:

Good corrosion resistance and excellent machinability

Often used in plumbing and electrical applications

Applications of Round Bars

Round bars are incredibly versatile and are used in various industries for numerous applications:

Construction:

Used as reinforcement bars in concrete structures

Employed in the fabrication of beams, columns, and other structural components

Manufacturing:

Utilized in the production of machine parts, tools, and equipment

Essential in the creation of fasteners such as bolts, nuts, and screws

Automotive:

Applied in the making of shafts, axles, and other critical components

Used in the production of engine parts and transmission systems

Aerospace:

Used in the construction of aircraft frames and landing gear

Integral in the manufacture of engine components

Marine:

Employed in the construction of ships and submarines

Used in the production of various marine hardware

Advantages of Round Bars

Round bars offer several advantages that make them a preferred choice for many applications:

Corrosion Resistance:

Materials like stainless steel and aluminium provide excellent resistance to corrosion, extending the lifespan of the components made from round bars.

Cost-Effectiveness:

Due to their widespread availability and ease of production, round bars are often more cost-effective compared to other forms of metal products.

Strength and Durability:

Round bars are known for their high tensile strength and durability, making them suitable for heavy-duty applications.

Versatility:

The wide range of materials and sizes available allows for round bars to be used in diverse industries and applications.

Machinability:

Round bars are easy to machine, cut, and shape, facilitating their use in manufacturing processes.

We are also top quality Aluminium Bronze Round Bar Manufacturer In India.We have established ourselves as one of the market's top names in Aluminium Bronze Round Bar. Rajkrupa Metal Industries has deliberately positioned itself as a top-tier manufacturer and retailer worldwide. Aluminium Bronze Round Bar Suppliers are well-known for their high strength, corrosion resistance, and thermal and electrical conductivity.

#Round Bars Manufacturers in India#Round Bars Manufacturers#Round Bars#Aluminium Bronze Round Bar Manufacturer In India#Aluminium Bronze Round Bar Manufacturer#Aluminium Bronze Round Bar#Aluminium Bronze Round Bar Suppliers

0 notes

Text

Aluminium Alloy 2024 Round Bars Manufacturers In India

Siddhgiri Tubes is a renowned Manufacturer, Supplier, Stockist, and Exporter of Aluminium Alloy 2024 Round Bars. We specialize in crafting and delivering a diverse range of Aluminium Alloy 2024 Round Bars to our valued clientele. Our round bars are meticulously manufactured using top-grade alloys and other alloying elements, ensuring superior quality and performance. These round bars exhibit a range of appearances, from a dull grey to a rough surface texture. Understanding Aluminum Alloy 2024 Aluminium Alloy 2024 is an aluminium-copper alloy, primarily composed of aluminium (90.7-94.7%), copper (3.8-4.9%), manganese (0.3-0.9%), and magnesium (1.2-1.8%). This specific composition lends the alloy its remarkable strength and machinability. It is often used in applications where high strength-to-weight ratios are crucial. Key Properties of 2024 Aluminium Alloy Round Bars

High Strength: One of the standout features of Aluminium Alloy 2024 is its high strength. This makes it ideal for structural components in the aerospace and automotive industries.

Excellent Fatigue Resistance: The alloy's ability to withstand repeated stress cycles without significant degradation makes it perfect for use in aircraft structures and other high-stress environments.

Good Machinability: Aluminium 2024 round bars are easy to machine, allowing for the creation of complex shapes and components with precision.

Corrosion Resistance: While not as corrosion-resistant as some other aluminium alloys, 2024 offers adequate protection in most environments, especially when treated with anodization or protective coatings.

Benefits of Choosing Aluminium Alloy 2024 Round Bars Siddhgiritubes are a trusted provider of Aluminium Alloy 2024 round bars, offering high-quality products that meet industry standards. Here are some benefits of choosing Siddhgiritubes:

Quality Assurance: Siddhgiritubes ensures that their products undergo rigorous quality checks to meet the required specifications and standards.

Wide Range of Sizes: They offer a variety of sizes to cater to different industrial needs, ensuring you find the right fit for your project.

Custom Solutions: Siddhgiritubes provides customized solutions to meet specific project requirements, ensuring optimal performance and efficiency.

Specification Chart of Aluminium Alloy 2024 Round Bars Hardness 8 HW Grade and Specification 6000 Series, ASTM B 211 ASME SB 211 / ASTM B 619 ASME SB 619 Temper T3 - T8 Size Ranges 15- 150" NB IN Al (Min) 98% ASME B36.10M Schedule Chart SCH5, SCH10, SCH40, STD, SCH80, SCH120, SCH160 Alloy Or Not is Alloy Surface Treatment Anodized, Powder Coated, Mill Finished Most popular types Seamless / ERW / Welded / Fabricated Forms / Shapes Square, Round Pipe End Forming Treaded Both Ends, Plain One End, Treaded One End, Bevel both ends, Bevel large end, Bevel one end, Beveled end, Plain Both Ends, Bevel small end, Beveled One end Technique Extruded or seamless

Conclusion These round bars find extensive applications across numerous industries. Our Aluminium Alloy 2024 Round Bars are available in various types, including AMS 4121 round bars, hexagonal bars, hot-rolled bars, bars and rods, cold-rolled round bars, cold-drawn bars, round rods, hot finish bars, half-round bars, cold finish round bars, and pump shaft quality bars.

0 notes

Text

Aluminium Rod Dealers In Chennai

Aluminium Round Bars or Rods, Types and Uses

Aluminium Metal

Aluminum is the most abundant metal in the Earth's crust and is silvery white in color. Aluminum is widely used as it is known for its low density and corrosion resistance. Corrosion resistance is provided by a thin layer of aluminum oxide that forms when the metal is exposed to air. It is non-magnetic or magnetic resistant, non-flammable, and also insoluble in alcohol. Aluminum shows excellent thermal and electrical conductivity. Aluminum is extracted from the main ore bauxite which is mined in open pit mining. Bauxite is purified using the Bayer method.

Aluminium Rod

Round, flat, hexagonal, and squareare the shapes of aluminum rods. A wide range of aluminum bars is available in different thicknesses, widths, and diameters depending on your needs. 6061-grade aluminum rod is the most commonly used and it is one of the most versatile aluminum alloys.

6061-grade aluminum bar is known for its strength, machinability, corrosion resistance, and ease of connection and is used in a wide variety of industries and applications. Machinability is inferior to the 2000 series.When extruded, the 6061 square bars or rodswill be easy to cut, weld, and machine. They are suitable for many applications requiring high strength-to-weight ratio and rust-proof nature. Are looking for reliable aluminium rod dealers in Chennai?

Due to aluminium rod’s versatility and special material properties, aluminum round bars are often used in the construction industry, in trade fairs and shelving structures, as well as indoor and outdoor decorative parts. Due to the special properties of aluminum rods, they are intended for use in mechanical engineering and production technology. The standard size of Aluminum Round Rods- Diameter: 3.17- 350 mm. Standard Sizes available: 2 - 20mm.Aluminum Rod - Grade: 1100, 6061, and 7075.

Advantages and Properties of Aluminum

Light Weight

Reflectivity

Ductility

Corrosion Resistance

Electrical & Thermal Conductivity

Strength at Low Temperatures

Impermeable and Odorless

Non-magnetic

Metal & Alloy Industries, one of the renowned aluminium rod dealers in Chennai offers aluminum rods that are highly valued in the market because of their excellent combination of properties. These have excellent dimensional stability, high tensile strength, excellent surface finish, robust construction, durability, longevity, and flexibility.

0 notes

Text

2024 Aluminium Round Bar

Aluminum Round bar ( Rod ) may be cold finished or extruded and Aluminum Round Bar (Rod) is availble in various alloys offering a range of weldability, corrosion resistance, and machinability. High strength Aluminum Round Rod can be used in aerospace applications, and high corrosion resistance aluminum alloy round rods are commonly used in marine applications.

Application of 2024 Aluminium Round Bar

It has high strength and good fatigue strength and is widely used in aircraft structures, especially where the wing and fuselage structures are under tension.

https://www.cnaluminiumsc.com/products/2024-aluminium-round-bar.html

0 notes

Video

tumblr

KUNSHAN CARSAI AUTO PARTS INDUSTRY CO., LTD https://www.carsai-precisionparts.com/ Whatsapp&WeChat: +8615212743691 email: [email protected] --------------------- customize China factory price 6063 4040 aluminum airfoil wing profile industrial extruded T slot 6063 anodized aluminum,3/4 6063 aluminum,6063 aluminum tube stock,6063-t832 drawn aluminum tubing,6063 aluminum price,6063 aluminum bar,6063 aluminum melting point,6063 aluminum chemical composition,6063 aluminum filler rod,6063 aluminum vs 5052,is 6063 t6 aluminum bendable,is 6063 aluminum bendable,6063 aluminum vs 3003,6063 aluminum architectural channel,6063 aluminum astm,6063 aluminum hardness,6063 aluminum square tubing,6063 aluminum tubing,6063 aluminum yield strength,how strong is 6063 aluminum,6063 aluminum properties pdf,how to bend 6063 aluminum,6063 extruded aluminum,t 6063 aluminium,can you bend 6063 aluminum tubing,6063 aluminum channel,can you paint 6063 aluminum,what wire to weld 6063 aluminum,5052 vs 6063 aluminum,6063 vs 6005 aluminum,6063 aluminium grades,what is 6063 aluminum bar,is 6063 aluminum food safe,6063 aluminum uses,what is 6063 aluminum,6063 aluminum heat treatment,what is 6063 aluminum used for,6063t5 aluminum,6063 aluminum vs 2024,how strong is 6063 aluminum,6063 aluminum modulus,what is 6063 t52 aluminum,6063 aluminum properties shear modulus,aluminum 6063 t5 yield strength,6063 aluminum electrical conductivity,aluminium 6063 kaufen,architectural 6063 aluminum 90 degree angle,6063 aluminum mechanical properties,is 6063 aluminum pipe bendable,6063 frame aluminum,6063 aluminum equivalent,6063 aluminum apple,6063 aluminum flat,architectural 6063 aluminum u-channel,6063 aluminum u channel,6063 aluminum formability,6063 aluminium young's modulus,is 6063 aluminum bendable,aluminum 6063-t6 modulus of elasticity,6063 aluminium round bar,aluminum number 6063,6063 aluminum cost,6063 aluminum vs 7075,what aluminum is bendable,which is stronger 6061 or 6063 aluminum,6063 aluminum bus pipe,aluminium 6063 weight calculator,6063 aluminum rectangular tubing,e of 6061-t6 aluminum,6063 aluminum round bar,6063 heat sink grade aluminum,6063 aluminum age hardening,6063 drawn aluminum tubing,aluminum 6063 vs 6065,can you weld 6063 aluminum,6063 aluminum bending,anodized architectural 6063 aluminum u-channel,what is 6063 aluminum tubing,6063 aluminum azom,6063 aluminum welding,can 6063 aluminum be welded,aluminum 6063 chemical composition,can 6063 aluminum be extruded,6063 aluminum sheet,6063 aluminum vs 6082,6063 aluminum alloy,can you anodized 6063 aluminum,welding 6063 aluminum to 6061,6063-t6 aluminum extrusion,is 6063 aluminum marine grade,6063 aluminum weldability,6063 aluminum welding rod,6063 aluminum composition,6063 aluminum extruded profile,which aluminum is stronger 6061 or 6063,density of aluminum 6063 in kg/m3,what is 6063 t5 aluminum,is 6063 aluminum pipe bendable,aluminum 6063-t5 vs 6061-t6,can 6063 aluminum be bent,6063 aluminum scrap price india,6063 aluminum vs 6060,6063 aluminum alloy yield strength,6063 aluminum grade,6063 aluminum alloy plasma electrolytic oxidation,6063-0 aluminum,6063 aluminum chemical properties,6063 aluminum tig rod,6063 aluminum matweb,6063 aluminum ultimate stress,6063 aluminum alloy price,is 6063 aluminum weldable,aluminum 6063 emissivity,what's the difference between 6061 and 6063 aluminum,6063 aluminum tube,is 6063 aluminum stronger than 6061,6063 aluminum square bar,what is 6063 aluminum,6063 aircraft grade aluminum,6063 aluminum vs 5083,6063 aluminium data sheet,6063 aluminum tempers,6063 aluminum block,6063 aluminum strength,6063 aluminum scrap,6063 aluminum price per pound,6063 aluminum compared to 6061,aluminum 6063 datasheet,is 6063 aluminum marine grade,6063 aluminium frame,6063 aluminum bendable,6063 aluminum properties,6063 aluminum billet,can you weld 6061 to 6063,6063 aerospace-grade aluminum,6063 aluminum profiles,6063 aluminum material density,6061 and 6063 aluminum,6063-t6 aluminum,what is 6063 t6 aluminum,aluminium 6063 uses,6063 aluminum tubing round,6063 aluminum plate,6063 aluminum ultimate tensile strength,6063 aluminum welding wire,6063 aluminum channel - sharp corner,6063 aluminum billet price,6063 aluminum msds,6063 t52 aluminum u channel,how to weld 6063 aluminum,6063 vs 6463 aluminum,6063 aluminum thermal conductivity,6063 aluminum material properties,6063 marine grade aluminum,6063 aluminum round tube,6063 aluminum t bar,6063 aluminum weight,aluminum 6063 extrusion billet price,which is better 6061 or 7075 aluminum,6063 aluminum anodizing,6063 vs 5052,6063-o aluminum,is 6063 aluminum,6063 aluminum properties yield,6063 aluminum salt water,6063 aluminum c channel,6063 aluminium rod,6063 aluminum machinability,al 6063-t6,what is 6063 aluminum used for,aluminium 6063 wikipedia,6063 aluminum rectangular bar,aluminum 6063 t6 properties,6063 aluminum density,6063 extrusion aluminum profile,6063 aluminum extrusion,aluminum grade 6063-t6,what is the difference

0 notes

Text

Everything You Need to Know About Aluminium Round Bar

Aluminium is the most plentiful metal resource on the planet and makes up around 8% of the Earth’s crust in one form or another. It is now the most commonly available of all non-ferrous metals. Its ease of availability, however, does not make it any less impressive. Aluminium products have incredible strength properties at extremely low weight; for example, it is three times lighter than steel.

Its other qualities include:

Can be recycled many times with little loss of its properties

Easily formed

Excellent corrosion resistance

Great conductivity

How To Use Aluminium Round Bar?

Aluminium products are fantastic for DIY projects and can be used for a myriad of different things

Common applications of aluminium round bar include supports, trim, shaft, braces, pins, and dowels.

Aluminium Round Bar is an extruded solid aluminium bar that is highly versatile, easy to work with, and has a wide range of applications. 6061 Aluminium Round Bar is our most popular aluminium product that is widely used for all types of fabrication projects where lightweight and corrosion resistance is a concern.

Because aluminium round bar is either extruded or rolled, it is suitable for use in several different industries and products. As an example, machine and equipment parts are frequently made with aluminium bars. It can also be used in architecture and engineering, for structural components, frames, and other parts.

The aluminium rod, on the other hand, is well-suited to indoor and outdoor applications as it’s corrosion-resistant and can withstand the effects of air, water, and heat. With a tensile strength of 295 MPa, it can bear a large amount of stress before it begins to break, bends or warp.

Aluminium round bar is exceptionally easy to machine. Complex parts can be turned quickly with outstanding results. Drilling and cutting are possible with basic DIY equipment and smaller diameters can be cut easily and precisely with a hacksaw.

Aluminium round bar is a popular product due to its lightweight, strength to weight ratio, and ease of machining. It has extremely varied uses such as wheels and pulleys, fasteners, machine components, and precision turned parts.

Aluminium products and aluminium round bars are often used in the manufacture of parts and components for machines, cars, and bikes – items such as footrests/pegs, stands, shafts, mountings & rings.

Our Aluminium Products

All of our aluminium is

6000 series material, the vast majority of which is produced in the UK to 6063T6.

We also keep significant stocks of 6060 and 6082, all produced to comply with the exacting standards set out in BSEN755.

Available nationwide

To date, we have supplied a vast array of Hobbyists, DIY fans, Inventors, Artists, and of course professional aluminium buyers from all over the world. Providing them with the best material to complete their projects. We are always happy to help, whatever your requirement.

For most applications, all the 6000 series alloys are suitable, however, if you are anodising an item, you may prefer 6063 or 6060, and if using an item in construction then perhaps 6082 might suit better.

However, if you need a specific alloy, just contact us and let us know. We can offer both 6063T6 and 6082T6 on much of our range of angles, channels, flat bars, and indeed across the entire range of extrusions.

0 notes

Text

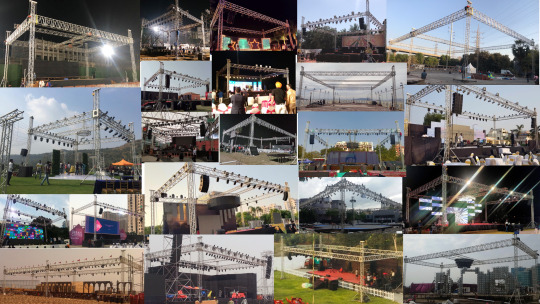

Magic of Truss!

We all like what it feels good and look good to our eyes, what is organized in its best possible way. We all love entertainment so that may be a choice of going to concerts, any indoor or outdoor shows, or may be a wedding! People enjoy such events to the fullest. What makes these events so successful and interesting? Well then it’s a Truss! A truss is an assembly of beams or other elements that creates a rigid structure.

Earlier trusses were constructed primarily of wood, with ropes sometimes serving as tension bars. Today, the trusses that are used to build the great things are Aluminium trusses. Though they look like simple aluminium alloys but are professionally designed and ostentatiously structured to create wonders to such events.

Choosing what is good and accurate for your event is vital as choosing what is right will only lead to a successful event. With our good quality products and experience, we can build the truss as per your needs. Shiv industries make the entire process quick and efficient as understanding your needs is our motive.

What is Aluminium Truss?

Aluminium trussing are the trussing that are used for lighting the stage, hanging the lights, sound system and decorative items which are mostly used in public events like music concerts, weddings and also corporate meetings and film industries have a wide range of usage. The material is often used to build up and set up temporary stage and that can be quickly removed at the end.

The aluminium trusses are made up of strong aluminium alloys. Special graded materials are used to manufacture this product. These materials are extruded as per size and requirement and have high strength with less weight. The advantage of aluminium alloy is that it is light and the truss structure is also easy to assemble and disassemble.

The setup of aluminium truss is quick and easy setup as light weight aluminum alloy material is used. Therefore it makes easy for loading and unloading the parts from pickup location to drop location which results in less number of manpower to assemble this product. Hence, aluminum trusses are widely used across the world due to its durability, light weight and ease of transport.

Shiv Industries manufactures a wide range of aluminium truss and offers truss of superlative quality

which includes Round Truss, Ladder Truss, Square truss, Rectangular truss, Exhibition Truss, Wedding Truss, Hanging Truss and Customize Truss.

Shiv industries produce the truss in variety of sizes, lengths and strengths as per the customer’s requirement.

To complete the whole setup of the stage it may take up to maximum 45 minutes. However, the additional time depends upon how huge the setup is going to be.

COMMON SIZES:

Aluminium truss comes in sectional lengths that are connected together to form the shapes and sizes of trusses. We offer square trusses of various sizes of sections such as 300mmx300mm, 400mmx400mm, 500mmx400mm, 600mmx400mm, 600mmx500mm, 820mmx600mm, 1060mmx600mm, 300mmx300mm.

The trusses that are used predominantly are in exhibition stalls which are mainly maximum12ft long for single piece.

We offer permanent installation of the aluminium truss, also provide multiple supports maximum length of 40ft long for single piece which can be also extended further as per the requirement.

OUR PRODUCTS:

• Truss Structure

• Aluminium Roof Truss

• Round Truss

• Aluminium Podium

• Aluminium Scaffoldings

• Goal Post Truss

• T-stand

• Truss Base Plate

• Corner Box

• Cross Support Pipe

• Clamp Fitting Accessories

• Fabricated and Wedding Dome

• Fabrication Service

QUALITY PARAMETERS

Shiv Industries is staunched to provide the highest quality of products and services to our all valuable customers. Also, our products are certified and tested for safety. We think in the customer’s point of view as we all are the customers in some or the other way and expect the best quality of products and services from the chosen industry.

We never compromise with Quality & Accuracy in any of our manufactured product throughout the process.

So, quality is our top priority and providing quality products to our clients is our assurance .

Shiv Industries has been manufacturing the aluminium truss since 2003 and tries the level best to make the events successful just the way you want it!

In today’s world of leading innovators we deliver the highest quality of products to meet the trussing needs and expectations of the clients. We bring the Innovation, we bring the Change and we make it Victorious.

#box truss#aluminiumboxtruss#boxtrusses#boxtrussing#usedboxtruss#aluminiumusedboxtruss#squaretruss#aluminiumsquaretruss#lightingboxtruss#stagelightingboxtruss#stageboxtruss#boxtrussforlights#4pillartrss#foursidetruss#uttam vaghela#vaghela truss#shivindustries#shiv truss#trusses#lighting trusses#lightingtruss#aluminium truss#design#aluminium round truss#advertising#business#graphic design#marketing#technology

0 notes

Text

What are the processing methods of industrial aluminum profiles?

The processing of industrial aluminum profiles mainly includes forming and surface processing.

Forming process

There are roughly two methods for processing and forming aluminum alloys: extrusion and rolling.

Extrusion is a common molding method for industrial aluminum profiles. First, an aluminum profile mold is made according to the profile cross-section. The extruder is used to extrude the round casting rod heated to the critical point from the mold. For example, 6063 aluminum alloy, there is an air-cooling and quenching process during the extrusion process and artificial aging treatment to complete the heat treatment and strengthening of aluminum profiles. Different aluminum alloys have different heat treatment methods.

Rolling method is only used when large batches are required, and the requirements for size and surface quality are not high for small and medium-sized bars and profiles with simple cross-sectional shapes.

2. Surface treatment

The surface processing methods of industrial aluminum profiles are generally surface anodizing, and some of them require spraying, electrophoresis and other processing methods.

Surface anodizing treatment uses the principle of electrolysis to form a thicker and denser oxide layer on the surface of industrial aluminum profiles, thereby increasing the corrosion resistance of aluminum alloy materials. After that, it is necessary to seal the industrial aluminum profiles.

Surface anodizing treatment uses the principle of electrolysis to form a thicker and denser oxide layer on the surface of industrial aluminum profiles, thereby increasing the corrosion resistance of aluminum alloy materials. After that, it is necessary to seal the industrial aluminum profiles.

Industrial Aluminium profile Aluminium Door&Window manufacturer - Foshan ChangYuan Aluminum Co., Ltd Foshan Changyuan Aluminum Co., Ltd. is located in Lishui Town, Nanhai District, Foshan City Guangdong PRC. It is close to Dali, the global aluminum material town, making full use of its location factors, the company are close to Hong Kong,Shenzhen, Guangzhou Nansha, Foshan Sanshan and other large ports. Changyuan Aluminum is a supplier of aluminum profile.

Source: https://www.fscyal.com/ba/what-are-the-processing-methods-of-industrial-aluminum-profiles/

0 notes

Link

aluminium alloy 6061 is a precipitation-hardened aluminum alloy, containing magnesium and silicon as its major alloying elements. Originally called "Alloy 61S",.IT is most known for its extreme durability, workability, machinability and toughness under extreme conditions like extreme atmosphere differences and seawater. It has good mechanical properties, exhibits good weldability, and is very commonly extruded (second in popularity only to 6063). It is one of the most common alloys of aluminum for general-purpose use. This makes it extremely resistant to corrosion. It’s also quite popular for its versatility when it comes to workability. Because it is a wrought alloy and not a casting alloy, it can be rolled, forged or extruded into a variety of shapes like aluminium round bar, aluminium square bar, rectangular bar, aluminium sheet or aluminium plate

0 notes

Text

Aluminum Stucco Embossed Sheet Suppliers

Aluminum stucco embossed sheet is a type of aluminum embossed sheet with stucco patterns. It’s obtained by rolling base aluminum sheets using a roller with stucco designs. Stucco embossed aluminum sheets cover a wide range of application, including lighting parts, reflective panels, wall cladding, interior decoration, ceilings, furniture, elevators, labels, cases, boxes, automobile decoration, domestic ornaments, home appliance (fridge panels, micro wave facial panels, sound equipment parts), military products, air planes, aircraft, satellites, machinery parts, mould, pipeline covering etc. Owing to extensive application areas of the sheet, aluminum stucco embossed sheet suppliers are springing up around the world.

Most aluminum stucco embossed sheet suppliers are integrated manufacturers of plain sheets, embossed sheets, anodized sheets and even mirror sheets, for the processing steps of these products overlap each other to different degrees. The production process of embossed aluminum sheets consists of raw material preparation, melting, casting, extruding and painting. Engineers should make a detailed calculation of element ratios in accordance with required alloys, then aluminum ingots and other metals are are placed into the melting oven for melting of these materials and removal of waste gases as well as solids. After being cooled, melted liquids come into a casting machine to turn into round bars of various specifications. The bars will further be extruded until they become aluminum sheets of desired thickness and size, during which corresponding heat treatment methods are adopted to different tempers required. At the same time, stucco patterns are embossed onto the sheet surface that must be anodized before being coated with paintings. Generally stucco embossed aluminum sheets are gray, but bright colors like red or blue are also available.

Reprinted from https://www.aluminum-coil.net/aluminum-stucco-embossed-sheet-suppliers.html

Try an inquiry to aluminium manufacturer with twenty years experience: Email: [email protected] wechat/skype: 0086 15838029491

0 notes

Text

A Guide to Choosing the Right Aluminium Bronze Round Bar

Rajkrupa Metal Industries is one of the Superior Quality Aluminium Bronze Round Bar Manufacturer In India. We are now the industry leader in Aluminium Bronze Round Bar. Our exceptional corporate and technical people abilities have allowed us to consciously establish ourselves as a top-tier manufacturer and retailer in the global market for aluminum bronze round bars.

Aluminium Bronze Round Bar Manufacturer is a type of metal alloy that combines copper and aluminium. It is known for its excellent mechanical properties, high strength, and corrosion resistance. The main alloying elements in aluminium bronze are aluminium and copper, but small amounts of other elements like iron, nickel, manganese, and silicon might be present to enhance specific properties.

What is an Aluminium Bronze Round Bar?

An Aluminium Bronze Round Bar is a cylindrical metal bar made from aluminium, and it is often used in a variety of manufacturing processes. The round shape makes these bars perfect for machining, welding, and forming. Depending on the grade and alloy of aluminium used, these round bars can have different properties, making them suitable for different industrial applications. Aluminium Bronze Round Bars are a special type of round bar composed primarily of aluminium and copper, with added elements like iron, nickel, and manganese.

Types of Aluminium Round Bars

Aluminium Bronze CUAL10NI5FE4 Round Bar : Aluminium Bronze CUAL10NI5FE4 Round Bar market because of its substantial business and technical personnel experience. We provide areas with various kinds and sizes of Extruded Aluminium Bronze Round Bars in significant quantities.

Aluminium Bronze C63000 Round Bar: The Aluminium Bronze Round Bar comes with the promise of high quality and dimensional precision. Our manufactured Aluminium Bronze C63000 Centrifugal Casting Round Bar, Square Bar, Bush, Pipe, Flat Bar, Ring, and Circle are used worldwide.

Aluminium Bronze C63200 Round Bar : Aluminum Bronze C63200, also known as C632, is a specific grade of aluminium bronze alloy. When using Aluminum Bronze C63200 Round Bar or any other material, it's essential to consider the specific requirements of your application and consult with material experts or suppliers to ensure you choose the right alloy and form (like round bar) for your needs.

C90300 Tin Bronze Round Bar: Metal Industries has strategically positioned itself as a top manufacturer and supplier in the global C90300 Aluminium Bronze Round Bar market because of its substantial business and technical personnel experience. We provide areas with various kinds and sizes of Extruded Aluminium Bronze Round Bars in significant quantities.

Aluminium Bronze CA104 Round Bar: The Aluminium Bronze Forged Round Bar comes with the promise of high quality and dimensional precision. CA104 Aluminium Bronze Round Bar have made a name for themselves in a variety of industrial application fields, including offshore, marine, and aerospace, etc.

Advantages of Aluminium Bronze Round Bars

Strength and Durability

The strength of the aluminium round bar will depend on the alloy used. If your application requires high tensile strength, ensure you select an aluminium alloy with superior strength properties. Aluminium Round Bars Suppliers are known for their high strength and durability, especially in conditions that require resistance to wear and tear.

Corrosion Resistance

One of the key advantages of aluminium is its resistance to corrosion, but some alloys, like Aluminium Bronze Round Bars, offer even better corrosion resistance. This makes them ideal for applications exposed to harsh elements like seawater, chemicals, or extreme temperatures.

High Strength

This alloy has high tensile strength and toughness, making it ideal for applications that demand durability and resistance to wear. Aluminium Bronze Round Bars are commonly used in components like pumps, valves, and propellers, where strength is critical.

Wear Resistance

Aluminium bronze alloys are highly resistant to wear and tear, making them excellent for parts that experience heavy friction and mechanical stress. This makes them suitable for high-performance machinery parts.

Marine and Shipbuilding

Aluminium bronze is widely used in the marine industry for components like propellers, pumps, and valves. Its resistance to corrosion in seawater and ability to withstand mechanical stress make it the material of choice for these applications.

Industrial Applications

These round bars are also used in the manufacturing of industrial machinery parts, such as gears, shafts, and valve seats, where strength and wear resistance are important.

Conclusion

Choosing the right Aluminium Bronze Round Bar depends on your specific needs, including material strength, corrosion resistance, and machinability. Aluminium Bronze Round Bars offer outstanding properties for marine, aerospace, automotive, and industrial applications, ensuring superior performance in challenging environments. By understanding the properties and advantages of different alloys, you can select the perfect round bar for your project. Partnering with a reputable Aluminium Bronze Round Bar Manufacturer in India will ensure you receive high-quality products tailored to your exact requirements.

To Know more on details visit our website: rajkrupametal.com

Product Source: Aluminium Bronze Round Bar Suppliers in India

#Aluminium Bronze Round Bar Manufacturer In India#Aluminium Bronze Round Bar Manufacturer#Aluminium Bronze Round Bar#Aluminium Round Bars Suppliers#Aluminium Bronze Round Bar Suppliers in India#Aluminium Bronze CUAL10NI5FE4 Round Bar#Aluminium Bronze C63200 Round Bar#C90300 Tin Bronze Round Bar#CA104 Aluminium Bronze Round Bar

0 notes

Text

Following the stunning debut of the Lotus Evora GT430, Lotus has introduced an expanded Evora GT430 line-up designed to appeal to a wider range of customers who want the ultimate in high-performance sports cars.

Adding to the acclaimed Evora 400 and Evora Sport 410 models, the new Evora GT430 range now includes two body options and a choice of manual or automatic transmission. Joining the recently announced Evora GT430 is the Evora GT430 Sport, a new member of the family that carries the same phenomenal firepower and sculptured body-style but without the additional downforce-creating aerodynamic elements. Both models are powered by the same 3.5-litre V6 supercharged and charge cooled engine, producing 430 hp and 440 Nm of torque (Automatic version: 450 Nm).

Without the aerodynamic elements, the Evora GT430 Sport weighs 10kg less at 1248 kg (dry), bringing the power-to-weight ratio to 345 hp / tonne and the top speed to 196 mph (315 km/h) making it the fastest Lotus production car ever.

The Evora GT430 is differentiated from the Evora GT430 Sport through the inclusion of motorsport derived aerodynamics provided by a carbon fiber splitter, a large, profiled carbon wing and louvers on top of each front wheel arch which reduces pressure within the front wheel arches together with wider wheels and tires.

Automatic transmission will be available from January 2018 for both the Evora GT430 body configurations. With 10 Nm more torque (450 Nm), the Automatic version is even quicker, with a 0-60 mph time of 3.6 seconds. The six-speed automatic transmission utilizes an optimised gearbox ECU for ultra-fast changes, whilst gear selection is made via lightweight aluminum paddles mounted to the steering wheel.

Boasting a high specification, the new Evora GT430 range includes, as standard, Öhlins TTX two-way adjustable dampers, J-grooved and ventilated brake discs – paired with AP Racing four-piston calipers all round, a Torsen-type limited slip differential (LSD) and an adjustable traction control system.

Announced last month, the Evora GT430 has already proved a knock-out success. Jean-Marc Gales, CEO, Group Lotus plc said:

The Evora GT430 already has cemented its place as a true collector’s car, but we know that many of our customers want the option of choosing a less aggressive version, with the same power, but without some of more arresting design and aero elements. With the Evora GT430 Sport, we have responded to this demand to add to the whole range of thoroughbred Lotus cars that are great on the track as well as supremely capable on the road.

Lotus Evora GT430 line-up in more detail

The new Evora GT430 Sport makes full use of carbon fiber to help hit its low kerb weight. This means that standard components include full carbon front and rear bumpers, front access panel, roof panel, rear quarter panels as well as a one-piece louvered tailgate with integrated spoiler.

The whole of the Evora GT430 range also benefits from advanced aerodynamics, including two enlarged carbon fiber front ducts, with integrated air blades, to efficiently move air through to the front wheel cavities and reduce turbulence created by the wheels. The curved rear edges of the front wheel arch panels also play a role, channeling air along the side of the car, while sculpted ducts behind each rear wheel vent air flow as quickly as possible from the wheel arches, balancing downforce. As a result, the Evora GT430 Sport generates up to 100 kg of downforce at 196 mph, some 56% more than the Evora Sport 410. The Evora GT430 generates up to 250 kg of downforce at 190 mph.

Jean-Marc Gales continued:

This is a car that epitomises a purity of engineering that many car manufacturers fail to match. Lotus founder, Colin Chapman not only pursued lightweight design, and pioneered the use carbon fiber in F1, but he also led the way in the field of aerodynamics in road and race cars. The Evora GT430 range continues this legacy, combining our expertise in highly efficient engineering and aerodynamics with more power and torque to provide one of the most rounded and rewarding driving experiences on the road or track.

Once inside, the use of visible-weave, carbon composite components continues. These include Lotus’ beautifully detailed carbon race seats, new carbon door sills and a new lightweight carbon instrument binnacle cover with a new design of graphic on the instrument panel. The steering wheel, dashboard, door panels, transmission tunnel and center console are all trimmed in a combination of black Alcantara® and perforated leather, complemented by contrast twin color stitching, in red and white, and matt black interior panels.

#gallery-0-4 { margin: auto; } #gallery-0-4 .gallery-item { float: left; margin-top: 10px; text-align: center; width: 33%; } #gallery-0-4 img { border: 2px solid #cfcfcf; } #gallery-0-4 .gallery-caption { margin-left: 0; } /* see gallery_shortcode() in wp-includes/media.php */

An integrated touch-screen infotainment system can be specified, including iPod® connectivity and Bluetooth® functionality, satellite navigation and reversing camera.

The variable traction control function, standard on all models, is linked directly to the ECU and allows the amount of wheel slip to be set by the driver whilst in ‘Race / Off’. The Evora GT430 has 10 mm wider Michelin Pilot Sport Cup 2 tires with 245/35 R19 at the front and 295/30 R20 at the rear, on one inch wider 10.5J rear wheels – these are optional fit for the Evora GT430 Sport.

Every new Lotus Evora GT430 Sport can be personalised through the increasingly popular Lotus Exclusive programme. Developed by the Lotus Design team to inspire customers, it combines traditional British craftsmanship with the best of modern design, and allows owners to tailor vehicles to their personal taste. Since its introduction last year, roughly a third of all new Lotus cars now undergo some form of customisation.

The new, fully homologated Lotus Evora GT430 range is available in two-seater configuration only and can be ordered now.

Evora GT430 and Evora GT430 Sport – Technical Specification

(Automatic) 3.8 seconds

3.7 seconds

3.8 seconds

3.7 seconds

0-100 mph (Manual)

(Automatic)

< 8 seconds

< 8 seconds

< 8 seconds

< 8 seconds

Max speed (Manual)

(Automatic)

190 mph (305 km/h)

174 mph (280 km/h)

196 mph (315 km/h)

174 mph (280 km/h)

CO2 emissions (Manual)

(Automatic)

234 g/km

TBA

234 g/km

TBA

Kerb weight (Manual)

(Automatic)

1,299 kg

1,310 kg

1,289 kg

1,300 kg

Dry weight (Manual)

(Automatic)

1,258 kg

1,269 kg

1,248 kg

1,259 kg

Power-to-weight ratio (dry weight) 342 hp per tonne 345 hp per tonne Aerodynamic downforce at maximum speed 250 kg 100 kg Hethel lap time (Manual) 1:25.8 seconds 1:26.8 seconds

ENGINE AND TRANSMISSION 3.5 litre V6, 24-valve, water cooled, all aluminium engine, with Edelbrock supercharger 6-speed manual transmission, with gearbox cooler, coupled to Lotus’ precision shift aluminium mechanism Optional 6-speed automatic transmission, with gearbox cooler, ultra-fast changes via steering wheel mounted lightweight aluminium paddles Lightweight, single-mass, low inertia fly wheel Torsen Type Limited Slip Differential Baffled sump Titanium exhaust system CHASSIS AND BODY Anodised, lightweight aluminium, extruded, epoxy bonded and riveted high-stiffness chassis Servo assisted, race-derived, lightweight two-piece J-hook ventilated brake discs and AP Racing four piston calipers (front 370mm x 32mm, rear 350mm x 32mm) Unequal length, high lateral stiffness, forged aluminium, double wishbone suspension with Eibach® tubular front and rear anti-roll bars Lotus-tuned, Öhlins® TTX aluminium two-way adjustable dampers – twenty click adjustment compression and rebound; twin tube design; low internal friction Eibach® ultra-light, low-sideload springs, front and rear Lotus tuned hydraulically-assisted, rigidly-mounted, rack and pinion steering system, with 2.86 turns lock-to-lock Driver selectable ESP modes – Drive/Sport/Race 6 position variable traction control, with five pre-set traction levels (1%, 3%, 6%, 9%, 12% slip) and “off” displayed via the instrument cluster Cruise control Tyre pressure monitoring system Lightweight lithium-ion battery EXTERIOR SPECIFICATION Carbon fibre front bumper, including drag-reducing air curtain Carbon fibre rear bumper, including venting for wheel arch Carbon fibre front access panel Carbon fibre roof panel Carbon fibre lower A panels Carbon fibre rear quarter panels Carbon fibre rear diffuser Lightweight carbon fibre tailgate with integrated rear spoiler and louvered backlight Polycarbonate backlight glass Brake calipers – red painted with black AP Racing logo Louvered wheel arch vents to reduce aerodynamic lift (Evora GT430 only) Carbon fibre profiled rear wing (Evora GT430 only) Carbon fibre front splitter (Evora GT430 only) Evora GT430: Lotus designed, ultra-lightweight, fully machined, forged aluminium wheels (19″ 8J front and 20″ 10.5J rear 10 spoke alloy wheels) in silver or matt black

Evora GT430 Sport: Lotus designed, ultra-lightweight, fully machined, forged aluminium wheels (19″ 8J front and 20″ 9.5J rear 10 spoke alloy wheels) in silver or matt black

Evora GT430: Michelin Pilot Sport Cup 2 tyres (front 245/35 R19, rear 295/30 R20)

Evora GT430 Sport: Michelin Pilot Sport Cup 2 tyres (front 235/35 R19, rear 285/30 R20)

Rear wing uprights linked to wheel colour choice (Evora GT430) Bi-xenon headlights LED daytime running lights Powerfold and heated door mirrors Rear parking sensors Thatcham approved immobiliser and remote activated alarm system

INTERIOR SPECIFICATION 2+0 seat configuration Carbon fibre sports seats, trimmed in black Alcantara® and perforated leather with contrast twin stitching Instrument panel, centre console and door panels trimmed in a combination of black Alcantara® and perforated leather, with contrast twin stitching Carbon fibre binnacle top Lotus developed steering wheel trimmed black Alcantara® Door grab handle in black Alcantara®, gear lever gaiter and hand brake sleeve in black leather Matt black console, door release levers, door grab handles and instrument panel surround finisher Steering wheel finisher and HVAC panel in matt black finish with gloss black finished bezels Lightweight aluminium gear knob Aluminium face level vents and blanking plate surround Dark grey headlining Black carpet Carbon fibre door sill covers Lightweight driver’s footrest Lightweight aluminium pedal pads Unique Evora GT430 Sport build plate

OPTIONS: TRANSMISSION AND PERFORMANCE UK RETAIL PRICE DE RETAIL PRICE 6-speed automatic transmission, with gearbox cooler, ultra-fast changes via steering wheel mounted lightweight aluminium paddles £2,600 € 3,600 10.5J rear wheels and wider Michelin Pilot Sport Cup 2 tyres (front 245/35 R19, rear 295/30 R20) – Evora GT430 Sport only £2,000 €2,800

OPTIONS: INTERIOR AND TRIM UK RETAIL PRICE DE RETAIL PRICE GT430 bespoke design, Sparco® sports seats with carbon backs, trimmed in black Alcantara® and perforated leather, with red or black Alcantara® stripes and contrast twin stitching £3,500 €4,900 Alcantara® Pack: Full black Alcantara® interior, including lower instrument panel, centre console and door panel (replacing perforated leather components) NCO NCO Leather Pack: Full black leather interior, including seats, instrument panel upper and door panel upper (replacing Alcantara® components) NCO NCO Lotus developed steering wheel trimmed in red Alcantara® £500 €700

OPTIONS: EXTERIOR AND BODY UK RETAIL PRICE DE RETAIL PRICE Lotus designed, ultra-lightweight, fully machined, forged aluminium wheels (19″ front and 20″ rear 10 spoke alloy wheels) in gloss black with machined rims (Evora GT430: rear wing uprights in black) £900 € 1,250 Lotus designed, ultra-lightweight, fully machined, forged aluminium wheels (19″ front and 20″ rear 10 spoke alloy wheels) in gloss red (Evora GT430: rear wing uprights in red) £900 € 1,250

OPTIONS: COMFORT AND COMMUNICATION UK RETAIL PRICE DE RETAIL PRICE Air conditioning £1,500 € 2,100 4 Speaker infotainment unit £2,000 € 2,800 Sub-woofer and amplifier £400 € 560 Sound insulation £500 € 700 Cup holder £120 €160

PAINT AND LIVERY OPTIONS UK RETAIL PRICE DE RETAIL PRICE Signature paint £1,200 € 1,650 Metallic paint £1,200 € 1,650

LOTUS EXCLUSIVE OPTIONS UK RETAIL PRICE DE RETAIL PRICE Exclusive Paint: Alternative metallic colours £2,400 € 3,300 Exclusive Paint: Alternative pearlescent colours £3,500 € 4,900 Exclusive Paint: Custom colour choice POA POA Exclusive Paint: Custom wing mirror choice £300 € 400 Exclusive Paint: Custom Interior Pack colour choice £650 €900 Exclusive Leather: Alternative colour £4,000 € 5,600 Exclusive Stitch: Alternative colour £500 € 650 The above options represent just a sample of what is available through Lotus Exclusive. Further information on the Lotus Exclusive programme, including a comprehensive list of the available customisation options can be found at: www.lotuscars.com/exclusive

MARKET EVORA GT430 RETAIL PRICE EVORA GT430 SPORT RETAIL PRICE UK £112,500 (incl. VAT at 20%) £104,500 (incl. VAT at 20%) Germany €151,000 (incl. VAT at 19%) €139,000 (incl. VAT at 19%) France €152,300 (incl. VAT at 20%) €140,200 (incl. VAT at 20%) Italy €157,260 (incl. VAT at 22% and transport) €144,960 (incl. VAT at 22% and transport)

Note: Press release courtesy of Lotus Cars.

The Expanding Lotus Evora GT430 Range Following the stunning debut of the Lotus Evora GT430, Lotus has introduced an expanded Evora GT430 line-up designed to appeal to a wider range of customers who want the ultimate in high-performance sports cars.

0 notes

Text

#ALUMINIUMALLOY6061T6SHEETSSUPPLIERS IN INDIA

Aluminium Alloy 6061 Exports from india to Dubai,Usa,Kuwait,Saudiarabia,Qatar,Iran,Kazakistan,israel.

Allo Sheet and Plate - Alloy 6061 Bars, Rods, Wire (rolled or cold finished) - Alloy 6061 Exporters & Supplier in Switzerland, New Zealand,Netherlands,Brazil,Colombia,Egypt, Iraq,Malaysia, Nigeria, Singapore.Technical Data SheetChemical Composition Limits

Weight%AlSiFeCuMnMgCrZnTiOther EachOthers Total

6061Bal0.40 - 0.800.70 max0.15-0.400.150.8-1.20.04-0.350.25 max0.15 max0.05 max0.15 max

Aluminum 6061 is an extremely versatile heat treatable aluminum alloy due to its content of silicon and magnesium. 6061 has a wide range of mechanical and corrosion resistance properties as well as having most of the good qualities of aluminum. 6061 is used in a many applications from aircraft structures, yacht construction, truck bodies, bicycle frames to screw machine parts.

Typical Mechanical PropertiesMaterialThickness (in)Tensile Strength (ksi)Yield Strength (ksi)Elongation

Alloy 6061 Sheet T60.020-0.500423510

Alloy 6061 Sheet T60.500-1.00042359

Alloy 6061 Sheet T61.00-2.0042358

Alloy 6061 Sheet T62.00-4.0042356

Alloy 6061 Sheet T64.00-6.0040356

MaterialTemperDiameter (in)Tensile Strength (ksi)Yield Strength (ksi)Elongation

Alloy 6061 Bar

Cold FinishedT651All423510

Alloy 6061 Bar

Cold FinishedT6511<0.25"38358

Alloy 6061 Bar

Cold FinishedT6511>0.25"383510

Alloy 6061 Bar - T651 / T6 condition and extruded T6511/T6

Availability : Aluminium Alloy 6061 Sheet, Plate, Wire, Rod, Bar (Hexagon, Round, Square), Tube and extrusions. 6061 Foil (Shim) is available in various thicknesses. View stock list for further information. Foil Stock List , Sheet Stock List, Plate Stock List. For all stock availability of Aluminium Alloy 6061 contact Sales.

0 notes

Text

Introduction to Round Bars: Types, Uses, and Benefits

Rajkrupa Metal Industries is a top Round Bars Manufacturers in India. We've established ourselves as one of the leading names in the Round Bars industry. Because of its strong commercial and technical staff capabilities, Rajkrupa Metal Industries has purposefully positioned itself as a leading Round Bar manufacturer.

What Are Round Bars?

Round bars are long, cylindrical pieces of metal that are produced through various manufacturing processes such as rolling, drawing, or extruding. They come in a variety of sizes, materials, and finishes, making them suitable for an extensive range of applications. The diameter of round bars can vary significantly, from a few millimeters to several inches, depending on their intended use.

Types of Round Bars

Round bars can be classified based on the material they are made from. Here are some of the most common types:

Stainless Steel Round Bars:

Highly resistant to corrosion and staining

Used in environments where hygiene and durability are critical

Carbon Steel Round Bars:

Known for their strength and hardness

Widely used in construction and manufacturing

Alloy Steel Round Bars:

Enhanced mechanical properties due to alloying elements

Ideal for applications requiring higher strength and toughness

Aluminum Round Bars:

Lightweight and corrosion-resistant

Commonly used in aerospace, automotive, and marine industries

Brass Round Bars:

Good corrosion resistance and excellent machinability

Often used in plumbing and electrical applications

Uses of Round Bars

Round bars are incredibly versatile and are used in various industries for numerous applications:

Construction:

Used as reinforcement bars in concrete structures

Employed in the fabrication of beams, columns, and other structural components

Manufacturing:

Utilized in the production of machine parts, tools, and equipment

Essential in the creation of fasteners such as bolts, nuts, and screws

Automotive:

Applied in the making of shafts, axles, and other critical components

Used in the production of engine parts and transmission systems

Aerospace:

Used in the construction of aircraft frames and landing gear

Integral in the manufacture of engine components

Marine:

Employed in the construction of ships and submarines

Used in the production of various marine hardware

Benefits of Round Bars

Round bars offer several advantages that make them a preferred choice for many applications:

Strength and Durability:

Round bars are known for their high tensile strength and durability, making them suitable for heavy-duty applications.

Versatility:

The wide range of materials and sizes available allows for round bars to be used in diverse industries and applications.

Machinability:

Round bars are easy to machine, cut, and shape, facilitating their use in manufacturing processes.

Corrosion Resistance:

Materials like stainless steel and aluminium provide excellent resistance to corrosion, extending the lifespan of the components made from round bars.

Cost-Effectiveness:

Due to their widespread availability and ease of production, round bars are often more cost-effective compared to other forms of metal products.

Customizability:

Round bars can be customized to specific dimensions and properties to meet the unique requirements of different applications.

We are also top quality Aluminium Bronze Round Bar Manufacturer In India.We have established ourselves as one of the market's top names in Aluminium Bronze Round Bar. Rajkrupa Metal Industries has deliberately positioned itself as a top-tier manufacturer and retailer worldwide. Aluminium Bronze Round Bar Suppliers are well-known for their high strength, corrosion resistance, and thermal and electrical conductivity.

#RoundBarsManufacturersinIndia#RoundBarsManufacturers#RoundBars#AluminiumBronzeRoundBarManufacturerInIndia#AluminiumBronzeRoundBarManufacturer#AluminiumBronzeRoundBar#AluminiumBronzeRoundBarSuppliers

0 notes

Text

C63200 Round Bar Is the Ideal Addition for Your Workshop

Because of its high feature offerings, the Aluminium Bronze C63200 Bar has been widely used in industries. It is made up of 77-93% nickel, manganese, iron, and copper. It is a corrosion-resistant material with high performance due to extensive treatment at low and high temperatures.

Round Bar C63200 Characteristics

Posse is a reliable product for instrumentation systems due to its low magnetic permeability in general. The aluminium bronze bar is a first-cast product with specified corrosion resistance that occasionally experiences selective corrosion.

The newly discovered wrought alloy undergoes tempering and quenching treatment to eliminate problems during structuring in the kappa phase. As a result, the tried-and-true alloy is now ready for use in applications. TIG and MIG procedures are utilised in conjunction with this aluminium bar. In addition to all of these, the newly created alloy has great wear resistance as well as good corrosion resistance.

The Benefits of Having a Round Bar in Your Workshop

One of the most useful steel components for any workshop is a round bar. They can be used for a variety of activities, including drilling, welding, and cutting. This post will go over the advantages of having round bars in your workshop as well as the different kinds that are available.

- Versatility: Owning a round bar has several advantages, one of which is its adaptability; depending on the intended application, it can be cut or drilled. Due to the lack of expensive welding equipment, simple repairs can also be made with this instrument using only basic tools like drill bits and saw blades.

- Strength: Another significant advantage of having a round bar in your shop is its strength; they are commonly made of stainless steel, making them highly durable while remaining lightweight enough to handle with ease during projects such as fabrication or art sculpture.

- Low Maintenance: As long as these bars are cleaned and oiled on a regular basis, their upkeep requires little effort, making them ideal for anyone who does not have time or energy to devote to extensive maintenance.

Before being sent to prestigious clients, we make sure that the aluminium bronze C63200 bar underwent a quality test. Mechanical testing, such as tensile testing of the region, chemical analysis, hardness testing, positive material identification testing, micro and macro, pitting resistance testing, intergranular corrosion testing, and flaring testing are all used to test the product. Quality assurance plans, heat treatment charts, raw material reports, fumigation certifications, packing list tests, commercial invoices with HS codes, and test certificates in compliance with NACE MR0175 are among the documentation for bronze C63200 bar. They are packaged in wooden cases after they have undergone testing and the necessary paperwork is completed. You are able to place an order based on your needs.

C63200 Round Bar Manufacturer in India

Aluminium Bronze C63200 Round Bar Manufacturer & Supplier in India. One of the main manufacturers of Aluminium Bronze C63200 Round Bar in India is Rajkrupa Metal Industries. We have developed into one of India's top names in the sand casting industry for aluminium bronze C63200 round bars.

Because of its extensive business and technical personnel experience, Rajkrupa Metal Industries has strategically positioned itself as a top supplier in the global Aluminium Bronze C63200 Round Bar manufacturer. Extruded Aluminium Bronze Round Bars of various types and sizes are available in large quantities from us. We are also a Aluminium Bronze CUAL10NI5FE4 Round Bar Manufacturer in India

0 notes