#erowa

Explore tagged Tumblr posts

Text

Edm Tooling System

Discover the ultimate EDM Tooling System at Maxx Tooling. Designed to revolutionize your electrical discharge machining operations, our cutting-edge system ensures precision, reliability, and efficiency like never before. Crafted with the highest quality materials and advanced technology, our EDM Tooling System delivers exceptional performance and durability. Whether you're a seasoned professional or a newcomer to EDM, Maxx Tooling has the solution to elevate your productivity and achieve outstanding results.

1 note

·

View note

Text

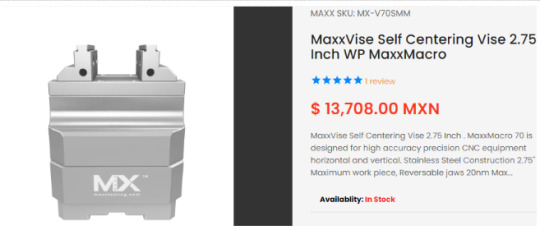

Enhance your machining capabilities with the exceptional range of Maxx Tools. From cutting tools to workholding solutions, we offer a comprehensive selection that caters to diverse manufacturing needs. Trust in the quality and performance of Maxx Tools to optimize your processes and achieve superior results. Visit our website, maxxtooling.mx, and unlock the potential of Maxx Tools for your success.

#maxx tools#3r edm tooling#system 3r#erowa edm tooling#erowa tooling#system 3r tooling#erowaedmtooling#system 3r edm#3redmtooling#maxxtools

0 notes

Text

EROWA EDM Tooling System

Maxx Tooling specializes in manufacturing a wide range of precision tools, including EDM Tooling, EDM Tooling Systems, 3R Erowa Systems, 3R Tooling, System 3R Mini, System 3R System, System 3R EDM, 3R Compatible Store, System 3R Macro Holders, Erowa Tooling, and more. Our extensive product line also includes Erowa Compatible, Erowa System, CNC Pneumatic Chuck Systems, Macro Magnum, 2D & 3D milling cutters, and CNC routers. All of our tooling undergoes rigorous testing and verification at multiple stages to ensure the highest quality standards. For detailed information, please visit our website.

1 note

·

View note

Text

Maxx Tooling provides a wide range of high-quality tools for various manufacturing applications. From cutting tools to precision measuring instruments, Maxx Tools deliver exceptional performance and reliability, helping businesses achieve their production goals with ease.

0 notes

Text

System 3r Tooling | Maxx Tooling

Maximize your productivity and precision with System 3R Tooling from Maxx Tooling. Designed for efficient and reliable machining operations, our System 3R Tooling solutions ensure optimal performance and accuracy. Explore our wide range of tooling options and experience the difference in your manufacturing processes. Visit maxxtooling.uk now to elevate your machining capabilities.

0 notes

Text

Boost Productivity and Efficiency with POFI Gripper for ITS Holders and Pallets

In today’s fast-paced manufacturing industry, automation plays a crucial role in enhancing productivity and reducing downtime. The POFI Gripper for ITS Holders and Pallets is a cutting-edge solution designed to revolutionize workpiece and electrode mounting processes in a no-human production line. With its compatibility with popular robotic systems like FUNAC and EROWA, this gripper offers seamless integration into existing handling devices, making it a versatile choice for various manufacturing environments.

Streamlined Workpiece and Electrode Exchange:

The POFI Gripper is specifically engineered to automate the exchange of workpieces and electrodes on electrode holders or ITS pallets. By eliminating the need for human intervention in these repetitive tasks, it brings a host of benefits to the production line. With its precise and reliable gripping mechanism, the gripper ensures accurate positioning and secure attachment, minimizing errors and reducing the risk of damage to delicate components.

Enhanced Productivity and Efficiency:

One of the key advantages of the POFI Gripper is its ability to significantly improve productivity in manufacturing processes. By automating workpiece and electrode exchange, it eliminates the time-consuming manual handling and minimizes machine center downtime. This leads to higher overall equipment effectiveness (OEE), allowing manufacturers to optimize their production capacity and meet demanding production targets.

Seamless Integration:

The POFI Gripper is designed to seamlessly integrate with popular robotic systems such as FUNAC and EROWA. Its compatibility with a wide range of handling devices ensures easy implementation and quick setup, saving valuable time during installation. The gripper’s flexible interface enables efficient communication and coordination with the robot, facilitating smooth operation and synchronization within the production line.

Robust and Reliable:

Built with durability in mind, the POFI Gripper is constructed using high-quality materials and advanced engineering techniques. Its robust design ensures long-term performance, even in demanding manufacturing environments. The gripper undergoes rigorous testing to guarantee its reliability, ensuring uninterrupted operation and minimizing maintenance requirements.

In the ever-evolving world of manufacturing, the POFI Gripper for ITS Holders and Pallets emerges as a game-changer. By automating the exchange of workpieces and electrodes, it empowers manufacturers to achieve higher productivity, reduced downtime, and improved efficiency. With its compatibility with leading robotic systems and seamless integration into existing handling devices, the POFI Gripper offers a versatile and reliable solution for various manufacturing applications. Stay ahead of the competition and embrace the future of automation with the POFI Gripper.

0 notes

Text

Erowa Tooling

Shop Erowa Tooling at price that lies within your budget from Max Tooling. We are here to provide you with best in class tools that are compatible to meet your tooling requirements. Our tooling is long lasting and does not get damaged easily in extreme conditions. To shop any of the products, hook to our website.

1 note

·

View note

Text

#CPWSworkholidng #EDMtooling #EROWAtooling #chinaEROWA #system3REDMtooling

#CPWSworkholidng #EDMtooling #EROWAtooling #chinaEROWA #system3REDMtooling

#mouldmaking #EDMfixture #CNCmachinetool #wireEDM #wireEDMtooling #wireEDMfixture

CPWS® is China manufacturer and exporter of compatible EROWA,System 3R EDM tooling workholding fixture, very competitive price, good precision 0.002mm repeatability, export to many European countries, USA,Canada for years, quality is stable, (www.workholdingtool.com [email protected])

The post #CPWSworkholidng #EDMtooling #EROWAtooling #chinaEROWA #system3REDMtooling appeared first on CPWS®-China Precision Workholding System Inc.

https://ift.tt/32tKykl https://ift.tt/2HL6krO

1 note

·

View note

Photo

🚬 _ #alters #internet #life #psycho #management #a #bass #art #smarthome #interiordesign #erowa #innovation #edmmachine #g #o #fitness #engineering #osddsystem #options #iam #dreambig #freeenergy #crazykeith #ckpower #teamboom #royaltyincome #systems #mrfreeeverything #gogetit #freewireless https://www.instagram.com/p/CS3mFJwHsSOhK15K69Xr8I8ngSNfmN1xbUEEpA0/?utm_medium=tumblr

#alters#internet#life#psycho#management#a#bass#art#smarthome#interiordesign#erowa#innovation#edmmachine#g#o#fitness#engineering#osddsystem#options#iam#dreambig#freeenergy#crazykeith#ckpower#teamboom#royaltyincome#systems#mrfreeeverything#gogetit#freewireless

0 notes

Text

Common 3r System Tools That Are Used In Machinery

Whether it is a metal industry or a machine shop there are ample number of tools without which it is not possible to carry out the manufacturing of metal components via machining. These tools cover an important aspect of machinery assisting in several processes like cutting, shearing, milling, and grinding. However, if you are looking for quality tooling, then it is best to have 3r System Tooling as it offers you with quick resetting and high precision at the workplace. Have a glance at below-given information to know about some common 3r system tools that are used in machines.

Spigots: Spigot is a kind of faucet device which is used to control the flow of water, leakage of gas from the barrels and containers used in manufacturing industries.

Chucks: These are a type of tooling equipped with jaws that help you to hold objects like drills, mills, and cylinders. These work as clamps which are mounted on rotating objects and workpieces that are needed to be machined in a symmetrical manner.

Centering Plates: These plates are an alternative to wooden plates that are used in construction and metal industries. With different shapes, sizes, and riveted angles, these plates are being extensively used to provide support to different materials used in constructing slabs, canopies, and beams.

Electrode holders: These are the most common tooling which is found in every kind of metal industry. This is a kind of clamping device which is used to hold the electrode having current securely without coming in contact with the body. There are several kinds of holders that are designed to use within a specified range of electrode diameters and welding current.

Pallets: These are kind of tooling plates which are used to assemble, store, protect, and transport different tooling and equipment like fixtures, forklifts, pallet jacks or conveyors. Also, it allows accurate placement of surface-mount components due to the presence of holes in it.

Where to Buy?

Looking to buy any of the above mentioned 3r toolings? Maxx tooling is the right place to visit. They are one of the prominent sellers of automotive and high tech System 3R Mini tooling. With the use of the latest technology and high precision, they provide unbeatable tooling which is exclusively designed to cater the machining needs of modern industries. Get in touch with them through their website to shop now.

1 note

·

View note

Text

Buy System 3R 3R-601.3, Pallet, hardened, 70x70 mm, MacroHighPerformance.

0 notes

Text

Maxx Tooling is amongst the top-notch companies to provide System 3r Chuck to address the needs of modern machinery. With a sleek design, rust, and water-resistant features our tooling ensures to last longer for years. Visit our website for more details!

#edm tooling system#system 3r chuck#erowa edm tooling#system 3r tooling#maxx tooling canada#system 3r#erowa compatible#erowa system#macro magnum

0 notes

Text

What Are The Functions Of Erowa EDM Tooling System?

Efficiency and accuracy are critical in the realm of precision machining and production. The Electrical Discharge Machining (EDM) procedure has transformed the profession. Using electrical discharges, EDM enables the exact shape and machining of complicated objects. The Erowa EDM Tooling System was created to improve the EDM process even more. This unique technology provides a variety of functionalities that expedite and improve the EDM workflow, resulting in significant industrial benefits.

Let’s Take a Closer Look To The Functions Of Erowa Edm Tooling:

Electrode Holding and Positioning:

Electrode holding and positioning is a critical components of the Erowa EDM Tooling System. Electrodes are used in EDM to generate the required form in the workpiece. Erowa's tooling technology ensures consistent and accurate machining results by firmly retaining and placing these electrodes. The modular nature of the system enables rapid and easy setup, decreasing downtime and enhancing productivity.

Workpiece Clamping:

Accurate workpiece clamping is critical for effective EDM operations. The Erowa system provides a variety of clamping methods with exceptional stability and repeatability. The system's varied clamping options provide perfect placement and fixation during machining, whether it's a single workpiece or several pieces. It reduces the possibility of workpiece movement or vibration, resulting in greater machining precision and surface finish quality.

Palletization and Automation:

The Erowa EDM Tooling System has palletization and automation features to increase productivity and efficiency. The technology enables rapid and easy workpiece interchange, minimizing setup times and enhancing machine usage. Palletization allows numerous workpieces to be machined at the same time, reducing idle time and increasing output. Furthermore, the system connects smoothly with automated systems, providing unmanned operations and 24/7 manufacturing capabilities.

Tool and Electrode Management:

Efficient tool and electrode management are critical for any machining operation. The Erowa EDM tooling system has complete tool and electrode management functionalities that allow for simple access, organization, and tracking of these crucial components. The tooling cabinets and holders in the system allow for systematic storage, reducing tool damage or loss. Furthermore, integrated RFID technology allows for precise inventory control, tool life monitoring, and automated tool presetting, all of which help to optimize machining operations.

Conclusion:

The possibilities for precise machining are endless with the Erowa EDM Tooling System. Are you looking to buy the same? If so, then explore the Maxx Tools collection at Maxx Tooling - Michigan's most reputable tool store. It concentrates on delivering cutting machines and instruments that are among the best in the industry. System 3R, Erowa tools, and CNC Pneumatic Chuck Systems are available from Maxx Tooling. Check out their website to get started on purchasing industrial cutting tools right away!

#Erowa Edm Tooling#3r Edm Tooling#Maxx Tools#System 3r Tooling#System 3r Edm#System 3r#Erowa Tooling#Tools#design

0 notes

Text

Why 3R System and EDM Tooling Better Than Conventional Machining?

In a normal machine shop, there are dozens, if not hundreds, of different types of equipment, some of which are more versatile than others and built for certain tasks. Operators typically switch between systems throughout projects according to what is necessary, such as utilizing a polisher to complete a piece, remove burrs, or smooth the outside. making use of a surface grinder.

One such tool called EDM Tooling System is classified as one of the most useful in the modern shop. EDM stands for Electrical discharge machining (EDM), sometimes called “spark machining.” It has a razor-sharp edge that effortlessly cuts through metal and other tough materials while producing complex shapes. That’s the major reason it’s more beneficial to use EDM over traditional machining solutions.

Here are specific reasons EDM can produce better results:

● EDM tooling is a reliable and efficient solution.

● Requires a low-maintenance and can be trusted to run indefinitely.

● Less susceptible to errors or interruptions which is why it's perfect for “lights out”

● EDM machines are so small that it’s perfect for deep or sharp cuts as compared to the conventional machine.

● EDM with System 3R Mini offers a solution for deep cuts in hard material, like hardened steel or tungsten carbide.

● EDM machining operates at low speed and power, which reduces the size of craters or pockmarks and results in a flawless mirror finish.

This is it! Are you looking to buy the best and high-quality machine tool? If so, then you must visit “MAXX Tooling.” They are the providers of the EDM tooling, 3R System range, which includes paddles, chucks, and pins to match your tooling needs. You can find more information about their products on their website.

#EDM Tooling#EDM Tooling System#3R Erowa System#3R Tooling#System 3R Mini#3R System#System 3R#System 3R EDM#3R Compatible Store#news#technology#tech

0 notes

Text

Exploring the Versatility of Erowa EDM Tooling in Manufacturing

In today's highly competitive manufacturing industry, companies are constantly seeking ways to enhance productivity and streamline operations. One crucial area where efficiency can be significantly improved is electrical discharge machining (EDM). Erowa EDM Tooling, coupled with the System 3R Chuck, presents a versatile and innovative solution that revolutionizes the manufacturing process. In this blog, we will explore the versatility and benefits of EDM tooling while highlighting the essential role played by System 3R.

Streamlining Operations with Erowa EDM Tooling:

Erowa tooling offers a comprehensive range of solutions designed to optimize EDM processes. By utilizing automated systems and tooling, manufacturers can significantly reduce setup times, enhance accuracy, and improve overall productivity. The Erowa System provides a modular approach, allowing for seamless integration into existing EDM machines and workpiece management systems. It ensures efficient handling of electrodes, workpieces, and tooling, minimizing human error and maximizing throughput. This versatility enables manufacturers to achieve consistent and reliable results across various EDM applications, including die sinking, wire EDM, and small-hole drilling.

Enhancing Efficiency with System 3R Compatible Chuck:

At the heart of the EDM tooling system is the System 3R Chuck, a versatile and highly precise workholding solution. The chuck's modular design enables quick and easy setup of workpieces, electrodes, and tooling, resulting in reduced idle time and increased machine utilization. Its superior clamping force ensures secure and rigid positioning, facilitating high-precision machining operations. Furthermore, the 3R Chuck's compatibility with a wide range of EDM machines allows manufacturers to leverage its benefits across multiple platforms. This adaptability enables seamless integration into existing workflows and enhances overall process efficiency.

Versatility Across Multiple Industries:

The adaptability of Erowa EDM and the System 3R tooling extends to a broad spectrum of industries. From aerospace and automotive to medical device manufacturing and mold-making, the Erowa system caters to the diverse needs of various sectors. By utilizing modular tooling and chuck, manufacturers can achieve consistent results in complex machining operations. The versatility of the system also extends to different workpiece materials, such as steel, aluminum, and exotic alloys, making it a preferred choice for a wide range of applications.

Conclusion:

In a manufacturing landscape driven by efficiency and precision, Erowa EDM tooling, complemented by the System 3R Chuck, emerges as a game-changing solution. The modular design, seamless integration, and versatile capabilities of the system enable manufacturers to optimize their EDM processes and achieve higher productivity. By reducing setup times, enhancing accuracy, and streamlining operations, Erowa EDM tooling and the System 3R Chuck empower companies to stay competitive in today's demanding market. Embracing these innovative technologies will undoubtedly unlock new opportunities for manufacturers, leading to improved profitability and customer satisfaction.

If you need these solutions for your process, then look no further. At Maxx Tooling, we offer tooling solutions that perfectly meet your challenging workholding tasks. Contact us for more queries!

#edm tools#macro magnum#maxx tools#erowa tooling system#maxx tooling#tools#Erowa Tooling System#Erowa Edm Tooling

0 notes

Text

Maxx Tooling: Streamlining Production with EROWA Tooling Solutions

Maxx Tooling offers top-of-the-line EROWA Tooling solutions to optimize your manufacturing processes. With Erowa Tooling, you can enhance your workflow efficiency, reduce setup times, and achieve consistent precision in your operations. Explore our comprehensive range of EROWA Tooling options and experience the benefits of streamlined production. Visit maxxtooling.uk now and unlock the power of EROWA Tooling.

0 notes