#epoxy primers market forecast

Explore tagged Tumblr posts

Text

The Business Research Company offers epoxy primer market research report 2023 with industry size, share, segments and market growth

#epoxy primer market outlook#epoxy primers market analysis#epoxy primers market forecast#epoxy primers market growth#epoxy primers market report#epoxy primers market research#epoxy primers market share#epoxy primers market size#epoxy primers market trends

0 notes

Text

Electronic Adhesives Market - Forecast (2024-2030)

Electronic Adhesives Market Overview

Electronic Adhesives Market Size is forecast to reach $ 6,820 Million by 2030, at a CAGR of 6.50% during forecast period 2024-2030. Electronic adhesives are used for circuit protection and electronic assembly applications such as bonding components, wire tacking, and encapsulating electronic components. The use of electronic adhesives in manufacturing components for electric vehicles such as printed circuit boards, lithium-ion batteries, and battery pack assemblies are facilitating growth of the market. Growing adoption of surface mounting technology to replace welding and soldering is one of the prominent trends in the electronics industry, shaping the demand for electronics adhesives.

Report Coverage

The report: “Electronic Adhesives Market – Forecast (2024-2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the Electronic Adhesives Industry.

By Type: Thermal Conductive, Electrically Conductive, Ultraviolet-Curing and Others.

By Resin Type: Epoxy, Cyanoacrylates, Polyamides, Phenolic, Silicones, and Others (Acrylics, and Polyurethane)

By Application: PCB’s, Semiconductor, and Others

By End-User Industry: Consumer Electronic (Wearable Devices, LEDs & TVs, Smart Phones & Tablets, Computers, Laptops, and Others), Healthcare, Energy & Power (Solar, Wind, and Others), Telecom Industry, Transportation (Automotive (Passenger Vehicles, Light Commercial and Heavy Commercial Vehicles), Marine, Locomotive, and Aerospace), Oil & Gas, Chemical, Pulp & Paper, and Others.

By Geography: North America, South America, Europe, APAC, and RoW

Request Sample

Key Take away

In 2020, North America held the largest share after APAC. Due to growing demand for electronic adhesives in electronics and telecommunication industry. The US hold the largest share in the region over the forecast period.

Growing adoption of electric vehicles is expected to provide a major growth opportunity for the market.

Emission of Volatile Organic Compounds (VOC’s) may deter the market's growth during the forecasted period.

COVID-19 has hindered the market growth owing to the disruption of supply chain and worldwide lockdown.

Electronic Adhesives Market Segment Analysis - By Type

Electrically Conductive segment held the largest share of more than 30% in the electronics adhesives market in 2020. Electrically Conductive are used in various industry verticals such as aerospace, automotive, medical, and telecom products. Electrically conductive is an excellent solution for making electrical contacts on PCBs and other temperature-sensitive substrates, as their curing temperature is below the soldering temperature. An increase in demand for Anisotropic Conductive Adhesives (ACA) in LCD connections, PCBs, and bonding antenna structures further boost the demand for the market. Electric conductive are also used in the LED industry for their capacity to serve as stable electrical contacts by absorbing mismatches, which will likely boost the market's growth for the forecasted period.

Inquiry Before Buying

Electronic Adhesives Market Segment Analysis - By Resin Type

Epoxy segments held the largest share of more than 25% in the market in 2020. Epoxy is widely used in electronic applications, either in two-part or single-part heat cure products. Epoxy has good resilience against environmental and media influences, it has a dry and non-tacky surface which is perfect to be used as a protective coating and is widely used in adhesives, plastics, paints, coatings, primers and sealers, flooring, and other. Curing epoxy adhesives can take place either at room or elevated temperature or through photoinitiators and UV light. Modern photoinitiators also react to the special UV spectrum of LED light sources, so that newly developed epoxide resin adhesives can be cured with both UV and UV LED light. Some epoxies exhibit optical properties and diffraction indexes, making them useful for applications in precision optics, lens bonding, and information technology, which will further boost the market's growth.

Electronic Adhesives Market Segment Analysis - By Application

Printed Circuit Boards (PCBs) segment held the largest share of more than 35% in the market in 2020. Electronic adhesives are used as a conformal coating in PCBs. Adhesive is used in wire tracking, potting & encapsulation of components, conformal coatings of circuit boards, and bonding of surface mount components. PCBs are highly reliable, cheap, less chance of short circuit, easily repairable, and are compact in size. The growing uses of laptops, smartphones, and household appliances coupled with developing living standards further drive the growth of PCB. Whereas, the growing uses of PCB’s in automotive, industrial & power equipment, control & navigation systems, and aerospace monitoring also contribute to the market growth. According to Aerospace Industries Association (AIA) report, in 2018, aerospace and defense exports amounted to $151 billion, an increase of 5.81% from the previous year, and civil aerospace accounted for the majority of exports with $131.5 billion.

Schedule a Call

Electronic Adhesives Market Segment Analysis - By End-User Industry

Consumer Electronics segment held the largest share of more than 30% in the Electronic Adhesives Market in 2020. Rapid urbanization and increase in the development of new technology have propelled the demand for consumer electronics. As per the United Nations, 55% of the world’s population lives in urban areas, which propel the demand for consumer electronics. The growing demand for lightweight and portable equipment such as smartphones, laptops, and digital cameras are playing a significant role in boosting the demand for the market. As per a report released by Nexdigm Private Limited, a private company, the global electronics industry is expected to reach $7.3 trillion by 2025, which will significantly propel the demand for the market during the forecasted period.

Electronic Adhesives Market Segment Analysis - By Geography

Asia-Pacific held the largest share of more than 45% in the Electronic Adhesives Market in 2020. China, India, and Japan are the major contributors to the growth of Electronic Adhesives Market in APAC. The large consumer base, developing manufacturing sector, and increase in middle-class population along with smart city projects are major factors for the market growth. As per the Indian Brand Equity Foundation (IBEF) report released in 2020, electronics manufacturing in India is expected to reach $163.14 billion by 2025, and demand for electronics hardware in India is expected to reach US$ 400 billion by 2024. The shifting of production lines to the APAC region for the low cost of production and the ability to serve the local emerging market is another factor for the growth of the market in the region.

Buy Now

Electronic Adhesive Market Drivers

Growing Need for Miniaturized Electronic Products

Growing demand for low-cost, reliable, and miniaturized electronic devices from consumers propel the market's growth. The increasing demand for miniaturized products has led to the development of smaller electrical components, which occupy less area. The need for smaller and thinner consumer electronics devices is a new trend among consumers. The surface mount technology helps in using and assembling much smaller components, thus facilitating a smaller, portable, and lightweight electronic device. Pocket calculators, smartwatches & other wearable devices are some of the examples. Such miniature devices will further drive the demand for electronic devices and in return will boost the demand for the Electronic Adhesives Market as they are used in manufacturing these devices.

Introduction of 5G Network

Introduction 5G networks are planned to increase mobile broadband speeds and added capability for 4K/8K video streaming, virtual reality (VR) or augmented reality (AR), Internet of Things (IoT), and mission-critical applications. Introduction of 5G will boost the telecommunication industry, with better coverage, and internet speed, which also create a demand for Electronic Adhesives Market as they are used in manufacturing telecom devices. 5G will transmit data ten times faster than 4G and is set to take hold in 2020. This will spark a revolution in many industries such as electronic, energy, medical, automotive, defense, aerospace and others, which will boost the market's growth. 5G will impact the viewing experience for consumer, with its VR & AR which will further boost the demand for consumer electronic industry, which in return will boost the demand for electronic adhesive market.

Electronic Adhesive Market Challenges

Technological Changes & VOC Emission

The market is facing challenges due to technological changes. Shorter leads can damage temperature-delicate components in several applications and to overcome such obstacles electrical components should be assembled after soldering. However, this hampers productivity due to higher costs of production and time consumed in the manufacturing process. Growing concern over the emission of volatile organic compounds (VOCs) is expected to hamper the market growth over the coming years. During the manufacturing of electronics adhesives, VOC is discharged that may pose health and environmental concerns. VOCs are the major contributors to smog and ozone formation at low atmospheric levels.

Emergence of COVID 19

The COVID-19 pandemic continues to unfold everyday with severe impact on people, communities, and businesses. And the Electronic Adhesives Market was no exceptional, as the global production facilities of the electronics, parts have been reduced due to the logistics slowdown and unavailability of the workers. Furthermore, various e-commerce sites had discontinued the delivery of non-essential items which included electronics devices, which affected the electronic industry.

Electronic Adhesive Market Landscape

Technology launches, acquisitions and R&D activities are key strategies adopted by players in the Electronic Adhesives Market. In 2020, the market of electronic adhesives has been consolidated by the top 10 players accounting for xx% of the share. Major players in the Electronic Adhesives Market are BASF SE, Panacol-Elosol GmbH, 3M Co., H.B. Fuller Co., Henkel AG & Co. KGaA, Hitachi, Ltd., Mitsui & Co., Ltd., Bostik, Inc., Chemence Inc., tesa SE, Parker Hannifin Corp., Meridian Adhesives Group, among others.

Acquisitions/Technology Launches

In November 2019, Bostik, Inc., announced it has launched a new range of innovative engineering adhesives Born2Bond™, for bonding applications in automotive, electronics, luxury packaging, and medical devices. With this new launch Bostik will not only expand its product portfolio but also expand it offering to various industries, which will further drive the market's growth.

In September 2020, Meridian Adhesives Group, a leading manufacturer of high-value adhesives technologies has announced that the “Company” would be serving the Electric Vehicles Market and provide its adhesive solution, with this announcement Meridian Adhesives would expand its product offering in automobile industry, which will further derive the market's growth.

Key Market Players:

The Top 5 companies in Electronic Adhesives Market are:

Panacol-Elosol GmbH

3M

H.B. Fuller Company

Henkel AG & Co.KGaA

Parker Hannifin Corp.

#Electronic Adhesives Market Size#Electronic Adhesives Market Trends#Electronic Adhesives Market Growth#Electronic Adhesives Market Forecast#Electronic Adhesives Market Revenue#Electronic Adhesives Market Vendors#Electronic Adhesives Market Share#Electronic Adhesives Market

0 notes

Text

Key Drivers Behind the Growth of the Waterborne Coatings Market

The global waterborne coatings market was valued at USD 57.67 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.6% from 2023 to 2030. This growth is primarily driven by an increase in construction activities worldwide. The surge in construction, fueled by rapid industrialization and urbanization, is expected to elevate the demand for waterborne coatings during the forecast period. There is a notable shift in coating preferences from low or high-volatility organic solvents to completely solvent-free options, which produce fewer emissions. This trend is likely to further boost the demand for waterborne coatings in both residential and commercial applications. Interior and exterior wall paint formulations predominantly use waterborne coatings, often based on acrylate/styrene dispersions. Manufacturers are concentrating on reducing the average binder requirement in these formulations by 8–12%, ensuring that the performance characteristics remain intact. Additionally, alkyd-based waterborne coatings are favored by many interior decorators due to their ease of application, glossy finish, and superior adaptability to climatic variations during application and drying.

The anticipated increase in automobile production capacities, along with innovations in design and aesthetics, is expected to be a significant driver of market growth in automotive applications. The rise in automobile production is projected to be fueled by population growth and increasing per capita disposable income, particularly in the emerging economies of the Asia Pacific and Latin America regions.

Gather more insights about the market drivers, restrains and growth of the Waterborne Coatings Market

Resin Insights

The acrylic resin segment led the market, capturing the largest revenue share of 83.4% in 2022. The rising demand from the infrastructure and automotive sectors, particularly due to the durability and glossy color retention of acrylic coatings under outdoor exposure, is expected to boost the demand for acrylic waterborne coatings. The need for acrylic resin-based coatings is anticipated to increase significantly in the foreseeable future, driven by expanding applications in radiation curing and electrodeposition.

In the transportation sector, there is a growing need for refinishing coatings for aircraft, automobiles, ships, railroads, and trucks, which is likely to enhance the demand for polyurethane (PU) coatings. These coatings are popular due to their properties such as abrasion resistance, toughness, and chemical and weather resistance. Stricter government regulations aimed at reducing volatile organic compound (VOC) emissions, combined with a shift in consumer preferences towards waterborne coatings over solvent-based alternatives, are significant factors propelling product demand. PU coatings are available in various forms, including oil-modified, two-component, moisture-curing, and lacquers. The rising demand for PU coatings across diverse end-use industries, such as electrical coils and automotive manufacturing, is expected to positively impact segment growth.

Furthermore, the increasing demand for ultra-low VOC, low-odor epoxy resin-based coatings in the transportation sector and DIY flooring applications is projected to drive segment growth during the forecast period. Epoxy coatings are known for their strong adhesion and anti-corrosion properties, making them suitable for metal surface primers. These coatings are also extensively used in electrical insulation applications due to their high heat resistance. The rapidly expanding electrical insulation industry is likely to support the growth of the epoxy coatings segment in the coming years.

Order a free sample PDF of the Waterborne Coatings Market Intelligence Study, published by Grand View Research.

#Waterborne Coatings Market#Waterborne Coatings Market Analysis#Waterborne Coatings Market Report#Waterborne Coatings Industry

0 notes

Text

Exploring Market Trends and Opportunities in the Global Epoxy Resins Paints Industry: A Comprehensive Market Research Study

Epoxy Resins Paints Market poised to grow at highest pace owing to rapid industrialization Epoxy resins paints are durable, water and chemical resistant coatings finding wide application across industries like construction, automotive and manufacturing due to their advantages. These paints provide excellent adhesion to non-porous substrates and resistance to humidity, moisture, chemicals and corrosion. They form a protective barrier and are increasingly used for automotive OEM coatings, floor coatings, concrete primers and protective coatings. The global epoxy resins paints market is estimated to be valued at US$ 13.62 Bn in 2024 and is expected to exhibit a CAGR of 5.6% over the forecast period 2024 to 2031 owing to rapid industrialization. The Global epoxy resins paints Market is estimated to be valued at US$ 13.62 Bn in 2024 and is expected to exhibit a CAGR of 5.6% over the forecast period 2024 to 2031. Key players operating in the epoxy resins paints are Momentive Performance Materials, Kukdo Chemical, Huntsman Corporation, The Dow Chemical Company, Atul Ltd, Sika AG, Cytec Industries Incorporation, DuPont, 3M, BASF SE, Aditya Birla Chemicals Ltd, NAMA Chemicals, LEUNA-Harze GmbH, and Spolchemie A.S. Key Takeaways Key players operating in the epoxy resins paints are Momentive Performance Materials, Kukdo Chemical, Huntsman Corporation, The Dow Chemical Company, Atul Ltd, Sika AG, Cytec Industries Incorporation, DuPont, 3M, BASF SE, Aditya Birla Chemicals Ltd, NAMA Chemicals, LEUNA-Harze GmbH, and Spolchemie A.S. The rapidly growing construction industry coupled increasing automobile production is fueling the demand for epoxy resins paints. Technological advancements are focused on developing low volatile organic compound and bio-based epoxy resins paints. The construction industry has been growing at a strong pace backed by rapid urbanization and industrialization in emerging economies of Asia Pacific and Middle East countries. Epoxy resins paints find extensive application in flooring, primers, protective and marine coatings in construction sector. The rapidly growing automobile production driven by rising vehicle ownership particularly in developing countries has increased the uptake of these paints in automotive OEM coatings and auto-refinish paints. Recent technological developments are focused on developing advanced epoxy resins paints with properties like low volatile organic compound (VOC) content, bio-based formulations and UV resistant coatings to suit varied end-use applications. These innovations are aimed at meeting stringent environmental norms along with improving product performance. Market Trends Some of the key trends in the global epoxy resins paints market include shift towards bio-based formulations driven by sustainability concerns and growing demand for low VOC content paints to meet environmental regulations. Another trend gaining momentum is development of UV resistant and high performance protective coatings for infrastructure and industrial applications like pipe coatings, machinery coatings etc. Rapid adoption of powder coatings for industrial use due to their advantages over liquid coatings is another major trend. Market Opportunities Rising investments in infrastructure development across developing nations provide significant growth opportunities. The Indian government's investments of USD 1.4 trillion in infrastructure till 2024 will boost adhesive demand. Another major opportunity lies in developing water-based and environment-friendly epoxy resins paints that can replace solvent-borne varieties to comply with stringent norms.

0 notes

Text

Adhesive Products Business Startup: Key Insights and Advice

The adhesive products sector represents a dynamic industry, riding the wave of global trends like sustainable living, rapid industrialization, and increased focus on infrastructure and construction. With an expansive array of applications spanning from automotive to packaging, and textiles to furniture, adhesive products offer a promising avenue for investors. visite pur website https://entrepreneurblog.in/

This article will explore some of the best manufacturing business ideas in the adhesive product sector, emphasizing why startups should invest in this industry, given the current market size, trends, and future opportunities.

Epoxy Resin Based Primer (Putty):

Reasons to Invest:

High Durability: Epoxy resins provide a hard and durable surface, making them ideal for industrial coatings, flooring, and marine applications.

Growth in Construction: With an increased focus on infrastructure and the construction industry, the demand for high-quality primers, such as epoxy-based ones, is set to rise.

Leather Binder (Resin Based):

Reasons to Invest:

Thriving Leather Industry: The leather industry is booming globally, requiring quality binders for leather processing and finishing.

Sustainability: Resin-based binders are more sustainable than traditional chemical binders, offering eco-friendliness as an added advantage.

Pigment Binders for Textile Printing:

Reasons to Invest:

Fashion Trends: With fashion’s ever-changing dynamics, the demand for unique textile prints is evergreen.

Technical Advancements: Innovations in textile machinery and digital printing necessitate advanced pigment binders.

BOPP Adhesive Tapes:

Reasons to Invest:

Packaging Growth: Biaxially oriented polypropylene (BOPP) tapes are essential for packaging. With e-commerce and retail industries growing, so is the demand for BOPP tapes.

Versatility: These tapes have applications ranging from packaging to stationery.

Pressure Sensitive Adhesives for BOPP Tapes (Acrylic Based):

Reasons to Invest:

Strong Adhesion: Acrylic-based adhesives are renowned for their strong bonding properties, making them a top choice.

Broad Applications: These adhesives are also used in labels, decals, and graphics, expanding their market reach.

Guar Gum:

Reasons to Invest:

Food Industry: Guar gum is a popular thickening agent in the food industry, particularly in bakery products and sauces.

Oil & Gas: It’s used in hydraulic fracturing in the petroleum industry, further increasing its demand.

Adhesive (Fevicol Type):

Reasons to Invest:

Furniture Boom: With a growing real estate industry and urbanization trends, there’s a rise in furniture manufacturing, requiring such adhesives.

Craft and DIY: The craft and DIY sector also heavily rely on such adhesives, ensuring steady demand.

Urea Formaldehyde Resin (Powder):

Reasons to Invest:

Wood Industry: Predominantly used as an adhesive in the wood industry, its demand will grow with the timber and furniture sectors.

Durability: It offers resistance to moisture, making it perfect for plywood and particleboard.

Alkyl Resin from Cotton Seed Oil:

Reasons to Invest:

Green Revolution: Derived from renewable sources, these resins offer a sustainable alternative to synthetic ones.

Diverse Applications: They serve various sectors like paints, inks, and rubber.

Corrugated Carton Boxes Gum Powder (Tamarind Kernel Powder Base):

Reasons to Invest:

Packaging Needs: The increasing need for packaging solutions ensures the demand for corrugated boxes and, subsequently, their adhesive needs.

Natural Base: Being based on tamarind kernel powder, it’s eco-friendly and sustainable.

Market Analysis & Trends

The international adhesives market dimension was valued at USD 50 billion in 2019 and is forecasted to sign up a CAGR of over 5% between 2020 and 2026. The vital chauffeurs consist of:

Sustainability: With global emphasis changing in the direction of lasting items, adhesive manufacturers are working towards environmentally friendly options, leading to ingenious products.

Rapid Industrialization: As markets grow, their sticky needs expand, using opportunities in locations like vehicle, building, and product packaging.

Technological Advancements: With development in chemical research, brand-new adhesive items with much better residential or commercial properties and applications are frequently emerging.

Detailed Market Analysis

As we dig much deeper into the adhesive industry, different elements arise that represent its vastness and capacity.

Global Perspective:

Geographically, the Asia-Pacific region controlled the sticky market in 2019, with China, India, and Japan as the frontrunners. The region’s rise in production tasks, infrastructure development, and raising non reusable earnings are leading to greater usage of glue products. Europe complies with the Asia-Pacific, with Germany being the main contributor as a result of its robust vehicle industry. North America, with the U.S. at its core, likewise provides a substantial share, driven by its sophisticated manufacturing industries and surging construction industry.

Segment Analysis:

Different types of adhesives cater to varied applications:

Reactive & Others: This segment held a dominant share in 2019. Products like epoxies, urethanes, and acrylics fall under this category. They’re pivotal in applications demanding high strength and durability.

Hot Melts: These are gaining traction due to their quick-setting nature. Predominantly used in packaging, bookbinding, and the footwear industry.

Water-Based: These are eco-friendly, catering to the rising demand for sustainable solutions. They have applications in packaging, construction, and woodworking.

Raw Material Analysis:

Synthetic: Derived from petroleum feedstock, synthetic adhesives like vinyl acetate are prominent due to their cost-effectiveness.

Natural: Obtained from organic sources like plants and animals. Products such as starch, dextrin, and casein glues are in this category. The drive towards sustainability is making natural adhesives a focal point of research and innovation.

End-Use Trends:

Packaging: With the e-commerce boom, there’s an undeniable demand for adhesive solutions in packaging. Furthermore, the food and beverage industry requires specialized adhesive solutions.

Construction: Urbanization and infrastructure projects globally ensure that adhesives for tiles, wallpapers, and insulation materials are always in demand.

Automotive: Modern vehicle assembly requires adhesives for various parts, from interiors to the engine assembly.

Emerging Trends:

Bio-Based Adhesives: With environmental concerns, there’s an increasing shift towards bio-based adhesive solutions. Algae, soy protein, and lignin are now being explored as potential adhesive sources.

Smart Adhesives: Research is underway to develop adhesives that can change their stickiness or cure when exposed to particular stimuli, such as light or specific temperatures.

Opportunities and Challenges:

Opportunities:

Green Building Standards: With more countries adopting green building standards, there’s a rising demand for eco-friendly adhesive solutions.

Technological Advancements: Innovations will lead to the discovery of adhesives with better durability, resistance, and applicability.

Challenges:

Volatility in Raw Material Prices: The fluctuating costs of petroleum-based feedstock impact the pricing of synthetic adhesives.

Environmental Concerns: Some adhesive manufacturing processes are pollutant-heavy, drawing criticism and demands for cleaner production methods.

Strategies for Startups in the Adhesive Sector:

Invest in R&D: The adhesive industry thrives on innovation. Investing in research ensures the development of superior products.

Diversification: Tapping into various adhesive segments ensures stability. For instance, if one sector faces a slump, another might be booming.

Eco-Friendly Focus: With the world shifting towards sustainability, developing green adhesive solutions can offer a competitive edge.

Global Outreach: While some regions might face market saturation, others, especially in the developing world, offer untapped potential.

Consumer Awareness: Educating the end-user about the advantages of a particular adhesive can lead to brand loyalty and preference.

Case Studies:

Eco-Friendly Shift:

Company: A European adhesive manufacturer.

Challenge: Facing criticism for its environmentally-unfriendly production processes.

Solution: The Company invested in R&D and shifted to water-based adhesives, reducing its carbon footprint and tapping into the eco-friendly adhesive market.

Innovation-Driven Growth:

Company: An Asian adhesive startup.

Challenge: Competing against established giants in the adhesive industry.

Solution: The startup developed a unique adhesive that could bond dissimilar materials, like glass to wood, effectively. Their niche product ensured they stood out and captured a significant market share.

Understanding the Adhesive Landscape:

The adhesive landscape is considerable, and to navigate it successfully, it is crucial to recognize its details, from historic evolution to future forecasts.

Historical Context:

Adhesives aren’t a contemporary development. Old people utilized all-natural compounds like tree sap, beeswax, and tar as binding agents. Over centuries, this art evolved. The 20th century saw a major shift with the introduction of artificial adhesives. Modern adhesives are the end result of hundreds of years of advancement, from nature-based to laboratory-engineered products.

Advancements in Adhesive Technologies:

Nano-technology in Adhesives:

The mixture of nanotechnology has been advanced. Nanoparticles modify the adhesive’s physical properties, boosting its thermal security, peel strength, and even supplying conductivity. For example, adding silica nanoparticles to epoxy resins can dramatically enhance its mechanical strength.

Structural Adhesives:

These are employed where load-bearing joints are required. Developing from simple binding representatives, modern-day architectural adhesives, especially in fields like automotive and aerospace, are expected to bear significant weights and withstand environmental difficulties.

Economic Factors Impacting the Adhesive Sector:

Economic dynamics globally play a vital role in determining the health of the adhesive industry.

Global Economy: A booming global economy leads to increased manufacturing and construction activities, directly propelling the adhesive market.

Trade Relations: Open trade policies and cordial international relations can significantly boost the adhesive market, especially if manufacturing hubs are involved.

Regional Economic Health: Economic health in areas like the Asia-Pacific can have a disproportionate impact on the adhesive industry due to the concentration of manufacturing units.

Adhesive Manufacturing Process:

To genuinely appreciate the nuances of adhesive production, understanding its manufacturing process is pivotal.

Raw Material Procurement: Depending on the adhesive type, raw materials can range from natural substances like tamarind and guar gum to synthetic elements derived from petroleum.

Synthesis: Raw materials undergo chemical reactions to form adhesive substances. For instance, in the production of epoxy resins, epichlorohydrin reacts with bisphenol-A.

Formulation: Additives, fillers, and other ingredients are introduced to give the adhesive its final properties.

Packaging: The finished product is then packed, ready for distribution.

Regulatory Framework & Environmental Considerations:

The adhesive industry is governed by several regulations, especially due to environmental and health concerns.

Volatile Organic Compounds (VOCs): Many adhesives release VOCs, leading to air pollution. Regulations in many countries limit VOC emissions, pushing companies to develop low-VOC or VOC-free products.

Sustainable Production: Emphasis on sustainable manufacturing processes is leading to the adoption of green technologies in adhesive production.

Challenges in Adhesive Manufacturing:

While the adhesive sector is lucrative, it’s not without challenges.

Environmental Impact: Many adhesive manufacturing processes are non-environmentally friendly. Transitioning to greener methods requires R&D investments.

Raw Material Scarcity: With depleting natural resources, sourcing raw materials, especially for synthetic adhesives, might become challenging.

Importance of Branding & Marketing in the Adhesive Sector:

In a competitive market, branding and marketing become essential.

Branding: Strong branding ensures customer trust and loyalty. Many end-users rely on brand reputation when choosing adhesives, especially for critical applications.

Marketing: Effective marketing strategies ensure that the product reaches its target audience. Digital marketing, given its wide reach, has become particularly crucial.

Case Studies in Innovation:

Sustainable Adhesive Production:

Company: A U.S.-based adhesive manufacturer.

Challenge: Facing backlash for its high environmental footprint.

Solution: The Company shifted to a water-based adhesive manufacturing process, drastically reducing its carbon emissions. This move, apart from being environmentally beneficial, also became a significant marketing point, attracting environmentally-conscious clients.

Overcoming Raw Material Challenges:

Company: A startup in South America.

Challenge: High costs and scarcity of synthetic raw materials.

Solution: The startup turned to local resources, utilizing plant-based materials to produce adhesives. Not only did this bring down costs, but it also resulted in unique adhesive products that stood out in the market.

Emerging Markets & Future Potential:

Areas like Africa and parts of Southeast Asia, while currently not dominant players in the sticky industry, hold considerable possibility. Quick urbanization, paired with raising manufacturing tasks, makes these regions potential future hubs for the glue field. Moreover, with global emphasis on sustainability, there is large capacity in the development and marketing of eco-friendly adhesives. Firms that can innovate and generate environment-friendly adhesive solutions will likely dominate the future market.

Conclusion:

The sticky field, while currently large, is still advancing. It presents myriad chances for those going to innovate and adjust. With sustainability as the brand-new rule, there’s uncharted region waiting to be explored in environment-friendly sticky options.

#project consultancy#business consultant#free business advisor in India#business consulting services#small business consultant#business advisory services near me#business model sample#project consulting firms#top ten consulting firms#big 10 consulting firms

0 notes

Link

0 notes

Text

Automotive Wheel Coatings Market - Major Revenue Gain is Predicted by 2032

The global automotive wheel coatings market is anticipated to reach a valuation of US$ 1,001.4 Mn by the end of 2032. Significant production volume of automotive all over the globe is leading to the high demand for automotive wheels.

It is subsequently pushing the need for automotive wheel coatings to protect and optimize the performance of wheels. The global automotive wheel coatings market is expected to grow at a moderate pace during the forecast period, with a CAGR of 3.1% owing to consistent demand from OEM wheel manufacturers.

Prominent players are investing huge sums in Latin America and South Asia to sign contracts with automotive OEMs for the supply of wheel coatings materials. This is expected to drive the market in the next ten years. Also, due to changing climatic conditions and region-wise weather conditions, wheel coating suppliers deliberately invest in research & development (R&D) activities to develop superior and unique coatings to gain a leading position in the market.

Apart from this, the market for automotive wheel coatings has been significantly influenced by demographic factors, macroeconomic factors, and certain innovation factors. Research & development in the coatings industry, urbanization, high demand for passenger cars, boost in electric vehicle production, and government regulations are also expected to drive the market.

Competitive Landscape: Automotive Wheel Coatings Market

The market for automotive wheel coatings is estimated to be highly consolidated, where key players are expected to account for more than 50% of the market share. Akzo Nobel N.V., Kansai Paint Co. Ltd., PPG Industries Inc., Axalta Coating Systems, BASF SE, Emil Frei Gmbh & Co. KG, Lankwitzer Premium Coatings, TIGER Coatings GmbH & Co. KG, Arsonsisi, and many others are some of the leading manufacturers of automotive wheel coatings.

Key players are primarily focusing on expanding their production capacity to increase their market presence all over the globe. They are also striving to gain maximum traction in the market. Further, top players are investing significantly to expand their existing product portfolios. For instance, in April 2022, PPG completed the acquisition of the powder coatings business of Arsonsisi, a leading industrial coatings company based in Italy.

Get a Sample Copy of the Report @ https://www.futuremarketinsights.com/reports/sample/rep-gb-3454

Automotive Wheel Coatings Market Outlook by Category

By Material Type:

Acrylic Enamel

Acrylic Urethane

Acrylic Lacquer

Zinc Phosphate

Epoxy

Epoxy Polyester

Polyester

Polyurethane

By Substrate:

Aluminum

Steel

Others

By Product Type:

Primers

Base Coat

Clear Coat/Topcoat

By Vehicle Type:

Passenger Cars

LCVs

HCVs

By Sales Channel:

OEMs

Aftersales

More Insights into the Automotive Wheel Coatings Market Report

In its latest report, Future Market Insights offers an unbiased analysis of the global automotive wheel coatings market, providing historical data from 2017 to 2021 and forecast statistics for the period 2022-to 2032. To understand the global market potential, growth, and scope, the market is segmented based on material type, substrate, product type, vehicle type, sales channel, and region.

Get More Information@ https://www.futuremarketinsights.com/reports/automotive-wheel-coating-market

0 notes

Text

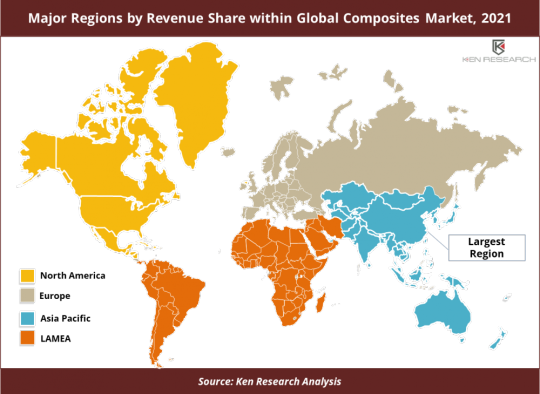

Global Composites Market is expected to record a positive CAGR of ~8% during the forecast period 2022-2028: Ken Research

Buy Now

A composite is created from two or more constituent materials. These constituent materials are combined to produce a substance with characteristics that are distinct from the constituent parts despite having chemical or physical qualities that are noticeably different. Composites are being increasingly adopted in different industries including electrical & electronics, automotive & transportation, wind energy, aerospace & defense, construction & infrastructure, and others.

According to Ken Research Analysis, the Global Composites Market is expected to record a positive CAGR of ~8% during the forecast period (2022-2028) and is expected to reach approximately US$ 120 billion by 2028.

The desirable performance of composites as well as the high adoption of composites in various end-user industries owing to their properties is positively impacting the market growth.

Customers' needs for a wide range of intricately engineered parts, design patterns, and structures are met through the use of composite materials. The product supports several sectors, including wind power, consumer goods, automotive, aerospace, and the maritime sector. Different materials are used in a variety of ways by these businesses. Regulations, consumer demand, cost criteria, and part performance requirements all influence this usage. For instance, there are significant differences between the materials, costs, and process technology used in the aerospace sector and the car industry. Due to their diversity, these materials can satisfy this wide range of demands. For instance, there are resins, a variety of fibers, equipment, process, and finishing options that can be used to fabricate almost any item for any application.

Concerns about improper disposal and recycling of composite products as well as the high production cost of composites limit the market growth.

Composites recycling and disposal raise problems that need to be resolved. One such problem relates to carbon fiber composites used in hexavalent chromium primer-coated end-of-life aircraft structures. Due to the possibility of the hexavalent chromium in these composites seeping into the ground, they may be categorized as hazardous waste and cannot be disposed of on land.

The COVID-19 outbreak had a huge impact on supply chains since key economies had to halt commerce. Additionally, the demand for composites had decreased across a range of end-use industries, including aerospace, automotive, and construction. However, the situation improved in 2021 due to the removal of trade barriers, which restored the market's growth trajectory.

Key Trends by Market Segment

By Fiber Type: The carbon fiber composites segment held the largest Market share in the Global Composites Market in 2021.

Carbon atoms are bonded in parallel crystals to create carbon fiber, which is then combined with other materials to create composites. Due to their beneficial characteristics, including high stiffness, low thermal expansion, good chemical resistance, high-temperature tolerance, and low weight, these fibers are used in industrial and manufacturing applications.

The strength and endurance of these Composites have been improved due to technical improvements, which have expanded their penetration in pipe production applications. The market is expected to be supported throughout the forecast period by rising demand for high-strength materials in the automotive and aerospace sectors.

By Resin Type: The thermoset composites resin type segment held the largest share of the Global Composites Market in 2021.

The significant growth in demand for thermoset composites in sectors of aerospace, transportation, and defense is boosting the market growth. Glass, carbon, and aramid fibers are the usual building blocks of thermoset composite, which is frequently mixed with resins such as epoxies, phenolics, vinyl esters, polyesters, cyanate esters, and polyimides.

By End-User: The automotive & transportation end-user segment held the largest share of the Global Composites Market in 2021.

Over the foreseeable term, this market segment is likely going to continue to lead. The transportation industry benefits from composites since the components are much lighter in weight, increasing fuel economy.

It is anticipated that rising consumer and industry demand for high-tech electronics would increase demand for composite materials. Terminal boxes, electrical enclosures, lamp housings, sockets, plugs, and parts for the distribution of energy are some of the electrical and electronics applications for composites that are most frequently used.

By Manufacturing Process: The layup process segment held the largest share of the Global Composites Market in 2021.

The layup method dominated the market and generated a sizeable portion of revenue when it came to the production of composites. Over the course of the forecast period, rising production of boats, wind turbine blades, and architectural moldings are anticipated to propel the growth of the layup process sector in the worldwide composites market.

Over the course of the projection period, rising output in the automotive and marine industries is anticipated to provide growth chances for the filament winding process. Golf club shafts, car drive shafts, tiny aircraft fuselages, spaceship structures, pressure vessels like firefighter oxygen canisters, and other products have all been made possible by improvements in the filament winding process.

Request for Sample Report @ https://www.kenresearch.com/sample-report.php?Frmdetails=NTk2MTA5

By Geography: Asia Pacific accounted for the largest market share in 2021 within the total Global Composites Market.

Historically, Japan, North America, and Europe dominated the glass fiber and carbon fiber composites market. However, there has been a noticeable trend in recent years toward the developing economies in Asia Pacific and the rest of the world.

For instance, the significant demand for low-cost carriers has raised the market for glass fiber and carbon fiber composites in the aircraft, wind energy, and transportation sectors in rising nations like India, Brazil, and China. China, whose rapid industrialization is anticipated to meet the growth in demand, has started several research projects involving glass fiber and carbon fiber composites.

Competitive Landscape

The Global Composites Market is highly competitive with ~500 players which include globally diversified players, regional players as well as a large number of country-niche players.

Large global players hold the highest market share of 45% which is followed by the regional players holding a 30% share. Some of the major players in the market include Huntsman Corporation LLC, SGL Group, Teijin Ltd., CooperVision, DuPont, Owens Corning, Toray Industries, Inc., Mitsubishi Chemical Holdings Corporation, Solvay, Exel Group, DOW, and others.

Recent Developments Related to Major and Emerging Companies

In September 2019, Solvay, at its USA facility in Anaheim, California, increased its capacity for thermoplastic composites by adding a new production line for meeting the strong demand growth from aerospace customers for this high-performance material and Solvay's proprietary and distinctive technology.

In July 2021, Hexcel, a leader in advanced composites technology, reported that a lightweight camera drone it built utilizing Hexcel HexPly carbon fiber prepregs completed its first flight. A group of students from the University of Applied Sciences Upper Austria in Wels created the composite drone using components provided by Hexcel Neumarkt in Austria.

In September 2019, the acquisition of Ashland Global Holdings Inc.'s composites business by INEOS Enterprises had been announced. A BDO office in Germany is also part of the acquisition. The companies involved in the transaction generate more than US$1.1 billion in annual sales. Over 19 locations in Europe, North and South America, Asia, and the Middle East, have 1,250 employees.

Key Topics Covered in the Report

Snapshot of the Global Composites Market

Industry Value Chain and Ecosystem Analysis

Market size and Segmentation of the Global Composites Market

Historic Growth of the Overall Global Composites Market and Segments

Competition Scenario of the Market and Key Developments of Competitors

Porter’s 5 Forces Analysis of the Global Composites Market

Overview, Product Offerings, and SWOT Analysis of Key Competitors

COVID-19 Impact on the Overall Global Composites Market

Future Market Forecast and Growth Rates of the Total Global Composites Market and by Segments

Market Size of Fiber Type / End User Segments with Historical CAGR and Future Forecasts

Analysis of the Composites Market in Major Regions

Major Production / Consumption Hubs in the Major Regions

Major Country-wise Historic and Future Market Growth Rates of the Total Market and Segments

Overview of Notable Emerging Competitor Companies within Each Major Country

For more insights on the market intelligence, refer to the link below: –

3 Key Insights on US$ 120 Bn Opportunity in the Global Composites Market: Ken Research

0 notes

Text

Flexible Epoxy Resin Market Revenue Share Analysis, Region & Country Forecast, 2022–2030

The flexible epoxy resin market is all set to explore its potential in various fields. Its percolation in paints & coatings, automotive, and in aerospace is unprecedented. In automobile sector, flexible epoxy resin finds use in underbody guards, mud-flaps, bumpers, ducting and sheeting, and impact panels. As a corrosion resistant, the product is getting traction from the construction sector which is witnessing significant growth due to urbanization. In addition, the flexible epoxy resin market is enjoying extensive support from verticals as a component used in electrical & electronic laminates, water borne coatings, flooring and paving, and powder coatings.

The flexible epoxy resin (FER) market was estimated at USD 540.5 million in 2020 and projected to reach USD 765.3 million by 2030, at a CAGR of 6.8% during the forecast period (2021-2030). The global flexible epoxy resin market can record substantial growth during the forecast period (2021-2030) due to its durability and moisture & chemical resistance among other features. Market Research Future’s (MRFR’s) report on the same market contains figurative analysis of the segments, detailed study on growth influencers, and research on the competitive landscape for a holistic understanding of the entire market.

Segmentation:

The global flexible epoxy resin market can be segmented by type, application, and end-use industry. This would ease the understanding of the market during the forecast period.

Type-wise segmentation of the global flexible epoxy resin market includes rubber modified, urethane modified, and dimer acid.

Application-based segmentation of the flexible epoxy resin market comprises adhesives, semiconductors, primer, composites, electrical laminates, and others.

Based on the end-user industry, the flexible epoxy resin market can be segmented into automotive, electrical & electronics, paints & coatings, military & defense, construction, and others.

Regional Analysis:

Regionally, the flexible epoxy resin market is segmented into five regions namely Asia Pacific (APAC), North America, Europe, Latin America (LATAM), and the Middle East & Africa (MEA) to provide a holistic view of the market.

The APAC market is in-charge of the global market. The region has several developing economies that are revamping their end-user industries such as paints & coatings, automotive, and construction. At the same time, regional market invasion by global behemoths can be seen as a positive sign. And as its acolyte, the flexible epoxy resin market can garner profits.

North America is the second largest flexible epoxy resin market. The credit can be attributed to the high demand generated by the military & defence and automotive industries.

Europe’s market is also gaining more from the robust automotive sector. But the market can experience slight slag owing to the preventive norms set by the governments.

Browse Complete Report @ https://www.marketresearchfuture.com/reports/flexible-epoxy-resin-market-6009

Competitive Landscape:

Major manufacturers in the global flexible epoxy resin market are Hexion (U.S.), Kukdo Chemical Co., Ltd. (South Korea), Olin Corporation (U.S.), Huntsman International LLC (U.S.), DIC CORPORATION (Japan), Aditya Birla Chemicals (India), Emerald Performance Materials (U.S.), Cardolite (U.S.), Atul Ltd. (India), INTERTRONICS (the U.K.), EPOXONIC (Germany), Spolchemie (Czech Republic), Conren Ltd. (U.K), Mereco Technologies (U.S.), and Resoltech (France).

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Raw Research Reports (3R), Continuous-Feed Research (CFR), and Market Research & Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

In order to stay updated with technology and work process of the industry, MRFR often plans & conducts meet with the industry experts and industrial visits for its research analyst members.

Contact:

Market Research Future®

99 Hudson Street,5Th Floor

New York, New York 10013

United States of America

Phone: +1 628 258 0071(US) +44 2035 002 764(UK)

Email: [email protected]

Website: https://www.marketresearchfuture.com

#Flexible Epoxy Resin Market#Global Flexible Epoxy Resin Market#Flexible Epoxy Resin Industry#Flexible Epoxy Resin Market Size

0 notes

Text

Global Automotive Coatings Market Industry Trends and Forecast to 2029

Data Bridge Market Research analyses that the automotive coatings market was valued at USD 16.24 billion in 2021 and will reach USD 28.26 billion by the year 2029, at a CAGR of 7.17% during the forecast period of 2022 to 2029.

Global Automotive Coatings Market Scope

The automotive coatings market is segmented on the basis of technology type, product type, application, end-use and resin. The growth amongst these segments will help you analyze meagre growth segments in the industries and provide the users with a valuable market overview and market insights to help them make strategic decisions for identifying core market applications.

Technology type

Water-borne

Solvent-borne

Powder coating

UV-cured

Others

On the basis of technology type, automotive coatings market is segmented into water-borne, solvent-borne, powder coating, UV-cured and others.

Product type

Electrocoat

Primer

Learcoat

Basecoat

Based on product type, automotive coatings market is segmented into electrocoat, primer, clearcoat and basecoat.

Application

Plastic

Metal

Based on application, automotive coatings market is segmented into plastic and metal.

End-User

Commercial OEM

Automotive refinish

Light vehicle OEM

On the basis of end-use, automotive coatings market is segmented into commercial OEM, automotive refinish and light vehicle OEM.

Resin

Epoxy

Polyurethane

Acrylic

Others

On the basis of resin, automotive coatings market is segmented into epoxy, polyurethane, acrylic and others.

Get the sample copy of the report here:

Global Automotive Coatings Market Analysis and Size

Automotive coatings are water-resistant dry coatings applied to various parts of a vehicle for functional, decorative, and protective purposes. Such coatings possess important properties such as good elastomeric finish and greater surface hardness. They serve different purposes for different substrates such as plastics, composites, and metal.

Data Bridge Market Research analyses that the automotive coatings market was valued at USD 16.24 billion in 2021 and will reach USD 28.26 billion by the year 2029, at a CAGR of 7.17% during the forecast period of 2022 to 2029.

Automotive Coatings Market Regional Analysis/Insights

The automotive coatings market is analyzed and market size insights and trends are provided by country, technology type, product type, application, end-use and resin as referenced above.

The countries covered in the automotive coatings market report are the U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

Automotive Coatings Market Share Analysis

The automotive coatings market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies' focus related to automotive coatings market.

Major players operating in the automotive coatings market

Major players operating in the automotive coatings market are

BASF SE (Germany),

Axalta Coating Systems (U.S.),

PPG Industries, Inc. (U.S.),

Kansai Paint Co., Ltd (Japan),

Nippon Paint Holdings Co., Ltd. (Japan),

The Valspar Corporation (U.S.)

KCC Corporation (South Korea),

Sherwin-Williams (U.S.),

AkzoNobel (Netherlands),

Jotun A/S (Norway)

COVID-19 Impact on Automotive Coatings Market

COVID-19 impacted various manufacturing industries in the year 2020-2021 as it led to the closure of workplaces, disruption of supply chains, and restrictions on transportation and it also very badly impacted the market of automotive coatings because of the covid-19 and lockdown all the shopping places and workshops are closed and it hindered the market. The cases of COVID–19 and decrease in sales of automobiles has limit the market growth. Major industry players are rapidly entering into long term contracts with suppliers so as to attempt to retain their customer base.

Get Full Access of Report @

MAJOR TOC OF THE REPORT

Chapter One: Introduction

Chapter Two: Market Segmentation

Chapter Three: Market Overview

Chapter Four: Executive Summary

Chapter Five: Premium Insights

Chapter Six: automotive coatings market

Get TOC Details:

Browse Related Reports@

Global Methylene Chloride Market – Industry Trends and Forecast to 2029

Global Waste Heat Recovery System Market – Industry Trends and Forecast to 2027

Global Shotcrete/Sprayed Concrete Market – Industry Trends and Forecast to 2027

Global High-Performance Insulation Market – Industry Trends and Forecast to 2027

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

#utomotive Coatings MarketAutomotive refinish coatings market#Automotive oem coatings market#Automotive coatings industry#Automotive coatings market share

0 notes

Link

The Middle East and Africa Architectural Coatings Market is supposed to observe market development at a pace of 3.5% in the gauge time of 2021 to 2028. Information Bridge Market Research report on compositional coatings market gives examination and bits of knowledge with respect to the different elements expected to be predominant all through the estimate period while giving their effects available's development.

0 notes

Text

Composite Coatings Market Size Forecast to Reach Us$1,764.7 Million by 2026

Composite Coatings market size is forecast to reach US$1,764.7 million by 2026, after growing at a CAGR of 7.2% during 2021-2026. Composite coatings are widely used in different industries which protect from water, corrosion, hot gas, UV Protection, thermal protection and heat radiation. The Composite Coatings are made of two or more substances that give effective protection from corrosion. These coatings are the combination of different resins types’ namely polyester, polyamide, epoxy which give excellent shield properties to increase the usage of coatings. Some of the prominent trends that the market is seeing are raising demand for greater finishing and protection. It consists of layers such as base coat, topcoat, primer, and adhesive substrate. These layers protect the substrate from getting damaged and give decorative color to end-use items. Laser melt injection is one of the techniques for the production of the protective layer of metals in the form of coatings. The rapid growth of the construction industry has increased the demand for composite coatings. Furthermore, the flourishing automotive and aerospace industry is also expected to drive the composite coatings industry substantially during the forecast period.

Composite Coatings Market COVID-19 Impact

The Covid-19 pandemic has impacted the global economy directly affecting the manufacturer's supply chain across the globe and shutdown production facilities to minimize the risk of virus spread. Currently, due to the COVID-19 pandemic, the core industries such as construction, aerospace, automotive and energy industry has highly impacted. Due to social distancing policy, most of the manufacturing plants of aircraft and automobiles were shut down, which declined the production of commercial aircraft and vehicles. There has been a sharped decline in the revenue of the different industries. Many industries like food and beverages, tours, and travel have been shut completely due to pandemics. The covid-19 also affected the construction industry badly due to inaccessibility of raw material, shortage of laborers which has decreased the demand for seal coats. The government and private sectors are taking necessary action and working for the growth of development of different industries which results in the boom of the composite coatings market as well.

Composite Coatings Market Segment Analysis – By Resin Type

One of the major segments of the composite coating is the resin which is used as organic material in the production of composite coatings. To obtain high resistant composites, the polymer is mixed with different fibers. These composites coatings are widely used in the automobile, aerospace, and defense industry, wind turbines, construction by providing lightweight, anti-corrosion, and thermal protection features to the end-use products. The thermoplastic segment is expected to register a high CAGR of 8.1% during the forecast period. Thermoplastic resins are widely used in different industries owing to the flexibility of recycling. The Carbon Fiber-Resin Composite Market is growing widely and is mainly used in Aerospace & Defence and is expected to grow in the forecast period. The Thermoplastic resins are preferred to thermoset resign as it is easily mixed with any other component and it is re-melted easily.

Request for Sample Report @ https://www.industryarc.com/pdfdownload.php?id=500178

Report Price: $4500 (Single User License)

Composite Coatings Market Segment Analysis – By Technology

The brazing segment is expected to hold a significant share in the global market and is also expected to grow at a CAGR of 7.3% between 2021-2026. The brazing technique helps the coating to give good toughness and is extensively used for giving higher resistance to coating. These Coatings provide waterproofing and corrosion protection. The brazing technique also protects from UV radiation, Scratch, excessive heat, and fire. The lightweight composite coatings market is being increased and is mainly used in the Aerospace, Automobile, and defense industry and is expected to grow in the coming years.

Composite Coatings Market Segment Analysis – By Substrate

The metal substrate segment accounted for the largest share of more than 35% in the composite coatings market in 2020 and is estimated to grow at a significant rate during the forecast period 2021-2026. It is widely used in automotive, electronics, energy, aerospace, and others to increase durability and productivity. It gives high resistance and anti-corrosion to coating by enhancing the visual appearance of a metallic part. The non-metal substrate segment is expected is grow at a high CAGR during the forecast period. The increasing growth rate is mainly due to the use of powder coating on a non-metallic substrates such as wood, plastics, glass, MDF, etc. Composite coatings act as a protective layer to different substrates owing to attributes such as consistency, precision, and uniform coating thickness.

Composite Coatings Market Segment Analysis – By Coating Type

The composite coating can be applied in different ways like brushing, rolling, air spraying. The brushing segment accounted for the largest share of more than 30% in the composite coatings market in 2020 and is estimated to grow at a significant rate during the forecast period. The brushing technique is mostly preferred by the manufacturers as it is easy to use and can be applied on a smaller substrate. The rolling segment is also expected to hold a significant share in the global market. Rolling coating is faster than brushing and is mainly used in construction industries. Furthermore, advanced techniques such as electroless, electrochemical plating are being used for better output.

Composite Coatings Market Segment Analysis – By End-Use Industry

The aerospace & defense segment held the largest share in the Composite Coatings market in 2020 and is growing at a CAGR of 7.9% during 2021-2026. Composite Coatings are used because of their beneficial properties for components that are subjected to high resistance in the aerospace and defense sector. Composite Coatings are used in aircraft components to provide durability, lightweight strength, and stiffness, thermal and fire protection. In the forecast period, the worldwide aerospace and defense sector is expected to show strong growth. For instance, according to Boeing, the global aerospace and defense market 2020-2029 will be at US$2.6 trillion over the next decade. The United States represents nearly 60% of the total market in the world. In many regions, such as Asia-Pacific, the Middle East, and Africa, stable GDP growth, relatively strong passenger demand, and lower commodity prices are driving the growth of the aerospace industry. The Construction industry is also expected to grow in the coming years in the Asia Pacific and Central Asia region due to the current investment plans in infrastructure structure.

Composite Coatings Market Segment Analysis – By Geography

North America region accounted for a significant share of more than 24% in the composite coatings market in 2020 and is estimated to grow at a significant rate during the forecast period. The accelerating aerospace & defense industry in the region is driving the market growth. The increasing population and per capita income are boosting the aerospace industry in the region. According to Boeing Commercial Market Outlook 2020-2039, the Commercial airplanes Economic Growth (GDP) is 4.3%, Airline Fleet Growth is 4.4%, aircraft deliveries is 8,600 over the next 20 years. According to Boeing's 2020 Commercial Market Outlook (CMO), Southeast Asian passenger traffic will rise at a rate of 5.7 percent per year until 2039. Thus, with the flourishing aerospace industry, there will be an upsurge in the demand for aerospace components, which is anticipated to drive the Composite Coatings market in the Asia-Pacific region. The automobile industry also holds a vital share of the composite coatings market due to lightweight vehicle and composite material applications for vehicle fabrication.

Composite Coatings Market Drivers

Growing demand from Automotive Industry

The Composite Coatings are becoming more popular in the automobile sector due to their excellent strength and decorative color. Composite Coatings are utilized in a variety of applications in the automobile industry, including Wheel, Heavy Duty Equipment, others transportation. China is the world's largest vehicle market, according to the International Trade Administration (ITA), and the Chinese government expects automobile manufacturing to reach 35 million by 2025. According to the Organization International des Constructeurs d'Automobiles (OICA), Africa produced 776,967 passenger cars in 2018, which increased by 1.3 percent to 787,287 in 2019. According to Invest in India, passenger car sales climbed by 2.70 percent, two-wheeler sales climbed by 4.86 percent, and three-wheeler sales climbed by 10.27 percent in FY 2018-19 compared to FY 2017-18. Thus, increasing automation production will require more automotive components, which will act as a driver for the Composite Coatings market during the forecast period.

Flourishing Construction Sector

The Asia-Pacific construction sector is the largest in the world and is growing due to the rising population. Increasing infrastructure construction activities and the foreign investments from the European Union into the cost-effective market of China have further fuelled the expansion of the construction sector. China’s construction industry developed rapidly in the past years as the central government focused on infrastructure investment for economic growth. The restrictions on foreign investment in land development and construction and operation of large theme parks have also been raised. The growth in the infrastructure and oil & gas sectors is expected to boost the composite coatings market in India. The Construction industry of Asia Pacific has been growing constantly due to urbanization and the government has launched many projects supporting this. The Construction Industry of India is expected to reach $1.4 Tn by 2025 with an investment of 24% on renewable energy, 19% on roads & highways, 16% on urban infrastructure, and 13% on railways with 2nd highest FDI investment in 2000-2020. The usage of polypropylene and carbon resin in industrial and construction sectors is growing and boosting the demand for construction composite coatings in the forecast period. Thus, it is anticipated that with the flourishing Construction industry, there will be an upsurge in the demand for composite, which will subsequently drive the Composite Coatings market growth during the forecast period.

Inquiry Before Buying @ https://www.industryarc.com/reports/request-quote?id=500178

Composite Coatings Market Challenges

Higher Price of Composites

The cost of Composite Coatings is much higher. The reason behind this is its production cost, while producing composite coatings, the machinery and the equipment which are used are tagged with higher expense, also, these machinery require high maintenance. Owing to this factor, the product of Composite Coatings comes with a higher price as compared to its alternative materials, which tends to constrain the growth of the market. In addition, even if the Composite Coatings provides better results, the customer usually prefers the less cost. Such factors have become the major challenge of Composite Coatings in terms of consumption, which constrains the growth of the market.

Composite Coatings Market Landscape

Technology launches, acquisitions, and R&D activities are key strategies adopted by players in the Composite Coatings market. Composite Coatings market top companies are A.W. Chesterton Co., Zircotec, PPG Industries, Inc, Axalta, Mader Group, A.W. Chesterton Company, K C Jones Plating Company, Om Sangyo Co. Ltd, Endura Coatings, Twin City Plating, Aztron Technologies LLC, Nickel Composite Coating Inc, and Endura Coatings.

Acquisitions/Technology Launches

In July 2021,ODG Composite Llc(Saginaw, Texas, U.S.) has launched Element Xtreme Coatings for mold coating designed for exterior durability, flexibility and adhesion when applied to infused, epoxy-based composite parts. The traditional gel coats can account for 15-25% of the total part weight. Element Xtreme, sprayed directly into the mold before infusion and cure to save weight up to 50% compared to gel coats. Less coating is required due to the hardness of Element Xtreme.

In March 2021, Pronexos(Tonex®) has launched a new composite coating for CFRP rollers that will provide a cost-effective solution for roller application designed to meet specific needs of the printing & packaging, converting, and non-woven markets

Key Takeaways

Asia-Pacific dominates the Composite Coatings market, owing to the increasing construction industry in the region with the growing demand for infrastructure is expected to boost the market growth in this region.

The increased automotive demand in Asia-Pacific has encouraged market growth in this region and can also be attributed to improved foreign policies in India and China due to which will increase in composite coatings manufacturers in this region.

The oil & gas industry uses composite coatings in different segments of refineries. The US country is developing the shale gas infrastructure helped in increasing the composite coating market.

North America is growing very fast in the composite coating market. The major factors that are helping in its growth are the aerospace and automobile industries. The latest technology and features of coatings helping these industries to give unique qualities, consistency, UV protection, scratch-free, efficiency which reduce maintenance among others.

Related Reports:

A. Automotive OEM Coatings Market

https://www.industryarc.com/Report/11697/automotive-oem-coatings-market.html

B. Decorative Coating Market

https://www.industryarc.com/Report/11716/decorative-coating-market.html

For more Chemicals and Materials Market related reports, please click here

0 notes

Link

0 notes

Text

Global Flat Glass Coatings Market Revenue, Trends, Growth Factors, Region and Country Analysis & Forecast To 2026

The Global Flat Glass Coatings Market is estimated to forecast to reach USD 5.98 Billion by 2026, according to a new report by Reports and Data. The coating on the flat glass is done to add special features to the glass products such as water and dirt retardation, increased durability, self-cleaning, corrosion resistance, and energy efficiency, among other things. Increase in demand for decorative products is also anticipated to boost the market for Global Flat Glass Coatings. Demand for decorative mirrors is anticipated to increase in sectors such as architecture, beauty and cosmetics, and other applications. The rise in the number of architectural structures is also expected to fuel the market for Global Flat Glass Coatings. High disposable income and changes in the standard of living are fueling market growth.

Get a sample of the report @ https://www.reportsanddata.com/sample-enquiry-form/1662

Prominent players analyzed in the report are :

Arkema Inc., Ferro Corporation, Nanotech Coatings, Fenzi Spa, Vitro S.A.B. De C.V, Hesse Gmbh & Co. Kg, Nippon Paint Holdings Co., Ltd, Yantai Jialong Nano Industry Co., Ltd, 3M, Unelko Corporation, and The Sherwin-Williams Company, among others.

Further key findings from the report suggest:

Water-based coatings held the largest market share of 37.1% in the year 2018. This type of coating takes a longer period to dry up but is cheap and is used by several commercial and building sectors that wants to minimize cost.

Polyurethane resin provides long term high-performance coating when applied over intermediate and primer coats. It is used in solar panels, architectural systems, and greenhouses. It held a market share of 33.4% during the forecast period.

Epoxy coatings provide a tough, protective coating with excellent hardness. It is used as anti-corrosion, mostly in industrial and automotive applications. It is forecasted to hold a market share of 21.9% in the year 2026.

Automotive and transportation is forecasted to grow with a CAGR of 21.5% during the forecast period. The growth of Global Flat Glass Coatings in this sector is promising, as the industry provides a plethora of opportunities. The development of innovative solutions due to the evolving consumer needs and rising demand, rapid transformation in vehicle design and technologies with intense competition will impact the market for Global Flat Glass Coatings positively.

Asia Pacific is forecasted to hold the largest market share of 34.1% in the year 2026. China and India are expected to constitute a prominent market share in the coming years. Expansion of the automotive sector, rapid adoption of solar panels in the region, and investment in infrastructure are fuelling the market for Global Flat Glass Coatings in the region.

Download Summary: https://www.reportsanddata.com/download-summary-form/1662

Market Insights:

Rising global energy demand, increasing regulatory & environmental pressure and highly volatile oil & gas prices have put great "deal" to other alternative energy sources. There is increased awareness and commitments across firms regarding "Green" energy sources. The demand for green has been driven by environmental pollution caused by conventional energy sources. The energy industry is largely controlled by utilities sector and government in most of the emerging nations like BRIC nations .However, dynamics are drastically changing driven by new policy changes, relaxing the FDI norms in the sector, increased privatization, new capital investments of power projects by both public & private, smart grid to better manage services & reduce transmission losses, use of smart metering and and growing electricity demand.

To know more about the report @ https://www.reportsanddata.com/report-detail/flat-glass-coatings-market

Resin Outlook

Polyurethane

Epoxy

Acrylic

Others

Applications Outlook

Solar Power

Architectural

Automotive & Transportation

Mirror

Others

Regional analysis covers the following key regions:

North America (U.S.A., Canada, Mexico)

Europe (U.K., Italy, Germany, France, Rest of Europe)

Asia Pacific (India, Japan, China, South Korea, Australia, Rest of APAC)

Latin America (Chile, Brazil, Argentina, Rest of Latin America)