#epoxy encapsulant

Explore tagged Tumblr posts

Text

Encapsulants Market: Global Industry Size, Share, Regional Outlook, Segmentation and Opportunity Analysis

Encapsulants are materials that are used to shield and insulate semiconductor devices. They are typically applied in the form of a liquid or paste and cured to form a protective layer around the semiconductor. Encapsulants are used to protect semiconductors from damage caused by environmental factors such as moisture, chemicals, or dust. They also provide electrical insulation and reduce the…

View On WordPress

#Covid 19 Impact on Encapsulants Market#electronic potting#electronic potting epoxy#electronic potting silicone#encapsulant solar panel#Encapsulants Industry#Encapsulants Market#Encapsulants Market Analysis#Encapsulants Market Forecast#Encapsulants Market Growth#Encapsulants Market Outlook#Encapsulants Market Research#Encapsulants Market Revenue#Encapsulants Market Share#Encapsulants Market Size#Encapsulants Market Trends#epoxy encapsulant#Europe Encapsulants Market#fiberlock mold encapsulant#glob top encapsulant#silicone encapsulant#solar cell encapsulant#thermally conductive encapsulant#UK Encapsulants Market#US Encapsulants Market

1 note

·

View note

Text

Epoxy Encapsulation for Superior Durability

Looking for advanced epoxy encapsulation solutions? MB Enterprises provides high-quality epoxy resin, ideal for protecting electrical components and materials from environmental factors. Our resins are engineered for superior durability and reliable performance, making them the preferred choice for industries requiring precision encapsulation.

With MB Enterprises, experience the benefits of epoxy encapsulation designed to meet industrial standards. Partner with us to ensure your projects are secure and long-lasting with cutting-edge epoxy solutions tailored to your needs.

#Epoxy Encapsulation#Epoxy for Encapsulation#Epoxy Encapsulation for Electrical Material#Advanced Resin Material

0 notes

Text

Claybridge - (pre-) Fuzzmaster

"... indeed a PRE-Fuzzmaster, Claybridge Sound Systems Fuzz Box! Everything was matching up: the two controls, the 15ft lead (or output cable), the sticker on the side that read the earliest name of the company; it was all there. ...

two major details jumped out as being definitive proof of its validity: A. The small white knobs used on this "prototype" were also found on a legitimate v1 Fuzzmaster, in addition to appearing on the original Fuzzmaster ads! B. The same label-maker seemed to be used on the MKIV Fuzzmasters!

... the circuit is completely encapsulated in an opaque epoxy resin. This is not unlike the infamous "brick" inside of an Ampeg Scrambler, and also not any less of a kick in the stomach for pedal nerds like myself. That initial disappointment aside, what is notable about the guts is that the enclosure seems entirely too small to hold a true Fuzzmaster circuit (which is essentially a 2 transistor fuzz that's smashing a treble booster). So even though this pedal matches most of the details described in the May 16th ad, I can't see how it would be possible to fit both the "improved" fuzz circuit and the "inbuilt treble boost" into such a tiny space. The other thing to note are the components we can see, like the two resistors and that big yellow cap hiding below the wires. Including the pots, jack and switch, everything matches up pretty well with a 1966 release. So, let's see how it sounds. ... [long fuzzologic description of the pedals sound, read here] ... No joke, and hyperbole aside, this is one of the best fuzz pedals I have ever heard. "

cred: tonemachinesblog.com

30 notes

·

View notes

Note

re: wooden bathtubs, there's a couple ways you can make wooden vessels watertight & protect the wood itself from the water (two different things!). none are 100% effective & eventually the wood will decay. easiest modern way to deal w/ both problems simultaneously is to encapsulate the wood in petroleum-based plastic of some kind (polyurethane varnish, epoxy resin), which basically removes the wood from the equation altogether except as a structural member (until the plastic fails from UV exposure, wear, stress, etc). you can of course also completely coat the wood in something like tar or paint, which act similarly, but then you lose the natural wood look, so we'll put those options aside.

other options are generally going to involve separating the goals of "protect wood from water" and "seal container", and will rely on the properties of the wood itself. when wood is wet, it absorbs water, which causes the fibers to swell. if a piece of wood is already closely pressed against other pieces of wood on both sides before getting wet, that swelling will make the seam VERY tight - almost perfectly watertight. (of course, this swelling also induces warping & distortion into the wood depending on the pattern of the grain, which needs to be planned for so the pieces of wood don't push each other out of alignment.)

however, most wood doesn't like being wet all the time and will start to rot pretty quickly, so you need to pick a kind of wood that won't do that, at least not on the timescale you're planning. depending on the kind of liquid you're planning on putting into the vessel (salt vs fresh water, different concentrations of alcohol, different acidities/alkalinities, amount of UV exposure, temperature, oxygen exposure), different woods do better or worse. for example, there are oaken foundation piers continually submerged in wet boggy soil in england that are close to a thousand years old. willow i believe is supposed to do well with long-term water exposure (think of the riverbank environments they normally grow in). cedar in particular is naturally permeated with lots of resins & oils that make it very resistant to rot - i would guess that the redder of the wooden baths in that picture is cedar.

also, vessels with continual water exposure usually do better at being watertight than ones that dry out & are refilled - when they dry out, the wood shrinks and the seams literally open up, causing leaks until they rehydrate.

this is so interesting and im in awe and i love you for giving such a detailed answer to my impromptu question

#I LOVE LEARNING NEW STUFF#when ppl share their knowledge with me im immediately in awe#caterjunes#gray answers

2 notes

·

View notes

Text

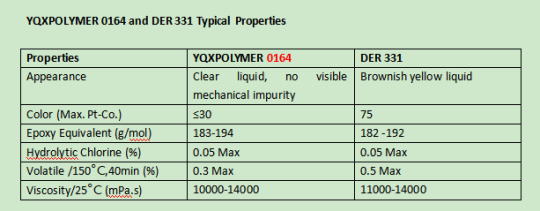

YQXPOLYMER 0164 as An Alternative of DER 331, was Launched into International Market

YQXPOLYMER Epoxy Resin 0164 is a liquid resin manufactured from bisphenol-A and epichlorohydrin. It is recognized as a standard from which many variations have been developed.

YQXPOLYMER 0164 Key Properties

High bonding strength, wide application.

Mild construction conditions, convenient for operation.

Multiple manufacturing processes, meeting various customer requirements.

Packaging and Storage

Packing: Barrels, tanks, or customization.

Storage: Under certain circumstances, such as low temperature, this product can crystallize after lengthy storage, this can be reversed by warming up to 60-70 °C while stimming. The product should be stored in a cool and dry place in its original closed packaging, and not be stored exposed to direct sunlight.

YQXPOLYMER 0164 exhibits the same performance with DER 331, which is suitable for use in applications such as: adhesives, filament winding, casting and tooling, civil engineering, composites, automotive coatings, can coating, oil coating, marine & protective coatings, potting and Encapsulation, etc.

Here is a parameters comparison of the two products:

YQXPOLYMER 0164 and DER 331 Typical Properties

From the chart comparison, it can be seen that YQXPOLYMER 0164 and DER 331 have some identical or similar parameters. In addition to better color transparency than DER 331, YQXPOLYMER 0164 has some other advantages, such as highly cost-effective, short lead time, in-time after-sales service, even OEM service.

YQXPOLYMER is looking for partners, distributors of its epoxy resins products globally.

About YQXPOLYMER

YQXPOLYMER is a leading manufacturer of Epoxy Resin, PBT, Polycarbonate and other chemicals and comprehensive polymer applications provider.

More information or free samples or price quotations, please contact us via email: [email protected]��, or voice to us at: +86-28-8411-1861.

#epoxy resin#YQXPOLYMER 0164#DER 331#DER 331 resin#epoxy adhesive#epoxy coating#epoxy resin manufacturer

2 notes

·

View notes

Text

Me, talking to a guy: "wanna see my Beetle?"

I reach into my purse and pull out a dead beetle that has been encapsulated in epoxy resin

"I got her at a flea market for $3"

3 notes

·

View notes

Text

From Liquid to Luminous: Captivating Artistry with Epoxy Resin

In recent years, the world of art has witnessed a mesmerizing transformation with the advent of epoxy resin. What was once limited to industrial applications, such as epoxy flooring, has now evolved into an extraordinary artistic medium. Epoxy resin art has gained immense popularity due to its versatility, vibrant colors, and captivating luminosity. Artists and enthusiasts alike are embracing this unique medium to create stunning masterpieces that defy traditional artistic boundaries. In this blog, we will explore the fascinating world of epoxy resin art, its remarkable properties, and the boundless possibilities it offers to unleash one's creativity.

The Magic of Epoxy Resin:

Epoxy resin is a two-part liquid material composed of epoxy resin and a hardener. When combined, they undergo a chemical reaction that transforms the mixture into a solid, durable, and glossy material. One of the most remarkable properties of epoxy resin is its ability to capture and reflect light, creating a luminous and ethereal effect. This characteristic, along with its self-leveling nature, makes it an ideal medium for creating captivating art.

Epoxy resin art offers an extensive palette of vibrant colors and textures. Artists can blend pigments and dyes into the resin to achieve stunning, translucent hues. The resin can also be manipulated using various techniques like pouring, layering, and swirling, enabling artists to create intricate patterns and abstract designs. The possibilities are truly limitless.

Creating Masterpieces:

Epoxy resin art has captivated artists worldwide, enabling them to unleash their creativity in exciting and unique ways. Let's delve into some popular techniques and styles within this medium.

Fluid Art: This technique involves pouring and manipulating the resin on a canvas or wooden panel, allowing it to flow and create mesmerizing abstract patterns. Artists can use various additives like alcohol inks, acrylic paints, or metallic powders to enhance fluidity and visual impact.

Geode Art: Inspired by the beauty of natural gemstones, geode art involves creating resin formations that resemble the intricate patterns and vibrant colors found in geodes. By using pigments, crystals, and metallic accents, artists can mimic the striking beauty of these geological wonders.

Resin Jewelry: Epoxy resin's versatility extends beyond traditional canvas art. Artists can craft exquisite jewelry pieces by pouring resin into molds and embedding various elements like dried flowers, gemstones, or metallic flakes. The result is a wearable work of art that encapsulates both elegance and individuality.

Beyond the Canvas: Epoxy Flooring:

While epoxy resin art has taken the art world by storm, its application extends far beyond galleries and studios. Epoxy flooring has become increasingly popular for its durability, easy maintenance, and aesthetic appeal. From residential spaces to commercial establishments, epoxy flooring offers a seamless, glossy finish that can withstand heavy traffic and resist stains.

Epoxy flooring comes in various styles, including solid colors, metallic finishes, and even 3D illusions. This versatile flooring option allows homeowners and business owners to transform their spaces into visually stunning environments that complement their unique style.

Conclusion:

Epoxy resin art has revolutionized the world of creativity, providing artists with a dynamic medium to express their imagination. From fluid abstracts to intricate jewelry pieces, the possibilities within epoxy resin art are endless. The luminous, glossy finish and vibrant colors of epoxy resin captivate viewers and bring life to any space. Moreover, epoxy flooring has become a practical and stylish choice for those seeking durability and visual appeal in their living or working environments. As epoxy resin continues to evolve and inspire artists worldwide, we can anticipate even more breathtaking and awe-inspiring creations in the future. So, grab some epoxy resin, unleash your artistic spirit, and let the magic unfold on canvas or floor, as you embark on a journey of liquid turned luminous artistry.

2 notes

·

View notes

Text

This is a piece I almost gave up on. I had an idea of using the mirror of a makeup palette as almost a canvas for me to paint on. Truly it was an inspired idea… as suggested by a tutor I went up to the 4th year painting rooms and wandered through them. I didn’t do this for inspiration but more for an idea of how far you can take paint as a medium when you let yourself. People were painting on wallpaper, teddy bears, fabric etc. one girl in particular had painted onto a mirror. It was more of an antique mirror with a handle to hold it.

I started this piece once in the beginning of the assemble project… then decided to give up on it but then towards the end of the year I came back to it…

I remembered I had a mirror in my makeup press at home that was once my bronzer and was now just an empty pallet … I took a picture of my eye as I wanted to create the idea of what the mirror would see while someone uses it to do there makeup but incapsulate one particular moment.

Me personally, I always wear false lashes so I’m constantly checking them to see if they’re still in place. I ran with that:

My idea was to then smash the mirror and encapsulate the pieces in the mirror with epoxy resin but as it was acrylic, the type of paint almost held it together and the broken mirror was unnoticeable. The mirror itself was also plastic so it didn’t have the desired effect. I have still taken a knife and outlined the cracks and it is displayed on my final wall.

I feel if I had spoken to a tutor more and expressed my idea I could have been given the right advice to achieve this better.

1 note

·

View note

Text

Resolver dropping glue process

It is an advanced manufacturing technique used to encapsulate electronic components, particularly resolvers, within a protective resin. This process involves injecting a highly durable, transparent or opaque epoxy resin into a mold containing the resolver. The resin hardens to form a robust, water-resistant, and vibration-resistant barrier, safeguarding the delicate electronics from environmental stressors. It enhances both the durability and aesthetic appeal of the resolver, ensuring reliable performance in various applications.

0 notes

Text

Choosing An EI Transformer For Your Application

Widely used in industries like manufacturing, audio systems, and power supplies, EI transformers derive their name from the way their core shapes resemble the letters E and I. These transformers, which are well-known for their reliability, affordability, and versatility, are economical options for supplying power to general-purpose electronics, audio equipment, and industrial machinery. They are perfect for managing power fluctuations and guaranteeing steady performance because of their sturdy build. However, for optimal performance and efficiency, you must select the right kind of EI transformer for your application. A thorough assessment of important aspects including performance, longevity, and efficiency is necessary when choosing an EI transformer to satisfy certain application requirements. This blog examines important factors to assist you in selecting an EI transformer that meets your operational requirements.

Key features to look for when purchasing an EI transformer

Power requirements

The first step in choosing an EI transformer is to ascertain its power handling capacity. When determining the load current, it is crucial to make sure the transformer can manage the input and output voltages required for your application in order to prevent underpowered systems. Check the transformer’s compatibility with variable frequencies for certain applications and make sure it supports the operating frequency, depending on where you’re situated. To ensure safe operation and future growth, use a transformer whose wattage rating is more than the maximum load. It is advised to provide a safety buffer of 20–30% in the estimated power requirements to improve durability and efficiency during peak loads.

Efficiency

In order to lower operating expenses and the impact on the environment, efficiency is essential. While grain-oriented steel cores are favoured for high efficiency needs, silicon steel cores are frequently employed due to their cost-performance balance. By lowering resistance, premium copper windings further maximize energy transfer. Additionally, transformers work best when they are operated between 75 and 90 percent of their rated capacity. Buyers should seek transformers that meet or surpass established energy efficiency criteria to guarantee peak performance.

Durability

The materials and construction of an EI transformer have a significant impact on how long it will last. For instance, laminated cores help reduce eddy current losses and prolong the transformer’s life, high-quality insulation assures endurance amidst temperature changes while avoiding electrical problems, and sealed or epoxy-encapsulated transformers offer improved protection in high-humidity or dusty settings, guaranteeing dependable operation even in the face of adversity. These design elements ensure that the transformer will function efficiently and last the duration of its functional life.

Thermal stability

Thermal stability is essential to an EI transformer’s dependable operation. Verifying the transformer’s thermal rating — such as Class A, B, or F — ensures that it can function safely within the application’s specified temperature range. Furthermore, transformers with the right cooling systems — like enough ventilation — maintain reliable operation and last a long time.

Compliance with safety standards

Choosing an EI transformer requires adherence to safety regulations. Make sure that the transformer complies with established certifications such as UL or IEC, as these ensure minimum standards for reliability and efficiency. Additionally, models that have thermal protection or built-in fuses offer crucial overload protection, protecting the transformer from possible harm during power surges.

Matching the EI transformer to your application

Every industry has its own unique requirements and setbacks. It is thus important to consider important elements pertaining to the particular industrial requirements when choosing an EI transformer.

Industrial applications: Prioritizing robust designs with high insulation and overload capacity is crucial for industrial applications in order to guarantee performance and durability under harsh circumstances. Furthermore, in contemporary industrial installations, compatibility with automation systems is essential for smooth operation.

Power supply systems: Choosing EI transformers with dependable thermal control and good efficiency is essential for power supply systems. Because of these characteristics, the transformer can efficiently manage continuous loads, guaranteeing steady and reliable power delivery.

Medical devices: It is imperative that medical devices adhere to strict safety and hygienic regulations. To guarantee safe and dependable operation in delicate healthcare settings, EI transformers used in this industry must adhere to strict requirements.

Audio equipment: Low-noise transformers are essential for audio equipment. To preserve the quality and clarity of sound output, they should minimize electromagnetic interference while delivering high fidelity.

Customizing your EI transformer

Custom-built EI transformers provide solutions for specific applications. Customization enables improved insulation, core materials designed to suit certain situations, and modified voltage, current, and frequency ratings. More adaptability is offered by extra features like EMI shielding or encapsulation for tough environments. When thinking about customization, find out from your manufacturer whether the transformer can be made to meet particular power or voltage requirements, what kind of materials will be used for the windings and core, and whether there are extra expenses or lead times for unique designs.

Partnering with the right supplier

The quality and dependability of your EI transformer are greatly impacted by your choice of manufacturer or supplier. A trustworthy provider ought to provide strong technical support and after-sales service, have a track record of success and industry knowledge, and provide thorough documentation and test results. Prioritize manufacturers who provide warranties and prompt customer care for long-term peace of mind. This will guarantee a trustworthy collaboration and superior product performance over time.

Whether you opt for a standard transformer or a custom solution, collaborating with a trusted supplier ensures you receive a product that exceeds your expectations. With a commitment to quality and precision, Miracle Electronics is a trusted EI transformer manufacturer in India that delivers transformers tailored to diverse industry needs. The secret to a successful purchase is careful consideration, open communication with a reputable manufacturer like Miracle Electronics, and an emphasis on longevity and outstanding performance.

Resource: Read more

0 notes

Text

Just ordered my first pcb, if it's not gonna work on the first try I will explode and evaporate everything in the 5km radius.

My sheer life and joy of my friends (its for a present) depends on five glass epoxy boards with carefully placed and interconnected smart rocks encapsulated in little black rectangles with metal legs so they can play the most wretched sounds that will annoy my friends.

#pcb#pcb fabrication#electonics#AAAAAAAAAAAAAAAA#If it works tho god himself won't be able to stop me

1 note

·

View note

Text

Durable Epoxy Encapsulation for Industrial Applications

For industrial projects that demand durability and precision, trust MB Enterprises’ epoxy encapsulation solutions. Designed to protect sensitive components in industries like electronics, aerospace, and automotive, our products deliver superior strength, resistance, and long-lasting performance.

Perfect for large-scale applications, MB Enterprises ensures your projects are safe from wear and tear while maintaining top-notch quality. Choose epoxy encapsulation from MB Enterprises and experience excellence in industrial materials!

0 notes

Text

Beautiful Basement Epoxy Floors: A Stylish Solution for Any Home

Introduction

When it comes to home improvement, the basement often takes a backseat regarding aesthetics and functionality. However, with the rise of innovative materials like epoxy floors, this underutilized space can transform into a stylish sanctuary or an efficient workspace. Beautiful Basement Epoxy Floors: A Stylish Solution for Any Home is not just a catchy phrase; it encapsulates the modern trend of enhancing basements through durable, easy-to-maintain flooring solutions.

In this comprehensive guide, we'll explore everything you need to know about epoxy floors—from their benefits and styles to installation methods and maintenance tips. If you're considering upgrading your basement or any part of your home with epoxy flooring, you've come to the right place!

What are Epoxy Floors?

Epoxy floors are made from a combination of resin and hardener that creates a durable coating suitable for various surfaces. They are particularly popular for garages and basements due to their resilience against moisture, stains, and heavy Great post to read foot traffic.

Understanding the Composition of Epoxy

The fundamental components of epoxy include:

Resin: The base material that provides adhesion. Hardener: This component activates the curing process.

Once mixed, these components chemically react to form a strong bond that adheres well to concrete surfaces, creating a robust floor that's both functional and visually appealing.

Benefits of Epoxy Floors in Your Basement

Choosing epoxy for basement floors comes with numerous advantages:

Artcrete Designs Durability: Epoxy floors can withstand heavy loads without cracking. Moisture Resistance: They act as a barrier against water damage. Easy Maintenance: Cleaning is straightforward; just a mop and mild detergent will do. Aesthetic Appeal: Available in various colors and finishes, including metallic and flake options. Why Choose Beautiful Basement Epoxy Floors? Aesthetic Versatility

One of the most compelling reasons for choosing beautiful basement epoxy floors is their versatility in design. You can opt for solid colors or even custom designs using color chips or flakes.

Metallic Epoxy Floors: These provide a stunning visual effect with swirling colors that mimic natural stone. Epoxy Flake Floors: This option adds texture and depth while providing slip resistance. Cost-Effectiveness

When comparing costs between different flooring types—like hardwood or tiles—epoxy stands out as an economical choice.

Cost Breakdown

| Flooring Type | Average Cost per Square Foot | |------------------------|-------------------------------| | Hardwood | $8 - $15 | | Tiles | $5 - $10 | | Epoxy | $3 - $7 |

Using epoxy can save homeowners money both in initial investment and future maintenance costs.

Exploring Different Types of Epoxy Floors

This section will discuss various types of epoxy flooring suitable for basements.

Residential Epoxy Floors vs. Commercial E

0 notes

Text

0 notes

Text

FCBGA Substrate: Understanding Its Importance in Electronic Manufacturing

What is an FCBGA Substrate?

FCBGA (Flip-Chip Ball Grid Array) is an advanced packaging technology used for encapsulating electronic chips. This packaging technique involves flipping the chip (flip-chip) and connecting it to the substrate through a grid of solder balls (Ball Grid Array). The FCBGA substrate is a critical component that provides support, thermal management, and electrical connections. It is typically used for high-performance microprocessors, graphics processing units (GPUs), and other chips that require high-speed signal transmission and high-density packaging.

How FCBGA Works

FCBGA packaging works by flipping the chip and connecting its pins to the substrate through tiny solder balls in a grid formation. This method differs from traditional packaging methods, such as QFP (Quad Flat Package) or BGA (Ball Grid Array), which use pins or pin arrays for connection, whereas FCBGA directly connects through solder balls.

The role of the FCBGA substrate is to provide mechanical support and electrical contact. The design of the substrate needs to ensure a high-density ball array layout and excellent thermal conductivity to handle the heat dissipation demands of high-power, high-frequency chips.

Structure of FCBGA Substrate

The design of an FCBGA substrate is complex and typically consists of multiple layers. The main layers include:

Chip Bonding Layer: This layer sits between the chip and the substrate, where solder balls are used to connect the chip’s pads to the substrate’s circuits. The solder balls are typically made from an alloy of tin and other metals, offering good electrical conductivity and thermal properties.

Circuit Layer: The circuit layer transmits electrical signals and is usually made of copper. These layers are created using multi-layer printed circuit board (PCB) technology. The layout and density of these layers are crucial for signal integrity and minimizing crosstalk.

Package Substrate: The package substrate serves as the foundation for the entire FCBGA package. It is typically made of materials like ceramics or glass fiber-reinforced epoxy resin (FR4). This layer provides structural support and ensures good connectivity between the solder balls and external circuit boards.

Heat Dissipation Layer: For high-power chips, heat management is crucial. FCBGA substrates often incorporate heat dissipation layers made of copper or other high thermal conductivity materials. These layers help transfer heat from the chip to the external environment, preventing overheating and chip damage.

Testing and Encapsulation Layer: During the manufacturing process, the FCBGA package undergoes extensive testing to ensure each package works as expected. The encapsulation layer is usually made of polymer materials and serves to protect the chip while adding mechanical strength to the package.

Advantages of FCBGA Substrate

FCBGA substrates offer many advantages due to their unique design and material choices. These benefits are especially apparent in high-performance and high-density electronic devices. Here are some of the key advantages:

High-Density Interconnects (HDI): The flip-chip design and ball grid array layout support extremely high interconnect densities. The circuit lines on the substrate can be packed more tightly, reducing the package size while enhancing electrical performance.

Excellent Thermal Management: FCBGA substrates excel in thermal management, effectively transferring heat from the chip. Since high-power chips generate a lot of heat, effective thermal design is essential to ensure reliable chip performance and longevity.

Smaller Package Size: FCBGA packages are typically smaller than traditional packages, making them ideal for applications where space is limited. This compact design allows for the integration of more functions into devices like high-end smartphones, servers, and portable electronics without increasing their size.

High-Speed Signal Transmission: The flip-chip design reduces the signal transmission path length, allowing for faster data transfer speeds. This feature is crucial for applications that require high-speed computation, such as processors and graphics chips.

Improved Reliability: The solder ball connection method used in FCBGA packages is more reliable than traditional pin-based connections. It can withstand higher mechanical stresses and temperature fluctuations, making it ideal for high-reliability applications.

Applications of FCBGA Substrate

FCBGA substrates are used across a wide range of electronic products, particularly in industries where high performance, high density, and high reliability are required. Some of the key applications include:

Central Processing Units (CPUs) and Graphics Processing Units (GPUs): FCBGA packaging is commonly used for high-performance computing chips like CPUs and GPUs, which require high processing power and effective heat management. The FCBGA substrate provides the necessary high-density connections and thermal dissipation needed for these chips to run efficiently at higher speeds and lower temperatures.

Servers and Data Centers: Processors used in servers and data centers need to handle large amounts of data, making their packaging requirements extremely demanding. FCBGA substrates' high-density interconnects and excellent thermal performance make them ideal for data center processors.

Mobile Devices: Processors and graphics chips in smartphones, tablets, and other mobile devices also utilize FCBGA packaging. The compact nature and efficient thermal management of FCBGA substrates are particularly suited for mobile devices that face size constraints.

Automotive Electronics: FCBGA substrates are also used in automotive electronics, such as self-driving, in-car entertainment systems, and electric vehicle control units. Automotive electronics must perform reliably in harsh environments, making the high durability and thermal management capabilities of FCBGA packaging a perfect fit.

Challenges and Future of FCBGA

While FCBGA substrates offer significant advantages, they also face some challenges:

Manufacturing Cost: The manufacturing process for FCBGA substrates is complex, involving precise fabrication and material selection, which increases the cost compared to traditional packaging methods. This could limit its use in lower-end products.

Thermal Issues: Although FCBGA substrates have good thermal management, as chip power increases, managing heat dissipation remains a challenge. Finding the balance between high-power density and effective cooling continues to be a key focus of packaging research.

Signal Integrity: High-speed signal transmission presents a challenge for FCBGA packaging. As chip frequencies increase, ensuring signal integrity and minimizing signal interference become critical issues in the design process.

FCBGA substrates are a crucial component in modern electronic packaging, offering high density, performance, and reliability. They are widely used in processors, GPUs, servers, mobile devices, and automotive electronics. As electronic devices continue to evolve and demand higher performance, FCBGA packaging will remain an essential technology.

The future of FCBGA substrates lies in overcoming challenges such as cost, thermal management, and signal integrity while pushing the boundaries of chip performance and miniaturization. With continuous advancements in packaging technology, FCBGA substrates will play a vital role in the next generation of high-performance electronic devices.

1 note

·

View note

Text

JB Engineering’s Double Corrosion Protection (DCP) Anchors are HOT DIP ZINC Coated & Fusion EPOXY COATED which provides protection from Corrosion for minimum 100 Years with two independent barriers between the anchor tendon and the environment.

Visit Here:-

#NIC#brige#Micropiles#BEST#bestquilty#pipling#compact#tightspaces#drilled#costeffective#manufactured#cheap#industrial#road#rockbolt#RebarCouplers#Coupler#JB#selfdrilling#anchorbolts#hollowbar#rod#threadedrods#threadedbars#tierods#coilrods#SDABars#Bridge#tunnel#construction

0 notes