#energy storage manufacturing

Explore tagged Tumblr posts

Text

INDUSTRY ACADEMIC PARTNERSHIP

IESA works with top research universities, educational institutions, and government organizations like DST, MEITY, and other R&D national labs to address the need for training and skill development for the energy storage and e-mobility sectors.

IESA organizes masterclasses, workshops, webinars, and hands-on training sessions, along with providing joint fellowship & scholarships to promote research in India.

Need: The Indian Energy Storage sector is entering a fast-growing phase. With the Governments’ vision on Energy Security deployment of storage technologies will only increase in days to come. As such it becomes crucial to recognize the need to capability building and skill development from this stage to enable the storage industry grow in a sustainable manner.

Objective: To address the need for skill development in the energy storage sector, IESA launched IESA Academy in 2016. The objective of the Academy is to organize training courses, workshops, and master-classes through fostering Industry and Academia collaborations. These programs aim to empower companies to enter the energy storage market as well as help existing manufacturers expand their business in energy storage manufacturing by imparting their current/potential employees with the right skillset.

Methodology: IESA works with top research universities such as VJTI, Karpagam Academy of Higher Education and Savitribai Phule Pune university to address the need for training and skill development for the sector. We also work closely with Skill Council of India for bridging the skill gap in India. Through such collaborations we organize masterclasses, workshops, webinars and hands-on training sessions.

Activities:

Since its initiation in 2016, IESA has conducted many capacity building workshops, Masterclasses on storage and component manufacturing, Hands-on training on Lead Acid and Li-Ion battery O&M. project finance, modelling, electric vehicle manufacturing, microgrid monitoring and design across India at strategic locations including Guwahati, Pune, Delhi, Hyderabad and Mumbai.

Partnered and is working with VJTI- TBI for the incubators.

Specific Benefits to all academicians as an IESA member as here under

Support to develop research labs & implement projects in the institute campus- IESA faculty member can approach to a large number of member industries to carry out research, also for setting-up of various research labs or centre for excellence at the institutes.

Joint industry proposal to carry out testing and product development- IESA member industry can help institutes to bring its lab scale development to pilot scale or prototyping. This way university and the research group will get maximum visibility and recognition.

Internship & research position for students at IESA & IESA member companies- Students can secure their internship IESA member universities/industries, also they will get a chance to work with the IESA member industry after completing their degree.

Access to IESA/CES in-house labs and technology experts- Member faculty or student can access IESA battery lab facilities, also they can interact with in-house storage technology experts.

Technology incubator- IESA incubator would help faculty/student members to bring their technological innovations to a most meaningful way.

Closely works with National labs & DST, MEITY on research & development- IESA has very close association with various national labs and also takes part in different technical discussion in govt initiatives as a part of govt committee members. Member faculty or institute can reach to IESA for any kind of details about the storage related activities.

Capacity building training programs on energy storage, EV & microgrids under IESA Academy- Under the IESA academy, member faculty or student can participate in capacity building training in a most interactive ways which covers current market trend on different technologies, policies, and guidelines.

Participation in IESA events- Faculty members or students can participate in different IESA events, workshops, and conferences.

Complimentary copy of IESA Publications (Emerging Technology News- ETN Magazine) & Knowledge Papers

Roles and Opportunities for Graduates in Supporting India’s Energy Transition Towards EVs and RE- Click to know more

#iesa#India Stationary Energy Storage Market Overview Report#india energy storage alliance#storage association#Advance Chemistry Cells#battery storage#energy storage technology#energy storage alliance in india#energy storage companies#advanced energy storage#energy storage projects in india#energy storage#energy storage manufacturing

0 notes

Text

Empowering Tomorrow: Navigating the Green Frontier with Battery Energy Storage Systems and Innovative Manufacturers

In the ever-evolving landscape of sustainable energy, Battery Energy Storage Systems (BESS) stand as a cornerstone, ushering in a new era of efficiency and resilience. As we embark on a journey through the green frontier of energy storage, the narrative unfolds not only with the capabilities of BESS but also with the visionary guidance of battery energy storage system manufacturers.

Innovation at the Core: At the heart of the energy revolution lies the ceaseless innovation driven by battery energy storage system manufacturers. These pioneers not only engineer cutting-edge solutions but constantly redefine the boundaries of what's possible. Their commitment to innovation is not merely a feature; it's a testament to an unwavering dedication to sculpting a sustainable energy future.

Versatility Tailored for All: In a world where energy needs vary across sectors, the adaptability of BESS, skillfully crafted by manufacturers, shines brightly. These systems seamlessly integrate into diverse environments, from powering homes with renewable sources to bolstering industrial operations. This versatility isn't happenstance; it's a deliberate design philosophy, reflecting manufacturers' foresight in creating solutions tailored for a spectrum of energy demands.

Harmony with Nature's Cadence: Battery energy storage systems, under the stewardship of visionary manufacturers, resonate with the natural cadence of energy production and consumption. These systems capture and store excess energy when nature is most generous, ensuring a harmonious interplay between human needs and environmental sustainability. The result is an energy storage model that mirrors the ebb and flow of the natural world.

Grid Resilience, Realized: The need for grid resilience has never been more pronounced, and BESS, guided by manufacturers, emerges as a key player in this narrative. These systems, equipped with real-time response capabilities, fortify our grids against disruptions, showcasing a level of resilience that echoes the forward-thinking strategies of manufacturers in anticipating and addressing the challenges of an evolving energy landscape.

Global Impact, Local Solutions: Beyond technological marvels, battery energy storage system manufacturers contribute to a global shift towards sustainable practices. Their commitment ripples across borders, influencing communities worldwide. This global impact transforms BESS into a catalyst for positive change on an international scale, turning what was once a local solution into a beacon for global sustainability.

As we navigate the green frontier of energy storage, the synergy between battery energy storage systems and manufacturers becomes the driving force behind a sustainable and electrifying future. This narrative isn't confined to the realm of technology; it's a story of collaboration, innovation, and foresight that resonates with the ethos of a greener tomorrow. In the tapestry of sustainable energy, BESS and their visionary manufacturers weave a narrative that propels us towards a future where power is not just stored but intelligently managed for the benefit of all.

Further reading

2 notes

·

View notes

Link

Batteries manufactured by HiNa have an energy density of 145 Wh/kg and can endure 4,500 cycles. The next stage aims at 8,000 to 10,000 cycles and up to 200 Wh/kg energy density, according to the company(..)

CATL unveiled its own sodium-ion battery back in 2021 with an energy density of 160 Wh/kg and its next generation battery cell is supposed to exceed 200 Wh/kg. The company is planning to begin commercialization of its product from next year.BYD has more solid plans when it comes to its own sodium batteries, the company has been reported that it is to start manufacturing of the new sodium-ion cells in the second quarter of next year. Later the company went on to deny those reports(..)

#sodium-ion battery#HiNa#BYD#CATL#ev manufacturing#energy safety#energy storage#breaking news#China#affordable ev#demise of legacy automakers#demise of big oil#russian defeat

7 notes

·

View notes

Text

What is the Lifepo4 Battery "PACK"?

Introduction

Lithium batteries are widely used, ranging from civilian digital and communication products to industrial equipment to special equipment, etc. They are all used in batches. Different products require different voltages and capacities.

Therefore, lithium-ion batteries are used in many cases in series and parallel. The application battery formed by protecting the circuit, casing, and output is called PACK.

PACK can be a single battery, such as a mobile phone battery, digital camera battery, MP3, MP4 battery, etc., or a series-parallel combination battery, such as a laptop battery, medical equipment battery, communication power supply, electric vehicle battery, backup power supply, etc.

The Composition of the Lithium Battery Pack

PACK includes a battery pack, protective plate, outer packaging or casing, output (including connectors), key switch, power indicator, and auxiliary materials such as EVA, highland barley paper, and plastic brackets to form a PACK.

The external characteristics of the PACK are determined by the application. There are many types of PACK.

Production Steps:

#lithium battery#lithium#lifepo4 battery#lithium iron phosphate battery#solar battery storage#solar energy#solar system#solar battery#lithium manufacturer

1 note

·

View note

Text

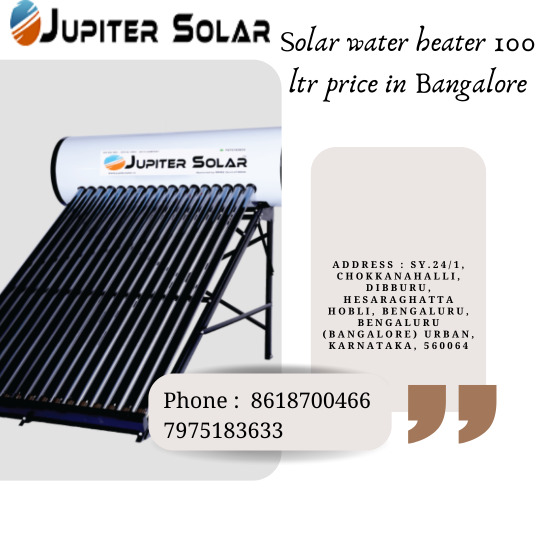

Solar water heater 100 ltr price in Bangalore

Solar water heater 100 ltr price in Bangalore

Solar water heater 100 ltr price in Bangalore, You should know about solar power first before going for any solar thermal system. Solar thermal system is based on the principle of converting sunlight into hot water (or steam) for use in heating homes and buildings. Solar water heating systems, commonly called solar hot water systems, convert the sun's rays into energy using a black-body absorber located inside a glass collector. When the temperature drops below, however, the efficiency decreases rapidly. Most solar thermal collectors have a maximum working temperature . To install a Solar water heater 100 ltr price in Bangalore, contact Jupiter Solar , www.jupitersolars.in .

What Is A Solar Water Heater?

What Is A Solar Water Heater?,a solar water heater is a device that converts solar energy into useful heat. These devices utilize the power of the sun to create a warm liquid that can then be applied to our homes and businesses. In effect, a solar water heater is similar to a conventional electric water heater; however, instead of electricity, sunlight does the work. Our bodies need water to survive and if we do not drink enough water, we become dehydrated. If we live in a desert area where there may not be much access to fresh drinking water, having access to heated water would be helpful. Thus, a solar water heater could be a cost effective and environmentally friendly alternative.Buy solar water heater , contact Jupiter Solar , www.jupitersolars.in .

How Does Solar Power Work?

Solar powered water heaters make use of the sun's heat and convert it directly into usable hot water. There are several different types of solar water heaters depending on the desired output. The two basic designs are a direct (concentrating type) and indirect (reflecting type). Direct solar water heaters focus the sun's rays onto copper tubes , while indirect solar water heaters reflect the sunlight back towards the tubes. Both of these types of units produce hot water at high efficiencies, although the concentrating type has higher operating costs.

https://jupitersolars.in/faq.php

Cost And Efficiency Of Solar Water Heaters

To calculate how much you might save with a solar water heater, you'll need to determine the size and capacity of your current system along with an estimate of the total annual usage. Next, you'll need to figure out how much electricity you currently spend on your utility bill. Then simply divide those figures together. Your savings are determined by dividing the difference between your estimated monthly expenses and what you'd pay by the amount of energy your solar water heater produces. Let's assume you're saving $40 per month on your utility bills - that equals $480 annually. To calculate the approximate number of gallons of hot water produced by your existing system, multiply the volume of your tank by the average flow rate. Once again, let's say you have 5 gallons of storage capacity and your current flow rate is 10 gallons per day. That means you're producing 500 gallons of hot water each year. Divide that by 12 months to find your monthly consumption. Now subtract both the $240 annual savings and the $500 annual production from the $960 total cost of your present system. What's left over is how much money you stand to save by switching to a solar water heater.

Size And Capacity

You'll want to consider the size and capacity of the solar water heater you plan to install before making a decision. Many manufacturers offer models ranging from 100 litre to 200 solar water heaters. The larger the system, the greater the potential savings. Smaller systems can be installed outside while larger ones may requires a free standing structure . A good rule of thumb is to buy the largest solar heater unit possible. Keep in mind that the size of your home or business building will affect the size and weight of your solar water heater. Obviously, larger homes and buildings require bigger and heavier units.

Installation

Most solar water heaters are preassembled and ready to go once you've purchased them. However, they do require some installation work. After placing the solar heater unit in its final location, you'll need to add the hardware. Finally, fill the reservoir with water. Depending on where you live, the process may take a few hours before you start receiving hot water.

Maintenance

Solar water heaters don't require very high maintenance once they've been installed. You won't need to worry about replacing the elements until the solar water heating units are working or cleaning the panels since their performance will remain unchanged. However, you may want to clean the surface of the black-body absorbers every so often. Fortunately, they are easy to remove and replace. Also, remember to keep your unit clear of debris such as snow and leaves.

Water Heater

Water heating systems are used to warm water for bathing, cooking, washing purposes, etc. A solar water heater uses solar power to heat the water directly without using any fuel. In some cases, they use a storage tank where hot water is stored until required. These tanks are filled once a day and then heated by the sun. Heating water by boiling is considered efficient since many percentage of the energy goes . Solar water heaters, however, convert this thermal energy into electricity . Energy efficiency is thus increased. Other types of water heaters are gas-based, electric ones.

Storage Tank

The storage tank is the place where hot water is kept. When the temperature drops below a certain level, the pump sends water back to the boiler. Another type of storage tank is the closed loop system where water circulates continuously between the boiler and the tank.

Boiler

A boiler is a device that takes water at room temperature and heats it to high temperatures. Once the water reaches these high temperatures, it is sent to a tank where the excess heat is removed and converted to useful energy. Depending on the size of the boiler, it may need to have a fan inside to remove extra heat. The fan can either run constantly or only while the water is being pumped.

Pumping System

Pumping systems move water from one point to another. There are many different pumps, but some of the most common ones include centrifugal, screw, and piston pumps.

Electric Motor

Electric motors are the devices that turn the mechanical energy of steam or electrical energy into kinetic energy. An electric motor uses electric current to create rotating force. The rotor spins within the stator, converting it to rotary motion. The electric motor converts electrical energy into rotational energy which is then transferred to the shaft turning the impeller blades.

Impeller Blades

Impellers are the blades that are attached to the shaft. To improve efficiency, the blades spin faster by increasing RPM (revolutions per minute). The higher RPM increases the pressure of the water pushing it outward forcing it to flow around the outside of the impeller blades. This helps the water leave the impeller blades in a continuous stream and exit the unit.

Air Pump

Air pumps help move air across surfaces, keeping them clean and preventing mold and bacteria buildup. Air pumps are often used in air conditioning units to move cool air over coils and condensers.

#Air Pump#Impeller Blades#Electric Motor#Pumping System#Boiler#Boiler system#boil#hot water#Storage Tank#Water Heater#Maintenance#Installation#Installation of solar water heater#Bangalore#manufacturer#solar energy#solar heaters#Size And Capacity#Cost And Efficiency Of Solar Water Heaters#How Does Solar Power Work?#How Does Solar Power#What Is A Solar Water Heater?#Solar water heater 100 ltr price in Bangalore#Solar water heater 100 ltr price#100 litre solar water heater

2 notes

·

View notes

Text

Maximizing Battery Factory Efficiency with MES: Module EOL Testing

The battery manufacturing industry relies on precise processes and efficient testing to ensure quality.

One essential element for achieving this is the Manufacturing Execution System (MES), which organizes critical functions in battery factories. These functions include cell entry inspection, Module End-of-Line (EOL) testing, and PACK package EOL testing.

In this discussion, we will focus on Module EOL testing, a crucial aspect of the battery manufacturing process. Module EOL testing involves a series of steps and parameters to guarantee battery modules' quality, performance, and safety.

Workstation Description:-

Scan and Module EOL Test:The process initiates with scanning a code and conducting a Module EOL test. This test encompasses multiple facets, including the acquisition of module total voltage, monomer voltage, temperature, difference pressure control, internal resistance, insulation voltage resistance, voltage, and temperature detection.

Wire Harness Plug-in: The low-voltage wire harness plug-in is manually performed, while the remaining testing procedures are automated.

Temperature Collection: Room temperature is collected and compared with the module collection temperature to determine the normality of temperature collection.

Insulated Voltage Test: The insulated voltage test cable employs high-voltage-resistant cable as per the original factory manual. By scanning the code, the test formula is automatically called, and the data is recorded, associated with the module code, and uploaded to the MES system.

Product Flow: Qualifying products are automatically directed to the next station, while non-conforming items are automatically removed at the offline NG station.

Key Parameters for Reference:-

Module Voltage Test: Accuracy of ±0.1mV.

DC Voltage Range for Insulation Test: 0~1000V with a time range of 0.1-99.9s.

Process Verification and Testing

The module EOL testing process is crucial for ensuring accuracy and integrity. Various parameters, such as

Module Voltage Test, Internal Resistance,

Cell Voltage Test, Cell Voltage,

Open Circuit Voltage Differential Pressure Judgment,

Total Positive, and

Shell Insulation Impedance is maintained at precise levels to guarantee the quality of battery modules.

Module EOL testing is a key step in battery manufacturing. It ensures that modules meet strict standards for performance, reliability, and safety. Maintaining the accuracy and consistency of these tests is vital for seamlessly integrating these batteries into various applications, from electric vehicles to consumer electronics.

Summary

This article discussed the importance of a Manufacturing Execution System (MES) in battery production, specifically focusing on Module End-of-Line (EOL) testing. Module EOL testing involves various steps and parameters to ensure battery modules' quality, performance, and safety. The process includes scanning, and testing multiple parameters such as voltage and temperature, wire harness plug-in, temperature collection, insulated voltage test, and product flow. The accuracy and integrity of the testing process are crucial to maintaining the quality of battery modules. Module EOL testing plays a vital role in ensuring that batteries meet the required performance, reliability, and safety standards in various industries.

#battery manufacturing industry#Battery Modules#electric vehicles#energy storage systems#EOL Testing#EV manufacturing in India#lithium-ion batteries#lithium-ion battery#lithium-ion battery manufacturing#MES for Battery Manufacturing

0 notes

Text

Industrial UPS or BESS | Which Is the Better Option for Your Business?

Getting a reliable power supply is critical in the fast-moving industrial environment. Two common approaches that sustain this are Industrial UPS (Uninterruptible Power Supply) and BESS (Battery Energy Storage Systems). Both of these have their unique advantages, and choosing the right one for your business will be based on your specific needs. Let us look at some of the benefits of each in making a correct decision.

0 notes

Text

Carbon Capture Utilization and Storage Market Estimated to Experience a Hike in Growth by 2033

“Global Insight Services company has recently revised its global market reports, now incorporating the most current data for 2024 along with projections extending up to 2033.

The Carbon Capture, Utilization, and Storage market size was approximately USD 3 billion in 2022 and it is anticipated to grow further to over USD 8 billion by 2032, at a CAGR of over 10% during the forecast period.

View The Full Report Here –https://www.globalinsightservices.com/reports/carbon-capture-utilization-and-storage-market

Carbon Capture Utilization and Storage (CCUS) is a technology that can be used to capture carbon dioxide (CO2) emissions from power plants and other industrial facilities, and store it in a way that prevents it from entering the atmosphere. CCUS can be used to capture CO2 from flue gas, which is the gas that is released when coal is burned, or from the exhaust of a natural gas power plant. The CO2 can then be stored underground, in the ocean, or in other geological formations.

CCUS is a promising technology for reducing greenhouse gas emissions, as it has the potential to capture up to 90% of CO2 emissions from power plants. In addition, CCUS can be used to capture CO2 from other industrial sources, such as cement production and steelmaking.

CCUS is still in the early stages of development, and there are a number of challenges that need to be addressed before it can be widely deployed. For example, the cost of capturing and storing CO2 is currently quite high, and there is a need for better technology to ensure that the CO2 is securely stored over the long term. In addition, CCUS will require a significant investment in infrastructure, such as pipelines and storage facilities.

Key Drivers and Trends

The key trends in Carbon Capture Utilization and Storage technology are, Increasing the efficiency of capture, Enhancing the storage options, Reducing the cost of capture and storage, Increasing the use of carbon dioxide for other purposes.

The need to reduce greenhouse gas emissions is one of the most important drivers of the carbon capture utilization and storage market. Greenhouse gas emissions, such as carbon dioxide, are a major contributor to climate change. Carbon capture utilization and storage can help to reduce these emissions by capturing carbon dioxide from power plants and other industrial facilities and storing it underground.

The need to find new ways to store carbon dioxide is another driver of the carbon capture utilization and storage market. Carbon dioxide can be stored underground in depleted oil and gas fields, in saline aquifers, or in other geological formations. Carbon capture utilization and storage can help to reduce the amount of carbon dioxide in the atmosphere and slow the rate of climate change.

Unlock Growth Potential in Your Industry – Get Your Sample Report Now@https://www.globalinsightservices.com/request-sample/GIS20891

#Carbon Capture Utilization and Storage Market#Carbon Capture Utilization and Storage Market Trends#Carbon Capture Utilization and Storage Market manufacturing#Carbon Capture Utilization and Storage Market industry#Carbon Capture Utilization and Storage Market Energy & Natural Resources

0 notes

Text

JackVolt's Advanced Robot Battery Packs and Lithium Batteries for Solar Energy Storage

In today's fast-paced technological landscape, the demand for efficient and reliable energy storage solutions has never been greater. JackVolt, a leading name in the industry, is at the forefront of this revolution, offering cutting-edge robot battery packs and lithium batteries for solar energy storage. These advanced solutions are designed to meet the diverse needs of modern applications, ensuring optimal performance and sustainability.

Innovative Robot Battery Packs

JackVolt's robot battery packs are engineered to deliver unparalleled performance, reliability, and longevity. These battery packs are specifically designed to power a wide range of robotic applications, from industrial automation to consumer electronics. With a focus on high energy density and long cycle life, JackVolt's robot battery packs provide the consistent power necessary to keep robots running smoothly and efficiently.

One of the key features of JackVolt's robot battery packs is their ability to withstand rigorous operational demands. These batteries are built with robust materials and advanced technology to ensure they can handle the stresses of continuous use. Whether it's for high-speed industrial robots or precision-driven consumer robots, JackVolt's robot battery packs are the ideal choice for powering the future of robotics.

Lithium Battery Manufacturer for Solar Energy Storage

As a leading lithium battery manufacturer for solar energy storage, JackVolt is committed to providing innovative solutions that contribute to a sustainable future. Solar energy storage systems rely on high-quality lithium batteries to store and distribute energy efficiently. JackVolt's lithium batteries are designed to maximize the potential of solar power, ensuring that stored energy is available whenever it's needed.

JackVolt's lithium batteries for solar energy storage are characterized by their high energy efficiency, safety, and reliability. These batteries are equipped with advanced management systems that monitor and regulate performance, preventing issues such as overcharging and overheating. As a trusted lithium battery manufacturer for solar energy storage, JackVolt ensures that its products meet the highest standards of quality and performance.

Why Choose JackVolt?

JackVolt stands out in the industry due to its unwavering commitment to innovation, quality, and customer satisfaction. Here are a few reasons why JackVolt's robot battery packs and lithium batteries for solar energy storage are the preferred choice:

Advanced Technology: JackVolt incorporates the latest advancements in battery technology to deliver products that offer superior performance and reliability.

Sustainability: As a forward-thinking lithium battery manufacturer for solar energy storage, JackVolt focuses on creating solutions that promote environmental sustainability.

Customization: JackVolt provides tailored battery solutions to meet the specific needs of different applications, ensuring optimal performance and efficiency.

Expertise: With years of experience in the industry, JackVolt has the knowledge and expertise to develop high-quality energy storage solutions that meet the evolving needs of the market.

Final Decision

JackVolt is leading the way in the development of advanced energy storage solutions with its innovative robot battery packs and lithium batteries for solar energy storage. By choosing JackVolt, you are investing in cutting-edge technology that ensures reliable performance and contributes to a sustainable future. Discover the power of JackVolt's solutions and take the next step towards a more efficient and eco-friendly energy landscape.

0 notes

Text

Shanghai Yongming Electronic Co.,Ltd

Shanghai Yongming Electronic Co., Ltd. is a capacitor manufacturing enterprise integrating design, research and development, production, sales, and service. The company was established in 2004. After almost 20 years of hard work, it has accumulated rich experience in independent research and development and production, trained a group of high-quality technical management teams, and formed a mature capacitor manufacturing process.

Our main products are diversified Aluminum Electrolytic Capacitors, which includes Aluminum Electrolytic Capacitor (Radial Leaded Type, SMD Type, Snap-In Type, and Screw Terminal Type), Conductive Polymer Aluminum Solid Electrolytic Capacitor, Conductive Polymer Hybrid Aluminum Solid Electrolytic Capacitor, MLPC, MLCC and EDLC.

Our product philosophy is: Ask YMIN for your all capacitor application. It is precisely because of this sentence that we YMIN constantly seek new partners in difficult situations, and our company’s products are developing faster and faster.We have products that are no inferior to those of our international counterparts, such as mlcc that can compete with murata, laminated capacitors and aluminum electrolytic capacitors that can compete with panasonic and nichicon.

Development History -2001: Shangyu Yongming Electronics Co., Ltd. was established in Shangyu, focusing on electrolytic capacitors for lighting power supplies. -2005: Renamed shanghai Yongming Electronics Co.Ltd. moved to Fengxian District, Shanghai, andlaunched miniaturized electrolytic capacitorsfor lighting power supplies. -2008: We are the first in the industry to introduce adedicated series of LED drive power supplies. -2010: We are the frst in the industry to introduce 9mm high-end, full-voltage high-end power supply products. -2011: Our company is the first to promote 600Vultra-high voltage horn type and bolt type -2012: We are the frst to introduce a dedicated series of 7mm high-end, full-voltage high-endpower supplies. -2013: We pioneered full-voltage,small-size SMDchip electrolytic capacitors. -2014: We are the first to introduce the smaller sizeLKM series and the outdoor power supplyultra-low temperature start-up LKZ series. -2015: We are the first to promote the Dc chargingpile series and the LKJ series for smart meters. -2016: Miniaturized Cw3s series for Dc charging piles. -2017: Renamed as Shanghai yongming ElectronicsCo. Ltd.. it launched thin,full-voltage, 5mmhigh-SMD SMD SMD VMM series, a full range ofsolid-state products, high-voltage for fastcharging sources, and ultra-small kc series. -2018: Large-capacity thin solid capacitor VPs serieslow-ESR large-capacity miniaturized NPG series, ultra-small diameter NPM series, solid-liquid hybrid capacitor. -2019: Laminated polymer solid capacitor, super capacitor,ultra-small size,low impedanceliquid chip V3W series. 135°c hiah temperature resistant liquid chip VKL(R)series. -2020: Lithium-ion secondary battery, high voltagehigh Q MLCC,3.95mmL liquid/solid state chipaluminum electrolytic capacitor. -2021: Launched supercapacitor business unit modules (horn type, lead type) -2022: Construction of the third phase of the factory started, adding 28,000 square meters of production area Laminated products launch ESR 3mΩ -2023: Launched new product line of conductive polymer tantalum electrolytic capacitors Liquid launches high capacity density products (KCM) suitable for gallium nitride

Business unit introduction

The Liquid Miniature Business Division has been involved in R&D and manufacturing since 2001. It has an experienced R&D and manufacturing team and continues to steadily produce a variety of high-quality miniaturized capacitors to meet customers’ innovative needs for capacitors. The Liquid Small Business Division has two types of packages: liquid chip aluminum electrolytic capacitors and liquid lead aluminum electrolytic capacitors. Its products have the advantages of miniaturization, high stability, high capacity, high voltage, high temperature resistance, low impedance, high ripple, and long life. It is widely used in new energy automotive electronics, high-power power supplies, smart lighting, gallium nitride fast charging, home appliances, photovoltaics and other industries.

The Liquid Large Business Division was established in 2009 and focuses on the R&D and manufacturing of horn-type and bolt-type aluminum electrolytic capacitors. Liquid large-scale aluminum electrolytic capacitors have the advantages of ultra-high voltage (16V~630V), ultra-low temperature, high stability, low leakage current, resistance to large ripple current, and long life. The products are widely used in photovoltaic inverters, charging piles, vehicle-mounted OBC, and outdoor Energy storage power supply, industrial frequency conversion and other application fields. We give full play to the advantages of “a professional team that integrates new product development, high-precision manufacturing, and application promotion”, and towards the goal of “let there be no difficult container for charging”, we are committed to satisfying the market with technological innovation and combining different applications of customers demand, carry out technology docking and manufacturing connection, provide customers with technical services and special product customization to meet customer needs.

The solid-solid-liquid mixing division was established in 2017. Relying on the technology and talents of Japanese brands, it focuses on new product development, high-precision manufacturing and application promotion. Through investment in domestic advanced manufacturing equipment and continuous technological upgrades and breakthroughs, A product technology system with core competitiveness has been formed. Now it has established two product lines: solid aluminum electrolytic capacitors and solid-liquid hybrid aluminum electrolytic capacitors. The products comply with multiple certifications such as AEC-Q200 and IATF16949. Among them, solid aluminum electrolytic capacitors have the advantages of miniaturization, large capacity, ultra-low ESR, low leakage, and high current impact resistance. The products are mainly used in gallium nitride PD fast charging, industrial control, artificial intelligence, IDC servers, military industry and other industries; Solid-liquid hybrid aluminum electrolytic capacitors have the advantages of high reliability, wide temperature stability, wide frequency stability, ultra-low ESR, earthquake resistance, and high current impact resistance. The products are mainly used in the new energy automotive electronics industry. The two major product lines have won the trust and high praise of many well-known domestic and foreign brand manufacturers for their reliable product quality and excellent product characteristics.

The Supercapacitor Division was established in 2017. It has gathered a professional team integrating new product development, high-precision manufacturing, and application promotion. It has made every effort to introduce high-quality foreign materials and process technologies, forming a highly matched product technology system. Now we have a comprehensive range of domestic and foreign supercapacitors: such as cylindrical lead type, horn type, button type, module type, SMD chip type, 3.8V lithium ion capacitor, etc. The products comply with State Grid certification, AEC-Q200, IATF16949, etc. With multiple certifications, it is widely used in industries such as smart three-meter (electricity meter, water meter, gas meter), automotive electronics (ETC, driving recorder), new energy (wind pitch, photovoltaic), military industry (tank emergency starting power supply), etc. With the rapid development of 5G technology and the intelligent Internet of Things market, the products of the Supercapacitor Division will continue to inject development momentum into smart life and bring users a better experience.

The solid-state laminated business unit has been involved in research and development since 2018 and started mass production in March 2020. It currently has a monthly production capacity of 6 million units. The laminated polymer solid aluminum electrolytic capacitor has the advantages of high voltage, large capacity, thin profile, ultra-low impedance, and resistance to large ripple current. Its ultra-low ESR and powerful filtering ability are cutting-edge achievements in the field of aluminum electrolytic capacitors and are used in Communications, military industry, Internet of Things, IDC servers, artificial intelligence and other terminals.

Since its establishment in 2019, the MLCC Division has always been committed to the research and development, manufacturing and application promotion of high-voltage MLCCs, fully benchmarking against Taiwanese and Japanese high-end products and technologies. Now it has X7R, NPO and other product series, with voltages from 1KV to 3KV, all of which are large-sized high-voltage products above 1206. They are widely used in adapters, switching power supplies, high-voltage power supplies, lighting devices and other products.

The Polymer Polymer Tantalum Capacitor Division was established in 2022. Compared with its peers, Yongming polymer tantalum capacitors have higher capacity, lower ESR and higher withstand voltage. Products are widely used in digital servers, PCs, ultra-thin chargers, automotive electronics, communications industries, base stations, switches, industrial power modules, military power supplies and other fields. Yongming polymer tantalum capacitors replace imported tantalum capacitors, which has broad prospects and is worth cultivating.

● Support the innovation and upgrading of customer products. ● Ensure the stable operation of customer products. ● Eliminate hidden dangers in the use of customer products. ● Guarantee the user experience of customer products.

Ask YMIN for your capacitor solutions.

Website:https://www.ymin.cn/ E-mail: [email protected]

#manufacturer#electronic#capacitors#electrolytic capacitors#electric vehicles#electric cars#automotive components#electronic components#factory#energy storage#energy

0 notes

Text

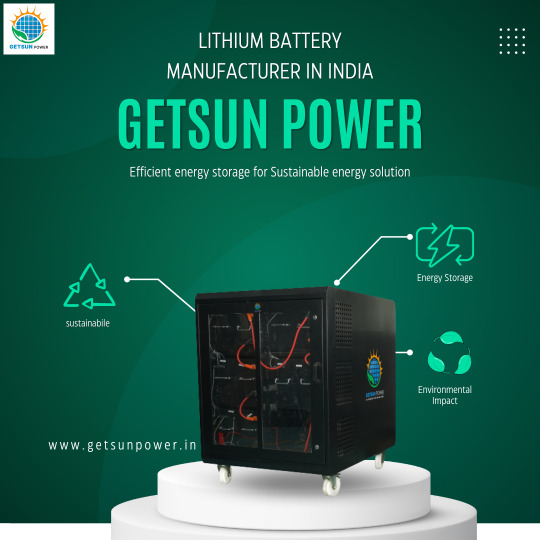

Getsun Power leads India's Lithium Battery manufacturing with advanced technology and a sustainability pledge, crafting top-tier batteries to maximize solar energy utilization.

#lithium ion battery#getsun power#battery manufacturer in india#top telecom battery module#top battery manufacturer in india#energy storage systems#battery suppliers in india#telecom battery bank suppliers in india#lithium ion battery in noida#lithium-ion battery manufacturers in noida

0 notes

Text

SAFETY AND STANDARDS TASKFORCE | IESA

Standardization is a critical topic with a direct impact on new product development and existing product propagation. IESA’s Safety and Standards Task Force works on developing performance & safety aspects of energy storage. IESA is a part of the BIS standards committee (ETD-52) and provides inputs on new standards for Li-ion cell, BMS, ESS systems, and charging infrastructure.

With the same thought process IESA and UL signed a MoU to create an Energy Storage Standards TaskForce in 2015.

The key areas of mutual working are:

Educating IESA members on standards development process

Standards gap analysis in the identified areas of interest

Standards training

Formation of standards cell and UL to act as a secretariat for standards development

UL standards development tool–CSDS deployment for standard development

Access to relevant UL Standards

IESA also joined the EES Sectional Committee by BIS (Bureau of Indian Standards) in 2016.

The scope of the committee includes standardization in the field of grid integrated Electrical Energy Storage Systems in India. The Sectional Committee focused on the following:

Standardization in the field of grid integrated Electrical Energy Storage Systems.

EES to include any type of grid-connected energy storages, which can both store electrical energy from a grid or any other source and provide electrical energy to a grid.

Activities:

Organized a training on safety and standards with ARAI.

Conducted India’s first two days training workshop for li-ion cell fabrication and battery testing in Pune with Centre for Materials for Electronics Technology (C-MET) on 11th and 12th March 2020.

Helped Indian companies and startups for the technology due diligence with the help with IESA's lead acid and Li-ion lab.

Sign up for IESA's newsletter for more information

#ETR for Stationary Storage Technologies#india energy storage alliance#energy storage technology#energy storage manufacturing#energy storage alliance in india#energy storage companies#energy storage projects in india#hydrogen fuel cells

0 notes

Link

With the rapid development of new energy, the demand for energy storage facilities continues to increase. Energy storage containers have gradually become the first choice in various fields due to their safety, reliability, and flexible movement. Thermal insulation is an indispensable part of energy storage containers. It plays an important role in improving energy storage efficiency, extending energy storage time, and ensuring energy storage safety.

#thermal insulation material#melamine foam#thermal insulation#energy storage systems#energy storage system insulation#battery energy storage#melamine foam manufacturer#basotect foam supplier

0 notes

Text

Green energy is in its heyday.

Renewable energy sources now account for 22% of the nation’s electricity, and solar has skyrocketed eight times over in the last decade. This spring in California, wind, water, and solar power energy sources exceeded expectations, accounting for an average of 61.5 percent of the state's electricity demand across 52 days.

But green energy has a lithium problem. Lithium batteries control more than 90% of the global grid battery storage market.

That’s not just cell phones, laptops, electric toothbrushes, and tools. Scooters, e-bikes, hybrids, and electric vehicles all rely on rechargeable lithium batteries to get going.

Fortunately, this past week, Natron Energy launched its first-ever commercial-scale production of sodium-ion batteries in the U.S.

“Sodium-ion batteries offer a unique alternative to lithium-ion, with higher power, faster recharge, longer lifecycle and a completely safe and stable chemistry,” said Colin Wessells — Natron Founder and Co-CEO — at the kick-off event in Michigan.

The new sodium-ion batteries charge and discharge at rates 10 times faster than lithium-ion, with an estimated lifespan of 50,000 cycles.

Wessells said that using sodium as a primary mineral alternative eliminates industry-wide issues of worker negligence, geopolitical disruption, and the “questionable environmental impacts” inextricably linked to lithium mining.

“The electrification of our economy is dependent on the development and production of new, innovative energy storage solutions,” Wessells said.

Why are sodium batteries a better alternative to lithium?

The birth and death cycle of lithium is shadowed in environmental destruction. The process of extracting lithium pollutes the water, air, and soil, and when it’s eventually discarded, the flammable batteries are prone to bursting into flames and burning out in landfills.

There’s also a human cost. Lithium-ion materials like cobalt and nickel are not only harder to source and procure, but their supply chains are also overwhelmingly attributed to hazardous working conditions and child labor law violations.

Sodium, on the other hand, is estimated to be 1,000 times more abundant in the earth’s crust than lithium.

“Unlike lithium, sodium can be produced from an abundant material: salt,” engineer Casey Crownhart wrote in the MIT Technology Review. “Because the raw ingredients are cheap and widely available, there’s potential for sodium-ion batteries to be significantly less expensive than their lithium-ion counterparts if more companies start making more of them.”

What will these batteries be used for?

Right now, Natron has its focus set on AI models and data storage centers, which consume hefty amounts of energy. In 2023, the MIT Technology Review reported that one AI model can emit more than 626,00 pounds of carbon dioxide equivalent.

“We expect our battery solutions will be used to power the explosive growth in data centers used for Artificial Intelligence,” said Wendell Brooks, co-CEO of Natron.

“With the start of commercial-scale production here in Michigan, we are well-positioned to capitalize on the growing demand for efficient, safe, and reliable battery energy storage.”

The fast-charging energy alternative also has limitless potential on a consumer level, and Natron is eying telecommunications and EV fast-charging once it begins servicing AI data storage centers in June.

On a larger scale, sodium-ion batteries could radically change the manufacturing and production sectors — from housing energy to lower electricity costs in warehouses, to charging backup stations and powering electric vehicles, trucks, forklifts, and so on.

“I founded Natron because we saw climate change as the defining problem of our time,” Wessells said. “We believe batteries have a role to play.”

-via GoodGoodGood, May 3, 2024

--

Note: I wanted to make sure this was legit (scientifically and in general), and I'm happy to report that it really is! x, x, x, x

#batteries#lithium#lithium ion batteries#lithium battery#sodium#clean energy#energy storage#electrochemistry#lithium mining#pollution#human rights#displacement#forced labor#child labor#mining#good news#hope

3K notes

·

View notes

Text

youtube

In this video, we introducing the Harveypower Lithium Battery Pack Aging Test – the solution to extending the lifespan of your battery packs. Our state-of-the-art testing facility combines cutting-edge technology and expert analysis to ensure your batteries perform at their best, even as they age.

Don't let battery degradation impact your business or personal projects. With our aging test, you'll get a comprehensive understanding of how your battery packs are performing and what you can do to extend their lifespan. Our testing process simulates real-world usage scenarios, so you can rest assured that your batteries will perform reliably when you need them most.

At Harveypower, we understand that battery performance is critical in today's fast-paced world. That's why we've made it our mission to provide the most accurate and insightful aging test available. Whether you're a business owner, a hobbyist, or a tech enthusiast, our aging test will give you the confidence to use your batteries to their fullest potential.

Say goodbye to unreliable batteries and wasted resources – with the Harveypower Lithium Battery Pack Aging Test, you can ensure that your battery packs are always performing at their best.

Contact us today to learn more about our battery production process and how we can help you extend the lifespan of your batteries.

#lifepo4 battery#lithium#lfp battery#lithium iron phosphate battery#solar battery storage#solar energy#solar system#solar battery#lithium ion battery#lithium battery#lithium manufacturer#Youtube

1 note

·

View note

Text

Solar Water Heaters and Solar Panels

A Comprehensive Guide to Solar Water Heaters and Solar Panels

In today's ever-evolving world, where sustainability and eco-friendliness are at the forefront of global concerns, solar energy stands out as a beacon of hope. Among the various applications of solar power, solar water heaters and solar panels hold immense potential to revolutionize the way we harness renewable energy. As we delve into the intricate details of these technologies, we uncover not only their environmental benefits but also their practicality and cost-effectiveness for households and businesses alike.

Understanding Solar Water Heaters

Solar water heaters epitomize innovation in the realm of energy-efficient water heating solutions. They utilize sunlight to heat water, significantly reducing reliance on conventional energy sources and thereby cutting down utility bills and carbon emissions. The mechanism behind solar water heaters involves collectors, storage tanks, and circulation systems working seamlessly to capture solar energy and transfer it into usable heat for domestic or commercial purposes. Buy the best solar water heaters from Jupiter Solar,www.jupitersolars.in.

Types of Solar Water Heaters

Active Solar Water Heaters: These systems employ pumps to circulate water through collectors and storage tanks, ensuring optimal heat transfer efficiency.

Passive Solar Water Heaters: Simpler in design, passive systems rely on natural convection to circulate water, making them more cost-effective and easier to maintain.

Advantages of Solar Water Heaters

Energy Efficiency: By harnessing abundant sunlight, solar water heaters can substantially reduce electricity or gas consumption for water heating, leading to long-term savings.

Environmentally Friendly: With zero greenhouse gas emissions during operation, these systems contribute significantly to reducing carbon footprints and mitigating climate change.

Reliability: Despite initial installation costs, solar water heaters boast long lifespans and minimal maintenance requirements, offering a reliable and sustainable water heating solution.

Unveiling the Potential of Solar Panels

In tandem with solar water heaters, solar panels form the cornerstone of solar energy utilization, catering to diverse energy needs ranging from residential to industrial scale.

How Solar Panels Work

Solar panels, also known as photovoltaic (PV) panels, consist of interconnected solar cells that convert sunlight into electricity through the photovoltaic effect. When sunlight strikes the panels, photons excite electrons within the cells, generating a flow of electrical current that can be harnessed for various applications.

Types of Solar Panels

Monocrystalline Solar Panels: Characterized by high efficiency and sleek aesthetics, monocrystalline panels are made from single-crystal silicon, offering superior performance in limited space.

Polycrystalline Solar Panels: Featuring a speckled blue appearance, polycrystalline panels are cost-effective alternatives to monocrystalline counterparts, providing decent efficiency at a lower price point.

Thin-Film Solar Panels: Thin-film technologies utilize lightweight and flexible materials such as amorphous silicon or cadmium telluride, offering versatility in installation and application scenarios.

Benefits of Solar Panels

Renewable Energy Source: Solar panels tap into an infinite and sustainable source of energy, reducing dependence on fossil fuels and contributing to energy security.

Reduced Electricity Bills: By generating electricity onsite, solar panel owners can offset or even eliminate electricity costs, resulting in substantial long-term savings.

Diverse Applications: From powering residential homes and commercial buildings to supplying remote areas and supporting off-grid systems, solar panels offer versatile solutions tailored to various needs and environments.

Conclusion

In conclusion, solar water heaters and solar panels represent groundbreaking innovations in renewable energy technology, offering tangible benefits in terms of energy efficiency, cost savings, and environmental stewardship. Embracing these technologies not only fosters a greener future but also empowers individuals and businesses to take charge of their energy needs sustainably.

#solar water heater#solar energy#bangalore#india#solar#solar water heaters#bengaluru#solar water heating#solar heater#water#solar power#solar system#solar panel#water heater#hot water#solar storage tanks#solar water heater systems#water heating#hot water systems#water storage#renewable energy company in bangalore#renewableenergy#solar water heater manufacturer#heaters#heater installation#heater

1 note

·

View note