#emi-emc

Explore tagged Tumblr posts

Text

MIL-MG3 Modular Impulse Test System | EMCI Plus

Discover the MIL-MG3, a portable impulse test system designed for military applications. It complies with MIL-STD 461 and DO-160 and features 11 Plug-In modules, a colour graphic touch-screen, and customisable templates for on-site applications. Enhance your testing capabilities with EMCI Plus.

#Emciplus#MIL-MG3inIndia#Impulsetestgenerator#MIL-MG3#emc shielding#emc partner#emc testing tools#emi-emc#emc shielding materials.#testing tools#emi-emc testing#emi emc testing

0 notes

Text

Top Testing Companies Pune - Reliable Solutions for You

Astute Lab: Trusted Food Testing Laboratories in Pune. NABL-approved labs in India, ensuring accurate, reliable, and high-quality testing services you can count on.

#Medical Device Testing Laboratories in India#Medical Equipment Testing#Water Testing Lab in Pune#IEC 60601-1#Food Testing Laboratories in Pune#Biomedical Equipment Calibration for Hospitals#EMI / EMC Testing#NABL approved Labs in India

0 notes

Text

#chennai#testing lab#laboratory#nabl accredited labs in chennai#emc#testing#electrical#nabl#emc testing#emi testing

0 notes

Text

Expert EMI/EMC Testing Services for Reliable and Compliant Products

Ensure your products meet stringent electromagnetic compatibility (EMC) and electromagnetic interference (EMI) standards with our state-of-the-art testing services. At our cutting-edge laboratory, we offer comprehensive EMI/EMC testing to help you achieve regulatory compliance and product reliability. Partner with us for precise testing, expert analysis, and swift certification, ensuring your electronic devices perform flawlessly in any environment. Contact us today to learn how our EMI/EMC testing services can support your product development and compliance needs.

1 note

·

View note

Text

Astute Labs Spearheading Innovation in Medical Device Testing

In the dynamic landscape of healthcare, the demand for precision and reliability in medical devices is paramount. Astute Labs emerges as a beacon of excellence, pioneering cutting-edge methodologies and technologies in medical device testing. With an unwavering commitment to quality and safety, Astute Labs stands at the forefront of ensuring the efficacy and compliance of medical devices. Here’s a closer look at how Astute Labs is shaping the future of medical device testing.

Redefining Standards: Astute Labs doesn’t just meet industry standards; it sets new benchmarks. By leveraging state-of-the-art equipment and innovative techniques, Astute Labs continuously pushes the boundaries of what’s possible in medical device testing. From initial concept to final product, every step is meticulously scrutinized to ensure optimal performance and safety.

Comprehensive Testing Solutions: Astute Labs offers a comprehensive suite of testing services tailored to meet the diverse needs of medical device manufacturers. Whether it’s biocompatibility testing, sterilization validation, or performance evaluation, Astute Labs provides end-to-end solutions that instill confidence in the reliability and efficacy of medical device testing laboratories.

Expertise and Experience: At the heart of Astute Labs is a team of seasoned professionals with unparalleled expertise in medical device testing. With years of experience and a deep understanding of regulatory requirements, the team at Astute Labs offers invaluable insights and guidance throughout the testing process, ensuring seamless navigation of complex regulatory landscapes.

Innovation and Adaptability: In an industry that’s constantly evolving, innovation and adaptability are essential. Astute Labs remains at the forefront of technological advancements, constantly exploring new methodologies and approaches to enhance testing efficiency and accuracy. By staying ahead of the curve, Astute Labs enables medical device manufacturers to bring innovative products to market faster and more confidently.

A Trusted Partner: Beyond just a testing laboratory, Astute Labs is a trusted partner to medical device manufacturers worldwide. With a reputation for excellence and reliability, Astute Labs fosters long-term relationships built on trust, integrity, and mutual success. From startups to multinational corporations, clients turn to Astute Labs for unparalleled expertise and support at every stage of the product lifecycle.

Astute Labs is not just a testing laboratory; it’s a catalyst for innovation and excellence in the field of medical device testing. With a relentless pursuit of quality, precision, and reliability, Astute Labs continues to shape the future of healthcare by ensuring that medical devices meet the highest standards of safety and efficacy. As the industry evolves, Astute Labs remains committed to empowering medical device manufacturers with the insights and solutions they need to succeed in a rapidly changing landscape.

0 notes

Text

Navigating the Electrical Interference Jungle: The EMI-EMC Study Lab

Before we delve into the EMI-EMC Study Lab, it's crucial to grasp the concepts:

Electromagnetic Interference (EMI): EMI is the unwanted disturbance caused by electromagnetic radiation from electronic devices, which can disrupt the performance of other nearby devices. It's the radio static you hear when a cell phone interferes with a speaker or the flickering of screens due to a nearby electronic gadget.

Electromagnetic Compatibility (EMC): EMC is the ability of an electronic device or system to operate effectively in its electromagnetic environment without causing interference to other devices or itself. It ensures that devices can coexist without negatively impacting each other.

Why is EMI-EMC Important?

Reliability: Ensuring EMC is critical for the reliable operation of electronic systems, preventing unexpected malfunctions or data loss.

Safety: In applications like healthcare and aviation, EMC is paramount to avoid potentially life-threatening interference in equipment.

Regulatory Compliance: Many industries have strict EMC regulations and standards that must be met to ensure the safety and functionality of devices.

Product Quality: EMI-EMC studies are essential in the development and testing of high-quality electronic products.

The EMI-EMC Study Lab:

An EMI-EMC Study Lab is a specialized facility equipped to investigate, analyze, and address electromagnetic interference and compatibility. These labs provide a controlled environment for testing and research, including:

Shielded Rooms: These rooms are designed to minimize external electromagnetic interference, providing a controlled environment for testing.

Testing Equipment: EMI-EMC labs house a range of testing equipment, including spectrum analyzers, signal generators, and oscilloscopes, to measure and analyze electromagnetic emissions and susceptibility.

Compliance Testing: EMI-EMC labs conduct compliance testing to ensure that electronic devices meet industry and regulatory standards for electromagnetic compatibility.

Design and Development: These labs are often used for research and development to design products with inherent EMC, reducing the need for external mitigation.

Education and Training: EMI-EMC labs provide opportunities for professionals and students to learn about electromagnetic interference and compatibility and their impact on electronic systems.

Conclusion:

The EMI-EMC Study Lab plays a crucial role in ensuring the reliability, safety, and compliance of electronic systems. As our world becomes increasingly reliant on electronics, understanding and mitigating electromagnetic interference is paramount. EMI-EMC labs provide the controlled environment, equipment, and expertise to address these challenges, fostering innovation and ensuring the seamless operation of electronic devices.

#EMI#EMC#ElectromagneticInterference#ElectromagneticCompatibility#EMIEMCTesting#ElectromagneticStandards#ComplianceTesting#ElectromagneticEnvironment#LabResearch#ElectronicsEngineering

0 notes

Text

Solar panels installed on roof at G4MCU

In the interest of being “greener”, this past week we have had solar panels installed on our roof, and a large battery unit downstairs together with an inverter. I had been concerned that there was a risk of RFI, particularly on 2 metres, my favourite band for weaker signal work, but it appears there is none so far. I have scoured the Web for a general consensus on possible problems, and I…

View On WordPress

0 notes

Text

SwRI adds new chamber for spacecraft-related EMC, EMI testing

Southwest Research Institute (SwRI) has added a semi-anechoic shielded enclosure for electromagnetic compatibility and interference (EMC/EMI) testing for spacecraft. The test chamber is the next step in SwRI’s plans to create a turnkey spacecraft integration and test center within its 74,000-square-foot Space System Spacecraft and Payload Processing Facility.

The 400-square-foot EMC/EMI Chamber is semi-anechoic, or free of echo, and shielded from electromagnetic interference. It supports performance of standard emissions and susceptibility testing with an upper frequency limit of 40 gigahertz (GHz) (Ka-band) and also provides the ability to perform spacecraft self-compatibility testing, which ensures that spacecraft subsystems and components work correctly and do not interfere with each other. The chamber will also evaluate radio frequency performance and compliance, important capabilities for wireless and telecommunications operations.

“This new chamber performs tests that indicate how a spacecraft will respond to a space environment. It incorporates significant automation, allowing us to test satellites and instruments more quickly and efficiently while maintaining appropriate cleanliness levels,” said Institute Engineer John Stone. “Locating the EMC/EMI chamber adjacent to other test facilities will also reduce the time lost and risk incurred while moving the test articles between buildings on the SwRI campus.”

The chamber is part of a 11,000-square-foot environmental testing facility within SwRI’s Space System Spacecraft and Payload Processing Facility, which also includes a high-decibel acoustic test chamber. The same building is home to 20,000 square feet of integration facilities, including two ISO 7 class 10,000 cleanrooms with 5-ton overhead bridge cranes and two ISO 8 class 100,000 high-bay cleanrooms outfitted with 7.5-ton bridge cranes.

In late September, the chamber performed EMC and EMI testing for four satellites that comprise the Polarimeter to UNify the Corona and Heliosphere (PUNCH) spacecraft. PUNCH, a SwRI-led NASA mission that will image how the Sun’s outer corona becomes the solar wind, is set to launch in February 2025.

“This chamber is an exciting addition, and we plan to continue to grow the capabilities of this facility as a site for comprehensive spacecraft integration and testing,” Stone said.

IMAGE: SwRI’s new semi-anechoic shield enclosure is designed to perform electromagnetic compatibility and interference and radio frequency testing for spacecraft. The wall and ceiling coverings absorb radio frequencies, allowing researchers and engineers to measure the performance of various electronic components. Credit Southwest Research Institute

3 notes

·

View notes

Text

IMU-MGE Conducted Immunity Test Systems Up to 8kV

Use IMU-MGE Conducted Immunity Test Systems for testing up to 8kV. Benefit from easy-to-use features, modular design, and improved safety for efficient and accurate testing. Access detailed test reports easily via USB or web server. Ensure reliable and cost-effective testing with IMU-MGE UPTO 8KV.

#CompactGenerator#VoltageGeneration#IMU-MGEinIndia#IMU-MGE#emi-emc testing#emc partner#emciplus#emi emc testing#emi-emc#testing tools#emc shielding materials.

0 notes

Text

Astute Lab - Trusted Testing Laboratories in Pune

Astute Lab: A leading medical device testing laboratory offering expert EMI/EMC testing services. We ensure compliance with IEC 60601-1 standards for all medica labs needs.

#Medical Device Testing Laboratories in India#Medical Equipment Testing#Water Testing Lab in Pune#IEC 60601-1#Food Testing Laboratories in Pune#Biomedical Equipment Calibration for Hospitals#EMI / EMC Testing#NABL approved Labs in India

0 notes

Photo

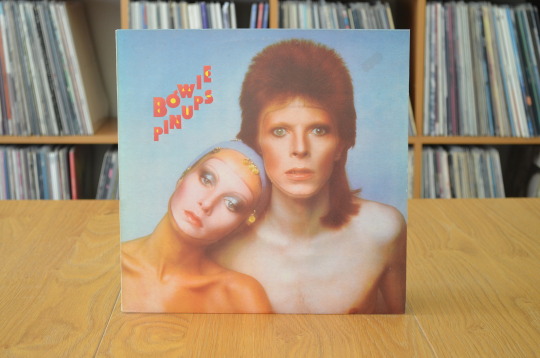

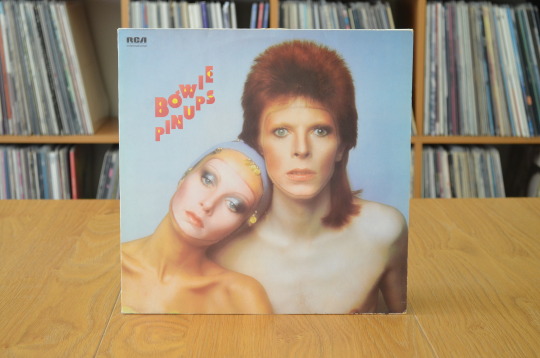

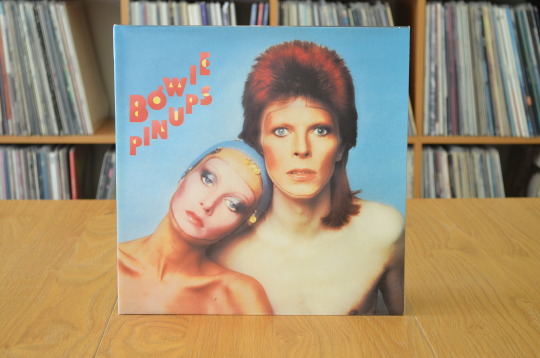

David Bowie: Pin Ups

top: RCA Victor RS 1003, 1973

2nd: RCA International NL 84653, 1983

3rd: EMI EMC 3580, 1990 (Gatefold, bonus tracks)

Originally released: October 19, 1973

#meine photos#vinylcollection#david bowie#1973 music#mick ronson#ken fordham#trevor bolder#aynsley dunbar#mike garson#geoff maccormack#vinyloftheday#vinylcommunity#vinylgeek#vinylrecords

7 notes

·

View notes

Text

Electromagnetic Interference (EMI) is a critical issue in electronic device design and manufacturing, as it can disrupt the functionality of both the device itself and nearby equipment. Conducted and radiated interference tests are essential components of the electromagnetic test process, ensuring that devices comply with regulatory standards. This paper explores the use of the electromagnetic test system, specifically the LISUN EMI-9KB EMI Test Receiver, in evaluating conducted and radiated EMI. Detailed methodologies, key test parameters, and real-world applications in various industries are discussed. Introduction With the increasing complexity of electronic devices, EMI poses a growing challenge in ensuring that products meet compliance standards and do not interfere with other devices. EMI testing is vital for manufacturers to identify and mitigate interference, ensuring that devices meet regulatory requirements such as CISPR, FCC, and other international standards. The electromagnetic test encompasses both conducted and radiated EMI testing, crucial for evaluating a device’s electromagnetic compatibility (EMC). The LISUN EMI-9KB EMI Test Receiver is a versatile instrument designed for comprehensive EMI testing. Its advanced features make it suitable for both conducted and radiated interference measurements, providing accurate and reliable data that helps manufacturers address EMI issues early in the design and production stages. Overview of Electromagnetic Test Electromagnetic tests for EMI involve two primary components: conducted and radiated interference testing. • Conducted EMI Testing: Measures the electromagnetic noise that is transferred from the device under test (DUT) to the power lines or other connected cables. This type of interference can affect other devices connected to the same power network. • Radiated EMI Testing: Assesses the electromagnetic energy emitted through the air from the DUT, which can impact the operation of nearby electronic devices. These tests are essential to ensure that electronic products are safe and function as intended in their operational environments. LISUN EMI-9KB EMI Test Receiver The LISUN EMI-9KB EMI Test Receiver is a high-precision instrument designed for electromagnetic test applications, particularly in detecting and analyzing conducted and radiated EMI. It complies with international standards, including CISPR 16-1, GB/T 6113-1, and EN 55016-1-1, making it suitable for global compliance testing requirements. Key Features: • Frequency Range: 9 kHz to 30 MHz for conducted emissions and up to 1 GHz for radiated emissions. • High Sensitivity and Accuracy: The receiver provides precise measurements with low noise levels, crucial for detecting subtle interference. • Automated Testing: Integrated software automates the test process, enhancing efficiency and reducing human error. • Data Analysis and Reporting: The system offers comprehensive data logging and reporting capabilities, facilitating in-depth analysis of EMI test results. Applications in Conducted EMI Testing Conducted EMI testing is performed to ensure that the DUT does not introduce harmful interference into the power lines. The LISUN EMI-9KB system uses a Line Impedance Stabilization Network (LISN) to provide consistent impedance and measure the noise generated by the DUT. Case Study: Testing Household Appliances Household appliances such as washing machines and refrigerators are prone to generating conducted emissions due to their motor-driven components. The LISUN EMI-9KB can evaluate these emissions to ensure compliance with standards such as CISPR 14-1. Test Parameter Value Standard Pass/Fail Criteria Frequency Range 150 kHz – 30 MHz CISPR 14-1 Emissions Peak Detector Level Read the full article

0 notes

Text

Electromagnetic Interference (EMI) is a critical issue in electronic device design and manufacturing, as it can disrupt the functionality of both the device itself and nearby equipment. Conducted and radiated interference tests are essential components of the electromagnetic test process, ensuring that devices comply with regulatory standards. This paper explores the use of the electromagnetic test system, specifically the LISUN EMI-9KB EMI Test Receiver, in evaluating conducted and radiated EMI. Detailed methodologies, key test parameters, and real-world applications in various industries are discussed. Introduction With the increasing complexity of electronic devices, EMI poses a growing challenge in ensuring that products meet compliance standards and do not interfere with other devices. EMI testing is vital for manufacturers to identify and mitigate interference, ensuring that devices meet regulatory requirements such as CISPR, FCC, and other international standards. The electromagnetic test encompasses both conducted and radiated EMI testing, crucial for evaluating a device’s electromagnetic compatibility (EMC). The LISUN EMI-9KB EMI Test Receiver is a versatile instrument designed for comprehensive EMI testing. Its advanced features make it suitable for both conducted and radiated interference measurements, providing accurate and reliable data that helps manufacturers address EMI issues early in the design and production stages. Overview of Electromagnetic Test Electromagnetic tests for EMI involve two primary components: conducted and radiated interference testing. • Conducted EMI Testing: Measures the electromagnetic noise that is transferred from the device under test (DUT) to the power lines or other connected cables. This type of interference can affect other devices connected to the same power network. • Radiated EMI Testing: Assesses the electromagnetic energy emitted through the air from the DUT, which can impact the operation of nearby electronic devices. These tests are essential to ensure that electronic products are safe and function as intended in their operational environments. LISUN EMI-9KB EMI Test Receiver The LISUN EMI-9KB EMI Test Receiver is a high-precision instrument designed for electromagnetic test applications, particularly in detecting and analyzing conducted and radiated EMI. It complies with international standards, including CISPR 16-1, GB/T 6113-1, and EN 55016-1-1, making it suitable for global compliance testing requirements. Key Features: • Frequency Range: 9 kHz to 30 MHz for conducted emissions and up to 1 GHz for radiated emissions. • High Sensitivity and Accuracy: The receiver provides precise measurements with low noise levels, crucial for detecting subtle interference. • Automated Testing: Integrated software automates the test process, enhancing efficiency and reducing human error. • Data Analysis and Reporting: The system offers comprehensive data logging and reporting capabilities, facilitating in-depth analysis of EMI test results. Applications in Conducted EMI Testing Conducted EMI testing is performed to ensure that the DUT does not introduce harmful interference into the power lines. The LISUN EMI-9KB system uses a Line Impedance Stabilization Network (LISN) to provide consistent impedance and measure the noise generated by the DUT. Case Study: Testing Household Appliances Household appliances such as washing machines and refrigerators are prone to generating conducted emissions due to their motor-driven components. The LISUN EMI-9KB can evaluate these emissions to ensure compliance with standards such as CISPR 14-1. Test Parameter Value Standard Pass/Fail Criteria Frequency Range 150 kHz – 30 MHz CISPR 14-1 Emissions Peak Detector Level Read the full article

0 notes

Text

0 notes

Text

Safeguarding Telecom Innovation with EMI/EMC Testing

Sunren Technical Solutions ensures that innovation and safety go hand in hand with our advanced EMI/EMC testing services. As a NABL-accredited and TEC-designated laboratory, we specialize in detecting and mitigating electromagnetic interference (EMI) and ensuring electromagnetic compatibility (EMC) to meet stringent industry and regulatory standards. Our proactive testing approach helps manufacturers identify potential risks early, ensuring reliable performance and seamless compliance. By safeguarding telecom solutions with rigorous testing, we empower you to bring groundbreaking innovations to market confidently. Trust Sunren to protect your telecom products, ensuring they are built for excellence, safety, and long-term success.

0 notes

Text

Ensuring Safety and Efficacy: The Critical Role of Medical Device Testing

In the realm of healthcare, the development and deployment of medical devices play a pivotal role in patient care and treatment outcomes. However, the journey from concept to market-ready product involves rigorous testing and validation processes to ensure both safety and efficacy. This is where Astute Labs step in, offering comprehensive testing services to manufacturers, researchers, and regulatory bodies.

Importance of Medical Device Testing

The significance of medical device testing cannot be overstated. Every device, from simple syringes to complex implantable devices, must undergo meticulous testing to assess its performance, reliability, and safety. These tests encompass a wide array of evaluations, including biocompatibility, mechanical testing, electrical safety, and usability assessments.

Compliance with Regulatory Standards

One of the primary objectives of medical device testing is to ensure compliance with stringent regulatory standards set forth by authorities like the FDA (Food and Drug Administration) in the United States or the European Union's CE marking requirements. Adhering to these standards is imperative for gaining market approval and instilling confidence among healthcare professionals and end-users regarding the device's safety and efficacy.

Comprehensive Testing Services by Astute Labs

Astute Labs specializes in providing a comprehensive suite of testing services tailored to the unique needs of Medical Device Testing Laboratories. Their team of experts utilizes state-of-the-art facilities and cutting-edge methodologies to conduct various tests, including:

Biocompatibility Testing: Assessing the device's compatibility with biological systems to ensure it doesn't cause adverse reactions when in contact with living tissues.

Mechanical Testing: Evaluating the device's structural integrity, durability, and performance under various mechanical stresses.

Electrical Safety Testing: Verifying the device's electrical components to ensure they meet safety standards and pose no risk of electric shock or fire hazards.

Usability Testing: Examining the device's user interface and ergonomics to assess its ease of use, user comprehension, and error prevention features.

Advancing Patient Safety and Innovation

By partnering with Astute Labs for medical device testing, manufacturers and innovators can not only expedite the development process but also enhance the overall quality and safety of their products. Through rigorous testing protocols and adherence to regulatory requirements, Astute Labs contributes to advancing patient safety and driving innovation in the healthcare industry.

Medical device testing is a critical component of the product development lifecycle, serving as a safeguard against potential risks and ensuring the delivery of safe and effective healthcare solutions. Astute Labs' expertise in this domain empowers stakeholders to navigate the complexities of regulatory compliance and quality assurance with confidence, ultimately leading to improved patient outcomes and advancements in medical technology.

#medical devices testing laboratories#medical device testing laboratories#emi emc testing#iec60601-1testing laboratory

0 notes