#electronic components finishing UK

Explore tagged Tumblr posts

Text

The Future of Electronic Industrial Finishing: What You Need to Know

Explore the latest trends in electronic industrial finishing, from miniaturisation to environmentally friendly processes. Discover how automation and advanced surface treatments are revolutionising the industry. Contact A-Gas Electronic Materials to stay ahead with innovative finishing solutions for your electronic products.

#electronic industrial finishing#advanced surface treatments UK#nanocoatings#graphene-based coatings UK#3D printing finishing UK#electronic components finishing UK#electroless plating UK#A-Gas Electronic Materials

0 notes

Text

2023 KTM 1290 Super Duke RR - Limited Numbers, Unlimited Fury

Following the roaring success of the KTM 1290 SUPER DUKE RR in 2021, 500 units of the 2023 KTM 1290 SUPER DUKE RR will go into production, promising the same levels of ferocity but with a meaner, darker look. The KTM 1290 SUPER DUKE RR will once again rip into the Tarmac, leaving a deep, lasting impression as the ultimate limited-edition Hyper Naked motorcycle in the KTM stable. The numbers tell the story – 1,301 cc, 180 hp, 180 kg and 140 Nm, with a phenomenal 1:1 power-to-weight ratio, making it every bit as beastly as its predecessor, but with a darker shadow. Sporting a gloss black and matt carbon base, contrasting white graphics and striking orange accents, the 2023 KTM 1290 SUPER DUKE RR casts an ominous shadow with menacing intentions. This is further exaggerated with a collection of unique custom-made components which are specific to the RR, adding more aggression and attitude. With the KTM 1290 SUPER DUKE RR being 11 kg lighter than a standard KTM 1290 SUPER DUKE R EVO, it is equally at home decimating lap times as it is carving up mountain roads, providing riders with the ultimate Hyper Naked package. However, it’s the collection of WP Suspension’s finest components worn by the 1290 SUPER DUKE RR that take it from a backroad brawler to accomplished track day terror. Upfront, a fully adjustable WP APEX PRO 7548 closed cartridge fork has been tailored specifically for the RR, while a custom-made WP APEX PRO 7746 shock takes charge of the rear. The WP APEX PRO 7117 steering damper keeps things in check, offering 30 clicks to dial it into your specification. Carbon fibre is used extensively, with the subframe also receiving the lightweight carbon treatment, creating a unique single-seat unit. The LED taillights are incorporated into the LED turn signals, as well as KTM’s adaptive brake light as standard. As an added extra to enforce the KTM 1290 SUPER DUKE RR exclusivity, owners will be presented with a bespoke carbon fibre box containing the keys to their new BEAST. For the absolute power-hungry, an Akrapovič EVO line full exhaust system is available as an optional extra, which adds even more bite to THE BEAST.

Notable features on the KTM 1290 SUPER DUKE RR include: - 1:1 power-to-weight ratio - WP APEX PRO COMPONENTS Suspension - Akrapovič Slip-on exhaust - Exclusive carbon fiber bodywork - Lightweight lithium ion battery - Ultra-lightweight forged wheel - Carbon fibre subframe with a single seat - New, black CTG - Limited to only 500 units - Unique, branded carbon key box - Factory triple clamp - Adjustable CNC-machined rearset

Not only impressive when it comes to hardware, the KTM 1290 SUPER DUKE RR boasts the most complete track-orientated electronics pack ever seen on a KTM motorcycle as standard, adding advanced TRACK and PERFORMANCE MODE. While the KTM 1290 SUPER DUKE RR already boasts a full range of exclusive components and bodywork, riders looking for more ferocity can browse a full range of specially developed KTM PowerParts, along with a dedicated range of KTM PowerWear. This includes a custom leather race suit, uniquely finished KTM 1290 SUPER DUKE RR branding and matching design.

The 2023 KTM 1290 SUPER DUKE RR will only be available in Europe and the United Kingdom. Orders open today, 13 March and can only be secured through a select number of authorised KTM dealers. For more KTM Motorcycles UK news check out our dedicated page KTM Motorcycles UK News or head to the official KTM Motorcycles UK website www.ktm.com/en-gb.html Read the full article

2 notes

·

View notes

Text

The Benefits of Choosing Custom Sheet Metal Plates from V and F Sheet Metal

If you’re in the market for custom sheet metal plates, there’s no better partner than V and F Sheet Metal. Based in Fareham, Hampshire, this family-run business has been crafting bespoke metal fabrications since 1985. Let’s explore why businesses across the UK trust them for their projects.

First, V and F combines decades of experience with cutting-edge technology. Their laser cutting process, powered by the Trumpf fibre laser, ensures precision and efficiency. Whether you need intricate designs or large-scale production, the process delivers reliable results. Moreover, their CNC bending capabilities allow for highly accurate folds and bends, even on complex shapes.

Another advantage lies in their tailored approach. Unlike off-the-shelf options, custom sheet metal plates are made to your exact specifications. Whether you require specific dimensions, materials, or finishes, their team collaborates with you to ensure the product fits seamlessly into your project. This is especially valuable for industries like lighting, where both functionality and aesthetics matter greatly.

Additionally, working with V and F saves time and effort. Thanks to their in-house capabilities, they can handle every stage of production under one roof, from initial design to final assembly. This reduces lead times and ensures a smoother workflow for your project.

Transitioning to cost considerations, custom sheet metal plates are surprisingly economical. By using advanced software and efficient production methods, V and F optimises material usage and minimises waste. This efficiency benefits businesses by reducing costs without compromising results.

Finally, their reputation speaks for itself. Serving industries like electronics, heating, and audio, V and F has built strong relationships with countless UK companies. Their commitment to meeting deadlines and exceeding expectations makes them a trusted choice.

In summary, choosing custom sheet metal plates from V and F Sheet Metal means investing in precision, versatility, and excellent service. With their combination of expertise and technology, they turn your design ideas into reality, keeping your project on track from start to finish. Why settle for less when you can get exactly what you need? Visit their website to learn more and start your next project today!

0 notes

Text

Global composite Metal Finishing Market — Forecast(2024–2030)

Global Composite Metal Finishing market size is forecast to reach $4.5 billion by 2030, after growing at a CAGR of 7.2% during 2024–2030.

Request Sample

There is an increasing demand for composite metal finishing as it improves chemical, wear, electrical, tarnish and corrosion resistance of the surface. Composite metal finishing even enhances solderability, visual appearance, conductivity, infrared reflectivity, hardness, and torque tolerance. Without metal finishing, products made from metals would last only a fraction of their present lifespan because of corrosion and wear. The rising demand for composite metal finishing to enhance electrical properties, form and shape components, and to augment the bonding of adhesives or organic coatings is driving the global composite metal finishing market during the forecast period. Its wide usage in automotive, electronics, aerospace and oil & gas industries is also driving the market growth.

The aerospace industry is poised for future growth, driven by a surge in passengers, a significant backlog of new aircraft orders, substantial investments, and ongoing advancements in research and development. Meanwhile, factors like increasing disposable income levels and shifting lifestyles are fueling the expansion of the electronics sector. Within the aerospace realm, this material finds application in various critical components including main engine shafts, propellers, gyro parts, engine mounts, oil nozzle components, servo valves, shear bolts, landing gear components, flanges, and engine oil feed tubes. Similarly, in the oil and gas industry, it is utilized for drilling components such as ball valves, cable glands, gate plugs, and tubular components, among others.

An increasing number of passengers, a large backlog of new aircraft orders, huge investments, and research and development advancements will propel the aerospace industry in the future. Similarly, the electronics sector is experiencing expansion fueled by increasing disposable income levels and shifts in lifestyle. Continuous technological progress, substantial investments, and the trend towards digitization will further boost demand for electronic products in the foreseeable future. Consequently, the electronics industry’s optimistic prospects will serve as a catalyst for future market expansion.

Inquiry Before Buying

COVID-19 Impact

The COVID-19 pandemic has had a significant impact on the global composite metal finishing market. With disruptions in supply chains, temporary shutdowns of manufacturing facilities, and fluctuations in demand across various industries, the market experienced challenges during the initial phases of the pandemic. Reduced industrial activities and construction projects further dampened market growth.

However, as economies gradually recovered and adapted to the new normal, the market started showing signs of recovery. The increasing emphasis on hygiene and cleanliness drove demand for antimicrobial coatings, which are commonly used in composite metal finishing.

Report Coverage

The report: “Global Composite Metal Finishing Market — Forecast (2024–2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the global composite metal finishing Industry.

By Process: Electroplating Process, and Electroless Composite Plating Process

By Filler Used: Diamond, Boron Nitride, Silicon Carbide, Polytetrafluoroethylene (PTFE), and Others

By End Use Industry: Aerospace, Automotive, Electronics, Oil & Gas, Heavy Machinery, and Others

By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia, and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), and Rest of the World (Middle East, and Africa).

Buy Now

Key Takeaways

Asia-Pacific dominates the global composite metal finishing market, owing to the rising demand for tough and corrosion resistant materials from the automotive, electronics and aviation sectors for applications such as pistons, shock absorbers, fuel injection rails, and fuel pumps in the region.

Electroless composite coating technology has various advantages such as energy and cost savings, automatic monitoring of chemical replenishment, and also, it aids in plating blind holes with stable thickness which acts as a driver for global composite metal finishing market.

Development of trivalent chromium hard chrome plating process is anticipated to drive the global composite metal finishing market growth during the forecast period as the hazardous nature of hard chrome plating and the potential risks to the environment and personnel can be drastically reduced.

Composite metal finishing market is driven by its wide usage in oil & gas sector for drilling components, ball valves, cable glands, gate plugs, tubular components and in electronic sector, for Printed Circuit Boards (PCBs), connectors, interlocks, junction fittings, computer drive mechanisms, chassis memory drums and discs, terminals of lead wires.

Global Composite Metal Finishing Market Analysis — By Process

The electroless composite plating process held the largest share in the global composite metal finishing market in 2023, owing to its extensive set of properties, such as improved corrosion resistance due to a more consistent thickness, the ability to plate complicated and irregular shapes, lower operating costs due to improved coating quality, improved mold and die release properties for stamping and drawing, uniform nickel coating composition for less waste and reduced downtime due to plating-related issues. The rising demand from automotive, oil & gas, and heavy machinery industries are expected to boost the market share of electroless composite plating process further during the forecast period.

Global Composite Metal Finishing Market Analysis — By End Use Industry

Automotive sector held the largest share in the global composite metal finishing market in 2023 and is growing at a CAGR of 7.9%, owing to its various applications in vehicle parts such as engines, other under-the-hood components, power steering systems, brake parts and systems, air conditioning components and systems, chassis hardware, climate control components, and fuel systems. Composite metal finishing is one of the prominent methods used to provide a protective layer on the metal components of vehicles. Various minor and major automotive parts need their contact surfaces to be smooth, stress relieved and without burrs or defects, which can be achieved by metal finishing. It is needed as it helps the automotive engines to achieve a surface with lower friction and heat, resulting in more horsepower generation and better overall performance. The constant demand for composite metal finishing from the automotive sector is anticipated to drive the global composite metal finishing market during the forecast period.

Global Composite Metal Finishing Market Analysis — By Geography

Asia Pacific region held the largest share in the global composite metal finishing market in 2023 up to 34%, owing to increased demand of aircrafts in the region. Aircrafts require composite metal finishing for corrosion protection of components such as landing gear and fasteners. For example, during May 2022, China Eastern released additional shares to fund fleet acquisitions. Over the span of 2022 to 2024, China Eastern Group, which encompasses Shanghai Airlines and OTT Airlines, plans to integrate 35 Airbus A320neo aircraft, nine Boeing 787–9s, nine A350–900s, 28 COMAC ARJ21s, and five C919s into its fleet. In February 2023, Air India agreed to buy 250 planes from Airbus and 220 from Boeing, worth a combined $70 billion. Air India plans to fund the order with internal cash and equity. The increasing demand from the aviation industry is anticipated to drive the global composite metal finishing market.

Global Composite Metal Finishing Market Drivers

Increasing Production of Automotives

Providing new coatings for automotive is by far the biggest industry for metal finishing. Automotive coatings revenue, including paint and base coat, is expected to increase the demand of composite metal finishing during the forecast period. In 2023, China’s automobile production and sales volume were 30.16 million and 30.09 million units, respectively. This represents an 11.6% increase in production and a 12% increase in sales. According to Royal Automobile Club of Victoria, 2023 was the best ever year for vehicle sales in Australia, with a total of 1,216,780 vehicles delivered, beating the previous sales record of 1,189,116 set in 2017. Due to the increasing expectations of consumers, the international automotive industry is required to extend vehicle warranties. Thus, improvements in corrosion protection are becoming increasingly important. The increasing automation production will require more composite metal finishing which will act as a driver for global composite metal finishing market.

Need for Durable and Wear Resistant Metal Products

Globally, large investments are being made in development of metals products for transportation infrastructure and vehicles, energy production and machinery, building materials and even consumer products. These investments are fueled by the need to develop metals that are durable, stronger and wear resistant throughout their use. The composite finishing of metals increases the strength, resistance to severe heat temperature, resistance to corrosion in alkaline and chlorine-bearing environments. Also, on proper composite finishing of metals, the metals do not scratch, bend, rot, warp, crack, split, catch fire or break over time. Moreover, finished metals provide strong structural integrity, weather resistance, and long-term strength. These extensive properties of metal finishing are anticipated to drive the global composite metal finishing market during the forecast period.

Global Composite Metal Finishing Market Challenges

Increasing Replacement of Metals by Plastics

Manufacturers have depended on metals due to the extensive properties of metal such as strength, stiffness, ideal traits related to electricity and chemical resistance. Replacing metal with plastic is beneficial as it saves cost and provides improved product quality. The weight of the products such as automobiles dramatically decreases on using parts manufactured by plastics due to which various automobile industries are shifting towards plastics instead of metals to manufacture light weight vehicles. Plastics also help with improving transportation for the end-use industries; by reduce shipping costs for the imports and exports of automotives. Scrap plastic parts or parts that need to be recycled can be ground into the original form, pellets, and reused for another injection process immediately. Also, plastics are preferred as they can be melted again to be reused while metal needs to be re-smelted, which is a longer process. All these enhanced properties of plastic acts as a restrain for the composite metal finishing market during the forecast period.

About IndustryARC™: IndustryARC primarily focuses on Cutting Edge Technologies and Newer Applications of the Market. Our Custom Research Services are designed to provide insights on the constant flux in the global demand-supply gap of markets. Our strong analyst team enables us to meet the client research needs at a very quick speed with a variety of options for your business. We look forward to support the client to be able to better address customer needs; stay ahead in the market; become the top competitor and get real-time recommendations on business strategies and deals. Contact Us: https://tinyurl.com/yk8khvpa Website URL: https://www.industryarc.com/

0 notes

Text

Global Air Knife Coater Market Assessment and Future Developments Analysis 2024 - 2031

The global air knife coater market is evolving rapidly, driven by advancements in coating technologies and increasing demand for precision coating in various industries. This article explores the key trends, applications, regional dynamics, and future outlook of the air knife coater market.

Key Trends in the Air Knife Coater Market

The global air knife coater market is poised for significant growth, driven by the demand for high-quality coatings and technological advancements. While challenges such as high initial investments and competition from alternative technologies exist

Growing Demand for High-Quality Coatings

The demand for high-quality coatings that enhance product performance and aesthetics is on the rise. Industries such as packaging, automotive, and electronics are increasingly adopting air knife coating technologies to achieve uniform coating applications with minimal material waste.

Technological Innovations

Recent innovations in air knife coater technology have significantly improved efficiency and effectiveness. New designs, such as adjustable air knives and automated systems, allow for better control of coating thickness and consistency, thereby enhancing product quality.

Focus on Sustainability

As industries strive to reduce their environmental impact, the air knife coater market is witnessing a shift towards sustainable coating solutions. Air knife coaters minimize material waste and VOC emissions, making them an attractive option for manufacturers seeking eco-friendly alternatives.

Applications of Air Knife Coaters

Packaging Industry

Air knife coaters are widely used in the packaging industry for applying coatings, adhesives, and inks. Their ability to deliver a precise and uniform coating makes them ideal for various packaging materials, including plastics, paper, and metal.

Automotive Industry

In the automotive sector, air knife coaters are employed for applying protective coatings and paints on vehicle components. These coaters ensure a smooth finish and uniform application, enhancing both the durability and aesthetic appeal of automotive parts.

Electronics Manufacturing

The electronics industry relies on air knife coaters for applying conformal coatings to circuit boards and other electronic components. These coatings protect sensitive parts from moisture, dust, and corrosion, ensuring long-term reliability and performance.

Regional Analysis

North America

North America is a significant player in the global air knife coater market, driven by advancements in manufacturing technologies and a strong focus on innovation. The region’s robust automotive and electronics sectors further bolster the demand for efficient coating solutions.

Europe

Europe is witnessing substantial growth in the air knife coater market, largely due to stringent environmental regulations and a focus on sustainable manufacturing practices. Countries such as Germany and the UK are leading the way in adopting advanced coating technologies across various industries.

Asia-Pacific

The Asia-Pacific region is experiencing rapid growth in the air knife coater market, fueled by expanding manufacturing capabilities and increasing investments in technology. Countries like China, Japan, and India are at the forefront, driven by the booming automotive and electronics industries.

Challenges Facing the Market

High Initial Investment

One of the primary challenges facing the air knife coater market is the high initial investment required for advanced coating systems. Smaller manufacturers may find it difficult to justify these costs, which could hinder widespread adoption.

Competition from Alternative Coating Technologies

The air knife coater market faces competition from alternative coating technologies such as roller coaters and spray coaters. Manufacturers must continuously innovate to differentiate their products and demonstrate the advantages of air knife coating systems.

Future Outlook

The future of the global air knife coater market appears promising, driven by ongoing technological advancements and increasing applications across various sectors.

Innovations in Coating Materials

Future developments in coating materials will likely enhance the performance of air knife coaters. The emergence of advanced polymers and eco-friendly coatings will open new avenues for application, catering to the growing demand for sustainable solutions.

Expansion of Automation

The integration of automation in air knife coating systems is expected to grow, improving efficiency and reducing labor costs. Automated air knife coaters can offer greater precision and consistency, making them an attractive option for manufacturers.

Conclusion

The global air knife coater market is poised for significant growth, driven by the demand for high-quality coatings and technological advancements. While challenges such as high initial investments and competition from alternative technologies exist, the overall outlook remains positive. As industries continue to seek sustainable and efficient coating solutions, air knife coaters will play a crucial role in shaping the future of manufacturing processes across various sectors.

#Global Air Knife Coater Market Size#Global Air Knife Coater Market Trend#Global Air Knife Coater Market Growth

0 notes

Text

Innovations Driving Growth in the Metal Stamping Market

The global metal stamping market size was estimated at USD 236.83 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 4.2% from 2024 to 2030.

Growing consumer electronics industry is likely to remain a key driving factor based on application of metal frames in mobile phones, headphones, speakers, and gamepads & controllers. In mobile phones, metal stamping is used in manufacturing antennas, chassis, and camera lens holders as it offers high tolerance, corrosion resistance, electrical conductivity, and a smooth finish. According to GSM Association, the global number of unique mobile subscribers was 5.31 billion in January 2021 and this number is growing at a rate of 1.8% per annum. This is likely to propel the demand for mobile phones and eventually metal stamping in coming years.

Gather more insights about the market drivers, restrains and growth of the Metal Stamping Market

The U.S. is one of the prominent player in the industry. However, emergence of COVID-19 and subsequent temporary lockdown measures countrywide impacted operations of the industry. Downstream demand from key sectors including automotive, aerospace, industrial machinery, and others was largely disrupted owing to challenges in supply chain and dried-up demand from end-use customers. The situation has normalized as rate of vaccination has picked up pace. Growing demand for metal stamping in the U.S. has compelled manufacturers to expand their facilities.

For instance, in December 2020, General Motors Co. announced its plans about investing USD 6 million in its metal stamping facility in Parma, Ohio, U.S. The investment will be used to construct four new metal assembly cells to support increasing production of Chevrolet Silverado and GMC Sierra pickup trucks.

According to International Energy Agency (IEA), global EV sales surpassed 3.4 million, out of which, China accounted for over 50% in 2021. Government initiatives, such as electric car subsidies to local manufacturers to support growth of EVs are major factors responsible for increased production. This is likely to boost the usage of sheet metal during production of auto components.

These components include chassis, interior and exterior structural, and transmission components. This, in turn, is expected to drive market growth during the forecast period. Market growth can be hindered as automobile manufacturers are replacing metals with plastic and carbon fiber as they assist in weight reduction of vehicles. A 10% reduction in weight of the vehicle results in a 5% to 7% increase in fuel efficiency.

Increasing production of lightweight vehicles owing to stringent government regulations in various countries is anticipated to drive demand for substitute products. For instance, in the U.S., developments in the Corporate Average Fuel Economy (CAFE) regulations to enhance fuel efficiency are encouraging use of these substitute products in automobiles, which, in turn, is likely to hamper the market for metal stamping.

Metal Stamping Market Segmentation

Grand View Research has segmented the global metal stamping market report based on process, press type, thickness, application, and region:

Process Outlook (Revenue, USD Million, 2018 - 2030)

• Blanking

• Embossing

• Bending

• Coining

• Flanging

• Others

Press Type Outlook (Revenue, USD Million, 2018 - 2030)

• Mechanical Press

• Hydraulic Press

• Servo Press

• Others

Thickness Outlook (Revenue, USD Million, 2018 - 2030)

• Less than & up to 2.5 mm

• More than 2.5 mm

Application Outlook (Revenue, USD Million, 2018 - 2030)

• Automotive

• Industrial Machinery

• Consumer electronics

• Aerospace

• Electrical & Electronics

• Building & Construction

• Telecommunications

• Others

Regional Outlook (Revenue, USD Million, 2018 - 2030)

• North America

o U.S.

• Europe

o Germany

o UK

o Italy

• Asia Pacific

o China

o India

o Japan

• Central & South America

• Middle East & Africa

Browse through Grand View Research's Advanced Interior Materials Industry Research Reports.

• The global copper pipes and tubes market size was estimated at USD 22.52 billion in 2023 and is estimated to grow at a CAGR of 5.9% from 2024 to 2030.

• The global aerostructure materials market size was estimated at USD 82.63 billion in 2023 and is projected to grow at a CAGR of 7.2% from 2024 to 2030.

Key Companies & Market Share Insights

Some of the key players operating in the market include CAPARO, Nissan Motor Co., Ltd and Goshen Stamping Company.

• CAPARO is mainly engaged in the designing, manufacturing, marketing, and distribution of value-added steel and niche emerging products. The group operates in North America, the UK, the Middle East, and India with its various subsidiaries such as Bull Moose Engineering Livonia, Caparo Engineering India Ltd – Chennai, and Caparo Middle East, among others.

• Nissan Motor Co., Ltd is engaged in the manufacturing, sales, and related business of automotive products. The company has several subsidiaries, dealers, and joint ventures, which are involved in R&D, design, production, automobile finance, and digital operations.

• Goshen Stamping Company specializes in producing high volumes with a combination of medium to high-speed presses with progressive dies. The company operates 36 presses ranging from 30-ton OBIs up to 400-ton SSDC. Its press bed sizes are up to 84" x 48" with stroke ranges from 2" to 8" for stamping. It offers a wide range of stampings in various materials such as carbon based steel, stainless steel, aluminum, or other metals.

• AAPICO Hitech Public Company Limited and Gestamp are some of the emerging market participants.

• AAPICO Hitech Public Company Limite is engaged in OEM auto parts manufacturing, car dealerships, and IoT connectivity and mobility. OEM auto parts manufacturing is further segmented into stamped or pressed parts, forged & machined parts, and plastic parts & plastic fuel tanks.

• Maoming Xingli Kaolin Co., Ltd. has a high-quality mine named acicular kaolin mine that spreads across 800 acres. The company offers several products such as bone china clay, clay for porcelain, kaolin clay, porcelain clay, and others. Its key focus is on washed kaolin (without acid), 90-degree ball clay, and 90- degree kaolin.

Key Metal Stamping Companies:

• Acro Metal Stamping

• Manor Tool & Manufacturing Company

• D&H Industries, Inc.

• Kenmode, Inc.

• Klesk Metal Stamping Co

• Clow Stamping Company

• Goshen Stamping Company

• Tempco Manufacturing Company, Inc

• Interplex Holdings Pte. Ltd.

• CAPARO

• Nissan Motor Co., Ltd

• AAPICO Hitech Public Company Limited

• Gestamp

• Ford Motor Company

Recent Developments

• In November 2023, Generational Growth Capital, an equity firm based in Milwaukee, U.S. acquired Federal Tool & Engineering, BP Metals, and Rockford Specialties based in Wisconsin, Minnesota and Illinois, U.S. respectively. The three manufacturers are metal stamping and structural steel manufacturers. This will enable the new entity to tap into various benefits such as expanding its manufacturing capacity, and support customers with interrupted delivery through a strong logistics supply chain.

• In October 2023, Ryerson acquired Norlen Inc., a metal stamping fabricator based Wisconsin, U.S. for an undisclosed sum. The latter mainly caters to the agricultural and defense markets.

• In June 2023, General Motors announced that it would be investing more than USD 500 million into its Arlington, Texas, U.S. assembly plant to produce the next generation SUVs. It intends to purchase new equipment for metal stamping, the body shop and other assembly parts.

Order a free sample PDF of the Metal Stamping Market Intelligence Study, published by Grand View Research.

#Metal Stamping Market#Metal Stamping Industry#Metal Stamping Market size#Metal Stamping Market share#Metal Stamping Market analysis

0 notes

Text

Shot Peening Abrasive Material Market Size,Volume,Revenue Trends Analysis Report 2024-2030

On 2024-8-1 Global Info Research released���Global Shot Peening Abrasive Material Market 2024 by Manufacturers, Regions, Type and Application, Forecast to 2030】. This report includes an overview of the development of the Shot Peening Abrasive Material industry chain, the market status of Consumer Electronics (Nickel-Zinc Ferrite Core, Mn-Zn Ferrite Core), Household Appliances (Nickel-Zinc Ferrite Core, Mn-Zn Ferrite Core), and key enterprises in developed and developing market, and analysed the cutting-edge technology, patent, hot applications and market trends of Shot Peening Abrasive Material. Shot Peening Abrasive Materials are materials used in the shot peening process, which is a surface treatment technique designed to enhance the mechanical properties of metal components. This process involves bombarding the surface of a material with small spherical media, or "shots," at high velocity to induce compressive residual stresses. According to our (Global Info Research) latest study, the global Shot Peening Abrasive Material market size was valued at US$ million in 2023 and is forecast to a readjusted size of USD million by 2030 with a CAGR of %during review period. This report is a detailed and comprehensive analysis for global Shot Peening Abrasive Material market. Both quantitative and qualitative analyses are presented by manufacturers, by region & country, by Type and by Application. As the market is constantly changing, this report explores the competition, supply and demand trends, as well as key factors that contribute to its changing demands across many markets. Company profiles and product examples of selected competitors, along with market share estimates of some of the selected leaders for the year 2024, are provided. Market segment by Type: Glass、Resin、Metal、Others Market segment by Application:Automotive、Aerospace、Others Major players covered: Abrasives Inc、Composition Materials、Sintokogio、Fuji Manufacturing、UJIDEN、NICCHU CO.,LTD.、Winoa、ITOH KIKOH、Opta Minerals、ABShot Tecnics、Advanced Finishing Technologies、AGSCO Corporation、SurfacePrep、Barton International、Synco Industries、Ervin Amasteel - UK、F.J. Brodmann、FROHN GmbH、Cym Materials、GMA Garnet、Ensio Resources、Naxos Diskus Schleifmittelwerke、Harsco Metals & Minerals、Prince Minerals、U.S Minerals、Blastrite、Saint-Gobain、K. C. Abrasive Company、Kramer Industries

Market segment by region, regional analysis covers: North America (United States, Canada and Mexico), Europe (Germany, France, United Kingdom, Russia, Italy, and Rest of Europe), Asia-Pacific (China, Japan, Korea, India, Southeast Asia, and Australia),South America (Brazil, Argentina, Colombia, and Rest of South America),Middle East & Africa (Saudi Arabia, UAE, Egypt, South Africa, and Rest of Middle East & Africa). The content of the study subjects, includes a total of 15 chapters: Chapter 1, to describe Shot Peening Abrasive Material product scope, market overview, market estimation caveats and base year. Chapter 2, to profile the top manufacturers of Shot Peening Abrasive Material, with price, sales, revenue and global market share of Shot Peening Abrasive Material from 2019 to 2024. Chapter 3, the Shot Peening Abrasive Material competitive situation, sales quantity, revenue and global market share of top manufacturers are analyzed emphatically by landscape contrast. Chapter 4, the Shot Peening Abrasive Material breakdown data are shown at the regional level, to show the sales quantity, consumption value and growth by regions, from 2019 to 2030. Chapter 5 and 6, to segment the sales by Type and application, with sales market share and growth rate by type, application, from 2019 to 2030. Chapter 7, 8, 9, 10 and 11, to break the sales data at the country level, with sales quantity, consumption value and market share for key countries in the world, from 2017 to 2023.and Shot Peening Abrasive Material market forecast, by regions, type and application, with sales and revenue, from 2025 to 2030. Chapter 12, market dynamics, drivers, restraints, trends and Porters Five Forces analysis. Chapter 13, the key raw materials and key suppliers, and industry chain of Shot Peening Abrasive Material. Chapter 14 and 15, to describe Shot Peening Abrasive Material sales channel, distributors, customers, research findings and conclusion.

Data Sources:

Via authorized organizations:customs statistics, industrial associations, relevant international societies, and academic publications etc.

Via trusted Internet sources.Such as industry news, publications on this industry, annual reports of public companies, Bloomberg Business, Wind Info, Hoovers, Factiva (Dow Jones & Company), Trading Economics, News Network, Statista, Federal Reserve Economic Data, BIS Statistics, ICIS, Companies House Documentsm, investor presentations, SEC filings of companies, etc.

Via interviews. Our interviewees includes manufacturers, related companies, industry experts, distributors, business (sales) staff, directors, CEO, marketing executives, executives from related industries/organizations, customers and raw material suppliers to obtain the latest information on the primary market;

Via data exchange. We have been consulting in this industry for 16 years and have collaborations with the players in this field. Thus, we get access to (part of) their unpublished data, by exchanging with them the data we have.

From our partners.We have information agencies as partners and they are located worldwide, thus we get (or purchase) the latest data from them.

Via our long-term tracking and gathering of data from this industry.We have a database that contains history data regarding the market.

Global Info Research is a company that digs deep into global industry information to support enterprises with market strategies and in-depth market development analysis reports. We provides market information consulting services in the global region to support enterprise strategic planning and official information reporting, and focuses on customized research, management consulting, IPO consulting, industry chain research, database and top industry services. At the same time, Global Info Research is also a report publisher, a customer and an interest-based suppliers, and is trusted by more than 30,000 companies around the world. We will always carry out all aspects of our business with excellent expertise and experience.

0 notes

Text

Global E-Textiles: The Rise of Connected Clothing How E-Textiles are Shaping the Future of Fashion.

Emergence of Smart Fabrics

Over the past decade, advances in materials science and electronics miniaturization have enabled the development of smart fabrics that can sense environmental conditions and user activity. By integrating functional components like sensors, batteries, and circuits into the fibers and threads themselves, researchers have created textiles with active and passive data collection capabilities. Some of the earliest prototypes included shirts that could monitor vital signs and interactive garments controlled by integrated touch displays. Commercially, smart socks entered to track steps and workout metrics. Behind the scenes, innovation in areas like electronic yarns, flexible displays, and embedded processors set the stage for richer interactions between garments and digital services. Expanding Functionalities

As the technology has matured, e-textiles have demonstrated widening use cases beyond healthcare and fitness. Designers have incorporated smart fabrics into futuristic concepts for fashion, interiors, and transportation. Military uniforms integrate armor, communications and environmental sensors for infantry. Performance apparel helps optimize training for athletes. Interactive garments respond to touches, gestures and motions as new interfaces. Smart PPE and workwear monitors worker safety. Embedded lighting, speakers and antennas turn garments into multi-purpose communication and entertainment hubs. Dynamic displays and controls bring interactivity directly to the surfaces of clothes. The functional range continues expanding as technical possibilities arise from flexible electronics research. Global Production and Supply Chains

To support growing and consumer demands, Global E-Textiles manufacturing has undergone scale up across global supply networks. Key textile producing countries in Asia like China, South Korea, India and Japan have made strategic investments nurturing domestic smart fabric. They provide critical hardware components, textile finishing, circuit integration and mass customization capabilities. In Europe, nations like Germany, Switzerland and the UK host prominent R&D labs and startups advancing next-gen materials. The US focuses on applications software and digital platforms. Regions work together leveraging their specialized competencies, from nanomaterials to full-stack development. Major brands have also built internal e-tech departments or outsourced to specialized manufacturers overseas. Thus international production partnerships shape the supply of smart garments worldwide. Data-Driven Business Models

In addition to products, e-textile companies develop complementary data services and platforms. Smart clothing generates streams of biometric, environmental and usage data that unlocks new monetization potentials when combined with analytics. Platforms aggregate anonymized multi-user insights to improve design, detect trends and optimize digital experiences. Some offer APIs for third party integrations. Subscription models provide ongoing access to data and app features. Brands gain consumer understanding to enhance design, and aftersales support. Enterprises utilize aggregated workforce data. Data sharing opens cross- partnerships between fashion, healthcare and IoT companies. As sensor-based data accumulates at massive scales, it will fuel advanced data-driven methods like machine learning with far-reaching impacts. Regulatory Harmonization

For the technology to achieve its full interconnected promise, international standards and regulations require coordination. Areas of focus include product safety certification, wireless spectrum allocations, data privacy and security protocols. Standards bodies work toward consensus on test methodologies, minimum performance levels and interoperability guidelines. National and trade regulators establish consistent baseline rules around issues like embedded medical devices, data sovereignty, consumer protections and unrestricted trade. As smart fabrics increasingly rely on borderless mobile networks and cloud services, collaboration helps prevent fragmentation that stifles innovation. roadmaps project technology needs to guide policy developments. Over time, streamlined regulatory frameworks can stimulate technology transfers between countries and smooth global trade flows of an emerging high-tech material sector. Future Directions and societal impacts

Looking ahead, E-Textiles represent a converging frontier where advanced materials, miniaturized flexible electronics and AI/IoT all intersect. As the hardware components continue decreasing in size at an exponential rate, smart fabrics are poised to dissolve into ordinary clothing almost invisibly while enhancing its functions tremendously. Fully washable, durable, self-powered garments with distributed sensors may one day unobtrusively collect physiological, behavioral and environmental data to empower personalized healthcare, wellness, safety, entertainment, communications and more. At a macro level, smart fabrics offer vast potential for socio-economic development by enabling new, connectivity access for remote populations and digital inclusion worldwide. However, issues around equitable access, data privacy, automation impact on jobs and environmental footprint will also require careful attention and governance to maximize benefits and mitigate risks of this revolutionary evolution in how technology interweaves with human lives.

Get More Insights on- Global E-Textiles

About Author:

Vaagisha brings over three years of expertise as a content editor in the market research domain. Originally a creative writer, she discovered her passion for editing, combining her flair for writing with a meticulous eye for detail. Her ability to craft and refine compelling content makes her an invaluable asset in delivering polished and engaging write-ups.(LinkedIn: https://www.linkedin.com/in/vaagisha-singh-8080b91)

0 notes

Text

Abrasives Market Trends, Challenges, and Future Prospects

The Global Abrasives Market is expected to register significant growth with a CAGR of around 4% over the period of 2021-2027. This can be attributed to the Increased demand for prefabricated building components and advancements in the manufacturing sector. Abrasives are materials that are repeatedly scraped against softer substances in order to polish them or to reduce the roughness of their surface. They are utilized in a variety of processes, including grinding, polishing, lapping, honing, pressure blasting, and others. Depending on the quantity of material to be removed, they come in a variety of particle or grit sizes. The automotive, metalworking, electrical, electronic, healthcare, and other end-use sectors all utilize abrasives extensively. For instance, according to IBEF reports, the automobile sector received cumulative equity FDI inflow of about US$ 32.84 billion between April 2000-March 2022. This is projected to boost the automobile sector and subsequently the abrasives market.

For a detailed analysis of the Global Abrasives Market browse through – https://univdatos.com/report/abrasives-market/

Based on type, the market is classified into bonded, coated, and super. The coated category holds a sizeable market share and is used in a number of sectors, including manufacturing, machine tools, furniture, and medical items. However, bonded abrasives are also anticipated to expand significantly throughout the anticipated period as they hold superior surface finishes in high precision edging sectors such as automotive, construction, and woodworking

Based on material, the market is classified into natural and synthetic. A considerable market share is held by the synthetic abrasive sector. Contrary to natural abrasives, which are mined, many synthetic abrasives are comparable to natural minerals but are produced artificially. This makes it far easier to alter the structure, size, and shape of grains. Furthermore, natural minerals lose some of their effectiveness due to impurities, making artificial abrasives a better option.

Request for Sample of the report browse through- https://univdatos.com/get-a-free-sample-form-php/?product_id=23656

For a better understanding of the market adoption of the abrasives industry, the market is analyzed based on its worldwide presence in the countries such as North America (US, Canada, Mexico); Europe (Germany, France, UK, Italy, Spain and Rest of Europe); Asia-Pacific (China, India, Japan, South Korea, Rest of Asia-Pacific), and Rest of World. It is projected that the abrasives market would expand more swiftly in countries like India and China due to rising development activities and accelerated economic expansion. Due to their enormous populations, these countries provide a sizable client base as well. The rising demand from the construction and automotive sectors is expected to drive up demand in the metal and chemical industries, leading to a growth in the APAC abrasives market. Since, abrasives are heavily used throughout chemical and metal processing operations in these industries, which stimulates the demand.

Some of the major players operating in the market include Robert Bosch GMBH, 3M Company, Saint-Gobain Abrasives, Inc, Fujimi Incorporated, LafargeHolcim, Balfour Beatty PLC, Kier Group PLC, Carillon PLC, Tyrolit Group and Asahi Diamond Industrial Co.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

0 notes

Text

UK Sheet Metal Fabrication Takes a Leap Forward with Innovative Ultra High Power Laser Cutting

In recent years, the field of sheet metal fabrication has seen remarkable advancements propelled by cutting-edge technologies. Among these innovations, ultra high power laser cutting stands out as a transformative method reshaping the industry landscape, particularly in the United Kingdom. This blog explores how this technology is revolutionizing sheet metal fabrication processes and its implications for the manufacturing sector.

Understanding Ultra High Power Laser Cutting

Ultra high power laser cutting machines utilize advanced laser technology capable of generating laser beams with significantly higher power levels than traditional laser cutting methods. This increase in power enables faster cutting speeds and the ability to process thicker and more robust materials with greater precision and efficiency. By harnessing this technology, manufacturers can achieve superior quality finishes and intricate designs that were previously challenging to produce.

The Impact on Sheet Metal Fabrication

Precision and Accuracy

One of the most significant advantages of ultra high power laser cutting is its ability to achieve precise cuts with minimal material distortion. This precision is crucial for industries requiring intricate components and complex geometries, such as aerospace and automotive sectors.

Increased Productivity

The enhanced cutting speeds offered by ultra high power lasers translate into increased productivity and shorter lead times. Manufacturers can fulfill orders more quickly without compromising on quality, thus improving overall operational efficiency.

Cost Efficiency

While initial investment in ultra high power laser cutting technology may be substantial, its long-term benefits include reduced operating costs due to faster processing times, lower energy consumption per part, and decreased material wastage.

Versatility

Ultra high power laser cutting is versatile enough to handle a wide range of materials, including stainless steel, aluminum, titanium, and various alloys. This versatility expands the application potential across multiple industries, from construction to electronics.

youtube

Innovations Driving Progress in the UK

The United Kingdom has been at the forefront of adopting and advancing ultra high power laser cutting technologies. Research institutions and manufacturing companies across the country are collaborating to push the boundaries of what is achievable with this cutting-edge method. Key innovations include:

Integration of AI and Automation

AI-powered systems are increasingly being integrated into ultra high power laser cutting machines to optimize cutting paths, monitor quality in real-time, and automate repetitive tasks.

Advancements in Beam Delivery Systems

Improved beam delivery systems enhance control over the laser beam, ensuring consistent and precise cutting across various materials and thicknesses.

Enhanced Cooling and Optics

Innovations in cooling systems and optics prolong the lifespan of laser components and maintain cutting quality over extended periods of operation.

Future Outlook

Looking ahead, the future of sheet metal fabrication in the UK appears promising with continued advancements in ultra high power laser cutting technology. As research and development efforts progress, we can expect further improvements in efficiency, cost-effectiveness, and the ability to handle even more challenging materials and designs.

SLTL is Excited to Connect with Florida's Growing Manufacturing Base

This year, we can't wait to bring SLTL’s Ultra High-Powered Laser Innovations to Orlando and provide the expanding Florida manufacturing sector with another opportunity to witness SLTL's cutting-edge laser technology up close. Manufacturers from all over the world will gather in Orlando for FABTECH 2024 to witness innovative solutions and remain ahead of the curve in manufacturing technology.

SLTL is going to offer attendees the opportunity to witness live equipment demonstrations, build strategic partnerships, identify solutions, and stay ahead of the curve in the ever-evolving manufacturing landscape.

Knowledge Hub at SLTL’s Booth

The 2024 SLTL booth will be a knowledge hub for attendees, featuring demonstrations and insights into laser cutting, laser marking, laser welding, automation, smart manufacturing, and much more. In addition, attendees will gain knowledge about IoT-integrated machinery and witness live demonstrations of them.

Prepare for the Groundbreaking Experience

Get ready because SLTL is prepared to have an amazing time with the attendees at this event, which promises to be an incredible experience in its own way. Come see us in Hall No – S31150 at Orange County Convention Center in Orlando, Florida, from October 15-17, 2024.

Conclusion

In conclusion, ultra high power laser cutting is not just a technological advancement but a catalyst for transformation within the sheet metal fabrication industry. Its adoption in the United Kingdom underscores the nation's commitment to innovation and competitiveness in global manufacturing. As these technologies evolve, they will undoubtedly reshape industries, drive economic growth, and pave the way for new possibilities in engineering and design.

For manufacturers and businesses operating in the UK, embracing these innovations could mean staying ahead of the curve in a rapidly evolving market landscape. By leveraging ultra high power laser cutting, they can unlock new levels of productivity, precision, and profitability, securing their position as leaders in the global manufacturing arena.

Stay tuned as we continue to explore the latest developments and trends shaping the future of sheet metal fabrication and manufacturing worldwide.

0 notes

Text

Sheet Metal Prototyping Process: Your Guide with HLH Rapid

Sheet metal prototype is an important phase in the product development process that helps make ideas become concrete products. To be successful, you must grasp the sheet metal prototype process, whether you're creating stylish enclosures for consumer electronics or precise components for aerospace applications.

Understanding the Basics:

Using thin metal sheets, sheet metal prototyping is the process of creating first models or prototypes. Before full-scale manufacturing starts, these prototypes act as testbeds for functional testing, design validation, and feasibility analysis.

The Prototyping Process

Starting a sheet metal prototype project with HLH Rapid requires an accurate approach that is marked by careful preparation and flawless execution:

Design Consultation: Work with the skilled engineers at HLH Rapid to refine your concept for maximum manufacturing feasibility. Identify possible hazards and investigate creative solutions by utilizing their experience.

Material Selection: Select from a wide variety of sheet metal materials, such as titanium, stainless steel, and aluminum, based on the specifications of your project. Superior performance and durability are guaranteed by HLH Rapid's access to high-quality materials procured from reliable vendors.

Prototyping Technologies: Use the cutting-edge laser cutting, CNC punching, and precise bending capabilities of HLH Rapid to your advantage. Gain from unmatched precision and quick turnaround times, which allow for quick prototype testing and improvement.

Quality Assurance: You may be guaranteed that every step of the production process involves thorough quality assurance inspections for your prototypes. Because HLH Rapid follows strict quality standards, you can be sure that your prototypes will be functional, accurately sized, and have a smooth surface.

Iterative Refinement: Use the iterative prototyping method of HLH Rapid to foster a culture of continual improvement. Achieve the best outcomes by integrating input, transitioning between design iterations and responding to problems immediately.

Finally, there are countless opportunities for product creation when you become proficient in the sheet metal prototype process. HLH Rapid gives you the capability to bring your ideas quickly, precisely, and dependably to life by using cutting-edge technology, skilled craftsmanship, and a dedication to quality.

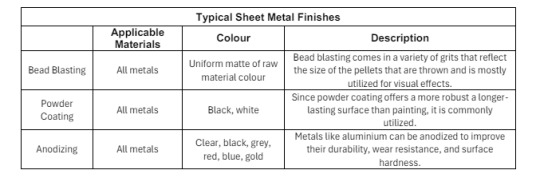

Here are few typical Sheet Metal Finishes:

If you would like to learn more about sheet metal prototyping, visit our site https://hlhrapid.com/sheet-metal-work/ or email us at [email protected].

About Us:

HLH is a unique fusion and the best of the West and East, founded by industry veteran Vader Yu from China and Director James Murphy from the UK. We support cutting edge companies globally, using our expertise and experience to enable innovation by rapidly manufacturing high quality prototypes and production parts.

0 notes

Text

Discover A-Gas Electronic Materials' EIF solutions for high-performance PCB production and electronic components. Our advanced chemistries ensure superior quality and reliability in electronic devices. Trust A-Gas for innovative industrial finishing technologies.

#Electronic Industrial Finishing#EIF solutions#high-performance PCBs#electronic components#plating solutions#metal stripping#cleaning agents#soldermask resists#A-Gas Electronic Materials#UK electronic manufacturing#electronic finishing services#PCB production#electroplating#metal treatment products

1 note

·

View note

Text

Choosing V and F Sheet Metal for your UK-based laser cutting and bending projects ensures efficiency, precision, and value from a company with nearly four decades of industry expertise. Based in Fareham, V and F Sheet Metal specialise in high-quality, UK-based laser cutting and CNC bending services that are ideal for both small and large production runs. Laser technology enables precise cuts across a range of materials and shapes, making it versatile for many sectors including lighting, electronics, and audio.

One reason to choose V and F Sheet Metal is their investment in advanced machinery like the Trumpf Tru-Bend and TruLaser equipment, which integrates with sophisticated CAD/CAM software to produce efficient and accurate results. This combination allows V and F to map out and optimise each bend and cut sequence before any materials are used, reducing material waste and production time.

Furthermore, with their in-house Radan software, they can generate detailed 3D models of your components, giving you a clear view of the final product. This process minimises design errors and enhances communication between you and the engineering team. The focus on efficiency and technological advancement makes them a reliable choice for competitive pricing without sacrificing effectiveness.

By sourcing laser cutting and bending locally from V and F Sheet Metal, you benefit from a seamless process handled entirely within the UK. This ensures faster turnarounds, reliable service, and a support team that understands the needs of UK-based projects. With V and F Sheet Metal’s extensive industry experience, you can trust that your project will be handled professionally from start to finish.

Come and take a look and ask us to quote on your next sheet metal project.

0 notes

Text

Choosing the Right Single Socket Outlet with USB for Your Home: Key Considerations

In an increasingly digital world, finding convenient and effective ways to power and charge electronic single socket with usb in UK ports have developed as viable options to fulfill this expanding need. Whether you're rebuilding your home or simply seeking to upgrade your electrical outlets, selecting the best single-socket outlet with USB takes considerable thinking. In this blog, we will look at essential factors to assist you make an informed selection.

1. USB Charging Capacity:

When choosing a single socket with USB in UK ports, it is critical to examine the charging capability of the USB ports. USB charging standards have developed over time, and newer versions support faster charging speeds. Look for outlets with USB connections that deliver at least 2.4 amps or more to ensure faster and more efficient charging for a wide range of devices, including smartphones, tablets, and other USB-powered electronics.

2. Number of USB Ports:

Determine your charging requirements and the number of devices you usually use in the allotted area. Single socket outlets with USB ports are available in a variety of layouts, each offering one or more USB ports. Consider how many gadgets you will be charging at the same time and select an outlet that meets your needs. Furthermore, outlets with several USB ports provide flexible charging options, accommodating a variety of devices without the need for extra converters or power strips.

3. Compatibility with Devices:

USB Type-A and Type-C are two popular connector kinds, and your devices may use one or both. Ensure that the single socket outlet you select has USB ports that are compatible with the devices you intend to charge. Some current outlets contain both USB Type-A and Type-C connectors to accept a wide range of devices, increasing versatility and future-proofing your charging arrangement.

4. Power Outlet Configuration:

Consider the total arrangement of a single plug outlet. Some outlets contain a single power outlet and one or more USB ports, whilst others may have numerous power outlets in addition to USB ports. Assess the power requirements in the area where you intend to place the outlet. If you need more power outlets for traditional gadgets appliances or lamps select an outlet that strikes the proper mix between standard power outlets and USB ports.

5. Design and Aesthetics:

Aside from utility, the style and aesthetics of the single socket outlet should complement the decor of your home. Outlets are available in a variety of styles, finishes, and colours to suit different decor preferences. Consider the design components of the room where the outlet will be located, and select an option that blends easily with the overall look. Some outlets even have customizable faceplates allowing you to match them to your wall colour or switch plate style.

6. Built-In Safety Features:

When working with electrical outlets, safety is the most important factor. Look for outlets that include safety features like overcurrent protection, short-circuit avoidance, and tamper-resistant receptacles. These safety precautions protect your electronics, the outlet, and, most importantly, the safety of your house and family.

7. Ease of Installation:

You should also consider the installation process while making your decision. If you are unfamiliar with electrical work, it is best to employ a skilled electrician for installation. However, some single socket outlets are designed for simple installation, with user-friendly designs and explicit instructions. If you're comfortable with DIY tasks, select an outlet that matches your installation skills.

8. Smart Outlet Options:

Explore smart outlet alternatives with USB ports for increased convenience and control. Smart outlets can be connected to home automation systems, allowing you to control and monitor your power consumption remotely. Some smart outlets even provide energy monitoring functions, which allow you to watch the power use of linked devices.

Conclusion:

Choosing the best single socket with usb in UK for your home requires careful consideration of your charging requirements, device compatibility, power outlet arrangement, design preferences, safety features, ease of installation, and possibilities for smart functionality. By taking into account these crucial elements, you can choose an outlet that not only fits your practical needs but also improves the usefulness and aesthetics of your living environment. A well-chosen single-plug outlet with USB, whether in the living room, bedroom, or home office, may simplify your charging routine while also contributing to a more efficient and organized home.

For more information click here

0 notes

Text

Powder Metallurgy Market Forecast 2024 to 2032

Powder Metallurgy (PM) is a manufacturing process used to produce components and parts from metal powders. This method offers several advantages over traditional metalworking techniques, as it allows for the creation of complex shapes and structures with a high degree of precision. Powder Metallurgy involves several stages, including powder production, blending, compacting, sintering, and finishing.

The Powder Metallurgy Market was valued at USD 12,700.2 Million in 2022 and is expected to register a CAGR of 4.10% by 2032.

The electronics industry requires components with specific electrical and thermal properties. Powder Metallurgy offers a way to produce components like electrical contacts, connectors, and heat sinks with consistent properties. This is a crucial factor expected to drive global market growth during the forecast period.

Get PDF Sample Report: https://www.xcellentinsights.com/enquiry/sample/502540

Key Company •GKN •Sumitomo Electric Industries •Hitachi Chemical •Fine Sinter •Miba AG •Porite •PMG Holding •AAM •Hoganas AB •AMETEK Specialty Metal Products •Allegheny Technologies Incorporated •Burgess-Norton •Carpenter Technology •Diamet •Dongmu •Shanghai Automotive Powder Metallurgy •Weida

Market Segmentation (by Type) •Ferrous Metals •Non-ferrous Metals

Market Segmentation (by Application) •Automotive •Aerospace •Medical •Industrial •Electrical & Electronics •Others

Get Full report + Tables + Graphs: https://www.xcellentinsights.com/reports/powder-metallurgy-market-502540

About Us:

Xcellent Insights is a market intelligence provider and consulting firm. We offer data-driven research services based on multiple analysis frameworks which helps businesses across the globe to understand current market scenario and align their strategic initiatives.

We offer syndicated research reports, customized research reports, consulting services and datasets which are mapped across multiple datapoints.

We provide research reports for all the industry sectors like Consumer Goods, Packaging, Chemicals and Materials, Healthcare, Pharmaceuticals, Medical Devices, Agriculture, Food and Beverages, Automobile and transportation, Electronics and Semiconductors, IT and Communication, Energy and Power, Machinery and Equipment.

Contact Us:

Name: Willie J

Phone: US: +1 4086277717

UK: +44 2086386439

Email: [email protected]

#Powder Metallurgy Market#Powder Metallurgy Market size#Powder Metallurgy Market share#Powder Metallurgy Market trend

0 notes

Text

Toy manufacturers shift focus to sustainability

Mattel and Hasbro increment supportability endeavors

Lately, there has been a shift to manageability and many organizations have experienced harsh criticism for adding to contamination and have been called out for not assuming sufficient social liability. Consequently, Mattel and Hasbro have been intensifying their environmental initiatives.

As additional shoppers are turning out to be progressively keen on the effect items they are buying have on the climate, putting vigorously in supportability will permit both Mattel and Hasbro to stretch out their scope to a more extensive objective market.

In January 2020, Mattel announced that its Mega Bloks line would now include three pre-school building sets—Polar Friends, Safari Friends, and Woodland Friends—that will all be constructed from bio-based resins.

The structure sets have Woods Stewardship Board affirmed (FSC) it is completely recyclable to bundle that. In addition, by 2030, Mattel pledged to use only recycled, recyclable, or bio-based plastics in all of its products and packaging.

Mattel outperformed its 2018 objective of progressing to 90% reused material for its paper and wood bundling. Currently, the company uses recycled or FSC-certified paper and wood fiber for 93% of the paper and wood fiber in its products and packaging.

Hasbro declares plans to progressively eliminate plastic from item bundling

Mattel's immediate rival Hasbro declared in 2020 that it wanted to start gradually getting rid of plastic from new item bundling, including plastic components like polybags, flexible groups, shrivel wrap, window sheets and rankle packs. The organization expects to take out essentially all plastic in bundling for new items toward the finish of 2022.

Hasbro director and Chief Brian Goldner said: " The most recent step in our more than a decade-long endeavor to create a more sustainable future for our company and the world is the removal of plastic from our packaging.

Hasbro has been committed to environmental sustainability for a very long time. In 2010, the maker disposed of wire ties and added How2Recycle marking in 2016. In an effort to reduce its reliance on resources that are not renewable, the company announced in 2018 that it would use plant-based bio-polyethylene terephthalate (bioPET) for plastic windows and blister packs. The company made it clear that it will make use of bioPET plastics that are made with 30 percent of the material coming from agricultural by-products.

Hasbro and Mattel join forces with TerraCycle In 2020, Hasbro extended its partnership with TerraCycle by expanding its toy and game recycling program to the UK. Customers will be able to pick up and drop off their Hasbro games and toys at any location in the country thanks to the new program in the UK. TerraCycle will then reuse them into reusable unrefined components, which can be utilized to make new items like outside furnishings, grower and comparable things.

That very year, Mattel sent off the Blocks and Blocks Reusing System and entered an organization with TerraCycle for purchasers to reuse Super Bloks, Mega Construx and other non-electronic Mega toys to make new items in Canada. At no charge, customers, including schools, workplaces, and local area associations, can send in their Mega toys to be reused utilizing a prepaid delivery name. TerraCycle will then dissolve them into hard plastic and remold them to make new items from the reused materials.

0 notes