#electrodes rod

Explore tagged Tumblr posts

Text

Exploring Welding Electrodes: Types and Applications

Dive into the world of welding electrodes, understanding their various types and versatile applications across industries. Headsup B2B, a platform connecting businesses with quality suppliers, presents this comprehensive overview.

1 note

·

View note

Text

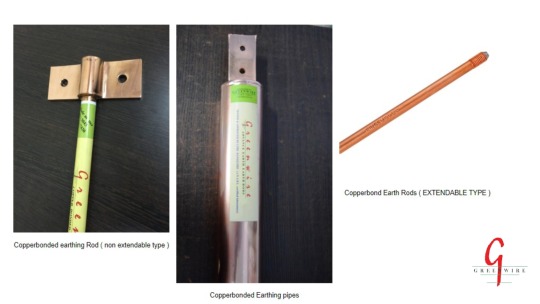

Copper Bonded Earthing Rods | Copper Coated Earthing Rods

Get high-quality Copper Bonded Earthing Rods from GSC Infra Solutions. We offer Copper Coated Earthing Rods & Copper Bonded Earthing Electrodes. Call 9999886013.

#Copper Coated Earthing Rods#Copper Bonded Earthing Electrode#copper bonded chemical earthing#copper bonded electrode#copper coated grounding rod#copper electrode for earthing#copper rod electrode earthing system#pure copper earthing electrode

1 note

·

View note

Text

Top Welding Electrode Suppliers: Your Guide to Quality and Reliability

Find top welding electrode suppliers for high-quality welding materials, rods, holders & electrode ovens. Get the best welding products from trusted suppliers!

#welding electrode suppliers in saudi arabia#electrode oven price#welding rod supplier#welding material#welding products#welding material supplier#welding holders

1 note

·

View note

Text

0 notes

Text

Graphite for modern industrial machinery graphite rod graphite bushing graphite block Graphite mold graphite sheet Graphite sleeve Graphite bearings graphite ring Graphite products for emerging markets Special graphite products Metal graphite products Graphite and carbon brush electrodes Carbon brushes for power tools Carbon brushes for micromotors and small household appliances Carbon brushes for automobiles and motorcycles Industrial carbon brushes

#carbon#business#Graphite for modern industrial machinery#graphite rod#graphite bushing#graphite block#Graphite mold#graphite sheet#Graphite sleeve#Graphite bearings#graphite ring#Graphite products for emerging markets#Special graphite products#Metal graphite products#Graphite and carbon brush electrodes#Carbon brushes for power tools#Carbon brushes for micromotors and small household appliances#Carbon brushes for automobiles and motorcycles#Industrial carbon brushes

1 note

·

View note

Text

Renown Earth: India’s Leading Copper Bonded Rod Manufacturer

Renown Earth is a leading Indian manufacturer and supplier of high-quality Copper Bonded Rods, designed for superior conductivity, corrosion resistance, and durability. These rods, created through advanced electroplating techniques, are ideal for grounding and earthing systems, ensuring reliable performance across varying soil and environmental conditions. Known for their efficiency and low maintenance, Renown Earth's Copper Bonded Rods are trusted worldwide.

Visit More : renownpower.com

#Copper Bonded Rod#Earthing Solutions#Electrical Safety#Grounding Systems#Copper Bonded Electrodes#Industrial Earthing

0 notes

Text

#welding consumables manufacturers#welding wire manufacturers#welding electrode manufacturers#welding rod manufacturers

0 notes

Text

Pure Copper Bonded Earthing Electrode Manufacturers In Hyderabad

When it comes to electrical safety and grounding solutions, investing in high-quality earthing systems is essential. One of the most efficient solutions is the pure Copper Bonded Earthing Electrode, renowned for its durability and conductivity. If you're in Hyderabad, you can rely on the pure Copper Bonded Earthing Electrode manufacturers in Hyderabad to provide reliable and superior products tailored to your needs.

#Pure Copper Earthing Electrode Manufacturers in Hyderabad#Pure Copper Electrode Manufacturers in Hyderabad#Pure Copper Earth Rod Manufacturers in Hyderabad#Pure Copper Electrodes Manufacturers in Hyderabad#Pure Copper Earthing Rod Manufacturers in Hyderabad#Pure Copper Chemical Electrode Manufacturers in Hyderabad#Pure Copper Earthing Electrode Suppliers in Hyderabad#Pure Copper Electrode Suppliers in Hyderabad#Pure Copper Earth Rod Suppliers in Hyderabad#Pure Copper Electrodes Suppliers in Hyderabad#Pure Copper Earthing Rod Suppliers in Hyderabad#Pure Copper Chemical Electrode Suppliers in Hyderabad

0 notes

Text

Why Nouve NiCrFe-2 Electrode is the Best Choice for Challenging Welding Applications

In the world of welding, not all electrodes are created equal. When it comes to challenging environments where extreme heat, aggressive chemicals, and structural integrity are crucial, a superior welding solution is required. Enter the Nouve NiCrFe-2 Electrode, a high-performance electrode specifically engineered to meet the toughest demands. Let’s explore why this electrode stands out as the best choice for welding in challenging applications across industries.

ENiCrFe-2 Electrode

1. Unmatched Resistance to Heat and Corrosion

One of the biggest challenges in welding, particularly in industries such as power generation, chemical processing, and oil and gas, is the constant exposure to high temperatures and corrosive elements. The Nouve NiCrFe-2 Electrode excels in these conditions thanks to its unique composition of nickel, chromium, and iron.

Heat Resistance: With its high nickel content, the Nouve NiCrFe-2 electrode is designed to withstand extreme temperatures without compromising strength. Whether it’s welding in high-heat environments like boilers and turbines or dealing with thermal stress in power plants, this electrode ensures that welded joints remain intact and durable under thermal cycling.

Corrosion Resistance: Corrosion can be a costly issue in many industries, leading to frequent repairs and downtime. The Nouve NiCrFe-2 electrode is formulated to resist corrosion from harsh chemicals, seawater, and oxidizing environments. This makes it an ideal solution for petrochemical plants, offshore platforms, and marine infrastructure where exposure to corrosive substances is constant.

ENiCrFe-2 welding rod

2. High-Performance Metallurgical Stability

Weld integrity is crucial, especially when dealing with challenging applications where failure is not an option. The Nouve NiCrFe-2 Electrode delivers exceptional metallurgical stability, minimizing the risks of cracking, distortion, or weakening in welded joints. The balanced composition of nickel, chromium, and iron ensures that the weld maintains its strength and durability even under demanding conditions.

Thermal Fatigue Resistance: In environments where temperatures fluctuate rapidly, materials are at risk of thermal fatigue. The Nouve NiCrFe-2 electrode is designed to handle these temperature changes without compromising the integrity of the weld, ensuring longevity and reliability in critical components.

Long-Term Durability: Welded structures in high-stress environments require durability over time. The Nouve NiCrFe-2 electrode creates joints that offer superior mechanical properties, maintaining high tensile strength and ductility even under constant strain.

3. Versatility Across Industries

The Nouve NiCrFe-2 Electrode is designed for versatility, making it the ideal choice for a wide range of industries where challenging conditions are the norm. Whether you are working in power plants, chemical processing facilities, or marine environments, this electrode offers unparalleled performance.

Power Generation: Ideal for welding components like heat exchangers, turbines, and boilers that are constantly exposed to high temperatures and thermal stress.

Petrochemical and Chemical Processing: Perfect for welding pipes, reactors, and pressure vessels exposed to corrosive chemicals, ensuring longevity and safety in critical infrastructure.

Marine and Offshore: Provides robust resistance to saltwater corrosion, making it ideal for welding offshore platforms, shipbuilding, and marine equipment that need to withstand aggressive environments.

Welding Electrode Manufacturer

4. Ease of Use and Consistent Performance

Despite its advanced capabilities, the Nouve NiCrFe-2 Electrode is surprisingly easy to work with. Its smooth arc stability and low spatter allow for precise, clean welds, reducing the need for post-weld cleanup. This ensures efficiency in the welding process, minimizing downtime while maximizing productivity.

Arc Stability: Welders appreciate the smooth and consistent arc control offered by the Nouve NiCrFe-2 electrode, resulting in cleaner welds and higher productivity.

Minimal Spatter: The low spatter nature of this electrode ensures less mess during welding, reducing the time and effort needed for post-weld cleaning and finishing.

5. Proven Performance in Critical Applications

The Nouve NiCrFe-2 Electrode has been widely adopted across industries for critical applications where performance and reliability are non-negotiable. From power plants to offshore platforms, this electrode has a proven track record of delivering consistent, high-quality welds that stand the test of time in the harshest environments.

Trusted by Professionals: Welding professionals in industries such as power generation, petrochemical, and marine sectors trust the Nouve NiCrFe-2 electrode for its reliability and consistent results, making it a preferred choice for challenging welding projects.

Welding Rod Manufacturer

Conclusion

When it comes to challenging welding applications, the Nouve NiCrFe-2 Electrode is the ultimate solution. Its ability to withstand extreme heat, resist corrosion, and maintain mechanical stability makes it the go-to choice for industries that demand durability, strength, and longevity. Whether you're working in high-temperature environments or dealing with aggressive corrosive elements, this electrode delivers unmatched performance, ensuring your welded structures stay safe and reliable for years to come.

For welders and project managers looking for the best in high-performance welding solutions, Nouve NiCrFe-2 Electrode is the clear choice. Trust in its proven capabilities and ensure your projects meet the highest standards of safety and efficiency.

0 notes

Text

Electrodes Maintenance Tips | Agricultural Tools | Tata Agrico

Proper storage and maintenance of electrode rods are vital for achieving high-quality welds and extending the life of your materials. Read to know more.

Visit at: https://www.tataagrico.com/blog-post/maintaining-storing-electrodes-best-practices-for-longevity-performance/

#maintenance of electrode rods#electrode rods#electrode rods usage#storage of electrode rods#best welding electrode rods#electrodes price#best electrodes#electrodes

0 notes

Text

Buy Welding Machines and Electrodes Online

In today’s digital age, buying welding machines and electrodes online has become a popular choice among both hobbyists and professionals. The convenience, variety, and competitive pricing available through online platforms are unmatched by traditional retail stores. But, with so many options available, how do you ensure you're making the right purchase? This guide will walk you through the essentials of buying welding machines and electrodes online, ensuring you get the best value for your money.

1. Understanding Welding Machines

1.1 What is a Welding Machine?

A welding machine is a device that uses electrical currents to fuse materials, typically metals, together. There are various types of welding machines, each designed for specific tasks and materials.

1.2 Types of Welding Machines

1.2.1 MIG Welders

Metal Inert Gas (MIG) welders are known for their versatility and ease of use. Ideal for both thin and thick materials, MIG welders are popular among both amateurs and professionals.

1.2.2 TIG Welders

Tungsten Inert Gas (TIG) welders offer precise and clean welds, making them suitable for tasks requiring high-quality finishes. They are perfect for working on thin materials.

1.2.3 Stick Welders

Stick welders are robust and can handle heavy-duty tasks, making them a go-to for construction and repair work. They are less expensive and more straightforward compared to MIG and TIG welders.

1.2.4 Multi-Process Welders

Multi-process welders combine several welding technologies into one machine, providing flexibility for various welding tasks.

2. Key Features to Consider When Buying Welding Machines

2.1 Power Output

The power output of a welding machine determines its ability to weld different thicknesses of materials. Make sure to choose a machine with adequate power for your needs.

2.2 Duty Cycle

The duty cycle indicates how long the machine can operate before it needs to cool down. A higher duty cycle means less downtime.

2.3 Portability

If you need to move your welding machine around frequently, consider its weight and whether it has features like wheels or handles for easier transport.

2.4 User-Friendly Controls

Look for machines with intuitive controls and settings that are easy to adjust, especially if you’re a beginner.

2.5 Safety Features

Ensure the welding machine has built-in safety features like overheat protection and proper insulation to prevent accidents.

3. Understanding Electrodes

3.1 What Are Electrodes?

Electrodes are conductive materials used in welding to create the arc that melts the metals being joined. They come in various types and sizes, depending on the welding process.

3.2 Types of Electrodes

3.2.1 Stick Electrodes

Stick electrodes are used in arc welding and are ideal for general-purpose welding. They are available in different coatings to suit various applications.

3.2.2 MIG Wire Electrodes

These are used with MIG welding machines. They come in spools and are available in various materials and diameters.

3.2.3 TIG Electrodes

TIG electrodes are made of tungsten and are used in TIG welding. They are known for their durability and ability to handle high temperatures.

3.3 Choosing the Right Electrode

Consider the type of welding you will be doing, the materials you will be welding, and the specific requirements of your welding machine when choosing electrodes.

4. Benefits of Buying Welding Machines and Electrodes Online

4.1 Convenience

Shopping online allows you to browse a wide range of products from the comfort of your home, avoiding the hassle of visiting multiple stores.

4.2 Price Comparisons

Online platforms often provide tools to compare prices across different retailers, helping you find the best deals.

4.3 Customer Reviews

Reading reviews from other customers can provide insights into the performance and reliability of the products you are considering.

4.4 Product Information

Detailed product descriptions, specifications, and tutorials are often available online, helping you make informed decisions.

5. Tips for Buying Welding Machines and Electrodes Online

5.1 Research and Compare

Before making a purchase, research different brands and models. Compare features, prices, and customer feedback.

5.2 Verify Seller Credentials

Ensure you are buying from a reputable seller. Check for certifications, customer service policies, and return options.

5.3 Check Warranty and Support

Look for products that come with a warranty and check the availability of customer support in case you encounter any issues.

5.4 Read Product Specifications Carefully

Make sure the product specifications match your needs and that the welding machine and electrodes are compatible with each other.

5.5 Consider Shipping and Delivery

Review shipping options and delivery times. Some products may require longer shipping times or have additional shipping costs.

6. Common Mistakes to Avoid

6.1 Ignoring Compatibility

Ensure that the welding machine and electrodes are compatible with each other to avoid operational issues.

6.2 Overlooking Reviews

Ignoring customer reviews can lead to purchasing products with poor performance or reliability.

6.3 Misjudging Power Needs

Buying a machine with insufficient power for your tasks can lead to subpar results and potential equipment damage.

7. Conclusion

Buying welding machines and electrodes online offers a range of benefits, including convenience, variety, and competitive pricing. By understanding the different types of welding machines and electrodes, and by following our tips for making an informed purchase, you can ensure that you get the best equipment for your needs. Always research thoroughly, compare options, and choose reputable sellers to make the most out of your online shopping experience.

FAQs

1. Can I trust online reviews for welding machines and electrodes? Yes, online reviews can provide valuable insights into the performance and reliability of products. However, it’s important to read multiple reviews and consider the overall consensus.

2. What should I look for in a welding machine’s warranty? Check the duration of the warranty, what it covers, and the process for making a claim. A good warranty should cover major components and offer support for repairs.

3. How do I know if an electrode is suitable for my welding machine? Check the manufacturer’s recommendations for compatible electrodes. Ensure that the electrode type and size match the specifications of your welding machine.

4. Are there any hidden costs when buying welding machines and electrodes online? Be aware of potential additional costs such as shipping fees, import duties, and handling charges. Always review the total cost before completing your purchase.

5. How can I ensure that the welding machine I buy is durable? Look for well-known brands with a reputation for quality and check customer reviews for durability feedback. Also, verify the warranty and support options provided.

1 note

·

View note

Text

Chemical Earthing Electrode Manufacturer in Jaipur

This chemical earth current based indicator, called a “chemical earth current electrode”, is used in electrical engineering. It is a type of grounding electrode that is used for electrical connection to the earth. It connects an electrical structure to the earth Which ensures the safety and failure of electrical communications. It is used in various industries, such as in the areas of power transmission, generation units, power transmission, and power distribution. It helps protect electronic devices from power outages.

BLC Power Solution is the foremost manufacturer of Chemical Earthing Electrodes in Jaipur, setting the standard for excellence and innovation in the industry. Our commitment to quality ensures superior performance and reliability in every product.

With a focus on customer satisfaction, we offer tailored solutions to meet diverse needs, backed by expert technical support and service. Trust BLC Power Solution for all your electrical safety requirements.

Contact us today at 72309 94400 to discover how we can elevate your safety standards.

Email: [email protected]

Website: www.blcpowersolution.com

0 notes

Text

Earthing Solutions, Earthing Electrodes, GI Earthing Electrodes, Chemical Earthing Rod, Pune, India

#Earthing Solutions#Earthing Systems#Earthing Electrodes#GI Earthing Electrodes#Chemical Earthing Rod#Copper Earthing Rod#Pure Copper Earthing Electrodes

0 notes

Text

Type of GI Earthing Electrode.

Earthing electrodes are crucial components in grounding systems, designed to provide a low-resistance path for the dissipation of fault currents to the ground. There are several types of Grounding (GI) electrodes commonly used for earthing purposes:

GI Pipe Electrode:

A galvanized iron (GI) pipe can be used as an earthing electrode. It is typically buried vertically in the ground. The length and diameter of the GI pipe depend on the soil resistivity and the electrical system requirements.

GI Plate Electrode:

A GI plate is another common type of earthing electrode. It is usually buried horizontally in the ground. The size of the plate is determined based on soil resistivity and the specific requirements of the grounding system.

GI Strip Electrode:

Similar to the GI plate, a GI strip can be used as an earthing electrode. The strip is buried horizontally in the ground, and its dimensions are determined based on the grounding system requirements.

GI Electrode with Backfill Compound:

Some grounding electrodes are treated with special backfill compounds to enhance their conductivity and reduce soil resistivity. This helps in achieving lower resistance to earth.

Chemical Earthing Electrode:

In chemical earthing systems, a compound or mixture is used around the electrode to improve conductivity. This type of electrode is designed to maintain a low resistance value over time, even in high-resistivity soils.

Copper-Bonded Electrode:

While not made of pure GI, copper-bonded electrodes have a thin layer of copper bonded to a steel core. This combination provides the benefits of both copper and steel, offering good corrosion resistance and electrical conductivity.

Cast Iron Electrode:

Cast iron electrodes are less common but are used in some specific applications. They are durable and have good corrosion resistance.

The choice of the earthing electrode depends on various factors such as soil resistivity, space availability, local regulations, and the specific requirements of the electrical system. It's essential to consider these factors to ensure an effective and reliable grounding system. Consulting with a qualified electrical engineer or following local electrical codes and standards is recommended when designing and installing an earthing system.

#advanced gel earthing electrode#copper bonded earthing electrode#earthing electrode#earthing strip#galvanized iron#lighting arrester#earthing rod copper

0 notes

Text

Use of Earthing Rod Copper in Making Your Dream Home

The immediate discharge of electrical energy by the use of a low-resistance wire to transfer charges straight to the earth is known as earthing. To reduce or eliminate the risk of electrocution, several forms of the earthing rod copper are utilized to connect the metallic components of electrical appliances or installations to the ground.

0 notes

Text

Currently attempting tens unit on my foot and this is hella weird

#unintentional pun#spoonies unite#tens unit#technically i got this for my back pain#but if you think im not trying it pretty much everywhere at least once you don't know me at all#next is my ankle probably#we're just gonna attack my whole bad leg eventually#mostly i do use it on my back and my neck but ya know#again just had to scream into the void this is the weirdest one yet#i can handle it though#still cannot begin to handle the electrode too close to my spinal rod but i can go above and below it okay#and anywhere else is fine okay whatever#but gdi this is close to the spinal sensation of just like visceral oh hell no#feel free to come tell me about your experiences btw

0 notes