#dumpling making machine price in India

Explore tagged Tumblr posts

Text

youtube

In Our company Healthy Enviro Solutions Pvt. Ltd. Automatic Momo making Machine used as advance technology for production of Momos in bulk. It is a best dedicated machine with the options of producing momos in various sizes and different sheet thickness. It comes with variable frequency drives. The Machine has humanized design and control panel for easy adjustment of stuffing and sizes of momos. It is suitable for Momos suppliers, quick frozen dumpling manufactures. We are the answer of Best Automatic Momo Making Machine Supplier distributor and Manufacturer of India.

We are providing our best possible Automatic Noodles Making Machine Installation service to all over India. We are leading Automatic Momo Making Machine Dealer Supplier and service provider at Bhubaneswar, Khurda, Odisha, Kolkata, New Delhi, Bangalore, Chennai, Pune, Hyderabad, Nepal etc.

#automatic momo making machine#automatic momo making machine price#automatic momo maker#automatic momo making machine price in india#automatic momo machine#Load Metrics (uses 9 credits)#Keyword#Automatic Momo Making Machine Manufacturer Supplier#automatic momo making machine manufacturer supplier in india#second hand momo making machine price#momo making machine amazon#momo maker#momo making factory#automatic momo making machine produce 100 3000pcs per batch#momos banane ki machine price#dumpling making machine price in india#Youtube

1 note

·

View note

Text

Dumpling Machine is easy for operation, cleaning, assembling, and repairing. The encrusting filling system can apply both wet and dry fillings. Different materials can be applied for the encrusting product skin, such as: Dumpling Machine can use all-purpose flour, high gluten flour, and yeast dough for different buns. The specially designed dough extruding device does less damage to the dough texture, which gives better results to your product.

Advantages of Dumpling Making Machine Using the Dumpling machine you can produce up to 150 kg Bun per hour. The dumpling making machine can produce up to 100 kg of double-colored Cookies per hour. It can produce up to 150 kg filled fruit balls per hour. It can produce up to 150 kg of Filled American cookies per hour. It can produce up to 150 kg of Filled Cake balls per hour. It can produce up to 150 kg of Filled meatballs per hour. It can produce up to 100 kg filled with roasted chickpea cookies per hour It can produce up to 60 kg filled bagel cookies per hour. It can produce up to 100 kg of homemade pastry per hour. Dumpling machine can produce up to 150 kg of chocolate bombs per hour. You can produce up to 100 kg of Filled cookies with delight cookies per hour. Dumpling Machine can do portioning. You can fill the bun with anything you want. It can produce up to 150 kg of pastry dough per hour. It can produce up to 100 kg of vegan cookies per hour It can produce up to 100 Kg. Pryanik Cookies. It can produce up tou 8.000 PCS Samosa Per hour. It can produce up tou 8.000 PCS Ravioli Per hour It can produce up tou 10.000 PCS Dumpling Per hour It can produce up tou 5.000 PCS Spring Roll Per hour Want to know about the Dumpling Making Machine price in India, Click on the given link and send an inquiry.

#dumpling machine#dumpling machine India#dumpling making machine price in India#dumpling making machine#dumpling making machine in India

0 notes

Text

Automatic Chapatti Machines for Large Scale Production

One of the foremost popular staples in India is chapatti. most households prepare them regularly. During our grandmother's time, chapattis were made in large quantities reception to feed large families. Women wont to make them in hundreds and thousands at weddings and in many other places where food is produced in large quantity . As times have changed and therefore the workforce is shrinking, the food industry must seek alternative means of manufacturing chapatti or rotis in large quantities. Automatic chapatti machines are presented as a solution to the need .

What are Chapatti automatic machines?

These are automatic machines that employment electrically which produce an outsized amount of chapattis during a short time. this is often an excellent chrome steel machine used for production of chapattis. It consists of two parts: one part makes dumplings of an equivalent size and therefore the other part presses the balls into chapattis and bakes them. on the average , around 800 chapattis are produced per hour.

Types of chapatti machines:

The main sorts of chapatti machines are semi-automatic and fully automatic. Both machines produce an identical number of chapattis during a similar way. The semi-automatic chapatti machine makes the dumplings in one section and therefore the pressing and cooking are wiped out another section of the machine. Requires an operator to review the whole process. the automated Chapatti machine performs the whole process directly with none human help. Effortlessly, around 800 chapattis are staked in an hour.

Tiny rotis or pooris also are prepared during a similar way. you'll find machines that also do that job specifically. A crude lean making machine will produce around 800 poor per hour which are then fried in oil. As a poori is smaller than chapatti, the amount of units produced in one hour increases dramatically.

The latest model of chapatti making machine is fully automatic. it's more efficient, saves energy and is more sophisticated compared to previous models. it's a built-in oven, hopper, rollers and belts to maneuver the chapattis and is totally made from chrome steel . This machine produces around 800 chapattis per hour.

Advantages of the chapatti making machine:

The first advantage is that it's completely hygienic compared to traditional methods of making chapatti. No human contact is required since most the work is completed by the machine. the sole person round the machine is that the operator who only watches the assembly process and monitors machine readings.

Second, the chapattis are an equivalent size and are evenly baked. The machine unfolds chapattis of an equivalent size both in diameter and thickness. The temperature of the machine is adjusted in such how that every chapatti is baked properly on each side .

The biggest advantage of an automatic chapatti machine is that it produces an outsized amount of chapattis during a short time compared to human production. it's perfectly suitable to be used in hotels, clutter, weddings, hospitals, large schools, hostels, and industrial areas. it's a price effective thanks to produce large quantities of chapattis without compromising on quality.

2 notes

·

View notes

Text

A necessary guide to investing in candy making machines for sweet supplies

An ingenious invention is a candy-making machine, just like a commercial sweet corner. There are some unknowledgeable things concerning this blog. Continue reading.

A candy-producing machine is a tool that facilitates the production of various candies. These gadgets are an essential complement to Indian restaurant equipment. People frequently have a few inquiries concerning candy vending machines. Here are some facts to make a note of.

How many different candy-processing equipment kinds are there on the market?

There is countless numbers of candy processing restaurant equipment India available. There is initially a hand-operated candy-making apparatus. A partially automatic machine and a completely automatic machine come next. These gadgets are all easily accessible on the market.

What elements influence the cost of a candy-making machine?

The price of a candy-processing machine depends on a few things. The type of machine is the first. Automatic machinery is very expensive, however manual machines for preparing candies are less expensive. The machine's quality comes in second. And last, the number of devices is yet another crucial element.

What is the commercial kitchen equipment India for the production of sweets?

Vertical Chillers and Freezers with 2 or 4 Doors: These freezers are one of the most important indian kitchen tools for sweet making. These are made specifically to store desserts and other sweet products. It not only offers the best freezer and chiller options, but it also uses less energy and is economical.

Complete SS Body GN Pan accommodation with adjustable shelves is one of the distinctive characteristics.

Removable gaskets make cleaning simple

Display of Digital Temperature

There are two versions of these: 2 Door Freezers and 4 Door Freezers, both of which are mounted on wheels for easy moving from one location to another.

Bend Glass Countertops with Customized Lower Panel Designs: These provide the ideal solution for candy storage and presentation. The apparatus is created in a way that will draw attention to attract customer attention. The unique characteristics include

Made entirely of stainless steel, with glass covering the front and sides.

With Chanelling, a light canopy.

Without a single air gap, completely sealed glass.

Using Emerson's Cold Refrigerator Compressor.

Available in cold, warm, and neutral.

Baked rosogolla maker: The Baked Rosogolla maker makes it easier to prepare the latest trend in the world of sweets, baked rosogolla. According to sweet making machine supplier kolkata, you will not be able to produce these sweet dumplings in bulk without such a machine.

The unique characteristics are:

Front Door and Panel are made of stainless steel.

Temperature control up to 450°C. Cooking quickly in five minutes.

Separate thermostat controls.

Reliable service door with reinforced door for frequent opening and closing.

High-temperature glass window with reinforcements for monitoring baking conditions.

Halogen lighting system with a long lifespan for easier inspection

Conclusion

Thus, get in touch with BestekLoza right away if you're interested in a candy production facility. They also focus on industrial kitchen Kolkata. What are you still holding out for? Visit them to purchase essential kitchen appliances for a fair price.

#commercialsweetcorner#sweetmakingmachinesupplierkolkata#essentialkitchenappliances#indiankitchentools#industrial kitchenkolkata#restaurantequipmen india#indian restaurantequipment#commercialkitchenequipmentIndia#commercial kitchen

0 notes

Text

How to use dumpling making machine

Prepare the dough: Make or buy dumpling dough and roll it into a thin sheet. Make sure the dough is pliable and not too sticky.

Prepare the filling: Prepare your favorite dumpling filling, such as a meat and vegetable mixture. Make sure the filling is cooked and thoroughly cooked before using.

Set up the Dumpling Machine: Attach the appropriate dumpling mold or attachment to the machine according to the manufacturer's instructions. Different machines may have different assembly methods, so refer to the user manual if necessary.

Fill the machine: Take a portion of the dumpling dough and place it on the mold or attachment of the machine. Make sure the dough covers the mold evenly.

Add the filling: Add a small amount of the prepared filling in the center of each dumpling wrapper. Be careful not to overfill the dumplings to avoid difficulties in sealing them.

Seal the dumplings: Close the machine or press firmly to seal the dumplings. The machine should press the edges of the wrapper together tightly, creating the desired dumpling shape.

Remove the dumplings: Open the machine or release pressure to remove the finished dumplings. They should be securely sealed and ready for cooking.

Repeat the process: Repeat the steps with the remaining dough and filling until you have made the desired number of dumplings. Remember to refer to the specific instructions provided by the manufacturer of your particular dumpling making machine for more precise usage instructions. Additionally, it is always a good idea to familiarize yourself with the safety guidelines and maintenance instructions outlined in the machine's user manual. We have written some technical details about the dumpling machine Commercial dumpling Machine produces high-quality products.The Dumpling machine continuously performs R&D work in its own factory.

Features of Commercial Dumpling Making Machine It works with the session of 1 or 2. (Changeable according to the dough) You can set the filling amount as much as you require. You can set the dough thickness as much as you require. The machine works with a 1.5 KW Italian motor without any problems. It works with 220V house electricity. All of the surface, which is in contact with the food, is removable and washable. With different kinds of Mold, you can easily produce such products; Ravioli , triangular ravioli , Uzbek ravioli , empanada , samboussek , samosa , fruit bar, chocolate pastry , vegan ravioli , turkish cezerye , marzipan. All running parts are removable easily with high-quality engineering. The main chassis is made of stainless steel. The capacity of the machine is 4000-8000 pieces per hour.

#dumpling making machine in India#dumpling making machine for sale#dumpling machine in India#dumpling making machine price in India#dumpling machine price#commercial dumpling machine

0 notes

Text

Dumpling Making Machine in India

There are many different types of dumpling making machines available on the market today. Depending on what type of dumplings you want to make, there will be different machines to suit your needs. Some machines are designed for making a variety of different dumplings, while others are designed to make only one type of dumpling. When choosing a dumpling making machine, it is important to consider the size and capacity of the machine, as well as the type of dumplings you plan to make. Additionally, you should take into account the cost of the machine, as well as the ease of use and cleaning. I am going to write here some most important features of dumpling making machine.

Features of Dumpling Making Machine

It works with the session of 1 or 2. (Changeable according to the dough) You can set the filling amount as much as you require. You can set the dough thickness as much as you require. The machine works with a 1.5 KW Italian motor without any problems. It works with 220V house electricity. All of the surface, which is in contact with the food, is removable and washable. With different kinds of Mold, you can easily produce such products; Ravioli , triangular ravioli , Uzbek ravioli , empanada , samboussek , samosa , fruit bar, chocolate pastry , vegan ravioli , turkish cezerye , marzipan. All running parts are removable easily with high-quality engineering. The main chassis is made of stainless steel. The capacity of the machine is 4000-8000 pieces per hour. Want to know about the dumpling making machine price in India, click on the given link and send an inquiry.

0 notes

Text

Dumpling Making Machine in India

Are you looking for dumpling making machine to produce the mass production of momos. This machine is produces produces high-quality products. This machine continuously performs R&D work in its own factory.

Features of Dumpling Making Machine

It works with the session of 1 or 2. (Changeable according to the dough) You can set the filling amount as much as you require. You can set the dough thickness as much as you require. The machine works with a 1.5 KW Italian motor without any problems. It works with 220V house electricity. All of the surface, which is in contact with the food, is removable and washable. With different kinds of Mold, you can easily produce such products; Ravioli , triangular ravioli , Uzbek ravioli , empanada , samboussek , samosa , fruit bar, chocolate pastry , vegan ravioli , turkish cezerye , marzipan. All running parts are removable easily with high-quality engineering. The main chassis is made of stainless steel. The capacity of the machine is 4000-8000 pieces per hour. here can know about the dumpling making machine price in India, so if you wish then click on the given link and send an Enquiry.

#dumpling making machine price in india#dumpling machine#dumpling making machine india#dumpling making machine

0 notes

Text

Revolutionize Your Dumpling Production with Commercial Dumpling Making Machines

Dumplings are a beloved staple in many cultures, from Chinese pot stickers to Polish pierogis. But for restaurants and food businesses that specialize in dumplings, the process of making them by hand can be time-consuming and labour-intensive. That's where commercial dumpling making machines come in. These innovative machines can revolutionize your dumpling production, making it faster, easier, and more efficient. In this article, we'll explore the benefits of using a commercial dumpling making machine and how it can help your business thrive.

What is a Commercial Dumpling Making Machine?

A commercial dumpling making machine is a specialized piece of equipment designed to automate the process of making dumplings. These machines can produce a large quantity of dumplings in a short amount of time, with consistent size and shape. They come in various sizes and models, from small table top machines to larger, industrial-sized ones. Some machines can also be customized to make different types of dumplings, such as wontons or empanadas.

Increased Efficiency and Productivity

One of the most significant benefits of using a commercial dumpling making machine is the increased efficiency and productivity it offers. With a manual dumpling-making process, it can take hours to produce a large batch of dumplings. But with a machine, you can produce hundreds or even thousands of dumplings in a fraction of the time. This allows you to meet the high demand for dumplings without sacrificing quality or consistency.

Consistent Size and Shape

Another advantage of using a commercial dumpling making machine is the consistent size and shape of the dumplings it produces. Handmade dumplings can vary in size and shape, which can affect the cooking time and overall appearance of the dish. With a machine, you can ensure that each dumpling is the same size and shape, resulting in a more professional and visually appealing final product.

Easy to Use and Clean

Commercial dumpling making machines are designed to be user-friendly and easy to operate. Most machines come with clear instructions and can be easily adjusted to make different types of dumplings. They are also easy to clean, with removable parts that can be washed and sanitized after use. This makes them a convenient and hygienic option for food businesses.

Cost-Effective

While commercial dumpling making machines may seem like a significant investment, they can actually save you money in the long run. By increasing efficiency and productivity, you can produce more dumplings in less time, reducing labor costs. Additionally, the consistent size and shape of the dumplings can help reduce food waste, saving you money on ingredients.

Final Thoughts

If you're in the business of making dumplings, a commercial dumpling making machine is a game-changer. It can help you increase efficiency, productivity, and consistency, all while saving you time and money. With the right machine, you can revolutionize your dumpling production and take your business to the next level.

Have you used a commercial dumpling making machine before? Share your experience in the comments below.

Original text:

Welcome to the World of Commercial Dumpling Making Machines!

Commercial dumpling making machines are revolutionizing the way dumplings are produced in restaurants and food businesses.

In this blog post, we'll delve into the functionalities and benefits of these machines. Let's explore how they can enhance efficiency and consistency in dumpling production.

#dumpling making machine#dumpling making machine for sale#dumpling making machine price#dumpling making machine in india

0 notes

Text

Dumpling Making Machine in India

A dumpling making machine is a kitchen appliance or device used to make dumplings, a traditional dish in many Asian countries. It is designed to streamline the process of making dumplings, which can be time-consuming and labor-intensive when made by hand.

The dumpling machine usually consists of a base with a motor, a dough container, and a filling container. The dough is placed in the dough container, and the filling is placed in the filling container. The machine then mixes the dough and filling together and forms the dumplings.

To use the dumpling making machine, follow these steps:

Prepare the dough: The dough can be made using flour, water, and salt, or you can use pre-made dumpling wrappers. If you are making the dough from scratch, mix the ingredients until a smooth and elastic dough forms.

Prepare the fillings: There are many variations of dumpling fillings, but they typically include a combination of ground meat, vegetables, and spices. Make sure the filling is finely chopped and mixed well.

Assemble the machine: Place the dough container and filling container on the base of the machine. Make sure they are securely connected.

Add the dough and filling: Place the dough in the dough container and the filling in the filling container.

Start the machine: Start the machine and let it run for a few seconds to mix the dough and stuffing together.

Adjust settings: Most machines have settings to adjust the thickness and size of the dumplings. Choose the desired settings based on your preference.

Make the dumplings: Place the dough and filling mixture in the designated opening of the machine. The machine will automatically shape the dumplings and push them out through a small hole.

Repeat the process: Continue making dumplings until all the filling and dough is used up.

Cook the dumplings: Depending on the recipe and your preference, you can steam, boil or fry the dumplings.

Clean the machine: Once you're done, turn off the machine and disassemble it. Clean parts thoroughly with warm water and soap. Be sure to dry parts completely before storing.

The dumpling making machine can save your time and effort in the kitchen and produce consistent and perfect dumplings every time. With practice, you can master the machine and make delicious dumplings for your family and friends.

0 notes

Text

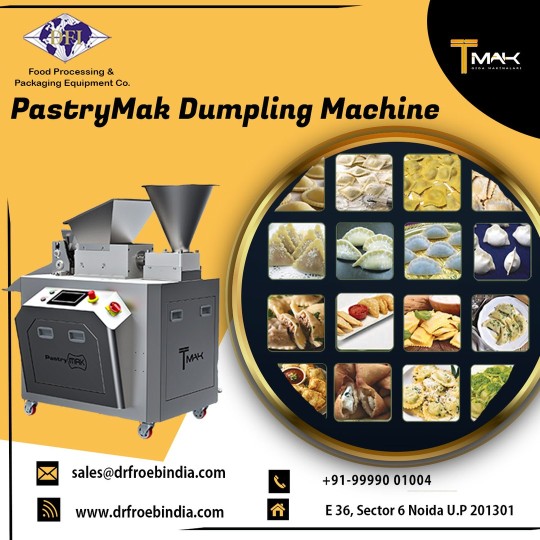

Looking for Dumpling Making Machine in India

Pastrymak Dumpling Machine produces high-quality products. The Dumpling machine continuously performs R&D work in its own factory. The main chassis is made of stainless steel. you can make with different kinds of Mold, you can easily produce such products; Ravioli, triangular ravioli, Uzbek ravioli, empanada, samboussek , samosa, fruit bar, chocolate pastry, vegan ravioli, Turkish celery, and marzipan.

Features of Pastrymak Dumpling Machine

It works with the session of 1 or 2. (Changeable according to the dough) You can set the filling amount as much as you require. You can set the dough thickness as much as you require. The machine works with a 1.5 KW Italian motor without any problems. It works with 220V house electricity. All of the surface, which is in contact with the food, is removable and washable. The capacity of the machine is 4000-8000 pieces per hour. All running parts are removable easily with high-quality engineering. Want to know about the Dumpling Making Machine price in India, click on the given link and send an inquiry.

#dumpling machine#dumpling making machine#dumpling machine India#dumpling machine price#dumpling maker machine#dumpling making machine price in India

0 notes

Text

Dumpling Making Machine in India

Dumpling Making Machine is designed to produce single-color-filled, double-color-filled, or unfilled products. It's highly demanded in various food processing industries.

Features of MiniFillMAK Encrusting Machine

It has the capability to produce different shapes of fruit bars.

You can produce up to Bun, pastry, chocolate bomb-filled cookies, etc.

It allows you to make dough cookies, salted cookies, kibbe, yeasty products, dumplings, fruit bars, and similar pastries.

You can use products such as praline, marmalade, cocoa, cheese, potatoes, crushed olives, ground meat, and sausages. Technical Specifications of Encrusting Machine

Width: 39 cm

Length: 84 cm

Height: 78cm

Dough Bunker: 10 kg

Weight: 85 kg

Electricity: 220V/ 1 KW

Capacity (1 hour): 20-40 kg Want to know about the Dumpling Making Machine price in India, click on the given link and send an inquiry.

#Dumpling Making Machine#dumpling Machine#dumpling machine price#dumpling making machine price in India

0 notes

Text

Dumpling Making Machine in India

Dumpling Making Machine is designed to produce single-color-filled, double-color-filled, or unfilled products. It's highly demanded in various food processing industries. Features of MiniFillMAK Encrusting Machine

It has the capability to produce different shapes of fruit bars.

You can produce up to Bun, pastry, chocolate bomb-filled cookies, etc.

It allows you to make dough cookies, salted cookies, kibbe, yeasty products, dumplings, fruit bars, and similar pastries.

You can use products such as praline, marmalade, cocoa, cheese, potatoes, crushed olives, ground meat, and sausages. Technical Specifications of Encrusting Machine

Width: 39 cm

Length: 84 cm

Height: 78cm

Dough Bunker: 10 kg

Weight: 85 kg

Electricity: 220V/ 1 KW

Capacity (1 hour): 20-40 kg Want to know about the Dumpling making machine price in India, click on the given link and send an inquiry.

#dumpling machine price#dumpling making machine india#dumplings making machine#dumpling making machine price in india#dumpling maker machine#dumpling machine#dumpling making machine

0 notes

Text

Dumpling Making Machine In India

The dumpling Machine is easy to operation, cleaning, assemble, and repair. The encrusting filling system can apply both wet and dry fillings. Different materials can be applied for the encrusting product skin, such as: Dumpling Making Machine can use all-purpose flour, high gluten flour, and yeast dough for different buns. The specially designed dough extruding device does less damage to the dough texture, which gives better results to your product. Advantages of Dumpling Making Machine • Using the Dumpling machine you can produce up to 150 kg Bun per hour. • It can produce up to 100 kg of double-colored Cookies per hour. • It can produce up to 150 kg filled fruit balls per hour. • It can produce up to 150 kg of Filled American cookies per hour. • It can produce up to 150 kg of Filled Cake balls per hour. • It can produce up to 150 kg of Filled meatballs per hour. • It can produce up to 100 kg filled with roasted chickpea cookies per hour • It can produce up to 60 kg filled bagel cookies per hour. • IT can produce up to 100 kg of homemade pastry per hour. • It can produce up to 150 kg of chocolate bombs per hour. • You can produce up to 100 kg of Filled cookies with delight cookies per hour. • Encrusting Machine can do portioning. You can fill the bun with anything you want. • It can produce up to 150 kg of pastry dough per hour. • It can produce up to 100 kg of vegan cookies per hour • It can produce up to 100 Kg. Pryanik Cookies. • It can produce up tou 8.000 PCS Samosa Per hour. • It can produce up tou 8.000 PCS Ravioli Per hour • It can produce up tou 10.000 PCS Dumpling Per hour • It can produce up tou 5.000 PCS Spring Roll Per hour Want to know dumpling making machine price in India, click on the given link and send an inquiry.

#dumpling making machine#dumpling machine#dumpling maker machine#dumpling making machine price in India#dumplings making machine#dumpling making machine India#dumpling machine price in India

0 notes

Text

Dumpling Making Machine in India

The dumpling Machine is designed to produce single colors with filling, double colors with filling, or products without filling. The machine allows you to make dough cookies, salted cookies, kibbe, yeasty products, dumplings, fruit bars, and similar pastries. You can use products such as praline, marmalade, cocoa, cheese, potatoes, crushed olives, ground, and sausages. It allows you to make products with a variety of different types of dough outfalls and filling molds. Capacity (1 hour): 60 - 100 kg if you wish to buy a Dumpling Making Machine in India click on the given link and send an inquiry.

#Dumpling Making Machine in India#dumpling machine#dumpling making machine india#dumpling making machine price in india

0 notes

Text

Momo Making Machine in India

Dumpling Making Machine produces high-quality products. The TMAK machine continuously performs R&D work in its own factory.

Features of Dumpling Making Machine

It works with the session of 1 or 2. (Changeable according to the dough) You can set the filling amount as much as you require. You can set the dough thickness as much as you require. The machine works with a 1.5 KW Italian motor without any problems. It works with 220V house electricity. All of the surface, which is in contact with the food, is removable and washable. With different kinds of Mold, you can easily produce such products; as ravioli, Turkish manti, Turkish raw pastry, etc. All running parts are removable easily with high-quality engineering. The main chassis is made of stainless steel. The capacity of the machine is 4000-8000 pieces per hour. Want to about the Momo making machine price in India, call us.

#Dumpling Making Machine#Momo making machine#momo making machine price india#momos making machine fully automatic#dumpling making machine price in India

0 notes

Text

The PastryMAK Encrusting Machine is a multifunctional filled product machine. You can use cheese, minced meat, potatoes, chopped vegetables, or meat variants as a filling and make Samosa, Momos, McPuff, Gujiya, Ravioli, etc.

Features of Pastrymak Encrusting Machine • You can set the filling amount as much as you require. • You can set the dough thickness as much as you require. • The machine works with a 1.5 KW Italian motor without any problems. • It works with 220V house electricity. • The entire surface, which is in contact with the food, is removable and washable. • With different kinds of Mold, you can easily produce such products; as ravioli, Turkish manti, Turkish raw pastry, etc. • All running parts are removable easily with high-quality engineering. • The main chassis is made of stainless steel. • The capacity of the machine is 4000-8000 pieces per hour. Want to about the Dumpling making machine price in India, call us.

#Encrusting Machine#Dumpling making machine#Encrusting Machine in India#dumpling making machine price in India

0 notes