#drilling motor industry

Explore tagged Tumblr posts

Text

Understanding Bearing Technology in the Oil and Gas Industry

Mud motor bearings are essential components that play a vital role in the success of drilling operations. By understanding the different types of bearings, the importance of bearing technology, and the role of bearing manufacturing companies and services, we can ensure that our drilling equipment operates at peak efficiency.

For More Info:- https://medium.com/@lodatechnology58/understanding-bearing-technology-in-the-oil-and-gas-industry-49d9bcff468

1 note

·

View note

Text

An Introduction to the Lathe Machine: Basics Every Engineer Should Know

A lathe machine is one of the most versatile and essential tools in mechanical engineering workshops. Its primary function is to remove unwanted material from a workpiece to shape it into the desired form. Whether you're a beginner or revisiting your engineering fundamentals, here's everything you need to know about the lathe machine:

Key Components of a Lathe Machine

Bed: The sturdy base that supports the entire machine and ensures stability during operations.

Headstock: Houses the spindle, gears, and motor that drive the workpiece.

Tailstock: Positioned opposite the headstock, it supports longer workpieces and holds tools like drills.

Carriage: Used to move the cutting tool along the bed. It includes the saddle, cross-slide, compound rest, and tool post.

Lead Screw: Enables precise movement of the carriage during threading operations.

Types of Lathe Machines

Engine Lathe: The most common type, suitable for various operations like turning, facing, and threading.

Turret Lathe: Ideal for mass production with repetitive tasks.

CNC Lathe: Computer-controlled for high precision and automation.

Common Lathe Operations

Turning: Shaping the outer surface of a cylindrical workpiece.

Facing: Smoothing the end of a workpiece to make it flat.

Drilling: Creating holes with the help of a drill bit mounted on the tailstock.

Threading: Forming screw threads using special tools.

Knurling: Adding texture to improve grip on cylindrical surfaces.

Why Are Lathe Machines Important?

Lathe machines are indispensable for crafting intricate components with high precision. They're widely used in automotive, aerospace, and manufacturing industries, making them a cornerstone of mechanical engineering.

💡 Follow "TIC Learning Center" for more insightful mechanical engineering posts!

#mechanical#engineering#material#sciences#lathe#lathe machine#cnc lathe#the lathe of heaven#lather rinse repeat

4 notes

·

View notes

Text

🎵 Disco Elysium

THOUGHT COMPLETE: WOMPTY-DOMPTY DOM CENTRE

BONUSES:

Encyclopedia passives give +10 XP and +2 real -2 Suggestion: Pretentious wanker

SOLUTION:

You're at home, stupid cop, not with the art crowd. You hate them, everyone hates them, even they hate themselves. It's nauseating -- an industry built on sprezzatura and sparkling wine. And, let’s be honest, tax evasion schemes. The Wompty Dompty Dom Centre is the heart of this unholy symbiosis of esthetics and tax optimization, and now that you've internalized it – you can have a piece too!

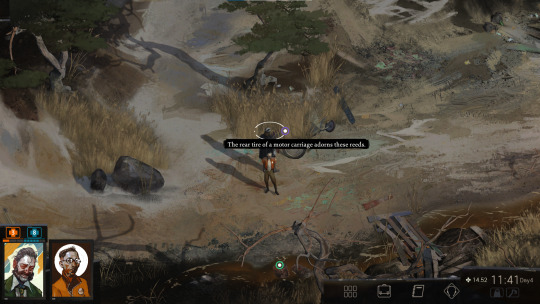

The rear tyre of a motor carriage adorns these reeds.

Relax, it's not yours. You didn't crash every mc in Revachol. (Hopefully.)

Rust-eaten letters read: "MAZUT."

Looking back at you from the rust-coloured water: you.

A kick drum pulse. The music is coming from somewhere on the ice.

Hm?

A school of fish huddle around the fence post. Then scatter into the dark.

Before you, a drawbridge. It can only be lowered from the other side.

Accidently covered up the bridge by hovering over the cash pickup, whoops.

Full of holes. Could the posts hide... treasure? Look inside.

The posts, as it turns out, all have various rewards in them, including money, medicine, and a bottle of alcohol.

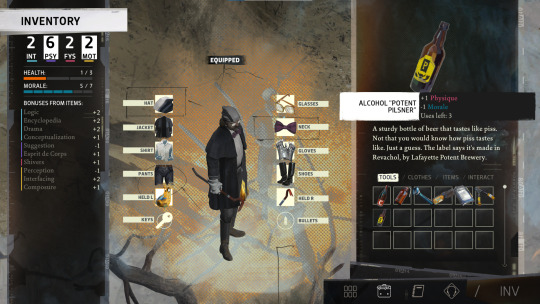

ALCOHOL "POTENT PILSNER"

A sturdy bottle of beer that tastes like piss. Not that you would know how piss tastes like. Just a guess. The label says it's made in Revachol, by Lafayette Potent Brewery.

Heading back slightly to the west of the ice, (or east of the telephone) there's a building.

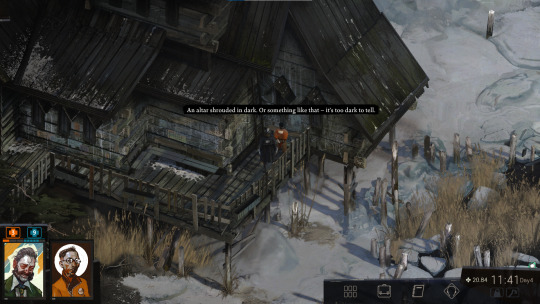

You feel the shadow of a very large building fall on you.

The sign reads: "Saint Brune 1147."

Dusty pews in the shadows. Many seem to be missing.

An altar shrouded in dark. Or something else like that -- it's too dark to tell.

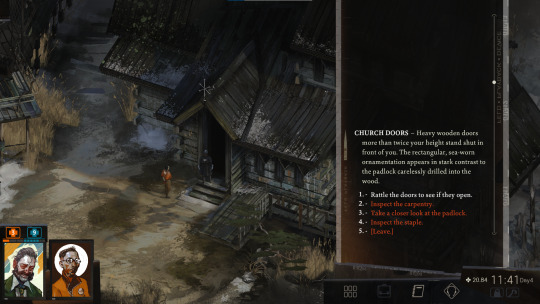

CHURCH DOORS - Heavy wooden doors more than twice your height stand shut in front of you. The rectangular, sea-worn ornamentation appears in stark contrast to the padlock carelessly drilled into the wood.

Rattle the doors to see if they open.

Inspect the carpentry.

Take a closer look at the padlock.

Inspect the staple.

[Leave.]

CHURCH DOORS - Nothing happens, only the sound of the padlock rattling against the door.

KIM KITSURAGI - "I don't think that's going to work..."

SHIVERS [Medium: Success] - High above, the wind wraps the church in its rush. Cold and wet from the ocean bay, it parts around the massive keel-shaped roof. Like a test tunnel washing both sides, the way it has done for three-hundred-and-forty years. The wind keeps its distance. So should you.

"What is this feeling?"

Back up and look at the door.

SHIVERS -

THERE IS A HOLE IN MY HEART.

KIM KITSURAGI - The lieutenant looks at the padlock. He didn't hear you asking, you were quiet enough.

2. Inspect the carpentry.

CHURCH DOORS - The carving on the door is blocklike and angular, like the church itself. Two large beams shoot downwards, sinking into the wood before they reach the threshold.

Run your hand over a beam.

Back up and look at the door.

CHURCH DOORS - The surface is smooth from the wind, but moist to the touch.

3. Take a closer look at the padlock.

CHURCH DOORS - This cheap-looking padlock is sturdily built. It shackles together a hasp and a staple screwed into the wooden door. The lock is adorned with a yellow sticker.

INTERFACING [Medium: Success] - It'll be easier to break the staple than the lock. Also -- that sticker is interesting, somehow...

4. Look at the sticker.

CHURCH DOORS - You see a yellow circle with two X's and a big curve below them that looks like a mouth. You're pretty sure you haven't seen it before, but what the symbol depicts is clear enough: a smiling dead guy. The curve makes it smile and the X's make it dead.

CONCEPTUALIZATION [Medium: Success] - There is something blindingly *modern* about this symbol. Its modernness puts to shame everything you've seen before.

What makes it so modern?

"Have you seen this symbol before?" (Point to it.)

Take another look at the boring padlock. For absurdity's sake.

CONCEPTUALIZATION - It's the contrast between the cheery, chemical yellow and the rigor mortis. As if the cheery guy didn't know he was dead or the dead guy didn't care that he was. Either way, you get the sense the forces of *future* are at work here.

INLAND EMPIRE [Challenging: Success] - These forces of future have chosen to depict something that reminds you of... you.

"Have you seen this symbol before?" (Point to it.)

KIM KITSURAGI - He takes off his glasses and uses a blue handkerchief to thoroughly wipe them clean before inspecting the sticker. Then he looks up, pauses, and replies...

"No."

"What does it look like to you?"

KIM KITSURAGI - "Looks like a dead man smiling. Suggests... junior delinquency."

"Okay, what is *junior delinquency*?"

"What is suggestive of junior delinquency here?"

KIM KITSURAGI - "For Revachol ZoC, the Moralintern defines junior delinquents as minors between the ages of 10 and 16 who have committed an act in violation of the law..."

"These acts aren't called *crimes* as they would be for adults. Crimes committed by minors are called 'delinquent acts'. This was part of your officer's exams." He puts the handkerchief in his coat pocket.

"What is suggestive of junior delinquency here?"

KIM KITSURAGI - "I haven't seen that sticker before. And I am not a youth."

"I agree -- it's very modern. But does the cheery guy not know he's dead, or does the dead guy not care that he is? What is the source of the irony here?"

Padlock, padlock, padlock!

KIM KITSURAGI - "That level of conceptual thinking is not part of my skill set."

5. Inspect the staple.

CHURCH DOORS - The padlock passes through a staple that's been hastily attached to the wood. Closer inspection reveals that one of the screws is not a screw at all, but a nail. The work has been done recently and is unprofessional, to say the least.

LOGIC [Easy: Success] - Should you want to get through, it might be easier to just pry the whole thing off.

(Turn to the lieutenant.) "This is where Mr. Prybar comes in handy."

Back off.

I just happened to have the prybar equipped from opening containers earlier.

KIM KITSURAGI - He takes a step back. "Maybe we should circle the building first and look for another way. The building has seen enough mistreatment."

EMPATHY [Easy: Success] - There is a touch of guilt in his voice.

"Should we start with that kick drum coming from the ice? I heard a sound, before."

KIM KITSURAGI - "Yes. The pulsing bass..." He raises his hand to his ear. "A sure sign of junior delinquency -- somewhere east of here."

6. [Interfacing - Easy 9] Try to peel of the sticker without ripping it.

INTERFACING [Easy: Success] - There's nothing like the sound of a sticker unpeeling. Now it's stuck to your thumb.

Put the sticker *in* your ledger -- after the last entry, where it belongs.

Put the sticker *on* your ledger -- right on the cover!

Shake it off your thumb and throw it in the wind.

INTERFACING - Voilà! Looks very modern.

Secret task complete: Style your paperwork

+10 XP

CONCEPTUALIZATION [Medium: Success] - You're part of the future-brigade now. And so is your formerly humdrum ledger. Neon, baby!

Let's not break into a church and check out that sick beat.

6. [Leave.]

It must have taken a lot of patience to do this.

ACELE - A shaggy-looking girl in her late teens or early twenties kneels on the ice with an electronic contraption in her hand. Hearing you approach, she looks up.

"Oh, hello there."

EMPATHY [Easy: Success] - It's cold out here, but she's not wearing a hat! She must be freezing.

ELECTROCHEMISTRY [Easy: Success] - Everyone knows drugs make you invulnerable to cold. You bet this one likes to *party*.

"Dear child, it's freezing. Where's your hat?"

"So, you wanna *party*?"

"I have some questions for you."

[Leave.]

ACELE - "Huh?" She looks up at you, distracted.

PERCEPTION (HEARING) [Medium: Success] - Maybe she didn't hear you. A little louder.

"I said, you should have a hat on."

ACELE - "So should you."

HALF LIGHT [Medium: Success] - You don't *have* to do anything.

"*I* don't have to do anything. I am the law. *You* have to do what the law says."

"I should -- and I do." (Point at your hat.)

"We're done here." [Leave.]

ACELE - "Real cool..." She looks down at the device, mumbling under her breath.

PERCEPTION (HEARING) [Medium: Success] - "Way to abuse that power, man..." she says, thinking you can't hear her.

COMPOSURE [Easy: Success] - She bats away your questions like flies. She's not intimidated by mere police officers.

"And the law says you have to wear a hat in this weather."

"So keep that in mind while I ask some questions."

ACELE - "Tsk..." She lets a quiet *tsk* roll off her tongue. "What kind of law says that?"

17 notes

·

View notes

Text

Intro: EDELSTAHL VIRAT IBERICA in #portugal An emerging importer Exporter, Supplier & Stockiest of Tool steel, Die & Mold Steels, Recycling products etc.

Tool Steel & Mold Steel Products: https://moldsteel.eu/steel-products/

🏆PLASTIC MOLD STEELS (DIN 2738, 2311 ) – Low / High Hard 🏆HOT WORK STEELS (DIN 1.2714, 2343, 2344) 🏆COLD WORK STEELS (DIN 2379, 2080) 🏆HIGH SPEED STEELS (DIN 3243, 3343, 3355) 🏆CHIPPER KNIFE STEEL (DIN 2631) 🏆ALLOY STEELS, BRIGHT BARS, EN-SERIES ETC.

Scrap / Recycling Products: https://moldsteel.eu/recycling-products/

👉 Used Tools(Carbide, Threading & HSS Cutting Tool Scrap) 👉Die & Mold Steel Blocks, Holder etc. 👉Steel lots, Cut short length, Prime over run 👉2344 Used Mandrel Bars 👉2344 Used Extrusion Dies 👉Forging Dies 👉Electric Motors 👉Used Machineries etc.

We are also involved in trading of Ferrous, Non Ferrous, Alloy steel scrap etc. The dynamic management has enabled the company to grow organically and sustainably in its search for Moving ahead globally with the exploration of Business Opportunities in several nations, including the USA, Canada, Europe, Australia, Middle East, Singapore, Japan, South Korea, India, and Philippines, etc.

Our business scope in B2B and B2C at many stages (finish products, scrap and recycling products, etc.), set us apart from other companies in this sector.

We work with a wide range of industries, including those related to Drop Forging, Aluminum Extrusion, Automotive, Mining, PDC, Power Generation, Petrochemical, Aviation, Railways, Agricultural, Oil and Gas, Drilling, Hand Tools, Bulk Material Handling, etc.

New Development in Special Steels, Recycled Products and Machine tools etc.

TO LEARN MORE >> https://moldsteel.eu/ WhatsApp Chat: +351-920016150 Email: info@moldsteel.eu

#europe#porto#portugal#din2738#edelstashlviratibrica#viratsteels#b2b#oportunidades#empresas#agricultura#din2714#din2343#din2344#din2379

3 notes

·

View notes

Text

auto shop

This trip to the auto shop is a very big deal for Charlie. It’s the culmination of a year’s worth of work. Maybe more, if he thinks about his adolescence, and that time he panicked after the fender bender with Sarah O’Connor at the 7-Eleven on Pelham. Back then, he swore he’d never drive a car again. Back then, he had no way of knowing that promise would kill his own brother. Back then, he wouldn’t have guessed that in 2022, he’d end up earning a driver’s license all his own. He wouldn’t have guessed that for Christmas that year, he’d buy himself a car, just to have, even if it’s pretty much useless in New York City.

And he most certainly wouldn’t have guessed he’d be here, now in the spring of ‘24, waiting at an auto shop back home in Detroit.

It’s a simple thing. At least, that’s what Daniel assured him when they spoke about it earlier today. Sometimes, you just need a new tire, and you’re not the one who can fix it. Daniel even helped Charlie get the car over here, like he would have when they were young.

Young. It’s hard to believe they’re not anymore.

Perhaps he’s putting too much stock into it. Hell, he knows he is. But Charlie can’t help but feel that if he makes it out of this auto shop with his car in one piece, then he’ll be a different kind of man. He’ll be the man that Elenore deserves, the father that his children deserve, the brother that Sadie (and Sam) could be proud of. It’s all tied up in a car.

That makes him laugh. Lots of men use cars as metaphors for their lives, especially here at home, where you can’t take two steps without meeting a few dads in the automotive industry. The Motor City is more than just a jingle on the radio. It’s just that Charlie was never one of those men. His metaphors were all about keys and chords and clefts. They still are. It’s just that when you change your life, your poetic devices change, too. At least, that’s what he thinks. He was never as good with words as he pretended to be.

He sits in the waiting room of the auto shop and tries to take it in. It smells like going with his dad to fix up the truck when he was a kid. Burnt, greasy, welcoming. Charlie can’t believe he forgot that fuel is the smell of summer and safety. Of course, you don’t really forget how to be a Motown kid. You just push it down until it comes back up.

He sits there and focuses on the radio, echoey somewhere in the back of the shop. Somebody’s tuned into a local station. Maybe even CKLW. They’re buzzing and drilling and fixing in time with “Jet.” It feels just like being a little kid and not understanding anything but smells and sounds. It’s great. Elenore should be here.

Elenore should be everywhere. He’ll think about that when he gets the car back.

One of the workers appears from the back with a smile on his face. Says that Charlie’s car is done, and they’ll have a total for him in a minute or two. Charlie smiles back.

He did it.

He didn’t do anything, but he did it.

It feels like something, and on the whole ride back to the hotel, he’ll try to figure out what that is.

(part of @nosebleedclub march challenge -- day 29!)

2 notes

·

View notes

Text

Best Data Science Courses Online - Skillsquad

Why is data science important?

Information science is significant on the grounds that it consolidates instruments, techniques, and innovation to create importance from information. Current associations are immersed with information; there is a multiplication of gadgets that can naturally gather and store data. Online frameworks and installment gateways catch more information in the fields of web based business, medication, finance, and each and every part of human existence. We have text, sound, video, and picture information accessible in huge amounts.

Best future of data science with Skillsquad

Man-made consciousness and AI advancements have made information handling quicker and more effective. Industry request has made a biological system of courses, degrees, and occupation positions inside the field of information science. As a result of the cross-practical range of abilities and skill required, information science shows solid extended development throughout the next few decades.

What is data science used for?

Data science is used in four main ways:

1. Descriptive analysis

2. Diagnostic analysis

3. Predictive analysis

4. Prescriptive analysis

1. Descriptive analysis: -

Distinct examination looks at information to acquire experiences into what occurred or what's going on in the information climate. It is portrayed by information representations, for example, pie diagrams, bar outlines, line charts, tables, or created accounts. For instance, a flight booking administration might record information like the quantity of tickets booked every day. Graphic investigation will uncover booking spikes, booking ruts, and high-performing a very long time for this help.

2. Diagnostic analysis: -

Symptomatic investigation is a profound plunge or point by point information assessment to comprehend the reason why something occurred. It is portrayed by procedures, for example, drill-down, information revelation, information mining, and connections. Different information tasks and changes might be performed on a given informational index to find extraordinary examples in every one of these methods.

3. Predictive analysis: -

Prescient examination utilizes authentic information to make precise gauges about information designs that might happen from here on out. It is portrayed by procedures, for example, AI, determining, design coordinating, and prescient displaying. In every one of these procedures, PCs are prepared to figure out causality associations in the information

4. Prescriptive analysis: -

Prescriptive examination takes prescient information to a higher level. It predicts what is probably going to occur as well as proposes an ideal reaction to that result. It can investigate the likely ramifications of various decisions and suggest the best strategy. It utilizes chart investigation, reproduction, complex occasion handling, brain organizations, and suggestion motors from AI.

Different data science technologies: -

Information science experts work with complex advancements, for example,

- Computerized reasoning: AI models and related programming are utilized for prescient and prescriptive investigation.

- Distributed computing: Cloud innovations have given information researchers the adaptability and handling power expected for cutting edge information investigation.

- Web of things: IoT alludes to different gadgets that can consequently associate with the web. These gadgets gather information for information science drives. They create gigantic information which can be utilized for information mining and information extraction.

- Quantum figuring: Quantum PCs can perform complex estimations at high velocity. Gifted information researchers use them for building complex quantitative calculations.

We are providing the Best Data Science Courses Online

AWS Certification Program

Full Stack Java Developer Training Courses

2 notes

·

View notes

Text

Zero Friction Coatings Market: Charting the Course for Enhanced Performance and Sustainable Solutions

The global zero friction coatings market size is estimated to reach USD 1,346.00 million by 2030 according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 5.6% from 2022 to 2030. Growth can be attributed to the fact that these coatings reduce friction and wear resulting in low fuel consumption and less heat generation. According to the European Automobile Manufacturers' Association, 79.1 million motor vehicles were produced across the globe in 2021 which was up by 1.3% as compared to 2020. Zero friction coatings can extend the time between component maintenance and replacement, especially for machine parts that are expensive to manufacture.

Zero Friction Coatings Market Report Highlights

In 2021, molybdenum disulfide emerged as the dominant type segment by contributing around 50% of the revenue share. This is attributed to its properties such as low coefficient of friction at high loads, electrical insulation, and wide temperature range

The automobile & transportation was the dominating end-use segment accounting for a revenue share of more than 35% in 2021 due to the rapid growth of the automotive industry across the globe

The energy end-use segment is anticipated to grow at a CAGR of 5.7% in terms of revenue by 2030, owing to the excessive wear on the drill stem assembly and the well casing during the drilling operations in the oil and gas sector

In Asia Pacific, the market is projected to witness the highest CAGR of 5.8% over the predicted years owing to the presence of car manufacturing industries in the countries such as Japan, South Korea, and China

For More Details or Sample Copy please visit link @: Zero Friction Coatings Market Report

Several applications in the automobile industry use wear-resistant plastic seals that require zero tolerance for failure and lifetime service confidence. Increasing demand for the product from the automotive industry across the globe for various applications including fuel pumps, automatic transmissions, oil pumps, braking systems, and others is expected to drive its demand over the forecast period.

Low friction coatings can be used in extreme environments comprising high pressure, temperatures, and vacuums. These coatings can provide improved service life and performance thereby eliminating the need for wet lubricants in environments that require chemicals, heat, or clean room conditions. The product containing molybdenum disulfide (MoS2) are suitable for reinforced plastics while those free from MoS2 are suitable for non-reinforced plastics.

Zero friction coatings are paint-like products containing submicron-sized particles of solid lubricants dispersed through resin blends and solvents. The product can be applied using conventional painting techniques such as dipping, spraying, or brushing. The thickness of the film has a considerable influence on the anti-corrosion properties, coefficient of friction, and service life of the product. Its thickness should be greater than the surface roughness of the mating surfaces.

ZeroFrictionCoatingsMarket #FrictionlessTechnology #CoatingInnovations #IndustrialEfficiency #ZeroFrictionSolutions #AdvancedMaterials #SurfaceCoatings #ManufacturingAdvancements #GlobalIndustryTrends #InnovativeCoatings #PerformanceOptimization #MechanicalSystems #SustainableTechnology #IndustrialApplications #FutureTech #InnovationInMaterials #EfficiencySolutions #ZeroFrictionMarket #TechnologyInnovation #EngineeringMaterials

#Zero Friction Coatings Market#Frictionless Technology#Coating Innovations#Industrial Efficiency#Zero Friction Solutions#Advanced Materials#Surface Coatings#Manufacturing Advancements#Global Industry Trends#Innovative Coatings#Performance Optimization#Mechanical Systems#Sustainable Technology#Industrial Applications#Future Tech#Innovation In Materials#Efficiency Solutions#Zero Friction Market#Technology Innovation#Engineering Materials

2 notes

·

View notes

Text

Choosing the Right Top Drive System Components: A Buyer's Guide

There is no overemphasising the role of a functioning top drive system in the world of drilling. This is because it is necessary for you to learn more about the main parts of top drive systems, which are critical in making drilling operations optimal. The aim of this buyer’s guide, therefore, is to unravel the selection procedure, taking into account the efficiency and performance aspects.

Top Drive System Drilling – Understanding the Basics

Some basics about the top drives and top drive system drilling before diving into the various drilling components. This advanced technology has changed the face of the drilling industry, making it possible to create a new approach to drilling the well bore. Unlike top drive systems, the traditional ones necessitate stopping and pulling out the whole drill string each time they occur, leading to lesser efficiency and productivity.

Key Components for Optimal Performance

a. Powerful Motors:

Motors dominate in any top drive. Effective rotation of the drill string is possible with high-powered electric hydraulic motors. For this reason, the motor should be very powerful as it ensures smoother drilling.

b. Pipe Handling System:

Because of this, the process should be smooth; hence, a dependable pipe-handling system is important. It is made up of components that are intended to handle a pipe connection or drills. Choose a system that can cater for various pipe sizes and loads for flexibility.

c. Top Drive Control System:

Its brain is the control organ that operates the whole drilling process. Drilling parameters should be easy to read for the operator during drilling. The control program determines how safe, efficient and well-conceived a drilling operation will be.

Important Considerations for the Best Top Drive System Components

a. Compatibility:

Ensure that your equipment has spare parts of the top drive system for your purchase. There could be operational problems or even shutdowns when using the wrong parts. Ensure that there is compliance with the specifications and ease of integration with the supplier.

b. Durability:

Utilise strong objects that will be able to deal with the extreme stresses of a drilling environment. Employing this type of top-quality parts enhances the longevity of your top drive system at a much lesser cost and shorter time.

c. Ease of Maintenance:

User-friendliness also includes ease of maintenance. Choose items that are simple to look at, replace, and store.- This minimises downtime and hence ensures maximum productivity for your drilling operation.

Importance of Regular Maintenance

Still, however, purchasing the most efficient drive system is just one of the things that are done. Periodic maintenance should be done for efficiency in running the equipment and longevity services. Create an extensive preventive maintenance schedule and observe it accordingly. This process is made smooth by periodic inspection, lubrication, and replacement of worn-out parts.

Conclusion: Elevating Your Drilling Operations

Hence, it is important to understand the main parameters which are necessary to be successful at drilling in the selection of the proper top drive system parts. Drill operations must target high-powered motors, pipe handling systems and modern control systems.

However, it should be remembered that the performance of these elements relies not only on their selection at the beginning but also on the permanent maintenance of these elements in the subsequent production phases. Consequently, ensure high efficiency of the top drive system in order to achieve maximum production rates and minimise downtimes. Having this buyer’s guide will help you select appropriately so as to improve your drilling activities.

2 notes

·

View notes

Text

Exploring the World of Precision Machining

In the world of manufacturing, precision is paramount. The ability to create intricate and accurate components is a game-changer, and it's made possible by cutting-edge machinery. This article'll delve into the fascinating realm of precision machining, focusing on CNC grinding machines, gun drilling machines, and steering machines. These technological marvels have revolutionised the manufacturing industry, and we'll uncover their significance in this journey.

CNC Grinding Machine: Precision at Its Finest

When achieving unparalleled precision in machining, CNC grinding machine takes centre stage. These machines are designed to smooth and shape materials with incredible accuracy. With computer numerical control (CNC) technology at their core, CNC grinding machines efficiently execute complex tasks. They are the artisans of the manufacturing world, sculpting components to perfection.

The Anatomy of a CNC Grinding Machine

To truly appreciate the capabilities of a CNC grinding machine, it's essential to understand its components. We'll break down each part's role in creating precision components from the grinding wheel to the control panel. The grinding wheel, driven by advanced motors, meticulously removes material, while the CNC control unit orchestrates the entire process. It's a symphony of motion and control resulting in unparalleled precision components.

Gundrilling Machine: Drilling with Precision

Gundrilling is a specialised drilling process used in various industries, including aerospace and medical device manufacturing. Gundrilling machine is the unsung heroes of precision drilling, capable of creating deep and accurate holes. Let's delve into gun drilling and discover how these machines make the impossible possible.

The Marvel of Deep Hole Drilling

Gundrilling machines excel in drilling deep, straight holes with minimal deviation. We'll explore the techniques and technologies that enable these machines to achieve such precision in drilling. The secret lies in specialised tooling and coolant systems that ensure the drill bit remains cool and sharp, even during extended drilling operations. This combination of engineering prowess and cutting-edge technology results in flawlessly drilled holes that meet the strictest tolerances.

Steering Machines: Navigating the Future

In the automotive industry, precision is essential, and steering systems play a critical role. Steering machine is responsible for crafting components that ensure smooth and reliable steering performance. Join us as we navigate through the world of steering machines and their contribution to the automotive realm.

Crafting the Perfect Steering Component

Steering machines are tasked with creating components that must withstand immense forces while maintaining precision. We'll unravel the challenges and innovations that drive the development of these essential components. From forging to precision machining, steering components undergo rigorous processes that demand the utmost precision. Advanced materials and quality control measures ensure that each element meets stringent safety and performance standards.

Conclusion

In the world of precision machining, where every micrometer matters, CNC grinding machines, gun drilling machines, and steering machines shine as unsung heroes. Their precision and accuracy make the impossible possible, shaping industries and driving innovation.

To learn more about the world of precision machining and the remarkable machines that power it, visit WIDMA. Discover a world where precision knows no bounds and technology meets craftsmanship in perfect harmony.

3 notes

·

View notes

Text

Application Of Tewatt Mobile Air Compressors In Water Wells And Geothermal Projects

Tewatt mobile air compressors, equipped with the world's leading heavy-duty VOLVO diesel engine, international top-tier dedicated electric motors for compressors, exceptional American Tewatt screw compressor host, an oversized military-grade radiator, a stable and straightforward control system, and a heavy-duty filtration system among other premium components. These specifications make Tewatt's mobile air compressors apt for the harsh conditions encountered in water wells and geothermal projects, making them extensively used in such constructions.

Requirements and Characteristics of Water Wells and Geothermal Projects:

The industry usually employs diesel mobile compressors for water wells and geothermal projects, demanding high exhaust volume, high pressure, and frequent mobility. Depending on the project, the requirements for compressors differ between water and geothermal wells. Since geothermal wells generally have a much deeper drilling depth than water wells, they often adopt multiple parallel machines.

Working conditions: Construction is more common in the colder northern parts of China, with some areas being at a higher altitude.

The typical compressor exhaust volume ranges from 21m3/min to 35m3/min, and the exhaust pressure is between 18kg/cm2 and 35kg/cm2. The drilling diameter ranges from 100mm-400mm.

Air drilling efficiency is significantly higher than the traditional water drilling method and is the inevitable trend for the drilling industry's future development.

Solutions:

Addressing the water well and geothermal industry's needs, our company has specifically developed a high-pressure compressor with an exhaust pressure of 25kg/cm2 and an exhaust volume of 31.5m3/min. With our drilling equipment, we can easily penetrate a 300mm diameter and 200m deep granite geological structure. If two 25kg/cm2, 30m3/min compressors are paired with a 100kg/cm2 booster, we can achieve up to 2800m for geothermal projects, marking a pioneering achievement with our partners.

Given the frequent mobility required by water wells and geothermal projects, we've designed a vehicular high-pressure compressor for easy relocation, eliminating the need for separate power drives, lifting, or transportation, saving users significant time and cost. It's exceptionally convenient for operations within a 100km range.

Our large exhaust volume, dual-stage high-pressure screw compressor, meets the needs of users requiring even higher pressures.

In terms of drilling and geothermal projects, our products have gained widespread recognition in places like Xinjiang, Shandong, Northeast, Henan, and Yunnan. Notably, in Yunnan's Qujing voluntary drought-resistance project, we completed our mission successfully, receiving attention from local television stations and government interviews.

We can provide all drilling clients with a set of efficient, advanced solutions and equipment plans based on their requirements. We also offer a comprehensive cost and maintenance plan for the entire equipment set, addressing professional air drilling issues.

Tewatt mobile air compressors boast reliability, stability, energy efficiency, and environmental friendliness. They are also resilient to extreme conditions, such as high temperatures, severe cold, high dust, and high altitudes, maintaining exemplary performance in harsh environments. The intelligent control system further ensures equipment stability and simplifies operations. Tewatt compressors undoubtedly have a promising application future in water wells and geothermal projects.

2 notes

·

View notes

Text

directional drilling mud motors

youtube

Galip Trenchless & Oil equipment Ltd. was born in October 2008, with a passion for producing screw drill tools, non-magnetic suspension joints, screw drill accessories, screw glue cleaners, PDC plane bearings, adjustable drill parts, 360-degree rotating bucking machines, Mud Motor Dynamometers, turbine drill parts, equal-wall screw drills and other non-excavation drilling and oil drilling tools, cementing tools and their accessories. The company established and always upheld the spirit of “integrity, pragmatism, efficiency, innovation” to create the Galip oil tool brand with full force. The business achieved rapid development and gained wide recognition from the industry insiders, becoming a brilliant new star in the oil and non-excavation equipment manufacturing industry.

2 notes

·

View notes

Text

Power Tools Market Drivers: Rising Infrastructure and Construction Projects Fueling Industry Expansion Globally

The global power tools market has witnessed exponential growth over the years, driven by numerous factors ranging from technological advancements to increasing infrastructure projects. As industries continue to evolve, the demand for efficient, high-performance power tools continues to surge.

Rising Construction and Infrastructure Development Projects One of the key drivers of the power tools market is the rise in construction and infrastructure development projects worldwide. Governments and private sectors are investing heavily in the construction of residential, commercial, and industrial spaces. With increasing urbanization and modernization, the demand for power tools such as drills, saws, and grinders has surged. Emerging economies, particularly in Asia-Pacific and the Middle East, are witnessing a boom in infrastructure projects, further propelling market growth.

Technological Advancements and Automation Technological advancements play a crucial role in the growth of the power tools market. Innovations such as cordless tools, brushless motors, and smart connectivity have revolutionized the industry. The introduction of Internet of Things (IoT)-enabled tools and artificial intelligence (AI) integration has enhanced efficiency, accuracy, and safety in various industrial applications. These advancements are attracting more professionals and DIY enthusiasts to invest in modern power tools, thereby increasing market penetration.

Growth of the Automotive and Manufacturing Industries The expansion of the automotive and manufacturing industries is another major factor driving the demand for power tools. The automotive sector relies heavily on power tools for assembly, maintenance, and repair work. As vehicle production and technological advancements in manufacturing increase, the demand for efficient and precise power tools continues to rise. Additionally, the shift towards electric vehicles (EVs) has led to a higher demand for specialized tools required for assembly and maintenance.

Rising Popularity of DIY and Home Improvement Trends The growing trend of do-it-yourself (DIY) projects and home improvement activities has significantly contributed to the growth of the power tools market. With the availability of user-friendly and affordable tools, homeowners and hobbyists are increasingly taking up renovation and repair tasks. Online tutorials and social media platforms have further fueled the DIY movement, encouraging more consumers to invest in power tools for personal use.

Shift Towards Sustainable and Energy-Efficient Tools Sustainability has become a key focus across various industries, including power tools. Manufacturers are increasingly adopting eco-friendly and energy-efficient technologies to meet regulatory standards and consumer demand. The introduction of battery-operated tools with extended battery life and reduced carbon emissions is gaining traction. Additionally, the shift towards recyclable materials and energy-efficient manufacturing processes is driving the market towards sustainability.

Increasing Safety Regulations and Workplace Efficiency Stringent workplace safety regulations and a growing emphasis on efficiency are also contributing to the power tools market's expansion. Industries are prioritizing worker safety by investing in advanced tools equipped with safety features such as automatic shut-off, anti-kickback, and ergonomic designs. These innovations not only enhance safety but also improve productivity, making power tools an indispensable asset in industrial and commercial settings.

Expansion of E-Commerce and Online Sales Channels The rapid expansion of e-commerce platforms has played a pivotal role in the power tools market growth. Online sales channels have made power tools more accessible to a global audience, allowing consumers to compare products, read reviews, and make informed purchasing decisions. The convenience of online shopping, coupled with discounts and promotional offers, has further boosted market demand, particularly among DIY enthusiasts and small business owners. Conclusion The power tools market is experiencing robust growth, driven by factors such as rising infrastructure projects, technological advancements, expanding automotive and manufacturing sectors, and increasing consumer demand for DIY tools. As sustainability and safety regulations continue to shape the industry, manufacturers are focusing on innovation to meet evolving market needs. With the continued expansion of e-commerce and the push for energy-efficient solutions, the future of the power tools market looks promising.

0 notes

Text

Choosing the Right Air Compressor: Features, Benefits, and Expert Tips

Air compressors play a vital role in various industries, from automotive and construction to manufacturing and medical applications. Choosing the right air compressor can significantly impact efficiency, performance, and operational costs. With various types and specifications available, making an informed decision is essential. This blog will explore the key features, benefits, and expert tips for selecting the ideal air compressor.

Understanding Air Compressors and Their Applications

An air compressor is a mechanical device that converts power into potential energy stored in compressed air. This energy is then used to power pneumatic tools, inflate tires, operate machinery, and even facilitate medical procedures. Whether you need a small, portable compressor for DIY projects or a heavy-duty industrial model, choosing the right one depends on several factors.

Common Applications of Air Compressors:

Manufacturing & Industrial Use – Powering production lines, painting, and assembling machinery.

Automotive Industry – Inflating tires, operating pneumatic tools, and spray painting.

Construction Sites – Running jackhammers, nail guns, and drills.

Medical Field – Providing clean, compressed air for ventilators and surgical instruments.

Agriculture – Operating irrigation systems and milking machines.

Key Features to Consider When Choosing an Air Compressor

When selecting an air compressor, you need to evaluate various features to ensure it meets your specific needs.

1. Type of Air Compressor

There are different types of air compressors, each designed for specific applications:

Reciprocating (Piston) Compressors – Best for high-pressure applications and intermittent use.

Rotary Screw Compressors – Ideal for continuous operation in industrial settings.

Centrifugal Compressors – Used for large-scale, high-volume air needs.

Oil Free Compressors – Suitable for industries requiring clean air, such as food processing and healthcare.

2. Power Source

Air compressors can be powered by electricity or fuel (gasoline/diesel):

Electric-Powered Compressors – Ideal for indoor use and quieter operation.

Gas/Diesel-Powered Compressors – Best for outdoor applications where electricity is not available.

3. Tank Size and Air Capacity (CFM & PSI)

CFM (Cubic Feet per Minute) – Determines the volume of air the compressor delivers.

PSI (Pounds per Square Inch) – Indicates the pressure level needed to power tools effectively.

Tank Size – Larger tanks store more air, reducing the frequency of motor cycling.

4. Portability and Size

Consider whether you need a stationary or portable unit:

Portable Compressors – Lightweight and equipped with wheels for mobility.

Stationary Compressors – Larger, more powerful, and ideal for industrial settings.

5. Noise Levels

Industrial air compressors can be noisy. Look for low-noise models if operating in noise-sensitive environments.

6. Energy Efficiency

Opt for models with Variable Speed Drive (VSD) technology to reduce energy consumption and operational costs.

7. Additional Features

Auto Shutoff – Enhances safety and energy efficiency.

Thermal Overload Protection – Prevents overheating.

Moisture and Air Filtration System – Ensures clean, dry air output.

Benefits of Choosing the Right Air Compressor

Investing in the right air compressor offers several advantages:

1. Improved Efficiency and Performance

A well-chosen air compressor ensures seamless operations with consistent airflow and pressure.

2. Cost Savings

An energy-efficient compressor reduces electricity bills and minimizes downtime.

3. Longer Equipment Lifespan

High-quality compressors with proper maintenance last longer, reducing replacement costs.

4. Versatility and Adaptability

From home DIY projects to industrial applications, the right air compressor enhances productivity across multiple industries.

5. Safety and Reliability

Modern compressors come with built-in safety features, reducing risks of overheating and system failure.

Expert Tips for Selecting the Best Air Compressor

1. Assess Your Air Needs

Identify the tools and equipment the compressor will power to determine the required CFM and PSI.

2. Consider Future Expansion

Choose a compressor with a slightly higher capacity than your current needs to accommodate future growth.

3. Check for Brand Reputation and Warranty

Buy from reputable manufacturers offering good customer support and extended warranties.

4. Compare Energy Efficiency Ratings

Look for energy-efficient models with ENERGY STAR ratings to save on operational costs.

5. Understand Maintenance Requirements

Regular maintenance, such as filter cleaning and oil changes (for lubricated models), ensures longevity and peak performance.

6. Factor in Noise Levels

If using the compressor in a workshop or indoors, opt for a quieter model.

7. Check for Additional Accessories

Some compressors come with built-in air dryers, regulators, and multiple hose connections for added convenience.

Conclusion

Choosing the right air compressor is a crucial decision that impacts performance, efficiency, and long-term cost savings. By considering factors like compressor type, power source, tank size, and energy efficiency, you can select a model that best suits your needs. Whether for industrial, commercial, or personal use, investing in a high-quality air compressor ensures durability, reliability, and optimal performance. Follow the expert tips provided to make a well-informed choice and maximize your investment.

Need help selecting the perfect air compressor? Reach out to experts or trusted suppliers to find the best solution for your business or personal projects!

0 notes

Text

Wanted to know about Dongcheng cordless drill machine

The Dongcheng cordless drill machine is a powerful and reliable tool for professionals and DIY enthusiasts. Whether you're working on construction projects, home repairs, or furniture assembly, this drill provides the performance and convenience needed to do the job efficiently.

Powerful Performance & Precision

Equipped with a high-torque motor, theDongcheng cordless drill machine delivers exceptional drilling and driving power across various materials, including wood, metal, and plastic. Its variable speed control allows for precise operation, ensuring smooth and accurate drilling with minimal effort. The reverse function further enhances versatility, making it easy to remove screws or back out of holes when necessary.

Cordless Convenience & Long-Lasting Battery

The cordless design eliminates the hassle of tangled wires, offering greater flexibility and ease of use, especially in tight or hard-to-reach spaces. Powered by a high-capacity lithium-ion battery, the drill provides extended usage time, allowing you to complete tasks without frequent recharging. The fast-changing technology ensures minimal downtime, keeping productivity at its peak.

Ergonomic & Durable Build

Designed for comfort and efficiency, the drill features a lightweight and ergonomic grip, reducing hand fatigue during prolonged use. The sturdy construction ensures durability, making it a long-lasting addition to any toolkit. The LED work light enhances visibility in dimly lit areas, ensuring precision even in challenging conditions.

Versatile Applications

Ideal for a wide range of applications, the Dongcheng cordless drill machine is perfect for:

Home improvement projects – drilling into walls, assembling furniture, and installing fixtures

Professional construction work – handling heavy-duty drilling and fastening tasks

Automotive repairs – working on vehicles and machinery with precision

Why Choose Perfect Engineers?

As a trusted provider of high-quality power tools, Perfect Engineers ensures that every Dongcheng cordless drill machine meets industry standards for reliability and performance. Committed to excellence, we provide top-notch products that help professionals and hobbyists achieve outstanding results. Upgrade your toolkit today with the Dongcheng cordless drill machine, where power, precision, and convenience come together for superior performance!

0 notes

Text

EDELSTAHL VIRAT IBERICA: A New Force in the Global teel Industry!

Based in Portugal, is rapidly making a name for itself as a versatile player in the global steel industry. It's making waves as an emerging importer, exporter, supplier, and stockist of Tool Steel, Die & Mold Steels, and Recycling products.

Let’s explore their impressive offerings:

Tool Steel & Mold Steel Products: https://moldsteel.eu/steel-products/

🏆PLASTIC MOLD STEELS (DIN 2738, 2311): Low to high hardness options for precision molding. 🏆HOT WORK STEELS (DIN 1.2714, 2343, 2344): Ideal for close die forging applications. 🏆COLD WORK STEELS (DIN 2379, 2080): Versatile for various cutting and shaping tasks. 🏆HIGH SPEED STEELS (DIN 3243, 3343, 3355): Perfect for high-speed applications. 🏆CHIPPER KNIFE STEEL (DIN 2631): Precision material for chipper knives. 🏆ALLOY STEELS, BRIGHT BARS, EN-SERIES, ETC.: A comprehensive range to meet diverse needs.

Scrap / Recycling Products: https://moldsteel.eu/recycling-products/

👉Used Tools (Carbide, Threading & HSS Cutting Tool Scrap): Sustainable recycling of valuable tools. 👉Die & Mold Steel Blocks, Holder, etc.: Reclaiming steel resources. Steel lots, Cut short length, Prime over run: Efficient utilization of excess materials. 👉2344 Used Mandrel Bars, Extrusion Dies, Forging Dies: Giving new life to pre-owned components. 👉Electric Motors, Used Machineries, and more: Contributing to circular economy practices.

What sets EDELSTAHL VIRAT IBERICA apart is its comprehensive business scope, which encompasses both B2B and B2C markets at various stages, from finished products to scraps and recycling items. This broad spectrum of operations positions them as a unique entity in the sector.

The industries served by EDELSTAHL VIRAT IBERICA are as diverse as their product range. They work closely with sectors involved in drop forging, aluminum extrusion, automotive, mining, power generation, petrochemicals, aviation, railways, agriculture, oil and gas, drilling, hand tools, and bulk material handling, among others.

EDELSTAHL VIRAT IBÉRICA isn’t just about steel; it’s about sustainability, innovation, and global exploration. Their dynamic management has positioned them for success across nations, from the Portugal to India.

TO LEARN MORE >>

WhatsApp Chat: +351-920016150 Email: info@moldsteel.eu

#europe#porto#portugal#din2738#edelstashlviratibrica#viratsteels#b2b#oportunidades#empresas#agricultura#specialsteels#moldsteel#Ribeira#Bolhão#Guimarães#Braga#edelstahl

2 notes

·

View notes

Text

Radial Drilling Machines Market Poised for USD 8.8 Billion by 2032

The market for radial drilling machines is expected to reach USD 8.8 billion by 2032, up from USD 4.2 billion in 2022, with a CAGR of 7.7%. Drilling operations like boring holes, reaming, countersinking, counterboring, tapping, and spot facing and tapping are in high demand due to the growing industrial sector and increasing applications, which propels the market’s expansion. High spindle speeds are used with radial drilling machines market to drill the desired hole quickly and affordably.

All the varieties of drilling machines, actually execute the same basic drilling function. But, there are certain operations that can be done with the desired accuracy and efficiency by specific types of drilling machines. They are widely used in several manufacturing processes, particularly in the construction industry. Radial drilling is a machine used to make holes supported by the radial axis and feed hand and the table base.

In the radial drilling machine, the drill head can be made to slide on the radial arm. Therefore, called as radial drilling machine. A motor acts as a driving force for the rotation of the drill. The parts of a radial drilling machine are a motor, spindle (for supporting the drill), elevating screw, column, table and table base. The radial drilling machine can be used to drill steel, cast iron as well as many other surfaces.

The radial drilling machine is amongst the most versatile drilling machine that can be used for multiple applications over any kind of surface.

Decoding Market Trends: Assess Market Potential and Discover Growth Opportunities - Request Our Sample Now: https://www.futuremarketinsights.com/report-sample#5245502d47422d35353431

Global Radial Drilling Machine Market: Dynamics

Market Drivers:

Augmenting industrial and commercial projects where drilling is required for the various purposes, such as boring holes, reaming, countersinking, counterboring, tapping and spot facing and tapping, is projected to drive the growth for the global radial drilling machine market. Infrastructure projects, industrial sectors, metal working applications are the key sectors that utilize radial drilling machine equipment and thus, drive the radial drilling machine market.

Market Restraints:

One of the major challenge faced by the global radial drilling machine market is the tool replacement rate, which is comparatively high. The parts of the machine are exposed to high risk of wear and tear at high speed. Hence, the demand for service and maintenance of such machines is high, which hampers the growth of the global radial drilling machine market.

Market Trends:

As the global market for radial drilling machine is fragmented with a large number of local players and China-based players, the manufacturers are focusing on product innovation as a differentiating strategy in order to win an edge over the other manufacturers in the market. In order to ease the operating process, significant evolution has been observed in the radial drilling machine market from manual clamping to electrical and hydraulic clamping. This has saved the time and has improved the efficiency of the drilling operations.

Global Radial Drilling Machine Market: Segmentation

The global radial drilling machine market can be segmented based on product type, application, drilling capacity and region.

By product type, the global radial drilling machine market can be segmented as:

Manual Clamping

Electrical Clamping

Hydraulic Clamping

By application, the global radial drilling machine market can be segmented as:

Construction

Metal Working

Wood Working

Others

By drilling capacity, the global radial drilling machine market can be segmented as:

40mm – 60mm

60mm – 80mm

80mm – 120mm

Global Radial Drilling Machine: Regional Outlook

The global radial drilling machine market is dominated by the Asia Pacific region, with China holding a significant share in the market. With the growing construction industry in the region, the regional market is projected to witness a significant growth.

Other regions, such North America and Europe, are also projected to showcase significant demand for radial drilling machines for various metal working applications. Latin America and the Middle East and Africa are projected to witness relatively sluggish growth over the forecast period.

Global Radial Drilling Machine Market: Participants

Examples of some of the market participants identified across the value chain of the global radial drilling machine market are:

Tailift Co., Ltd., Esskay International Machine Tools, Jay Industries, Complete Machine Tools Pty. Ltd., HMT Machine Tools Limited, Dalian Machine Tool Group Corporation, Kanematsu KGK Corp, Taian Hiscience Machinery Co. Ltd.

The research report presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, and statistically supported and industry-validated market data. It also contains projections using a suitable set of assumptions and methodologies. The research report provides analysis and information according to market segments such as geographies, application, and industry.

The report covers exhaust analysis on

Market Segments

Market Dynamics

Market Size

Supply & Demand

Current Trends/Issues/Challenges

Competition & Companies involved

Technology

Value Chain

Regional analysis includes

North America (U.S., Canada)

Latin America (Mexico. Brazil)

Western Europe (Germany, Italy, France, U.K, Spain)

Eastern Europe (Poland, Russia)

Asia Pacific (China, India, ASEAN, Australia & New Zealand)

Japan

Middle East and Africa (GCC Countries, S. Africa, Northern Africa)

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

Key Segments in the Radial Drilling Machine Market

By Product:

Sensitive Drilling Machine

Upright Drilling Machine

Radial Drilling Machine

Gang Drilling Machine

Multiple Spindle Drilling Machine

Deep Hole Drilling Machine

By Type:

Manual Clamping

Electrical Clamping

Hydraulic Clamping

By Application:

Construction

Metal Working

Wood Working

Others

By Drilling Capacity:

40mm – 60mm

60mm – 80mm

80mm – 120mm

By Region:

North America

Latin America

Europe

Asia

Middle East and Africa

0 notes