#double piston air compressor

Explore tagged Tumblr posts

Text

What is a Piston Air Compressor? A Complete Guide

The Blog Piston air compressors, also known as reciprocating compressors, are among the oldest and most widely used industrial air compressors. They operate on the principle of positive displacement, where air pressure is increased by reducing its volume. Available in single-acting, double-acting, oil-lubricated, and oil-free variants, these compressors cater to a wide range of industrial applications.

In single-acting compressors, air is compressed on one side of the piston, while double-acting models utilize both sides, making them ideal for heavy-duty tasks. Oil-lubricated models provide smooth operations but are unsuitable for industries like food and pharmaceuticals, where oil-free compressors are preferred.

Piston air compressors find applications in automotive industries for spray painting and tire inflation, manufacturing for powering tools and air separation, and healthcare for ventilators and lab equipment. They are also used in construction and workshops.

Key advantages of piston air compressors include durability, versatility, easy maintenance, cost-effectiveness, and high-pressure capability. Modern piston compressors are quieter, more efficient, and available in various power ranges to suit diverse needs.

If you’re planning to invest in a piston air compressor, consult Delta Industries, a trusted name in Ahmedabad, for reliable and high-performing options tailored to your requirements.

0 notes

Text

What Are Pneumatic Cylinders? Simple Guide For Beginners

Pneumatic cylinders are useful parts of many machines and are powered by compressed air to work. These devices are used in various industries, such as manufacturing, packaging, etc. In this post, we will explore the principles of operation of pneumatic cylinders, their different types and uses, and the benefits they offer in automation. Having an understanding of these components will help you make better decisions related to your projects, and thus improve your operational efficiency.

What are Pneumatic Cylinders?

Pneumatic cylinders also known as air cylinders are devices that use compressed gas energy to create linear motion. Basically compressed air drives a piston that is inside a cylinder, and the piston moves in linear motion by pushing or pulling.

Working Principle or Functionality

Pneumatic cylinder Components

Cylinder body: This is the outer framework that contains the internal parts and provides stability.

Piston: A cylindrical or disc-shaped component that rotates within the cylinder body. It is responsible for transmitting the force generated by compressed air.

Piston rod: A metal rod attached to the piston, which extends outside the cylinder. It transfers the linear motion of the piston to the load.

Air inlet and outlet ports: These ports allow compressed air to enter and exit the cylinder, controlling the movement of the piston.

Seal: A sealing mechanism prevents air leakage between the piston and the cylinder wall.

End caps: These components seal the ends of the cylinder and provide mounting points.

How Pneumatic cylinders Work

Pneumatic cylinders are machines that use compressed air and provide linear motion. Because they are very simple, reliable, and versatile, they have wide application in many industries.

Air supply: Compressed air is supplied to the cylinder from an external source, such as an air compressor.

Air inlet: Compressed air enters the cylinder chamber through the inlet port.

Piston movement: Air pressure forces the piston to move in a specific direction, either extending or retracting.

Load application: The piston rod attached to the piston transmits linear motion to the load, causing the desired work.

Air exhaust: As the piston moves, the air in the opposite chamber is exhausted through the outlet port.

Types of Pneumatic Cylinders

Pneumatic cylinders are versatile devices that convert compressed air energy into linear motion. While they share a common principle of operation, they come in a variety of types, each of which is suitable for specific applications. Here is a description of the most common types:

Single-acting cylinders: Single acting cylinders have the most basic configuration of all pneumatic cylinders, they have one air port and operate in only one direction which is usually an extension stroke. In most cases there is a spring. They are ideal for simple processes such as turning a switch on and off or controlling a valve.

Double-acting cylinders: Double-acting cylinders are superior to single-acting cylinders. Since they have two ports that allow for both extension and retraction strokes, they can be used in a wide range of applications such as automating tasks involving robotics, material handling, and more.

Telescopic cylinders: Telescopic cylinders are designed with more compact dimensions but have a longer stroke length. Their design includes multiple stages that allow them to be extended one at a time and so they are useful in applications requiring long strokes but suffer from space limitations. This makes them suitable for heavy-duty applications such as lifting and positioning heavy loads.

Rodless Cylinder: Rodless cylinders are a special type of pneumatic actuator that can be called space-efficient, and in this case, they can be called space-efficient and they do not use a standard piston rod. Instead, they use a magnetic or mechanical coupling that provides the force to the load. This construction eliminates the rod seals which reduces frictional forces and improves performance. However the rodless cylinder design is best for systems with limited space, where contamination may be a concern or where a long stroke length is required.

Other special types:

Through-rod cylinder: This has a rod that passes through both ends of the cylinder, ensuring that force and speed are uniform in both directions.

Cushion cylinder: This includes a built-in damping feature that reduces shock and vibration at the end of the stroke.

Rotary cylinder: Enable rotational motion in the linear direction and are widely used in rotary indexing tables.

Tandem cylinder: A set of two cylinders that are fixed longitudinally end to end to enable a longer stroke length.

Pneumatic cylinder Design and Manufacturing

Modern pneumatic cylinders are becoming more intelligent, more powerful and increasingly more functional across a variety of industries. They are also designed to be more compact and integrate seamlessly with automated equipment. So, let’s take a look at the constructional features of today’s industrial cylinders, the materials used in them, their installation methods and their relevance in today’s world.

Types of Pneumatic cylinder Construction

The design and construction of pneumatic cylinders is determined by their purpose. The following are some common types:

1. Tie Rod Cylinder:

This is a common cylinder design that features great strength and protection.

Aircraft cylinder cover plates contain tie rods that make this structure robust and suitable for heavy-duty applications.

These are often plated to allow for better corrosion resistance and survival in aggressive environments.

2. Compact Cylinders:

Designed for situations where space is a constraint.

Have a significant force to size ratio making them suitable for use in automated systems with limited space.

Mostly used in production lines that require power but in small sizes.

3. One-piece Welded Cylinder:

Lowest cost, with welded or crimped ends, which makes this cylinder unsuitable in terms of servicing.

These cylinders are easy to handle and can be used for primary operations which do not require much handling.

4. Threaded End Cylinders:

Have threads at both ends, which are attached to the tube body with the help of screws.

Although they are relatively light in weight, there may be some restrictions regarding their strength and stability.

5. Integrated-Sensor Cylinders:

Sensors obtain information such as position, force, etc. in an automated manner.

Recommended for applications requiring high accuracy as well as in combination with smart factory applications.

Materials Used for Pneumatic Cylinders

The material selected greatly affects the running and working life of the cylinder in extreme working conditions such as:

Aluminum is a common metal used in the manufacture of pneumatic cylinders because it is strong enough for a good strength-to-weight ratio. Stainless steel works well in low-stress applications and humid or high-moisture environments due to its high strength and durability. New composite resins and alloys improve the durability of parts and yet reduce weight. A large percentage of today’s pneumatic cylinders are manufactured from green and recyclable materials to reduce pollution.

Mounting options

The ease of installation and mounting of a pneumatic cylinder is influenced by its design, as it makes using the cylinder much easier. For horizontal mounts, foot mounts are common; for rotary units, clevis and trunnion mounts are used; for high-stress applications, flanged mounts are provided; and where cylinders need to be changed quickly, magnetic and quick-change mounts come in handy. Such modern fixing systems on pneumatic cylinders reduce idle time and increase operational efficiency in factories, making automation less difficult and managing pneumatically operated cylinders easier.

Cylinder Size

Depending on the application, pneumatic cylinders can be small, standard or large. Miniature examples are used when more precise movements are required for activities such as electronics and medical equipment handling. On the other hand, other examples are used in applications that require the lifting of heavy objects, such as moving materials.

Smart Technology Integration

Pneumatic cylinders are being equipped with intelligent technology features that include IoT and sensor integration to enable predictive maintenance as well as programmable logic control for precise movement of the cylinders. This makes the cylinders suitable for automated processes that require high precision.

Industrial Application of Pneumatic Cylinders

Due to their simplicity of maintenance, dependability, and efficacy, pneumatic cylinders can be found in almost all industries. They are able to convert compressed air energy into linear motion, which is fundamental in countless industrial uses. Below are several industries and applications where pneumatic cylinders are important:

1. Manufacturing and Assembly:

Material Handling: In conveyor systems, pneumatic cylinders are used to lift, push or pull material in a production line.

Clamping and Holding: These are used in assembly during processes such as welding, drilling or fastening by joining and holding parts together.

Pressing and Stamping: These are widely used in metal working for punching, stamping and pressing materials into required forms.

2. Automotive industry:

Automation of assembly lines: In particular, pneumatic cylinders control robot arms as well as automated systems that assemble vehicle parts.

Lifting mechanisms: These are useful machines in assembly lines by lifting and positioning heavy automotive parts.

Automatic door and hood test systems: The cylinders replicate the entire opening and closing movements of doors and hoods in durability testing.

3. Packaging Industry:

Sorting and counting: The use of these cylinders makes it easier to sort, count and transfer items in packaging lines, making the production flow more efficient.

Sealing and cutting: Shells are used in sealing machines for bags or packages, as well as, in machines that cut parts in paper or plastic packages.

Bottle and container filling: Pneumatic cylinders make the entire process of filling, capping or even labeling bottles and other containers precise.

4. Food and beverage industry:

Bottling and canning lines: Filling, sealing and labelling operations are controlled by pneumatic cylinders that guarantee hygiene and performance.

Food processing machines: Used to cut, portion or pack foods.

Automated sorting: Enables bulk sorting of foods as well as organisation and speed in mass production.

5. Pharmaceutical Industry:

Tablet Press Machines: This involves the use of machines that compress powders into tablets of specific dimensions in the manufacturing process.

Packaging and Labeling: This involves the proper packaging and labeling of products which is important for correct compliance.

Sterile and Controlled Environment: Speed and controlled environment are achieved by using pneumatic systems in sensitive areas to prevent hydraulic fluids from contaminating the area.

6. Textile Industry:

Loom machines: In the weaving process, pneumatic cylinders activate the movement of the loom to maintain the quality standards of the fabric.

Fabric cutting: Used in automatic cutting machines to enable different shapes and sizes of fabrics.

Dyeing and printing machines: Cylindrical mechanisms ensure that the process of dyeing and printing on textiles is carried out in a smooth and repetitive manner.

7. Construction and mining:

Excavation equipment: Cylinders are used in hammers, rock drills and other excavation equipment to move or break up material.

Concrete pumps: These are relevant in construction to allow concrete to flow or pump in a certain direction.

Lifting and positioning equipment: These are useful in positioning heavy equipment or materials on construction sites.

8. Aerospace industry:

Aircraft component testing: cylinders move an aircraft component for the purpose of testing its durability.

Assembly and maintenance: pneumatic systems achieve the desired precision when assembling aircraft parts to the required quality standard.

Landing gear and braking systems: for some airplanes, pneumatic systems can be used for retractable landing gear and brakes.

9. Printing and Paper Industry:

Paper Feed and Alignment: In printing machines refinishing cylinders are used to assist in the feeding, the alignment and the cutting of paper.

Printing Press Operations: Assist in the process of applying printing pressure to maintain proper depths of impression and clear prints.

Binding and Folding: The machines that tuck, fold and stack, and bind paper products also use pneumatic actuating systems.

Best Brand for Pneumatic Cylinder

Top Pneumatic cylinder Manufacturers in India:

1. Mercury Pneumatics

2. Janatics Pneumatic Cylinders

3. SMC Pneumatic Cylinders

4. Festo Pneumatic Cylinders

5. Nishaka Pneumatics

6. Hydro-Pneumatic Controls

7. Hydraulic & Pneumatic Products

8. A. Tech

9. Mehta Hydraulics Equipments LLP

10. Proline Industrial Valves

11. Jyoti Hydraulic

12. Honeytech Controls Pvt. Ltd

1. Karma Automation

Why Choose VS Enterprise

Choosing VS Enterprise as your partner in pneumatic solutions is the best decision, as they certainly understand the needs of the customers as the leader in the industry. This is why customers across India choose us for all their pneumatic needs:

Top Dealer of Leading Pneumatic Brands

VS Enterprise takes pride in being the main dealer of high-caliber brands such as Mercury Pneumatics, Janatics Pneumatic cylinders and Techno Pneumatic Cylinders. We concentrate on getting them genuine, high-end products from these perfect makers for their customers to get only the best in the market.

Comprehensive Product Range

Our products range covers a vast spectrum of various pneumatic parts and components which include cylinders, valves, fittings and accessories. For special pneumatic tools or standard tools, you can rely on VS Enterprise.

Industry Expertise and Experience

Our team has extensive experience and knowledge across the entire spectrum of the pneumatic industry. Understanding the nature of pneumatic systems helps us provide valuable advice on specific products used in their applications.

Unmatched Customer Support

Customer satisfaction is guaranteed at VS Enterprise. The well-trained support staff can gladly assist with product purchase and technical issues as well as after-sale services making the process much easier starting at the point of sale and continuing up until implementation.

Competitive Pricing

There are many businesses which consider quality to be expensive. However, we do not believe in that. We collaborate with eminent manufacturers in order to provide quality pneumatic products at reasonable prices.

Timely Delivery and Reliable Service

The reason why we make it a point to have a fast and effective order management and delivery process is because we know that downtime is costly for you. In working with VS Enterprise, you can be assured that your equipment will be delivered in a went state and at the right time.

Technical Details of Pneumatic cylinders

Download PDF

Frequently Asked Questions

Q1. How can pneumatic cylinders be used as hydraulic cylinders?

Pneumatic actuators cannot directly replace hydraulic actuators, because pneumatically actuated cylinders operate at low pressures of a gas, dry air, while hydraulic cylinders operate at pressures of a fluid that are significantly higher. Nevertheless, there are some applications in light and low-pressure operations where the speed of a pneumatic actuator can be similar to that of a hydraulic cylinder.

Q2. How can I control the distance of a pneumatic cylinder?

The range of motion of a pneumatic cylinder can be controlled by manipulating the control valve, stroke limit setting or displacement sensors used to monitor and adjust travel, respectively.

Q3. Which are the best pneumatic cylinder manufacturers?

The most well-known manufacturers of pneumatic cylinders include Mercury Pneumatics, Genetics, Techno Pneumatics, SMC, Festo and Parker.

Q4. Can hydraulic cylinders be used as pneumatic cylinders?

Hydraulic cylinders are made for high-pressure liquid and pneumatic cylinders are made for compressed air. Although they are both intended to perform the same function, one should never confuse a pneumatic cylinder with a hydraulic cylinder as a pneumatic cylinder will not work on compressed air and may burst instead.

Q5. How do you reduce the speed of a pneumatic cylinder?

There are several ways to reduce the speed of a pneumatic cylinder such as the use of a flow control valve, adjustment of air pressure or the connection of a silencer.

Q6. How do you fix a pneumatic cylinder?

To successfully repair a pneumatic cylinder, the first step is to find out what went wrong (leak, incorrect speed etc.). The next step is to check the piston seals, valves and piston. While giving the final touches make sure all the replaced parts are aligned and any broken parts are replaced.

Q6. How does a pneumatic cylinder work?

A pneumatic cylinder functions by using compressed air to generate linear force. In such cases when air enters the cylinder, it exerts force on the piston located inside, causing the rod to either expand or contract depending on the direction of the air flow, which is controlled by a set of valves.

#pneumatic valves types#types of pneumatic valves#pneumatic valves#vs enterprises#what is pneumatic valves#Pneumatic Cylinders#Pneumatic Cylinder#Mercury pneumatic Dealer

0 notes

Text

China Manufacturer Large end cap assembly DG600-240-04-19-00 for steam turbine

China Manufacturer Large end cap assembly DG600-240-04-19-00 for steam turbine Deyang YOYIK is a strong technical force, first-class product quality, brand reputable large-scale mechanical and electrical equipment Limited. Company products covered a wide range of products sold worldwide, a number of users trust. Acting foreign first-class brand, EATON VICKERS, star, and so on products. Guarantee genuine, the spot sale. Yoyik can offer many spare parts for power plants as below: #DF-Large end cap assembly DG600-240-04-19-00-DF pressure hose SMS-10/20-610mm-C screw pump diagram HSNS210-54NZ OPC solenoid valve 4WE10D-L3X/CW220-50NZ5L/V seals (cylinder diaphragm, packing, valve sealing gasket) 0125ZMAW16BQ13UNOERHDN125 roots vacuum pump KZ/100WS radial piston pump PV2R3-76-RBAF1 switch valve M765-004000A screw pump working principle 3GR42*4A oil pump replacement 80SG50-30 double mechanical seal 15F4-IC-20 hydraulic power 300S90B Hydraulic hose 35MPa, 20mm chemical pump centrifugal 65-250B soft coupler suction DN800, PN1.0MPa, OD1019mm, ID950mm, Distance between 2 Flanger: 320mm. mechanical seals LTJ-GJ-125A/R servo valve J761-001 HP ball valve BKH20-FPM-1.4571 Lubrication Oil Pump 150LY-32-B butterfly valve K65DSF4PB3 oil station globe check valve J20C-1.6P hydraulic screw pump ACF080K41RBP mechanical seal 41 mm 90NY/JXMF motor universal coupling 125LY-35-2 safety valve 3.5A25F-16P chemical pump centrifugal DFB80-80-240 piston pump hydraulic MOOG0514 7005 37 butterfly valve K150D0F4PB3 Governor O-ring DH00.010 vacuum pump compressor PVH098R01AJ30A250000002 ac vacuum pump P-1937A oil transfer electric pump SDNH440REM3NW53 sealing ring HB4-56J8-19 Packing B05-8076Z-06TS rotary piston pump PV29-2R5D-C00 screw pump manufacturer ACF090N4 electric transfer oil pump DLZB820-R64B Large end cap assembly DG600-240-04-19-00 vacuum pump valve spring P-540 hydraulic actuator solenoid valve 4WE6H62/EW230N9DL multi stage centrifugal pump YCZ50-25 piston pump hydraulic PVH141R13AF30A230000002001AB01A axial piston variable pump A10VS071DRS/32R-VPB22U99 mechanical seal types LTJ-GJ-125A/R shaft coupling 65-250B liquid ring vacuum pump 2S-185A AST SOLENOID VALVES G1211177 Fluoro Rubber O-Ring ORO250023 generator self-lock nut M12*3mm fluid transfer pump 50FSB-30 gear oil transfer pump SDH-50 screw pump working HSNH80Q-48NZ vacuum hand pump P-1803 screw pump manufacturer KF090NZ/15F6 pressure hose SMS-12-3048mm-C magnetic coupling centrifugal pump DFB125-80-250-20 centrifugal pump prices ISG150-160 armoured platinum Thermal resistance WZGPK2-33U-M100A150J120A-M212 vacuum pump price 2S-185 hydraulic electric pump 70LY-34*2-1 pressure hose S100-AC-AC-0150 (G1/4)M14*1.5 Pneumatic head diaphragm 125ZMAW16BQ piston vacuum pump PV292R5DC00 transfer oil pump YW100-250 dc screw pump HSNH80Q-48NZ vacum pump air vacuum WS-30 MOOG pump electric vacuum pump 30WS water pump DFB100-80-250-14 pressure hose SMS-12/20-610mm-B HP globe valve 600KG vacuum pump compressor P-1759 OPC solenoid valve HQ16.110Z electric vacuum pump 2S-185 Large end cap assembly DG600-240-04-19-00 DFYLSYC-2024-6-3-A

0 notes

Text

Its facsinating to me how different heat pumps are good at different things and not interchangable

Steam turbines are 7.5 times more efficient than double acting steam pistons

And yet

Piston internal combustion engines are more efficient than ICE turbines

But turbines are 33% more efficient for propulsion since much of the waste heat can get turned into thrust

Similarly a screw compressor can’t really be used for refrigeration or an as engine but a rotary engine is functionally similar. There are very large screws for compressing natural gas but they are actually quite inefficient which is odd because they are quite good at compressing air/gas but phase changes seem to destroy their efficiency

A scroll compressor can be used for refrigeration or compression but not power generation but can also be used as a pump and collect gravitational energy

Any compressor can be used to recover energy from compressed air/steam/gas so when I say can’t be used for power generation I mean you can’t add energy to make a net gain of useful work. I think there are scroll refrigeration systems

Interestingly turbopump cryo is 78.8% efficient which is fucking crazy

Propane or methane fuel cells have major issues but they aren’t as good as engines in terms of efficiency but hydrogen is better in a fuel cell than an engine and hydrogen might be better in a turbine than a reciprocating engine which isn’t odd considering the light propellant (steam) has higher ISP for a rocket and steam is better in turbines anyway

The physics reasons are all really interesting too. Also the textbook definition of friction is literally worthless in the real world. Higher speed should mean higher friction and surface area shouldn’t matter since the force (and therefore friction) is distributed across all the contact area. But that doesn’t hold up in the real world. Pistons are usually the least efficient because of the high friction involved. So while there is theoretically higher friction with a high speed turbine they are better in the end for a lot of industries but not cars.

I love perpetual motion machines for this reason. I would love to see anyone who say they have a perpetual motion machine show me the friction that is in their system. Like we can’t get turbines more than 31% efficient and reciprocating engines more than 52% efficient and a lot of that is friction but most of it is that you must put energy in to start the combustion/chemical reaction/whatever and you think your system doesn’t have some massive losses?

0 notes

Text

LIUGONG WHEEL LOADER SPARE PARTS 142

SP210845 SEAL KIT SP210846 MOTOR SKELETON OIL SEAL SP210847 ONE-WAY VALVE 67A3604 PIPE 92A9403 PLATE 41C3663 RIM AS 69A5196 PLATE 51C0982 MIDDLE DRIVE SHAFT 51C0983 FRONT DRIVE SHAFT&BRG AS SP208205 PRESSURE REDUCING VALVE 12B3008 O-RING 32B0904 INDICATOR 46D4324 PLATE 24C4001 LINK 24C4002 LINKAGE 70C6197 STEERING HARNESS 24C4162 LINKAGE 69A4947 PLATE 08D4967 TUBE AS 08D4966 TUBE AS 19D6506 BRACKET 19D4625 BRACKET 48D2133 COVER 19D4413 BRACKET 19D4412 BRACKET SP198732 BOWL-TYPE PLUG SP198661 INTAKE MANIFOLD PRESSURE SENSOR 69A4161 PLATE 11D2338 PIN 30D4870 FRONT FRAME 23D6531 DOOR 39Y0209X0 GRAPPLE 24C4030 BOOM 44D1054 COVER 92A9223 PLATE 25D0903 LOWER FORK 08D5360 TUBE AS 02G2866 PLATE 70C5670 CAB HARNESS SP217101 CAMSHAFT BUSH 04C2018 HOSE AS 04C2019 HOSE AS 19C1301 HOSE AS 04C2015 HOSE AS 69A5345 PLATE 70C6227 HARNESS 35B0831 INSTRUMENT 37B3758 WIPER BLADE 37B3759 WIPER ARM 70C6245 WORK LIGHT HARNESS 79A7235 DECAL 38B0394 RESISTOR 55C1651 WIPER GP 70C6292 CAB HARNESS 01B1572 BOLT 51C0949 FRONT DRIVE SHAFT 51C0950 REAR DRIVE SHAFT 18C1555 HOSE AS 12C9179 CONTROL VALVE SP212766 ADAPTER HYDRAULIC PUMP SP212767 GASKET 58A8895 PLATE 01G2137 PLATE 55C0586 FUSE RELAY AS 55C0587 FUSE RELAY AS 55C0697 FUSE RELAY AS 70C5979 HARNESS 46D4382 BRACKET 18C1852 HOSE AS 18C1853 HOSE AS 15D1848 FLANGED JOINT 18C1792 HOSE AS SP182414 BOLT SP182470 ECU HARNESS 40C4866 AIR FILTER SAFETY ELEMENT 14D1096X0 PISTON ROD 61A4064X0 PISTON ROD 97A3686 CUTTING EDGE 45D3621 SHROUD AS 45D3618 PROTECTION SHIELD 04G3298 SIDE PLATE 04G3297 SIDE PLATE 55G2157 BUSHING 70C6354 BACKUP ALARM HARNESS 12C9187 CONTROL VALVE 55C0880 HOSE 30D4918 FRONT FRAME 30D4935 REAR FRAME 24C4118 BOOM 19D6149 BRACKET 53A3487 CYLINDER HEAD 24C4004 CONTROL LEVER AS 47A1103 PUMP IMPELLER 69A3761 BRACKET 69A3762 PLATE 71A2506 PLATE 58A8601 PLATE 70C6229 HARNESS 30D5235 FRONT FRAME SP210765 BRUSH SP210766 BRUSH BAFFLE SP210767 MOTOR HOUSING SP210768 BEARING HOUSING SP210769 DOUBLE ROW ANGULAR CONTACT BALL BEARINGS SP210770 LIP SEAL FB-70-90 SP210771 BEARING CAP 60C3952 DIESEL ENGINE 40D2083 GUARD-LH 40D2081 GUARD-RH 40D2080 GUARD-RH 40D2082 GUARD-LH 38C0808 DIPSTICK 47C5070 WINDOW GP 96A9258 EDGE-LH 96A9259 EDGE-RH 18C1834 HOSE AS 18C1860 HOSE AS 18C1837 HOSE AS 18C1836 HOSE AS 18C2023 HOSE AS SP217106 ECU SP217107 CUSHION BLOCK SP217108 PISTON SP217109 DRIVE RETAINER Ⅱ SP217110 AIR COMPRESSOR SP217111 PREFILTER HOLDER SP217112 FUEL INJECTION PUMP SP217113 AIR COMPRESSOR AIR INLET TUBE SP217114 PREFILTER SP217116 INJECTOR PARTS SP217117 AIR COMPRESSOR OULET CONNECTOR SP217118 CUSHION BLOCK SP217119 CUSHION BLOCK SP217120 STRAP 35 11D2411 PIN 19D6951 MAST 08D2991 TUBE AS 18C1535 HOSE AS 38Y0848X0 BUCKET AS 55C0972 HOSE 55C0973 HOSE 18C1731 HOSE AS 27A5827 COVER 27C1730 COUNTERWEIGHT 30A9616 SUCTION TUBE 15C1180 FUEL FEED PUMP 00A9336 FITTING 00A9337 CHECK VALVE 70C5655 HARNESS 55C0988 RELAY AS 24C4082 LINKAGE 32A5543 SUCTION HOSE 30A9645 SUCTION HOSE 08D4690 TUBE AS SP210772 MANDREL SP210773 CONNECTING SHAFT SP210774 MOTOR SP210776 HARD TUBE B SP210777 OUTRIGGER PIN SP210778 SAFETY PIN%X45 SP210779 FRONT LEG SP210780 CONNECTING SPINDLE SP210781 CYLINDER BASE SP210782 BASE SEAL COVER SP210783 CYLINDER SP210784 CYLINDER PIN SP210785 VALVE BLOCK SP210786 SOLENOID VALVE GROUP (SET) SP210787 CONNECTOR A SP210788 CONNECTOR B SP210789 HOSE A SP210790 HOSE B SP210791 HOSE C SP210792 HOSE D SP210793 HOSE E SP210794 CONNECTOR C SP210795 HOSE F SP210796 CONNECTOR D SP210797 HOSE G SP210798 ELECTROMAGNETIC REVERSING VALVE LEFT (4W SP210799 ELECTROMAGNETIC REVERSING VALVE (4WE6E) SP210800 ELECTROHYDRAULIC REVERSING VALVE RIGHT ( SP210801 SEAL KIT SP210802 MOTOR SKELETON OIL SEAL SP210803 SEAL KIT SP210804 CYLINDER SKELETON OIL SEAL SP210805 SIDE BLADE 58A8653 PLATE 58A8678 PLATE 58A8642 PLATE 58A8660 PLATE 49C2714P01 HEATER 49C2714P02 HEATER SP215670 CONVERTER 08D4005 TUBE AS 08D4006 TUBE AS 67C6760 HOSE AS 02C3232 TUBE AS 79A7132 DECAL 79A7133 DECAL 18C1747 HOSE AS 18C1748 HOSE AS 48A6760D1 PLATE 93A6987D1 PLATE 58A3022D1 PLATE SP212804 CONTRAL LEVER SP212805 FLEXIBLE SHAFT 30A9187 INTAKE HOSE 67A3622 PIPE 02G1662 PLATE 19D4070 BRACKET 11D2315 PIN 19D4135 BRACKET 03G1261 PLATE 67C5551 HOSE AS 18C1252 HOSE AS 08D4261 TUBE AS 58A8445 PLATE 08D4262 TUBE AS 30A9260 SUCTION HOSE 30A9259 SUCTION HOSE 22D2455 LOWER FORK 69A5634 PLATE 24C3988 BOOM 12C9054 SAFETY VALVE 12C9055 SAFETY VALVE 12C9056 SAFETY VALVE 00G2165 PLATE 45D3615 PROTECTION SHIELD 67C7205 HOSE AS 19C1439 HOSE AS 18C2080 HOSE AS 08D5444 TUBE AS 08D5442 TUBE AS 83A2892 JACKET 83A2891 JACKET 34C9862D1 SIDE HOOD 34C9864D1 SIDE HOOD 19D6114 BRACKET 48D2215 DOOR 30D5040 REAR FRAME 55C0544 HOSE GP 41D2179 PROTECTIVE BARRIER 18C1777 HOSE AS 67C6490 HOSE AS 18C1776 HOSE AS 19C1182 HOSE AS 59A5565 MOUNTING PLATE 67C6551 HOSE AS 12C9286 05B0434 STUD BOLT 48C7659 TOP COVER 48C7656 SIDE HOOD 48C7657 SIDE HOOD 03G3082 LOCK PLATE 00G3608 PLATE 67C7111 HOSE AS 67C7113 HOSE AS 18C2028 HOSE AS 19C1381 HOSE AS 19C1382 HOSE AS 67C7112 HOSE AS 67C7114 HOSE AS 18C2027 HOSE AS 48C7669 DOOR 42D3916 SIDE HOOD 42D3915 SIDE HOOD 00G3638 PLATE 10C5699 CYLINDER 25D0985 LOWER FORK 18C2031 HOSE AS 18C2032 HOSE AS 18C2033 HOSE AS 18C2034 HOSE AS 18C2036 HOSE AS 18C2035 HOSE AS 19C1392 HOSE AS 67C7121 HOSE AS 18C2053 HOSE AS 67C7120 HOSE AS Read the full article

0 notes

Video

tumblr

Manufacturer of Double Piston Air Compressor - PM Air Compressor, Single Stage Air Compressor, Two-Stage Air Compressor and Piston Air Compressor offered by roteck.

0 notes

Text

Heavy Duty 30 Ltr Air Compressor Auto Cut WITH Pipe Air Nozel - Krishitool.in

Book Now: https://www.krishitool.in/product_details/Heavy_Duty_30_Ltr_Air_Compressor_Auto_Cut_WITH_Pipe_Air_Nozel

Buy 30Ltr With Air Nozel online in India at wholesale rates. If you have been looking for Reciprocating Air Compressors, your search ends here as you can get the best Air Compressor in top cities such as Delhi NCR, Mumbai, Chennai, Bengaluru, Kolkata, Chennai, Pune, Jaipur, Hyderabad and Ahmedabad, Coimbatore, Tamil nadu, Andhra Pradesh, Karnataka, Kerala, Vishakhapatnam, Assam, SALEM, Hubli, MAHARASHTRA, Orissa, Jharkhand, Kochi, Ernakulam, Kakinada, Goa, Vijayawada, Gujarat, Rajasthan, Madurai, UttarPradesh, Madhya Pradesh, Hyderabad, Punjab, Haryana, Chandigarh, Kurnool, Davanagere, Bilaspur, Tumkur, Tirupati, Chittoor, Satara etc. You can purchase Heavy Duty Air Compressor of the finest quality and rest assured to get the best in terms of both durability and performance. If you are bothered about the Portable Air Compressor prices, you can be totally sure to get the best rates as Krishitool brings you genuine Air Compressor rates and quality assured products only from the best of brands with exclusive brand discounts you won’t find anywhere else. An air compressor is a pneumatic device that converts power into potential energy stored in pressurized air. It is highly efficient and durable in nature. Krishitool Air Compressor is more reliable as it has best quality of motor which makes it an easy to maintain type of product as you do not need to take extra precautions regarding the product. Oiled pump for maintenance-free ownership and strong, reliable motor output. Conveniently placed gauges are easy to read and this compressor's compact design makes it easily portable.Suitable for tire and ball inflation, it's also perfect for powering air brushes, air/ brad nailers, upholstery projects and more.

#air compressor#air compressor 50 Liter#air compressor 50 litre#air compressor 3 HP#compressors#Air Compressors#air compressor combo#portable air compressor#Heavy duty air Compressor#air compressor 30 Liters#air compressor 1 HP#air compressor online#compressor online#electric compressor#Painting compressor#spray painting machine#Industrial Air Compressors#Spray paint compressor#small air compressor#air compressor double piston#double piston air compressor#Ferm air compressor#industrial air compressor#30L Air Compressor#30 ltr air compressor combo#Mini air compresssor for spray painting#Air compressor price online#electric air compressor#Air compressor machine#portable compressor

1 note

·

View note

Text

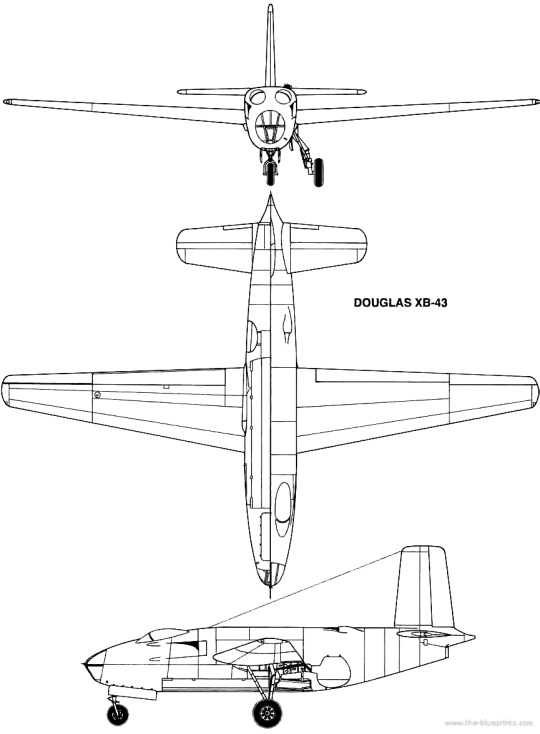

-Composite photo of the XB-42 and XB-43. | Photo: USAF (Edit: Justin Gibb)

FLIGHTLINE: 169 - DOUGLAS XB-42 MIXMASTER/XB-43 JETMASTER

The Mixmaster was designed as a fast bomber early in WWII, and later the Jetmaster replaced the piston engines with jets, though neither saw service.

MIX MASTER, CUT FASTER

Originally an unsolicited proposal, what became the XB-42 was presented to the US Army Air Forces in May 1943. Douglas' team wanted to create a medium bomber capable of flying as fast and as far as possible, and the resulting aircraft was quite unusual for the time. The aircraft was highly streamlined, with the engines buried in the fuselage and a contra-rotating propeller mounted in a pusher configuration, thus keeping the wings clear of drag-inducing pods, pylons or other protrusions. The aircraft had tricycle landing gear and a cruciform tail to prevent the propeller blades from striking the runway as the aircraft rotated.

-Orthograph of the XB-42 showing its unusual planform. | Illustration: Dr. Dan Saranga

The aircraft, given the designation XB-42 and the name Mixmaster, was 53' long and had a wingspan of 70'. The plane weighed almost thirty-six thousand pounds fully loaded, and sat a crew of three, a pilot and co-pilot under separate bubble canopies, and a bombardier in the plexiglass nose. Power was provided by a pair of Allison V-1710 V-12 engines (variants of which powered the P-38, -39, -40, -51 and later the F-82), giving the Mixmaster a speed of 410mph and a combat range of 1,800 miles. Production B-42s would have been armed with six .50 machine guns, two each in retractable blisters (aimed remotely by the co-pilot) in the trailing edge of the wing and two more firing forwards in the fuselage. A bomb load of 8,000lbs was planned.

-The first XB-42 prototype, with the twin bubble canopies, on its first flight in 1944. | Photo: USAAF

The first XB-42, s/n 43-50224, took its maiden flight on 6 May 1944. The aircraft was found to perform to expectations, though the separated canopies hampered communications and were replaced by a single piece canopy on the second aircraft. The second Mixmaster soon joined the first, and in December 1945 Captain Glen Edwards (for whom Muroc Army Airfield was later renamed) and Lt. Col. Henry E. Warden set a new transcontinental speed record when they flew XB-42 No. 2 (s/n 43-50225) from Long Beach, California to Bolling Air Force Base in Washington, D.C., a distance of 2,300 miles, in 5 hours, 17 minutes, at an average speed of 434mph. Testing uncovered some stability issues with the XB-42, specifically excessive yaw, as well as problems with vibration and engine overheats due to poor cooling. On December 17th 1945, the second prototype was destroyed after suffering a double engine failure, all three crew survived after bailing out of the stricken aircraft at 400'.

-The second XB-42 prototype, with its single piece canopy. | Photo: USAAF

The end of WWII and the aircraft's own teething troubles saw the USAAF reduce the tempo of the B-42 program, choosing to retain the aircraft as a test-bed. The remaining Mixmaster was modified with the addition of underwing pods containing two Westinghouse 19XB-2A turbojets and was subsequently redesignated the XB-42A. This modification pushed the aircraft's top speed to 488mph, but after 22 flights a hard landing in 1947 saw the aircraft retired. It was repaired and placed into storage before being dismantled for transport and turned over to the Smithsonian Institution in 1949. The aircraft's wings were lost in the move, and it has remained in storage, awaiting restoration, ever since. In 2010 the aircraft, along with the surviving XB-43, were transferred to the National Museum of the USAF for eventual restoration and display.

-The XB-42A with it's podded engines and distinctive double bubbled cockpits. | Photo: USAF

REMOVE "MIX", ADD "JET"

In response to USAAF inquiries about substituting the XB-42's piston engines with jet, Douglas confirmed that the idea was at least feasible, and in 1944 the Mixmaster's contract was amended to include the parallel development of a jet-powered derivation, the XB-43 Jetmaster. In order to save both time and money, Douglas used the XB-42 static test airframe as a starting point, removing the Allison engines with GE J35 jets, which required adding intakes into each side of the fuselage. The tail was remodeled as well, with the ventral fin no longer being needed it was removed and the dorsal fin and rudder being enlarged to compensate. Despite finding on the second XB-42 that a single-piece canopy was better for communications, the XB-43 retained the twin bubble canopies of the first Mixmaster.

-Orthograph of the XB-43. | Illustration: Dr. Dan Saranga

The Jetmasters were somewhat shorter than their older brothers, 51 feet instead of 53, and were somewhat wider at 71'. The XB-43 was heavier too, with a maximum take off weight of 39,533lbs, but GE's turbojets made it faster, with the max speed increased to 515mph and cruise now 420mph. As with all early jet engines, range suffered, with combat range shortened to 1,100mi and ferry range now slightly more than 2,800mi. The bomb load of the XB-43 was still 8,000lbs, but the six fifty cal machine guns were cut to just two in a tail stinger. A separate A-43 attack variant was planned as well, which would mount eight machine guns in a new, solid nose, as well pods of unguided rockets under the wings, but the A-43 was canceled early in the program.

-The XB-43 on the runway at Muroc (later Edwards AFB). | Photo: USAAF

Douglas made short work of modifying the aircraft (s/n 44-61508), but delays in the J35 saw almost two year pass before the XB-43 was ready for a ground test. This test ended spectacularly and inauspiciously, as one of the engines failed catastrophically, sending compressor blades through the casing and the surrounding airframe, injuring a technician. Repairs and a replacement engine took 7 months, but the Jetmaster's maiden flight finally took place on 17 May 1946, making it the first jet bomber to fly for the US. The XB-43 proved it was effective, and the newly independent USAF considered ordering 50, with Douglas assuring them it could deliver up to 200 B-43 and A-43 aircraft per month. The B-43 was old technology though, and the B-45 Tornado outclassed it in almost every category. The XB-43 and it's sibling, the YB-43 (44-61509) kept flying however, providing the USAF much needed data on operating and maintaining jet bombers.

-The YB-43 (s/n 44-61509) in flight. | Photo: USAF

The XB-43 was joined in 1948 by the second prototype, the YB-43, which was occasionally flown with one J35 and one J47. The YB-43s plexiglass nose soon began cracking due to temperature variations, so mechanics at Muroc built a replacement nose, partially from plywood. Ground crews were rather fond of the second Jetmaster, nicknaming it 'Versatile II', which was eventually painted on both sides of the fuselage.

-Color photo of the YB-43 taking off from Muroc air field. The replacement nose, painted bright red, is apparent in this image. | Photo: USAF

Despite their accomplishments and the information they provided, the Jetmasters found themselves rapidly eclipsed by the advance of both technology and aerodynamic theory, and by 1953 the USAF had moved on. The XB-43 had been damaged in a rough landing in 1951, and was cannibalized for spares to keep the YB-43 flying, until it too was retired in 1953. The first aircraft was used for target practice and was eventually destroyed, while the YB-43 was turned over to the Smithsonian like the XB-42, where it languished until 2010 when the two aircraft were turned over to the USAF Museum for eventual restoration.

-The YB-43 in storage, with the weathered 'Versatile II' name still visible. The XB-42 is barely visible to the right. | Photo: George Baczkowski

#aircraft#aviation#avgeek#airplanes#cold war#airplane#cold war history#coldwar#aviation history#usaf#douglas aircraft company#xb42#xb43#yb43#xb 42#xb 43#yb 43#mixmaster#jetmaster

173 notes

·

View notes

Text

Elephant Double Piston Mini Air Compressor with High Power

Elephant Double Piston Mini Air Compressor with High Power Trending Now:waterfilterindia.com Products on more than 50% Discount Price offer:Get yours from https://waterfilterindia.com Exclusive Offer Ending Soon.......Learn more from This Link https://waterfilterindia.com/elephant-double-piston-mini-air-compressor-with-high-power/ Trending Now: WaterFilterIndia.com ...................Products on more than 50% Discount Price offer.....................:Get yours from https://waterfilterindia.com/shop ............Exclusive Offer Ending Soon.......................WaterFilterIndia.com..............Our Fast Moving Products on Discount Sale Offer................#WaterFilter ..........#WaterPurifier ...........#Filter .......... #Kitchen .........#HomeAppliance .............#WashingMachineHose .............#WaterFilterSpareParts #BathFilter ...............#Antiscalant ...............#ROMembrane #ROPump ............ #BoosterPump ..................#WaterFilterValve #WashingMachineTapAdapter .............#KitchenSinkFilter #FootValveFilter ...............#DripIrrigationParts.......#DripIrrigationHose........#Aquarium....#PetFood......#Garden....#Garden Hose.......#ROSpanner #ROWaterFilterService #ROParts ............#WaterFilterPowerAdapter ..............#Valve ..................#ROFilter #CarbonFilter ......................#WaterPurifierCover...........................Limited Time Sale Offer................Visit - https://waterfilterindia.com/shop

0 notes

Photo

- مساعدات فوكس 2.0 ستيج 1 - سوبر لفت 2.5 الطرية - ضاغطة ثنائية المكبس من ARB تم تركيبها تحت المقعد . - ابيكس فالف لتفريغ ضغط الهواء المسكات الطرية من امريكان اوف رود . - اشكمان بورلا اتاك مع الفتحات باللون الاسود فتحتين على كل طرف تم تركيبها على جيب رانجلر جلاديتور RAMY Project Jeep Wrangler JT. .. List of Products Installed:- - FOX 2.0 IFP Stage 1 Shocks - Superlift Suspension 2.5" Smooth Ride Lift Kit - ARB On-Board Twin Piston Air Compressor with AOR Under Passenger Seat Mount - APEX Fast Deflation Tire Valves - AOR Sport Soft Handles - Borla ATAK Cat-Back Exhaust, Double Black Tips .. Order online: www.ramyautomotive.com .. WhatsApp: Amer (UAE, Dubai): +971 564542529 Showroom (UAE, Dubai): +971 4 269 8138 Raja (UAE, Abu Dhabi): +971 50 464 9142 Aaron (Oman): +968 9121 8910 More info: [email protected] .. T's and C's apply. .. #RAMYautomotive #uae #abudhabi #alain #dubai #oman #fox #superliftsuspension #apexdesignsusa #borlaexhaust #arb4x4 #americanoffroad #methodracewheels #jeepjt #jeepgladiator #arabcars #jeepuae #dubai #dubailife #الدفع_الرباعي (at RAMY Automotive) https://www.instagram.com/p/CPYXjOJNC3t/?utm_medium=tumblr

#ramyautomotive#uae#abudhabi#alain#dubai#oman#fox#superliftsuspension#apexdesignsusa#borlaexhaust#arb4x4#americanoffroad#methodracewheels#jeepjt#jeepgladiator#arabcars#jeepuae#dubailife#الدفع_الرباعي

1 note

·

View note

Text

The Noises an AC May Make and What Do They Mean

Owing to being equipped with amazing sound dampening technology and double compressors, the modern-day air conditioning systems are absolutely quiet. In case you hear strange noises coming from the AC, make sure to call the best technician in your locality. Suppressing or neglecting the problem compels it to turn into something much more complicated.

For details, please check out the rest of the discussion right now.

1. Rattling and Chattering

A renowned electrician Montgomery County said rattling or chattering indicates your AC has started to deteriorate and some of its parts have loosened. Another cause could be accumulation of leaves and twigs in the filters. The electrical contractor can also make a chattering sound, which can in turn completely damage the other components. Your foremost defense strategy is to look out for loose bolts or screws in the casing, clean the condenser coil, and change the filter.

2. Squealing

The fan and blower noises like the squeals and squeaks are usually generated through the ducts. When the motors have ceased to function, they make an immensely loud sound – loud enough to disturb the neighbors and ruin your sleep. Call an expert right away. For a few units, the squeals are normal when the AC is starting. These decrease gradually after the AC has run for a couple of minutes.

3. Banging

Banging is a sure shot indication of something broken – be it the connecting rod, crankshaft, or piston pin. Such a sound is also possible if the indoor blower lost its balance and began rubbing against the other components of the AC while circulating air. Banging also proves that you have to replace the compressor immediately. Contact an expert and allow him to undertake the necessary action.

4. Clicking

The experts offering air conditioning repair Montgomery County said clicking when you are turning the AC off and on is normal but if the sound continues, consider it a red flag that must be addressed. It could be a sign of improper regulation or a faulty thermostat. An air conditioner is made of a wide range of components, so, please do pay attention to the potential problems before you are bound to face bigger problems.

5. Buzzing

Finally, yet importantly, a buzzing sound from outside the unit means any of the following:

• Loose parts • Failing fan motor • Debris in the outdoor and indoor unit • Dirty condenser coil • Friction in the copper lines • Refrigerant leakages • Imbalanced blower

If the AC is making excessive noise and if you know for sure it is a warning sign, please do turn off the central machine. Now call a technician, who will arrive at time, and examine the insides, identify the glitch, and implement the right solution. Carrying out a yearly inspection is beneficial since it keeps the chances of expensive repairs and frequent replacements at bay.

1 note

·

View note

Text

Grasso RC Series Compressor In Dubai, UAE.

We at Grasso believe that Reciprocating Compressors are metaphorically the crocodiles of the technological ecosystem of compressors, especially when they are observed with respect to its application in the HVAC industry, not just because the early air compression technology began with the use of reciprocating compressors but even today Reciprocating compressors remain at the top as the most widely used technology.

Even though scientific advancements introduced many new technologies in compressors that fiercely compete within the market one may note that reciprocating compressor as a technology has remained essentially unchanged over the decades, except for some new augmentations or the change in the material used as well as the way the constituent parts are manufactured.

A reciprocating compressor is characterized by a crankshaft attached to a piston, thus they are also known as piston compressors. The crankshaft is attached to a motor that causes the piston to moves back and forth along a straight line within a cylinder just as seen in a combustion engine. The strategic placement of the inlet and exhaust valves result in the suction of air or gas into the cylinder when the piston moves outwards, whereas compressing and pushing the pressurised air out of the cylinder when the piston moves inwards, this is.

When the cylinder has an assembly of a crankshaft that attached with a piston on one end it is called single acting and when the pistons are on both the ends it is called double acting assembly. A cylinder is called a stage, when using a single motorized shaft, multiple cylinders can be operated along a parallel sequence, this mechanical assembly is called multi stage compressor.

The reciprocating compressor’s main feature is its ability to give a high value compression ratio (Discharge : Suction) of air pressure, even if the flow rate value is comparatively small. Thus the multistage compressor can easily give us options of multiple differential values of compression ratio as, the assembly of two, three, four, six, eight cylinders, etc. are possible. The GRASSO V SERIES compressors provide each of these options but RC611, RC612, RC911 and RC912 compressor models are the favourites worth mentioning.

Thus, reciprocating compressors have many uses across different types of industries such as oil and natural gas industry, chemical industry, pneumatic or mechanical drilling industry and HVAC industry. It is also priced for its energy efficiency while handling applications that involve large amounts of gas. It is noteworthy that the applications of reciprocating compressors within the HVAC industry has also resulted it in its wide spreads usage not just in air conditioning but also the food industry as well as automobile industry thus GRASSO has dedicated the series of BOCK Transport compressors.

Where the BOCK FK series is customised for air conditioning in BUSES. With the advent of new theories, inventions and perspectives these compressors are used for cooling as well as heating using augmentations techniques such as reversing valves, they are used in a much more energy-efficient manner as well as with higher environmental responsibility by using refrigerants or gases such as CO₂ and NH₃ for cooling and heating respectively. In fact the latest application involves using CO₂ and NH₃ in a cascade effect that leads to using the wasted heat in powering the refrigeration process which cuts down the energy expense drastically.

Another vital augmentation is the use of ATEX equipped and approved explosion proof material in the reciprocating compressors suited for hazardous areas thus our industrial compressors namely the BOCK HG compressors are ATEX compliant. GRASSO is committed to providing a comprehensive one-stop service to its clients therefore we provide all the COMPRESSOR PARTS including the highly essential Shaft Seal to arrest any kind of leakage.

CONTACT US:

SAHARA AIR CONDITIONING & REFRIGERATION TRADING L.L.C

P. O. Box: 251539, Deira

Near union square metro

Dubai, United Arab Emirates.

Phone: +971 503245143

Fax: +971 4 2950801

#Grasso rc 611 compressor#Grasso RC Series 612 Compressor#Grasso rc 911 compressor#Grasso rc 912 compressor#Grasso V series compressor#Grasso compressor Parts

1 note

·

View note

Text

Trane Screw Compressors in Dubai.

Reciprocating vs Screw Compressors

Compressors can be defined as machines that compress any gas to create pressurised gas by essentially reducing their volume using different methods. These different methods form the basis of classifying compressors.

The compressors are broadly classified in two categories namely Dynamic compressors and Positive displacement compressors.

Dynamic compressors are typically compressors that use the rotary movement of blades (therefore, it is also called Roto-dynamic compressor) to accelerate the air trapped between the blades that begins its compression, as the speed of the air which can be increased to very high levels increases, its kinetic energy is converted to pressure when the high speed air is allowed to move to a duct i.e. a diffuser. Thus dynamic compressors are used where the volume of air flow required is less but the required pressure levels are very high e.g. a coal refinery where oxygen has to be pumped into the refining process at a high pressure. Another striking feature is that the air flows continuously.

Positive Displacement compressors uses a fixed amount of space within a container i.e. fixed volume of air, inside this container a mechanical assembly with shafts or screws or scrolls are used to reduce this volume trapping and compressing the air to produce pressurised air. Thus positive displacement compressors are useful when very high pressured air is less significant as compared to the air flow volume e.g. applications in air-conditioning or refrigeration. The complexity of its mechanical process is far less as compared to a dynamic compressor thus making it a user friendly and cost friendly technology which can adapt to a large variety of applications especially in HVAC industry for example something like transport refrigeration to air-conditioning a hospital facility. Even though the air flow is pulsating in this technology with an exception rotary compressors, but it quieter and does not generate as much vibration as compared to the earlier technology.

Focusing on positive displacement based on the usage of the internal mechanical assembly we can differentiate these compressors as Reciprocating compressors vs Rotary compressors.

Reciprocating compressors uses a model which is similar to an internal combustion engine that is commonly known associated with automobiles. In a reciprocating compressor the assembly has a piston that moves with a motorised crankshaft within a compression cylinder. The piston compresses the air due to its up and down movement while regulating the air flow that moves in one direction only through inlets and outlets with valves taking in low pressure air and discharging high pressure air. These compressors can be customised based on your requirement wherein one crankshaft used with a piston on both ends thus simultaneously compressing air on both ends using two sets of suction and exhaust valves, thus the two types are called single acting and double acting compressors. Each cylinder is called a stage and for higher compression ratio (Discharge : Suction) of air pressure, multiple cylinders can be used in a sequence with a single motorised shaft, this assembly is called multistage compressor. This technology has been used for the longest time right from gas lifting in oil rigs, applications in industrial and chemical air compression as well as refrigeration. Thus, Trane Compressors can pride in offering a comprehensive variety in this type namely CRHR, CRHE, CRHM and CRHF compressors at the most competitive prices.

Rotary Compressors as the name suggests use a variety of rotor blade settings that move relative to a fixed volume container of a specific shape in a sliding vane compressor whereas the scroll and the screw compressors have a pair of blades that move relative to each other inside a container.

Let’s focus on the Screw Compressors, this primarily consists of a pair of helix shaped screws known as rotors that compress air by its rotary-type circular movement. When both the screws turn in tandem, the air gets pressurized due to the decrease in its volume within the narrowing space in between the two blades when they pass closely to one another. This compressor is priced for generating none-pulsating steady flow of pressurised air quietly as well as with much lesser vibration as compared to the Reciprocating compressors as even though the design is more complex but it has lesser moving parts. So Trane compressor has strived to provide the best Screw compressors that are engineered for high quality performance as well as a variety of options to choose from, namely CHHP, CHHN and CHHB compressors.

Trane compressors provides all the necessary parts for each and every type and model of compressor to meet all your requirements.

#Trane Screw Compressors in Dubai#CRHR Trane Compressor#CRHE Trane Compressor#CHHP Trane Screw Compressor#Trane Compressor Parts

1 note

·

View note

Text

Asymmetrical Plate Bending Machine

Technical specification

Two rolls powered by a single gearbox and gear system for top and bottom rolls;

Structure:

1.The down rollers is the main drive, do the movement of elevation. Through the meshing of the gear between the up and bottom roller to drive the upper roller rotate. The side roller for tilting lifting motion.It’s have double function of pre-bending and circle.Compact structure and easy operation and maintenance.

2.The machine consists of two parts, the operation part and the transmission part which are welded at the whole bottom pallet. The operation part consists of left and right bearing housing, one upper roller, one lower roller and one side roller, lifting gears and some accessories. The lower roller is the main one, upper roller can be adjusted at the height. The transmission part consists with the main motor, speed-reducing motor and other accessories.

3.The lower roller is driven by the main motor through the reducer. The main reductor output shaft transmits to the two lower rollers through a group of gear wheel. Through the meshing with lower roller gear and upper roller gear to drive the upper roller.

4.The down rollers’ elevation come from the handle wheel rotate to drive the cam.

5.The auxiliary engine drive the worm screw, worm wheel,screw nut,screw mandrel to make the side roller do elevation movement.

6.Drop the roller to the appropriate height when unloading.After the machine stopping,take the sliding set from upper roller.Turn the upper roller to certain angle,the rolled metal cylinder can be dropped out from one side of the upper roller.

Application:

Fuel Tanks, Storage Systems, Shipyards, Water Heaters, Autoclaves, Food Processing Equipment, Coolers, Structural Steel, Filters, Pressure Vessels, Mining Equipment, Mixers, Heat Exchangers, Boilers, Pipelines, Drilling Rigs, Chimney Tubes, Air Compressors, Wind Towers, Nuclear Reactors and that's just some!

Features:

The structure of the machine is symmtrical 3-roll, two lower rolls are symmetrical central location, so it is convenient for machine vertical movement.

The machine is started bu manually under pressure, and then the two rollers rotates through the output gear reducer with roller gear meshing.

The machine is cheaper than the traditional one, and the structure is simple and easy for operation.

The machine is cost-effective, and has long performance life.

Only one operator is required.

For High Productivity

Description:

The hydraulic asymmetrical roller bending machine is a kind of hydraulic plate rolling machine in the form of three roller asymmetry. The upper roll is used as the main drive. The lower roll moves vertically to clamp plates tightly. It has dual function of pre-bending and rolling. The machine uses the hydraulic oil in hydraulic cylinder to make piston rod drive the work rolls do up and down movement. This hydraulic plate rolling machine is designed for rolling light or medium plates. HB manufactures a wide variety of hydraulic asymmetrical roller bending machines that have unique designs and features. Our rolling machines employ the latest technology to handle a broad range of materials without any difficulty. Our hydraulic plate rolling machines are highly demanded by the chemical industry, shipbuilding industry, water treatment plant, power plant, petroleum industry, etc.

1 note

·

View note

Text

Double Piston | Piston Air Compressor Manufacturers & Suppliers

Double Piston Air Compressor - Roteck Compressor is leading the industry of Double Piston Air Compressor Manufacturers, Traders & Suppliers in India. We specialize in producing Industrial Air Compressors, Double Piston Air Compressor at the customer requirements.

0 notes

Photo

Flake Ice Machine 0.3T/24h,Flake Ice Machine 0.3T,0.3T Flake Ice Machine

Share:1.Ice production 0.3 Ton Per Day

2.Fresh Water /Salt Water

3.Air Cooling/Water Cooling

4.Flake Ice Thickness: 1.5-2.2mm

5.Refrigerant: R22/R404A

6.With PLC Controller

Flake Ice Machine 0.3T/24H

DAKA FREEZER commercial ice machines are widely used in supermarket chains, hotels, seafood markets, food processing and vegetable preservation,etc

Ice production from 300kg/d-2500kg/d, which can meet the commercial requirements.

DAKA FREEZER commercial ice machines are equipped with various brands of compressors such as the danfoss/Copeland scroll and the semi-closed piston.

The ice bin made of double-sided stainless steel. Customers can choose integral type or separate type (unit + ice bin) according to the different application.

The flake ice machine can start and stop automatically to make the evaporator mechanical operation system and water suppling circulation system

coordingation matched and work safely and effictiently under the function of PLC programmable controller.

1 note

·

View note