#disperse dyes manufacturers

Explore tagged Tumblr posts

Text

How Disperse Dyes Manufacturers are Shaping the Textile Industry in 2024?

In 2024, the textile industry is undergoing a profound transformation, propelled by innovations in dyeing technology. Disperse dye manufacturers play a pivotal role in this evolution, shaping the way fabrics are colored and enhancing the efficiency and sustainability of textile production processes.

The Rise of Disperse Dyes

Disperse dyes have gained significant traction in the textile industry due to their ability to color synthetic fibers effectively. Unlike traditional dyes that are designed for natural fibers like cotton or wool, disperse dyes are formulated specifically for polyester, nylon, and other synthetic materials. This specialization has fueled their adoption in a wide range of applications, from apparel and home textiles to automotive upholstery and technical fabrics.

Key Advantages of Disperse Dyes

Vibrant Colors: Disperse dyes offer a vibrant and long-lasting color palette, allowing textile manufacturers to create eye-catching designs and patterns that resonate with consumers.

Durability: These dyes are known for their excellent color fastness, ensuring that fabrics maintain their appearance even after repeated washings or exposure to sunlight.

Versatility: Disperse dyes can be applied using various dyeing techniques, including exhaust, pad, and printing methods, making them versatile for different production processes.

Environmental Sustainability: Manufacturers are increasingly focusing on eco-friendly dyeing solutions, and disperse dyes are playing a crucial role in reducing water consumption, energy usage, and chemical waste in textile manufacturing.

Technological Innovations

The landscape of disperse dyes manufacturing has evolved significantly in recent years, driven by advancements in chemical engineering and process optimization. Key innovations include:

Nano-dispersion Technology: This cutting-edge approach enables the creation of ultra-fine dye particles, resulting in improved color penetration and uniformity on synthetic fibers.

Low-Temperature Dyeing: Manufacturers are developing dyes that can be applied at lower temperatures, reducing energy consumption and environmental impact during the dyeing process.

Digital Printing: Disperse dyes are compatible with digital printing technologies, allowing for precise and customizable color application, even on complex fabric designs.

Market Impact

The demand for disperse dyes is on the rise, driven by factors such as:

Fashion Trends: Consumers are increasingly drawn to vibrant, color-rich textiles, driving the need for advanced dyeing solutions that can meet evolving design preferences.

Technical Textiles: Industries like automotive, aerospace, and healthcare rely on technical textiles that require specialized dyeing techniques, where disperse dyes excel.

Sustainability Initiatives: Textile manufacturers are aligning with sustainability goals, opting for dyes that minimize environmental impact without compromising on color quality.

Future Outlook

As we look ahead, the role of disperse dyes manufacturers will continue to be pivotal in shaping the textile industry. Anticipated developments include:

Bio-based Dyes: Research is underway to develop bio-based disperse dyes derived from renewable sources, further enhancing the sustainability profile of textile dyeing processes.

Smart Dyeing Solutions: Integration of smart technologies like IoT sensors and data analytics in dyeing equipment to optimize dye usage, reduce waste, and enhance color consistency.

Regulatory Compliance: Manufacturers are proactively addressing regulatory requirements related to chemical usage, ensuring that disperse dyes remain compliant with global standards.

Conclusion

In conclusion, disperse dyes manufacturers are at the forefront of innovation in the textile industry, driving advancements in color technology, sustainability, and performance. Their contributions are instrumental in meeting the demands of a dynamic market landscape while paving the way for a more sustainable and vibrant future for textiles.

0 notes

Text

RK Industries | Wide Range of Disperse Dyes in India

Find top-quality disperse dyes for textiles at RK Industries, Baroda. Explore our vibrant, high-performance range for all your coloring needs.

#top disperse dyes producers in India#top disperse dyes in india#best disperse dyes manufactur industry in india#disperse dyes manufactur industry in india

0 notes

Text

Dye, doll, dye

I did a dyeing thing - a white Resinsoul centaur (Dawn) and different vinyl shell parts of an Obitsu 50 cm body (whitey and super whitey).

What I used:

A big shiny pot. Life pro tip - if you have an induction cooktop, check your crappy pot that you ordered from Amazon right away. Amazon sellers are liars.

Lots of towels (water everywhere). Dye (RIT DyeMore is what I used, because it's specifically for synthetics), isopropyl (rubbing) alcohol and a melamine sponge (Magic Eraser) for oopsies, and weed whacker trimmer string for the parts. Plus coffee.

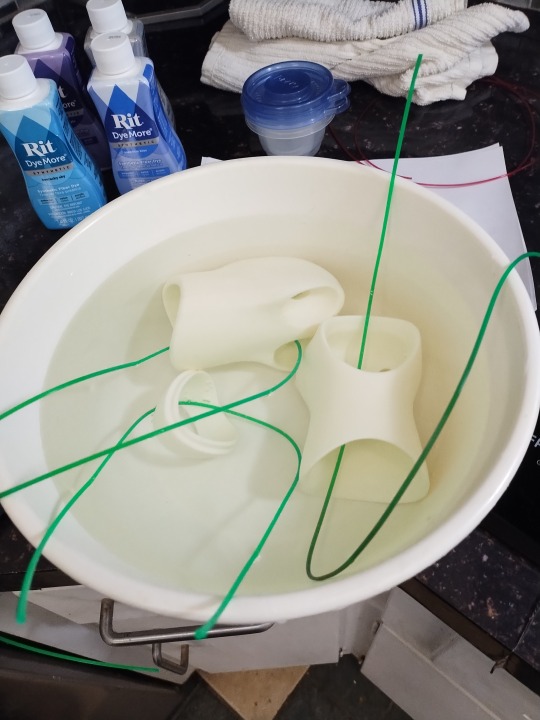

Strung doll parts. NOTE: before I dye resin or vinyl, I soak it in cold water for 10-15 minutes. Resin is porous. Water will help open the pores for a slightly more even dye distribution.

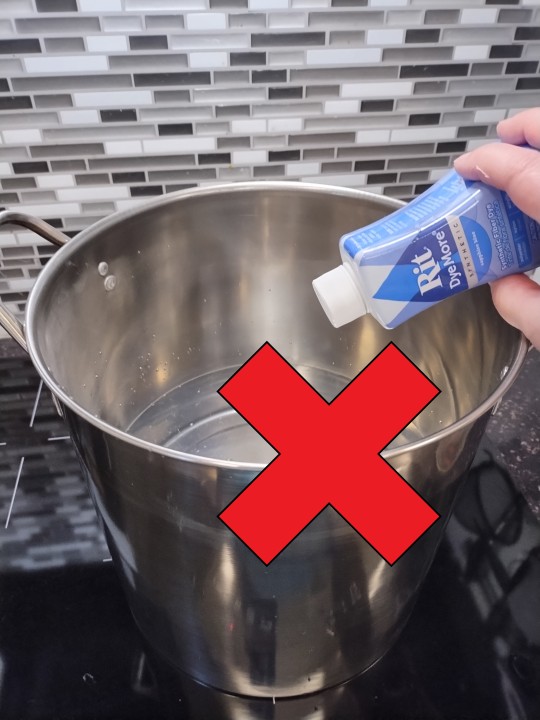

So one thing I see over and over that drives me CRAZY is people dumping the whole bottle of dye directly into the water.

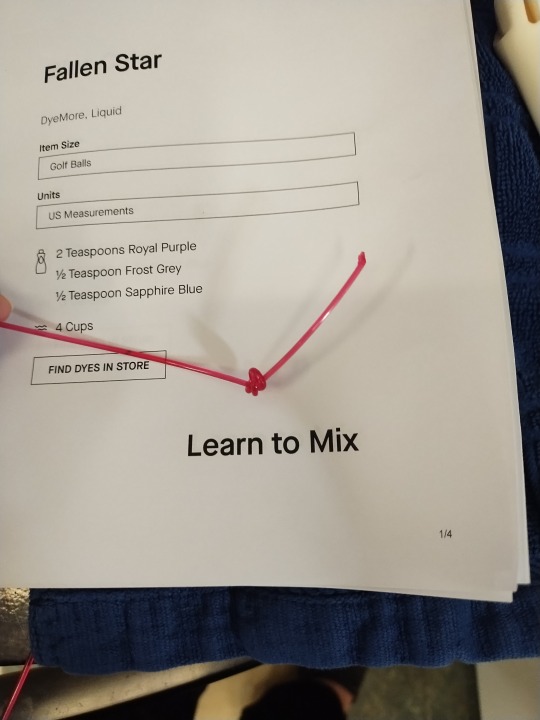

RIT has recipes. Here's the recipe for Fallen Star using "small" items:

It doesn't matter which small item you pick - the recipe is the same. For a more intense color, increase the amount of dye (Fallen Star is 2 teaspoons of Royal Purple, 1/2 teaspoon Frost Grey, 1/2 teaspoon Sapphire Blue per 4 cups of water). If you dump in the whole bottle, 1) you're wasting dye, and 2) you're not going to get the color that the dye is supposed to produce.

Dye measured - and then I measure one more batch in a separate cup. As stuff goes in the water, dye is absorbed and removed from the water - so you gotta add a little back. Like, an eyedropper at a time, a little.

I set the water to be just under a boil - no bubbling, but still painful when you accidentally stick a finger in there. It's soapy because RIT recommends adding a tiny bit of dish soap and a little salt to the dye bath to help disperse the color evenly.

Dunk:

The resin parts got 3 minutes each. The vinyl parts got 6 minutes.

Horse butt magnet came unglued, and there's something on the butt that prevented it from absorbing dye. I don't know what it is. I'll have to color correct with pastels. Also: the horse body was cast in two parts that were glued together, and the seams sanded. This became immediately apparent post-dye.

The floating blobs top left are vinyl thigh parts after 3 minutes in the dye bath. The darker blue human parts of vinyl parts after a six minute bath.

A few more things: whatever that butt glue was, it liquified in the pot and stuck to stuff. I am not happy about this.

Because parts are thinner in some places and thicker in others, when I pulled a part out of the bath, I would run it under cool water. Then I grabbed my melamine sponge and scrubbed areas where the dye was darker or absorbed funny. Isopropyl alcohol can also help remove some of the dye.

The dye continued to process, even after I rinsed all the parts. When I woke up the next morning, everything was an even more intense blue - especially the vinyl.

My self-imposed max time for resin in a hot water dye bath is 3 minutes. 2-part epoxy resin reacts quickly and hardens to equilibrium - NOT completion. When resin parts are put into almost-boiling hot water, the reaction is reactivated. The resin parts will shrink. I read on a resin manufacturer's website that after 20 minutes, the resin will become extremely brittle and fragile. From past experience, I know that 3 minutes in hot water is enough to make a resin part shrink.

Since the resin parts were dyed for 3 minutes each, this means I will NOT be attempting a gradation with dye. I'll use pastels instead.

But vinyl, however - vinyl can take some heat. Heh heh heh.

Next up: purple!

60 notes

·

View notes

Text

New polymerization approach could transform the manufacturing of specialty plastics

Researchers in Carnegie Mellon University's Department of Chemistry have improved a popular technology used to generate a range of industrial plastics for applications ranging from paints and coatings to adhesives and sealants. Using environmentally-friendly reaction conditions, including running the reaction in water with light and a water-soluble dye, the novel method offers a promising approach for creating polymers in a greener and more practical way during the emulsion polymerization process. In a commercial setting, emulsion polymerization is one of the least expensive ways of making a range of useful polymers. The process is limited, however, because scientists cannot precisely control the molecular weight and dispersity of the resulting polymers. And controlling the polymer structure is key to making specialty polymers that have very specific features.

Read more.

#Materials Science#Science#Polymerization#Polymers#Materials processing#Plastics#Carnegie Mellon#Infrared

13 notes

·

View notes

Text

What Products can the Vacuum Homogeneous Emulsifier Produce?

The vacuum homogeneous emulsifier is a kind of cosmetic equipment, but due to the development of science, the production technology has been continuously innovated. The vacuum homogeneous emulsifier is not only used in the cosmetics industry, but also in many industrial production fields. Let’s follow the editor of YeKeey, a professional emulsifying machine manufacturer to see what products can be produced by the vacuum homogeneous emulsifier.

Vacuum Homogeneous Emulsifier Application

From the scope of application, the emulsifier can be used in a wide range of liquid products. For products with low viscosity, the emulsifier can handle them easily, and you don’t even need to turn on the homogenization function. You only need to mix, and even two-way mixing is sometimes a bit wasteful. To be precise, it is a bit overkill, and the price of the emulsifier is not cheap, and there is no need to use such a piece of good equipment. Ordinary stainless steel mixing tanks can be used for products such as lotion. But for products with a certain viscosity, it can only be produced by a vacuum homogeneous emulsifier.

The emulsifying machine

widely used in producing food sauces

Food sauces, such as salad dressing, mayonnaise, custard sauce, etc. The function of the emulsification tank of vacuum emulsification equipment is to dissolve one or more food materials in another liquid phase and make the combination into a relatively stable emulsion. Therefore, it is widely used in the emulsification and mixing of edible oils, powders, sugars, and other raw and auxiliary materials.

The emulsifier in the chemical industry

In the chemical industry, some ink coatings, paint emulsification, and dispersion also use vacuum emulsification tanks, especially suitable for mixing and emulsifying some insoluble colloidal additives CMC and other raw materials. The emulsifier is ideal for producing cosmetics, medicine, food, chemical dyeing, printing, ink, and other industrial products. It is more effective, especially for the emulsification of materials with high matrix viscosity and relatively high powder content.

High-shear vacuum homogenizing emulsifiers are widely used in the field of cosmetics

In the field of cosmetics, high-shear vacuum homogenizing emulsifiers are widely used in cosmetic creams, shampoos, shower gels, sunscreens, and other cream products. The emulsifier performs high-speed shearing, dispersion, and impact on the material through the high-speed rotation of the homogenizing head connected to the engine. In this way, the material will become more delicate and promote the fusion of oil and water. The material will be mixed with air during the production process, which will cause the product to become air-bubbled, bacterially polluted, easily oxidized and the appearance is not smooth. This situation will not occur when using a vacuum emulsifying machine.

It will disperse and emulsify evenly in a vacuum state, and air bubbles are no longer mixed in the process of production and mixing, so it can ensure the cream is delicate and stable.

Yekeey

YeKeey vacuum homogeneous emulsifier is easy to operate, has stable performance, good homogeneity, and high production efficiency. Moreover, this equipment also has the characteristics of convenient cleaning, reasonable structure, and a high degree of automation. YeKeey can also provide customers with the service of sending materials to the factory for test machines. If you have a demand for a vacuum homogeneous emulsifier, please consult YeKeey.

2 notes

·

View notes

Text

Top Masterbatches Manufacturers: Why BS Masterbatch Stands at the Forefront

In the world of plastic manufacturing, masterbatches are an essential ingredient in producing high-quality, functional plastic products. These concentrated formulations of pigments, additives, and resins help to enhance the appearance, performance, and durability of plastic materials. As one of the top masterbatches manufacturers, BS Masterbatch has earned a reputation for delivering premium-quality masterbatch solutions that meet the diverse needs of industries ranging from packaging to automotive, textiles, and beyond.

What Are Masterbatches?

Masterbatches are a key component in the plastic production process. They are highly concentrated mixtures of pigments, dyes, and functional additives that are pre-dispersed in a polymer carrier. Masterbatches are used to impart specific properties to plastic products, such as color, UV resistance, flame retardancy, and improved mechanical properties.

There are several types of masterbatches, including:

Colour Masterbatch: Used to add color to plastic products.

Additive Masterbatch: Includes additives like UV stabilizers, antioxidants, and anti-static agents.

Masterbatches simplify the production process by eliminating the need for additional steps like direct coloring or adding loose additives, ensuring a more efficient and consistent manufacturing process.

The Role of Masterbatches in Plastic Manufacturing

Masterbatches play an essential role in enhancing the aesthetic, functional, and performance qualities of plastic materials. Some of the key advantages of using masterbatches include:

Consistency: Masterbatches provide consistent coloration and uniformity across large batches of plastic products, ensuring quality control during production.

Customization: With the ability to customize formulations, masterbatches can meet specific customer requirements, from vibrant colors to functional additives that improve durability and performance.

Cost-Effectiveness: Using masterbatches reduces waste and ensures more precise formulation, making them a cost-effective solution for plastic manufacturers.

Ease of Processing: Masterbatches are easy to use and integrate into the plastic manufacturing process. The pre-dispersed nature of masterbatches eliminates the challenges associated with adding pigments or additives manually, ensuring better flow and easier handling.

BS Masterbatch: A Leading Masterbatch Manufacturer

With a focus on innovation, quality, and customer satisfaction, the company produces a wide range of masterbatch solutions designed to meet the varied needs of its clients. From vibrant color masterbatches to performance-enhancing additive masterbatches, BS Masterbatch offers a comprehensive portfolio of products that provide excellent color, consistency, and functionality.

Why BS Masterbatch is a Top Choice for Manufacturers

Exceptional Quality Control: As one of the leading masterbatch manufacturers, BS Masterbatch places a strong emphasis on maintaining the highest quality standards. The company uses premium raw materials and state-of-the-art technology to produce masterbatches that offer superior consistency and performance.

Customization Options: BS Masterbatch understands that every plastic product has unique requirements. That's why the company offers highly customizable masterbatch solutions, enabling clients to create masterbatches that meet their specific needs. Whether you need a specific color, additive formulation, or enhanced durability, BS Masterbatch can tailor products to suit your precise specifications.

Wide Product Range: BS Masterbatch offers a broad range of masterbatch products, including color masterbatches, additive masterbatches, black and white masterbatches, and more. Their extensive product range ensures that manufacturers can find the perfect solution for virtually any application, whether it’s for packaging, automotive, textiles, or construction.

Sustainability: BS Masterbatch is committed to producing environmentally responsible products. The company incorporates sustainable practices in its manufacturing process and produces eco-friendly masterbatches that comply with international environmental standards. This commitment to sustainability is an essential factor for businesses looking to reduce their carbon footprint and adhere to environmental regulations.

Innovative Solutions: BS Masterbatch is constantly investing in research and development to stay ahead of industry trends. The company’s team of experts works closely with customers to develop innovative masterbatch solutions that address evolving market demands and enhance product performance.

Technical Expertise and Support: As a top masterbatch manufacturer, BS Masterbatch offers expert technical support to help clients achieve optimal results. The company’s experienced team assists customers in selecting the right masterbatch for their production processes and ensures that the masterbatch integrates seamlessly into their systems.

Applications of BS Masterbatch Products

Packaging: Whether for food packaging, consumer goods, or industrial packaging, BS Masterbatch offers color and additive solutions that enhance the aesthetic and functional properties of packaging materials.

Automotive: BS Masterbatch provides masterbatches that improve the appearance and durability of automotive parts, offering UV protection, flame retardancy, and weather resistance.

Textiles: BS Masterbatch’s color masterbatches are used in the production of fibers, films, and fabrics, delivering vibrant, long-lasting color and durability.

Construction: BS Masterbatch’s additives help improve the strength, UV stability, and weather resistance of construction materials.

Conclusion

As one of the top masterbatches manufacturers, BS Masterbatch stands out for its commitment to quality, innovation, and customer satisfaction. The company’s diverse range of masterbatch solutions helps manufacturers across industries enhance the aesthetic appeal, performance, and durability of their plastic products. Whether you need color masterbatches, additive masterbatches, or custom formulations, BS Masterbatch provides reliable, high-quality products that exceed customer expectations. With a strong focus on sustainability and continuous innovation, BS Masterbatch remains the partner of choice for businesses looking for top-tier masterbatch solutions.

0 notes

Text

Essential Advantages of Textile Auxiliaries in Contemporary Fabric Processing

The textile industry is a cornerstone of modern manufacturing, producing a wide range of fabrics that meet diverse consumer needs. Behind the scenes of this dynamic industry, textile auxiliaries play a critical role in ensuring the quality, performance, and functionality of fabrics. These chemical substances, used at various stages of textile production, enhance processing efficiency, improve fabric properties, and enable innovative finishes. In this article, we will explore the essential advantages of textile auxiliaries in contemporary fabric processing and why they are indispensable in the industry.

What Are Textile Auxiliaries?

Textile auxiliaries are chemical compounds applied during different stages of fabric processing, including pre-treatment, dyeing, printing, and finishing. These substances assist in:

Improving process efficiency.

Enhancing the appearance and texture of fabrics.

Adding functional properties like water repellence or anti-microbial protection.

Examples of textile auxiliaries include wetting agents, dispersing agents, softeners, and anti-static agents, each serving a specific purpose in fabric processing.

Advantages of Textile Auxiliaries in Fabric Processing

1. Enhanced Efficiency in Pre-Treatment

Pre-treatment is a critical stage where raw fabrics are prepared for subsequent processes like dyeing or printing. Textile auxiliaries ensure thorough cleaning, uniform preparation, and optimal fabric conditioning.

Scouring Agents: Remove natural oils, waxes, and impurities from fibers.

Bleaching Agents: Achieve bright and consistent fabric whiteness, a crucial step for dye uptake.

Desizing Agents: Eliminate starches and other sizing materials used during weaving, improving fabric absorbency.

These auxiliaries streamline the pre-treatment process, reducing time and energy consumption while enhancing fabric readiness for further processing.

2. Improved Dyeing and Printing Results

Dyeing and printing are pivotal stages in textile production, where fabric gains color and design. Textile auxiliaries optimize these processes by:

Leveling Agents: Promote uniform dye penetration, preventing streaks or uneven shades.

Dispersing Agents: Stabilize dyes in the solution, ensuring consistent application.

Printing Binders: Enhance color fastness and durability in printed designs.

By ensuring precise color application and minimizing defects, textile auxiliaries contribute to vibrant, long-lasting fabrics.

3. Enhanced Fabric Finishing

Finishing is the final stage where fabrics are treated to achieve specific characteristics or enhance their performance. Textile auxiliaries play a vital role in this stage:

Softeners: Provide a smooth, soft hand feel to fabrics, enhancing comfort.

Anti-Static Agents: Reduce static build-up, particularly in synthetic fibers.

Water Repellents: Impart water resistance, ideal for outdoor and sportswear applications.

Anti-Microbial Agents: Inhibit bacterial growth, promoting hygiene in medical textiles or activewear.

These specialized treatments add significant value to fabrics, aligning them with consumer preferences and functional requirements.

4. Environmental Benefits with Sustainable Auxiliaries

The textile industry faces growing scrutiny over its environmental impact. Modern textile auxiliaries are increasingly designed to be eco-friendly, supporting sustainable manufacturing practices.

Low-Impact Chemicals: Reduce water and energy usage during processing.

Biodegradable Auxiliaries: Minimize environmental harm by breaking down naturally.

Efficient Processes: Enable shorter cycles, lowering the carbon footprint of textile production.

Sustainable textile auxiliaries not only meet regulatory standards but also appeal to environmentally conscious consumers.

5. Enhanced Fabric Properties and Versatility

Textile auxiliaries enable fabrics to achieve properties that cater to specific industries and applications. For example:

Flame Retardants: Provide fire resistance, essential in protective clothing and home textiles.

UV Protectants: Block harmful ultraviolet rays, ideal for outdoor garments.

Wrinkle-Free Agents: Enhance fabric resilience, ensuring a polished appearance after use.

These functional benefits make textile auxiliaries indispensable for producing high-performance fabrics.

6. Cost-Effective Production

By improving process efficiency and reducing material waste, textile auxiliaries contribute to cost-effective manufacturing. Faster processing times, reduced energy usage, and fewer defects translate to significant savings for textile producers.

The Future of Textile Auxiliaries

Innovation continues to shape the role of textile auxiliaries in the industry. Advancements include:

Smart Auxiliaries: Chemicals that respond to environmental changes, such as self-healing fabrics.

Digital Printing Enhancers: Auxiliaries designed for precise digital printing techniques.

Bio-Based Auxiliaries: Derived from renewable resources, aligning with green manufacturing goals.

As consumer demands evolve and sustainability becomes paramount, textile auxiliaries will remain at the forefront of fabric innovation.

Conclusion

Textile auxiliaries are the unsung heroes of fabric processing, offering unmatched advantages in efficiency, quality, and functionality. From pre-treatment to finishing, they ensure fabrics meet the highest standards of performance and aesthetics.

In a competitive industry driven by innovation and sustainability, textile auxiliaries are integral to producing fabrics that align with consumer expectations and environmental goals. By embracing advanced and eco-friendly auxiliaries, the textile industry continues to push the boundaries of what’s possible in fabric production.

0 notes

Text

Hire Top Dyes Manufacturer in Ahmedabad to Produce Sustainable Dyes for Your Textile Business

Ahmedabad, a well-known and major city in Gujarat, is known for its fastest growing textile sector. And as dyes play a crucial role in the textile sector, with the extreme growth of textile sector in Ahmedabad, the number of dyes manufacturer in Ahmedabad is increasing simultaneously. And Venus Dye Chem dyes manufacturing company in Ahmedabad stands out among all of them as a leader with their exceptional quality and large variety of textile dyes.

In this blog, we will give a brief overview of Venus Dye Chem, discuss the reasons behind its huge success that make customers choose this leading dyes manufacturer and supplier in Ahmedabad over others.

Venus Dye Chem- The Foremost Dyes Manufacturer in Ahmedabad, India

The extreme level of expertise and experience make Venus Dye Chem a pioneer in the dyes manufacturing sector now. Their success story is based on their continuous commitment to quality, innovative approach, eco-friendly practices. By using advanced technology and tools, their expert manufacturing team members have taken the company’s success to the next level. Over the years, they have successfully done 250+ dyes projects for several textile business and paints sectors as well. Their excellent quality services have given worldwide fame to the company and now they have customers from different countries as well.

Why Choose Venus Dye Chem for Dyes Manufacturing?

Running a textile business without an expert team of dyes manufacturer is next to impossible as the colorful dyes are the major part of textile. India now has a countless numbers of dyes manufacturing companies and most of them are from Ahmedabad as Ahmedabad is a hub of textile. Among all of them, Venus Dye Chem is exceptional. Check the reasons below why textile companies should hire Venus Dye Chem instead of others. See what makes them the foremost dyes supplier in Ahmedabad.

1. Quality Assurance

The first major reason that makes customers consider Venus Dye Chem as the top trusted dyes manufacturer in India is their non-stop quality assurance. Their full team work tirelessly and use est materials to create world-class quality dyes for the textile sector. To ensure quality, they do several testing of the dyes before finally delivering them to the customers.

2. Customized Dye Formulations

AT Venus, we analyze everyone’s unique needs and create suitable dyes using customized formula as per the client’s needs to make everyone’s products different from others and help them maintain individuality.

3. Eco-friendly Practices

We have a unique aim of making our dyes environment-friendly. To fulfill this aim, we adopt eco-friendly practices only during dyes manufacturing. This helps us stands out as a leading dyes manufacturer in Ahmedabad.

4. Expertise in Wide Variety of Dyes Manufacturing

Venus Dye Chem is a one-stop destination to get all varieties of dyes. We specialize in Reactive Dyes, Reactive printing dyes, Reactive cold dyes, Reactive HE and ME dyes, Pigment powder, Pigment paste, Sulphur dyes, disperse dyes and a lot more.

5. Cost-effective Solutions

We want to make dyes affordable for everyone. With this aim, we have started selling dyes at reasonable rates but it won’t affect the quality. You can always get cost-effective but finest quality dyes from us.

6. Quick Responsiveness

Our customer support team is always there to answer any queries and help you with any issue almost instantly.

7. Customer-centric Practice

Our practice is based on our customers. Our team closely discusses the entire project with every customer to analyze their requirements.

Conclusion

Venus Dye Chem has created a positive impact on the textile sector of India with their innovation and expertise. They are shaping a bright future of the textile Industry in a unique and eco-friendly way. If you want bright, colorful and very durable quality dyes and want color and quality guarantee, choose this top dyes manufacturer in Ahmedabad.

1 note

·

View note

Text

Povidone Prices Trend | Pricing | News | Price | Database | Chart

Povidone a water-soluble polymer widely used in the pharmaceutical, cosmetic, and industrial sectors, has been gaining attention as a crucial component in many formulations, including as a binder, stabilizer, and solubilizer. The global market for povidone has seen fluctuating trends in prices, which are influenced by a mix of supply chain challenges, manufacturing costs, and shifting demand across various industries. Understanding the pricing dynamics of povidone is essential for manufacturers, suppliers, and end-users to make informed decisions. Over the past few years, povidone prices have been impacted by raw material costs, labor shortages, transportation challenges, and regulatory policies that affect the production and distribution processes.

The market for povidone is significantly shaped by its applications in pharmaceuticals. It is widely used as a binder in tablet formulations, a stabilizer in vaccines and biological products, and an excipient in topical drugs. The pharmaceutical industry’s demand for povidone has been steady, supported by the growing global need for medications, particularly in emerging markets. However, fluctuations in raw material prices and production challenges can directly affect povidone availability and pricing. For example, during periods of high demand, manufacturers may face challenges in maintaining consistent supply levels, which can push prices upward. Conversely, periods of economic downturn or reduced pharmaceutical production can lead to a decrease in demand, creating pressure on prices to stabilize or decline.

Get Real time Prices for Povidone: https://www.chemanalyst.com/Pricing-data/povidone-1393

In addition to pharmaceutical uses, povidone finds applications in the personal care and cosmetics industry, where it acts as a film-forming agent, thickener, and stabilizer. The growing consumer focus on skincare and cosmetic products has contributed to a steady demand for povidone. The increasing popularity of products such as moisturizers, anti-aging creams, and hair care solutions has further boosted its market presence. This segment of the market is affected by consumer trends, shifts in product formulations, and the introduction of new cosmetic technologies. If consumer preferences shift towards products that require more specialized or higher-quality povidone grades, this can influence the pricing trends accordingly.

The industrial sector also represents a significant part of the povidone market. Povidone is utilized in manufacturing adhesives, coatings, and as a dispersing agent in paints and dyes. The demand in this segment is often tied to construction and automotive industries, which are susceptible to economic cycles. During periods of robust industrial growth, increased demand for povidone in adhesives and coatings can drive prices upward. Conversely, during economic slowdowns or declines in construction and automotive production, industrial demand may decrease, potentially lowering prices. Additionally, raw material price fluctuations, such as those related to petroleum products, can affect the cost of povidone in the industrial market due to its chemical derivation.

Regulatory factors also play a critical role in shaping the povidone market. The regulatory requirements for povidone used in pharmaceutical applications are stringent, necessitating compliance with standards set by global regulatory bodies like the FDA and the European Medicines Agency. Any changes in regulatory frameworks can impact production costs, particularly if new testing, quality control measures, or certifications are required. Such factors can either increase production expenses, leading to higher market prices, or reduce market supply if manufacturers face difficulties in meeting compliance standards. Conversely, regulatory relaxation in certain regions may encourage more production and subsequently reduce prices.

Looking ahead, the povidone market is expected to face further shifts influenced by technological advancements and sustainability initiatives. The development of more efficient production methods can potentially lower production costs and stabilize prices over time. However, sustainability concerns related to the production and disposal of synthetic polymers may drive demand for alternative materials or environmentally friendly production methods. Such shifts could result in price adjustments as the industry transitions to meet new standards. Moreover, the emergence of new applications, such as in biopharmaceuticals and innovative drug delivery systems, might provide growth opportunities that could influence the overall market demand and pricing strategies.

In conclusion, povidone prices are influenced by a complex interplay of factors, including raw material costs, production and labor expenses, regulatory environments, and shifts in demand across pharmaceuticals, cosmetics, and industrial uses. While prices can rise due to supply chain disruptions or increased demand, economic downturns and reduced consumption can drive prices lower. A comprehensive understanding of these factors can help market participants anticipate price trends, optimize procurement strategies, and remain competitive in a constantly evolving market.

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Povidone#Povidone Price#Povidone Prices#Povidone Pricing#Povidone News#Povidone Price Monitor#Povidone Database

0 notes

Text

Capital Colours: A Leading Colour Masterbatch Manufacturer Company in India

In the ever-evolving world of plastics and polymers, the demand for high-quality, vibrant colors has led to the rise of color masterbatch technology. Capital Colours, a premier Colour Masterbatch Manufacturer Company in India, has become synonymous with innovation, quality, and sustainability in the production of color masterbatches. With a deep understanding of the market and a commitment to excellence, the company has earned its place as a trusted name in the industry.

What Are Colour Masterbatches?

Colour masterbatches are highly concentrated mixtures of pigments or dyes encapsulated in a carrier resin, designed to impart vibrant colors to plastics. These masterbatches are added to the base resin during the manufacturing process to achieve consistent and uniform coloration throughout the product. Used in a wide range of applications—from packaging to automotive components—color masterbatches play a crucial role in enhancing the aesthetic appeal and functionality of plastic products.

The use of color masterbatches provides manufacturers with several benefits, such as easy handling, precise color matching, and improved processing efficiency. This has led to their widespread adoption in industries such as packaging, textiles, consumer goods, and automotive manufacturing.

Capital Colours: A Trusted Name in Colour Masterbatches

As a leading Colour Masterbatch Manufacturer Company in India, Capital Colours is renowned for its high-quality products, cutting-edge technology, and customer-centric approach. With years of experience in the industry, the company has honed its expertise in producing masterbatches that cater to a diverse range of requirements.

Capital Colours prides itself on its ability to deliver color masterbatches that meet the highest standards of quality and performance. By utilizing advanced manufacturing processes and state-of-the-art equipment, the company ensures that each masterbatch is formulated to provide excellent dispersion, stability, and consistency. Whether customers need vibrant hues or subtle tones, Capital Colours offers a wide range of options to suit every need.

Key Features of Capital Colours’ Masterbatches

Customization: One of the standout features of Capital Colours is its ability to provide tailored solutions. Whether it's a specific shade or an application requirement, the company can customize its color masterbatches to match exact specifications, ensuring that clients get the best possible result for their projects.

High-Quality Pigments: Capital Colours uses only high-quality pigments sourced from trusted suppliers. This ensures that the colors are vibrant, long-lasting, and resistant to fading over time.

Environmental Considerations: In an era where sustainability is paramount, Capital Colours remains committed to environmentally friendly practices. The company’s masterbatches are designed with eco-consciousness in mind, offering options that are compatible with recycling processes and compliant with industry standards.

Superior Dispersion: The company’s color masterbatches are engineered for optimal dispersion in the polymer matrix. This ensures that the colors are evenly distributed, resulting in a consistent and high-quality finish for every product.

Cost-Effectiveness: Despite offering premium products, Capital Colours ensures that its color masterbatches are competitively priced. This makes it a cost-effective choice for businesses looking for high-quality, durable color solutions without compromising their bottom line.

Industries Served by Capital Colours

Capital Colours’ color masterbatches are used across a wide array of industries, including:

Automotive: Supplying automotive manufacturers with durable, high-performance color masterbatches for interior and exterior parts.

Consumer Goods: Providing color solutions for plastic products ranging from toys to household items.

Textiles: Supplying the textile industry with color masterbatches for synthetic fibers and fabrics.

Agriculture: Producing color masterbatches for agricultural films and products that require UV stability and durability.

Innovation and Research

At Capital Colours, innovation is at the core of the company’s operations. The company continuously invests in research and development to improve the performance, stability, and environmental sustainability of its products. Their team of experts works closely with clients to develop new formulations that meet the ever-changing demands of the market.

This focus on innovation ensures that Capital Colours remains ahead of the curve, providing customers with the most advanced and reliable color solutions available.

Conclusion

As a top Colour Masterbatch Manufacturer Company in India, Capital Colours stands as a leader in the field of plastic coloration. Through a combination of high-quality products, innovation, and commitment to sustainability, the company has built a strong reputation among manufacturers across a wide range of industries. Whether you are looking for vibrant, long-lasting colors or need custom solutions, Capital Colours offers the expertise and products to bring your vision to life, making them the go-to choice for all your color masterbatch needs.

0 notes

Text

SVC: Leading the Way in Advanced Surfactant Manufacturing for Diverse Industrial Applications

Surfactants are critical components in various industries, serving as essential ingredients for emulsification, wetting, dispersion, and stabilization. SVC, a leading surfactant manufacturer in India, has established itself as a key player in the production of a wide array of surfactants tailored to meet the unique demands of sectors such as textiles, pharmaceuticals, agrochemicals, construction, personal care, and more.

Pioneering Surfactant Technology

SVC’s EO/PO Condensate Division is at the forefront of surfactant innovation, utilizing advanced technology and stringent quality norms to create eco-friendly, high-performance surfactants. The division specializes in manufacturing Non-Ionic, Anionic, Cationic, and Amphoteric surfactants, using sophisticated reactions like ethoxylation, propoxylation, esterification, alkylation, sulfonation, and amidification.

These high-quality surfactants are not only produced to meet rigorous industry standards but are also customized to fulfill specific requirements for different applications. The state-of-the-art facilities at SVC-Dehgam, Gujarat, ensure efficient production and timely delivery, supported by a robust R&D center that is continuously developing new products to enhance the existing portfolio.

A Deep Dive into SVC’s Product Offerings

EO/PO Condensate Surfactants

Alkyl Phenol Ethoxylates: These are versatile surfactants used as emulsifiers, wetting agents, and dispersing agents. SVC’s range includes Nonyl Phenol Ethoxylates, Octyl Phenol Ethoxylates, Styrenated Phenol Ethoxylates, and Card Phenol Ethoxylates. These products find widespread use in textile, detergent, agrochemical, and paint industries.

Fatty Acid Ethoxylates: Primarily used in textile formulations and spin finishes, this product line includes Oleic Acid, Stearic Acid, Coconut Fatty Acid, and Lauric/Palmitic/Myristic Acid Ethoxylates. SVC provides tailor-made solutions with specific moles to suit various needs.

Polyethylene Glycols (PEGs): SVC’s PEGs are stable, non-toxic solvents compliant with IP/USP/NF standards, utilized in pharmaceuticals, cosmetics, oral care, and other industries. Their molecular weights range from 200 to 10,000, making them adaptable for diverse applications.

Fatty Amine Ethoxylates: These surfactants are used as dye leveling and wetting agents in textiles and detergents. The product range includes Stearyl Amine Ethoxylates, Tallow Amine Ethoxylates, Coco Amine Ethoxylates, and Ethylene Diamine Ethoxylates.

EO/PO Co-Polymers These co-polymers are non-ionic surfactants that exhibit low foaming properties, making them ideal for water treatment, paint formulations, and oil field applications. Customization of specific moles is available to meet unique industrial demands.

Fatty Alcohol Ethoxylates SVC offers a broad spectrum of fatty alcohol ethoxylates used in shampoos, detergents, emulsifiers, and other personal and home care products. The product line includes Lauryl Alcohol, Ceto Stearyl Alcohol, Oleyl Cetyl Alcohol, and more, ensuring comprehensive coverage for multiple applications.

Castor/Natural Oil Ethoxylates Known for their wide range of applications, these surfactants are crucial in agriculture, textile, leather, and paint formulations. The products include Castor Oil Ethoxylates, Hydrogenated Castor Oil Ethoxylates, and Soya Oil Ethoxylates, designed for superior emulsification and stabilization.

Polysorbate (TWN) Ethoxylates TWNs, or Polysorbates, produced by SVC are of high purity, low color, and odor, making them ideal for sensitive applications. They include TWN 20, TWN 40, TWN 60, TWN 65, TWN 80, and TWN 85, with customization options to suit specific industrial needs.

Amides SVC manufactures a variety of amides such as Coco Monoethanolamide, Coco Diethanolamide, and Coco Betaine. These products are essential in personal care applications like shampoos and conditioners, offering foaming, thickening, and emulsifying properties.

Ester Products Esters have broad applications, including cosmetics, food, and mechanical oils. SVC’s range includes Glycol Esters, Glyceryl Esters, Sorbitan Esters, and Phosphate Esters, all produced to exacting standards for optimal performance.

Specialty Chemicals for Diverse Applications

SVC’s Specialty Chemicals Division provides tailored solutions across multiple industries. These chemicals are developed to achieve specific performance criteria set by the customers and are backed by a competent R&D team. Some of the key industry segments catered to include:

Commitment to Quality and Sustainability

SVC is committed to producing eco-friendly surfactants using sustainable methods. The company adheres to strict quality norms and employs advanced manufacturing technologies to ensure product consistency and environmental safety. Each product undergoes rigorous testing to meet both Indian and international standards, making SVC a trusted name in the surfactant manufacturing industry.

Customization and Research Excellence

One of SVC’s key strengths lies in its ability to develop customized solutions. By understanding the specific requirements of different industries, the company can produce tailor-made surfactants and chemical blends that meet the exact needs of its clients. The Advanced Research & Development Center plays a crucial role in this, constantly innovating and expanding the product portfolio to keep up with evolving market demands.

0 notes

Text

Explore the future of disperse dye manufacturing and its emerging trends in this informative article. Discover how technological advancements, sustainability, and changing consumer demands are shaping the future of this industry.

1 note

·

View note

Text

RK Industries | Micro Disperse Vat Dye for Various Applications

RK Industries provides Micro Disperse Vat Dyes, known for their color vibrancy, durability & versatility ensuring consistent quality across various industries

#Micro Disperse of Vat Dyes manufactur industry in india#top Micro Disperse of Vat Dyes producers in India#best Micro Disperse of Vat Dyes manufactur industry in india#top Micro Disperse of Vat Dyes in india

0 notes

Text

Exploring the Magic of Color Powder: From Festivities to Fashion

Color powder has become an iconic symbol in modern celebrations, photo shoots, and even fashion, with its vibrant hues creating dazzling visuals. Whether you’ve experienced a color run or marveled at the vibrancy of Holi festivals, color powder adds a dynamic element to events that’s impossible to ignore. But what exactly is color powder, and how has it gained such popularity across cultures and industries? Let’s dive into the magic of color powder, its uses, and what makes it so special.

What is Color Powder?

Color powder, often made from cornstarch and natural dyes, is a non-toxic, biodegradable material used to create a burst of color when tossed or thrown. The lightweight powder easily disperses in the air, creating a stunning visual effect as it settles on surfaces and people. Traditionally, color powder has its roots in India’s Holi festival, where the powders, called gulal, are thrown during celebrations to welcome the spring season.

Over time, its vibrant visual appeal has inspired different applications, from sporting events to creative fashion statements, proving that it’s more than just a party essential.

The Popularity of Color Powder in Modern Events

One of the major reasons color powder has taken off in recent years is the rise of color runs. These events are not just about completing a 5K race; they’re about the experience. As participants run through designated color stations, they’re showered in clouds of bright, happy hues, creating both a memorable experience and an amazing photo opportunity. The mix of fitness and fun has made color runs a worldwide sensation.

Another notable use is during photo shoots—especially for maternity, engagement, or artistic projects—where color powder brings a playful, dynamic aesthetic. Photographers use the powder to create dramatic effects, capturing moments of vibrant energy.

Fashion’s Bold New Accessory

While initially limited to festivals and races, color powder has also found its way into the fashion world. Designers and brands have embraced its unique visual effects in both fabric dyeing and runway presentations. This method allows for bold, unexpected splashes of color that feel spontaneous yet intentional.

In photo shoots, models are often seen covered in clouds of color powder, lending an ethereal, otherworldly feel to the images. This trend has also expanded to social media influencers and creative makeup artists who use color powder to create artistic looks that stand out in a sea of online content.

Eco-Friendly Fun

One of the major concerns with any mass-produced item today is sustainability, and color powder scores well in this department. Since it's made of organic materials like cornstarch and naturally sourced dyes, it’s usually non-toxic and biodegradable. This means it’s safer for the environment compared to synthetic materials. However, it’s still essential to ensure the powders you use are verified eco-friendly, as not all manufacturers adhere to these standards.

How to Use Color Powder Safely

While color powder is generally safe, there are a few precautions to keep in mind:

Protect your eyes and mouth: Wearing sunglasses or goggles can prevent powder from irritating your eyes, while masks can help avoid inhaling it.

Washable clothes: Most color powders will wash out, but it’s still advisable to wear clothes you don’t mind staining, especially in large quantities.

Skin care: If you have sensitive skin, using a barrier like lotion or coconut oil before exposure can help prevent irritation.

Making Your Own Color Powder

For the DIY enthusiast, making your own color powder at home is surprisingly simple and fun. All you need is cornstarch, water, and food coloring. Mix the ingredients into a thick paste, spread it out to dry, and then crush it into fine powder once hardened. This gives you control over the colors and ingredients, ensuring a safe and personal touch to your event or project.

Conclusion: Unleashing Creativity with Color Powder

Color powder isn’t just a fun addition to a party—it’s a versatile tool for creative expression, community celebration, and artistic exploration. Whether you’re attending a color run, celebrating Holi, or setting up a dramatic photo shoot, the dynamic nature of color powder promises to bring a splash of joy and creativity into any setting.

Let the colors fly and watch the magic unfold!

0 notes

Text

Colour Masterbatch Manufacturers: BS Masterbatch Leading the Way

In the world of plastics manufacturing, achieving vibrant, consistent, and high-quality color in products is essential for enhancing their aesthetic appeal and ensuring brand recognition. This is where colour masterbatch plays a crucial role. Colour masterbatch is a concentrated mixture of pigments or dyes that are blended with a polymer carrier, allowing manufacturers to achieve a wide range of colors in their plastic products. Among the top colour masterbatch manufacturers, BS Masterbatch has distinguished itself by offering innovative, high-performance solutions that meet the needs of various industries.

What is Colour Masterbatch?

Colour masterbatch is a highly concentrated formulation of pigments, dyes, and additives that are encapsulated in a polymer base. This masterbatch allows plastic manufacturers to incorporate specific colors into their products without the need for time-consuming and costly coloring processes. Colour masterbatch is available in various shades and formulations, ranging from basic primary colors to more complex and specialized tones.

The key benefits of using colour masterbatch include its ease of use, consistency, and the ability to achieve a precise, uniform color across large volumes of plastic products. This makes it an indispensable tool in a variety of industries, including packaging, automotive, textiles, and consumer goods.

The Importance of Colour Masterbatch in Plastic Manufacturing

Colour masterbatch is crucial for ensuring that plastic products have a consistent and vibrant color, whether for functional or aesthetic purposes. Some of the primary advantages of using colour masterbatch in plastic production include:

Consistency: Colour masterbatch ensures uniform color dispersion, meaning every batch of plastic products will have the same appearance, whether produced in small or large quantities.

Cost-Effectiveness: By using colour masterbatch, manufacturers save on the cost of additional processes, such as mixing and pre-blending, and they avoid the waste associated with inconsistent coloration.

Customization: Colour masterbatch is highly customizable, offering a wide spectrum of colors. Manufacturers can work closely with colour masterbatch manufacturers to create unique, tailor-made hues that fit specific branding or product requirements.

Improved Aesthetic and Branding: Vibrant and consistent colors help products stand out on the market. Whether it’s for food packaging, consumer electronics, or toys, a consistent color enhances the product’s visual appeal and strengthens branding efforts.

Performance Enhancement: Many colour masterbatches are enhanced with functional additives, such as UV stabilizers or flame retardants, which improve the longevity and performance of plastic products, especially in outdoor applications.

BS Masterbatch: A Trusted Colour Masterbatch Manufacturer

BS Masterbatch has built a strong reputation as one of the leading colour masterbatch manufacturers in the industry. The company prides itself on delivering masterbatch solutions that are tailored to the unique needs of its clients. Using state-of-the-art technology and the highest quality raw materials, BS Masterbatch ensures that each batch of colour masterbatch offers superior color consistency, excellent dispersion, and long-lasting results.

BS Masterbatch offers an extensive range of colours, from vibrant, eye-catching shades to more subtle tones. The company’s expertise extends beyond simple color matching – they also provide advanced custom formulations that include functional additives to improve the performance of plastic products. Whether it’s for outdoor durability, increased UV resistance, or enhanced heat stability, BS Masterbatch’s colour masterbatch products are designed to meet the exact specifications of various industries.

Why Choose BS Masterbatch?

Unmatched Quality: BS Masterbatch is committed to providing the highest quality colour masterbatch. The company uses only premium pigments and materials to ensure vibrant, long-lasting color. Each product undergoes rigorous testing to guarantee consistency, performance, and safety.

Tailored Solutions: BS Masterbatch works closely with customers to create custom colour formulations, meeting the unique requirements of each project. Whether you need a special effect or a color that matches your brand’s exact specifications, BS Masterbatch can deliver a solution that fits your needs.

Wide Range of Colors: From basic colors to sophisticated custom hues, BS Masterbatch offers an extensive palette of colour masterbatch options. This variety makes it easier for manufacturers to choose the right color that aligns with their product and market requirements.

Sustainability: BS Masterbatch is dedicated to producing environmentally friendly colour masterbatch products.

0 notes

Text

Achieve Flawless Blending: A Comprehensive Guide to High-Speed Dispersion Mixers with Variable Speed.

Conquer tough mixing challenges with high-speed dispersion mixers! Explore their benefits, applications, and the importance of variable speed control. Learn how Phoenix Mixer empowers efficient blending (Contact: +91 91452 40124).

In the world of manufacturing, achieving a homogenous mixture is crucial for a wide range of applications. Whether it's creating smooth paints and coatings, formulating pharmaceuticals, or developing innovative food products, uniform dispersion is essential for optimal performance and product quality.

This is where high-speed dispersion mixers come into play. These powerful tools utilize high shear forces to effectively break down solids, disperse them uniformly throughout a liquid phase, and create a stable, consistent mixture.

The Power of High Speed Dispersion:

Traditional mixing methods often struggle with challenging mixtures, particularly those containing solids with high viscosity or a tendency to agglomerate (clump together). High-speed dispersion mixers tackle these difficulties head-on by incorporating several key features:

High Shear Forces: The core principle lies in the high rotational speed of the mixing head. This generates intense shear forces that effectively break down agglomerates and disperse solids throughout the liquid.

Disc-Shaped Design: Many high-speed dispersion mixers incorporate a disc-shaped mixing head. This design creates a vortex within the mixture, further promoting uniform distribution of solids.

Adjustable Blade Configurations: Depending on the specific application, different blade configurations are available to optimize mixing efficiency. These configurations can range from simple saw-tooth blades to more complex designs.

The Importance of Variable Speed Control:

While high-speed dispersion mixers offer tremendous power, the ability to control that power is equally important. This is where variable speed control comes in.

Optimizing for Viscosity: Different materials have varying viscosities. By adjusting the mixing speed, you can tailor the intensity of the shear forces to the specific material. This ensures optimal mixing for both low and high viscosity liquids.

Preventing Damage to Delicate Ingredients: Some ingredients, particularly in pharmaceuticals and food applications, can be sensitive to high shear forces. Variable speed control allows for a more gentle mixing process, protecting these delicate components while still achieving a homogenous blend.

Enhanced Mixing Control: Variable speed control offers greater control over the mixing process. This allows operators to fine-tune the process for different applications, leading to superior results and greater consistency.

Applications of High-Speed Dispersion Mixers:

The versatility of high-speed dispersion mixers makes them valuable assets across various industries. Here are some prominent applications:

Paints and Coatings: High-speed dispersion mixers efficiently disperse pigments and fillers within the base paint, ensuring a smooth, consistent finish.

Pharmaceuticals: These mixers are crucial for uniformly suspending active ingredients within a liquid base, guaranteeing consistent drug delivery and potency.

Cosmetics: Achieving a smooth, creamy texture in cosmetics requires the uniform dispersion of pigments and thickeners. Variable High speed dispersers excel in this role.

Food and Beverages: From homogenizing milk to creating sauces and spreads, high-speed dispersion mixers play a vital role in the food and beverage industry.

Inks and Dyes: Dispersing pigments uniformly within inks and dyes is essential for consistent color and optimal printing results. High-speed mixers achieve this task effectively.

Adhesives and Sealants: Ensuring a homogenous mixture is crucial for the performance of adhesives and sealants. These mixers provide the necessary power and control.

Choosing the Right High-Speed Dispersion Mixer:

With various models available, selecting the right high-speed dispersion mixer for your needs requires careful consideration. Here are some key factors to consider:

Batch Size: The capacity of the mixer should be suitable for your typical batch sizes.

Viscosity of Materials: Choose a mixer with a motor powerful enough to handle the viscosity of your materials.

Desired Shear Force: Evaluate the level of shear force required to achieve uniform dispersion for your application.

Variable Speed Control: Ensure the mixer offers variable speed control for optimal mixing flexibility.

Phoenix Mixer: Your Partner in Efficient Blending

At Phoenix Mixer, we understand the importance of achieving flawless blending. We offer a comprehensive range of high-speed dispersion mixers with variable speed control, catering to diverse needs.

Superior Performance: Our mixers are designed for rigorous use, delivering exceptional mixing results for even the most challenging applications.

Customizable Solutions: We understand that one size doesn't fit all. We offer customizable

Tailored Solutions for Your Specific Needs:

Customized Solutions: We understand that one size doesn't fit all. Our team of experts will work closely with you to design a high-speed dispersion mixer that perfectly suits your unique requirements.

Expert Support: Our dedicated team of engineers and technicians is available to provide expert guidance and support throughout the selection and installation process.

After-Sales Service: We prioritize customer satisfaction. Our comprehensive after-sales service ensures the long-term performance and reliability of your mixer.

High-speed dispersion mixers with variable speed control are essential tools for achieving uniform and efficient blending in a wide range of industries. By choosing Phoenix Mixer, you gain access to superior quality, customization options, and expert support.

Visit:- https://www.phoenixmixer.com/products/lab-equipments/high-speed-disperser/

Contact: +91 91452 40124

0 notes