#differencebetweenwroughtsteelandcaststee

Explore tagged Tumblr posts

Text

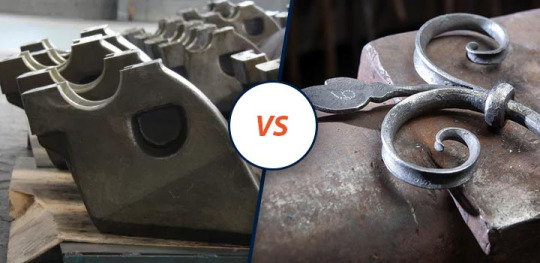

Know The Difference Between Wrought Steel And Cast Steel

Steel is one of the maximum versatile materials in manufacturing, extensively used in industries starting from production to automobile engineering. However, no longer all steel is created equal. Two common sorts, wrought metal and solid metallic, vary of their manufacturing methods, residences, and packages. Understanding the variations among that two paperwork is vital for choosing the right cloth for your unique needs.

1. The Manufacturing Process

The number one distinction among Wrought Steel And Cast Steel lies in how they may be produced. Wrought steel is produced by way of time and again heating and operating the metal via forging, rolling, or extrusion processes. This mechanical process refines the fabric, improves its grain structure, and strengthens the metallic. The non-stop deformation ensures the metallic is free from voids and defects, making it harder and extra ductile.

On the other hand, cast steel is created through pouring molten metal into a mildew in which it solidifies. The casting manner allows for the advent of complex shapes that could be hard or high priced to obtain via forging. While solid steel is commonly less difficult to provide for intricate designs, the rapid cooling at some stage in solidification can result in inner stresses or defects like porosity.

2. Material Properties

Due to the difference of their formation, Wrought Steel and Cast Steel showcase distinct mechanical residences. Wrought metallic is normally stronger, greater ductile, and has better fatigue resistance due to its delicate grain structure. The system of rolling or forging aligns the metal grains, making the cloth able to withstanding high-pressure programs. As a result, wrought steel is frequently selected for structural components wherein power and toughness are crucial.

In comparison, forged steel tends to be extra brittle and less ductile, because it doesn’t undergo the identical mechanical refining manner as wrought steel. However, it has a distinct gain in terms of pliability in design and production. Cast steel may be synthetic into complex shapes without requiring additional machining or meeting, making it ideal for elaborate parts like equipment housings, engine additives, and big business equipment.

3. Applications

The differences in production processes and residences directly influence the applications of wrought and solid steel. Wrought metallic is typically utilized in applications wherein energy and sturdiness are essential, along with in pipelines, girders, shafts, and railroad tracks. These components need to undergo high loads and vicious environmental conditions, and wrought steel’s inherent durability makes it suitable for such uses.

Meanwhile, solid metal is frequently hired in situations that require complicated geometries and shapes. Examples include components like pump housings, engine blocks, and valve bodies. The casting system permits producers to create elements with difficult designs and ranging thicknesses that might be costly or impossible to attain with wrought steel.

4. Cost and Production Efficiency

When it comes to price, there are differences between the two styles of metal. Wrought metal is regularly extra costly to supply because of the tremendous labour and system worried in the rolling and forging procedures. However, its advanced mechanical homes justify the higher price in many applications, especially wherein protection and overall performance are priorities.

In contrast, cast metallic tends to be more price-effective for generating huge or complex shapes. The casting manner lets in for the manufacturing of complex additives with fewer secondary methods, which reduces each hard work and fabric fees. However, the danger of defects and the ability want for submit-casting treatments like warmth remedy or machining can add to the general fee.

5. Conclusion.

And from this view, it becomes possible to understand how important are differences of Wrought Steel And Cast Steel for particular applications. Wrought steel has ductility and elasticity, and has shock resistance, thus, being very good for strength-demanding parts size and flexibility His In contrast with such properties strengthening, melt-iron is poured into Molds in order to produce cast iron. Different shapes and designs are achieved in this way. Although cast iron is often lighter than wrought iron, it also offers the advantage of larger production and more complex geometries Ultimately, a choice must be made between wrought iron and cast iron based on the particular demands of the application.

0 notes