#diesel engine crankshaft

Explore tagged Tumblr posts

Text

Service Providing For Crankshaft Grinding Repair

With regard to the more traditional onsite crankshaft grinding equipment utilized by businesses, we have the most recent design of onsite crankshaft grinding equipment. By using the crankshaft grinding method to repair the crankshaft, we are able to keep the crankpin and main journal's taper and ovality strictly within the manufacturer's specifications and tolerances specified in the handbook. More than 10,000 crankshaft grinding and crankshaft repair services have been completed successfully by our company. For more information on crankshaft polishing, marine crankshaft repair, and crankshaft grinding repair services email [email protected] or call +91 9582647131, tel. 124-425-1615.

#Crankshaft Repair#Crankshaft Grinding Services#crankshaft grinding repair#Crankshaft repair#grinding of crankshaft#metal stitching#crankshaft grinding machine#crankshaft polishing on vessel#Crankshaft Repair Services#onsite crankshaft grinding#crankshaft repair and crankshaft grinding#diesel engine crankshaft#Crankshaft grinding#onsite crankshaft grinding machine#Onsite repair of crankshaft

2 notes

·

View notes

Text

Onsite Crankshaft Grinding & Polishing for Marine Engines | Over 44 Years of Expertise

With over 44 years of experience, RA Power Solutions offers onsite crankshaft grinding and polishing services for marine engines. Their skilled technicians have successfully repaired more than 10,000 crankshafts. Utilizing innovative crankshaft grinding machines, they maintain strict dimensional tolerances as per original equipment manufacturer specifications, ensuring minimal equipment downtime. Currently, they handle crankpin and main journal grinding and repair up to 700 mm in diameter. Our services include a variety of engine models, including Wartsila, Mirrlees Blackstone, Ruston, Allen, Yanmar, MAN B&W, and Daihatsu. For more information on marine crankshaft repair and grinding services, contact them at [email protected] or [email protected], or call +91 9582647131 or +91 9810012383.

#crankshaft grinding#crankshaft repair#onsite repair#insitu crankshaft grinding repair#marine engine#onsite crankshaft grinding#grinding of crankshaft#diesel engine repair#wartsila engine#engine overhauling#onsite crankshaft grinding machine

0 notes

Text

Ship Managers in Dubai approached RA Power Solutions Pvt. Ltd. to report a crankshaft failure on a MAN B&W Diesel Engine Model CME 5L16/24. In a short period, RA Power Solutions specialists boarded the vessel to repair and inspect the crankshaft of the MAN B&W Diesel Engine Model CME 5L16/24. Our technicians are qualified and certified for sailing, allowing them to maintain and repair diesel engines as well as replace crankshafts and other components while the vessel is still at sea. This method lowers the expense of docking or holding the vessel in port for engine repairs. For more information, about MAN Diesel Engine, and diesel engine crankshaft repair, please email us at [email protected], or [email protected], or call us at +91 9582647131 or +91 9810012383.

0 notes

Text

#td42 engine rebuild kit#1HZ CRANKSHAFT#engine rebuild kits#1HZ HEAD#TD42 BILLET CRANK#1hz engine rebuild kit#DIESEL PERFORMANCE#1hz engine for sale#td42 engine for sale

1 note

·

View note

Text

Revitalize your Yanmar Diesel Engine 6N18AL-DV with our expert Onsite Crankshaft Repair services! Dive into our latest blog detailing the precision machining techniques applied to enhance the performance of your engine—experience unrivaled expertise in crankshaft restoration. Visit our page now for insights and solutions. Maximize your Yanmar engine's lifespan and efficiency—trust us for top-notch onsite repair and superior crankshaft machining. Dial +91-9582647131 or email [email protected] for more details on Yanmar crankshaft repair, and insitu machining equipment.

#On Site Crankshaft Grinding Repair#crankpin journal repair#onboard crankshaft repair#crankpin repair machine#Diesel Engine Crankshaft Repair#REPAIR OF CRANKSHAFT OF YANMAR DIESEL ENGINE#insitu machining equipment#yanmar crankshaft repair#ship crankshaft machining#Onsite Crankshaft Repair services

0 notes

Text

0 notes

Text

Onsite Crankshaft Repair Of Small Diameter

We have undertaken repair of crankshafts of small bearing width & diameter successfully installed on the vessel and regarding this you must connect with us at : +91-9582647131, 0124-4251615, or [email protected].

#Onsite Crankshaft Repair#overhauling of marine engine#diesel engine repair#repairing of crankshaft onsite#marine crankshaft repair#marine engine spares#crankshaft grinders#crankshaft grinding#onsite diesel engine repair#overhauling of diesel engine

0 notes

Link

Our highly trained and experienced team provides in-situ crankshaft grinding services as well as repair services. Email [email protected] or call +91 9582647131, tel. 124-425-1615 for detail.

#crankshaft grinding services#crankshaft repair services#crankshaft grinding and repair services#crankshaft grinding#crankshaft grinding repair#onsite crankshaft grinding repair#crankshaft repair#grinding of crankshaft#repair of crankshaft#onsite crankshaft repair services#onsite crankshaft grinding#repair of Crankshaft and diesel engine#grinding of crankpin#crankshaft repair on vessel

0 notes

Text

compiling information about the kineema, because I'm normal

hi. you may remember me from this post talking about how the kineema doesn't have a hood. I've decided to compile all the *other* info I can get on the kineema and comment on it. hopefully this is okay to read

---

let's start with what I could find on fayde

INTERFACING - With its air-cooled, rear-mounted twelve cylinder compression ignition engine driving the rear wheels through a four-speed manual gearbox, the Kineema is able to reach 100 kilometres per hour in 13.5 seconds. And go on to a top speed of 180 kilometres an hour. YOU - Won't it roll over in the first sharp corner? INTERFACING - The high centre of balance is offset by a large battery bank mounted at the bottom of the cabin, feeding all the auxiliary systems and making the Kineema effectively a mobile power plant.

air-cooled: no radiator. I assume this is what those big heat-sink looking things on sides of the engine are for

compression ignition engine: diesel, no spark plugs (diesel engines are named after a guy, rudolph diesel, so I guess in elysium they didn't do that)

rear wheel drive: this is pretty obvious just looking at the thing

100 kilometres per hour in 13.5 seconds: not very fast acceleration compared to modern cars, but the history of cars in elysium is obviously very different to irl

battery bank: this is the only thing keeping the kineema from tipping backwards onto its ass as soon as you accelerate

YOU - "What's it packing there?" (Point to the engine.) KIM KITSURAGI - "Hundred-and-thirty." INTERFACING - I reckon that's a seven-litre V12 there. ENCYCLOPEDIA - Man, that's got to be a major advancement over the KR18GU engine on the old Coupris 40. YOU - "Wait, hundred-and-thirty what?" KIM KITSURAGI - "Kilowatts," the lieutenant replies laconically.

130 kilowatts: ~174 horsepower

YOU - "That's what..." (Rub your chin.) "... a seven-litre V12?" KIM KITSURAGI - "Seven-point-two. Supercharged." The lieutenant is trying to suppress a smug smile. Unsuccessfully. EMPATHY - Saying these words brings him immense joy.

7.2 litre engine: space inside the cylinders. 7.2L/12 = 600cc per cylinder

supercharged: has a supercharger. forces more air into the engine, powered by the crankshaft (as opposed to turbochargers which are powered by the exhaust)

YOU - Run your fingers over one of the steering levers. COUPRIS KINEEMA - The white suede feels luxurious under the touch and the metal clutch handle so very familiar in your palm... INTERFACING - Your fingers waste no time closing around the handle. Clutch disengaged. Release the handle -- clutch drops -- right foot yearns for the familiar touch of the accelerator pedal. You have synced with the machine's mechanical circulation.

YOU - "A *driver* would wear down their right shoe before the left -- the accelerator is on the right. And remember that abandoned lorry cabin we found?"

steering levers: instead of a steering wheel. not exactly sure how they'd work. I *really* don't want it to have differential steering like a zero-turn mower looking at this video of kim driving it looks like the front wheels are the ones steering

clutch handle: instead of a pedal, the clutch is a handle on one of the levers. seems that accelerator and (probably) brake are still pedals

accelerator is on the right: does everyone left-foot brake??? I guess if the clutch handle is standard then that would make sense

ABANDONED LORRY - The glass on the side windows is tinted and covered with dust. You can barely make out the shape of a seat and two steering levers. [...] YOU - Check the pedals. ABANDONED LORRY - You wedge yourself under the steering-wheel to get a better look. Seems like the few tools lying around here -- a hammer, a pair of pliers, a rusty wrench -- have been casually thrown there by the disorganized driver. ABANDONED LORRY - But one odd detail does catch your eye: A piece of sandpaper has been glued to the throttle.

STEERING WHEEL TYPO

---

alright, let's actually take a look at this thing

two door: the kineema has a single driver's seat and two seats in the back. looks like you'd need to move the front seat forward to let anyone else in

suspension: the back wheels look like they have some sort of spring (the axle is connected to it, so how are the wheels being driven??? same with the coupris 40). I assume the front arms also act as a spring

rear view mirror: looks like there's no rear view mirror, since you wouldn't see shit

aerodynamics: bad

seat belts:

¯\_(ツ)_/¯

187 notes

·

View notes

Note

is a crankshaft inert?

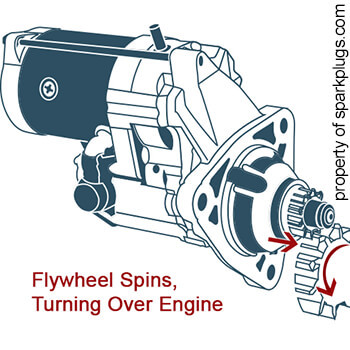

sorry if this doesnt make sense but like you said the crankshaft moves the pistons n then the pistons keep the crankshaft moving so what starts the crankshaft moving to start with?

also why would an engine suddenly die if the pistons keep it moving?

Ok trying this again. Sorry I deleted the previous response on accident and then immediately has the desire to commit violence. That'll teach me for trying to answer a long post on mobile.

Anyway!

1. Yes.

2. This is a starter motor and flywheel.

In modern cars (we're pretending for a minute that handcranks don't exist) when you turn the key in the ignition, the ignition coils take low battery output, convert it to high power input through magnetic coils, and provide that power to the starter motor. The starter motor (pictured above) engages the flywheel, which is connected to the crankshaft. The crankshaft then turns in time with the camshaft (connected by the timing belt) which releases a vaporised mixture of air and petrol into the cylinder. As the crankshaft rotates, the belt makes the camshaft close its valves, the crankshaft moves the piston up which creates compression in the engine, and then the sparkplug ignites the vapour and starts the engine. The piston is then forced downward by the explosion, rotating the camshaft, and so the next piston repeats the same process according to firing order (which varies from engine to engine).

All the handcrank does it replace the job of the starter motor and the flywheel. Instead of electricity forcing the engine to turn over, the handcrank lets you turn the engine over manually on your own.

3. That depends. There's actually a few reasons an engine can die suddenly.

Loss of accelerant. "I know what's wrong with it! It ain't got no gas in it!" This can be anything from you ran out of petrol to your fuel lines being clogged. Remember folks—never buy petrol if the fuel trucks are refilling while you're there. When they reload the fuel into the tanks it stirs up sediment and if you fill your car you might get some of that sediment into your tank. If it gets sucked up it can clog your lines and kill your engine.

Loss of compression. This can be a blown head gasket (which is bad news and most likely to result in an all-around dead engine) or a blown piston. Blown pistons are worse as they have the capacity to damage everything else in the engine. You can also lose compression from cracks in the engine block itself, which is worst news cuz you can't fix that.

Overheating. Metal warps when it gets hot, and too much heat means the pistons don't seal the way they should (or might blow your gaskets). This results in loss of compression and a dead (or weak) engine. Sometimes it can make your engine explode.

Electrical issues. If your alternator has failed then your car battery will drain itself trying to provide power to the sparkplugs (which you need to combust the vapour in the engine). A COMPLETELY dead battery means no sparky to your sparkinators, which means no combustion and therefore the engine won't work. You can also get dead sparkplugs (they wear out) which means the vapour won't combust.

Loss of air. Engines need oxygen to vaporise the petrol, and fire needs oxygen to burn. Without air the engine will die. This is why off-roading vehicles often have snorkels—so the engine can still breathe even if it's submerged. This is also why the only way to stop a runaway diesel is by obstructing the air intake (usually by chucking a rag into the intake).

Retarded timing belt. As we went over earlier, the timing belt is what connects your crankshaft and camshaft. They're meant to move at a certain pace to each other. If that's interrupted in any way (the belt has worn and stretched with time and the teeth don't make contact the way they used to, or the belt has slipped off slightly) then the camshaft and crankshaft won't be aligned, and the fuel won't be released when it needs to be. If the misalignment is bad enough it can kill your engine entirely as the piston will be compressing nothing but air, so no explosion happens. Or, since the timing belt controls when the sparkplugs spark (through the distributor), it can mean that the spark happens when there's low compression in the engine, resulting in poor combustion and a weak (or even dead) engine.

Backup of fumes. Say your catalytic converter (or muffler or tailpipe) gets clogged somehow. Those fumes will back up, to the engine, not allow the resident gases to escape, and will kill your engine. Sometimes it'll make the engine or the backed up part explode, depending on your engine's horsepower (and how much air pressure it's putting out) and where exactly the blockage is.

I'll be here all day.

#blu whos#ford blu#tw r slur#r slur#I'm tagging that so people triggered by the word don't have to see it used in any context

15 notes

·

View notes

Text

The Convoluted Mess of Revavroom's Anatomy

"If we were going to make a Pokémon based on the motif of a car, for example, what would it eat? Would you make it able to suck up gasoline? How would it use the energy it got from that—how would it use that source of power? Even if the design is based on a car, a Pokémon is a living creature, so we would work over and over how to express its "car-ness" and what its source of energy should be."

Does this sound familiar? Probably not. This is a quote by Ken Sugimori, illustrator for Pokémon. In an interview for Pokémon Ultra Sun & Pokémon Ultra Moon Edition: The Official National Pokédex (yes, that is a mouthful), Ken was discussing the process of designing a Pokémon. Nearly 5 years after the guide was published, Pokémon Scarlet and Violet for the Nintendo Switch were released, and among the 102 new Pokémon first spotted in the vast Paldea region, we got two Pokémon that live up to Ken's point.

Varoom, the Single-Cyl Pokémon, and Revavroom, the Multi-Cyl Pokémon.

As you can tell by their designs, Varoom and Revavroom... certainly are genetic anomalies. A lot of people may be confused as to their digestive biology, but no fear, trainers! After having to rewrite this entire post after accidentally deleting it, I, Professor Athena, am here to tell you all about these mechanical marvels.

#0965 - Varoom

Before we can properly dissect what Varoom's diet consists of, we must first ask an important question regarding it...

..what is it exactly?

Well, in terms of origins, Varoom seems to be based on an internal combustion engine, a heat engine used in gasoline and diesel vehicles to convert gasoline into fuel for the car to run.

This actually ties into a small tidbit that we know about Varoom from Pokémon. According to Varoom's Pokédex entry in Pokémon Violet, the metallic part of Varoom is its actual body, the part that controls Varoom's movement and thought patterns. Meanwhile, the deep purple rocks that it carries around are supposedly its source of energy, converting the minerals of said rocks into energy.

While it may seem preposterous for a biotic creature such as Varoom to feed off of abiotic materials, this is an actual behavior present in numerous species of microorganisms. These microorganisms, often referred to as lithotrophs, use the energy of inorganic substrates to feed. Varoom does the same thing, but generalized to the rocks it will carry around with it

Although, while this does answer one question, it raises another all the same:

If Varoom feeds solely off the rocks that lay on its underbelly, then why does it have a "mouth" (which is truthfully a crankshaft)? It can't speak, and it's easy to assume that Varoom as a species doesn't rely too heavily on emotions for communication.

Well, there is a simple explanation for this: It does. The way that lithotrophs turn inorganic materials into energy isn't an evolutionary choice based on effectiveness, but rather necessity. What I mean is, lipotrophic means of consumption are much less practical than the things you and I are able to consume. While this low energy intake works for the sessile microorganisms, there are much better methods of intaking energy, rendering lipotrophy useless for more complex organisms, let alone Varoom. Despite what its in-game mechanics may suggest, Varoom is capable of long-term levitation and floats around the player at impeccable speeds. In order for a 35-kilogram-heavy being to be able to levitate at such speeds, it would require much more than occasional lithotrophy to rely on.

That begs the question of what Varoom actually eats with its "mouth". Since Varoom is devoid of teeth (thank Arceus for that decision), there are one of two reasonable conclusions that we can draw.

Varoom feeds exclusively off liquids and the energy it absorbs from rocks. Seeing as it's a car engine, while animalian in biology, it's still likely that it possesses some traits of IC engines. Given its Poison-typing, it's likely that poisonous/energetic liquids (slime, mucus, gasoline, fuel, etc.) are its main source of energy, leaving it motile for hours on end if it consumes enough.

It has an organ inside of its body that helps properly digest the food it eats once it swallows it. Avians (birds) have an organ for this purpose, being the gizzard. Once the avian swallows its food, the gizzard breaks the food down until it's safe enough for full consumption. A similar thing could be present within Varoom's anatomy, and there's a likely chance that this organ is Varoom's equivalent of a piston. In an IC engine, the pistons move up and down along the crankshaft, generating torque. This could be Varoom's "gizzard", breaking down the food it eats with its up-and-down movement. As for what it would digest if this was the answer, I suspect that its diet would consist of some of the many rock-like monsters that make up the vast world of Pokémon.

There is one more problem, with a plausible solution that could help to decipher the entire anatomical structure of Varoom as a whole, but we will focus on that as we talk briefly about Revavroom.

#0966 - Revaroom

Now, our discussion of Revavroom is going to be very brief, seeing as much of what we said with Varoom doubles for its evolution. However, there is one part of Revavroom that concerns me but will make the whole evolutionary family make a lot more sense.

Do you see anything off?

If you were pointing to the very ominous and out-of-place tongue that Revavroom has on its air filter mouth, you would be correct! This singular detail raises heaps of odd questions, all of which make the anatomy of this Pokémon an absolute mess.

Why is there a tongue in its air filter mouth?

Why does its actual "mouth" not have a tongue?

Why does it still consume energy from the rocks that are magnetically connected to it?

Does this mean that Revavroom could hypothetically eat three meals at once? And if so, why?

I almost gave up trying to decipher this, but then, in the throes of confusion, a paranormal answer spawned. I mentioned Varoom's Pokédex entry in Pokémon Violet but had completely neglected to look over its entry in Pokémon Scarlet; an entry that would explain everything.

Varoom's Pokédex entry in Pokémon Scarlet states that Varoom is said to be an inspirited car engine, with Varoom actually being an unnamed poisonous Pokémon controlling and powering the host, which is what we see.

This... explains it all! Sure, the wording does make it seem like nothing but conspiracy hokum that trainers use to gossip around the campfire with, but this could actually make perfect sense.

All Varoom are born from a parasitized mother, and many from a parasitized father as well. The parasite transfers to the offspring through their genetics (similar to some real-world examples). From there, Varoom is now fully controlled by the spirit possessing it, explaining the levitation and the ability to display lithotrophic traits despite being a complex organism (the spirit is sucking out the energy of the minerals).

Over time, the parasite grew stronger, thus growing a second, actual mouth. The spirit tries to grow past the confines of what we see with Revavroom. Revavroom, now having two mouths to feed, has to get as much energy as possible to sustain the energy it's consuming. Furthermore, tongues and ghosts in Pokémon are symbolic of each other, with the move Lick being one of the first Ghost-type Pokémon moves ever created.

This... was a lot. And yes, I did have to write most of this twice. But, trainers, I'm glad you enjoyed another lesson from Professor Athena! Tune in next time when they go over more burning scientific Pokémon questions! Ta ta!

#pokemon lore#pokemon theory#pokemon#pkmn#pokemon biology#pokemon headcanons#worldbuilding#revavroom#revaroompokemon#varoom#varoompokemon

26 notes

·

View notes

Text

RA Power Solutions was contacted by a leading power generation company based in South Africa. The company is engaged in generating power and supplying to the government-regulated grid. They have multiple nos. of Wartsila diesel generating sets of different models. For more details on the crank pin grinding repair please email us at [email protected] or Call +91-9582647131, or +91 9810012383.

#Wartsila Engine 16V32LN Crankshaft Repair#Wartsila Engine 16V32LN Crankshaft#Wartsila Engine 16V32LN#wartsila 16V32LN diesel generating#Repair of Crankpin of Wartsila 16V32LN Crankshaft#Repair of Engine Wartsila 16V32LN Crankshaft#crankshaft of wartsila Engine 16V32LN#Wartsila Engine 16V32LN crankpin#damaged Wartsila 16V32LN crankpin#Crankpin Polishing

0 notes

Text

Onsite Crankshaft Repair with Pneumatic Grinding Machine | RA Power Solutions

Onsite crankshaft grinding using pneumatic grinding machines is a game-changer for industries like shipping, power plants, and heavy engineering. This innovative approach eliminates the need for crankshaft disassembly, saving time and costs. Portable and lightweight equipment enables expert technicians worldwide to complete repairs up to 700 mm in diameter efficiently. RA Power Solutions offers high-quality, reliable, and cost-effective services. For more details, on the pneumatic grinding machine then email [email protected] or [email protected], or call +91 9582647131 / +91 9810012383.

#crankshaft grinding#grinding of crankshaft#onsite crankshaft grinding#crankshaft repair#diesel engine repair#penumatic grinding machine#onsitecrankshaftgrindinbgmachine#onsite repair#insitu crankshaft grinding repair#insitu crankshaft machining

0 notes

Link

For grinding and polishing of crankshaft onsite all the required tools and machines are provided. Through use of a specially designed compact onsite grinding machine we are capable of undertaking crankshaft grinding on vessel without involving dismantling of the shaft from the entablature. Get detailed information through contacting us at [email protected], 0124-4251615, or +91-9582647131.

#grinding and polishing of crankshaft#crankshaft grinding on vessel#crankshaft grinding#grinding of crankshaft#Crankshaft grinding machine manufacturer#crankshaft grinding and repair#crankshaft repair services#crankshafts#in situ grinding crankpins#onsite diesel engine repair#onsite repair services#onsite grinding and polishing#grinding and repair#Insitu Crankshaft Repair of MAN B&W#crack repair#Crankshaft Grinding Machine#onsite crankshaft grinding machine#insitu crankshaft grinding machine

0 notes

Text

How does an engine contribute to a car's powertrain?

The powertrain in a vehicle is the system responsible for generating power and delivering it to the wheels to propel the vehicle forward. The operation of a powertrain can vary depending on whether the vehicle is powered by an internal combustion engine (ICE) or an electric motor (in the case of electric vehicles). Here's a general overview of how a powertrain works in both types of vehicles:

Internal Combustion Engine (ICE) Vehicle - Combustion Process: In an ICE vehicle, the powertrain starts with the combustion process in the engine. Fuel (gasoline or diesel) mixes with air in the combustion chamber and is ignited by spark plugs (in gasoline engines) or compression (in diesel engines).

Power Generation: The combustion process generates energy in the form of mechanical power, causing pistons to move up and down within the cylinders of the engine. This motion drives the crankshaft, converting linear motion into rotational motion.

Transmission: The rotational motion from the crankshaft is transmitted to the transmission, which consists of gears that allow the driver to select different ratios (speeds). This enables the engine to operate efficiently across a range of vehicle speeds.

Drivetrain: The transmission sends power to the drivetrain components, including the driveshaft, differential, and axles, which transfer power to the wheels. The differential allows the wheels to rotate at different speeds, enabling smooth turns.

Wheel Movement: The power transmitted through the drivetrain causes the wheels to rotate, propelling the vehicle forward or backward depending on the gear selection and throttle input from the driver.

Electric Vehicle (EV) -

Battery Pack: The primary source of power for the EV, storing electricity in chemical form.Powers the electric motor and provides electricity for all electronic devices within the EV.

Battery Management System (BMS): Monitors battery cell conditions, including voltage, current, temperature, and state of charge (SoC).It protects the battery against overcharging, deep discharging, and overheating and helps balance the charge across cells. Ensures optimal performance and longevity of the battery by regulating its environment.

Inverter: Converts DC from the battery pack into AC to drive the electric motor.Adjusts the frequency and amplitude of the AC output to control the motor’s speed and torque. Critical for translating electrical energy into mechanical energy efficiently.

Onboard Charger: Facilitates the conversion of external AC (from the grid) to DC to charge the battery pack. Integrated within the vehicle, allowing for charging from standard electrical outlets or specialized EV charging stations. Manages charging rate based on battery status to ensure safe and efficient charging.

DC-DC Converter: Steps down the high-voltage DC from the battery pack to the lower-voltage DC needed for the vehicle's auxiliary systems, such as lighting, infotainment, and climate control. Ensures compatibility between the high-voltage battery system and low-voltage electronic components.

Electric Motor: Converts electrical energy into mechanical energy to propel the vehicle. It can be of various types, such as induction motors or permanent magnet synchronous motors, each offering different efficiencies and characteristics. Typically provides instant torque, resulting in rapid acceleration.

Vehicle Control Unit (VCU): The central computer or electronic control unit (ECU) that governs the EV's systems. Processes inputs from the vehicle’s sensors and driver inputs to manage power delivery, regenerative braking, and vehicle dynamics. Ensures optimal performance, energy efficiency, and safety.

Power Distribution Unit (PDU): Manages electrical power distribution from the battery to the EV’s various systems. Ensures that components such as the electric motor, onboard charger, and DC-DC converter receive the power they need to operate efficiently. Protects the vehicle's electrical systems by regulating current flow and preventing electrical faults.

In both ICE vehicles and EVs, the powertrain's components work together to convert energy into motion, enabling the vehicle to move efficiently and effectively. However, the specific technologies and processes involved differ significantly between the two propulsion systems.

#electric powertrain technology#conventional powertrain#Electric vehicle components#revolo hybrid car kit#ev powertrain development services#software (SW) platforms for all Electric vehicles components#Battery Management Systems#Inverter#Smart Charger#VCU solutions

3 notes

·

View notes

Text

For more informationengine crankshaft repair equipment and ship crankshaft machining contact us at [email protected] [email protected] or call us at +91-9582647131 or +919810012383.

#ship crankshaft machining#crankshaft repair equipment#crankshaft of YANMAR Diesel Engine 6N18AL-DV#YANMAR Diesel Engine 6N18AL-DV#YANMAR Diesel Engine#crankshaft of YANMAR Diesel Engine#crankshaft of YANMAR Diesel Engine repair#Diesel Engine Crankshafts Repair#onsite grinding & polishing#onsite grinding & polishing of Diesel Engine

0 notes