#dairy transformation Kenya

Explore tagged Tumblr posts

Text

Kenya Dairy Board Partners with ILRI to Boost Milk Safety and Quality in Informal Markets

The Kenya Dairy Board (KDB) and the International Livestock Research Institute (ILRI) have launched a four-year initiative dubbed More Milk: more milk for lives and livelihoods in Kenya that aims at transforming the country’s informal dairy sector, which accounts for about three quarters of the country’s milk supply. L-R: Dr. Fabian Kausche, Deputy Director General Research and Innovation at the…

#dairy sector in Kenya#dairy sector Kenya#dairy sector modernization#dairy transformation Kenya#dairy vendor certification#ILRI dairy project#informal dairy vendors#informal milk markets#KDB initiatives#Kenya Dairy Board#Kenya informal dairy sector#milk handling practices#milk safety in Kenya#milk safety standards#More Milk initiative#nutrition security Kenya.#quality milk solutions#regulated milk markets#safe milk production#small-scale dairy businesses#sustainable dairy practices

0 notes

Text

Automatic Industrial Batch Pasteurizers Market Set to Reach $1530.8 Million by 2035

The Automatic Industrial Batch Pasteurizers market is expected to experience significant growth, with industry revenue projected to rise from $552.9 million in 2024 to $1530.8 million by 2035. This reflects a Compound Annual Growth Rate (CAGR) of 9.7% during the forecast period. The growth is primarily driven by increasing demand for high-efficiency pasteurization systems and greater adoption of automated solutions across the food, beverage, and pharmaceutical sectors.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/automatic-industrial-batch-pasteurizers-market-research-report

Key Applications Driving Market Expansion

Automatic Industrial Batch Pasteurizers are vital in ensuring food safety, extending shelf life, and preserving product quality across several industries. Key application areas include:

Dairy Product Pasteurization: Ensures safe consumption of milk, cream, and yogurt while preserving nutritional content.

Beverage Processing: Widely used in juice, tea, and fermented drinks to eliminate harmful microorganisms without altering taste.

Pharmaceutical Sterilization: Applied in heat-sensitive pharmaceutical solutions to maintain product efficacy and safety.

High-Pressure Processing (HPP): Increasingly used in non-thermal food preservation, particularly in premium, minimally processed products.

Competitive Landscape and Industry Leadership

The market is highly competitive, with top manufacturers continually innovating to enhance product efficiency, automation, and regulatory compliance. Major players include:

Alfa Laval

Tetra Pak

GEA Group

SPX Flow

API Heat Transfer

MicroThermics

Scherjon Dairy Equipment Holland

Stephan Machinery

These companies are expanding their production capabilities and geographical presence to capture demand across new industrial applications.

Growth Drivers and Strategic Opportunities

The Automatic Industrial Batch Pasteurizers market is set to benefit from:

Stricter food safety regulations pushing manufacturers toward reliable, validated pasteurization equipment.

Technological advancements such as energy-efficient and compact pasteurizers tailored for flexible production volumes.

Expanding applications in the dairy sector, one of the largest consumers of pasteurization equipment globally.

Emerging economies are also becoming hotbeds of demand, particularly with rising urbanization and packaged food consumption in regions like Southeast Asia, Africa, and Latin America.

Regional Insights and Market Dynamics

North America and Asia-Pacific dominate the market due to:

Strong food safety frameworks and modernized dairy industries in the U.S., Australia, and Japan.

Rapid expansion of food processing infrastructure in countries like China, India, and Vietnam.

As the supply chain continues to mature — from raw material sourcing to pasteurizer assembly and delivery — manufacturers are expected to optimize production and reduce cost barriers, particularly for small and mid-sized processors in Vietnam, Kenya, and Brazil.

Future Outlook

The Automatic Industrial Batch Pasteurizers market is poised for robust growth, driven by:

Automation and sustainability-focused innovation

Regulatory compliance pressures

Expansion in underpenetrated regions

With strategic investments in R&D and regional expansion, the next decade will be transformative for market players catering to evolving industry demands.

About DataString Consulting

DataString Consulting is a global leader in market research and business intelligence, offering customized solutions across B2B and B2C industries. With over 30 years of combined industry expertise, DataString provides:

Strategy consulting

Comprehensive opportunity assessments

Real-time tracking of high-growth sectors in over 15 industries

Our tailored approach filters out market noise and delivers actionable insights to help you make informed, strategic decisions for sustainable business growth.

#Automatic Industrial Batch Pasteurizers Market#Batch Pasteurization Equipment#Pasteurization Technology Trends 2025#Food Processing Equipment Market#Dairy Pasteurization Machines#High-Pressure Processing Market#Pharmaceutical Pasteurizers#Beverage Pasteurization Solutions#Global Pasteurizer Market Forecast 2035#Food Safety and Automation#GEA Pasteurizers#Alfa Laval Pasteurization Systems#Tetra Pak Batch Pasteurizers#Energy-Efficient Pasteurization#Pasteurization in Emerging Markets#Pasteurizer Industry Growth Analysis#Food and Beverage Processing Trends#Sustainable Pasteurization Technology#Heat Treatment Equipment Market#Automated Food Safety Equipment

0 notes

Text

Grain Gains: Nichrome’s 1kg–10kg Packaging Powering Africa Forward

In the diverse landscape of African agri-economy, where every grain matters, packaging has morphed from a final touch into a dynamic component for profitability, product preservation, and brand attractiveness. From pulses to rice, seed packing to maize bags the ton demand for reliable, efficient, and accurate packaging machines is at full throttle.

At Nichrome Packaging Solutions, we’ve been blazing a trail with packaging solutions — providing full-scale, advanced packaging machines designed to meet diverse needs across Africa and beyond. True to your level of operation, we design systems ranging from high–end VFFS machine systems to versatile electronic weigh fillers tailored to help you streamline your operations and improve productivity while the quality of your packaging outputs is up to standard.

Join us as we explore the evolution of Packaging machines in Kenya, and showcase how Nichrome’s complete offering meets the dynamic needs of Africa’s modern food packaging industry.

Addressing Growing Food Packaging Needs

The agriculture and food processing industries are constantly going through transformative growth. As customers require better quality and fresher goods, the role of effective packaging has never been more important. Today it’s not simply about putting food in a bag; it’s about maintaining integrity, delivering hygiene and providing a product that’s even better than those in competitive markets.

Why is packaging innovation essential?

Efficient & Accurate: Picture a packaging line that runs seamlessly with anything from delicate pulses to tough grains, at blistering speeds.

Quality Assurance: While attaining high output is paramount, the perils of nonconformity due to inconsistent weight, seal integrity, and overall product safety cannot be overlooked—all of which are goals that the conventional packaging methodologies may struggle to achieve.

Flexibility: As the modern consumer needs different sizes of packaging, especially from 1kg to 10kg, which takes care of his home and bulk purchase.

Your partner in packaging innovation — Nichrome

Nichrome is more than a machine manufacturer, we are innovators. We have meticulously designed our machines, including our flagship VFFS machines and intelligent electronic weigh fillers, to meet the multifaceted demands of Africa’s vibrant market. Whether you need a custom-built seed packaging machine, a robust pulses packaging machine or the best-selling rice packaging machine, our state-of-the-art machine lineup is designed for best-in-class performance, durability and reliability.

Automated Packaging Machines on the Rise in Africa

There have been multiple transformations in the food production, processing and packaging industry throughout the continent. Whether in big cities or in the towns of the emerging markets, the need for smart packaging machines is pursuing the growth and the innovation.

Packaging Machines in Kenya: Embracing Innovation

There has been a significant increase in demand for packaging machines in Kenya. From dairy to grains, industries are investing in automated systems to expand production capacity and enhance quality control. Amongst all this, our machines have now become essential in the transition of businesses from manual to high-speed, automatic processes.

Some the leading factors in this are:

Form Fill Seal Packaging Machines: Our machinesensure that every package is sealed off effectively and in a hygienic manner. This is especially important in case of commodities like rice, pulses, grains.

Vertical Form Fill Seal Machines: Known to be extremely versatile, these systems are becoming a popular choice for reliable packaging solutions because they can handle a range of product textures and sizes.

Commercial Food Packaging Machines — The automated packaging function is not the end of a food product only; it includes packaged beverages, personal care products, and even industrial applications. In the case of Kenya, the demand for high efficiency has been expediting adoption of advanced commercial food packaging machines across the country.

Nichrome: A Leader in Automated Solution

Focusing our lens on Africa’s progressive market, Nichrome is an established forerunner in offering high-quality packaging solutions. We are known for our build quality and our machine's ability to adapt to a variety of operating environments. From a packaging machine that South Africa manufacturers trust to advanced machine manufacturer technologies, Nichrome is at the edge of the tech frontier.

Driven by a deep understanding of market requirements, our systems—free from a profit-driven mindset—are designed to address the demands of the moment, offering everything from precise agricultural seed packaging machines to large-scale production lines that deliver seamless speed and unmatched quality.

The Game-Changer: Intelligent Electronic Weigh Fillers

An intelligent electronic weigh filler is a key piece of technology that has transformed the way products get measured and filled in so many packaging lines today. This technology is revolutionary as it solves industry challenges ensuring maximum efficiency and accuracy yet crucial for disconnecting a variety of products like grains, powders and pulses.

How Do Intelligent Weigh Fillers Work?

Traditional ways of filling usually depended on manual treatment or mechanical systems that were at risk of disparity. On the contrary, intelligent weigh fillers have the latest digital systems and sensors to carry out real time monitoring of weight and to ensure that every pack weighed is in accordance with the precise measures needed.

Key improvements include:

Speed: The weigh filler can work at high speeds, which greatly reduces package time and ensures that the production line isn’t idle for long.

Accuracy: Cutting-edge sensors identify micro-changes in weight, erasing overfill and underfill mistakes. Part of keeping the product quality and integrity.

Versatility: These systems can manage an array of commodities from the nuanced profile of pulses to the grainy toughness of maize.

Ease of Integration: Intelligent weigh fillers seamlessly integrate with other packaging solutions such as auger filler packing machines and form fill seal packaging machines, creating a comprehensive production flow that minimizes waste and maximizes efficiency.

Complete Solution for Packaging Various Food Products — Nichrome

In a segment where one size doesn’t fit all, Nichrome’s range of packaging solutions is as diverse as the products it caters to. Catering from grains and rice to pulses and even commodities such as coffee and sugar, our machinery lineup is fortified to fulfill the strict specifications of contemporary food processing.

Grain, Rice, Pulses Packaging and more

Agriculture is the backbone of many economies in Africa and the world at large. The products, including rice, maize, pulses, and so on, feed millions and also form the backbone of strong industries.

Let’s understand how our specialized machinery provide you with best solutions these segments:

Rice Packaging Machine

We manufacture rice packing machine solutions that are both efficient and precise. Whether its 1kg bag or 10kg our systems take care of all fine details right from weight control to air sealing with our rice bag sealing machine technology to make sure that there is no loss of the freshness and quality of the rice.

Grains Packaging Machine

Grains require gentle, specific handling—and our grain packaging machine solutions are a reflection of that philosophy. Designed to strike the perfect balance between care and performance, Nichrome’s machines deliver speed and accuracy to ensure your product reaches the market uncompromised.

At the same time, we know that long-term operational success hinges on investing in quality machinery. With grain packing machine price being a key parameter, our focus on quality, durability, and low maintenance ensures maximum value. Nichrome machines are built to minimize downtime, maximize throughput, and lower manufacturing costs—offering you the best ROI.

Pulses Packaging Machine

Efficiency is the key for businesses packaging pulses. Packaging these delicacies can be a challenge, but our pulses packaging machine is up to the task. As leading pulses packaging machine suppliers in Kenya and across other regions, we know that even minor variations might result in tremendous product losses. Our machines produce consistent fill weights and dependable performance every time, you leave your consumer satisfied.

Maize Packaging Machine

Due to its sturdiness, maize needs machinery capable of handling different consistencies. Our solutions for maize packaging machine are tailored to the unique characteristics of maize kernels so that the final product is uniform and of top quality.

Rice Bag Sealing Machine

Sealing is also an important process, as it contributes to longevity and quality of the product. We provide rice bag sealing machine designed to ensure tamper-proof sealing, keeping rice packaging safe. This new technology is beloved by businesses looking to get ahead in a more crowded market.

Wheat Packing Machine

Wheat is the staple for billions of people in Africa and around the world. The technology behind the wheat packing machine allows to fill each bag perfectly and preserve the product freshness during the whole cycle.

Other Commodities: Broadening the Scope of Nichrome

Our expertise is not just limited to grains & pulses, but also to the principles of efficiency, accuracy and operational flexibility. Below are some extra domains in which our machines do particularly well:

Seed Packaging Machine

One of the most precious agricultural inputs is seed. The seeds can be sensitive products, which is why our seed packaging machine solutions are optimized to ensure they are handled with care.

Coffee Packaging Machine

Freshness is critical for the coffee industry. We use a state-of-the-art coffee packaging machine that guarantees aroma and flavor are sealed into the bags.

Sugar Packaging Machine

It requires equal emphasis on accuracy and hygiene. Our systems are designed to work with sugar’s specific attributes to verify the quality expected from every package.

An extensive range of packaging solutions like ours at Nichrome, means that we cover every packaging need irrespective of the commodity.

Speed & Efficiency: 1kg to 10kg Bagger Performance

Packaging a wide variety of sizes, particularly from 1kg to 10kg, has its own challenges and opportunities. In a complex operational environment, speed and efficiency aren’t simply attractive, they are actually required.

Different products have different packaging requirements. For example, how a 1kg rice bag requires a different filling speed and sealing precision compared to a 10kg grains bag. At Nichrome, our machines are built to be flexible, making customisation for a particular product type and size very easy.

Bagger Speed: Thanks to our world-class baggers, the process remains fast and efficient — no matter how big or small the bag.

Customized Machine Speed: Machine speed adjusted based on the product is enhancing productivity, lowering waste and ensuring that every package meets high-quality standards.

When you’re outputting at incredibly high volumes, every second matters. Tuned for performance, our VFFS systems (Vertical Form Fill Seal) and form fill seal packaging machines guarantee a continuous flow on packaging lines without affecting quality.

The Nichrome Advantage

As we pack up, it is quite evident that the advancement of packaging technology is not a passing phase but rather a paradigm shift that is reshaping the landscape of food production and processing in the African continent. Our journey through the realm of innovative packaging solutions has underscored the incredible benefits of adopting intelligent weigh fillers, advanced VFFS machines, and versatile packaging systems that can handle everything from delicate pulses to robust grains.

At Nichrome, we believe in the simplicity of our mission: equipping your processes with machines that meet the requirement of today, with the capability to scale for tomorrow. We know that your packaging line is the lifeblood of your business in today’s quick moving manufacturing environment. Our cutting-edge solutions help you to reduce downtime, enable you to use fewer resources and increase your throughput so that you can be ahead of your competitors.

Let’s embrace the future of packaging together—because when it comes to delivering excellence in food processing, every second counts and every package matters.

#packaging machines#packaging solutions#VFFS machine systems#electronic weigh fillers#Packaging machines in Kenya#machine manufacturer#intelligent electronic weigh fillers#seed packaging machine#pulses packaging machine#rice packaging machine#Form Fill Seal Packaging Machines#Vertical Form Fill Seal Machines#packaging machine that South Africa#packaging lines#auger filler packing machines#rice packing machine#rice bag sealing machine#grain packaging machine#pulses packaging machine suppliers in Kenya#maize packaging machine#wheat packing machine

0 notes

Text

Cultivating Change: How Collaborative Partnerships are Transforming Agriculture in Southeast Asia, Africa, and Beyond

Agriculture remains the economic cornerstone for millions in developing nations, yet smallholder farmers grapple with challenges like limited technological access, climate volatility, and market exclusion. Amid these hurdles, innovative partnerships between governments, research institutions, NGOs, and the private sector are driving transformative change. By analyzing success stories from Southeast Asia, Africa, and beyond, this paper distills actionable models that blend cutting-edge research with collaborative frameworks to enhance productivity, sustainability, and equity. In an era of climate crises and population growth, scaling such partnerships is not merely beneficial, it is imperative.

Southeast Asia: Digital Tools and Aquaculture Breakthroughs

Digital Green: Empowering Farmers Through Video Technology

Originating in South Asia and scaling across Africa, Digital Green empowers farmers via localized video content produced by and for rural communities. By training farmers to create videos in local dialects, the initiative ensures culturally relevant guidance on best practices, from pest control to irrigation.

Why It Works:

Local Ownership: Farmers co-design content, fostering trust and relevance.

Cost Efficiency: Low-tech solutions (e.g., battery-operated projectors) enable scalability in remote areas.

Visual Learning: Simplifies complex techniques, bypassing literacy barriers.

Impact: Over 1.5 million farmers reached, with adopters reporting 10–30% yield increases (Digital Green, 2023).

Vietnam’s Shrimp Farming Revolution

Vietnam’s shrimp sector exemplifies sustainable aquaculture through tripartite collaboration among researchers, businesses, and policymakers. Innovations include disease-resistant shrimp breeds, eco-friendly feed, and recirculating water systems, reducing environmental harm while boosting yields.

Key Success Factors:

R&D-Industry Synergy: Research institutions like Can Tho University partner with companies to pilot solutions.

Risk Mitigation: Public-private cost-sharing accelerates tech adoption.

Global Adaptability: Models replicated in Bangladesh and Nigeria.

Outcome: Vietnam’s shrimp exports surged to $4.2 billion in 2022, with a 30% reduction in disease-related losses (Vietnam Association of Seafood Exporters, 2023).

Africa: Cassava Innovation and Digital Marketplaces

West Africa’s Cassava Renaissance

Led by the IITA, initiatives in Nigeria and Ghana have revitalized cassava production through drought-tolerant varieties and strengthened value chains. Farmer cooperatives link to processing hubs, reducing post-harvest losses and connecting growers to regional markets.

Drivers of Success:

Climate-Resilient Crops: Varieties like TMS30572 resist pests and thrive in low rainfall.

End-to-End Support: Extension agents provide training, while partnerships with agro-processors ensure market access.

Economic Uplift: Yields increased by 40% in project areas, lifting incomes by 25% (IITA, 2022).

Kenya’s M-Farm: Bridging the Digital Divide

M-Farm’s mobile platform connects 15,000+ farmers to buyers, offering real-time pricing data and bulk sales opportunities. By eliminating middlemen, farmers now retain 70% more revenue.

Why It Works:

Mobile Penetration: 90% of Kenyan households own a phone, enabling rapid adoption.

Data Democratization: Farmers track trends to align planting cycles with demand.

Women’s Empowerment: 60% of M-Farm users are women, enhancing gender equity.

Global Models: Cooperatives and Agro-Industrial Integration

India’s White Revolution: The Power of Cooperatives

Operation Flood transformed India into the world’s largest dairy producer via a network of 15 million farmer-members. Cooperatives like Amul streamlined milk collection, processing, and marketing, ensuring fair prices and reinvestment in rural communities.

Lessons:

Collective Ownership: Cooperatives retain profits locally, funding schools and infrastructure.

Tech Integration: AI-driven quality checks reduced spoilage by 20%.

Brazil’s Soybean and Sugarcane Innovations

Brazil’s agribusiness giants’ partner with EMBRAPA (agricultural research agency) to pioneer climate-smart crops and precision farming. Soybean yields doubled since 1990, while sugarcane ethanol meets 45% of national fuel demand.

Success Factors:

Research Commercialization: EMBRAPA licenses 100+ technologies annually to private firms.

Sustainability Mandates: Zero-deforestation policies in the Amazon coupled with crop intensification.

Strategies to Scale Success

Build Regional Innovation Hubs Create centers where academia, governments, and businesses co-develop solutions tailored to local ecosystems (e.g., Nigeria’s Tech Hubs fostering agri-tech startups).

Incentivize Multi-Stakeholder Partnerships Offer tax breaks or grants for PPPs, as seen in Kenya’s M-Farm subsidies.

Invest in Digital Infrastructure Expand rural internet access to replicate models like Digital Green and M-Farm.

Align Policy with Innovation Streamline regulations for GM crops or drone usage, as Vietnam did for aquaculture tech.

Prioritize Farmer Training Deploy mobile academies (e.g., India’s Kisan Rath app) for continuous skill-building.

Conclusion

From Vietnam’s shrimp farms to Kenya’s digital marketplaces, collaborative partnerships are redefining agriculture. These models prove that combining local knowledge with global innovation can overcome systemic barriers. To replicate success, developing nations must prioritize inclusive policies, invest in scalable tech, and foster ecosystems where farmers, researchers, and businesses thrive together. The future of agriculture lies not in isolated efforts but in collective, adaptive resilience.

#AgricultureInnovation#SustainableFarming#CollaborativePartnerships#SmallholderFarmers#DigitalTools#ClimateResilience#SoutheastAsia#AfricaAgriculture#DigitalGreen#ShrimpFarming#CassavaRevolution#MFarmKenya#CooperativeModels#AgroTech#GlobalFoodSecurity

0 notes

Text

Rare Archealogical find in kenya

Kenyan Thropus product contains a variety of premium nuts, seeds, and superfruits thus creating the optimal nutritional combination of antioxidants, omega fatty acids, protein, fiber, vitamins, and minerals. The “seed” for SuperFuzion was planted in Founder Jackie as a child growing up with her father who believed passionately in the power of healthy eating to transform lives. Jackie’s strongest memories were of family dinners spent “talking business” — over healthy food, of course! Jackie began pursuing her dream when she decided to build a healthy “superfoods” company. Inspired by a “super fusion” of family, friendship, and food, SuperFuzion was born! We hope SuperFuzion transforms your life!

Some people call our Blend a crumble because they sprinkle it on salads, smoothies, yogurt, ice cream, fruit, pasta – you name it.

We like to say that SuperFuzion® Blend is an outrageous fusion of superfoods, so packed with good-for-you stuff that you can feel good about eating! And it’s so yummy, that you’ll feel like you’re indulging, too! It’s also “Better Than Granola!TM,” since most granola is predominantly oats and sugar and it’s cooked, while SuperFuzion® Blend is mainly “the good stuff,” with a touch of gluten-free rolled oat and it’s raw for maximum nutrition – it also has no added sugar!

With 14 superfoods – supercharged with health-boosting and disease-preventing nutrients, SuperFuzion® Blend is an excellent source of antioxidants, omega fatty acids, fiber, protein, vitamins & minerals. It’s all-natural, gluten & dairy-free, vegan, and paleo-friendly. …And it’s peanut-free and cashew-free, too. It’s nutty and delicious. SuperFuzion® Blend is simply a healthy and delicious addition to any meal or snack!

1 note

·

View note

Text

NICHROME INDIA AT PROPAK AFRICA

On 8th March 2022, the world's industry headed to Johannesburg to visit Propak Africa 2022. Propak Africa is Africa's leading packaging, printing, food processing, plastics and labelling trade exhibition. It’s the place to see latest innovations and technologies, packaging initiatives and cutting-edge machinery, products, consumables, systems and services.

Whether as an exhibitor or a visitor, Propak Africa offers 4 exciting days to meet knowledgeable exhibitors, network with suppliers and service providers, source cutting-edge products & technologies, and enjoy live demos, free seminars and more.

Nichrome at Propak Africa

Nichrome India was at Propak Africa, with a stall to display its offerings, network with industry representatives, and showcase its expertise in packaging.

Nichrome is already a well-known name in Africa and other parts of the world. A highly reputable packaging machine manufacturer, with its own impressive design and manufacturing capabilities, Nichrome has presence in 45+ countries of the world and over 10,000 installations. So, their participation in Propak Africa certainly helped to expand their footprint in Africa and neighbouring countries.

Nichrome and Africa

Nichrome is committed to Africa and to its industry. For the last 25 years, they have partnered with food, pharma and non-food manufacturers and marketers to enhance their packaging and retail value.

Nichrome has several achievements to their credit. They helped to successfully launch oil and drinking yogurt in flexible pouches and reintroduced milk pouches in Kenya. They have developed and installed rice plants and efficiently handled turnkey mini dairy plants in Kenya. Nichrome also introduced the penta seal pouch in Africa.

Today, they have a long list of esteemed clients and many successful projects in Africa. The aim is to go further and deeper, growing their reach and improving their support network so they can serve more and more industries across Africa.

Infinite possibilities with Nichrome

For startups, medium sized businesses or large MNCs, for existing or emerging applications, Nichrome offers infinite possibilities in packaging solutions. That too, with one-stop convenience.

With Nichrome’s strong thrust on R&D, they partner with customers, study their market and specific application, and innovate integrated solutions that deliver relevant advantages.

It could be a small variation in a pouch format or customization of an existing machine; a pro-actively developed filling system or consultancy & system design for a complete packaging plant - Nichrome has the expertise, capabilities and innovation to transform productivity and enrich customer relationships in endless ways.

Nichrome’s packaging expertise

Since Nichrome developed India's first indigenous milk packaging machine in 1977, they have been at the forefront of next-generation packaging technologies; a brand trusted for its rich legacy of pioneering innovation, extensive domain knowledge and manufacturing competency in packaging systems.

Nichrome’s expertise covers the complete spectrum of food, non-food and pharma applications. Snack packaging machine, milk packaging machine, powder filling machine, sugar packaging machine, oil filling machine, pulses & grain packaging machine, bottle filling lines, tin filling lines, mini dairy plants, tablet/capsule packaging lines, blister packaging – the list of Nichrome’s offerings can go on and on. Nichrome also offers filling systems and integrated packaging systems for a wide range of applications.

Nichrome has also partnered with renowned international companies for some technologies, especially for the Pharmaceutical sector. For enterprises big and small, for applications existing and emerging, Nichrome offers infinite possibilities in integrated, automated packaging solutions - as they partner with customers through the complete lifecycle, offering application-specific solutions, backed by dependable service and support.

Conclusion

In case you missed the Nichrome stall at Propak Africa, please contact Nichrome India directly, to discover their latest, cost-effective solutions for Africa’s industry. The leading manufacturer of packaging machines India, Nichrome has proved itself overseas as well with presence in 45 countries and more than 10,000 successful installations worldwide. So, customers in Africa or anywhere can expect top-of-the-line technology and reliable service at any location.

0 notes

Text

Milking Done Easy With Delmer

The Delmer Group is globally famous in the Weighing Technology and manufacturing Machines. They have an immense experience in the Electronics and Mechanics of Machine Making. They provide high end technology products at a budget friendly price range and of good quality.

Delmer is known for its milking machines for simple automatic milking solutions it has easy to use wheel-supported chassis which is important for milking systems. Our different components have been specially designed to provide a well-balanced and lightweight cluster, high milking performance.

It is essential to ensure good animal health and milk quality. Good milking systems results into good management of milk. Our milking parlours use high rate technology to guarantee high-performance milking.We provide top quality results and easy to use for the customer.

Our rotary machines are in outstanding working conditions. It gives high milking performance and effectiveness for constant and regular operations. Our milking trolleys are easy to handle and use.

Made in Italy, our milking buckets guarantee durability and reliability, buckets are in different litre capacities and materials. We give variety components for milking buckets, allowing you to create a customised milking solution according to your dairy.

RTS lines in milking units provides clusters significantly increase operator efficiency and milking rate. Our high quality automatic cleaning system and rapid milk cooling will make milk of top-quality.

Our milk metering devices can be merged with our milking control units. The data collected during milking can be transformed to the herd management software to see daily herd management.

Pulsators have all different types from the easiest to the most useful. Pulsators are the best solution for bucket and mobile milking systems. They are reliable and long lasting electronic pulsators, durable, robust and are the excellent for fast, real time and complete milking.

Milk Pumps put milk from the receiver to the milk tank. Milk transfer is swift and gentle so that no bio-chemical alterations occur within the milk, altering the quality of the product. Our Vacuum Pumps are used for many type of milking system or herd size, for milking trolleys and buckets.

We are waiting to serve you with our machines. We are available in Italy, India, USA, Uganda, Kenya and UAE. You can also check our work on our social Medias.

0 notes

Text

Kenya Co-operative Creameries taps SAP technology

Kenya Co-operative Creameries taps SAP technology

With low operational visibility, slow, outdated processes and a vision of growing its footprint, one of Africa’s oldest dairy processor & distributor turned to technology to transform its operations and get it in shape for the 21st century digital economy.

The Kenya Co-operative Creameries (KCC) was founded in 1925 and is the largest dairy distributor in East Africa. The company was registered…

View On WordPress

0 notes

Text

ANIMAL HEALTHCARE MARKET ANALYSIS

Animal healthcare focuses on effective animal health management through diagnosis and treatment of various diseases in animals.

Statistics:

The global animal healthcare market is estimated to account for US$ 61,168.31 Mn in terms of value by the end of 2027

Global Animal Healthcare Market: Drivers

Increasing consumption of meat, milk and other animal byproducts is expected to boost growth of the global animal healthcare market over the forecast period. For instance, the USDA National Agricultural Statistics Service (NASS) estimated November 2019 U.S. milk production at 17.440 billion pounds, 0.5 percent higher than November 2018.

Moreover, increasing prevalence of foodborne and zoonotic diseases is also expected to propel growth of the market. For instance, according to May 2019 report of the Centers of Disease Control and Prevention (CDC), salmonella infection (salmonellosis) causes approximately 1.2 million illnesses and 450 deaths annually, in the U.S. and in 2018, there were 18 reported outbreaks, 15 of which were linked to food.

Statistics:

North America held dominant position in the global animal healthcare market in 2019, accounting for 33.1% share in terms of value, followed by Europe and Asia Pacific, respectively

Figure 1. Global Animal Healthcare Market Share (%), by Region, 2019

Source: Coherent Market Insights Analysis (2020)

Global Animal Healthcare Market: Restraints

A lack of surveillance and diagnostics for zoonotic diseases in developing economies is expected to hinder growth of the global animal healthcare market.

Moreover, stringent regulations over use of antibiotics in animal feed is also expected to limit growth of the market. For instance, in the U.S. state of California Senate Bill 27—known as SB 27—aims to minimize the feeding of antibiotics to animals and it prohibits the use of antibiotics “solely for purposes of promoting weight gain or improving feed efficiency.”

Statistics:

The Production Animal segment was valued at US$ 26,374.5 Mn in 2019 and is forecast to reach a value of US$ 39,159.8 Mn by 2027 at a CAGR of 5.1% between 2019 and 2027

Market Trends/Key Takeaways

In the U.S., beef export has declined, which is expected to hinder growth of the market. For instance, according to the USDA National Agricultural Statistics Service (NASS), in November 2019, beef exports from the U.S. totaled 245 million pounds, 21 million pounds below the November 2018 total.

Asia Pacific is expected to witness significant growth in the market, owing to increasing production of milk. For instance, according to the UN's Food and Agriculture Organization (FAO), in 2018, India produced 186 million tons of milk, which was 22% of that year's global total milk production of 843 million tons.

Regulations

North America

In order to reduce the use of antibiotics as growth promoters in animals, the Danish Veterinary and Food Administration (DVFA) restricted the use of fluoroquinolones (banned) and cephalosporins in 2002. In 2010, an industrial voluntary ban (Sweden, France and Denmark) on the use of cephalosporins was implemented for a 2-year period, and a Yellow Card initiative was implemented in Denmark, targeting the largest consumers of antibiotics in the swine production industry. As a result, the consumption of antibiotics from January 2011 to June 2011 was 25 % lower compared to the same period the previous year.

2005: FDA banned the use of Baytril – a fluoroquinolone antibiotic – also known as enrofloxacin – in chicken and turkey. The antibiotic leads to the emergence of antibiotic resistant bacteria such as Campylobacter in humans, as its chemical composition is similar to that of Cipro – a human antibiotic – which is a common prescription drug to treat foodborne illnesses in humans.

2012: Maryland banned the usage of arsenic-based drugs in chicken feed. However, it is used across other states in the U.S. The drug received FDA approval as its arsenic content is within safe limits for human consumption.

2014: The FDA directed 26 major pharmaceutical companies in the U.S. to cease production of weight-gain drugs for animals by December 2016. It further directed the companies to stop OTC sales of antimicrobials such as Roxarsone (sold under the brand 3-Nitro) administered to livestock through feed and water, which are also used in human medicine. The objective of this move is to reduce health risks associated with the consumption of antimicrobial treated meat products.

Ractopamine hydrochloride – a growth promoter drug – is banned in Europe and 160 other countries such as China, Taiwan, Russia, India, Turkey, Iran, Egypt, Kenya and Zimbabwe. However, its use is permitted in the U.S., Brazil and Canada to increase muscle production in swine, turkey and cattle. Since December 2012, meat imports in Russia from countries such as the U.S. is subject to ractopamine-free certification.

U.S.

GROUP I. Drugs with No Allowable Extra-label Uses in Any Food-producing Animal Species

CHLORAMPHENICOL

CLENBUTEROL

DIETHYLSTILBESTEROL (DES)

FLUOROQUINOLONE–CLASS ANTIBIOTICS

GLYCOPEPTIDES — all agents, including VANCOMYCIN

MEDICATED FEEDS

NITROIMIDAZOLES-all agents, including DIMETRIDAZOLE, IPRONIDAZOLE, METRONIDAZOLE and others

NITROFURANS — all agents, including FURAZOLIDINE, NITROFURAZONE and others

GROUP III. Drugs with Special Restrictions for Grade "A" Dairy Operations

Grade A Pasteurized Milk Ordinance

NON-MEDICAL GRADE DIMETHYLSULFOXIDE (DMSO) — no use or storage allowable

DIPYRONE — no use allowable

COLLOIDAL SILVER — no use or storage allowable

SYSTEMICALLY–ACTING DRUGS THAT ARE APPLIED TOPICALLY (including Fenthion, Famphur and Xylene, Phosmet, Levamisole and all ivermectins and avermectins — no use allowable

GROUP II. Drugs with Restricted Extra-Label Uses in Food-Producing Animal Species

ADAMANTANE & NEURAMINIDASE INHIBITORS in all poultry, including ducks – these agents are approved for treatment or prevention of influenza A

CEPHALOSPORIN–CLASS ANTIBIOTICS except CEPHAPIRIN in all classes of cattle, chickens, pigs and turkeys – ELDU restrictions apply to ALL PRODUCTION CLASSES OF MAJOR FOOD-ANIMAL SPECIES.

1) No ELDU for purpose of disease prevention

2) No ELDU that involves unapproved dose, treatment duration, frequency or administration route

3) Agent must be approved for that species and production class

– ELDU restrictions DO NOT APPLY to minor–use food animal species.

GENTIAN VIOLET — prohibited for use in food or feed of food-producing animal species

INDEXED DRUGS — some exceptions for minor-use species

PHENYLBUTAZONE — in female dairy cattle (20 months of age or older)

SULFONAMIDE–CLASS ANTIBIOTICS — in lactating dairy cattle– approved uses are allowed for Sulfadimethoxine, Sulfabromomethazine and Sulfaethoxypyridazine

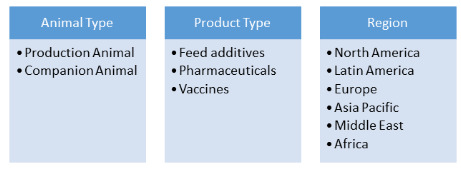

Segmentation:

Global Animal Healthcare Market: Competitive Landscape

Major players operating in the global animal healthcare market include, Bayer AG, Boehringer Ingelheim GmbH, Cargill, Inc., Ceva Santé Animale, Eli Lilly and Company, Koninklijke DSM N.V., Merck & Co., Inc., Novartis AG, Nutreco N.V., Sanofi S.A., SeQuent Scientific Ltd., Virbac S.A., Vétoquinol S.A., and Zoetis Inc.

Global Animal Healthcare Market: Key Developments

Major players in the market are focused on adopting partnership and collaboration strategies to expand their product portfolio. For instance, in 2018, Boehringer Ingelheim Animal Health collaborated with Kamraan Veterinary Medicine Co. Group, a veterinary medicine wholesaler and retailer in U.A.E, for marketing veterinary medicines.

Major players in the market are also focused on launching new products to expand their product portfolio. For instance, in March 2020, Kinetic Vet, an animal health company, launched ArmourGuard RTU, an EPA-approved spray-on antimicrobial biosecurity solution that provides continual antimicrobial activity against microorganisms for up to 90 days.

About Us- Coherent Market Insights is a global market intelligence and consulting organization focused on assisting our plethora of clients achieve transformational growth by helping them make critical business decisions. What we provide: Customized Market Research Services Industry Analysis Services Business Consulting Services Market Intelligence Services Long term Engagement Model Country Specific Analysis Mr. Shah

Coherent Market Insights Pvt.Ltd. Address: 1001 4th Ave, #3200 Seattle, WA 98154, U.S. Phone: +1–206–701–6702 Email: [email protected]

0 notes

Text

Boomtown - A World is Grown

While the cows are away the Boomtowners play. From the fields of a dairy farm every year for just a few days a whole whimsical world grows.

This year Boomtown is on even more of a mission. Known being ahead if it’s time and quite possibly the most forward thinking festival, being green and a philosophy towards sustainability has always been in the festivals heart.

This year they have taken things much further expanding and evolving their green mission. The festival are providing advice and incentives on how to travel greener including the opportunity for free Wednesday entry as a thank you to everyone who supports by arriving by public transport.

There is also an education on Campsite Waste and leaving no trace through debunking the myth that leaving your tent is a charitable move, and spreading the word about how they can't be recycled. Boomtown states that this is a main focus for this year, encouraging all to work together to create positive change.

There is a dedicated Eco Campsite, in collaboration with Environmental Recovery Solutions. This is located in the Downtown Bowl (previously DSTRKT 5 camping) as this was identified as the area with the most tents and campsite waste left behind in 2018, and therefore, the ones that will need the biggest help to transform it into a zero waste space.

The phrase 'Reduce, Reuse, Recycle' has been adopted as a mantra for the festival. In 2018 Boomtown signed the Drastic on Plastic pledge and banned plastic straws and serveware (opting for compostable solutions instead) and encouraged everyone to bring their own reusable bottle and coffee cup. From this year there will no longer be any plastic water bottles sold on the festival site. Festival goers are encouraged to purchase a reusable Boomtown branded bottle or bring their own from home! Visitors are assured there will be plenty of water points around the site as well as WaterAid refill stations.

The Drastic on Plastic campaign was set up by the Association of Independent Festivals (the AIF is 60+ independent festival members including Boomtown) in 2018, whereby all participating festivals have committed to banning the use of plastic straws on-site as a minimum first step, and pledged to eliminate all single-use plastic at their events by 2021.

Boomtown’s waste management plan has been developed with their waste contractor and sustainability is at the core of all planning and on-site stages. A 40% recycling rate target has been set (the festival achieved 35% last year) with a long-term goal of reaching 50% in three years.

Going even further Boomtown has made a commitment to sustainably sourced food. This includes an increased amount of vegetarian and vegan stalls, and a strict criteria that all traders who apply to Boomtown must meet including: All meat and dairy products must be British and from a Free range source, providing local produce where possible, providing organic and seasonal produce where possible and using Fair Trade products. In addition, to limit the impact they make throughout the five-week build process Boomtown has reduced its meat consumption by having Meat Free Mondays for all crew.

Quite possibly the most ambitious and exciting of Boomtown’s green directives is to grow a tropical forest. Boomtown organisers have connected with reforestation and culture change charity ‘TreeSisters’. For over a decade TreeSisters have been planting fast-growing tropical trees across Madagascar, India, Kenya, Brazil, Cameroon and Nepal. TreeSisters exists to make it as normal to give back to nature, rather than as it is currently, to take nature for granted.

Boomtown recognised the urgency of supporting projects like this and vehemently believe that there really is no more important thing that we could be doing right now. By partnering with such a charity, along with the size and reach Boomtown has, and all the passion from those involved there can only be an immensely positive outcome.

Quite beautifully Boomtown are planning to plant one tree for every person who has bought a ticket to the festival, that’s a incredible 48,000 trees! They feel this is just the very beginning though and want to see just how huge a forest can be grown with the incredible Boomtown community. Boomtown see this not just as an act to clean up our carbon, but as a gesture of love back to the world that gives what is needed to help restore the balance.

Boomtown has built a blue print of a sensible sustainable system which may be ambitious but is certainly achievable. The green core has become merged completely with the ethos and structure of the festival itself. It does make you wonder why towns and cities that exist all year round can’t adopt such directives, in the least there’s certainly some lessons they could learn.

The festival founders have created a documentary about the evolution of the festival. In this short film you get to meet the people behind the show as they discuss big dreams, how they grew a festival from seed to sapling, and the sustainable future of Boomtown.

https://youtu.be/7vGfn9gxbtk

This years Boomtown line-up is as eclectic and groundbreaking as always, including:

Ms. Lauryn Hill, UB40 Ft Ali Campbell & Astro, The Streets, Ms. Dynamite, Salt-n-Pepa, Goldie Lookin Chain, Groove Armada, Prophets of Rage, Seth Lakeman, Jurassic 5’s Soup presents: Fullee Love Collective, Ozomatli Ft Chali 2na, Shy FX, Nubya Garcia, Asian Dub Foundation, Carl Cox, Chase & Status, Altern8, Napalm Death, Hotsteppas, Kenny Dope, Swindle Live, Eva Lazarus, Gentlemen’s Dub Club, Cut Capers, Dizraeli, Bellatrix, DJ Yoda, Dreadzone, General Levy, Gaudi, Fizzy Gillespie, Count Bassy, DJ Chris Tofu, Don Johnston, Ed Cox & E Coli, Sacha Dieu, Hiphoppapotamus, Karl Phillips & The Rejects, Backbeat Sound System, Danny Wav, Snazzback, The Boot Hill All Stars, The Brandy Thieves, and Wiltshire’s best known punk duo 2 Sick Monkeys, plus many many more.

youtube

Photo Credits:

1.Leora Bermeister

2. Scott Salt

3.Charlie Raven

4. Jodie Hartley

5. Derek Bremner

6. Derek Bremner

7. George Harrison

8. Poster

7. Derek Bremner

0 notes

Text

How the USAID Shutdown Threatens Kenya’s Agriculture Ahead of the Planting Season

The imminent shutdown of the United States Agency for International Development (USAID) this Friday threatens to derail Kenya’s agricultural sector just weeks before the crucial planting season, potentially affecting millions of farmers across the country who depend on various American-funded programmes. The shutdown, which will place all USAID direct hire personnel on administrative leave…

#agricultural development Kenya#climate resilience Kenya agriculture#county agriculture support Kenya#dairy farming impact USAID shutdown#food security Kenya#food systems Kenya#impact of USAID shutdown#Kenya agribusiness crisis#Kenya agriculture crisis#Kenya agriculture funding#Kenya agriculture transformation#Kenya Crops and Dairy Market System#Kenya economic impact USAID#Kenya farming challenges#Kenya irrigation projects USAID#Kenya maize farming USAID#Kenya planting season 2025#Kenyan farmers affected by USAID#Strengthening Agricultural Water Innovations Kenya#USAID agricultural programs#USAID agriculture projects halted#USAID dairy and maize projects#USAID Feed the Future Kenya#USAID food aid Kenya#USAID funding freeze#USAID rural development Kenya#USAID shutdown Kenya#USAID smallholder farmers#USAID soil fertility programs#USAID-supported projects Kenya

1 note

·

View note

Text

Top Investment Opportunities in Tanzania 2020

Tanzania is a thriving hub of East African markets and its rapidly joining the ranks of its neighbors, such as Kenya, in revitalizing its economy. This growth has resulted in a rush as many investment opportunities emerge in the country. If you are looking for an investment opening in Tanzania, the following are some of the opportunities you can exploit;

Logistics and Warehousing

Tanzania lags behind in its road, railway, and airway infrastructure. However, the government has been working to uplift this situation with increased investments in the sector. This is done by engaging international companies to create state of the art road networks which are strategically linked to railways lines. The networks support both the sea and dry ports. Through company registration in Tanzania you can provide legal logistics and warehousing in the country. Transportation of cargo in Tanzania is lucrative due to the active port and the need to supply landlocked countries such as Uganda and Rwanda. An investment in the coordination of logistics and warehousing is a promising venture in Tanzania in 2020.

Agribusiness

Another good investment is agribusiness in Tanzania. The country has thriving agriculture that is split between food crops and cash crops. However, marketing these crops has been a challenge for many farmers. Therefore, closing this barrier is an opportunity that can be exploited successfully. The market for many products in Tanzania is available locally, where it is sold in urban areas. You can also supply the international market through exports, which are well regulated in Tanzania. Lucrative opportunities exist in chicken, dairy and beef cattle, cashew nuts, cloves, coffee, and fruits.

Rental Services

Tanzania thrives with a very communal culture that is still reliving the famous ujamaa or socialist system. Remnants of this culture are seen in the close association of people in ceremonies, music concerts, religious and political gatherings, and even sports. This can be exploited by setting up rental services focused on events management and facilities supplies. These include public address systems, events, tents and chairs, MCs, among others. Company registration in Tanzania provides you with a license to organize for events which will allow access to the thriving market.

Tourism and Travel

Tanzania is a tourism hub in East Africa, especially supplied by unique attractions. You can provide traveling services for tourists to these centers and reap the associated services such as accommodation, promotion, and booking services. The tourism sites include the Serengeti National Park, Mt Kilimanjaro, and the Ngorongoro Conservatory, among others. Tourism is well established in the country, thus presenting numerous niches that you can invest in 2020. Meeting the needs of tourists, both local and international is a viable investment in Tanzania that can be easily tapped by providing quality travel, accommodation, and reliable booking services in the country.

Clean Water Services

Another lucrative investment in Tanzania is providing clean drinking water in the country's residential areas. Tanzania is grappling with the lack of clean drinking water, which means that its growing urban population is undersupplied. The drainage systems in the country have rendered many sources unhygienic due to contamination. Therefore, if you organize on how water can be economically ferried from clean sources, purified and supplied to residents, you are in for a profit. Water is a basic need that is consumed in huge amounts daily. The residents pay for transport, purification, and storage, which can be done economically in huge amounts. As the governments close in on the purification of public supplies, 2020 may be just your year in providing clean water in Tanzania.

Food Processing

The thriving agricultural industry is complemented by food processing. In Tanzania, processed food is taking hold in urban centers due to costs and storage. Many people do not shy away from mildly processed food hence creating a lucrative market. Processing food makes it easy to break bulk, package, and price. Your customers will mostly be retail and wholesale business and sometimes individual customers if you open a retail center. This opportunity allows you to reap high margins from buying raw food from the farms and transforming it into the consumer market. Most farmers lack the technical know-how or capital to dub in processing. Many businesses will gladly outsource this service to focus on their core business.

0 notes

Text

Preserving Purity: Nichrome's Milk Packing Machines Nurturing Growth in African Dairy Industry

In the heart of Africa, where the sun-kissed savannas meet bustling cities, a revolution is quietly unfolding in the dairy industry. At the forefront of this transformation are the ingenious milk packaging machines by Nichrome, seamlessly blending technology and tradition to ensure the freshest milk reaches every corner of the continent.

In the rolling hills of Kenya, where the Maasai's cattle graze under the vast African sky, the significance of milk is deeply ingrained in the culture. Enter the stage, the milk packaging machine in Kenya, a silent hero empowering local dairy farmers to share the goodness of their produce with the world.

Advantages of having Nichrome’s milk packing machines for Dairy Industry

Preservation of Freshness:

Nichrome's milk filling machines are designed with a primary focus on preserving the freshness of milk. Advanced technology ensures that each package seals in the natural goodness, extending the shelf life and maintaining the quality of the dairy product.

Precision and Efficiency:

The precision engineered into Nichrome's milk pouch packaging machines guarantees an efficient and accurate packaging process. From the milk filling machine to the VFFS packaging machine, every component works seamlessly to minimize wastage, enhance productivity, and optimize resources.

Versatility in Packaging Formats:

Nichrome understands the diverse needs of the dairy industry. Our milk packaging machines offer versatility in packaging formats, accommodating various sizes and types of milk containers, from pouches to bottles. This adaptability is crucial for meeting market demands and consumer preferences.

Automation for Increased Productivity:

Embracing automation, Nichrome's machines significantly increase productivity and reduce operational costs. The integration of smart technology not only streamlines the packaging process but also minimizes the risk of errors, ensuring consistency and reliability in every package.

Reduced Downtime and Maintenance:

Nichrome's dedication to reliability extends to the durability of their machines. With robust construction and advanced engineering, these milk packaging machines are built to withstand the rigors of continuous operation, minimizing downtime and maintenance costs.

Vertical Form Fill Seal Machines by Nichrome

In the realm of innovative packaging solutions, Nichrome's Vertical Form Fill Seal (VFFS) technology emerges as a meaningful change, redefining efficiency, versatility, and reliability in the packaging industry.

Filpack CMD ALPHA

FILPACK CMD Alpha is another efficient packaging solution for milk and other liquids. Built shorter than conventional machines, it also occupies less floor space as no side opening is required. The impulse seal system is controlled through solid state control technology, and there is a specially designed film roll unwinding mechanism for smooth bag pulling.

FILPACK CMD Alpha offers twin heads so you can pack two different products at the same time. You can even conduct maintenance on one track while the other is in operation.

Filpack Servo 12K

This machine is the fastest milk pouch packaging machine, with a speed of 12,000 packs/hour. It can pack CSPP pouches of 200 ml, 500 ml and 1000 ml with equal ease and accuracy. FILPACK SERVO 12K is a heavy duty machine with simple maintenance-friendly construction. It is built for hygiene with product contact parts of stainless steel and a UV film sterilisation system for the packaging material.

Independent balance tanks offer flexibility to manage single or different products simultaneously.

Conclusion:

The future is bright for Africa's dairy sector, with the milk packaging machine in Kenya and beyond playing a pivotal role. Nichrome's continuous innovation ensures that the freshness of Africa's milk becomes a global standard, fostering a legacy that transcends borders.

In conclusion, as Africa's dairy industry evolves, Nichrome's milk packaging machines emerge as catalysts for positive change. They are not just machines; they are enablers of dreams, custodians of purity, and architects of a future where every sip of milk tells a story of growth and prosperity.

#milk filling machine#powder filling machines#vertical form fill seal machines#powder packaging machine#milk packaging machine#milk pouch packing machine#automatic filling machine#automatic packaging machines

0 notes

Photo

Illustration Photo: Through the creation of solar powered micro-grids, Maasai of the Moduli district in northern Tanzania are receiving power in their mud huts inside their bomas (corralled community). The solar power is providing life-saving water purification, a shared refrigerator for food and medicines, a computer for the community, and lights for the cow and goat corrals to frighten away the hyenas. (credits: USAID / Flickr Creative Commons Attribution-NonCommercial 2.0 Generic (CC BY-NC 2.0))

Call for applications: AECF Innovation Fund - Support #Innovations in #CleanEnergy technologies for #Africa’s #RuralCommunities, #CleanCooking #Minigrid #SolarPV, Innovations for #PUE, for #Companies in Ethiopia, Uganda, Kenya, Rwanda, Tanzania, Zambia, Malawi, Mozambique, Zimbabwe, Burkina Faso, Ghana, Nigeria, Mali, Sierra Leone

The Innovation Fund is a component of the AECF's Renewable Energy and Adaptation to Climate Technologies Sub-Saharan Africa Programme (REACT SSA) a US$61 million project funded by the Swedish International Development Authority (SIDA).

The programme seeks to reduce poverty through a transformational increase in the use of renewable energy by off-grid households in sub-Saharan Africa, with a particular focus on innovations originating out of Western and Southern Africa.

Through the Innovation Fund, AECF aims to support businesses and entrepreneurs to validate market fit and potential of innovations in technological products, software, business models and distribution models that contribute to increasing access to clean cooking solutions and productive use energy for people living in rural areas and particularly for the poor.

The fund will support the testing of new innovations or extreme iterations to existing innovations to validate market fit and potential including

Scalable supply chain models for providing clean cooking solutions (especially in rural areas). Acknowledging that supply chains for cleaner fuels lack the necessary scale to reach many rural communities, the fund seeks to support supply chain innovations that can for example address demand uncertainty by matching demand and supply. Alternative clean cooking technologies (stoves and fuels) including mini-grid and solar PV powered electric cooking Business models and technological innovations for Productive Use of Energy (PUE) appliances such as milling, threshing, grating, specific value chains (poultry, dairy, and coffee) and commercial scale refrigeration. Solutions that narrow the energy access affordability gap for clean cooking and productive use for example sustainable consumer financing models that could bring Tier 3 appliances and above within reach of a larger share of the population. Innovations that can be seamlessly incorporated into prevailing or growing business and distribution models (such as PayGo and 'tool and fuel' business models) are encouraged.

Eligibility Criteria

The applicant needs to have a minimum viable product/service (i.e. a product/service that has already gone through a prototyping phase). The applicant must have undertaken market research demonstrating the need for the innovation in the selected geography. It is desirable for the applicant to demonstrate sales and/or a tangible demand of the proposed innovation. Please note, our investments are not intended to support any technology/innovation development.

Eligible Applicants

Only private companies with a direct interest in commercialising the innovation being tested can be eligible lead applicants, however applicants are free to partner with non-private sector players for the implementation of their projects. The innovation fund seeks to support targeted, output-based activities that can be completed within 24 months.

Funding and Co-financing

Between US$100,000-US$200,000 per company and up to $300,000 for exceptional innovations.

The co-financing requirement is a minimum of 30% of the project cost (the innovation fund will only cover up to 70% of the total project cost). In-kind contributions are acceptable.

Application Deadline: 26th November 2021

Check more https://adalidda.com/posts/TG79nNLkpaYdwbGsF/aecf-innovation-fund-support-innovations-in-clean-energy

0 notes

Text

Agribusiness and Food Companies Join Forces to Address Hunger and Nutrition Crisis in East Africa

In a first-ever collaboration on emergency hunger relief, leading global agribusiness and food companies Cargill, Bunge, ADM and Louis Dreyfus Company are partnering to prevent famine and contain the spread of hunger in East Africa.

The companies will contribute a combined $525,000 to help the World Food Programme (WFP)—the world’s leading humanitarian agency fighting global hunger—reach tens of thousands of families in East Africa. WFP has launched a coordinated response to conflict-induced famine in South Sudan, and to acute malnutrition in Somalia, Ethiopia and Kenya, where drought has destroyed thousands of acres of crops and left millions of families in need of emergency food assistance.

“We can turn the tide and save millions of lives,” said President and CEO of World Food Programme USA Rick Leach. “Support from leading companies and individuals will be the key to reaching millions of people as quickly as possible before it’s too late.”

Currently drought, economic instability and conflict are having a profound impact on more than 16 million people, including:

In Somalia, two consecutive below-average rainy seasons have resulted in near total crop failure, widespread water and pasture shortages, an increase in livestock deaths and spikes in staple food prices, leaving 3 million people unsure of where their next meal is coming from.

In South Sudan, more than 40 percent of the population requires urgent emergency food assistance as a result of conflict-induced food insecurity, and 100,000 people are facing life-threatening famine conditions.

In Ethiopia, 5.6 million people require emergency food assistance as a result of drought.

In Kenya, nearly 344,000 young children are acutely malnourished as a result of the ongoing drought in the country’s arid and semi-arid northern and eastern regions.

Because of the generosity of private sector donors, WFP is able to provide emergency food and nutrition assistance, including e-voucher-cards for local food purchases, in-kind food rations, and targeted nutrition support for pregnant women, nursing mothers and young children.

“Companies and individuals are stepping up to address the emergency and advance longer term solutions,” said Leach. “We hope it inspires others to donate and get involved today.”

To learn more and donate, visit wfpusa.org.

About World Food Program USA World Food Program USA is a 501(c)(3) charity that proudly supports the mission of the World Food Programme (WFP), the largest humanitarian agency addressing hunger worldwide. By mobilizing individuals, lawmakers and businesses in the U.S. to advance the global movement to end hunger, we bolster an enduring American legacy of feeding families in need around the world. Learn more at www.wfpusa.org.

About ADM For more than a century, the people of Archer Daniels Midland Company (NYSE: ADM) have transformed crops into products that serve the vital needs of a growing world. Today, we’re one of the world’s largest agricultural processors and food ingredient providers, with approximately 32,000 employees serving customers in more than 160 countries. With a global value chain that includes approximately 500 crop procurement locations, 250 ingredient manufacturing facilities, 38 innovation centers and the world’s premier crop transportation network, we connect the harvest to the home, making products for food, animal feed, industrial and energy uses. Learn more at www.adm.com.

About Bunge Limited Bunge Limited (www.bunge.com, NYSE: BG) is a leading global agribusiness and food company operating in over 40 countries with approximately 32,000 employees. Bunge buys, sells, stores and transports oilseeds and grains to serve customers worldwide; processes oilseeds to make protein meal for animal feed and edible oil products for commercial customers and consumers; produces sugar and ethanol from sugarcane; mills wheat, corn and rice to make ingredients used by food companies; and sells fertilizer in South America. Founded in 1818, the company is headquartered in White Plains, New York.

About Louis Dreyfus Company Louis Dreyfus Company is a leading merchant and processor of agricultural goods. We leverage our global reach and extensive asset network to serve our customers around the world, delivering the right products to the right location, at the right time – safely, responsibly and reliably. Our activities span the entire value chain from farm to fork, across a broad range of business lines (platforms). Since 1851 our portfolio has grown to include Oilseeds, Grains, Rice, Freight, Finance, Coffee, Cotton, Sugar, Juice, Dairy, Fertilizers & Inputs and Metals. Our products are originated, processed and transported around the world, helping feed and clothe some 500 million people every year. Structured as a matrix organization of 5 geographical regions and 12 platforms, Louis Dreyfus Company is active in over 100 countries and employs more than 22 000 people globally at peak season. For more information, visit www.ldc.com

About Cargill Cargill provides food, agriculture, financial and industrial products and services to the world. Together with farmers, customers, governments and communities, we help people thrive by applying our insights and 150 years of experience. We have 150,000 employees in 70 countries who are committed to feeding the world in a responsible way, reducing environmental impact and improving the communities where we live and work. For more information, visit Cargill.com and our News Center.

For more information and media interviews, contact:

M.J. Altman Editorial Director [email protected] (202) 627-3932

source: http://www.csrwire.com/press_releases/39816-Agribusiness-and-Food-Companies-Join-Forces-to-Address-Hunger-and-Nutrition-Crisis-in-East-Africa?tracking_source=rss

0 notes

Text

Processed Foods Industry Leverages Freedom Foods to Catalyze Demand across the Globe

Focus on product strategy, consumer wellness and sustainability will boost leadership in global agriculture and nutrition market, finds Frost & Sullivan's Visionary Science team

SANTA CLARA, California, Feb. 23, 2017 /PRNewswire/ -- Though highly fragmented, the global processed food and beverage market will see high growth due to several Mega Trends. Key transformative forces include emerging business models such as crowdsourcing, marketplaces, gamification and mass customization, which are shaping retail, socioeconomics, connected eating in a cognitive era, and increasing popularity of "Freedom Foods" that meet ethical production standards. Major contenders, such as ADM, Clover Corporation, Coca-Cola, Dole Food, Tyson Foods and Unilever, are already rethinking product lines to align with these changes, focusing on consumers' health, wellness and embracing sustainable measures in processing to keep their lead.

2017 Global Processed Food & Beverage Industry Outlook, a part of Frost & Sullivan's Visionary Science Growth Partnership Service program, finds that total global expenditure on processed food and beverage products by final consumers will grow to $4.675 trillion in 2017. The research delivers critical insights that enable food and beverage companies to successfully assess trends that will shape market sub-segments such as canned food, confectionery, dairy and ice cream, frozen and perishable groceries, and pet and processed food.

Click on the following link for complimentary access to more information on this analysis or to register for a Growth Strategy Dialogue, a free interactive briefing with Frost & Sullivan's thought leaders: http://frost.ly/1bu

"The food and beverage market tends to be a safe investor haven in bad economic times due to its relative inelasticity of demand when compared with other industry sectors such as consumer durables," said Frost & Sullivan Agriculture & Nutrition Global Director Christopher Shanahan. "However, certain categories, like dietary supplements, may take a disproportionate hit due to the perception of the products as 'less essential'."

In contrast to the saturated markets for processed food and beverage products, emerging markets such as Asia-Pacific and Eastern Europe will display higher growth. However, increasing consumer demand for pollutant and allergen-free products that are ethically produced without wasting natural resources will add to the cost of the production as well as to the overall pricing. This might discourage a large section of the targeted consumers. Food producers must launch extensive campaigns to promote Freedom Food or RSPCA Assured products since consumers are often willing to pay extra for them. Participants must also continue investing in state-of-the-art processing technologies to teach consumers about compliance and top-notch quality.

"The rise of Freedom Foods, specifically the need for enhanced nutrition and health, will dominate new food and beverage product innovation in 2017 and beyond," said Shanahan. "The transformation will start from the development of safer and cleaner seeds and livestock to extend to value-added functional foods and more environmentally friendly packaging."

Recent topics covered under the Visionary Science subscription include Omega-3 Ingredients, Smart Agriculture Technology, Maize and Wheat Milling Industry in Kenya, Nitrogen Nutrients for Fermentation-Derived Specialty Biochemicals, US and European Nutraceutical Ingredients, Rapid Bacteriological Test Kits for Raw Meat and Raw Dairy Applications in the US, and much more. All studies in the subscription present detailed market opportunities and industry trends evaluated following extensive interviews with market participants.

About Frost & Sullivan

Frost & Sullivan, the Growth Partnership Company, works in collaboration with clients to leverage visionary innovation that addresses the global challenges and related growth opportunities that will make or break today's market participants. For more than 50 years, we have been developing growth strategies for the global 1000, emerging businesses, the public sector and the investment community. Contact us: Start the discussion

Global Processed Food and Beverage Market Outlook, 2017 K14D-88

Contact: Jaylon Brinkley Corporate Communications – North America P: (210) 247.2481 F: (210) 348.1003 E: [email protected]

http://ww2.frost.com

Read this news on PR Newswire Asia website: Processed Foods Industry Leverages Freedom Foods to Catalyze Demand across the Globe

0 notes