#dairy processing equipment manufacturers

Explore tagged Tumblr posts

Text

No.1 from dairy processing equipment manufacturers in India

The dairy industry is ever growing, and therefore having the equipment that meets and fits the current trends is very vital in the processing of the product. Aviva Equipment is serving as upcoming and most sought-after dairy processing equipment manufacturers in India. Selecting Aviva means working with a company that knows the specifics of the dairy processing and provides equipment that is reliable and durable.

Aviva Equipment Pvt. Ltd. was formed in 2011 by Mr. Bharat Shah, whose main goal is to bring innovative changes into the dairy and pharmaceutical sectors in India. Beginning with dairy and pharmaceutical equipment needs, Aviva Equipment continued to develop its offerings while maintaining high standards of quality. Today, Aviva Equipment is one of the leading dairy processing equipment manufacturers in India and is aimed at providing dedicated and quality equipment to dairy businesses to grow wel

Aviva Equipment provides all Dairy Processing Equipment such as Milk Pasteurization Plants, Paneer Processing Plants, Ice Cream Plants etc. Aviva Equipment emerges as the leading dairy processing equipment manufacturers in India amidst the stellar competition in the country. We offer superior built dairy equipment that is specifically tailored for increased productivity, uniformity, and effectiveness in meeting the various demands of the dairy sector. You can find out a broad scope of dairy processing equipment by visiting our website following the link indicated below.

#dairy processing equipment manufacturers in India#dairy processing equipment manufacturers#dairy processing equipment#Aviva Equipment

0 notes

Text

#dairy equipment#dairy equipment manufacturers#dairy processing equipment#dairy processing equipment manufacturers#dairy plant manufacturers#dairy plant#dairy plant machinery

0 notes

Text

#dairy plant machinery manufacturers#dairy equipment suppliers#dairy processing plant manufacturer#SM Engineering

1 note

·

View note

Text

Fast and High-Quality Dairy Product Production with Mini Dairy Plant Machinery and Equipment

Efficient and high-quality production is essential in the ever-changing dairy industry. To keep up with the rising demand for high-quality, freshly-dairy products, small and medium-sized dairy companies require dependable, high-performance solutions. Milk Processing Plant and Machines for micro dairy plants come into play here, allowing for rapid, scalable, and high-quality milk production.

#Milk Processing Plant and Machines#Milk Processing Plant and Machines Manufacturers#Milk Processing Plant and Machines Suppliers#Milk Machines#Milk Processing Machines#Milk#Dairy Equipment#Dairy Machines#Dairy Machine Manufacturers

0 notes

Text

Saffron Machinery is a leading dairy plant and equipment manufacturer in India, specializing in milk processing plant solutions. Our extensive range includes dairy machinery, milk storage tanks, juice processing plants, and industrial chillers, all designed to meet the highest industry standards. Based in Ahmedabad, Gujarat, we are committed to delivering reliable and efficient products that enhance productivity and profitability. Our mission focuses on optimizing resources while promoting self-employment in rural India, thereby improving living standards. Additionally, we provide industrial erection services, ensuring comprehensive support for our clients in the dairy and food processing sectors.

1 note

·

View note

Text

Mini Dairy Plant Cost in India

Looking for a reliable Mini Dairy Plant Manufacturer in India? Look no further than Divyom Processing Machinery & Equipments. While we are well-known for our Mini Dairy Plant, we also specialize in state-of-the-art milk processing solutions. Contact us today for more details!

#Mini dairy plant manufacturer#Mini dairy plant manufacturer in India#Mini dairy plant supplier inn Inida#Mini dairy plant manufacturer in Ghaziabad#Mini dairy plant manufacturer in Delhi NCR#Mini dairy plant supplier in Delhi#Mini dairy plant supplier in Ghaziabad#divyom process machinery & equipments

1 note

·

View note

Text

How to start and run a milk processing plant?

The milk plant is a place, premises where milk is collect, process, store, pasteurize, packaged and prepared for supply. The milk processing plant machine must have license for it. In this license, a mini milk processing plant may prefer to process to dairy and milk products. There are many dairy business plants all over India. The whole process starts in dairy farms which have cattle such as cows, buffaloes and goats for milking purposes.

Capacity of Milk Processing Plants

Milk Plants are small, medium and big. These use different types of milk processing equipments according maximum milk capacity per day. There are number of dairy products like ghee, cream, butter, toned milk, double toned milk and skimmed milk that are also manufactured in milk plant. Milk is initially dumped in big milk tank from the milk tankers after that it chilled in a chilling unit. This chilled milk is pasteurized in the milk pasteurizer and cream is divided from the cream separator which gets skimmed milk. Milk is generally depends on the necessity of toned milk, skimmed milk, double toned milk or full cream milk.

Process of dairy Processing Plants

The proper milk production is very vital in the dairy farm. Dairy cows are milked 2 times in a day in all dairy farms. The big farms use good equipments for the processing procedure. After that, it is transferred to big refrigerated milk tanks. These milk tanks are collected by big trucks that transport the product to the milk processing plants. It is important to check the taste and temperature of product before transporting the product to milk processing plants that is suitable for use or not. If the truck is transported to the processing plants then the milk processing plant is pumped into special tanks. After that, it is taken for separation and clarification procedure.

Advertisements

In the milk processing plants, the product separates from bacteria that it is perfect for use. This procedure is well-known as clarification. It is turn in huge vats for some time and the initial spin separates every types of bacteria and fragments from the product. It turns again to separate heavy and light milk. After that, the process involves heat the product to destroy the remaining bacteria present in it. The product is heated and passed all the way through steel pipes in procedure of pasteurization. The next step is homogenization that eliminates fat from the product. The product is heated to decrease the fat particles that present in it. Without the procedure of homogenization, fat particles would float over the milk. Therefore, these processes are very helpful for milk processing business and also for plants.

if you have any query please feel free to ask me

Pranam Ji Engineering Works Khasra No 346, Jalapur, Raghunathpur Muradnagar, Ghaziabad, Uttar Pradesh-201206 +91 7017598033, 9315662914 8920968610, 8126573005

#milk dairy#dairy equipment#plant milk#manufacture#suplier#dairy cows#milk products#milk processing plant

0 notes

Text

Milton Orr looked across the rolling hills in northeast Tennessee. “I remember when we had over 1,000 dairy farms in this county. Now we have less than 40,” Orr, an agriculture adviser for Greene County, Tennessee, told me with a tinge of sadness.

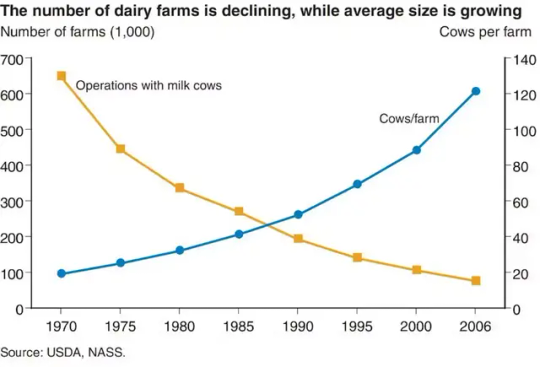

That was six years ago. Today, only 14 dairy farms remain in Greene County, and there are only 125 dairy farms in all of Tennessee. Across the country, the dairy industry is seeing the same trend: In 1970, more than 648,000 US dairy farms milked cattle. By 2022, only 24,470 dairy farms were in operation.

While the number of dairy farms has fallen, the average herd size—the number of cows per farm—has been rising. Today, more than 60 percent of all milk production occurs on farms with more than 2,500 cows.

This massive consolidation in dairy farming has an impact on rural communities. It also makes it more difficult for consumers to know where their food comes from and how it’s produced.

As a dairy specialist at the University of Tennessee, I’m constantly asked: Why are dairies going out of business? Well, like our friends’ Facebook relationship status, it’s complicated.

The Problem with Pricing

The biggest complication is how dairy farmers are paid for the products they produce.

In 1937, the Federal Milk Marketing Orders, or FMMO, were established under the Agricultural Marketing Agreement Act. The purpose of these orders was to set a monthly, uniform minimum price for milk based on its end use and to ensure that farmers were paid accurately and in a timely manner.

Farmers were paid based on how the milk they harvested was used, and that’s still how it works today.

Does it become bottled milk? That’s Class 1 price. Yogurt? Class 2 price. Cheddar cheese? Class 3 price. Butter or powdered dry milk? Class 4. Traditionally, Class 1 receives the highest price.

There are 11 FMMOs that divide up the country. The Florida, Southeast, and Appalachian FMMOs focus heavily on Class 1, or bottled, milk. The other FMMOs, such as Upper Midwest and Pacific Northwest, have more manufactured products such as cheese and butter.

For the past several decades, farmers have generally received the minimum price. Improvements in milk quality, milk production, transportation, refrigeration, and processing all led to greater quantities of milk, greater shelf life, and greater access to products across the US. Growing supply reduced competition among processing plants and reduced overall prices.

Along with these improvements in production came increased costs of production, such as cattle feed, farm labor, veterinary care, fuel, and equipment costs.

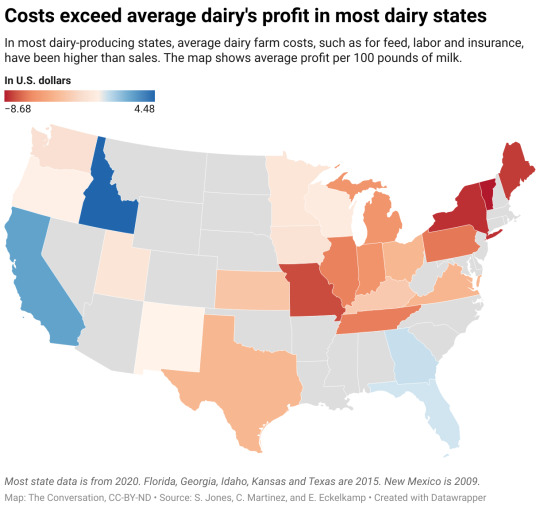

Researchers at the University of Tennessee in 2022 compared the price received for milk across regions against the primary costs of production: feed and labor. The results show why farms are struggling.

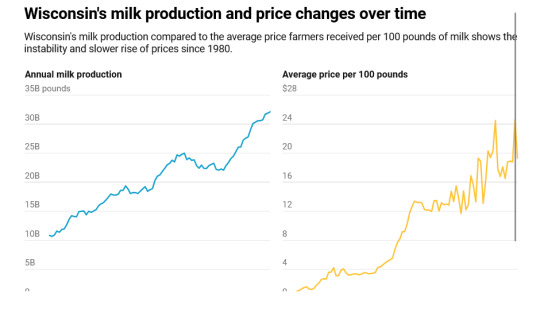

From 2005 to 2020, milk sales income per 100 pounds of milk produced ranged from $11.54 to $29.80, with an average price of $18.57. For that same period, the total costs to produce 100 pounds of milk ranged from $11.27 to $43.88, with an average cost of $25.80.

On average, that meant a single cow that produced 24,000 pounds of milk brought in about $4,457. Yet, it cost $6,192 to produce that milk, meaning a loss for the dairy farmer.

More efficient farms are able to reduce their costs of production by improving cow health, reproductive performance, and feed-to-milk conversion ratios. Larger farms or groups of farmers—cooperatives such as Dairy Farmers of America—may also be able to take advantage of forward contracting on grain and future milk prices. Investments in precision technologies such as robotic milking systems, rotary parlors, and wearable health and reproductive technologies can help reduce labor costs across farms.

Regardless of size, surviving in the dairy industry takes passion, dedication, and careful business management.

Some regions have had greater losses than others, which largely ties back to how farmers are paid, meaning the classes of milk, and the rising costs of production in their area. There are some insurance and hedging programs that can help farmers offset high costs of production or unexpected drops in price. If farmers take advantage of them, data shows they can functions as a safety net, but they don’t fix the underlying problem of costs exceeding income.

Passing the Torch to Future Farmers

Why do some dairy farmers still persist, despite low milk prices and high costs of production?

For many farmers, the answer is because it is a family business and a part of their heritage. Ninety-seven percent of US dairy farms are family owned and operated.

Some have grown large to survive. For many others, transitioning to the next generation is a major hurdle.

The average age of all farmers in the 2022 Census of Agriculture was 58.1. Only 9 percent were considered “young farmers,” age 34 or younger. These trends are also reflected in the dairy world. Yet, only 53 percent of all producers said they were actively engaged in estate or succession planning, meaning they had at least identified a successor.

How to Help Family Dairy Farms Thrive

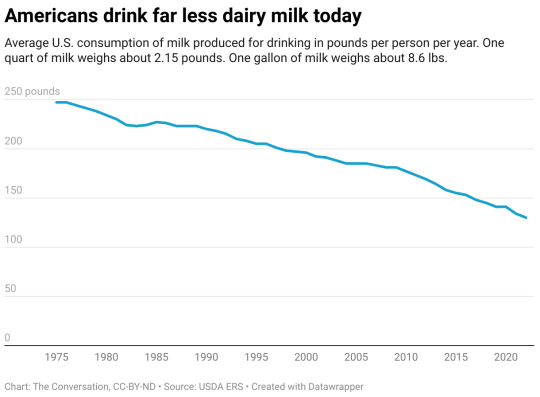

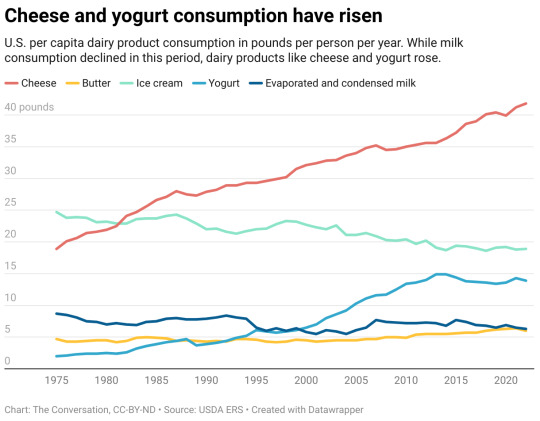

In theory, buying more dairy would drive up the market value of those products and influence the price producers receive for their milk. Society has actually done that. Dairy consumption has never been higher. But the way people consume dairy has changed.

Americans eat a lot, and I mean a lot, of cheese. We also consume a good amount of ice cream, yogurt, and butter, but not as much milk as we used to.

Does this mean the US should change the way milk is priced? Maybe.

The FMMO is currently undergoing reform, which may help stem the tide of dairy farmers exiting. The reform focuses on being more reflective of modern cows’ ability to produce greater fat and protein amounts; updating the cost support processors receive for cheese, butter, nonfat dry milk, and dried whey; and updating the way Class 1 is valued, among other changes. In theory, these changes would put milk pricing in line with the cost of production across the country.

The US Department of Agriculture is also providing support for four Dairy Business Innovation Initiatives to help dairy farmers find ways to keep their operations going for future generations through grants, research support, and technical assistance.

Another way to boost local dairies is to buy directly from a farmer. Value-added or farmstead dairy operations that make and sell milk and products such as cheese straight to customers have been growing. These operations come with financial risks for the farmer, however. Being responsible for milking, processing, and marketing your milk takes the already big job of milk production and adds two more jobs on top of it. And customers have to be financially able to pay a higher price for the product and be willing to travel to get it.

33 notes

·

View notes

Text

Key sectors in KSA manufacturing market:

Here’s a concise overview of the key sectors in Saudi Arabia's manufacturing market:

1. Petrochemicals

- Central to Saudi Arabia's manufacturing, leveraging vast oil and gas reserves to produce chemicals like ethylene and polypropylene.

- Major players include SABIC and Saudi Aramco.

2. Pharmaceuticals

- Rapidly expanding with a focus on local production of generics, vaccines, and biotech products.

- Supported by government initiatives to reduce import dependency.

3. Food and Beverage

- Vital for food security and economic growth, focusing on dairy, processed foods, beverages, and halal products.

- Expanding into regional and international markets.

4. Automotive

- Developing sector with a focus on assembling vehicles, manufacturing parts, and electric vehicles (EVs).

- Growing interest from global manufacturers.

5. Construction Materials

- Driven by mega-projects, producing cement, steel, aluminum, and sustainable materials.

- Key to supporting infrastructure development.

6. Metals and Mining

- Emerging sector with significant resources like gold, phosphate, and bauxite.

- Focus on extraction, processing, and downstream industries like aluminum smelting.

7. Textiles and Apparel

- Small but growing, with potential in high-quality textiles and traditional clothing.

- Opportunities in fashion and design.

8. Renewable Energy Equipment

- Focused on producing solar panels, wind turbines, and related components to support renewable energy projects.

- Significant growth potential aligned with sustainability goals.

9. Packaging

- Expanding due to growth in food, pharmaceuticals, and e-commerce.

- Innovation in sustainable packaging solutions is on the rise.

10. Defense and Aerospace

- Strategic priority with efforts to localize military equipment production.

- Supported by GAMI, focusing on parts manufacturing and maintenance services.

These sectors highlight Saudi Arabia's drive toward economic diversification, with strong government support and strategic investments fostering growth across the manufacturing industry.

#KhalidAlbeshri #خالدالبشري

#advertising#artificial intelligence#autos#business#developers & startups#edtech#education#finance#futurism#marketing

16 notes

·

View notes

Text

Others have probably said this more eloquently than I, and I know I've griped about related issues in the past, but let me just say again, it is downright criminal how little food manufacturers and retailers care about people with food allergies.

My daughter has EOE. It's not life threatening in an anaphylactic sense, but it does severely limit quality of life for her, and impacts every facet of her existence. We're in the process of identifying her triggers, one of which we know for sure is dairy. The amount of stuff that's unnecessarily made with dairy is awful; it's even worse how much stuff gets casually contaminated, and companies aren't required to label it.

Those little "made in a facility with/that also processes" tags? The "may contain" warnings? Voluntary. Optional. So unless it's made in a dedicated dairy-free facility, it could have traces in it, and we simply wouldn't know unless they decide to be kind.

The worse part is, in our case, we don't always know what food did it. EOE is a delayed reaction. It could have been something from yesterday, or last week. Trying to pin down which foods are safe and which aren't becomes a billion times harder when we can't rely on labeling. Sure it doesn't contain milk or whey or caseinate or butter, but could it have been made in the same processing line? Who knows! The manufacturer didn't bother putting that on the label!

And grocery stores and restaurants aren't much better. Those deli meats are sliced on the same equipment as the block cheeses. The lettuce is right next to the shredded cheese at the taco bar. I watched an employee use the same serving utensils for the ice cream as the dairy free sorbet.

And we're lucky! Her allergy isn't going to kill her outright if she gets contaminated. But it is turning out to be extremely sensitive, so we're struggling. I spent two and a half hours the other day trying to shop for 10 things, because I had to keep researching the different brands' manufacturing processes and ingredient sources. I had to go to three different stores. Again, we're lucky; we live in an area with a pretty big market for vegan and "specialty" foods.

We're facing down the very real possibility of having to also eliminate soy and/or wheat in the near future, and I'm so exhausted just thinking about it. Soy is in everything. Wheat is in everything. Dairy is in everything. To avoid it, you either have to eat exclusively from the produce section and/or pay through the nose for one of about three specialty products that have an extremely limited distribution. Just going fully dairy free alone has almost doubled our grocery bill, and it's not like we were splurging before.

It's just frustrating. And if it's this bad for us, who have the luxury of not needing an epi pen and an emergency plan, I don't even want to imagine how bad it is for people with near-fatal or anaphylactic allergies. People shouldn't have to jump through a billion hoops and pay quadruple price for infinitely fewer options just to not die.

#food tw#food allergies#eoe#ranting#i'm off to the woods to build a neo-hippie agri commune who's in?

25 notes

·

View notes

Text

Innovative Applications of Stainless Steel Plates in Various Industries

Stainless steel plates have become a cornerstone material in various industries, thanks to their remarkable properties such as corrosion resistance, strength, and versatility. These plates are used in a wide range of applications, from construction and manufacturing to food processing and energy production. Their ability to withstand extreme environments, coupled with low maintenance costs, makes them a go-to choice for engineers, designers, and manufacturers across the globe.

In this blog, we will explore the innovative applications of stainless steel plates in different industries, highlighting how they contribute to improved efficiency and durability. As a trusted stainless steel plates dealer in Vadodara and Gujarat, Tube Trading takes pride in offering top-quality materials to meet the diverse needs of businesses across sectors.

Properties That Make Stainless Steel Plates Stand Out

Before diving into the various applications, it is essential to understand the key properties that make stainless steel plates such a valuable asset in industrial applications:

Corrosion Resistance: One of the most significant advantages of stainless steel is its ability to resist corrosion, even in harsh environments. This property is essential for industries such as marine, chemical processing, and food production, where materials are constantly exposed to moisture, chemicals, or salts.

Strength and Durability: Stainless steel plates offer exceptional strength, allowing them to withstand high-pressure environments and heavy loads. This makes them ideal for construction, infrastructure, and manufacturing industries.

Heat Resistance: Stainless steel can maintain its properties even at high temperatures, making it a preferred choice for applications in energy, aerospace, and automotive industries.

Aesthetic Appeal: The smooth, shiny surface of stainless steel plates gives them a modern, sleek look, which is often used in architectural applications and interior design.

Hygiene and Easy Maintenance: Stainless steel is easy to clean and maintain, making it a popular choice in the food, beverage, and pharmaceutical industries where hygiene is of utmost importance.

With these properties in mind, let us delve into the innovative applications of stainless steel plates in various industries.

1. Construction and Architecture

Stainless steel plates are a vital component in the construction industry due to their structural integrity and aesthetic appeal. In architectural design, stainless steel is often used in building facades, roofing, cladding, and interior décor. Its corrosion resistance ensures long-lasting durability in outdoor environments, while its sleek appearance adds a modern touch to buildings.

Additionally, stainless steel plates are used in the construction of bridges, tunnels, and other infrastructure projects. Their strength makes them ideal for load-bearing structures, while their resistance to rust ensures that they can withstand environmental exposure without degradation over time.

As a leading stainless steel plates dealer in Vadodara, Tube Trading has supplied high-quality stainless steel plates for numerous construction projects, ensuring the safety and longevity of these structures.

2. Food and Beverage Industry

The food and beverage industry requires materials that meet stringent hygiene standards. Stainless steel plates are widely used in this sector for the construction of food processing equipment, storage tanks, and countertops. Their non-porous surface prevents the buildup of bacteria, ensuring that food and beverages are processed in a clean and safe environment.

In addition to hygiene, stainless steel’s corrosion resistance is crucial when handling acidic or salty foods. For instance, in dairy processing or brewing, stainless steel ensures that equipment does not corrode or affect the taste and quality of the final product.

As a stainless steel plates supplier in Vadodara, Tube Trading works closely with food manufacturers to provide plates that meet industry standards for cleanliness, durability, and efficiency.

3. Chemical and Petrochemical Industries

In chemical and petrochemical industries, equipment is exposed to harsh chemicals, high temperatures, and corrosive environments. Stainless steel plates are used to construct reactors, storage tanks, pipelines, and other processing equipment. Their ability to resist chemical corrosion and withstand extreme temperatures makes them an ideal material for these applications.

Moreover, stainless steel's non-reactive properties ensure that it does not contaminate the chemicals being processed, maintaining the purity of the products.

In Gujarat, a hub for the chemical and petrochemical industries, Tube Trading stands as a reliable stainless steel plates supplier. Our stainless steel products are specifically designed to handle the rigorous demands of these industries, ensuring safety and operational efficiency.

4. Automotive and Transportation Industry

Stainless steel plates play a crucial role in the automotive and transportation industries due to their strength, durability, and ability to withstand impact. They are used in the construction of vehicle frames, exhaust systems, and various components that require resistance to heat and corrosion.

In addition to cars, stainless steel plates are essential in the railway and aerospace sectors, where safety and performance are critical. For example, stainless steel is used in the construction of airplane fuselages, train carriages, and ship hulls to ensure that these vehicles can handle extreme conditions without compromising safety.

As a stainless steel plates dealer in Gujarat, Tube Trading has a longstanding reputation for supplying top-quality materials to automotive and transportation manufacturers, helping them build safe, reliable, and efficient vehicles.

5. Energy and Power Generation

The energy sector, including oil and gas, nuclear, and renewable energy, requires materials that can withstand high temperatures, pressure, and corrosive environments. Stainless steel plates are used in the construction of pipelines, turbines, heat exchangers, and reactors.

In nuclear power plants, stainless steel is used to build containment vessels and other critical infrastructure that must remain operational under extreme conditions. In renewable energy projects, such as solar or wind power, stainless steel is employed in equipment that needs to be durable and weather-resistant.

In oil and gas refineries, stainless steel plates are essential for constructing equipment that handles corrosive materials and extreme temperatures, ensuring that operations run smoothly without frequent repairs or replacements.

Tube Trading supplies the stainless steel plates in Vadodara and Gujarat needed by power generation and energy companies to maintain efficient and safe operations.

6. Marine Industry

The marine industry is particularly challenging due to constant exposure to saltwater, which can rapidly corrode many metals. Stainless steel’s corrosion resistance makes it a preferred material for building ships, offshore platforms, and marine equipment.

In addition to corrosion resistance, stainless steel plates offer high strength, ensuring that marine structures can withstand the harsh conditions of the open sea. From ship hulls to underwater pipelines, stainless steel is a trusted material that guarantees long-lasting performance.

As a stainless steel plates supplier in Gujarat, Tube Trading caters to the unique needs of the marine industry, providing materials that perform reliably in saltwater environments.

7. Medical and Pharmaceutical Industry

In the medical and pharmaceutical industries, maintaining a sterile and clean environment is crucial. Stainless steel plates are widely used in the manufacture of surgical instruments, medical devices, and hospital equipment due to their easy-to-clean and non-reactive surfaces.

Moreover, stainless steel is essential in the construction of pharmaceutical processing equipment where contamination must be avoided. Its non-porous surface ensures that bacteria and other contaminants do not accumulate, ensuring the safety and efficacy of pharmaceutical products.

Tube Trading, a leading stainless steel plates dealer in Vadodara, supplies high-grade stainless steel to meet the strict hygiene and safety standards of the medical and pharmaceutical sectors.

Conclusion

Stainless steel plates have proven their versatility and durability across a wide array of industries. From construction and food processing to energy production and healthcare, the innovative applications of stainless steel plates continue to grow, driven by their corrosion resistance, strength, and ease of maintenance.

As a trusted stainless steel plates dealer in Gujarat and Vadodara, Tube Trading is proud to supply high-quality materials that meet the diverse needs of these industries. Our commitment to quality and customer satisfaction ensures that our clients receive the best possible products to enhance their operations, improve safety, and boost efficiency.

For businesses in need of durable and reliable stainless steel plates, Tube Trading is your go-to supplier in Gujarat. Whether you are in construction, automotive, or food processing, we provide solutions that cater to your specific requirements, ensuring long-term success and operational excellence.

#Stainless steel plates dealer in Vadodara#Stainless steel plates dealer in Gujarat#Stainless steel plates supplier in Vadodara#Stainless steel plates supplier in Gujarat

4 notes

·

View notes

Text

Transform Packaging Efficiency with Film Lamination Adhesives

In today's fast-paced world, efficiency and sustainability are more important than ever. For film manufacturers, print industry professionals, and product packaging designers, finding ways to reduce waste while improving efficiency is crucial. Enter film lamination adhesives—a game-changing solution that can transform your packaging processes. This blog post explores how film lamination adhesives can help you achieve these goals, making your packaging not just better but also greener.

Understanding Film Lamination Adhesives

Film lamination adhesives are specialized compounds designed to bond layers of film together, creating a single, cohesive material. Used extensively in packaging, these adhesives offer numerous benefits, including enhanced durability and improved barrier properties.

Why Use Film Lamination Adhesives?

Film lamination adhesives are essential for creating multi-layered packaging that protects products effectively. They provide a strong bond between different types of films, ensuring that the final product is both durable and functional.

Types of Film Lamination Adhesives

There are several types of film lamination adhesives available, each designed for specific applications. These include water-based, solvent-based, and solvent-free adhesives. Each type has its own set of advantages, making them suitable for various packaging needs.

Applications in Packaging

Film lamination adhesives are used in a wide range of packaging applications. From seed and pesticide packaging to dairy products and vacuum pouches, these adhesives offer versatile solutions for various industries.

Benefits of Film Lamination Adhesives

Using film lamination adhesives in your packaging processes can significantly reduce waste and improve efficiency. Here are some key benefits:

Enhanced Durability

One of the primary advantages of film lamination adhesives is their ability to create highly durable packaging. This means your products are better protected, reducing the risk of damage during transit.

Improved Barrier Properties

Film lamination adhesives help enhance the barrier properties of packaging, making it more resistant to moisture, oxygen, and other external factors. This is particularly important for products like dairy and vacuum-sealed items.

Versatility

Film lamination adhesives are incredibly versatile, making them suitable for a wide range of applications. Whether you're packaging seeds, pesticides, or consumer goods, these adhesives can meet your needs.

Improving Efficiency in Packaging

Efficiency is key to staying competitive in the packaging industry. Film lamination adhesives can streamline your processes, making them more efficient and cost-effective.

Faster Production Times

Film lamination adhesives can significantly speed up production times. By creating strong bonds quickly, they allow for faster assembly of multi-layered packaging, increasing your overall output.

Reduced Downtime

Using high-quality film lamination adhesives can reduce downtime caused by equipment malfunctions or material failures. This ensures a smoother production process and higher efficiency.

Cost Savings

By minimizing waste and improving production efficiency, film lamination adhesives can lead to significant cost savings. This makes them a smart investment for any packaging operation.

The Future of Packaging with Film Lamination Adhesives

The packaging industry is constantly evolving, and film lamination adhesives are at the forefront of this evolution. By adopting these advanced adhesives, you can stay ahead of the curve and ensure your packaging processes are both efficient and sustainable.

Innovations on the Horizon

Ongoing research and development in film lamination adhesives promise even more exciting innovations in the future. Stay tuned for new products and technologies that will further enhance your packaging capabilities.

Commitment to Sustainability

At [Your Company Name], we're committed to sustainability. Our film lamination adhesives are designed to minimize environmental impact while delivering superior performance. Join us in our mission to create a better, more sustainable future.

Taking the Next Step

Ready to revolutionize your packaging processes? Contact us today to learn more about our film lamination adhesives and how they can benefit your business. Our team of experts is here to help you find the perfect solution for your needs.

2 notes

·

View notes

Text

The World of Pink: Unveiling the Magic Behind Your Favorite Food Colors

Pink food coloring takes center stage in countless treats, from bubblegum frosting to rosy macarons. But have you ever wondered how this vibrant hue transforms your favorite dishes? Delving deeper, we'll explore the fascinating world of pink food colour manufacturer, uncovering the science and creativity behind these delightful pigments.

Natural vs. Synthetic: A Spectrum of Pinks Helvetica Neue

Pink food colour manufacturer offer a spectrum of options, catering to both health-conscious consumers and those seeking bold hues. Here's a breakdown of the two main categories:

Natural Pink Colors: Derived from fruits, vegetables, and minerals, these colorings offer a subtler, softer pink. Beetroot juice, hibiscus extract, and anthocyanins (found in berries) are some popular natural sources.

Synthetic Pink Colors: Manufacturers create these vibrant pinks through a controlled chemical process. They are often more cost-effective and produce a wider range of intense shades. However, some consumers prefer natural options due to potential concerns about artificial ingredients.

The Art and Science of Pink Perfection

Creating the perfect pink shade requires a delicate balance of science and artistry. Manufacturers employ sophisticated equipment and expertise to ensure consistent color, stability, and safety for consumption. Here's a peek behind the curtain:

Selection of Raw Materials: Whether natural or synthetic, the starting materials undergo rigorous testing to ensure purity and suitability for food applications.

Color Formulation: Food scientists meticulously blend different colorants to achieve the desired pink shade. Factors like lightfastness (resistance to fading) and shelf life are crucial considerations.

Quality Control: Throughout the production process, stringent quality checks guarantee consistent color and adherence to food safety regulations.

Beyond the Bakery: A World of Pink Applications

Pink food coloring isn't limited to frosting and candy. It plays a vital role in various food applications, including:

Dairy Products: Yogurt, ice cream, and pink-hued milkshakes often incorporate pink food coloring.

Meats and Seafood: Some processed meats and seafood may utilize pink colorings to enhance their appearance.

Beverages: Pink drinks like fruit punches and sports drinks often rely on food coloring for a visually appealing hue.

The Future of Pink: Innovation and Sustainability

As consumer preferences evolve, Pink food colour manufacturer are constantly innovating. are some exciting trends to watch:

Natural Color Focus: The demand for natural colorings is on the rise. Manufacturers are exploring new and sustainable ways to extract vibrant pinks from natural sources.

Clean Label Movement: Consumers are increasingly interested in products with recognizable ingredients. Manufacturers are responding by developing "clean label" pink colorings with simpler formulations.

A Touch of Pink: Adding Vibrancy to Your Plate

Pink food colour manufacturer plays a significant role in creating visually appealing and delightful food experiences. From the vibrant hues in candies to the subtle blush in yogurt, these colorings add a touch of magic to our plates. As the industry continues to evolve, we can expect even more innovative and sustainable ways to bring the world of pink to life!

2 notes

·

View notes

Text

Export Import Products List

Exporting and importing products is a major part of the global economy. In 2022, the value of global merchandise trade was over $28 trillion. This means that businesses and consumers all over the world are exchanging goods and services on a massive scale.

There are a wide variety of products that are exported and imported, but some of the most common include:

Agricultural products: This category includes food crops, such as wheat, rice, and corn, as well as livestock and animal products, such as meat, dairy, and eggs.

Chemicals: This category includes a wide range of products, such as petrochemicals, pharmaceuticals, and fertilizers.

Electrical machinery and equipment: This category includes products such as generators, motors, and computers.

Food and beverages: This category includes processed foods and drinks, as well as fresh produce.

Machinery and equipment: This category includes products such as machine tools, engines, and construction equipment.

Manufactured goods: This category includes a wide range of products, such as textiles, clothing, and electronics.

Minerals and fuels: This category includes products such as crude oil, natural gas, and coal.

Other goods: This category includes products that do not fall into any of the other categories, such as furniture and toys.

Textiles and clothing: This category includes products such as yarn, fabric, and garments.

Transport equipment: This category includes products such as cars, trucks, and airplanes.

The specific products that are exported and imported vary from country to country. For example, the United States is a major exporter of agricultural products, machinery, and equipment, while China is a major exporter of manufactured goods and electronics.

Factors to Consider When Choosing Export Import Products

There are a number of factors that businesses should consider when choosing which products to export or import. These factors include:

Demand: Is there a strong demand for the product in the target market?

Competition: How much competition is there for the product in the target market?

Profitability: Is the product profitable to export or import?

Regulations: Are there any regulations that restrict the export or import of the product?

Logistics: How will the product be transported to and from the target market?

Benefits of Exporting and Importing Products

There are a number of benefits to exporting and importing products. For businesses, exporting can help to increase sales and profits, and it can also help to diversify the business's customer base. Importing can help businesses to access products that are not available domestically, and it can also help businesses to reduce costs.

For consumers, exporting and importing can help to lower prices and increase the availability of goods. For example, consumers in the United States can buy fresh produce from all over the world, and they can also buy electronics and other manufactured goods at lower prices because of imports.

Conclusion

Exporting and importing products is a vital part of the global economy. It helps businesses to grow and consumers to save money. If you are considering starting an export import business, there are a number of resources available to help you get started.

#Export Import Products List#export import products#export import data#exporter#bussiness#export#import#importers

2 notes

·

View notes

Text

The Role of Bottle Cap Torque Tester in Product Quality

Source of Info: https://www.perfectgroupindia.co.in/blog/the-role-of-bottle-cap-torque-tester-in-product-quality

Introduction

The Bottle Cap Torque Tester is a reliable equipment used in various industries to analyze the force required to open bottle caps. It helps manufacturers to maintain their bottle seals strong enough to stop leaks and save products from damage. Only high-quality products are delivered to customers thanks to this simple to use yet powerful tool to find faulted caps. Perfect Group India guarantees that your products fulfill the highest quality standards by offering accurate and dependable testing solutions. By guaranteeing that each bottle is correctly sealed, and these equipment increases customer satisfaction and trust in the company.

What is The Bottle Cap Torque Tester?

A Bottle Cap Torque Tester improves correct sealing by analyzing the force needed to open or close a cap. It is simple to use and helps in testing whether the cap is secured. The beverage, pharmaceutical, cosmetic, and food packaging industries all make regular use of this testing tool to avoid problems like spills, leaks, and customer dissatisfaction.

Why is Bottle Cap Torque Testing Important?

1. Prevents Leakage and Contamination

The quality of the product can be impacted by leakage that results from improperly sealed caps. Even a small sealing flaw can lead to damage in sectors like food and medicine, making products not suitable to be used by humans.

2. Ensures Consumer Convenience

Customers can become irritated with tightly sealed bottles because they are challenging to open. A Bottle Cap Torque Tester helps in providing a perfect balance between user comfort and safe product.

3. Maintains Brand Reputation

The reputation of a brand can be impacted by product complaints resulting from incorrectly sealed or strongly tightened caps. Manufacturers can increase customer trust by offering consistency in packaging quality through the use of an accurate torque tester.

4. Understands Industry Standards

Strict packaging quality requirements are followed by industry associations, especially in the food and pharmaceutical sectors. By offering accurate torque measurement, a torque tester guarantees to follow those guidelines.

5. Reduces Product Wastage

Variations in torque levels can result in packaging damage and product waste. Manufacturers can reduce losses and increase productivity by regularly testing torque.

How Does a Bottle Cap Torque Tester Work?

The method in which this equipment works is by strongly clamping the bottle and turning the cap. By measuring the torque force needed to open or close the cap, the device shows the results on an electrical or digital interface. Usually, this process includes:

• Placing the bottle – The tester secures the bottle to prevent movement.

• Rotating the cap – The cap is either opened or closed to measure the applied force.

• Recording the torque value – The device displays the exact force needed to remove or tighten the cap.

The Potential Uses of Bottle Cap Torque Tester

1. Beverage Industry

Water bottles, juices, and soft drinks need to be perfectly sealed to keep the carbonation levels high and stop leaks. A Bottle Cap Torque Tester allows simple opening while guaranteeing proper sealing.

2. Medical Industry

To avoid damage and guarantee child safety, medicinal bottles require accurate capping. Maintaining the right closure strength is helped by a bottle tester.

3. Cosmetic Industry

To avoid leaks, cosmetic items like lotions, shampoos, and perfumes need to be securely caped. The tester guarantees the accuracy and usage of the packaging.

4. Food Packaging Industry

To maintain freshness, edible oils, sauces, and dairy products need to be tightly sealed. Torque testing increases shelf life and helps avoid spoiling.

Choosing the Right Bottle Cap Torque Tester

When selecting a cap torque tester, consider the following factors:

• Accuracy – Reliable test results are guaranteed by a high-precision instrument.

• Digital or Analog Display – Digital displays are simpler to read and offer greater accuracy.

• Ease of Use – A user-friendly interface improves operational effectiveness.

• Durability – In industrial settings, a strong design guarantees long-term simplicity.

Why Choose Perfect Group India for Bottle Cap Torque Tester?

High-quality industrial equipment with accurate and trustworthy results are available from Perfect Group India. Our testing tools are made to help makers in improving product quality, reducing flaws, and raising customer satisfaction. Our torque testers are the perfect choice for your packaging requirements because of their innovative features, strong creation, and simple designs.

Key Benefits of Perfect Group India’s Bottle Cap Torque Tester:

• High-precision measurement of torque

• Digital interface that is easy to use

• Perfect for a range of bottle sizes and cap styles

• Made for maintained industrial use

• Helps in following to industry standards

Conclusion

A Bottle Cap Torque Tester is important to make sure that bottle caps are both safe and simple to open. In order to stop leaks and maintain product safety, it helps manufacturers in getting the proper amount of force required to tighten or loosen caps. Businesses can increase customer satisfaction and packaging quality by using this device. Products are reliable when they have a well-tested cap, which guarantees freshness and security. This device technique is very beneficial to industries like beverages, medical, and cosmetics. Perfect Group India helps companies maintain high standards and productive production by offering innovative methods for exact torque measurement. A trustworthy torque tester guarantees that packaging satisfies industry standards.

0 notes

Text

How Sterile Vacuum Bags Prevent Contamination in Storage

Keeping a high-quality product and avoiding any contamination during the storage and transporting process is imperative. Sterilized vacuum bags have become an essential need nowadays to safeguard sensitive integrity in these types of food, agriculture, and pharmaceutical items. It provides perfect protection against moisture, pests, oxidation, and other extraneous conditions when there is the presence of long-lasting freshness and hygiene.

This blog will discuss how large vacuum seal bags, along with other sterile vacuum bags, help minimize contamination, the benefits of those bags, and how they can be used in different fields.

What Are Sterile Vacuum Bags?

Sterile vacuum bags are specifically designed to package products that eliminate air and maintain an airtight seal. These bags are made from robust material that is safe for food products to come in contact with and are further able to preserve the quality of the products.

Vacuum sealing is removing oxygen from the bag and then shutting it so that no air can enter. Finally, the type of atmosphere that would have been formed is anaerobic; this will reduce the rate at which microorganisms such as bacteria, fungi, and any decomposing microbes may develop.

How Sterile Vacuum Bags Work to Prevent Contamination

Removing Oxygen

The principal nutrient for microbes is oxygen. Drawing out all air from the contents of these bags arrests bacterial growth, mold, and oxidation. For this reason, they are also used in such products as coffee, grains, and spices.

Water Barrier

The prime cause of contamination is water. Vacuum bagging prevents any exterior moisture from coming into contact with the product so that there would be no occurrence of dampness or mold and mildew.

Insect Protection

Conventional packaging makes it very easy for pests like insects and rodents to access products. Vacuum-sealed bags provide a total barrier that eliminates infestation.

Preservation of Nutrients

For perishable products, such as food, the nutritional value results from air and moisture. Vacuum storage bags seal out air and moisture, therefore ensuring freshness and nutrients within the product, preserving it as fresh as viable.

Reduction of Cross-Contamination

Due to vulnerability to environmental factors or adjacent items in common warehouses or transit, cross-contamination may happen. Vacuum bags have a barrier added for protection from this.

Applications of Sterile Vacuum Bags

1. Food Sector

Coffee and Tea: Using vacuum-packaged coffee bags avoids the contamination of moisture, air, and odor and keeps the smell and flavor of the roasted coffee beans or tea leaves from being destroyed.

Meat and Dairy: Vacuum packing does help preserve some fragile items, such as meat, cheese, and butter, from decomposition and other modes of deterioration leading to loss.

Fruits and Vegetables: These types of bags keep fruits fresh and prevent fruits and vegetables from losing their freshness by evading moisture and microbiological spoilage.

2. Agriculture

Grains and Pulses: A great vacuum seal bag is extensively used in storing grains, pulses, and seeds to safeguard for the long storage process against the ravages of rodents and mold as well as oxidation.

Fertilizers and Pesticides: Since they are put in vacuum bags, sealed so that no particles can pass, they won't decompose and will therefore be effective.

3. Pharmaceuticals

In pharmaceutical manufacturing, sterilization storage bags are used to preserve or deliver drugs, clinical equipment, and raw components so they do not become contaminated.

Retail and E-Commerce

Retail and e-commerce stores maintain their merchandise, which includes clothing, electronics, and specialty food, in vacuum bags so that such products reach the clients in the best condition.

Advantages of Sterile Vacuum Bags

1. Long Shelf Life

Packaging in a vacuum minimizes negative factors such as oxidation, which contributes to spoilage, and in the long run, waste and expenses are cut.

2. Storage Space

Reducing the quantity of the packaging approach means that more products can fit into the available area, consequently growing space utilization.

3. Enhanced Product Safety

It also helps keep out environmental elements that may corrupt the quality of the products and hence reduce their value.

How to Pack Using Vacuum Seal Storage Bags

When selecting vacuum-sealed bags for your business, consider the following factors:

Material Quality: The bags should be made from strong material and can be used for food storage.

Size and Capacity: Consider a bag with a large capacity volume to carry more products at once, for instance, big vacuum-sealed bags.

Barrier Properties: Choose good moisture and oxygen barrier properties in the bag

Eco-Friendliness: Choose an ecotact that meets your green goals.

Why Ecotact Bags?

As experts in innovative, eco-friendly hermetic packaging solutions at Ecotact, we offer diverse industries vacuum-sealed bags. We ensure fresh products, minimize contamination, and help our customers develop environmentally conscious habits. This sets us apart as a leader in the packaging industry.

We cater to food, agricultural, and pharmaceutical applications, from high-quality vacuum packaging bags to tailor to any needs.

Visit Ecotact Bags today and browse through our series of vacuum storage bags and how we could protect your product with sustainability at its best.

#large vacuum seal bags#vacuum packaging bags#best vacuum seal storage bags#vacuum sealed coffee bags

1 note

·

View note