#custom resin molds for sale

Explore tagged Tumblr posts

Text

We at Silicone Resin Molds have selected the most cost-effective rates for our custom resin mold, so anyone can try it. It is indeed mandatory to get in touch with the best team of professionals for help and that’s when the team of experts comes to the rescue. We have the best custom candle molds for your candle-making business.

#custom resin molds for sale#custom resin molds#Silicone Resin Molds#custom resin mold#best custom candle molds

0 notes

Text

#cheap silicone mold making#silicone molds for resin#rubber concrete molds for sale#custom popsicle molds

0 notes

Text

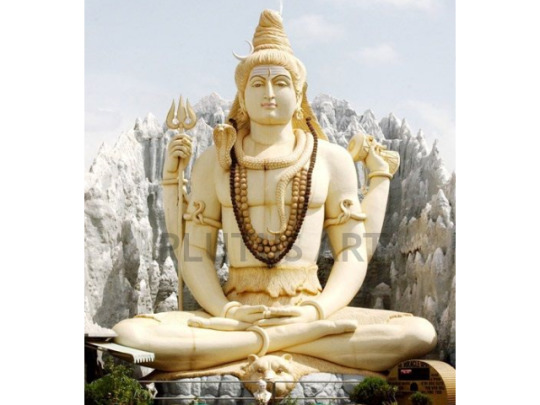

How Custom Fiberglass Statues made by Plutus Art can elevate your Brand

Introduction to Plutus Art and their custom fiberglass statues

In a world where branding is everything, standing out from the crowd can feel like an uphill battle. Enter Plutus Art and their stunning custom fiberglass statues. These eye-catching pieces are not just decorative elements; they are powerful tools that can elevate your brand to new heights. Imagine captivating your audience with vibrant, unique sculptures that tell your story and embody your values. With Plutus Art’s expertise in crafting exquisite fiberglass statues, you hold the key to transforming how people perceive and connect with your brand. Let’s explore how these remarkable creations can make a lasting impression on potential customers while enhancing brand visibility like never before.

Benefits of using custom fiberglass statues for branding purposes

Custom fiberglass statues serve as powerful branding tools that captivate audiences. Their vibrant colors and unique designs instantly grab attention, making them ideal for attracting foot traffic. These eye-catching pieces can effectively convey your brand message. Whether it’s showcasing a mascot or representing a core value, custom sculptures create memorable experiences that resonate with customers. Fiberglass statues are versatile and durable. They withstand various weather conditions, ensuring your investment remains intact over time. This longevity adds to their appeal, providing continual visibility without the need for frequent replacements. Additionally, these statues foster engagement on social media platforms. People love sharing photos with visually striking art installations, broadening your online reach effortlessly. Incorporating custom fiberglass sculptures into your marketing strategy creates an emotional connection with potential clients while enhancing overall brand recognition in innovative ways.

Examples of successful brand campaigns with Plutus Art's statues

Plutus Art's fiberglass statues have played a pivotal role in various successful brand campaigns. One notable example is their collaboration with a popular beverage company. The vibrant, oversized statue of the drink’s mascot became an Instagram sensation, drawing crowds and boosting social media engagement. Another campaign featured a retail brand that utilized custom sculptures to enhance its store façade. Shoppers were instantly attracted by the eye-catching designs, leading to increased foot traffic and sales during peak seasons. In addition, local businesses have leveraged Plutus Art's creations for community events. A festival showcased whimsical animal statues that represented each sponsor, creating memorable photo opportunities for attendees while promoting brand awareness. These real-world applications highlight how strategic use of fiberglass sculptures can resonate deeply with target audiences. They invite interaction and create lasting impressions that extend beyond mere advertising.

The process of creating a custom fiberglass statue with Plutus Art

Creating a custom fiberglass statue with Plutus Art begins with an idea. Clients share their vision, whether it’s a unique character or a larger-than-life replica. Next comes the design phase. Skilled artists at Plutus Art turn concepts into detailed sketches, ensuring every aspect aligns with your brand's identity. Feedback is crucial here; adjustments are made until you’re satisfied. Once approved, the sculpting process starts. Using high-quality materials, artisans craft a durable mold that captures intricate details. This step requires precision and creativity to bring your vision to life. After molding, they pour in fiberglass resin for strength and flexibility. Once cured, the surface gets polished and painted according to your specifications—color choices can really make an impact. The final touch involves adding protective coatings to ensure longevity against various elements while preserving vibrant colors. Each statue reflects not just art but also the essence of your brand’s message.

Factors to consider when choosing a design for your custom statue

When designing a custom fiberglass statue, think about your brand’s identity. What message do you want to convey? The design should reflect your values and resonate with your target audience. Scale is crucial too. A larger statue can create an impactful presence, while smaller pieces might fit better in intimate settings. Consider where the statue will be displayed; visibility plays a significant role in effectiveness. Colors matter as well. Choose hues that align with your branding palette for cohesion. This helps reinforce recognition and strengthens brand recall. Durability is another essential factor. Ensure that the materials used are suited for both indoor and outdoor environments based on where you plan to showcase it. Budget constraints can influence design options. Discussing these limitations early on ensures realistic expectations without compromising creativity or quality.

Maintenance and care tips for long-lasting use of your custom statue

To ensure your custom fiberglass statue from Plutus Art stands the test of time, proper maintenance and care are essential. These statues are designed to be durable, but a little attention can go a long way in preserving their beauty. First, regularly clean your statue using a soft cloth or sponge with mild soap and water. This prevents dirt buildup and keeps the colors vibrant. Avoid abrasive cleaners as they can scratch the surface. Next, consider placing your statue in an area protected from harsh weather conditions. Direct sunlight may fade colors over time, while rain or snow could lead to damage if not treated properly. If possible, cover it during extreme weather events for added protection. Check for any signs of wear or damage periodically. Addressing small issues right away can prevent more significant problems down the line. For example, tiny cracks might be repaired easily without needing extensive work later on. Use caution when moving your fiberglass sculptures to avoid chipping or cracking them accidentally. With these simple tips in mind, you’ll enjoy the artistic impact of your custom fiberglass statue for many years to come—enhancing both aesthetics and brand identity alike.

0 notes

Text

Why FRP Swimming Pools Are the Future of Modern Pool Design

As the demand for elegant, low-maintenance, and quick-to-install swimming pools grows, FRP Swimming Pool manufacturers are rising to the occasion with innovative solutions. Whether for residential backyards, luxury hotels, or rooftop installations, FRP (Fiberglass Reinforced Plastic) pools are becoming a top choice due to their durability, customization options, and aesthetic appeal.

In this blog, we’ll dive into why FRP swimming pools are changing the game in modern construction and how choosing the right manufacturer can make all the difference.

What is FRP and Why Is It Used in Pools?

FRP stands for Fiberglass Reinforced Plastic – a composite material made by reinforcing a plastic matrix with fine glass fibers. It’s well-known for its lightweight, corrosion resistance, and exceptional strength-to-weight ratio. These features make it ideal for environments exposed to moisture, chemicals, and sunlight – just like swimming pools.

Unlike traditional concrete pools that require long construction periods and continuous maintenance, FRP pools are factory-molded and arrive ready for installation. This reduces both construction time and labor costs significantly.

Key Benefits of FRP Swimming Pools

1. Durability and Strength FRP pools are highly durable and can last for decades with minimal wear and tear. They resist cracking, blistering, and UV degradation, which are common issues in concrete pools.

2. Low Maintenance The smooth surface of an FRP pool prevents algae build-up, meaning fewer chemicals are required. This not only saves on maintenance costs but also supports eco-friendly practices.

3. Leak-Proof Design Unlike traditional tiled pools that may develop cracks and leakage points, FRP pools are single-molded structures that are leak-proof by design.

4. Quick Installation Most FRP swimming pools are prefabricated and can be installed within a few days. This makes them ideal for projects with tight deadlines or locations where traditional construction is impractical.

5. Aesthetic Versatility FRP swimming pools are available in various shapes, sizes, and colors. Manufacturers often offer customization to match the theme or design of the surrounding property.

Where Are FRP Pools Commonly Used?

FRP swimming pools are ideal for a wide range of settings:

Residential homes: Compact and stylish pools that can fit even in small backyards or terraces.

Hotels and resorts: Premium designs with added features like seating, steps, lighting, and water jets.

Schools and clubs: Safe and low-maintenance pools for regular use.

Rooftops: Due to their lightweight construction, FRP pools can be safely installed on terraces.

Role of FRP Swimming Pool Manufacturers

A high-quality FRP swimming pool begins with a reliable manufacturer. Leading FRP Swimming Pool manufacturers use premium resins, gel coats, and reinforcement techniques to ensure their pools withstand environmental wear and tear. They also provide value-added services such as:

Custom design and engineering support

On-site installation and supervision

Filtration system integration

Post-installation care and warranty packages

By working with professional manufacturers, customers receive not just a product but a complete swimming pool solution that’s built to last.

Choosing the Right Manufacturer

Before investing in an FRP pool, it’s essential to evaluate manufacturers based on:

Experience and reputation in the industry

Product range and customization capabilities

Certifications and quality assurance practices

After-sales service and support

Ask for references or review past projects to assess their quality and workmanship.

Conclusion

In today’s fast-paced world, convenience, efficiency, and aesthetics matter more than ever. FRP Swimming Pool manufacturers are delivering all three by offering prefabricated pool solutions that meet modern needs without compromising on quality. Whether you're a homeowner looking to transform your backyard or a hotel owner aiming to enhance guest experiences, FRP pools provide a perfect blend of durability, beauty, and functionality.

As the market for modular and quick-installation pools continues to expand, it’s safe to say that FRP swimming pools are not just a trend—they are the future.

0 notes

Text

An Inside Look at Manufacturing Materials with RapidMade’s Micah Chaban

Introduction

Micah Chaban is the Founder and VP of Sales at RapidMade, a company that has been revolutionizing manufacturing with cutting-edge 3D printing, thermoforming, and machining solutions. With a background in advanced manufacturing and a commitment to customer-focused innovation, Micah has helped businesses across industries optimize their production processes with the right materials.

In this interview, Micah provides insights into how manufacturers can select the best materials for their needs, the latest advancements in 3D printing, and how RapidMade is helping companies navigate modern manufacturing challenges.

What makes material selection so critical in manufacturing?

Material selection determines a product’s durability, weight, flexibility, and performance—it’s one of the first decisions that needs to be made in any manufacturing process. If you choose the wrong material, you could end up with a part that’s too brittle, too heavy, or unable to withstand heat, chemicals, or mechanical stress.

At RapidMade, we work with clients to balance material properties with cost and manufacturability. You can have the strongest material in the world, but if it’s too expensive or difficult to produce at scale, it may not be practical. We always look for the right combination of strength, weight, cost, and environmental resistance for each application.

How has 3D printing changed material capabilities in manufacturing?

3D printing has completely transformed the way we think about materials and part production. Traditional manufacturing methods often require expensive tooling, long lead times, and design constraints. With 3D printing, we can create complex geometries, lightweight structures, and customized components without costly molds or machining setups.

One of the biggest advancements has been the development of stronger and more diverse materials. In the past, 3D printing was mostly used for prototyping, but today, we’re using materials like Nylon PA-12, carbon-filled composites, Ultem, and metal alloys to create end-use, production-grade parts. These materials allow manufacturers to replace traditionally machined or injection-molded parts with 3D printed alternatives that are just as strong—if not stronger—but significantly lighter and more cost-effective.

What are the key material options available for 3D printing?

At RapidMade, we work with four main 3D printing technologies, each with its own material strengths.

For Multi Jet Fusion (MJF), we offer Nylon PA-12, which is lightweight, chemical-resistant, and durable, making it great for industrial and consumer applications. We also use TPU (Thermoplastic Polyurethane) for flexible, rubber-like parts that need high wear resistance.

With Stereolithography (SLA), we have high-resolution resins that produce ultra-smooth parts. We use flame-retardant SLA resins for aerospace and automotive applications and elastomers for seals, grips, and impact-resistant parts.

For Fused Deposition Modeling (FDM), we work with high-performance thermoplastics like ABS, Polycarbonate, and Ultem 9085, which are commonly used in aerospace, medical, and industrial applications due to their heat resistance and mechanical strength.

Finally, we offer Metal 3D Printing with materials like 316L Stainless Steel and 17-4 PH Stainless Steel, which are ideal for high-strength, corrosion-resistant parts used in medical, aerospace, and industrial tooling.

How does thermoforming compare to 3D printing when it comes to material options?

Thermoforming is a great alternative for medium-to-large production runs of plastic parts. Unlike 3D printing, which is typically better for small-batch production and intricate geometries, thermoforming is ideal for scaling up production while keeping costs low.

The material selection is different too. With thermoforming, we use durable, lightweight plastics like HIPS (High-Impact Polystyrene), ABS, PETG, and HDPE for packaging, automotive panels, and protective covers. For high-performance applications, we offer Polycarbonate, Kydex, and even thermoformable carbon fiber, which provide superior impact resistance, flame retardancy, and lightweight strength.

If you need large, affordable plastic parts with strength and flexibility, thermoforming is the way to go. If you need highly complex, customized, or low-volume parts, 3D printing is the better option.

Why is machining still an essential manufacturing method despite advancements in 3D printing?

Machining will always be essential because some parts require extreme precision, high-strength materials, or specific surface finishes that 3D printing or thermoforming can’t achieve. It’s the best method for low-to-medium production runs of highly engineered components that need tight tolerances.

We machine a wide range of metals and plastics, including Aluminum, Stainless Steel, Carbon Steel, and Copper for structural and aerospace components. For non-metal applications, we machine Delrin, Nylon, PEEK, and PTFE (Teflon), which are great for low-friction, high-wear applications in medical and industrial fields.

If you’re making structural parts, load-bearing components, or medical implants that need precise dimensions and wear resistance, machining is often the best choice.

What are the biggest mistakes companies make when selecting materials for manufacturing?

One of the biggest mistakes is choosing a material based solely on cost without considering performance and manufacturability. A cheaper material might work initially, but if it doesn’t hold up in real-world conditions, you’ll end up with product failures, higher replacement costs, and lost production time.

Another mistake is not considering the full production process. Some materials are great for prototyping but can’t scale efficiently. Others might be strong but too brittle for certain applications. That’s why we always ask our customers:

What environment will the part be used in?

What mechanical stresses will it experience?

What’s the expected production volume?

By answering these questions upfront, we can recommend the right material for both prototyping and full-scale production.

What trends do you see shaping the future of manufacturing materials?

We’re seeing a lot of exciting developments, especially in composite materials and sustainable manufacturing.

Carbon-filled and fiber-reinforced materials are growing in popularity because they provide high strength with reduced weight, making them ideal for aerospace, automotive, and industrial applications. We’re also seeing biodegradable and recycled materials gain traction as companies focus more on sustainability and reducing plastic waste.

On the technology side, 3D printing continues to advance, with new materials being developed for higher heat resistance, improved flexibility, and even conductive properties for electronics applications.

Overall, the future of manufacturing is about better materials, faster production, and smarter design choices—and that’s exactly what we focus on at RapidMade.

How can businesses get expert advice on material selection and manufacturing?

We know material selection can be overwhelming, which is why our team works closely with clients to help them choose the best material for their application. Whether you’re in aerospace, medical, industrial manufacturing, or consumer products, we can guide you through the best 3D printing, thermoforming, or machining solutions to meet your needs.

If you need a 3D printing service or expert guidance on materials and manufacturing, contact us at [email protected] or visit rapidmade.com to learn more about how we can help optimize your production process.

0 notes

Text

The Genesis of Sangue Di Drago: How a Love for Dragons and a Little Frustration Created an Art Brand

Every artist has a beginning—an origin story that shapes their craft and fuels their creativity. Sangue Di Drago wasn’t born from a long-term plan but rather from a mix of passion, heritage, and a little bit of frustration.

A Name Rooted in Heritage

The name Sangue Di Drago is a tribute to my Italian roots, but more importantly, it’s a nod to someone who always encouraged me to embrace who I am—my Noni. She was my biggest inspiration when it came to fully owning my creativity and letting my weird, wonderful ideas flourish. No matter what I decided to pursue, she was there, supporting me without hesitation.

When it came time to name my art brand, I knew I wanted something that honored both my heritage and the spirit of individuality she helped nurture in me. Sangue Di Drago, meaning Blood of the Dragon, felt like the perfect fit. It carried strength, passion, and a connection to the mythical creatures I’ve always loved. It wasn’t just a name—it was a way to honor where I came from and the person who always believed in me.

A Dragon Mold That Changed Everything

I've always had a deep love for dragons, so incorporating them into my art was a no-brainer. But the real turning point came when I discovered the dragon mold I use today. It was adorable—small, expressive, and incredibly versatile. With the right paint job, I could transform that little dragon into any character I wanted, adding an unexpected charm to horror icons and pop culture figures alike.

From Frustration to Creation

Ironically, my journey into resin art began with a bad experience as a customer. I had ordered a custom resin piece from a small seller, but after endless delays and getting brushed off, I never received it. Instead of dwelling on the frustration, I decided to take matters into my own hands.

That Black Friday, I grabbed some resin and molds on sale and started experimenting. My first pieces were simple—I used the molds as intended, focusing on mastering painting techniques. But it wasn’t long before I wanted to push the boundaries of what I could create.

The Moment That Changed Everything

The real shift came when I applied for a local art show. I was excited to share my work, but the feedback I received stung: "This isn’t really art."

At the time, those words hit hard. But looking back, I’m grateful for that moment. It was the push I needed to evolve. That rejection inspired me to take my resin art to the next level—to build scenes, add bases, and create full dioramas that immersed my dragons in their own little cinematic worlds. My first major piece after that? Sam from Trick ‘r Treat, surrounded by a fully realized setting that made the character come to life.

The Evolution Continues

Since that moment, Sangue Di Drago has continued to grow, driven by my love for dragons and storytelling. Every piece I create is a fusion of nostalgia, fandom, and artistic challenge. What started as a simple idea has become a passion, and I can’t wait to keep pushing my art even further. If you’ve ever had someone tell you that your work isn’t really art—use it as fuel. Let it push you forward. Because sometimes, the best creations are born from a little bit of frustration and a whole lot of love for what you do.

1 note

·

View note

Text

BOPP – Biaxially Oriented Polypropylene Bags

BOPP bags are produced by laminating a reverse printed film to a woven fabric which is then manufactured into a bag. The film is stretched in both the machine direction (MD) and across machine direction (AMD). The result is a material with superior strength at low gauges, flatness, clarity, and excellent printability. This construction is in high demand due to its strength and superior picture-like print quality. Printing is achieved by applying the inks directly onto the film which is adhered to a woven fabric using a laminate coating. BOPP film is reverse printed, resulting in a protected interior print (between the film and laminate/woven fabric) which will not scratch or be easily damaged during normal use. The BOPP bag’s appeal includes dimensional stability, maximum water resistance, and high impact graphics that improve marketability, as well as optional anti-skid features.

Uses of a BOPP Bag: Since the BOPP bag is so versatile, its list of uses is infinite! They are used for dog and cat food, and other animal feed. Agricultural industries use them for fertilizer bags or storage for their animal feed and seeds. The food industry uses these bags to store grains, beans, and other food products. Builders and Construction companies used BOPP bags for concrete and plaster mixes, resins, and other dry materials.

Benefits of BOPP Bags: A major benefit of BOPP bags is that they are water-resistant. Locking out all moisture and keeping mold and mildew away. Another great benefit is that when they are empty, they are easily stored, allowing you to optimize your storage space. Once they are filled, they are so durable that they can be stored stacked on top of each other with no worry of damage. Unlike boxes or buckets that take up more space and crack under pressure.

An additional benefit of a BOPP bag is you can print your custom business logo on them. So, no need to buy a box with your logo to place the bag in, you save money and space by investing in BOPP bags. Allowing for increased production and more business exposure! Lastly, BOPP bags are recyclable.

If you have been looking for a BOPP bag supplier call us at 813 242 6995 or reach out to [email protected] for more information. We would be more than happy to tell you of all our services and how we can help. BOPP bags are great for business and advertising as well as for safekeeping your products.

#stretch film pricing#quick pak inc#free pallet wrapper#pricing news#stretch film#free machine#quickpakinc#resin pricing#youtube#coreless film#bopp film#bopp bags

0 notes

Text

What Are The Benefits of Synthetic & Natural Paeonol?

Natural Paeonol (C9H10O3), with CAS number 552-41-0, is an organic compound known for its analgesic, anti-inflammatory, antipyretic, and antiallergic properties.

Natural sourcing:

Paeonol is primarily extracted from moutan bark and Cynanchum paniculatum with an average content ranging from 0.5% to 2.0%. Common extraction methods include organic solvent extraction, distillation, macroporous resin extraction, and supercritical fluid extraction, among which steam distillation is most widely used.

Synthetic sourcing:

Paeonol is synthesized through chemical methods. Common synthetic approaches include Friedel-Crafts acylation, Fries rearrangement, and montmorillonite-catalyzed microwave synthesis.

Paeonol SpecificationItemsSpecificationAppearanceWhite crystals powderOdorCharacteristicTasteCharacteristicLoss on Drying≤1.0%Residue on Ignition≤0.1%Melting point49-51℃Extract SolventWaterHeavy Metal≤20ppmAs≤2ppmResidual SolventsEur.Pharm.2000Total Plate Count≤1000cfu/gYeast & Mold≤100cfu/gE.ColiNegativeSalmonellaNegativeAssay paeonol≥99.0%

Differences between Natural and Synthetic Paeonol:

Source and Preparation:

Natural Paeonol is extracted from moutan bark and Cynanchum paniculatum

Synthetic Paeonol is prepared through chemical synthesis methods, typically starting from phenol or other chemical raw materials and undergoing a series of reactions.

Chemical Composition and Purity:

Natural Paeonol usually contains other bioactive compounds.

Synthetic Paeonol is a single compound.

Applications and Effects:

Natural Paeonol is widely used in various industries such as food, leather, textile, and pharmaceuticals, serving as preservatives, dyes, tanning agents, and medicines.

Synthetic Paeonol, due to its higher purity and controllability, may have advantages in certain industrial applications, but there may be usage restrictions or regulatory requirements in fields such as food, pharmaceuticals, and cosmetics.

Common Application Areas:

Personal care and cosmetics products, such as toothpaste

Health supplements and pharma products: such as Liu Wei Di Huang Wan also known as Liuwei Dihuang tea pills or Six Flavor Rehmanni

Topical ointments such as Paeonol Ointment.

Prospects:

Paeonol as an organic compound with broad application prospects, has a promising market outlook. It holds significant development potential in the pharmaceuticals, cosmetics, and food industries. Strengthening scientific research, improving product quality, expanding market channels, and enhancing brand building can better exploit the market potential of Paeonol, thereby promoting its prosperous development.

Our Advantages:

Our products can provide certifications such as HALAL, HACCP, and KOSHER. The company is ISO-certified, and product production strictly adheres to GMP standards for quality control and stability.

We offer professional and economical shipment ways, including express, air, and sea freight, ensuring safe and prompt delivery to customers.

We have a professional business team that quickly understands your requirements for the correct product specifications through communication and provides technical support.

We have 20 years of experience in overseas sales, our products are sold in Southeast Asia, North America, Europe, the Middle East, and other regions.

GMP standard, Synthetic paeonol

0 notes

Text

custom resin mold

We at Silicone Resin Molds have selected the most cost-effective rates for our custom resin mold so that anyone can give it a try. It is indeed mandatory to get in touch with the best team of professionals for help and that’s when the team of experts comes to the rescue. We have the best custom candle molds for your candle-making business.

0 notes

Text

Fiberglass Tank Manufacturers

Benefits of Fiberglass Tanks

Fiberglass tanks are known for their durability, corrosion resistance, and versatility. These tanks are ideal for a wide range of applications, from water storage to chemical processing.

Durability and Longevity

Corrosion Resistance: Unlike metal tanks, fiberglass tanks do not rust and can withstand harsh chemicals and environmental conditions.

Strength and Lightweight: Combining strength with a lightweight structure, these tanks are easier to handle and install.

Versatility

Customizable: Fiberglass tanks can be tailored to specific needs, including size, shape, and features.

Wide Range of Applications: Suitable for numerous industries, from water storage and chemical processing to wastewater treatment and agriculture.

Cost-Effectiveness

Low Maintenance: These tanks require minimal maintenance, reducing long-term costs.

Longevity: Their extended service life leads to fewer replacements and cost savings.

Manufacturing Process of Fiberglass Tanks

Design and Engineering

Initial Design: Specifications such as size, capacity, and features are determined.

Engineering Analysis: Structural analysis ensures the tank can withstand intended loads and conditions.

Material Selection

Resins and Reinforcements: FRP materials, with different resins chosen based on the application.

Fiberglass Reinforcement: Materials like fiberglass mats or woven roving provide additional strength.

Molding Process

Filament Winding: Continuous fiberglass filaments are wound around a rotating mandrel.

Hand Lay-Up: Layers of fiberglass mat are manually applied and saturated with resin.

Curing: The tank is cured to harden the resin and achieve desired properties.

Quality Control

Inspection and Testing: Tanks undergo rigorous inspections and tests.

Final Finishing: Includes adding fittings, nozzles, and other accessories.

Applications of Fiberglass Tanks

Water Storage

Potable Water: Suitable for storing drinking water, meeting safety standards.

Rainwater Harvesting: Used in rainwater harvesting systems for water conservation.

Chemical Processing

Chemical Storage: Ideal for storing acids, alkalis, and solvents.

Process Tanks: Used in various stages of chemical processing.

Wastewater Treatment

Sewage and Industrial Effluent: Used in treatment plants for sewage and industrial effluent.

Agriculture

Irrigation Storage: Used for storing water, fertilizers, and pesticides in agriculture.

Key Considerations When Choosing a Fiberglass Tank Manufacturer

Experience and Reputation

Industry Experience: Opt for manufacturers with extensive experience in the industry.

Customer Feedback: Review testimonials and case studies to gauge reputation.

Quality Standards

Certifications: Ensure the manufacturer holds relevant certifications like ISO 9001, NSF/ANSI 61, and ASME RTP-1.

Quality Control Procedures: Check for stringent quality control procedures.

Customization Capabilities

Custom Design Options: The ability to customize tanks to specific needs is crucial.

Technical Support: Reliable manufacturers offer support throughout the process.

After-Sales Service

Warranty and Maintenance: Look for manufacturers that provide warranties and maintenance services.

Installation Assistance: Some manufacturers offer installation services or guidance.

Why Choose Pipeco?

Pipeco is a leading name in the fiberglass tank manufacturing industry, known for its high-quality products and exceptional customer service. Here’s why Pipeco stands out:

Expertise and Innovation: With years of experience and a focus on innovation, Pipeco continuously improves its products and processes.

Stringent Quality Control: Adhering to the highest quality standards, every tank undergoes rigorous testing and inspection.

Custom Solutions: Offering a wide range of customizable options, Pipeco ensures each tank meets specific requirements.

Comprehensive Support: From initial consultation to after-sales service, Pipeco provides comprehensive support, ensuring customer satisfaction at every stage.

Conclusion

Fiberglass tanks offer numerous advantages, making them a preferred choice across various industries. When selecting a fiberglass tank manufacturer, it is essential to consider factors such as experience, quality standards, customization capabilities, and after-sales service. Pipeco, with its commitment to excellence and customer satisfaction, stands out as a trusted partner for all your fiberglass tank needs. By choosing Pipeco, you can be assured of receiving high-quality, durable, and cost-effective solutions tailored to your specific requirements.

0 notes

Text

Unlocking the Mystique: Agarwood Products Wholesale Supplier

This precious resin-embedded wood, also known as oud, is highly sought after for its use in perfumes, incense, and traditional medicine. Finding a reliable agarwood products wholesale supplier is essential for businesses looking to tap into this lucrative market. This article delves into the key factors to consider when choosing an agarwood products wholesale supplier.

Understanding Agarwood and Its Value

The Origin and Harvesting of Agarwood

The resin, which gives agarwood its unique scent, forms when the tree is infected by a type of mold. This natural process makes agarwood rare and valuable. Harvesting requires the expertise of an experienced agarwood products wholesale supplier to ensure sustainability and quality, as only a small percentage of trees produce agarwood resin.

Applications of Agarwood

Agarwood's primary use is in the production of high-end perfumes and incense. Its deep, complex fragrance is prized in both Eastern and Western markets. Additionally, agarwood is used in traditional medicine, particularly in Chinese and Ayurvedic practices, where it is believed to have numerous health benefits, including stress relief and anti-inflammatory properties.

Keys Factors:

Quality Assurance

A reputable supplier should provide detailed information about the source of their agarwood, including the region it is harvested from and the methods used. Look for suppliers who offer certifications and testing reports to verify the purity and authenticity of their products.

Product Range and Customization

An agarwood products wholesale supplier should offer a diverse range of agarwood products to meet various business needs. This includes raw agarwood chips, essential oils, incense sticks, and more. Additionally, the ability to customize products based on specific requirements, such as fragrance intensity or packaging, can be a significant advantage.

Pricing and Value

While agarwood is inherently expensive, pricing should still be competitive and reflect the quality of the product. Transparent pricing policies and the availability of bulk discounts are essential factors to consider. Assess the overall value offered by the supplier, which includes not only the product cost but also the quality, service, and reliability.

Customer Support and Service

Excellent customer service includes responsive communication, efficient order processing, and after-sales support. A supplier who can provide expert advice on product selection and usage can be invaluable, particularly for businesses new to the agarwood market.

Reputation and Reviews

Researching a supplier's reputation is crucial. Positive feedback regarding product quality, delivery times, and customer service can provide confidence in your choice. Additionally, consider suppliers with a strong presence in the industry and a track record of long-term relationships with clients.

Partnering with a reputable agarwood products wholesale supplier is essential for businesses aiming to succeed in the competitive market of luxury fragrances and traditional remedies. By focusing on quality assurance, sustainable practices, product range, pricing, customer service, and reputation, you can ensure a reliable and fruitful partnership. As the demand for agarwood continues to grow, finding the right agarwood products wholesale supplier will position your business for long-term success and customer satisfaction.

1 note

·

View note

Text

How to create a custom art toy?

The first step to creating a custom art toy is to gather inspiration. Look at popular art toys, explore various art styles, and think about which themes or characters resonate with you. Sketch out your ideas and let your imagination run wild. Inspiration can come from anywhere—nature, city life, pop culture, or your own experiences.

Once you have some ideas, refine them into a cohesive concept. Identify the character, theme, and story behind the toy. Think about the emotions and messages you want to convey through your design. Your concept should be clear and unique, making your art toy stand out from the crowd.

Start by sketching your design on paper or using digital tools. Create multiple drafts and iterations until you are happy with the overall look. Pay attention to proportions, details, and how different elements of the design fit together.

To bring your design to life, you need a 3D model. Create a digital version of your art toy using 3D modeling software like Blender, ZBrush, or Tinkercad. This step allows you to visualize your toy from all angles and make necessary adjustments.

Once your 3D model is ready, the next step is to create a physical prototype. 3D printing is a popular method for prototyping art toys. Look for a reliable 3D printing service, or use your own 3D printer if you have one. Choose the right material based on your design requirements and budget. After 3D printing, you may want to refine your prototype by sanding, smoothing, or manually adding additional details. This step ensures that your final product has a refined and professional look.

Before painting, apply a coat of primer to the prototype to ensure that the paint adheres well. Use a high-quality paint that is suitable for your chosen material. Acrylic paint is a popular choice for making art toys. Take the time to meticulously paint each detail, and consider using an airbrush technique to achieve a smooth, even coverage.

After the primer has dried, add any final details, such as shading, highlights, or decals. These finishing touches can enhance the overall look of your art toy and make it truly unique.

If you plan to produce multiple copies of your art toy, you will need to make a mold. Silicone molds are often used for this purpose. The process involves creating a mold of the prototype, which can then be used to cast multiple copies in resin or other materials.

Once you have a mold, you can begin casting copies of your art toys. After casting, assemble any individual parts and make sure everything fits perfectly. Clean up any imperfections and prepare the toy for final painting and finishing.

Successfully marketing your custom art toys requires you to create a strong brand identity. Design a logo, packaging, and an engaging backstory for your toys so that a cohesive brand can attract collectors and fans.

Leverage social media platforms, dedicated websites, and online marketplaces to showcase and sell your art toys. Engage with your audience through behind-the-scenes content, progress updates, and interactive posts. Building a community around your brand can bring in loyal customers and increase sales. Network with other artists and collectors by attending art toy conferences and shows, providing valuable exposure for your artwork and showcasing your work to a wider audience.

0 notes

Text

What is the Pultrusion Molding Process of Epoxy Resin Composites?

The pultrusion profile process is a method of forming FRP profiles by pulling continuous glass fibre bundles impregnated with epoxy resin glue and other continuous reinforcing materials such as glass cloth tape and polyester surface mats under traction, forming FRP profiles by extruding the mold and curing them with heat in the mold and curing furnace.

The epoxy resin pultrusion process is an efficient manufacturing process that is widely used in electric power, chemical industry, metallurgy and other fields to produce products with high strength, corrosion resistance and wear resistance. This process uses epoxy resin as the basic material and is manufactured through multiple processes such as preheating, pressure heating, and extrusion molding.

The requirements for epoxy resin glue in the pultrusion molding process are: low viscosity, easy to penetrate into reinforced materials, long gel time (usually requires a service life of more than 8 hours), and fast curing to meet the requirements of continuous molding, good adhesion, the curing shrinkage is small, the flexibility is good, and the products are not prone to cracks.

Advantages of epoxy resin pultrusion process

High flexibility: The epoxy resin pultrusion process can manufacture products of various shapes, such as pipes, plates, etc., and can be customized as needed to meet the needs of different fields.

High strength: Epoxy resin has high strength. During the production process, the pultrusion process uses high-pressure heating to make the resin more uniform, thus greatly improving the strength of the product.

Good corrosion resistance: Epoxy resin has excellent corrosion resistance and can withstand the erosion of corrosive media such as acids, alkalis, and salts, thereby extending the service life of the product.

Strong wear resistance: Epoxy resin has good wear properties and can be used in high-strength, high-friction environments, greatly extending the service life of the product.

Comparison between epoxy resin pultrusion process and traditional processing methods

Compared with traditional processing methods, the epoxy resin pultrusion process has the following advantages:

High production efficiency: Using the pultrusion process can greatly improve production efficiency, shorten the production cycle, and reduce production costs.

Energy saving and environmental protection: The pultrusion process does not require the use of a large amount of auxiliary agents, which can save energy. At the same time, the epoxy resin can be recycled, reducing environmental pollution.

High technical content: The epoxy resin pultrusion process requires multiple manufacturing processes, which requires high production technology and can improve the quality and service life of the product.

Application prospects of epoxy resin pultrusion process

With the increasing awareness of environmental protection, the application prospects of the epoxy resin pultrusion process are becoming more and more broad. Epoxy resin products can replace traditional metal materials and have the advantages of lightweight, high strength, safety and reliability. They are widely used in various fields such as electric power, chemical industry, metallurgy and so on.

The epoxy resin pultrusion process is an efficient, flexible, corrosion-resistant, and wear-resistant manufacturing process. Compared with traditional processing methods, it has the advantages of high production efficiency, energy saving, environmental protection, and high technical content. With the increasing awareness of environmental protection, its application prospects in various fields are broad.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#epoxy resin manufacturer#bisphenol a type epoxy resin#epoxy resin supplier#pultrusion molding process#epoxy resin composites#composite pultrusion molding process#pultrusion composites#pultrusion process#pultrusion products#filament winding

0 notes

Text

Can Resin be a Good Business Idea

Yes, resin crafting can indeed be a lucrative business idea for several reasons:

Growing Demand: A growing market for handmade, personalized, and unique items exists. Resin crafts offer many possibilities for creating custom pieces, making them highly desirable among consumers looking for something special. Also Read: How to start a resin art business complete guide.

Customization: Resin crafts can be highly personalized, allowing you to cater to specific tastes and preferences of your customers. Whether it's jewelry, home decor, or accessories, you can create items tailored to individual needs, making them more attractive to potential buyers.

Low Startup Costs: Starting a resin crafting business typically requires minimal initial investment compared to other ventures. Basic supplies such as resin, molds, and pigments are relatively affordable, making it accessible for hobbyists to turn their passion into a business.

Creative Flexibility: Resin crafting allows for endless creativity. You can experiment with different colors, techniques, and materials to create unique and eye-catching products that stand out in the market. This flexibility enables you to continuously innovate and keep your offerings fresh.

Multiple Revenue Streams: Beyond selling finished resin products, you can also offer workshops, tutorials, and DIY kits to generate additional income streams. Teaching others how to work with resin can be both fulfilling and profitable.

Online Marketplaces: With the rise of online marketplaces like Etsy, Shopify, and social media platforms, reaching potential customers has never been easier. You can showcase your products to a global audience and leverage digital marketing strategies to drive sales.

Sustainability: Resin crafting can be eco-friendly by using sustainable and biodegradable materials such as eco-resin or recycled elements. This eco-conscious approach can appeal to environmentally-conscious consumers and set your business apart from competitors.

Seasonal Demand: Certain resin products, such as holiday ornaments, wedding favors, or seasonal decorations, experience spikes in demand during specific times of the year. Capitalizing on seasonal trends can boost your sales and profitability.

However, like any business venture, success in resin crafting requires dedication, creativity, and effective marketing strategies. It's essential to conduct thorough market research, establish a strong brand identity, and provide excellent customer service to thrive in this competitive industry.

0 notes

Text

What’s Next For The Plastic Industry?

The plastics industry is experiencing rapid global expansion, encompassing a diverse array of plastic products. This sector includes materials utilized in crafting items such as plastic bottles, cups, toys, and various other industrial goods like plastic pallets. Being a substantial contributor to the global economy, the plastics industry wields considerable influence on both societal and environmental fronts. Plastic manufacturers specialize in producing plastic products, offering a range of options for businesses seeking to manufacture their plastic goods.

How Plastic Products are usually made?

Plastic products are predominantly manufactured using injection molding, a process that entails melting plastic resin and injecting it into a mold to attain the desired shape. Renowned for its speed and efficiency, injection molding remains a favored method among plastic product manufacturers.

Furthermore, an increasing number of plastic products are crafted from recycled materials, contributing to both environmental sustainability and cost reduction. These recycled materials often exhibit comparable strength and durability to their virgin counterparts, making them a compelling option for a diverse range of products.

Why is customization expensive?

Numerous manufacturers in the plastic products industry offer customized solutions tailored to the unique specifications of their clients, enabling businesses to procure items precisely suited to their requirements. While custom products often come with a higher price tag compared to standardized options, the investment may be justified for certain businesses seeking tailored solutions.

Are plastic products a part of the global economy?

Manufacturers from plastic industry play a crucial role in the global economy by supplying businesses with the necessary products and contributing to job creation in the manufacturing sector. Producing high-quality goods is key for these manufacturers to support the sustained success of companies they serve. When selecting a plastic product manufacturer, factors such as experience, reputation, and capabilities should be carefully considered. Conduct thorough research to identify a manufacturer with a track record of producing products that align with your requirements and standards.

What are the Benefits of Investing in the Plastics Industry

Investing in the plastics industry encompasses expanding production capacity and enhancing efficiency, thereby minimizing environmental footprint, and fostering avenues for innovation. Through such investments, companies can develop more sustainable products, mitigating environmental harm. Moreover, integrating plastics production into an existing company can bolster sales and stimulate overall growth.

What are the prospects for the Plastics Industry?

The outlook for the plastics industry indeed holds promise, but it’s crucial to consider both the opportunities and challenges it faces. While advancements in technology and innovation can lead to the development of more sustainable products and processes, there’s also a growing demand for solutions that address environmental concerns such as plastic pollution, carbon footprint. Companies that prioritize sustainability, invest in research and development for alternative materials, and adapt to changing consumer preferences will likely fare well in this evolving market.

What are the Requirements for a Good Plastics Business?

The requirements for a good plastics business vary depending on the industry. Still, a plastics business must generally have a good understanding of plastic manufacturing and be able to find and supply high-quality plastics products. Additionally, the company should be prepared to handle customer service and warranty claims.

What are the key considerations when collaborating with plastic product manufacturers?

The first consideration is the type of plastic used. Many plastics are derived from fossil fuels, making them non-renewable and potentially harmful to the environment. Conversely, some plastics are crafted from plant-based materials, offering a more sustainable alternative. It’s crucial to inquire about the plastic type employed by a manufacturer before making a selection.

Next, the manufacturing process warrants attention. Certain methods can emit hazardous chemicals into the environment. Therefore, it’s important to evaluate the environmental impact of a manufacturer’s production process.

How can recycling plastics lead to cost savings?

Recycling plastics can indeed lead to cost savings. Many manufacturers opt to utilize recycled plastics in the production of durable goods. However, these recycled plastics can also find application in end packaging products. Certain items, such as print paper, command higher prices, and utilizing recyclable materials can offer both quality and economic benefits. While some manufacturers may hesitate to embrace recycled plastics, governments are increasingly supporting plastic recycling industries by providing incentives.

How to Get Started in the Plastic Industry?

Finding the right supplier for your plastic products can be a challenge. To get started, you’ll need to find a company with a good reputation and an understanding of the plastics industry. You should also ensure that the supplier has the necessary manufacturing capabilities and resources to produce your product.

Which things to consider while choosing a plastic manufacturer?

When selecting a plastic manufacturer, several critical factors should guide your decision-making process. Firstly, ensure that the manufacturer possesses significant experience in producing the specific plastic products you require. Additionally, familiarize yourself with their manufacturing processes and quality control measures to ascertain the reliability and consistency of their output. Equally important is evaluating the company’s customer service standards and return policies, as these aspects can significantly impact your overall experience as a client.

By prioritizing these essential considerations, you can confidently choose a plastic manufacturer that aligns with your needs and expectations.

What are the benefits of collaborating with plastic manufacturers?

Experience and Expertise:

Plastic manufacturers offer extensive experience and expertise in producing plastic products. They assist in designing and delivering high-quality products tailored to specific needs.

Access to Various Plastic Types:

Manufacturers typically have access to a diverse range of plastic materials, enabling the creation of a wide variety of products.

Time and Cost Savings:

Collaborating with plastic manufacturers saves time and money. They possess the necessary equipment and resources for efficient large-scale production, aiding in meeting deadlines and cost-effectiveness.

Support Services:

Plastic manufacturers provide comprehensive support services, including product design, production assistance, and marketing and sales support. This support ensures product success in the market.

Conclusion

Plastic manufacturers bear a dual responsibility to both the environment and consumers, ensuring the safety and eco-friendliness of their products. While the industry has made significant strides in recent years, there remains a continuous need for further improvement. Consumers also play a vital role in this endeavor by actively participating in recycling and reusing plastic products whenever feasible. Through collaborative efforts between manufacturers and consumers, we can collectively contribute to a more sustainable future.

0 notes

Text

20 Resources That'll Make You Better At Mingja Restaurant Furniture

Flash Omega Chaise for Poolside Relaxation

We tend to love this toptier brand for their incredible quality and a spotlight to detail in each piece they turn out, together with their extensive expertise in furniture industry that results in highend patio furniture meant to face the take a look at of your time.

Outdoor Furnishings Brands and Manufacturers

Wicker and cast aluminum furniture are two of the foremost resilient choices obtainable for outdoor seating, ready to withstand changing weather conditions, direct sunlight, and different outside components. And, both materials come back with varied finishes and colors therefore that you'll notice specifically what fits into your condo space.

Select from Nordic galvanized patio sets, eyecatching Acacia wood loveseats and weatherproof resin wicker furniture woven in with weatherproof cushions to seek out your excellent style! Your biggest challenge will be selecting just one!

Industrial Rated Out of doors Furniture. Commercialgrade out of doors furniture is made to withstand frequent use and the elements. Though a lot of pricey, this type of outside furniture will typically outlive its residential counterpart.

Home Depot offers another fantastic choice in outdoor furniture: it carries items from numerous manufacturers and styles from inexpensive to highend choices, continually adding new pieces as time goes on. They are known for providing low costs for cushions and throw pillows in addition to giving grills and other outside living necessities! Contract Furnishings International provides all the industrial pool furniture you need for any outside space massive pool clubs, public swimming pools or private resorts alike at Contract Furnishings International. From vinyl strap chaise lounges and pool side chairs designed to make sure comfortable relaxation to cheap nevertheless American created options; our pool furniture is on sale currently!

LBO is the premier wholesale provider of aluminum metal patio and pool furniture for public swimming pools, private swimming pools, water parks, YMCA's, residences, home house owners associations (HOA's), hotels and resorts. Their prime quality business grade patio and pool furniture product are manufactured using superior materials like Marine Grade Polymer that resist warping, fading or chemical breakdown perfect to be used at private and non-private pools alike! Contract Furnishings International provides trendy yet comfy out of doors furniture to any business, perfect for restaurants, hotels or clubs alike. Our wide selection of patio furniture matches any theme or style with styles designed to stand up to rain, snow and sun an essential consideration when selecting out of doors seating for any restaurant, hotel or club.

Whether you�re looking for outside furniture for your porch or deck, Notable Outside Living has the right items to satisfy your wants. We tend to supply a big variety of designs and sizes to fit any house, and our customer service is unparalleled. To learn more about the varieties of furniture we carry, contact us nowadays.

A number of the simplest pool furniture ideas for out of doors spaces include chaise lounges and alternative chairs crafted from longwearing materials like teak or resin wicker. Though more expensive than alternative patio furniture pieces, these chairs can rise higher over time and create a better aesthetic in your pool area. Furthermore, adjustable backrests could add comfort.

Homeowners ask for weatherproof out of doors furniture that can stand up to the elements, like weatherproof and rustresistant pieces that are simple to maintain with fabrics that dry quickly and resist mildew and mold growth. Contemplate furniture created of recycled materials with faderesistant finishes as ideal choices.

Outside resin furniture makes an enticing and purposeful addition to any home, while being ecofriendly and weather resistant. Furthermore, it resists mould growth in addition to mildew growth.

Resort Life Extendable Table made from premium Eucalyptus Wood with a light-weight aluminum frame is another fantastic option, featuring natural organic features including cracks and colour variations that enhance its beauty. Treated with Duragrain waterbased end to shield its surface while displaying natural grain options of wood surface.

youtube

Textilene

Resin furniture may still draw householders to its natural organic charms, but nextgeneration materials such as resin are quickly gaining in popularity thanks to their sturdiness and flexibility. Resin furniture items could prove worthy alternatives to wooden tables and chairs thanks to their look while not compromising on quality; but, before creating a final decision concerning getting resin furniture.

Choose from Nordic galvanized patio sets, eyecatching Acacia wood loveseats and weatherproof resin wicker furniture woven in with weatherproof cushions to find your perfect vogue! Your biggest challenge can be selecting simply one!

Eco-Friendly Flash Furniture Options

Resin plastic outside furniture could be a nice alternative for restaurants, patios and pool areas. It�s simple to scrub, durable and appearance stylish. Several styles can be stacked for convenient storage, and many are proof against stains and UV rays. They�re additionally lightweight, therefore they'll be easily moved around your house to accommodate guests and events. There are a number of types of resin plastic, together with polyethylene (PE), highdensity PE (HDPE), and polypropylene (PP). HDPE is additional sturdy than polyvinyl chloride (PVC) and is immune to fading, chemical degradation, and warmth harm. It�s conjointly abrasionresistant and punctureproof. Polypropylene may be a stronger, lighterweight option than PE and is more flexible. It�s less costly than HDPE, however isn't as strong or weatherproof.

Flash Furniture Colors and Finishes

Brian's Furniture offers a comprehensive choice of out of doors furniture appropriate for every size yard and budget. We tend to carry each brand name items from trusted manufacturers also exclusive styles created inhouse whether you are searching for luxurious wrought iron sets or more casual conversation items, you are certain to seek out your ideal item at Brian's. If you're wanting to create a snug out of doors lounge space, strive this reclining chair and ottoman set. Its elegant design and neutral hues build it appropriate for any yard style. We have a tendency to offer several other reclining chairs, chaise lounges, and sectionals in several styles and sizes too.

Eco-Friendly Omega Chaise Options

Selecting Outdoor Furniture For Your Hoa. Take into account how residents and guests can use your hoa's outside furniture when purchasing it for them. Weatherproof tables and chairs bring indoor comfort outdoors while rockers or Adirondacks give relaxing lounging options.

Outdoor Furnishings for Yoga and Exercise

Brian's Furniture attracts its name from Louisiana culture's love affair with its signature sugar kettles from planters and fountains to simple estate ornaments, sugar kettles are an integral half of its style and you can get one for your own residence here at Brian's.

BFM Seating Omega Chaise for Solo Relaxation

Floating chairs are increasingly changing into fashionable because of their versatility and comfort. Constructed of polystyrene beads, these chairs return equipped with cushioned backs, armrests and an connected ottoman for relaxing by your pool. Many stackable models will easily fit into storage during winter months.

Outdoor FurnishingsOutdoor FurnitureOmega Chaise for Picnic Excursions

BFM Seating offers highend out of doors lounge furniture that's made with antistatic and moisture resistant resin, that includes elegant yet practical styles crafted in Italy for complete Made in Italy production processes.

Gar FurnitureOutdoor FurnitureRestaurant Furniture for Spring Renewal

An inflatable pool lounge chair will take your poolside expertise to the next level. Select from numerous colours, dimensions and shapes.

Outdoor Furnishings for Entertaining Guests

Selecting the proper balcony furniture for your condo is essential to creating it actually your own space. Your selection ought to replicate both your style and temperament whereas simultaneously increasing its value. Outer furniture offers stylish and durable patio items made with highgrade materials and come complete with lifetime warranties with money back guarantees, making them a sound investment.

Rustic Omega Chaise Inspirations

Teak wood could be a fashionable selection for patio furniture as a result of it can be left outside yearround in all environments and needs terribly very little maintenance. The wood has a high oil content that protects against pests, minimizes rot and resists weather injury. Another sustainable option is shorea, a reddishgold Southeast Asian hardwood. This sturdy hardwood is sourced responsibly and has similar qualities to teak.

Eco-Friendly Omega Chaise Options

Versatility

youtube

Flash Omega for Sustainable Living

Pottery Barn offers an impressive assortment of outdoor furniture if you are willing to travel the additional mile when selecting out of doors pieces for your patio, from chairs and dining tables, through custom orders. Their teak wood furniture stands up well against weather parts. Additionally, this complete provides highend merchandise with luxurious details like handapplied finishes and custom stitching.

Resin furniture may still draw homeowners to its natural organic charms, however nextgeneration materials such as resin are quickly gaining in popularity due to their sturdiness and suppleness. Resin furniture items may prove worthy alternatives to wood tables and chairs because of their appearance without compromising on quality; however, before making a final decision concerning getting resin furniture.

Industrial Rated Outdoor Furniture. Commercialgrade outside furniture is constructed to stand up to frequent use and the elements. Though a lot of pricey, this type of out of doors furniture can usually outlive its residential counterpart.

The worldwide out of doors furniture market is experiencing unprecedented growth, driven by rising disposable incomes of consumers who invest in creating visually appealing sitting areas for his or her gardens and balconies. Lounge chairs and seating sets are key product driving this market's growth.

Everyday Restaurant Omega for Reading Nooks

When purchasing patio furniture, it is wise to appear for items that may face up to adverse atmospheric condition. If you reside in an area liable to frequent rainfall, choose weatherresistant fabrics or furniture with protecting umbrella bases and canopies as this will offer additional rain protection. Similarly, considering galvanized steel is also an option as this material provides additional sturdiness against corrosion or rusting. Additionally to tables and chairs offered from Costco, Costco conjointly offers patio furniture covers which feature fitted styles to permit air circulation thus mildew doesn't develop; these covers come back in numerous colours/ sizes creating this an invaluable addition for any patio space!

BFM Seating Furniture for Small Spaces

Online is typically the most effective place to search out highquality outdoor furniture. Not like traditional brickandmortar stores, on-line shops carry a wider selection of products and types than physical locations do some even having dedicated sections for out of doors furnishings! Customers will simply shop and compare choices. Plus, these websites offer detailed product descriptions with their features and financing solutions. Some outside furniture brands use social media channels as a further avenue for customer and industry engagement, and to produce more tailored client service whereas meeting business needs. This allows these firms to satisfy trade demand more easily while meeting client expectations more reliably.

When choosing patio furniture for your pool patio, it's essential that it be both sturdy and fashionable. Business outdoor furniture designed to resist sun, water and temperature fluctuations can face up to constant use whereas offering you numerous styles and materials to form an inviting ambiance around your pool.

Based on your atmosphere, usage, and storage wants, selecting sturdy furniture materials will be essential to its longterm functionality. Some materials are higher suited to bound weather conditions than others and some require constant maintenance in order to stop damage or discoloration.

Grand resort outside furniture is typically constructed of premium materials like teak wood and stainless-steel, that includes sleek up to date and minimalist designs furthermore modular pieces designed to be simply reconfigured as required. Many pieces additionally boast classic or traditional parts for an aesthetically pleasing ensemble look.

Resort Life Extendable Table made from premium Eucalyptus Wood with a light-weight aluminum frame is another fantastic possibility, featuring natural organic features together with cracks and colour variations that enhance its beauty. Treated with Duragrain waterbased end to shield its surface while displaying natural grain features of wood surface.

Materials create all the distinction from aluminumframed rattan lounge sets to teak dining tables that can stand the check of your time, these sturdy designs will stand the check.

Homecrest stands out among US brands providing outside furniture by combining design and sturdiness into their merchandise. Homecrest provides an extensive range of styles and sturdy items using high quality materials with rigorous testing processes to confirm long lasting furniture items. Additionally, they promote green living through using recycled aluminum, steel and wrought iron elements furthermore recycled wood pieces in all their wood furnishings.

0 notes