#corrosion Inhibitor in Gujarat

Explore tagged Tumblr posts

Text

The Role of Oilfield Chemicals in Enhanced Oil Recovery

Oil has been a vital source of energy for decades, and its demand continues to grow exponentially. However, with the depletion of easy-to-reach reserves, the industry is now turning to enhanced oil recovery (EOR) techniques to extract oil from older and more challenging reservoirs. One crucial aspect of EOR is the use of oilfield chemicals, which play a critical role in improving the efficiency and effectiveness of the recovery process.

Oilfield chemicals are specialty chemicals that are used in the exploration, production, and transportation of oil and gas. These chemicals can be broadly classified into three categories: drilling chemicals, production chemicals, and EOR chemicals. EOR chemicals are specifically designed to increase the amount of oil that can be extracted from a reservoir, which makes them a critical component in the oil production process.

The primary objective of EOR chemicals is to reduce the interfacial tension between the oil and water phases, allowing the oil to flow more easily through the porous rock formations. Some of the most commonly used EOR chemicals include surfactants, polymers, and alkaline chemicals. Surfactants are used to reduce the interfacial tension between the oil and water phases, while polymers are used to increase the viscosity of the injected water, thereby improving the sweep efficiency. Alkaline chemicals, on the other hand, are used to neutralize the acid present in the reservoir, which can increase the permeability of the rock.

Oilfield chemicals manufacturer in India, such as the best Oilfield chemicals company in Vadodara and the best Oilfield chemicals company in Gujarat, play a critical role in the production of EOR chemicals. These companies develop and manufacture a wide range of EOR chemicals that are specifically designed to meet the unique needs of the oil industry. They use the latest technology and state-of-the-art facilities to produce high-quality chemicals that are both effective and environmentally friendly.

Oilfield chemicals exporter in India also plays an essential role in the global oil industry. They are responsible for exporting EOR chemicals to oil-producing countries around the world, helping to improve the efficiency and effectiveness of oil production.

In conclusion, EOR chemicals play a critical role in the oil production process, and the oilfield chemicals manufacturer in India, the best Oilfield chemicals company in Vadodara, the best Oilfield chemicals company in Gujarat, and oilfield chemicals exporter in India are all essential players in this industry. With their expertise and commitment to quality, these companies are helping to ensure a steady supply of oil for years to come.

#best Oilfield chemicals company in Vadodara#Oilfield chemicals manufacturer in India#Oilfield chemicals exporter in India#best Oilfield chemicals company in Gujarat#corrosion Inhibitor in Gujarat#corrosion Inhibitor exporter in India#corrosion inhibitors manufacturers In India#corrosion Inhibitor supplier in Gujarat#Corrosion Inhibitor exporter in Gujarat

4 notes

·

View notes

Text

Guardians of Durability: Imperialchem - Leading Corrosion Inhibitors Manufacturer and Supplier in Vadodara and Gujarat, India

Imperialchem stands tall as the go-to source for Corrosion Inhibitors in Vadodara and across Gujarat. As a trusted Corrosion Inhibitor Manufacturer in India, we take pride in delivering solutions that safeguard against deterioration. Elevate your protection standards with Imperialchem, your dedicated Corrosion Inhibitor Supplier known for excellence in the best chemical company in Vadodara. Trust Imperial Oilfield Chemicals Private Limited for reliability that preserves and enhances the longevity of your assets.

#Corrosion Inhibitor in Vadodara#Corrosion Inhibitors Manufacturer in India#Corrosion Inhibitor Supplier in Vadodara#Corrosion Inhibitor Supplier in Gujarat#Best chemical company in#Best chemical company in Vadodara#Chemical

6 notes

·

View notes

Text

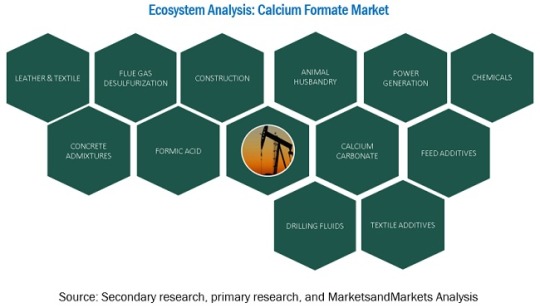

Growing demand of calcium formate in the construction industry

Calcium formate is used as cement additive and concrete accelerator, tile adhesives and cement-based mortars. The growth in the consumption of cement from the construction industry effectively boosts the demand for calcium formate market.

Calcium fromate is used as a cement additive in the construction industry for quick setting and increasing hardness of cement products. Cement is also used in the production of various products such as bricks and blocks, slabs and sheets, adhesives and concrete. In addition, calcium formate is also used as an inhibitor, PH regulator, corrosion protector to substrates of buildings and infrastructure, and for cementation of oil drilling. It is mostly used in the production of concrete in China which is one of the most dominant countries in the production and consumption of cement. Thus, the growing demand of cement in the construction industry is driving the market for calcium formate

Download PDF Brochure: https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=191530782

The global calcium formate market size is estimated to grow from USD 545 million in 2020 to USD 713 million by 2025, at a CAGR of 5.5% during the forecast period. The market is projected to witness decent growth in the near future, owing to the wide application areas of calcium formate ranging from leather and textile to the construction industry. Increasing demand from APAC will further drive the growth of the global calcium formate market.

The construction industry will continue to lead the calcium formate market, , accounting for a share of 29.7% of the overall market, in 2019 terms of value. Increasing construction and infrastructural activities is expected to boost the rising demand for cement and concrete in the near future. The use of calcium formate as an accelerator in the concrete setting application decreses the setting time and increases the strength, thus boosting the global calcium formate market

Recent Developments

In November 2019, Perstorp, invested in the construction of a new Pentaerythritol (Penta) production facility in Gujarat, India. The Gujarat plant will produce Penta, including the renewable grades of Voxtar, providing up to a 60% reduced carbon footprint. Commercial production is planned to start in Q1 2022.

In February 2020, LANXESS completed the acquisition of Itibanyl Produtos Especiais Ltda. (IPEL). With the acquisition, LANXESS is strengthening its position as one of the world’s leading manufacturers of antimicrobial active ingredients and formulations.

APAC is estimated to be the leading calcium formate market during the forecast period. The growth in this region can be attributed to the rapidly increasing demand for calcium formate from the end-use industries, especially construction, leather & textile and animal husbandry. The market is witnessing moderate growth, owing to increasing application, technological advancements, and growing demand for these calcium formate additives in the APAC and Europe.

0 notes

Text

Chemicals & Pharmaceutical Manufacturer in Vadodara, India

Exporter, supplier, manufacturer, dealer & distributor of chemicals & pharmaceutical intermediates, APIs, bulk drugs at Vadodara, Gujarat, India regularly available with COA and customized packing & ready stock available in Gujarat, India.

Industrial Chemicals

Industrial Acid

Specialty Chemicals

Pharmaceutical Chemicals

Active Pharma Ingredients

Agriculture Chemicals

Fine Chemicals

Cosmetic Chemicals

Bulk Drugs

Epoxy Coating chemicals

Construction Chemicals

Oil field chemicals

Water Treatment Chemicals

Swimming Pool Chemicals

Phase Transfer Catalyst

Chlorinated Intermediates

Chlorine Chemicals

ETP Chemicals

STP Chemicals

Pharma Raw Materials

Importer of Industrial & Pharma Chemicals in India

Buyer & Seller Used Machinery for Pharma & Chemicals Industries in India

Surplus/Non-Moving Chemicals buyer & Seller in India

Byproduct/Waste Grade Chemicals Buyer & Seller in India

Best & Top Chemical & Pharma companies in India

Pharma Impurities for formulation manufacturer & pharma companies

Contract Manufacturer of Pharmaceuticals & Chemicals

Solvents (Distilled, Recovered & Pure)

Quats & Phase transfer catalyst

Detergent Chemicals

Detergent Raw materials

BASF Products

Ashland pharma excipients dealer & distributor in India

COA & MSDS available for All products in India

Epoxy Coatings

Hand Sanitizers raw materials and ready made hand sanitizers manufacturer

RO Antiscalants

RO Maintenance Chemicals

Polyelectrolytes

Iron Removal Media

Filter Media

Ion Exchange Resins

Hospital Disinfectants

Biocides

Swimming Pool Chemicals

Boiler Chemicals

Cooling Tower Chemicals

Microbial Culture

Corrosion Inhibitors

Speciality Chemicals

Thickeners

Super Absorbent Polymers

Agriculture Chemicals

Defoamer imported & BASF

Fire Retardant Chemicals

Paper Chemicals

Sugar Chemicals

Housekeeping Chemicals

Bulk Chemicals

0 notes

Photo

Corrosion Inhibitor and Oil Field Chemicals

Corrosion Inhibitor is essentially a chemical compound that can decrease rate of corrosion of a metal that is in full exposure to nature. For example, it can be added to a chemical stream to reduce chances of corrosion.

The main purpose is to prevent corrosion, however the effectiveness depends on several factors. Main factors are the fluid composition, flow and percentage of water. The way it works is by forming a coat around the metal so that this layer prevents direct contact of environmental elements with the metal.

It is possible to deal with the issue of corrosion in many different ways. One method is chrome plating, although this is a permanent solution. The other solution is making use of corrosion inhibitor which is essentially an additive to a liquid substances that surround a metal. Such types of inhibitors are commonly found and can be a spray with some form of lubricant or can even be a penetrating oil.

Rimpro India with registered office at Mehsana, Gujarat is one of the largest manufacturer & exporter of oilfield chemicals, cosmetic waxes and specialty chemicals in India. Purity and highly concentrated oilfield chemicals to achieve extended quality production is the main objective to deliver the best quality products like surfactant, demulsifier, emulsifier, ethoxylate and other chemical substances. These specialty chemicals are used in various industries like cosmetics, pharmaceuticals, textiles, paper and pulp, pigment, leather, agro chemical, oilfield etc. Apart from oilfield chemicals, Rimpro also offers best quality demulsifiers for crude oil demulsification in oilfield and pipeline corrosion inhibitors including inhibitor for gas oil and water corrosion, oil line corrosion inhibitor and water and oil line corrosion inhibitors to prohibit corrosion in pipelines and equipment in oilfield.

For More Corrosion Inhibitor Visit - https://www.rimpro-india.com/corrosion-inhibitor.html

For More Oil Field Chemicals Visit - https://www.rimpro-india.com/oil-field-chemicals.html

Follow Us on

Facebook: https://www.facebook.com/rimproindia/

Twitter: https://twitter.com/rimproindia

Google Plus: https://plus.google.com/+Rimproindiacom/posts

Pinterest : https://pinterest.com/rimproindia/

0 notes

Text

Gujchem - Manufacturer And Exporter Of Special Chemicals

Gujarat chemical is the issuer of area of expertise chemical substances, surfactants and emulsifiers to diverse industries like cosmetics, pharmaceuticals, textiles, paper and pulp, pigment, leather, agro chemical, oilfield etc. All our products noted below provide cost-effective value powerful solutions and to permit increase in productiveness and offer value reduction benefits to our clients. Our steady R & D and required infrastructure is used to fabricate pleasant and constant oilfield chemicals, numerous varieties of surfactants, demulsifiers and corrosion inhibitors following the worldwide exceptional practices to supply effective, excessive quality chemicals at very less costly prices.

Surfactants are compounds that decrease the surface anxiety of a liquid, between drinks or between a liquid and a strong. Surfactant act as emulsifiers, wetting and foaming retailers, dispersants and detergents. We offer a wide range of surfactants which includes alkyl alcohol ethoxylate, fatty acid ethoxylate, fatty amines ethoxylate, alkyl phenol ethoxylate, polyethylene glycols (peg), castor oil ethoxylates, hydrogenated castor oil ethoxylates, amino silicon oil emulsifier, silicon oil emulsifier, demulsifier surfactant, paraffin wax emulsifier, glycerin ethoxylates, paraffin and silicon oil emulsifier with extraordinary after income services.

Gujarat chemicals covers essential Oilfield programs like drilling, making and offering thru offering oilfield chemicals categorically. We assist with our pinnacle variety of surfactants which guide in more than one sorts of drilling programs in oil fields.

Our surfactants were carried out across worldwide oil subject industries for controlling corrosion, scaling formation, foaming, and so on. We produce both oil and water soluble demilsifiers which might be precise formulations created to reap quick outcomes of water from oil separation. field treatment procedure of crude oil is the top maximum software in oil discipline this is additionally costly.

we're engaged in the manufacturing of a variety of Phosphate Ester like Triphenyl Phosphate, Tricresyl Phosphate, Cresyl Diphenyl Phosphate, Tri Octyl Phosphate, Triaryl Phosphate and Trixylenyl Phosphate. The Phosphate Esters produced with the aid of us are broadly used in Polyester fibers, p.c of Upholstery, e-book Binding and Seat Covers, Photographic films, Cellulose Acetate and for severa other programs. We welcome custom designed chemical formula for synthetic Triaryl Phosphate Ester. The range of chemical substances which we manufacture are easy to dispose as they're green in nature and do now not harm the environment. we're a few of the primary Tri 2-Ethylhexyl Phosphate Exporters in India.

0 notes

Text

Corrosion Inhibitors for Marine Environments: Protecting Ships and Offshore Structures

Corrosion is a natural process that can cause significant damage to ships and offshore structures if left unchecked. In marine environments, the presence of saltwater, humidity, and harsh weather conditions can accelerate the corrosion process, making it essential to use effective corrosion inhibitors.

Corrosion inhibitors are substances that can slow down or prevent the corrosion of metals in a particular environment. They work by creating a protective layer on the metal surface, which acts as a barrier against corrosive agents such as water, oxygen, and chemicals.

In the marine industry, corrosion inhibitors are commonly used to protect ships, oil rigs, and other offshore structures from corrosion. These structures are exposed to harsh marine environments, which can cause significant damage over time. The use of corrosion inhibitors helps to extend the lifespan of these structures and reduce maintenance costs.

There are several types of corrosion inhibitors available in the market, including organic and inorganic inhibitors. Organic inhibitors are made from organic compounds, such as amines, carboxylic acids, and imidazolines. These inhibitors are commonly used in freshwater environments, but they may not be effective in marine environments due to their solubility in water. Inorganic inhibitors, on the other hand, are made from inorganic compounds, such as chromates, molybdates, and phosphates. These inhibitors are more effective in marine environments as they are insoluble in water and can form a protective layer on the metal surface.

Corrosion inhibitors can be applied to metal surfaces in several ways, including immersion, spray, or brushing. The application method depends on the type of inhibitor and the structure to be protected. For example, immersion is commonly used for large structures such as oil rigs, while spray or brushing is used for smaller structures such as ships.

In India, there are several manufacturers, suppliers, and exporters of corrosion inhibitors. Gujarat is a significant hub for the production and export of these inhibitors. Corrosion inhibitor exporters in Gujarat offer a wide range of inhibitors suitable for marine environments, including inorganic inhibitors such as chromates and molybdates. These inhibitors are manufactured using state-of-the-art technology and are tested for quality and effectiveness.

In conclusion, the use of corrosion inhibitors is essential for protecting ships and offshore structures from the damaging effects of corrosion in marine environments. The choice of inhibitor depends on the type of metal, the environment, and the application method. Corrosion inhibitor manufacturers and suppliers in India, especially in Gujarat, provide a variety of options for protecting against corrosion. It is crucial to choose the right inhibitor to ensure the long-term protection of these valuable assets.

#corrosion Inhibitor in Gujarat#corrosion Inhibitor exporter in India#corrosion inhibitors manufacturers In India#corrosion Inhibitor supplier in Gujarat#Corrosion Inhibitor exporter in Gujarat#Oilfield chemicals manufacturer in India#Oilfield chemicals exporter in India#Best Oilfield chemicals company in vadodara#Best Oilfield chemicals company in Gujarat#Leading Oilfield Chemicals Manufacturer and Exporter in India#petrochemical products#petrochemical product#petrochemical companies#petrochemical industries#petrochemical solutions#Business#oil and gas industry#oil and gas companies#oil and gas pipelines#chemical product#chemical industry#chemical companies#exporter#manufacturer

4 notes

·

View notes

Text

High-Quality Corrosion Inhibitors from Imperial Group - Made in India

Imperial Group is a trusted name in the corrosion inhibitors industry, manufacturing top-quality inhibitors that are highly effective and affordable. Our products are made in India with the latest technology and meet the highest industry standards. Whether you need inhibitors for industrial or commercial use, we have a solution for you.

Contact us today to learn more about our range of inhibitors and how they can benefit your business.

#corrosion Inhibitor in Gujarat#corrosion Inhibitor exporter in India#corrosion inhibitors manufacturers In India#corrosion Inhibitor supplier in Gujarat#Corrosion Inhibitor exporter#in Gujarat#Oilfield chemicals manufacturer in India#Oilfield chemicals exporter in India#Best Oilfield chemicals company in vadodara#Best Oilfield chemicals company in Gujarat#Leading Oilfield Chemicals#Manufacturer and Exporter in India#petrochemical products#petrochemical product#petrochemical companies#petrochemical industries#petrochemical solutions#Business#oil and gas industry#oil#and gas companies#oil and gas pipelines#chemical#chemical product#chemical industry#chemical companies#exporter#manufacturer#oil products#oil companies

4 notes

·

View notes

Text

Corrosion Inhibitor in Vadodara | imperialchem

Imperial Oilfield Chemicals Pvt. Ltd. is a leading Water Soluble Corrosion Inhibitor Manufacturer in India, committed to providing high-quality solutions for industries worldwide. As trusted Corrosion Inhibitor manufacturers in India, we specialize in advanced formulations that protect vital infrastructure from damage. Our expertise extends to being a prominent Corrosion Inhibitor exporter in Gujarat, with a strong presence in global markets.

Based in Vadodara, we pride ourselves on delivering cutting-edge corrosion control products tailored to the specific needs of various industries.

#Water Soluble Corrosion Inhibitor Manufacturer in India#Corrosion inhibitor manufacturers in India#Corrosion Inhibitor exporter in Gujarat#Corrosion Inhibitor in Vadodara

4 notes

·

View notes

Text

Corrosion Inhibitors manufacturer in India | imperialchem

Imperial Oilfield Chemicals Pvt. Ltd. (ICPL) is a leading corrosion inhibitor in Vadodara, specializing in high-performance solutions to protect your assets. As the best chemical company in Vadodara, we are recognized as top corrosion inhibitors manufacturer in India. Our expertise as corrosion inhibitor manufacturers in Vadodara, Gujarat, India ensures products that meet the highest standards of quality and reliability. As a trusted oilfield chemical exporter, we deliver effective corrosion protection solutions to clients around the world.

Choose ICPL for unmatched performance and global expertise!

#Corrosion Inhibitor in Vadodara#Best chemical company in Vadodara#Corrosion Inhibitors manufacturer in India#Corrosion Inhibitor manufacturers in Vadodara#Corrosion Inhibitor manufacturers in Gujarat#Corrosion Inhibitor manufacturers in India#Oilfield chemical exporter

4 notes

·

View notes

Text

Oilfield chemicals manufacturer in India | imperialchem

Imperial Oilfield Chemicals Pvt. Ltd. is a premier turbine cleaner manufacturer in India, providing effective solutions for maintaining optimal turbine performance. As a leading oilfield chemicals manufacturer and exporter in India, we specialize in high-quality products tailored to the energy sector. Recognized as the best oilfield chemicals company in Gujarat, we are committed to delivering innovative and reliable solutions.

Trust Imperial Oilfield Chemicals for all your oilfield chemical needs, crafted with expertise and precision.

#Oxygen scavenger manufacturer in India#Oxygen scavenger Chemical in Vadodara#Corrosion inhibitor in Vadodara#Corrosion inhibitors manufacturer in India#Foamer manufacturer in India#Foamer exporter in Gujarat#Turbine cleaner manufacturer in India#India#Gujarat#Vadodara

3 notes

·

View notes

Text

Preserving Assets: The Role of Corrosion Inhibitors in Industrial Maintenance

Corrosion is a persistent threat to industrial assets, causing billions of dollars in damages annually across various sectors. From oil and gas facilities to manufacturing plants, the impact of corrosion can be devastating, leading to equipment failures, production downtime, and costly repairs. However, with the right preventive measures in place, such as corrosion inhibitors, industrial facilities can effectively mitigate the risk of corrosion and prolong the lifespan of their assets. As a leading chemical company in Vadodara, Imperial Oilfield Chemicals Pvt. Ltd. (ICPL) understands the critical role of corrosion inhibitors in industrial maintenance. In this blog post, we'll explore the importance of corrosion inhibitors, their applications, and the expertise of ICPL as a corrosion inhibitor manufacturer and exporter in India.

Understanding Corrosion Inhibitors

Corrosion inhibitors are chemical compounds designed to protect metal surfaces from the damaging effects of corrosion. By forming a protective barrier on the metal surface or altering the corrosion process, inhibitors prevent or slow down the oxidation and deterioration of metals in corrosive environments. Corrosion inhibitors are widely used in various industries, including oil and gas, petrochemicals, power generation, water treatment, and manufacturing, to safeguard critical assets and infrastructure from corrosion-related failures.

The Importance of Corrosion Inhibitors in Industrial Maintenance

1. Asset Protection: Industrial facilities rely heavily on equipment and infrastructure made of metal, such as pipelines, tanks, vessels, and machinery. Corrosion inhibitors play a crucial role in protecting these assets from corrosion, extending their service life and reducing the need for frequent repairs or replacements.

2. Cost Savings: Corrosion-related failures can result in significant financial losses due to equipment downtime, production disruptions, and repair expenses. By incorporating corrosion inhibitors into maintenance programs, industries can minimize the risk of corrosion-related failures and realize substantial cost savings in the long run.

3. Safety and Reliability: Corrosion compromises the structural integrity of industrial assets, posing safety hazards to personnel and the surrounding environment. Corrosion inhibitors help maintain the reliability and safety of critical infrastructure, reducing the likelihood of accidents, spills, and environmental contamination.

4. Environmental Protection: Corrosion-related leaks and spills can have detrimental environmental consequences, polluting soil, water bodies, and ecosystems. By preventing corrosion and minimizing the risk of leaks and spills, corrosion inhibitors contribute to environmental protection and sustainability efforts.

Applications of Corrosion Inhibitors

Corrosion inhibitors find applications across various industrial sectors, where metal components are exposed to corrosive environments. Some common applications of corrosion inhibitors include:

Oil and Gas Production: In the oil and gas industry, corrosion inhibitors are used to protect pipelines, well casings, and production equipment from corrosion caused by corrosive fluids, gases, and environmental conditions.

Water Treatment: Corrosion inhibitors are added to cooling water systems, boilers, and wastewater treatment facilities to prevent metal corrosion caused by dissolved oxygen, scale formation, and aggressive ions.

Manufacturing: In manufacturing processes involving metal components, such as automotive, aerospace, and electronics manufacturing, corrosion inhibitors are used to protect parts, components, and machinery from corrosion during production, storage, and transportation.

Marine and Offshore Structures: Corrosion inhibitors are applied to marine vessels, offshore platforms, and coastal structures to protect against corrosion in seawater environments.

ICPL: Your Trusted Corrosion Inhibitor Manufacturer and Exporter in India

As the best chemical company in Vadodara, ICPL is dedicated to delivering high-quality corrosion inhibitors tailored to the specific needs of industrial clients. Here's why ICPL is the preferred choice for corrosion inhibitors in India:

Expertise and Experience: With decades of experience in the chemical industry, ICPL possesses the expertise and technical know-how to develop and manufacture corrosion inhibitors that meet the highest quality standards and regulatory requirements.

State-of-the-Art Facilities: ICPL operates state-of-the-art manufacturing facilities equipped with advanced technologies and production processes to ensure the consistent quality and performance of its corrosion inhibitors.

Customized Solutions: ICPL offers customized corrosion inhibitor formulations tailored to the unique requirements and operating conditions of industrial applications. Our team of experts works closely with clients to develop solutions that address specific corrosion challenges and performance objectives.

Global Reach: As a corrosion inhibitor exporter in India, ICPL serves clients worldwide, exporting its products to diverse markets across Asia, Africa, the Middle East, and beyond. With a strong global presence and distribution network, ICPL delivers reliable corrosion protection solutions to industries around the globe.

Conclusion

In conclusion, corrosion inhibitors play a crucial role in industrial maintenance by protecting metal assets from the damaging effects of corrosion. As a leading corrosion inhibitor manufacturer and exporter in India, ICPL is committed to providing high-quality corrosion inhibitors that safeguard critical infrastructure, ensure operational reliability, and promote cost-effective maintenance practices. With ICPL's expertise, customized solutions, and global reach, industries can effectively mitigate the risk of corrosion and preserve the integrity of their assets for years to come. Contact ICPL today to learn more about our corrosion inhibitor products and solutions.

#Corrosion inhibitor Vadodara#Best chemical company in Vadodara#Corrosion Inhibitor exporter in India#Corrosion inhibitors manufacturer in India#Oxygen scavenger Chemical in Vadodara#Oxygen scavenger Chemical supplier in Gujarat#Oxygen scavenger Chemical Manufacture India#Oxygen scavenger Chemical exporter in Gujarat#Oil and gas industry#Oil and gas companies#Oil and gas pipelines#leading Oilfield Chemicals manufacturer and exporter in India

7 notes

·

View notes

Text

Corrosion inhibitors manufacturer in India | imperialchem

Imperial Oilfield Chemicals Pvt. Ltd. (ICPL) leads the way in providing a comprehensive range of high-quality oilfield chemicals essential for mud drilling, oil recovery, water treatment, well stimulation, and refining industries. As a trusted corrosion inhibitor supplier in Gujarat, headquartered in Vadodara, ICPL ensures superior products that meet stringent industry standards.

Count on ICPL, a leading corrosion inhibitors manufacturer in India, for innovative solutions that optimize performance and ensure reliability across diverse oilfield applications.

Corrosion inhibitor Vadodara

Corrosion Inhibitor supplier in Gujarat

Corrosion inhibitor in Vadodara

Corrosion inhibitors manufacturer in India

#Corrosion inhibitor Vadodara#Corrosion Inhibitor supplier in Gujarat#Corrosion inhibitor in Vadodara#Corrosion inhibitors manufacturer in India

4 notes

·

View notes

Text

How do Coker Unit Corrosion Inhibitors Help in Saving Assets and Ensuring Safety?

Within the dynamic and always-changing realm of the oil and gas sector, it is of utmost importance to prioritise the durability of assets and the security of operations. The application of corrosion inhibitors in coker units is a crucial factor that significantly contributes to the attainment of these objectives. The aforementioned inhibitors play a crucial role in safeguarding equipment, preserving assets, and ensuring the well-being of workers, but sometimes without receiving due recognition. Experience the strength of Coker Unit Corrosion Inhibitors. Safeguard your investments with the best Coker Unit Corrosion Inhibitor Manufacturer in India – Imperial Oilfield Chemicals Pvt. Ltd. (ICPL)!

This blog article aims to examine the role of corrosion inhibitors in coker units, specifically focusing on their contributions to the preservation of assets and the strengthening of safety measures.

Understanding Coker Units:

Prior to delving into the significance of corrosion inhibitors, it is imperative to first have a comprehensive understanding of coker units and their indispensability within the context of the oil refining process. Coker units play a vital role in petroleum refineries as they are responsible for the conversion of heavy residual oils into useful products, including petrol and diesel fuel. These systems function in challenging environments, exposing their components to elevated temperatures, pressures, and corrosive agents, rendering them susceptible to degradation as time progresses.

The Corrosion Challenge:

Coker units are significantly affected by the detrimental effects of corrosion. Metal equipment degradation is a phenomenon that arises from the interaction between metals and the surrounding environment, resulting in a slow deterioration of the equipment. Corrosion can have significant ramifications, encompassing equipment malfunction, interruptions in production, potential environmental perils, and jeopardising the safety of employees. Additionally, this might lead to significant financial setbacks for the organisation. Corrosion inhibitors play a significant role in this context.

The Role of Corrosion Inhibitors:

Corrosion inhibitors refer to chemical substances that are specifically formulated to mitigate the detrimental effects of corrosive processes on the structural integrity of equipment within coker units. The function of these inhibitors is to create a protective film on the metal's surface, thereby impeding its interaction with corrosive agents such as sulphur compounds and water. Corrosion inhibitors play a crucial role in the preservation of assets and the maintenance of safety. From pipelines to processing units, trust Imperial Oilfield Chemicals - an excellent Corrosion Inhibitors manufacturer in India for corrosion-free operations!

Asset Preservation:

Prolonged Equipment Life: Corrosion inhibitors play a crucial role in prolonging the lifespan of essential components in coker units, hence mitigating the need for frequent maintenance and replacement. This practice not only reduces operational expenses but also optimises the utilisation of assets.

Reduced Downtime: The utilisation of inhibitors effectively mitigates unscheduled downtime by reducing failures caused by corrosion. This facilitates enhanced dependability and uninterrupted manufacturing, hence augmenting the refinery's overall operational effectiveness.

Enhanced Asset Value: The preservation of assets by employing corrosion inhibitors contributes to the enhancement of their worth, thereby ensuring their long-term maintenance. This is particularly vital in a sector where significant capital investments are involved.

Safety Enhancement:

Personnel Safety: The safety of people in coker units can be significantly compromised by equipment failures caused by corrosion. Inhibitors play a crucial role in promoting a safer working environment by effectively mitigating corrosion.

Environmental Safety: The occurrence of corrosion can also result in the occurrence of leaks and spills, hence causing adverse impacts on the environment. Inhibitors play a crucial role in mitigating the occurrence of such accidents, hence enhancing environmental safety and ensuring adherence to regulatory standards.

Regulatory Compliance: Regulatory compliance is a crucial aspect of the oil and gas business, as numerous regulatory organisations enforce stringent safety and environmental protection regulations. The utilisation of corrosion inhibitors can assist in achieving adherence to these regulatory obligations.

Choosing the Right Corrosion Inhibitors:

The process of choosing suitable corrosion inhibitors holds significant importance for refineries. Various factors need to be taken into account, including the specific equipment utilised, the makeup of the feedstock being processed, and the prevailing operating circumstances. Corrosion inhibitors are available in diverse forms, encompassing film-forming inhibitors, passivating inhibitors, and vapour-phase inhibitors, which are specifically designed to cater to distinct requirements. Preserve your infrastructure with top-tier Corrosion Inhibitors manufactured and exported by Imperial Oilfield Chemicals - an excellent Corrosion Inhibitor exporter in Gujarat!

Furthermore, it is imperative to continuously monitor and evaluate the efficacy of inhibitors. To guarantee the effective performance of the inhibitors, it is imperative to implement regular inspections, corrosion rate monitoring, and maintenance practices.

Final Thoughts:

Within the realm of coker units, where corrosion poses a persistent challenge, corrosion inhibitors serve as steadfast guardians of valuable resources and advocates for maintaining a secure environment. The oil and gas industry heavily relies on the indispensable capability of corrosion prevention to counteract the detrimental effects posed to both equipment and workers. Corrosion inhibitors play a crucial role in the preservation of assets and the sustained success of refinery operations by prolonging equipment lifespan, minimising downtime, and improving safety measures.

In a sector where the value of each asset is crucial, the utilisation of corrosion inhibitors represents a prudent allocation of resources that yields advantageous outcomes in terms of both safety and financial gain. From maintenance to asset preservation, choose the state-of-the-art Coker Unit Corrosion Inhibitors manufactured and supplied by Imperial Oilfield Chemicals!

#Coker Unit Corrosion Inhibitor#Coker Unit Corrosion Inhibitor Manufacturer in India#Corrosion Inhibitors Manufacturer in India#Corrosion Inhibitor exporter in Gujarat

7 notes

·

View notes

Text

Top Corrosion Inhibitor Manufacturer in India | Imperial Oilfield Chemicals Pvt. Ltd.

Looking for reliable corrosion inhibitor manufacturers in India? Look no further! Imperial Oilfield Chemicals Pvt. Ltd. is a leading supplier and exporter of high-quality corrosion inhibitors.

Explore our wide range of products and protect your assets from corrosion today!

#Corrosion Inhibitor Manufacturers in India#Corrosion Inhibitor Exporter in Gujarat#Corrosion Inhibitor Supplier in Vadodara

7 notes

·

View notes

Text

Leading Coker Unit Corrosion Inhibitor Manufacturer in India | Imperial Oilfield Chemicals Pvt. Ltd.

Imperial Oilfield Chemicals Pvt. Ltd. (ICPL) is a trusted name as a Coker Unit Corrosion Inhibitor Manufacturer in India, specializing in high-quality Corrosion Inhibitors. We are also a renowned Corrosion Inhibitor exporter in Gujarat.

Discover our superior products for ultimate corrosion protection.

#Coker Unit Corrosion Inhibitor Manufacturer in India#Corrosion Inhibitors Manufacturer in India#Corrosion Inhibitor exporter in Gujarat#Coker Unit Corrosion Inhibitor#chemical

6 notes

·

View notes