#core cutting drill machine

Explore tagged Tumblr posts

Text

i read a fic that changed my brain chemistry and now i can't stop thinking about a universe where amy works for eggman... and metamy ensues. naturally. you know the drill by now. also roboticized sonic theory because it makes it more deliciously potent.

DESERT ROSE: A prickly young girl with terrifying strength and a love for the finer things in life, like frilly dresses and deadly high-powered machinery. She thinks maintenance is a romantic couples activity. Not only is the "desert rose" highly poisonous, it can't really be considered a rose, can it…? However, its resilience means it could bloom even in a rusty scrapyard...

notes for the au under cut!

rose believes metal sonic when he says he is the original. he hasn't told her what happened. that he failed to save her. that he failed to save everyone. that there was a time when he was organic like she is. he just said "the other sonic is the copy" and she said "okay! let's kill him :)"

metal sonic is constantly torn between guilt and adoration at who rose has grown into. she became so much stronger. strong enough to protect herself - strong enough, even, to protect him (if he ever let her, that is. he might not be a hero any more but it's burned into his core forever that > KEEP AMY ROSE SAFE is a KEY goal.) on the other hand... he feels like he remembers someone different. a girl who loved animals and flowers and sunshine. who would give her life to protect everything she's now destroying. but his memories are so fuzzy...

i'm not so sure that amy would be big on programming and constructing machines herself, but she's always eager to "test" them... and it goes without saying she is frankly terrifying when she wants to be and is a beast on the battlefield

what a helpful young lady! im so glad i didn't just kill her!! - eggman probably.

"wait if rose calls metal sonic 'sonic' then. what does she call sonic" -> she calls him faker. copycat. knockoff. off-brand. etc. in short, she doesn't acknowledge him by name

i have the feeling that metal sonic is a bit more... enthusiastic? i guess? about his mission in this universe. it's not "ME VS. EVERYONE WHO COULD HAVE LOVED ME HAD I NOT FAILED" its "ROSE AND I VS. THEM" don't get me wrong he's furious and undead and vengeful and jealous and still insane. but. i think rose helps jog the vaguest of memories of who he used to be? unfortunately the person he used to be is a hero so i also imagine he's ever so slightly more conflicted in this universe... ("the old amy wouldn't have liked this, would the old me feel the same?")

codependence is my favorite flavor so i imagine metal really, really, REALLY appreciates having rose around. someone who is kind to him. someone who believes that he used to be more than this, and treats him like maybe he isn't worth less after all... i imagine if sonic ever tried recruiting amy, metal would go BALLISTIC. "YOU ALREADY HAVE EVERYTHING ELSE. YOU CAN'T HAVE HER TOO." she's mine -> she's my (partner) she's my (memory) she's my (friend) she's my (tether) she's my (hope) she's my (rose)

metal sonic is. (gestures) metal. and he lives in a metal box on a metal ship surrounded by metal debris. but down the hall there is a single remaining rose. and in this state she is perfectly preserved. nothing can hurt her. eggman can't hurt her if she's on his payroll, huh...?

i can't put it into words properly (and ive tried) but the idea of "killer metal robot (whose objective is to destroy natural life) falls in love with a gentle girl named rose" makes me start frothing at the mouth. just shut up. why don't you hold his hand too. and he can't FEEL it like he should . and it hurts. and it's infuriating. but he Can tell that her pulse is higher than average and the temperature of her cheeks are strangely high. and he supposes that can comfort him for now.

i feel a little "if i had to choose between the world and sonic i would choose sonic" vibe.

this took me so incredibly long so if it flops im dropping out of college.

i wanna update these designs later, these are just the beginning concepts for the au :)

#sonic the hedgehog#metal sonic#amy rose#sonic#metamy#this took me so long. i spent two nights up until 6 or 7 am working until my hands started shaking. but its done. worth#i... truly cant say much more rn#ive got another comic sketched out but i cant draw any moere tonight i can barely type i eed to go to slepe#toxic metamy . toxic metamy. toxic for everyone else i mean theyre fine'#probably mostly.#i miss queue#my nyart#if this flops ill cry and kill myself forever. /j#btw the idea came from the fic... but these concepts r my own#of course eggho/gs going around inspired me a bit too wink wonk.#hha almost forgot the binary text in the bg of img 3 is:#'this is super self indulgent.'#heheheh#desert rose au#If you call him “Metal Sonic” in front of Rose she'll break your fingers. After all he is the original Sonic the Hedgehog!#<- from the notes but didnt fit so eh

121 notes

·

View notes

Text

Cloud Striders and the Veil

I've been musing about some lore that we got from the exotic quest for the glaive, Winterbite. I think that quest is more important than people realise in general, outside of the bombastic message at the end of it. There are some insanely interesting and potentially wholly revealing things, and I want to talk about it here at length because it's hard to parse through.

Long post ahead, with contents (highly recommended to open in a new tab or separately on mobile or you will be scrolling for a while):

The Strider and the creation of the Sidereal

Bluejay and the creation of the CloudArk as we know it

Stargazer and discovery of Earth

Maelstrom and the doubt in Cloud Striders

Imagery and symbology of the Cloud Striders

First and foremost, what happens to initiate the quest? Well, Quinn tells us that when the Witness used the Veil to make the link, that event briefly rebooted the CloudArk. As soon as it rebooted, the Vex noticed something, broke into the Hall of Heroes and destroyed five Cloud Strider memorials. They are irreplaceable, made from each Cloud Strider's core. When interacting with them, our Strand connected with one of the Cloud Striders and rebuilt the memorial. Quinn realised that if we connect with others, we will be able to restore all of them and figure out why the Vex wanted to destroy them.

We are able to restore them all and learn about them, how they connect to each other and what they occupied themselves with.

The Strider

The Strider, real name Mikaela Julaha, was the first Cloud Strider. In her lore, which is a version told in some sort of show for kids, we're told:

Before the Strider, we did not have a special protector for the city, and that meant we all had to fight every day. We had many weapons and implants to make ourselves strong, but not the special synthesis that makes the Cloud Striders special. And many more Neomuni had to be soldiers and transform their bodies to protect the city and get hurt.

Makes sense! Before Cloud Striders, everyone had to fight, which meant more people suffering and more victims, as well as more people having to use augmentations. However, there's a difference between regular implants and what the Cloud Striders have. Cloud Striders get a "special synthesis." How? Strider made the Sidereal.

What is the Sidereal? Fret not! We know! The Sidereal was created by the first Cloud Strider:

The Strider saw us suffering. She worried that fighting so much would hurt our hearts, and she knew that one person can make all the difference. So, she took her courage and her wits and her strength and created the Sidereal.

Do you know what the Sidereal is, niños?

That's right! The Sidereal is a special place where one person gives up their normal life to become a Cloud Strider and live for us all!

The Strider gave us the Sidereal. The Cloud Strider fights so we can have peace so we could be more than just soldiers.

It's some sort of a machine that does the process of becoming a Cloud Strider. It is somewhat described in the lore tab where Nimbus becomes a Cloud Strider, Foremost Vimana:

There are no smiles to go around when drills bore into bone until they taste marrow, and metal latticework replaces the dermis of their flayed-open throat. As the cradle lowers them into the Sidereal, the droning hum of a nonillion nanites fills their ears and drowns their fear.

The Sidereal is a special machine able to integrate the nanites into Cloud Striders so fully that they merge in a way that makes Cloud Striders what they ar; big, strong and also with their lifespans cut short. Intriguing process, possibly discovered by Mikaela through her own situation; Mikaela had an unspecified accident which led to her body being heavily augmented, but then those augmentations started aggressively deteriorating her body. It's implied that the lifespan part was unknown when this was first done, though the full timeline of these events is unclear.

Needless to say, Strider also found the whole topic of the exotic quest, the friendly Vex Mind called the Occlusion. Strider was the first to find it and she protected it and kept it safe, leaving it alone in the CloudArk. It is apparently integral to the function of the CloudArk; Quinn describes it as "loadbearing." I can't help but wonder if those two things are connected; if the creation of the Sidereal is directly related to Strider's discovery of the Occlusion or the other way around.

The Bluejay

Bluejay, real name Conrad Jain, is a really interesting Cloud Strider because he became one in order to have legal access to simulation tech. He was a tech genius and a game designer. He basically turned CloudArk into what it is today; at first it was just used for storage, but his simulation research and insight into the Vex allowed him to turn it into a real virtual space where people could go, live and play. Basically without him, CloudArk would still just be storage. And he researched the Vex as well:

So Bluejay helped us expand how we use the CloudArk—he made it a place we could play or even live, if we needed to. And when he made his game in there, he also learned that the Vex used the CloudArk, too. ... Bluejay learned he could jump from the CloudArk to the Vex network, and he sabotaged their machines from the inside. The Vex were very confident and did not think he could find them, so they were careless. And so Bluejay scared them, and they ran away!

Naturally, he found the Occlusion, from Strider's files and information. He left the Occlusion alone, clearly, which means that he knew its importance. Given his drive to stop the Vex, if the Occlusion was a threat or unimportant, he could've pushed it out.

In his other lore tab, the one that features a record of a hearing of him in court (he was arrested for illegal simulation research), he is arguing with the judges about his deeds, insisting that he is helping everyone. He is not remorseful at all and mentions how important his work is. Some relevant excerpts:

JAIN: We're the last of humanity, trapped in a bubble. Simulation is an entire frontier we can explore to re-define what it means to be human. And you outlaw it just because we fear others' bad experiences from hundreds of years ago!

It's unclear which experiences he's referencing. Possibly something from before Neomuna. Ishtar Collective was aware of Vex simulations and are possibly the ones who banned research of it. Only Cloud Striders, who answer to the council, are allowed to research it, and Conrad calls them "council's lapdogs."

JAIN: The CloudArk is an nth dimensional paracausal fold, and we use it to store library books.

C. BOUDAN: We use it to support the public need. Not as some playground.

JAIN: Play?! You bastard, I lost friends shutting down the Vex Isometry! You wouldn't be sitting there i—

Conrad knew a lot about the CloudArk and its abilities and possibilities. He was also aware of how it ties into the Vex Network and how important it is to expand the knowledge of it. And, unsurprisingly, he knew something about the Veil. In his own words:

It's... it's the shadow of every story and memory and hope we brought with us. The stars are off limits, but the Veil knits an entire universe for us. We just had to embrace it!

It's unclear, again, but we do know that CloudArk is powered by the Veil. Conrad, aka Bluejay, was pivotal in turning the CloudArk into what it is today, which means he must've known more about the Veil as well. This directly ties the Veil's power with the CloudArk; it's the Veil that "knits an entire universe" for them via the CloudArk where they can upload their consciousness and live inside unimpeded. These are all breadcrumbs for us to follow.

The Stargazer

I did a write-up on Stargazer as they relate to the question of why Neomuna never helped Earth during the Dark Age. In short, Stargazer (real name Laminak Li) was a mathematician before becoming a Cloud Strider and they were able to use math to re-discover the location of Earth and scan it for signs of life. Upon finding them, they went to Earth, learned of the Lightbearers, killed one, made contact with the Warmind in the bunker and deleted all records of the exodus ship and Neomuna to protect it from violent warlords of Earth.

Stargazer was aware of the Occlusion and named it:

Yes, hmm. How to describe... "Algorithm" is inaccurate but acceptable shorthand. It's... an occlusion. In the way? Perhaps. But if we ride along the edge... hm. Accelerated processing, gravitational lensing as applied to data.

Highly unclear what it means, but their story is tied to the math and science of rediscovering Earth. It appears they may have used this "algorithm" to do it. I'll briefly mention another Cloud Strider (Siegebreaker aka Telluride Magsi), the one whose memorial we first rebuilt and who first mentioned the algorithm:

Built a data crawler app to scour Siegebreaker's database for mentions of the other four Cloud Striders targeted in that Vex attack. He references Stargazer! And some kind of secret "number-crunching algorithm".

He thought it was a "number-crunching algorithm" and Stargazer claims that "algorithm" is not accurate enough. Is Occlusion responsible for this math and "number-crunching" to pinpoint where Earth is? Here, I also want to point out that "sidereal" is not a made-up word, it's a real concept:

Sidereal time is a timekeeping system that astronomers use to locate celestial objects.

That... can't be a coincidence given that the machine that makes Cloud Striders is called the Sidereal. Like, it's too much for the Sidereal to be called that for no reason. Perhaps this machine can be used for things other than making Cloud Striders or maybe the technology it's based on is also applicable elsewhere. This also relates to Bluejay who explicitly talked about the stars being "off limit" but that the power of the Veil and CloudArk can allow them to access the world otherwise. How do the Occlusion and the Sidereal tie into this? Are all of these things connected somehow?

The Maelstrom

Maelstrom was a military leader before becoming a Cloud Strider. Her real name was Sedderik Assur. In the kid's version of her story it's explained that she was a great warrior who fought off not just the Vex, but also other people causing problems. She founded the Assur Academy which trains people into leadership and they also train Cloud Striders.

It's also explained that she ended something called the "Uplift Coven" who were a group of bad people that wanted to be Cloud Striders. They hurt people and stole from people and Maelstrom stopped their attack.

What else do we know? "She was one of the city's greatest military leaders. Ended the Cobalt Occupation before she even became a Cloud Strider." (1) She knew about the Occlusion hiding in the CloudArk and she called it a "simulation echo" (2). This is interesting in relation to Bluejay, who was doing simulation research and knew of the Occlusion as well. Maelstrom's Occlusion data comes from Bluejay and Stargazer. She also said the following herself:

This little electronic oracle may be useful, but I don't like anyone standing behind me, whether they've got a knife or not. So the question is, tear it out and let the whole network fall apart? Or leave it in... and maybe things get a whole lot worse?

The "electronic oracle" she speaks about is most likely the Occlusion. Oracle is an interesting word to use; the Occlusion is somehow tied to Soteria, the Augurmind who was half-Warmind, half-Vex and had predictive technology. Like an oracle. Another interesting connection with Soteria is that Soteria's predictive technology was used to locate other habitable systems outside the solar system and predict the best ways to map them, reach them and colonise them. Aka we're talking about math and simulations to find planets again.

Maelstrom's other lore entry, the one that's a record of a log she made herself and isn't a watered down story made for kids, is her message to her rookie Cloud Strider partner called Geist. Maelstrom explains that she's sorry for shooting Geist, but that she had to and that she hopes this apology would be enough. It's safe to assume Geist survived.

Maelstrom focuses a lot more on what she finds to be her biggest mistake; creating the whole Cloud Strider training. She thinks it's her "stupidest idea ever" to pick twenty two kids and train them all to be Cloud Striders and then only pick one. She also thinks she didn't fully explain to them just how much the process of turning into and being a Cloud Strider takes from people.

She says she's right for picking Geist because:

All of you were driven, talented. But, Geist, you were the only one who didn't need it. You were the one who'd help this city as a civvie or a Strider.

The "it" Geist didn't need is presumably the augmentations and the full power of a Cloud Strider (aka the "special synthesis" through the Sidereal) since Maelstrom explains that Geist would've helped either way, with or without becoming one. At least ten of the group she trained turned out to be "terrorists with Cloud Strider training." Aka the Uplift Coven. Possibly Cloud Strider candidates who weren't too happy about not being given the luxury to become one.

And Maelstrom names some of them. Two to be exact:

And looks like I was right to not pick Ahpoor and Laghari and their little coven.

Laghari? Hm. I noticed this back then but there were a lot of names happening so I didn't want to jump to conclusions, but we still only have one Laghari character in the game: Quinn Laghari. The Hall of Heroes archivist who gave us the quest. Was she a Cloud Strider candidate who has a problematic past? Or was this an ancestor of hers? How old is she? Did she know Maelstrom personally? It seems like we have a lot more to find out about the history of characters we interact with. Even if this is Quinn's ancestor, it would still be interesting to find out what happened here.

Maelstrom ends her account with one more peculiar piece of information:

But I'm leaving you a present. Something my mentor left me: the kill codes for the Sidereal.

Interesting. Maelstrom's mentor (unknown right now) gave her the "kill switch" for this machine. And she passed it onto Geist, saying that once the Sidereal is destroyed and there are no more Cloud Striders, things would be better and "the rest of the city would have to step up" instead of "dooming another soul to this life."

Very strong words from Maelstrom. This obviously didn't happen for whatever reason. The Sidereal is fine, though we obviously don't know where it is or how it works. Given that it was created by the first Cloud Strider who was also the first person to find the Occlusion and this whole storyline hinges on the Occlusion since it connects all the Cloud Striders mentioned, I have a feeling the Occlusion has something to do with the Sidereal.

And given everything from Bluejay, as well as the fact that the Occlusion resides within CloudArk, both CloudArk and the Veil must be involved as well. Quinn even makes a comment about it at the start of the quest, something people may have forgotten by now, when our Strand recreates a destroyed memorial. Quinn is surprised and interested and then says:

I've read some academic studies on Veil transcription of the collective unconscious. I bet if I put you in cryo, I could—

The Veil, its ties to the "collective unconscious" and its ability to power the CloudArk are clearly relevant here when it comes to Strand, the memorials and this whole story. Quinn also thinks that we would be able to find out more if we were to be placed into cryo and linked to the CloudArk. Maybe one day!

Another thing that makes the connection is the imagery and motifs of the Neomuna symbols, especially as they relate to the symbol of the Veil:

This is from the in-game badge, but it appears everywhere. You can see it on Neomuna on the panels and everywhere in the menus for Neomuna collections and lore books.

The full part, the lattice? That's on the Cloud Strider Legacies lore book art, which is where all this lore is from:

This lattice can also be seen on Cloud Striders themselves, most notably on Nimbus' neck (also referenced in the lore I copied where Nimbus is lowered into the Sidereal where it's idenfitied as "lattice"), but also as a smaller motif on all Cloud Strider memorials and, I believe, as a motif on the Cloud Strider core which can be seen in Nimbus' hand in the training montage cutscene:

It also reminds me of the view of the Veil from below, as it's shown in this concept art:

Is there a connection relevant for any future reveals or is most of this just flavour and some background on past Cloud Striders, politics of Neomuna and its history? I feel like there has to be something more going on with CloudArk and the Occlusion, which naturally involves the Veil but also possibly the Sidereal and Cloud Striders themselves. And how does it tie into the Vex, their network and Soteria, whose arrival to Neptune was the catalyst for everything to follow?

This quest was A LOT and I think it was meant to be and that it was meant to give us leads and things to think about. It took me a while and a lot of re-reading and re-organising things to figure out the whole relatively chronological order of things, as well as possible connections between them and why this quest links these specific Cloud Striders and their experiences with the Occlusion, the Sidereal, the CloudArk and indirectly with the Veil. I'm still not sure where all of this leads, but these are starting points that were made to get us to talk.

If you've read through all and maybe it juggled your ideas and brain worms, feel free to share your thoughts on anything I said, any details I might've missed or things I might've gotten wrong!

#destiny 2#destiny 2 spoilers#lightfall#lightfall spoilers#cloud strider#neomuna#the veil#sidereal#occlusion#cloudark#lore vibing#long post#i've been losing my mind over this whole quest for three weeks now#there's so much stuff here and so much that might be hinting at future reveals#i would love if cloud striders were innately tied to the veil and this whole thing#especially looking forward to learn more about the occlusion#we have to... obsessed

114 notes

·

View notes

Text

Some of the current discourse is mentioning the James Damore Google doc again, as an example of DEI backlash within big tech. Nobody's rehashing the contents of the doc, but for those that haven't seen it or don't remember it that well, I just want to reiterate that it was really stupid.

It alleges that Google's DEI practices unfairly discriminate against men, and that acknowledgement--much less criticism--of this fact is strongly discouraged internally. Reasonable enough, if he had left it at that.

But then it goes on a long tangent about "Possible non-bias causes of the gender gap in tech", in which he makes many different claims about innate biological differences between men and women, ostensibly supported by embedded links to the shakiest of personality "science" and unfalsifiable evo-psych speculation. It is transparently the result of Damore googling things that he already believed and picking abstracts that agreed with him. (In some cases, the linked study does not even support what Damore is claiming in the link text!)

In short, despite being sandwiched between largely-unobjectionable generalities and reassurances, the gooey center of questionable assertions revealed Damore's own biases (and his ignorance thereof), which is a bad look when you're trying to call out other people's bias.

As an example, and because I was fired up about it, I dug into the very first claim:

Women, on average, have more: Openness directed towards feelings and aesthetics rather than ideas. Women generally also have a stronger interest in people rather than things, relative to men (also interpreted as empathizing vs. systemizing).

The first link is a Wikipedia page, which ultimately cites a study based on the NEO PI-R, a personality inventory used in psych research. Here are some example questions which might relate to "openness to ideas" (source):

I sometimes lose interest when people talk about very abstract, theoretical matters.

I enjoy working on "mind-twister"-type puzzles.

I have little interest in speculating on the nature of the universe or the human condition.

The second link goes to a study that is... pretty sus. It opens with a Margaret Thatcher quote, for one thing. And the author really likes to cite himself for his core claims (out of 48 citations, 5 are his own papers, with no co-authors). Anyway, the "people-things orientation" aspect is about reported vocational preferences in three other papers--two of which are his own. One of those two supposedly tracks sex differences across 53 nations, but it drills down to this:

BBC Internet survey participants also completed a 10-item measure of gender-related occupational preferences, which asked them to rate on 7-point scales ranging from ‘‘strongly dislike’’ to ‘‘strongly like’’ how much they were interested in the following jobs: car mechanic, costume designer, builder, dance teacher, carpenter, school teacher, electrical engineer, florist, inventor, and social worker.

...and of course, this BBC survey is only available in English. Plenty of cultural variety captured there, I'm sure.

The third source is actually the strongest, though it's included as an aside. The link goes to a Wikipedia page that cites research using an Empathy Quotient and Systemizing Quotient. These quotients include such questions as:

If I were buying a stereo, I would want to know about its precise technical features.

When I hear the weather forecast, I am not very interested in the meteorological patterns.

I am fascinated by how machines work.

When I was a child, I enjoyed cutting up worms to see what would happen.

After the above, Damore continues:

These two differences in part explain why women relatively prefer jobs in social or artistic areas. More men may like coding because it requires systemizing and even within SWEs, comparatively more women work on front end, which deals with both people and aesthetics.

Does it explain that, though, or just demonstrate it? Where is the evidence that these preferences are actually due to innate differences, and not gender bias? And, crucially, how much do these slight differences in preference actually matter when there are millions of dollars on the line?

If you simply want to prove that Google is discriminating, there are more direct ways to do that than speculating about the gender ratio of people who may be innately drawn to software. And if you want to argue that a skewed gender ratio doesn't necessarily imply overt discrimination, you can just say that, instead of writing several hundred words about what you think the innate differences are between men and women, and then sharing that with all your coworkers. Stupid.

2 notes

·

View notes

Text

Creating a granite washbasin involves a series of steps that transform raw granite into a polished and functional sink. Here’s a breakdown of the process:

1. Material Selection

Granite Slab Selection: Choose a high-quality granite slab based on desired color, pattern, and durability. The slab should be free of cracks and flaws.

Thickness: Ensure the slab is of appropriate thickness for durability and aesthetics (usually 2-3 cm).

2. Design Planning

Shape and Size: Decide on the washbasin's shape (round, rectangular, oval, or custom) and dimensions.

Template Creation: Use a paper or wooden template to outline the sink's shape on the granite.

3. Cutting

Rough Cutting: Use a diamond saw or water jet cutter to cut the granite slab according to the template.

Sink Hole: If the design includes a built-in sink, use a core drill to create the drain hole.

4. Shaping

Edge Shaping: Carve the edges of the washbasin using hand tools, grinders, or CNC machines, depending on the design.

Inner Contouring: For recessed sinks, shape the inner bowl area with precision tools.

5. Smoothing

Use diamond-grit abrasives to smooth the surface and remove tool marks. Start with coarse grits and progress to finer ones for a uniform finish.

6. Polishing

Surface Polishing: Polish the surface using a granite polishing pad and polishing compound to achieve a glossy or matte finish.

Edge Polishing: Ensure all visible edges are polished to match the surface finish.

7. Drilling and Finishing

Drill holes for faucets or other fittings if needed.

Smooth and polish these areas to avoid rough edges.

8. Sealing

Apply a high-quality granite sealer to protect the stone from water, stains, and scratches.

9. Quality Check

Inspect the washbasin for imperfections such as cracks, uneven polishing, or irregular shapes.

Test the drainage and fitting compatibility.

10. Packaging and Installation

Carefully package the washbasin to avoid damage during transport.

During installation, ensure the basin is securely mounted and properly sealed.

#home#stone#granite#kitchen#food#cooking#fountain#washbasin#interior#design#architectdesign#home decor#decor#construction#buildings#bathroom#bathtub#bigg boss tamil#tamizh#cinema

2 notes

·

View notes

Text

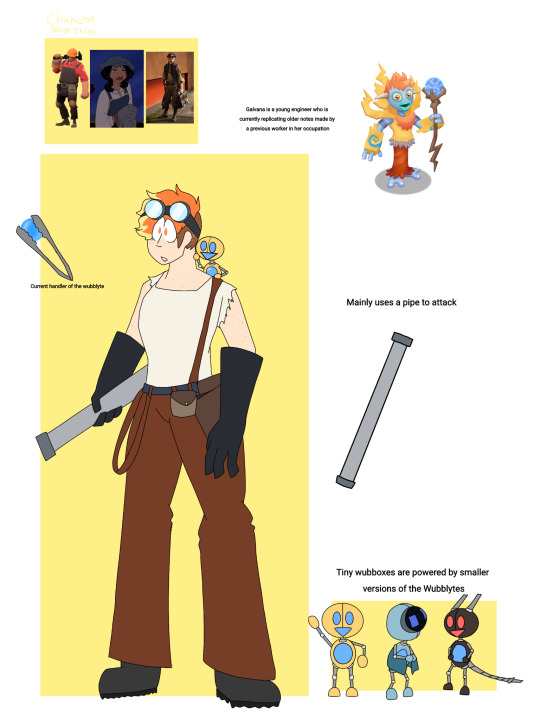

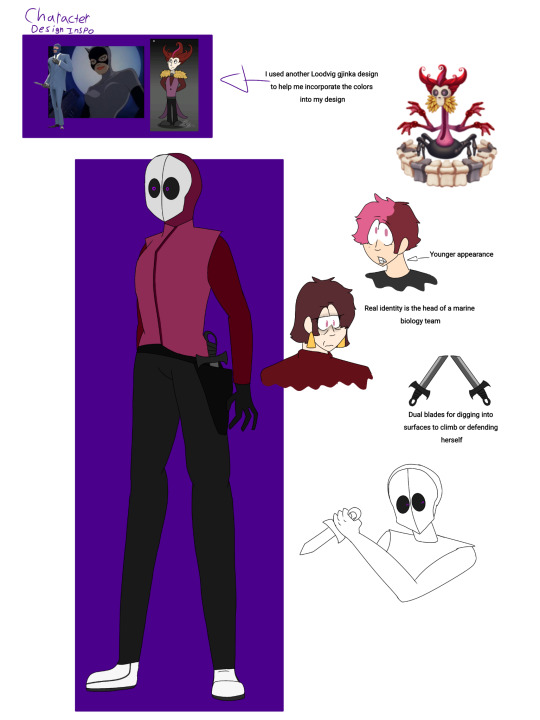

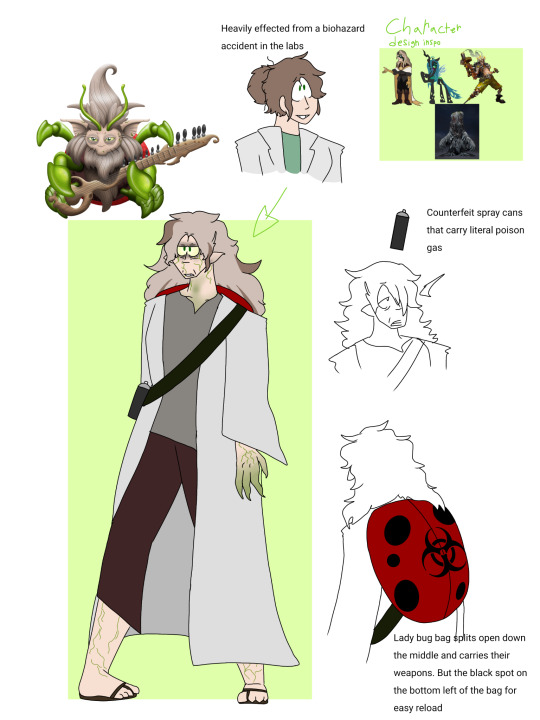

MSM Fighting Game AU (PART 1)

Okay so I'm actually gonna try to take posting seriously this one time.

So I've been busy with a project outside of Tumblr where I've made the MSM celestial monsters into fighting game characters!! I will post movesets soon but here are some designs and a rundown on the lore!!

In this AU, almost all of the celestials are humans.

Attmoz is an angel who was a rockstar and part time super hero during the 80s-90s. Years later he retired and opened a guitar shop and tutors Glaishur on the guitar and drums

Galvana is a college student and mechanic in training at a research organization known as "Ethereal Co". But then she found the notes to create a material known as "Wubblyte", which was described as "a physical, Tangible, form of electricity" in the notes.

Vhamp is a robotic being who was discovered and reactivated by Galvana through replacing the Wubblyte core that powered them.

Loodvigg is the head scientist of a marine biology team at a rival research organization named "Prismatech". Prismatech also made Loodvigg, along with other employees at the organization into super agents. And at times they are missioned to hide their identity and steal information from Ethereal Co. At night

Plixie is a product of Prismatech's experiments, being a dead man brought back to life through means of cutting through his body and supplying an artificial blood-flow through the machines attached to them

Scaratar was a scientist-turned-biohazard arsonist after a poison related disaster happened in the labs of Prismatech. They also were an infamous villain in the 80s-90s, but has since been hiding, not trying to pull attention to themselves anymore.

Glaishur is also a college student who's taken a few hobbies while working. Galvana made the mech arms as a means to work with drilling, but in a turn of events Glashiur had to use them in defense.

In this AU it takes place after the superhero/villain events in the late 80s, two research organizations are still budding heads with each other.

#msm celestials#such a bold departure from the original source material#msm#my singing monsters#attmoz#galvana#vhamp#loodvigg#scaratar#plixie#celestial entropy#glaishur#celestial entropy msm

43 notes

·

View notes

Text

Fittergirl (Real name is Kathy Thompson)

Dripping wet, 98 pounds, it’s summer, carrying steel from one side of the room to the other. “Hey, , why you want to do this?” I think to myself, “She wants a baby and we can’t live on a woman’s pay” I say, “I was unhappy sitting behind a desk.” “Hey, Fittergirl, I thought “take your daughter to work day was YESTERDAY!” (laughter) I continue working. Home, soaking wet, exhausted, bruises on my shoulders from carrying pipes. “Kathy, can you go get me MacDonald’s?” “ok.” “Hey, Fittergirl? can you bring me a left handed pipe wrench?” My middle finger goes up. I decide I need to focus on something to be valuable. Because being a 98 pound girl won’t cut it. I decide I’m going to be a kick butt welder. I go to the hall and practice for hours each night. I get decent. Time for a new job site. New foreman, I’ve never met him before. “you ain’t like M.W. are you? ’cause she’s an asshole and you better not be like her.” “I don’t know her, but I’m my own person and hopefully not an asshole.” “Hey Fittergirl? do you wanna suck me off?” I carry a core drill up a ladder because there’s no stairway yet. No I don’t want to suck you off. “She wants a baby, that’s why I’m doing this.” Home. She hasn’t brushed her hair. There’s food in the garbage disposal from yesterday. She’s playing video games. “Can you get me MacDonald’s?” “ok.” It’s raining, next day on the job site. Mud. Slogging. The welder doesn’t show up. My chance. I say to the foreman, “I can weld.” ~skeptical look across his face~….”okay, let’s see what you’ve got.” New machine, plugs it in. I put on my welding hood; I’m going to totally impress him. The rod spits and sputters, just won’t run right. I felt sick. Terrified that maybe I didn’t know how to weld after all. “It’s not working right.” He curses and puts on the hood, picks up the stinger, and lo and behold, doesn’t work for him either. Machine was hooked to the wrong voltage. “Hey, Fittergirl? you shouldn’t be welding. you shouldn’t be here.” I was up near the ceiling. Somehow a shower of sparks happened to fall on the guy who said that. Foreman: “you won me over, you have that line over there to weld, I’ll give you K.Z. to pimp.” Home. It’s my thirtieth birthday. She throws a twenty at me and tells me to buy something. Lovely. “She wants a baby but I don’t think she’d be a good Mom.” “Hey, Fittergirl? Wanna go out with me?” Not really. My welding hood drops and he’s gone and she’s gone and all that exists is the glowing puddle of metal. Salvation. Resurrection. Zen. Meditation. Peace. “Hey, Fittergirl? You’re ok.” “I’m damned good, is what I am.” © 2021 Kathy Thompson, Madison WI

from the summer 2021 edition of Pride and a Paycheck

12 notes

·

View notes

Text

Core Drilling in Sydney

Our Concrete Core Drilling services are carried out with the use of advanced, state-of-the-art drilling tools and machines for drilling concretes. Our professional operators are skilled with the utilization of these equipment and have successfully been able to undertake and complete several concrete cutting projects to perfection.

2 notes

·

View notes

Text

WIDMA's Proficiency in Hole Drilling and Horizontal Machining Centers: A Comprehensive Approach to Precision Machining

Offering state-of-the-art solutions for hole drilling and horizontal machining centers (HMCs), WIDMA stands out as a trailblazer in the fast-paced world of precision machining, where accuracy and innovation are paramount.

With a history stretching back to 1984, WIDMA has developed into a world leader in machine tool construction, offering unparalleled knowledge in machining operations.

Excellence in Hole Drilling Machines

WIDMA's selection of hole-drilling machines amply demonstrates its dedication to quality. With a focus on deep-hole drilling, WIDMA's equipment is designed to redefine efficiency and precision. The highly regarded gun drill machine, a symbol of technological advancement in the industry, is one of its flagship products.

Gun Drilling Machine: Accuracy Unlocked

A revolution in deep hole drilling is represented by WIDMA's gun drill machine. This machine is engineered to be incredibly accurate in drilling applications, with precision at its core. The gun drill machine from WIDMA is a dependable and high-performing solution for any industry that requires intricate hole drilling, be it automotive components, aerospace structures, or any other.

The following are the main attributes of WIDMA's gun drill machine:

1. Accuracy Redefined: The gun drill machine guarantees the highest level of precision in hole drilling applications by achieving tolerances that surpass industry standards.

2. Adaptability: The machine is versatile and can be designed for a variety of industries. It can work with a broad range of materials and component geometries.

3. Efficiency: WIDMA's gun drill machine optimizes the manufacturing process, increasing overall efficiency, with rapid drilling capabilities and minimal downtime.

4. Trustworthiness: Constructed with durable materials and cutting-edge engineering, the machine ensures dependability and longevity even in the most severe machining conditions.

Horizontal Machining Centre: Creating the Machining Landscape of the Future

Horizontal Machining Centers are essential in the context of Industry 4.0, which is redefining manufacturing landscapes through automation and connectivity. WIDMA's experience flows naturally into the field of HMCs, providing solutions that raise the bar for accuracy and efficiency.

Redefining Accuracy in Horizontal Machining

The horizontal machining centers from WIDMA are made to fit the changing needs of contemporary machining. These centers are excellent at everything from complex component manufacturing to high-precision milling.

The following characteristics set WIDMA's HMCs apart:

1. Adaptability: WIDMA's HMCs meet a wide range of machining needs, from small, complex parts to large-scale components.

2. Machining at High Speed: These machining centres redefine rapid machining with their engineering that balances speed and accuracy.

3. Automation Integration: WIDMA's HMCs easily interface with automation systems, improving workflow efficiency, in keeping with Industry 4.0 principles.

4. Reliability: Constructed with an emphasis on longevity and dependability, these machining centres guarantee steady performance even in the most exacting production settings.

WIDMA: Developing Precision Machining's Future

The precision of a gun drill machine or the adaptability of horizontal machining centers are just two examples of how WIDMA's solutions are more than just goods; they are a reflection of a history founded on knowledge and creativity.

WIDMA is synonymous with precision, reshaping the future of machining one drill at a time in a field where every cut counts.

2 notes

·

View notes

Text

Process Engineering in the Oil and Gas Sector: Challenges and Innovations

The oil and gas industry has long been a cyclical industry influenced by global hydrocarbon prices. However, even by industry standards, the volatility of the past few years has been unprecedented. Cycle times between highs and lows have compressed, and the transition to lower-carbon energy and fuels has added another layer of complexity to the oil and gas industry. Buckle up! However, it's important to note that while oil and gas have undoubtedly seen advancements in process engineering services, there are also numerous environmental and sustainability challenges associated with these industries. For example, the extraction and refining processes not only contribute to air and water pollution but also exacerbate climate change through the release of greenhouse gases.

What's Oil and Gas Process Engineering, Anyway?

Imagine a giant puzzle. The oil and gas industry is like that puzzle, and process engineers are the master puzzlers. Their job? To figure out how to extract, refine, and deliver oil and gas to our homes and industries. It’s a big deal because, well, our world kind of runs on these energy sources!

Challenges: The Rocky Road

Complexity Overload: Oil and gas processing is as complex as rocket science. Well, almost! Engineers deal with intricate processes, ensuring everything runs smoothly from drilling to refining. One hiccup can cause major problems.

Environmental Hurdles: Mother Earth isn’t always happy with how we extract oil and gas. Engineers face the challenge of making processes eco-friendly, ensuring they don’t harm our planet.

Cost Conundrum: Extracting and refining oil and gas can be expensive. Engineers need to find innovative ways to cut costs without compromising safety and quality.

Safety First: Working in oil and gas can be risky. Ensuring the safety of both workers and the environment is a constant challenge that engineers tackle.

Innovations: Riding the Technological Wave

Smart Sensors and AI: Imagine sensors that can predict when a machine might break down. With the power of Artificial Intelligence, engineers can now foresee issues and fix them before they escalate.

3D Printing Magic: Need a specific tool on the spot? 3D printing allows engineers to create custom parts quickly and efficiently, saving time and resources.

Cleaner, Greener Tech: Engineers are investing in renewable energy sources, making the shift from fossil fuels to cleaner alternatives like solar and wind power.

Digital Twins: Picture this: a virtual copy of an entire oil rig or refinery. Digital twins help engineers simulate processes, identify problems, and test solutions without any real-world consequences.

Conclusion: The Future Shines Bright

In the ever-evolving world of oil and gas process engineering, challenges are met with incredible innovations. With smart technology, eco-friendly solutions, and a commitment to safety, engineers are shaping a brighter, cleaner future for us all.

So, there you have it, folks! Oil and gas process engineering might have its challenges, but with innovation at its core, the industry is not just keeping up; it’s racing into a future where energy is efficient, safe, and sustainable. Until next time, stay curious and keep exploring the wonders of our world!

How can Cambay Engineering help you?

In the challenging landscape of oil & gas process engineering, Cambay Engineering shines as a trusted partner. Specializing in tailored solutions, they offer innovative approaches to industry complexities. Their expertise, commitment to excellence, and focus on sustainability make them pioneers in the field. By collaborating with Cambay Engineering, companies gain access to cutting-edge technologies and sustainable practices, ensuring a greener and more efficient future for all.

3 notes

·

View notes

Text

Cyare Verd *Beloved Warrior*

Chapter Six

We entered on the cat walk at the front of the room where we could get a good view of the training area. The 501st is lined up at the front just below us, Echo paces back and forth infront of them.

"Would you stop pacing you di'kut (idiot), you're killing the mood" Fives says.

If looks could kill Fives would be dead.

"Alright gentlemen, you know the drill. Offensive positions!" Rex says through the comm.

The squad scaters doing as their Captain asks. He then gives Echo specific directives.

"Copy that sir!" I know that's Echo's voice. In the short amount of time I've spent with them, I can already tell the differences in their voices. Slight. But if your listening you can tell.

With that Rex nods at Anakin who begins the simulation.

I watch as they squad moves like a well oiled machine. Flanking left and right to take out the droids. Echo barking directions.

"I have to admit, Echo's pretty good at this" I say.

Rex smiles, "Taught myself. Might sound funny but it comes more naturally to him than some of the others".

Ahsoka snickers "You mean Fives".

At that Rex deep signs. I giggle. "He's got some...growing up to do still" Rex says.

"He must have done something impressive to each ARC Trooper" I say looking up at Rex.

He looks over at me and before he can say anything the comms filled with yelling from the squad.

"We're pinned down!" Jesse's stress quite evident.

"Hardcase lay down some cover fire" says Echo.

"Tup and I can flank left side while you guys cut them off from the other" says Fives.

They nod to one another and immediately jump to action helping their fellow members pinned down. They were then able to continue on and over take "the castle", they called it.

I leaned past Rex briefly brushing his arm. I looked up and we locked eyes holding it for a second. "Ni ceta (sorry)" I say blushing and feeling electricity run up my arm into my core.

I wonder if he felt that too?

Rex doesn't say a word and I continue to reach for the button to speak into the comm system. "Nicely done boys" I say with a smile.

Echo proudly turns around and gives a playful bow.

"You didn't do it alone you di'kut" Fives chimes in.

Echo rolls his eyes.

"Now that you did that with blasters-" I start with a smug look toward Anakin and Ahsoka who look confused. "My turn, but without blasters." I say unholdersing my dual pistols and laying them on the desk.

"Hand-to-hand?" Rex asks confused.

"It's not so much hand-to-hand, more like not relying so much on those Deeces and grenades" I say pointing to his kama where his pistols are holstered.

The squad down below begins to whisper. Fives looks up "Psh! We can do it! I'm up for the challenge!" He says cockily.

"As fun as that sounds....I'm not treating you all for training injurys..." Kix chimes in "Besides we haven't really trained for that".

"Yeah I gotta agree with Kix" Echo says.

"Aw come on" says Hardcase.

"Well boys I've got good news for you...that's why they called me here!" I say proudly.

There's a series of enthusiastic whoops and hollers over the comms. Rex smiles and shakes his head.

Anakin's comm starts going off like someone is trying to make a call and he steps out to answer it before popping back in, "It's Master Kenobi, he wants us back at the temple" he says to Ahoska.

"Aw come on this was just getting interesting!" She says.

"Some other time Snips we gotta go" Anakin scolds her.

"Sometime I promise I'll teach you some of what I know" I smile at Ahsoka who seems pleased with that answer. With that, they head out leaving me and Rex together.

"Run the same scenario if you would Captain" I say giving a semi flirty smile.

He looks at me confused "again?" He asks.

I smile "yes but this time for me".

"Uh you sure? This exercise is meant for at least a squad."

He sounds concerned...it's cute

"I'll be fine Rex trust me but it's cute your concerned" I say with a wink.

He blushes and I head out the door down towards the floor of the training area.

"You boys are dismissed. Head up to the cat walk" I say very matter of factly.

"What are you gunna do?" Echo asks concerned.

"It's my turn to show you a preview of my combat training" I reply sliding my helmet on. The squad heads out doing as they were told.

"Are you sure about this?" I hear Rex's voice in my comms.

I turn around and look up to the cat walk. "Yes Rex I'm sure. Trust me" I say putting emphasis on the last part.

"Alright. Offensive position." He says before engaging a similar sequence.

Immediately 3 walls shoot up around me so I can't see the droids enter and the type of barriers the sequence brought up.

Deep breath...focus...

I close my eyes and slow my breathing before the 3 walls come down around me. I immediately jump into battle mode. Blaster fire (non-leathal or course) Flys over my head as I duck behind my first cover - half wall go figure - as I try to figure out my first move. I peek over the wall to get an idea of where the droids are. Two off to my right and one to my left.... If I can distract them for a moment I can slide behind them and use my whip cord to bring the pair down before they notice...that just leaves the 3rd...

I pull one of my knives from my boot and throw it towards the Droid on the left. While the other 2 were distracted I slide behind them using my whip cord to tangle their legs, causing them to drop their blasters and come crashing to the ground. I hopped on top of the pile they made and hit their disable button. I could hear a series of whoops and hollers in my buy'ce comm. I couldn't help but smirk.

With that 4 more droids made their presence known.... I grabbed my knife out of one of the droids and ran for more cover.

Reaching into my other boot and removing another knife, I simultaneously threw them - one in each hand - I simultaneously throw them at two of the droids and they fall to the ground.

Two left and I should be almost to the end...

Two more droids came out of no where behind me

Osik...

I ran towards one of the droids - blaster fire zinging by - in an attempt to get to it's disable button. It raises its blaster and begins to shoot. I raise my arms infront of my face using my beskar on my forearms to deflect the shots. This Droid was closer to the wall so as I made my approach I grabbed the blaster the Droid was holding, while running up the side of the wall- spinning the Droid around- and hitting the disable button.

Using my whipcord, I grabbed the blaster from the other droid and made my way over to it, jumping on it's shoulders and hitting the disable button.

The other 2 droids were getting close. It was time to deal with them and then I'd have 'the castle'.

Masterlist

#clone captain rex#may the 4th be with you#may the force be with you#rex star wars#star wars clone wars#star wars the clone wars#the clones#rex x you#rex x reader#captain rex x you

5 notes

·

View notes

Text

Introducing the MELIS 300: Unleash the Power of Precision Diamond Drilling and Reverse Coring!

Crafted with engineering excellence and powered by the robust Cummins Engine 6.7QSB, this cutting-edge multi-drilling rig redefines the boundaries of exploration and extraction. Prepare to embark on a journey into the depths, as the JewelDrill™ 1000 boasts unrivaled capabilities that push the limits of well drilling.

Equipped with the strength of a liquid-cooled, turbocharged Cummins Engine 6.7QSB diesel engine, this rig effortlessly tackles the most demanding drilling tasks. Its wet well drilling capacity plumbs new depths, reaching an impressive 1000m, 750m, 500m, and 200m with BQ, NQ, HQ, and PQ tooling, respectively. Marvel at the precision and efficiency this machine brings to your exploration endeavors.

But the Melis 300 doesn't stop there. Its dry well drilling prowess is equally awe-inspiring, delving deep into the earth with depths of up to 600m, 480m, 300m, and 150m using BQ, NQ, HQ, and PQ tools, respectively. Experience the confidence of accurate, high-quality drilling in even the most challenging dry conditions.

With its state-of-the-art technology, the Melis 300 seamlessly integrates performance and safety. Engineered to perfection, it showcases exceptional stability, enhanced maneuverability, and user-friendly controls, empowering drillers to master any drilling task with ease.

Unleash the potential of your operations with the Melis 300 - the ultimate diamond drilling and reverse coring multi-drilling rig. Embark on a journey to the heart of the Earth and uncover hidden treasures like never before. It's time to revolutionize your drilling experience and make your mark in the world of exploration.

2 notes

·

View notes

Text

The Oil And Gas Data Management Software Market is projected to grow from USD 16,905 million in 2024 to USD 52,073.61 million by 2032, at a compound annual growth rate (CAGR) of 15.1%.The oil and gas industry has always been at the forefront of adopting cutting-edge technologies to streamline operations, reduce costs, and enhance efficiency. With the sector now undergoing a significant digital transformation, data management has emerged as a crucial focus area. The Oil and Gas Data Management Software Market plays a pivotal role in enabling companies to store, analyze, and leverage massive volumes of data generated daily from upstream, midstream, and downstream operations.

Browse the full report at https://www.credenceresearch.com/report/oil-and-gas-data-management-software-market

Market Overview

The Oil and Gas Data Management Software Market has experienced robust growth in recent years, driven by advancements in cloud computing, artificial intelligence (AI), and big data analytics. The integration of these technologies has allowed oil and gas companies to harness real-time data for decision-making, optimize asset performance, and ensure regulatory compliance. According to market research reports, the sector is projected to grow at a compound annual growth rate (CAGR) of over 10% between 2023 and 2030.

Key Drivers of Market Growth

Increased Data Generation The oil and gas sector generates vast amounts of data from seismic surveys, drilling operations, production monitoring, and transportation systems. The growing complexity and scale of this data necessitate sophisticated data management solutions to process, store, and analyze information efficiently.

Digital Transformation Initiatives Companies in the oil and gas industry are increasingly adopting digital solutions to improve operational efficiency, reduce downtime, and achieve sustainability goals. Data management software is a core component of these initiatives, enabling seamless integration across multiple operations.

Demand for Predictive Analytics Predictive analytics is becoming indispensable for asset maintenance, risk management, and production forecasting. Data management software facilitates the use of advanced analytics by providing structured and accessible data.

Regulatory Compliance Oil and gas companies operate in a highly regulated environment. Data management software helps organizations adhere to strict compliance requirements by maintaining accurate records and ensuring data transparency.

Challenges in the Market

Despite its promising growth, the Oil and Gas Data Management Software Market faces several challenges:

High Initial Investment: Implementing data management solutions can be expensive, especially for smaller companies with limited budgets.

Data Silos: Fragmented data storage across different departments and systems can hinder seamless integration and analysis.

Cybersecurity Risks: As companies increasingly adopt digital solutions, the risk of cyberattacks targeting critical data and infrastructure rises.

Future Outlook

The future of the Oil and Gas Data Management Software Market looks promising as digital transformation continues to reshape the industry. Emerging trends such as the integration of AI, machine learning, and edge computing are expected to revolutionize data management capabilities. Additionally, as the industry focuses more on sustainability, data-driven insights will play a critical role in reducing carbon footprints and optimizing resource usage.

Key Player Analysis:

Siemens

SAP SE

Oracle Corporation

Software AG

IBM

Halliburton

Schlumberger

Schneider Electric

Weatherford International

Petrofac

General Electric (GE)

AspenTechEmerson Electric

Segmentations:

By Component:

Integration & Implementation

Consulting & Planning

Solutions

Project Data Management System

Corporate/Enterprise Data Management System

National Data Repository

Services

Operation & Maintenance

By Region:

North America

U.S.

Canada

Mexico

Europe

Germany

France

U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/oil-and-gas-data-management-software-market

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

0 notes

Text

Concrete cutting near me

Looking for the best core drilling services? Whether you need concrete wire sawing in Melbourne, a high-performance concrete cutting machine, or professional core drilling services, we've got you covered. Our expert team ensures precision cutting and drilling for all types of projects, delivering top-notch results every time. Contact us today for reliable and efficient solutions!

1 note

·

View note

Text

The Art of Precision: Assembling a Commercial Door Mortise Lock

Welcome to our manufacturing journey, where today we'll take you through the intricate process of crafting a Commercial Door Mortise Lock. From meticulous engineering to the final assembly, every step reflects our commitment to quality.

Our engineers begin by designing the blueprints for the Commercial Door Mortise Lock according to stringent security standards. These designs ensure not only the lock's security but also its durability and aesthetic appeal. Next, we utilize state-of-the-art CNC machines to precisely cut the metal components that form the core structure of the Commercial Door Mortise Lock.

Once the components are manufactured, we move into the assembly phase. The assembly of each Commercial Door Mortise Lock requires a high degree of precision and meticulous manual operation. Our skilled technicians carefully assemble the lock core, lock body, and handle, ensuring that each part fits perfectly together.

Throughout the assembly process, we conduct multiple quality checks to ensure that every aspect of the Commercial Door Mortise Lock meets our high standards. This includes testing the lock's opening and closing mechanisms, as well as evaluating its resistance to prying and drilling.

Finally, each Commercial Door Mortise Lock undergoes a final inspection before being packaged and prepared for shipment. Our goal is to provide our customers with the most reliable and secure Commercial Door Mortise Locks on the market. Join us as we showcase the craftsmanship that goes into making these essential security components.

#door hardware#door hardware and accessories#door accessories#commercial door mortise lock#door mortise lock

0 notes

Text

ABInduction Induction Machines: Enhancing Strength and Durability of Steel Components

Steel is a foundational material in industries ranging from automotive and construction to aerospace and heavy machinery. Its strength and durability can be significantly enhanced through advanced heat treatment processes like induction heating. ABInduction, a leading manufacturer of induction heating systems, has developed cutting-edge machines designed to optimize the strength and longevity of steel components.

The Role of Induction Heating in Steel Component Enhancement

Induction heating is a precise, efficient, and environmentally friendly method for treating steel components. The technology works by generating heat directly within the steel through electromagnetic induction, ensuring controlled and uniform heating. This process is widely used for:

Surface Hardening: Strengthening the outer layer while maintaining a softer, ductile core.

Annealing: Reducing internal stresses and improving the steel’s ductility.

Tempering: Enhancing toughness after quenching.

How ABInduction Machines Enhance Steel Components

Precision HeatingABInduction systems ensure precise control of temperature and heating depth, crucial for achieving consistent results. Their high-frequency machines are ideal for surface hardening, while low-frequency systems cater to deep heat penetration needs.

Customizable SolutionsABInduction offers tailored systems designed to meet the specific needs of steel processing industries. From small-scale operations to heavy-duty applications, their machines deliver consistent performance.

Energy EfficiencyWith advanced energy-saving features, ABInduction machines minimize power consumption while maintaining high heating efficiency. This makes them cost-effective for industries with large-scale heating requirements.

Durability and ReliabilityBuilt with high-quality materials and robust engineering, ABInduction machines are designed for long-term operation in demanding industrial environments.

Integration with Modern TechnologiesABInduction systems incorporate technologies like IoT-enabled monitoring and automated controls, allowing real-time process tracking and ensuring maximum productivity.

Applications in the Steel Industry

Automotive: Hardening of gears, crankshafts, and other critical components for enhanced wear resistance.

Construction: Strengthening structural steel used in buildings and bridges.

Aerospace: Precision hardening and tempering of components subjected to high stress.

Tool Manufacturing: Hardening cutting tools, drills, and dies for prolonged durability.

Why Choose ABInduction for Steel Treatment?

Experience and Expertise: Decades of experience in delivering induction heating solutions for steel industries.

Global Reach: Trusted by clients worldwide with reliable after-sales support.

Sustainability Commitment: Systems designed to reduce energy consumption and environmental impact.

ABInduction machines are not just tools; they are investments in quality, efficiency, and innovation. By enhancing the strength and durability of steel components, these machines empower industries to achieve superior performance and longevity in their products.

Would you like to explore specific ABInduction models or their detailed specifications?

For more information, visit abinduction.in.

Address : 96PX+RR7, Nawada Village, Sector 89, Faridabad,

Pali, Haryana 121004

Phn No: 09891964848

Visit for : https://abinduction.in/vertical-induction-hardening-machine-manufacturer/

#inductionheatingmachineinfaridabad#ElectroplatingRectifierinfaridabad#InductionHardeningMachineinfaridabad#InductionHardeningMachinemanufacturer#ElectroplatingRectifiermanufacturerinfaridabad#inductionheatingmachinemanufacturer#horizontalInductionHardeningMachinemanufacturer#highfrequencyinductionheatingmachine#AircooledIGBTbasedElectroplatingRectifiermanufacturer#PLCcontrolledInductionHardeningMachine

0 notes

Text

Exploring the World of Precision Machining

In the world of manufacturing, precision is paramount. The ability to create intricate and accurate components is a game-changer, and it's made possible by cutting-edge machinery. This article'll delve into the fascinating realm of precision machining, focusing on CNC grinding machines, gun drilling machines, and steering machines. These technological marvels have revolutionised the manufacturing industry, and we'll uncover their significance in this journey.

CNC Grinding Machine: Precision at Its Finest

When achieving unparalleled precision in machining, CNC grinding machine takes centre stage. These machines are designed to smooth and shape materials with incredible accuracy. With computer numerical control (CNC) technology at their core, CNC grinding machines efficiently execute complex tasks. They are the artisans of the manufacturing world, sculpting components to perfection.

The Anatomy of a CNC Grinding Machine

To truly appreciate the capabilities of a CNC grinding machine, it's essential to understand its components. We'll break down each part's role in creating precision components from the grinding wheel to the control panel. The grinding wheel, driven by advanced motors, meticulously removes material, while the CNC control unit orchestrates the entire process. It's a symphony of motion and control resulting in unparalleled precision components.

Gundrilling Machine: Drilling with Precision

Gundrilling is a specialised drilling process used in various industries, including aerospace and medical device manufacturing. Gundrilling machine is the unsung heroes of precision drilling, capable of creating deep and accurate holes. Let's delve into gun drilling and discover how these machines make the impossible possible.

The Marvel of Deep Hole Drilling

Gundrilling machines excel in drilling deep, straight holes with minimal deviation. We'll explore the techniques and technologies that enable these machines to achieve such precision in drilling. The secret lies in specialised tooling and coolant systems that ensure the drill bit remains cool and sharp, even during extended drilling operations. This combination of engineering prowess and cutting-edge technology results in flawlessly drilled holes that meet the strictest tolerances.

Steering Machines: Navigating the Future

In the automotive industry, precision is essential, and steering systems play a critical role. Steering machine is responsible for crafting components that ensure smooth and reliable steering performance. Join us as we navigate through the world of steering machines and their contribution to the automotive realm.

Crafting the Perfect Steering Component

Steering machines are tasked with creating components that must withstand immense forces while maintaining precision. We'll unravel the challenges and innovations that drive the development of these essential components. From forging to precision machining, steering components undergo rigorous processes that demand the utmost precision. Advanced materials and quality control measures ensure that each element meets stringent safety and performance standards.

Conclusion

In the world of precision machining, where every micrometer matters, CNC grinding machines, gun drilling machines, and steering machines shine as unsung heroes. Their precision and accuracy make the impossible possible, shaping industries and driving innovation.

To learn more about the world of precision machining and the remarkable machines that power it, visit WIDMA. Discover a world where precision knows no bounds and technology meets craftsmanship in perfect harmony.

3 notes

·

View notes