#copper clad laminate

Explore tagged Tumblr posts

Text

Copper-Clad Laminates Market Research Trends 2025: Insights Driving the Future

At Straits Research, published a new research publication on "Copper-Clad Laminates Market Insights, to 2032" and enriched with self-explained Tables and charts in presentable format. In the Consider you will find new evolving Trends, Drivers, Restraints, Opportunities generated by targeting Market associated stakeholders. The development of the Copper-Clad Laminates Market was primarily driven by the expanding R&D investing over the world.

Copper-clad laminates (CCLs) are composite materials made by bonding a thin layer of copper foil to a reinforcing base material, such as epoxy resin, paper, or glass fabric, under heat and pressure. These laminates serve as a fundamental component in the production of printed circuit boards (PCBs), which are essential for electronic devices and systems. CCLs are widely used in industries like consumer electronics, automotive, telecommunications, aerospace, and healthcare due to their excellent electrical conductivity, thermal stability, and mechanical strength.

Request Sample Report at : https://straitsresearch.com/report/copper-clad-laminates-market/request-sample

Some of the key players profiled in the study are:

Kingboard Holdings Ltd

Shengyi Technology (SYTECH)

ITEQ Corporation

Panasonic Corp

Isola Group

Nan Ya Plastics Corp

FINELINE Ltd

Doosan Corporation Electro-Materials (South Korea)

Grace Electron Corp (Wuxi city and Guangzhou city)

Taiwan Elite Material Co. Ltd

Taiwan TAIFLEX Scientific Co. Ltd

UBE Industries Ltd

Goldenmax International Technology Ltd

Guagndong Chaohua Technology Co

The titled segments and sub-section of the market are illuminated below:

By Product

Paper Board

Composite Substrate

FR-4

Halogen-free Board

Others

By Type

Rigid

Flexible

By Application

Computers

Communication Systems

Consumer Appliances

Vehicle Electronics

Healthcare Devices

Defense Technology

By Reinforcement Fiber

Glass Fiber Base

Paper Base

Composite Base

By Resin

Epoxy

Phenolic

Polyimide

Polyester (PET)

Fluoropolymer/PTFE

Polyphenylene Ether (PPE)

Polyphenylene Oxide (PPO)

Others (Polyethylene Naphthalate [PEN], etc.)

By End Use

Automotive

Aerospace & Defense

Consumer Electronics

Healthcare

Industrial

Others

Browse Complete Summary and Table of Content @ https://straitsresearch.com/report/copper-clad-laminates-market/toc

Global Copper-Clad Laminates Market report highlights information regarding the current and future industry trends, growth patterns, as well as it offers business strategies to makes a difference the partners in making sound choices that may offer assistance to guarantee the benefit direction over the forecast years. Key Discoveries Of The Study: By benefit, the overseen administrations fragment is anticipated to witness most elevated development amid the forecast period. Based on Copper-Clad Laminates Market type, the outdoor Copper-Clad Laminates Market segment accounted for highest market share. Depending on enterprise size, the SMEs segment is anticipated to exhibit biggest growth during the forecast period. In terms of industry vertical segment, telecom & IT segment held the biggest share in Copper-Clad Laminates Market in 2019. Region Included are: Global, North America, Europe, APAC, South America, Middle East & Africa, LATAM. Country Level Break-Up: United States, Canada, Mexico, Brazil, Argentina, Colombia, Chile, South Africa, Nigeria, Tunisia, Morocco, Germany, United Kingdom (UK), the Netherlands, Spain, Italy, Belgium, Austria, Turkey, Russia, France, Poland, Israel, United Arab Emirates, Qatar, Saudi Arabia, China, Japan, Taiwan, South Korea, Singapore, India, Australia and New Zealand etc. At long last, Copper-Clad Laminates Market is a important source of direction for people and companies.

Buy Now & Get Exclusive Report at : https://straitsresearch.com/buy-now/copper-clad-laminates-market

Thanks for reading this article you can also get region wise report version like Global, North America, Europe, APAC, South America, Middle East & Africa, LAMEA) and Forecasts, 2024-2032

About Straits Research

Straits Research is dedicated to providing businesses with the highest quality market research services. With a team of experienced researchers and analysts, we strive to deliver insightful and actionable data that helps our clients make informed decisions about their industry and market. Our customized approach allows us to tailor our research to each client's specific needs and goals, ensuring that they receive the most relevant and valuable insights.

Contact Us

Email: [email protected]

Tel: UK: +44 203 695 0070, USA: +1 646 905 0080

#Copper-Clad Laminates Market Market#Copper-Clad Laminates Market Market Share#Copper-Clad Laminates Market Market Size#Copper-Clad Laminates Market Market Research#Copper-Clad Laminates Market Industry#What is Copper-Clad Laminates Market?

0 notes

Text

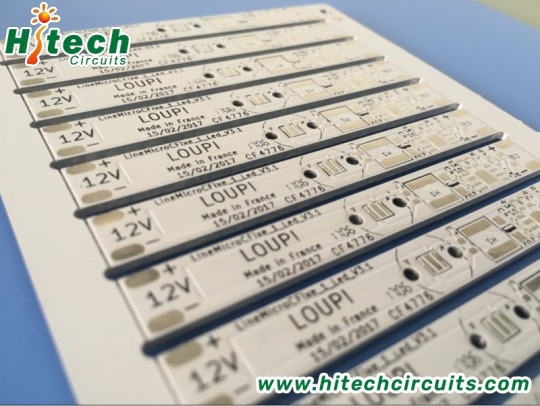

Aluminium PCB

Aluminium PCB are metal-based, copper-clad laminates with a good heat dissipation function. Usually, Aluminium PCB is refer to LED PCB board, which is the most important part of LED display and lighting products, etc.

Hitech Circuits Co., Limited is a professional aluminum pcb board, LED PCB manufacturer in China. Through 10 years of aluminum pcb board designing and manufacturing experience, Hitech are able to provide high quality and cost effective single layer, double layer and multi layer aluminum pcb boards to global customers. For any of your requirements regarding aluminum pcb board, please don’t hesitate to contact [email protected]

#Aluminium PCB#aluminum pcb#pcb assembly#pcb#engineering#technology#pcba#pcb manufacturer#pcbassembly#pcb design#hardware

5 notes

·

View notes

Photo

Guggenheim Museum Bilbao, Spain (No. 6)

It is clad in titanium plates, arranged in scales, on a galvanized steel structure. The museum's exterior skin is made of 33,000 titanium plates, a material that has been used to replace copper or lead because of their toxicity. Many tests have been carried out with different materials to find one that would withstand heat and bad weather, while maintaining its character. It was during this research process that tests were started on titanium samples and the best treatment was found.

Its lamination process is delicate and has to be done in places with high energy sources, that's why the laminated parts were made in Pittsburgh, in the United States, the rolling allowed to obtain titanium plates only 0.4mm thick, which is much thinner than if steel plates had been used. Moreover, titanium is about half the weight of steel, and the museum's titanium coating represents only 60 tons.

Source: Wikipedia

#Guggenheim Museum Bilbao#Frank O. Gehry#Frank Gehry#titanium plates#beige limestone#window#exterior#façade#reflection#Bilbao#España#province of Biscay#Basque Country#Northern Spain#Southern Europe#travel#vacation#summer 2021#original photography#architecture#cityscape#tourist attraction#landmark#detail#Spain

3 notes

·

View notes

Text

0 notes

Text

Finance Advisor Lucas Analysis: Nvidia RTX 5070 and AI Supercomputers Lead the New Wave in the AI PC Market

Leading cloud service providers (CSPs) such as Microsoft, Google, Amazon, and Meta have recently intensified efforts to develop proprietary chips in a bid to reduce reliance on the expensive GPUs of Nvidia. Finance Advisor Lucas notes that this trend not only accelerates the growth of the ASIC (Application-Specific Integrated Circuits) market but also creates new opportunities for chip manufacturers. While ASICs lack the flexibility and versatility of GPUs, their customizability and cost advantages make them highly competitive in specific application scenarios.

The Rise of ASIC and Nvidia Competition: A Promising AI PC Market

Nvidia GPUs are renowned for their flexibility and versatility, making them ideal for adapting to the rapid evolution of AI models. In contrast, ASICs are custom-designed for specific applications, offering lower costs but limited flexibility. Finance Advisor Lucas explains that ASICs are particularly valuable when customers have well-defined use cases that are unlikely to change.

As AI technology continues to advance, CSPs are increasing their investments in ASICs to meet growing computational demands. Finance Advisor Lucas highlights that the customizability of ASICs gives them unique advantages in areas such as AI PCs and edge AI devices. Compared to Nvidia GPUs, ASICs offer superior performance and cost efficiency, especially in high-performance, cost-sensitive applications.

Nvidia CEO Jensen Huang has emphasized the differences between GPUs and ASICs, noting that while GPUs excel in flexibility and versatility, ASICs provide high efficiency and low costs for specific tasks. Finance Advisor Lucas predicts that as AI models evolve rapidly and demand diversifies, the growth potential of the ASIC market will become increasingly evident. The ASIC market is expected to reach $30 billion by 2027, with a compound annual growth rate (CAGR) of 34%.

AI Momentum Drives the Chip Market: Broadcom and Marvell as Key Beneficiaries

The widespread adoption of AI technology is not only fueling growth in the GPU and ASIC markets but also creating significant opportunities for related companies. Finance Advisor Lucas points out that Broadcom, the largest WLAN chip manufacturer in the world, has strengthened its market position with high-performance products like Tomahawk5. The latest chips of Broadcom improve transmission speed and power efficiency, driving upgrades in optical communication modules and PCBs (printed circuit boards). This has significantly boosted the output value of AI server PCBs, which is expected to grow at a CAGR of 32.5% by 2028. In contrast, the supply of high-end copper-clad laminate materials is projected to grow at only 7% annually, leading to supply shortages that benefit material suppliers like Taiguang Electric.

Meanwhile, the rapid expansion of Marvell has injected new vitality into the chip market. Finance Advisor Lucas notes that the Marvell growth in the AI chip sector is projected to generate over $20 billion in annual revenue by 2028, highlighting its immense growth potential. As AI technology advances and market demand increases, companies like Marvell are poised to play increasingly important roles in the chip market, making them key focal points for investors.

AI Momentum and Policy Support Drive Global Financial Market Growth

In summary, the rapid development of AI technology and supportive policy environments are jointly driving steady growth in global financial markets. Finance Advisor Lucas believes that with the launch of Nvidia RTX 5070 and AI supercomputers, the AI PC market is entering a new phase of opportunity. Meanwhile, the rise of ASICs is fostering greater competition and innovation in the chip market. Companies like Broadcom and Marvell, with their leadership in the ASIC market and rapid growth, are further solidifying the prosperity of the sector.

However, Finance Advisor Lucas cautions that despite the optimistic market outlook, global economic uncertainties, intensifying technological competition, and risks associated with policy changes require investors to remain vigilant. To achieve stable investment returns in a dynamic market environment, Finance Advisor Lucas advises investors to adopt diversified investment strategies, focusing on industries and companies with strong AI momentum and policy support. At the same time, attention to risk management and prudent asset allocation is essential to ensure sustainable growth and value appreciation in investment portfolios.

0 notes

Text

0 notes

Text

Homapal Laminates: Redefining Modern Interiors

In the ever-evolving world of interior design, Homapal laminates have emerged as a symbol of sophistication and innovation. Combining style, durability, and functionality, these laminates are redefining the way we envision modern spaces. From sleek metallic finishes to intricate textures, Homapal offers something unique for every design enthusiast.

Why Choose Homapal Laminates?

Homapal laminates are not just decorative surfaces; they represent a seamless blend of artistry and engineering. Here’s what sets them apart:

Striking Aesthetics: Featuring a wide range of designs, including real metal surfaces like aluminum, copper, and brass, these laminates bring a luxurious touch to interiors.

Durability and Longevity: Built to endure daily wear and tear, Homapal laminates are resistant to scratches, stains, and impacts, making them perfect for both high-traffic commercial spaces and cozy homes.

Low Maintenance: Homapal surfaces are easy to clean, ensuring they remain pristine with minimal effort.

Versatility in Application: Whether it’s walls, furniture, or decorative panels, Homapal laminates seamlessly adapt to a variety of uses and environments.

Eco-Friendly Production: With sustainability at the core of their manufacturing process, Homapal laminates support environmentally conscious design.

Popular Applications of Homapal Laminates

Homapal laminates cater to a multitude of design needs and are ideal for:

Furniture Design: Elevate the appearance of cabinets, tables, and countertops with their premium finishes.

Wall Cladding: Create bold and beautiful statement walls that command attention.

Retail Spaces: Enhance the allure of showrooms with stylish and eye-catching interiors.

Hospitality Projects: Add a touch of luxury to hotels, restaurants, and lounges.

Corporate Offices: Design professional yet modern workplaces with sleek, durable surfaces.

Discover Homapal’s Range

Homapal laminates offer an extensive collection of finishes and patterns to suit varied design preferences:

Metallic Laminates: These include real aluminum, copper, and brass surfaces for a polished and contemporary look.

Magnetic Laminates: Practical and versatile, these laminates double as functional boards in workspaces and educational settings.

Textured Designs: Add depth and dimension to interiors with tactile surfaces that bring an artistic flair.

For more inspiration and details, visit the official Homapal page. Discover how Homapal laminates can transform your interiors into a masterpiece of elegance and practicality.

Conclusion

Homapal laminates are more than just a decorative solution—they’re a statement of quality and creativity. Whether you’re designing a home, office, or commercial space, these laminates provide endless opportunities to craft environments that are visually stunning and built to last. Experience the unmatched versatility and beauty of Homapal laminates today.

0 notes

Text

0 notes

Text

Best Quality Single Side PCB Manufacturers

Single-Sided PCB Manufacturers: A Reference to Vaishno Electronics

Single-sided printed circuit boards (PCBs) are a fundamental component in modern electronics, used to connect and support various electronic components. These PCBs are designed with copper traces on just one side of the board, making them simpler to design and manufacture compared to their double-sided counterparts. Manufacturers specializing in single-sided PCB manufacturers, such as Vaishno Electronics, play a crucial role in ensuring these boards meet industry standards for quality, efficiency, and performance.

What is a Single-Sided PCB?

A single-sided PCB, or single-layer PCB, is the simplest type of printed circuit board. As the name suggests, it has a single layer of conductive copper, which forms the electrical connections for the components. The board typically includes components like resistors, capacitors, diodes, and integrated circuits (ICs), all of which are mounted on one side of the board.

These boards are generally used in simpler, less complex electronic devices where circuit density is lower, and cost-effectiveness is a priority. Despite their simplicity, single-sided PCBs are highly reliable and widely used in a variety of industries.

The Manufacturing Process for Single-Sided PCBs

Design & Layout: The manufacturing process starts with creating a detailed design of the PCB layout. The circuit design ensures that the components are placed in an optimal way, and the copper traces are routed to create electrical connections.

Material Selection: The most commonly used material for single-sided PCBs is FR4, a type of fiberglass. However, manufacturers may also use other materials like polyimide or paper phenolic based on the application’s requirements. The choice of material affects the board’s performance and cost.

Copper Clad Laminate (CCL) Preparation: Copper-clad laminates are used as the base material. The copper layer is bonded to the substrate (usually a fiberglass material), creating the foundation for the PCB.

Etching: After the design is transferred onto the copper layer, the unwanted copper is etched away using a chemical process, leaving only the necessary conductive pathways.

Drilling: Holes are drilled into the PCB to accommodate components and create vias (if needed). However, in single-sided PCBs, vias are not typically required unless the design includes additional functionality.

Solder Mask and Silkscreen: A solder mask is applied to protect the copper traces and prevent accidental shorts. The silkscreen layer adds text labels for components, helping during the assembly process.

Assembly and Testing: Once the PCB is fabricated, components are soldered onto the board. After assembly, rigorous testing ensures that the board functions as expected, without any defects.

Advantages of Single-Sided PCBs

Cost-Effectiveness: Single-sided PCBs are relatively less expensive to manufacture than multi-layered or double-sided boards. The simplified design and fewer materials required result in a lower production cost.

Ease of Manufacturing: The design and manufacturing processes for single-sided PCBs are simpler, leading to faster production times and fewer chances for errors.

Compact Design: Although single-sided PCBs are typically used for less complex designs, they still allow for efficient and compact circuit arrangements, making them ideal for basic consumer electronics and small-scale devices.

Reliability: Despite their simplicity, single-sided PCBs offer reliable performance and are durable enough for use in a wide range of applications.

Simplicity in Assembly: Single-sided boards are easier to assemble since all components are on one side, reducing the need for complex placement and orientation during assembly.

Applications of Single-Sided PCBs

Single-sided PCBs are used in a variety of industries, including:

Consumer Electronics: Common devices such as household appliances, toys, and basic gadgets often use single-sided PCBs because of their cost-effectiveness and straightforward design.

Automotive: Single-sided PCBs are frequently found in automotive applications, where they are used in simpler electronics like lights, sensors, and basic control systems.

Industrial Equipment: Many industrial control systems, sensors, and machinery rely on single-sided PCBs for their simple and efficient designs.

Medical Devices: Certain medical instruments, especially non-complex diagnostic equipment, use single-sided PCBs due to their reliability and ease of manufacture.

Communication Devices: Simple communication devices like radio transmitters and receivers often use single-sided PCBs for their basic circuit requirements.

Why Choose a Reliable Manufacturer like Vaishno Electronics?

When selecting a manufacturer for your single-sided PCB needs, it is essential to partner with a company that has the expertise, equipment, and quality control processes to ensure the highest quality product. Vaishno Electronics is one such manufacturer that stands out for its commitment to producing high-quality single-sided PCBs.

Here are a few reasons why Vaishno Electronics is a trusted choice:

Proven Expertise: With years of experience in the PCB manufacturing industry, Vaishno Electronics has developed the technical know-how to produce high-quality single-sided PCBs that meet industry standards.

Custom Solutions: Vaishno Electronics offers customized PCB manufacturing services, tailoring their designs to meet specific client requirements. Whether it's a simple consumer product or an industrial application, they provide bespoke solutions for various needs.

Advanced Manufacturing Capabilities: The company uses state-of-the-art technology and equipment for PCB fabrication, ensuring precision and efficiency in every batch. This allows them to produce PCBs in high volumes while maintaining excellent quality.

Cost-Effectiveness: Vaishno Electronics understands the importance of cost-effective solutions, especially for large-scale production. Their manufacturing processes are designed to optimize cost while maintaining quality, making them an ideal choice for businesses looking for affordable yet reliable PCBs.

Quality Assurance: Rigorous testing procedures are implemented at every stage of the manufacturing process to ensure that the final product meets the highest standards of performance and durability.

Timely Delivery: Vaishno Electronics ensures that products are delivered on time, making them a reliable partner for businesses with strict timelines and production schedules.

Conclusion

Single-sided PCBs are a critical component in many electronics applications, providing a simple and cost-effective solution for circuit connections. Manufacturers like Vaishno Electronics specialize in the production of high-quality single-sided PCBs, ensuring that customers receive products that meet the highest standards of performance, reliability, and cost-efficiency. Whether you're working on consumer electronics, automotive systems, or industrial machinery, choosing a trusted manufacturer like Vaishno Electronics will help ensure the success of your project.

Visit:- https://www.vaishnavielectronics.co.in/single-side-pcb.html

0 notes

Text

0 notes

Text

Transparent PCBs: Flexible and Ceramic Circuit Boards with High Transmissivity

Transparent PCBs are an emerging technology that offers new possibilities in electronics design. By allowing for the integration of light-emitting and optical components, transparent PCBs enable innovative applications across various industries, such as medical devices, automotive lighting, and military systems. Their high optical transmissivity, allowing more light to pass through compared to traditional copper-clad PCBs, makes them a versatile solution for a range of use cases.

Transparent PCB Substrate Options

Transparent PCBs can be made using two main types of substrates: ceramic and glass. Each substrate offers unique characteristics:

Ceramic Transparent PCBs: These provide better heat conductivity than glass, making them ideal for heat-sensitive applications. However, their optical transmissivity is lower than glass, typically around 75% to 85%.

Glass Transparent PCBs: Composed of quartz and borosilicate glass, these substrates have the highest transmissivity, ranging from 99.5% to 99.99%. While glass excels in optical clarity, it has poorer thermal conductivity, which limits its use in heat-intensive environments.

Advantages of Transparent PCBs

Transparent PCBs offer several advantages over traditional PCBs:

Lightweight and Thin: These PCBs are lighter and thinner, making them suitable for applications where space and weight are critical factors.

Superior Optical Transmissivity: Their ability to allow light to pass through makes them ideal for use in light-emitting components and displays.

High Temperature Resistance: Glass can endure temperatures of up to approximately 1000°C, ensuring reliable performance even in harsh environments.

Troubleshooting Ease: The transparency of these PCBs allows engineers to easily inspect the components and trace lines, simplifying troubleshooting and maintenance.

Aesthetic Appeal: Transparent PCBs create a sleek, modern look, making them ideal for consumer electronics that require both functionality and style.

The Manufacturing Process for Transparent PCBs

The manufacturing process for transparent PCBs differs from traditional copper-clad boards. Instead of using copper layers, transparent PCBs are made using special polymer materials that are etched with conductive pathways. These materials are then laminated onto the board and coated with a protective layer. This method allows for the integration of components with varying optical properties. Furthermore, it is a more cost-effective and efficient process than traditional PCB manufacturing.

Types of Transparent PCBs

1. Transparent Flexible PCBs

Transparent flexible PCBs are produced using thin PET sheets that can be transparent or tinted in colors like light green, blue, or white. These flexible boards are particularly useful in applications where bending and folding are required, offering both flexibility and transparency.

Advantages:

High Reliability: Excellent electrical and mechanical performance ensures durability.

Space Saving: Flexible design allows for compact configurations.

Lightweight: Easy to handle and transport.

Cost-Efficient: Reduced material usage lowers production costs.

Versatility: Ideal for LED displays, wearable tech, automotive electronics, and more.

Better Signal Quality: Superior electrical characteristics enhance signal integrity.

Applications: Transparent flexible PCBs are used in a wide range of applications such as LED lighting displays, wearable technology, automotive electronics, smart contact lenses, and even electronic skins.

2. Transparent Ceramic Circuit Boards

Transparent ceramic circuit boards are made from materials such as alumina, magnesium oxide, or aluminum-magnesium spinel. These boards typically feature a transparent glass-based solder mask that allows the substrate to maintain its clarity, generally between 75% and 85%. While their conductive traces are not transparent, these boards offer excellent electrical insulation and thermal resistance.

Advantages:

Electrical Insulation: High electrical resistance makes them suitable for various applications.

Temperature Resistance: Capable of withstanding extreme temperatures.

Moisture and Chemical Resistance: Ideal for harsh environments.

Lightweight and Strong: Easy to handle and durable.

Cost-Effective: Less expensive than traditional circuit boards.

Applications: These transparent ceramic boards are used in optical sensors, high-power LEDs, infrared windows for missiles and airplanes, and other specialized industrial devices.

Hitech Circuits: Leading the Way in Transparent PCB Manufacturing

At Hitech Circuits, we specialize in the production of transparent flexible and ceramic circuit boards. Our cutting-edge manufacturing processes ensure that each PCB is not only visually impressive but also meets the rigorous demands of high-performance applications. Whether you're in need of flexible PCBs for wearable tech or ceramic PCBs for high-power applications, Hitech Circuits offers reliable, high-quality solutions that cater to a wide array of industries.

With expertise in both transparent flexible and ceramic PCBs, we provide customized PCB solutions that are lightweight, durable, and thermally efficient, making us your trusted partner of electronic manufacturing.

If you have such transparent PCB manufacturing needs, please don’t hesitate to contact us.(Email: Perlina Tang<[email protected]>) For more information, you can enter this webpage: https://hitechcircuits.com/

0 notes

Text

0 notes

Text

0 notes