#continuous stirred tank reactor

Text

Master CSTR technology with this guide. Learn key principles, applications, and best practices. Optimize your chemical processes, boost efficiency, and enhance product quality. Discover K-Jhil Scientific's advanced CSTR solutions.

For more information visit: https://kjhil.com/understanding-continuous-stirred-tank-reactors-key-principles-and-practices/

0 notes

Note

the first trio go to nibelheim a few years before crisis core and do the same reactor mission. what happens?

AU Storytime!

Sephiroth, Genesis, and Angeal make their way into the tiny little town of Nibelheim after reports of strange monsters invading the area. They are to make their way up to the Nibelheim Mako reactor to examine the cause of the issue.

Genesis jokes that of COURSE Shinra would reserve such an incredibly miniscule, mundane task for their best and brightest. Angeal feels slightly uneasy though. Sephiroth doubly so since his final check-in with Hojo had the scientist behaving a bit sneakier than usual. What did he know that they didn't? Very odd.

Entering Nibelheim, Sephiroth is instantly perturbed at how FAMILIAR his surroundings feel. Almost nostalgic. Genesis tells him he's being weird. As for Angeal...Angeal isn't feeling so great. He'd had a HUGE headache on the ride over. It only seems to be getting worse the farther they go.

By the time they reach the reactor, all three are actually beginning to feel rather off, bordering on very ill. Angeal's headache has made him feverish. Sephiroth seems quiet and exhausted. Genesis is the only one who feels good enough to fidget, even though he admittedly feels less than his best.

Trudging through the darkness, the trio discovers the cause of the malfunction, Angeal wearily stooping down to close the valve while Genesis complains about their state of affairs. They really SHOULDN'T be here. Maybe the air is toxic from all the mako. How can they work efficiently if all three of them are falling ill from the fumes?

That's when they see it.

When the agonized creature comes sliding out of the ruptured tank, all three soldiers freeze in place. They watch as it writhe and twists in agony, its unnatural body contorting in pain before going still.

Genesis begins to shout frantically, going from tank to tank. What the FUCK is this? What's going on? What ARE these things? Beside him, Angeal tries to regain a sense of calm over the situation, stumbling back when another wave of nausea hits him. He falls to his knees, nearly collapsing as his world sways dizzily before his eyes, wondering if he's about to die, if the shock has become too much for him to handle. Genesis shakes him furiously, telling him to get AHOLD of himself, damn it! They have to get OUT of here!

That's when Sephiroth begins to scream.

The silver soldier's frenzied eyes flick from the rusty plaque that looms in the center of the doorway, to Genesis' hunched form at the bottom of the stairway. A ripple. A pulse. Some unfurling ricochet of memory. He holds his head, mouth agape, the noise coming out of him half strangled, almost inhuman.

Genesis tries to reach for him, but Sephiroth stumbles away in a panic. He can hear the foggy decompression of another tank in the dim light, the eerie wail of another dying monster in the sea of pain and terror. He flees before it has the chance to greet him, vanishing into the dark as the hazy protests of his friends fade behind him.

Genesis doesn't understand what's happening. And with Angeal close to falling unconscious, he's left having to drag his friend back into town, hoping and praying that Sephiroth hasn't gone far.

For days, he tends to Angeal at the inn, too anxious and exhausted to figure out where Sephiroth has gone. Angeal's condition only seems to worsen, his sickness rendering him nearly comatose, wracked with terrible fever. Genesis tries in vain to uncover Sephiroth's whereabouts but is continuously left empty handed. No one knows where he went. Or what's even happening.

A week passes. Angeal finally begins to stir. But his mind is still addled and his movements are very lethargic. Genesis worriedly helps him to his feet, telling him that he's made up his mind--they're calling in all the Turks in the area for backup and they're getting the HELL out of here. FUCK this shit. Genesis doesn't know what's going on, but he knows bad news when he sees it. They're going to head back to HQ where Angeal can recover. And Genesis himself will help oversee the search for Sephiroth.

No search will be required. By the time the chopper arrives and Genesis moves to load Angeal inside, Sephiroth emerges from the Shinra manor. His blade is drawn, his expression blank, eyes hollow and unblinking. Angeal has just enough time to direct Genesis' attention to the small ball of flame forming in Sephiroth's open palm, using the last of his strength to throw them both to the side as the chopper behind them explodes.

Genesis' blood runs cold, panting and clutching at Angeal for dear life, the world around him erupting into flames, panicked screams filling the air.

But Sephiroth does not go for the villagers. He is not interested in them. His movements are direct, single-minded, Masamune glinting against the firelight as he slowly raises his weapon and lurches towards the battered soldiers.

Genesis frantically calls to him but there is nothing there. No light in his eyes. No recognition.

It's too late now.

Far too late.

Mother has spoken.

Mother has made Her desires known to him.

He is a monster.

He is an experiment.

He is chosen.

And there can only be one true God.

#asks#ff7#ffvii#final fantasy 7#crisis core#sephcanons#genesis rhapsodos#sephiroth#angeal hewley#jenova#AU

27 notes

·

View notes

Text

I Found My Victory When I Fell

For centuries, the ruins stayed quiet, empty. None of Cybertron’s lingering scavengers came to the small valley, the city it once housed. Nothing of any value to them remained, in the place once called Tyger Pax. Elsewhere, a few traces of life lingered on the planet, in sheltered, hidden places, eking out a meager existence with what little natural energon remained. And the war that brought Cybertron to such a standstill continued, amid the stars and across other, far flung worlds.

Until it ended.

“You robbed me of my voice - you will never, rob anyone, of anything again!”

A massive infusion, of a near-mythical substance, delivered straight to the enormous chamber suspended in Cybertron’s core. Severed connections were brought back together. Ancient equipment, restored to a pristine state. The faint remnants of a slumbering titan, nudged to awaken once more.

Reactors hummed back to life, and the first new energon in millennia began to flow down the dusty pipes - sluggishly, but then with greater speed, and growing brightness. Light spread from the gleaming liquid as it rushed to fill passages older than recorded history. One by one, the great channels overflowed, excess energon spilling into carefully placed tanks and aquifers, then into smaller conduits that spread their way throughout the entire planet, and eventually up towards the surface. Where the old paths were blocked or destroyed, the currents found cracks and holes to turn to instead, or else the pressure built, straining, until erupting into open air.

The few lifeforms that had remained for so long could only stare with astonishment, before leaping into the new pools and streams with delighted abandon.

And yet, their reactions remained a rarity, most of the planet still very much abandoned.

Aside from the dramatic resurgence of energon, the conflict’s conclusion meant little to Cybertron at large. Only a few tired souls returned in those early days, to begin rebuilding by hand, and they landed far from Tyger Pax’s ruins in the quiet valley. No great stirring of wind heralded the dawn of a new day; no passing ship or soaring Predacon graced the visible horizon. If anyone had yet survived in the shattered rubble, their one clue of something changing would be the sudden arrival of a new river: a great crack in the ground abruptly full of flowing energon, with meager crystal growths beginning to bloom along its banks.

Nothing else changed. Not even when a being of Darkness returned to the planet, eager to see it utterly destroyed. The massive, pitched battle took place elsewhere on Cybertron, and though it shook the ground and rattled the skies, none of its echoes could stretch far enough to disturb the stillness that continued to hold sway in Tyger Pax.

At least, not until an ending of a different sort.

“All I ask, my fellow Autobots, is that you keep fighting the noblest of fights.”

“You can count us to keep the peace.”

And a beginning, all its own.

A beginning, in the form of newsparks.

Large and small, massive and miniscule, blazing bits of life ranging through all the visible colors soared across Cybertron’s sky. And for each individual that leapt free from the Well, a dozen more instead entered the energon tunnels, to be carried along by flowing currents all throughout the planet. Brand new, fearless, and intensely curious, the delicate sparks surged towards anything that caught their attention.

Some headed for distant spires. Others delighted in the deep aquifers. More still sought out surface pools to splash across, or crystal-lined walls that reflected their pulsing light, or great wide open spaces that stretched out far beyond their limited sensory capabilities.

Each one, unique. Each, a new chance for life.

The sparks alone, by their nature, couldn’t last. Those that sought to explore too long gradually faded back into nothingness, or sped so fast they collided with too hard a surface and burst apart into mere motes, which also grew dark. But most- most of them, after a time, slowed down, to seek calmer, steadier places. They came down from the sky, or flitted up from the tunnels, or drifted into eddies at the edges of energon currents. Wherever they touched bare metal and mineral, the ground shifted, obliging. Each spark burrowed in, warming the area around them, and the nearest bits of material began to shift- change-

-transform.

At the newly formed river in the place once called Tyger Pax, several sparks settled along the energon banks, and crafted new homes for themselves. Some wished to return to moving quickly, and developed slender, lightweight frames. Others wanted defensibility, and built up extra layers of armor around their central components. There were those that desired flight, or to be able to swim, and each new lifeform that emerged from the hotspots immediately headed for their chosen purview.

Megatron watched them all.

#transformers#maccadams#tfp#post predacons rising#transformers prime#megatron#newsparks#terratron AU#took me AGES to be satisfied with this#and it's just the intro#got a longer post on my ko-fi#and the entire first chapter on patreon#eventually it'll go on AO3#but I want significant progress with Part Two before that happens#work in progress

11 notes

·

View notes

Text

Chemical Processing: A Comprehensive Guide

Chemical processing plays a crucial role in various industries, transforming raw materials into valuable products that drive modern society. This comprehensive guide delves into the fundamentals, techniques, equipment, safety measures, and modern advancements in chemical processing, providing a detailed overview for students, professionals, and enthusiasts alike.

Introduction

Chemical processing involves the conversion of raw materials into finished products through chemical reactions, physical changes, or a combination of both. It encompasses a wide range of industries, from pharmaceuticals and petrochemicals to food processing and materials manufacturing. The evolution of chemical processing over the past century has significantly impacted industrial development, contributing to innovations that shape our daily lives.

1. Fundamentals of Chemical Processing

What is Chemical Processing? Chemical processing refers to the application of chemical reactions and physical processes to convert raw materials into useful products. It can involve altering the chemical structure of substances, separating mixtures into their components, or enhancing the properties of materials.

Types of Chemical Processes

Physical Processes: These involve physical changes without altering the chemical composition, such as distillation, filtration, and crystallization.

Chemical Reactions: These involve changing the chemical structure of substances through processes like oxidation, reduction, polymerization, and synthesis.

Chemical Process Industries Chemical processing is integral to industries like oil and gas, pharmaceuticals, agrochemicals, food processing, and materials manufacturing. Each sector has unique requirements and challenges that shape its chemical processing methods.

Chemical Processing Principles

Mass and Energy Balance: A fundamental principle in chemical processing is the conservation of mass and energy, ensuring that the inputs and outputs of a process are accounted for.

Thermodynamics: Understanding energy changes and equilibrium conditions is crucial for designing efficient chemical processes.

Kinetics: Reaction rates and mechanisms guide the design of reactors and influence process efficiency.

2. Key Chemical Processing Techniques

Separation Processes

Distillation: A method used to separate components based on differences in boiling points. Fractional distillation is common in petrochemical industries for refining crude oil.

Filtration: Utilizes physical barriers to separate solids from liquids or gases. Types include gravity filtration, vacuum filtration, and ultrafiltration.

Extraction: Involves transferring a substance from one phase to another, such as liquid-liquid extraction for separating compounds based on solubility.

Chemical Reaction Processes

Catalysis: Catalysts speed up chemical reactions without being consumed. Homogeneous and heterogeneous catalysis are widely used in industrial chemical processes.

Reactors: Vessels designed to carry out chemical reactions efficiently. Batch reactors, continuous stirred-tank reactors (CSTR), and plug flow reactors (PFR) are common types.

Mixing and Blending Proper mixing ensures uniformity in product composition and enhances reaction rates. Industrial mixers range from simple agitators to complex static mixers designed for specific applications.

Heat Transfer Processes Heat transfer is crucial in controlling reaction rates and separation efficiency. Heat exchangers, such as shell-and-tube and plate heat exchangers, facilitate temperature control in chemical processes.

Mass Transfer Processes

Absorption: A gas is dissolved into a liquid, often used for gas purification.

Adsorption: Molecules adhere to a solid surface, useful in applications like water treatment and air purification.

3. Chemical Processing Equipment

Reactors Reactors are the heart of chemical processing. They come in various designs, such as batch reactors for small-scale operations and continuous reactors for large-scale production. Reactor design considers factors like temperature, pressure, mixing, and residence time.

Heat Exchangers Heat exchangers transfer heat between two fluids without mixing them. They are essential for maintaining optimal temperatures in reactors and separation processes.

Distillation Columns These columns separate mixtures based on boiling points through multiple stages of vaporization and condensation. Fractionating columns are commonly used in oil refineries to produce gasoline, diesel, and other products.

Filters and Centrifuges Filters separate solids from liquids or gases, while centrifuges use centrifugal force for rapid separation, essential in industries like pharmaceuticals and food processing.

Mixers and Blenders Mixers ensure uniform distribution of reactants, while blenders are used for homogenizing mixtures. Proper mixing enhances reaction efficiency and product consistency.

Pumps and Compressors Pumps transport liquids, and compressors move gases within processing plants. Their selection depends on fluid properties, flow rates, and system requirements.

4. Process Control and Automation

Importance of Process Control Process control ensures the safety, efficiency, and quality of chemical processing. It involves monitoring and adjusting process variables like temperature, pressure, flow, and concentration.

Automation in Chemical Processing Modern chemical plants use automation to enhance process control. Distributed Control Systems (DCS) and Programmable Logic Controllers (PLCs) automate complex processes, reducing human intervention and errors.

Process Control Strategies

PID Control: Proportional-Integral-Derivative (PID) control is a fundamental strategy for maintaining process variables at desired levels.

Advanced Control: Techniques like model predictive control (MPC) use mathematical models to predict future process behavior, enabling proactive adjustments.

Process Analytical Technology (PAT) PAT involves real-time monitoring and control of processes to ensure consistent product quality. Techniques like spectroscopy and chromatography provide instant feedback for process optimization.

5. Safety in Chemical Processing

Chemical Process Safety Safety is paramount in chemical processing due to the risks of chemical exposure, fires, explosions, and toxic releases. Proper safety measures protect workers, the environment, and the public.

Safety Management Systems

Process Safety Management (PSM): A systematic approach to identifying, evaluating, and controlling process hazards.

Hazard and Operability Study (HAZOP): A structured method for identifying potential hazards and operational issues in chemical processes.

Personal Protective Equipment (PPE) PPE, including gloves, goggles, and respirators, protects workers from chemical hazards. Proper training and adherence to safety protocols are essential.

Emergency Response and Risk Management Emergency response plans address potential incidents like chemical spills, fires, and explosions. Regular safety drills and risk assessments minimize the impact of accidents.

6. Environmental Considerations and Sustainability

Environmental Impact of Chemical Processing Chemical processing can generate waste, emissions, and pollutants. Managing these by-products is crucial to minimizing environmental impact and complying with regulations.

Sustainable Chemical Processing Green chemistry principles focus on reducing the use of hazardous substances, minimizing waste, and improving energy efficiency. Sustainable practices benefit the environment and enhance economic viability.

Waste Treatment and Recycling Waste treatment techniques include neutralization, incineration, and biological treatment. Recycling and reuse of by-products reduce the environmental footprint of chemical processes.

7. Modern Advancements in Chemical Processing

Digital Transformation and Industry 4.0 The integration of IoT, AI, and Big Data enables real-time monitoring, predictive maintenance, and process optimization. Smart sensors and advanced analytics enhance decision-making and efficiency.

Advanced Reactor Technologies Microreactors offer precise control over reaction conditions, enabling safer and more efficient processes. Modular processing units allow flexibility and scalability in chemical production.

Novel Separation Technologies Membrane separation and supercritical fluid extraction provide energy-efficient alternatives to traditional separation methods, improving purity and reducing environmental impact.

Bioprocessing and Biotechnology Bioprocessing uses biological organisms or enzymes to carry out chemical transformations. It has applications in pharmaceuticals, biofuels, and food production.

8. Chemical Processing and Quality Assurance

Quality Control in Chemical Manufacturing Analytical techniques like spectroscopy and chromatography ensure product quality and compliance with specifications. Continuous monitoring detects deviations and maintains consistency.

Regulatory Standards and Compliance Chemical processing must adhere to regulations set by bodies like the FDA, EPA, and OSHA. Compliance ensures product safety, environmental protection, and worker safety.

Quality Assurance Practices

Good Manufacturing Practice (GMP): A set of guidelines ensuring products are consistently produced and controlled to quality standards.

Standard Operating Procedures (SOPs): Detailed instructions for performing tasks to ensure consistency and compliance.

9. Challenges and Future Trends in Chemical Processing

Current Challenges

Process Safety: Preventing accidents and minimizing risks in complex chemical processes.

Environmental Compliance: Reducing emissions and waste to meet regulatory requirements.

Future Trends

Sustainable Processing: Development of green chemical processes that minimize environmental impact.

AI and Machine Learning: Advanced algorithms for process optimization, predictive maintenance, and quality control.

Opportunities for Innovation New catalysts, energy-efficient processes, and alternative feedstocks offer potential for enhancing chemical processing efficiency and sustainability.

10. Case Studies and Applications

Case Study 1: Pharmaceutical Industry Chemical processing in pharmaceuticals involves precise control of reactions and separations to produce high-purity drugs. Continuous manufacturing and PAT enhance product quality and efficiency.

Case Study 2: Petrochemical Industry Crude oil refining uses complex separation and reaction processes to produce fuels, lubricants, and chemicals. Innovations in catalytic cracking and distillation improve yields and reduce environmental impact.

Case Study 3: Food and Beverage Processing Chemical processing in the food industry includes extraction, purification, and preservation of food products. Ensuring safety and compliance with food regulations is paramount.

Conclusion

Chemical processing is a dynamic field that continues to evolve with advancements in technology, safety practices, and sustainability. Its impact on various industries underscores its importance in modern society. By embracing new technologies and sustainable practices, the chemical processing industry can address current challenges and pave the way for a safer and more sustainable future.

0 notes

Text

Center Enamel Provides Food Waste Anaerobic Process Solutions for Global Customers

Center Enamel Provides Food Waste Anaerobic Process Solutions for Global Customers

As the global focus shifts toward sustainability and waste reduction, the treatment and management of food waste have become critical challenges for industries and municipalities alike. Shijiazhuang Zhengzhong Technology Co., Ltd. (Center Enamel) is at the forefront of providing advanced solutions to tackle this issue, offering food waste anaerobic process sections for global customers. With over 30 years of experience in the environmental industry, Center Enamel’s innovative approach to food waste management is transforming organic waste into renewable energy through its cutting-edge anaerobic digestion technology.

Turning Food Waste Into Renewable Energy

Food waste is one of the largest contributors to global waste streams, and its improper disposal can lead to significant environmental and economic challenges. Landfills worldwide are filled with decomposing food, which releases harmful methane emissions—a potent greenhouse gas. To address this, anaerobic digestion has emerged as a sustainable solution that converts food waste into biogas, reducing both landfill waste and emissions.

Anaerobic digestion is a biological process where microorganisms break down organic matter, such as food waste, in the absence of oxygen. This process produces biogas, a valuable renewable energy source composed primarily of methane, which can be used to generate electricity, heat, or fuel. Additionally, the process generates nutrient-rich digestate, which can be repurposed as a natural fertilizer. Center Enamel’s food waste anaerobic process sections provide efficient and sustainable methods for converting food waste into energy while also offering environmental benefits.

Zhongzhong Technology, considering the distinctive characteristics of kitchen waste in various projects, develops practical and feasible process flows and utilizes independently researched and produced equipment to provide reliable technical and equipment support for kitchen waste treatment projects. Through the innovation and development of a comprehensive kitchen waste treatment system, not only can the efficiency of kitchen waste processing be enhanced, but resources can also be effectively utilized, maximizing their value and reducing environmental pollution, aligning with the principles of sustainable development.

CSTR Reactor

The CSTR (Continuous Stirred Tank Reactor) is a core technology in the anaerobic process segment of kitchen waste and biogas engineering. It is a type of anaerobic treatment technology conducted within a closed tank, where fermentation materials and microorganisms are fully mixed to generate biogas. The CSTR reactor is equipped with a mechanical stirring device and facilitates continuous or semi-continuous feeding under constant temperature conditions. This ensures that high-suspended solids, high-concentration organic wastewater, and anaerobic microorganisms are in a state of relatively complete mixed fermentation, effectively degrading organic compounds in the wastewater.

Advanced Anaerobic Process Sections by Center Enamel

Center Enamel’s food waste anaerobic process sections are designed to handle the complex needs of modern food waste treatment. With extensive expertise in glass-fused-to-steel (GFS) tanks, engineering design, and EPC project management, Center Enamel offers customized, full-service solutions to meet the specific requirements of its customers.

The company's anaerobic process solutions are powered by innovative mixed raw material digestion technology, allowing food waste to be processed without the need for classification or pre-treatment. This technology significantly enhances digestion efficiency, ensuring higher biogas yields and optimal energy production.

Key features of Center Enamel’s anaerobic process sections include:

Durable GFS tanks for food waste storage and digestion, known for their corrosion resistance and longevity.

High-efficiency biogas production through advanced digestion techniques and optimized microbial processes.

Maintenance-free large anaerobic digesters, designed for long-term operation and equipped with insulation technology using residual heat from biogas power generation.

Resource recovery, with biogas used for power generation and digestate repurposed as natural fertilizer, contributing to a circular economy.

Center Enamel’s process ensures that customers maximize the energy potential of food waste while minimizing environmental impact. This technology provides an eco-friendly alternative to traditional waste disposal methods, supporting global efforts to achieve sustainability goals.

Full-Service Solutions for Global Customers

Center Enamel stands out as a leader in the environmental industry by offering end-to-end services for its customers. From project design and R&D to manufacturing, installation, and commissioning, Center Enamel delivers turnkey anaerobic process sections that are tailored to the unique demands of each project.

The company's global expertise extends to more than 90 countries, with over 10,000 completed projects across diverse sectors, including municipal waste treatment, agriculture, industrial waste management, and biogas engineering. Center Enamel’s international presence and comprehensive service network ensure that customers worldwide receive top-tier solutions with timely and efficient project execution.

For each food waste anaerobic process project, Center Enamel provides:

Custom engineering and design to ensure optimal performance and seamless integration with existing infrastructure.

High-quality manufacturing of key components, including GFS tanks and advanced anaerobic digestion equipment.

Professional installation and commissioning services, ensuring projects are completed to the highest standards of quality and safety.

Ongoing technical support and maintenance services, ensuring long-term reliability and performance.

Driving Sustainability and Innovation

At the core of Center Enamel’s food waste anaerobic process sections is the company’s commitment to sustainability, innovation, and resource recovery. By transforming food waste into biogas, Center Enamel’s solutions provide a renewable energy source while reducing landfill usage and greenhouse gas emissions. This not only benefits the environment but also supports businesses and municipalities in meeting their sustainability targets.

Center Enamel’s leadership in the environmental industry is driven by its continuous investment in research and development. The company’s advanced R&D team focuses on improving the efficiency and scalability of anaerobic digestion technology, ensuring that customers receive the most innovative and cost-effective solutions available.

As a global leader in food waste anaerobic process solutions, Center Enamel is helping industries and municipalities turn food waste into a valuable resource—biogas. With its advanced anaerobic digestion technology, durable GFS tanks, and full-service EPC project management, Center Enamel delivers sustainable, efficient, and profitable solutions for managing food waste.

By focusing on quality, innovation, integrity, and win-win partnerships, Center Enamel is shaping the future of food waste management and contributing to global environmental protection efforts. With its innovative approach to anaerobic digestion and commitment to sustainability, Center Enamel is empowering global customers to embrace renewable energy and achieve their environmental goals.

Together, we are turning food waste into a resource for a cleaner, greener future.

0 notes

Text

In the production equipment of organic fertilizer and biological organic fertilizer, Compost Turning Machine is the first essential equipment. So, what is the important role of Compost Turning Machine in the production of organic fertilizer? What are the benefits of using Windrow Compost Turning Machine for the production and fermentation of organic fertilizer?

Tipping machine sorting

Stacking machines are divided into two types: the type of stacking machine that can walk on the ground and the trough type stacking machine that works on the fermentation tank.

Application and benefits of ground type pile tilter

The raw materials for the production of organic fertilizer are more extensive, and the more common ones are chicken manure, pig manure, cow manure, sheep manure and other livestock and poultry manure. Such raw materials need to undergo biological fermentation, and then let it reach the standard of harmless treatment, so as to further produce into commercial organic fertilizer.

The specific operation of the pile turning machine:

Determine the fermentation site, the ground fermentation site needs to be open, the site needs to be smooth, so that it can be convenient for large-scale fermentation production.

Under normal circumstances, the water content of raw materials is large, and a certain proportion of dry materials need to be added for water adjustment, such as straw powder, mushroom residue, etc. Take the sheep manure as an example, pile the sheep manure on the ground, sprinkle the fermentation agent for sheep manure compost on the surface of the raw material, according to the size of the water, add the appropriate amount of dry material/auxiliary materials, the general ratio of raw materials: auxiliary materials are 3:1, the width and height of the pile are determined according to the respective pile model number.

Taking the Wheel Type Windrow Compost Turning Machine as an example, the width and length are determined according to the length of the field. Then the pile turning machine itself walks on top of the material pile, evenly turning, stirring and crushing the raw materials, so that the sheep manure and dry materials and bacteria are fully stirred and evenly, the pile turning machine has the crushing function, even if the sheep manure or dry materials and accessories are large, under the action of the pile turning machine, the large materials can be crushed and decomposed to facilitate full fermentation.

After turning the pile, a new flat material pile is formed, and the new pile body is fluffy and loose, creating a favorable aerobic state for material fermentation, which is very conducive to the production and fermentation of organic fertilizer. In this state, the overturned reactor can rise to the fermentation high temperature within 24 hours, and the reactor can maintain the high temperature for 2-3 days, and then the reactor can be turned. This state has basically become fat in 7 days. At high temperatures, bacteria, grass seeds, and eggs in sheep dung will be killed, and large molecular proteins will be broken down into small molecular proteins that are conducive to crop absorption. In the process of biological fermentation, it can effectively prevent the production of harmful and odorous gases such as hydrogen sulfide, amine gas and indole in feces, and completely remove the odor in feces.

With the high temperature, turning the pile, the moisture in the raw material will gradually decrease, and the general fermentation cycle is 12-15 days. Can continue the next step of deep processing, screening, crushing, granulation, etc. As long as the early fermentation work is done well, the quality of organic fertilizer will be better, and the late deep processing will be easier to carry out, such as granulation, there will be no problems such as not easy to form balls.

In summary, it can be seen that the role played by the turnover machine in the production and application of organic fertilizer is very critical, and it is crucial to choose the right high-quality and inexpensive Organic Fertilizer Compost Turning Machine.

Stack turning machine compared with other products

Some customers want to save costs, with a forklift instead, in fact, the role of the forklift is far less than a special organic fertilizer turning equipment, and the cost will not be reduced.

Fermented organic fertilizer semi-finished products are brown, dark brown, no odor, there will be a little ammonia smell.

Such organic fertilizer applied to the field, do not worry about will produce soil-borne diseases, will not burn the roots, organic fertilizer in nitrogen, phosphorus and potassium and other nutrients are rich and comprehensive, more easily absorbed by crops, long-term application, will completely improve the soil dry crack, the situation of compaction, so that the soil water retention performance is enhanced, so that crop increase and income, quality is further improved!

#Organic Fertilizer Compost Turning Machine#Wheel Type Windrow Compost Turning Machine#Windrow Compost Turning Machine

0 notes

Text

Bioreactors Market - Forecast(2024 - 2030)

Bioreactors Market Overview

Bioreactors Market size is estimated to reach 2.1Bn, growing at a CAGR of 6.91% during the forecast period 2020-2025. Bioreactors are devices used to develop biological processes by closely monitoring controlled environment. It is a closed system used for bioprocessing, that supports the growth of cells or tissues and organisms (yeast, bacteria, or animal cells) under controlled conditions. Bioreactors are used in industrial processes to produce vaccines, antibodies and others. It converts raw materials into useful byproducts in the bioconversion of corn into ethanol. These are commonly cylindrical, ranging in size from liters to cubic meters, and are often made of stainless steel. Single-use material is widely used in the field of mammalian cell culture and is now rapidly replacing conventional bioreactors owing towards increase the quality of the end product by reducing automation complexity.

Report Coverage

The report: “Bioreactors Market – Forecast (2020-2025)”, by IndustryARC covers an in-depth analysis of the following segments of the Bioreactors Market.

By Type: Continuous Stirred Tank Bioreactors, Bubble Column Bioreactors, Airlift Bioreactors, Fluidized Bed Bioreactors, Packed Bed Bioreactors and Photo-Bioreactors.

By Control Type: Manual Control and Automated Control.

By Application: Lab-Scale Production, Pilot-Scale Production and Full-Scale Production.

By Material: Glass, Stainless Steel and Single-Use Plastic Polymer.

By End User: Research & Development, Biopharmaceutics and Others.

By Geography: North America, Europe, Asia-Pacific and Rest of the World.

Request Sample

Key Takeaways

The increase in the number of personalized medicines coupled with rising number of FDA approved orphan drugs has increased bio production, accelerating the bioreactors demand over the forecast years.

Rising chronic diseases and favorable government initiatives to improve healthcare infrastructure is likely to be the major driving factor for the market’s growth.

Asia-Pacific region is projected to record the fastest growth rate during the forecast period 2020-2025

By Type - Segment Analysis

In 2019, Continuous Stirred Tank Bioreactors segment dominated the Bioreactors Market in terms of revenue is estimated to grow at a CAGR of 5.91% owing towards rising production of monoclonal antibodies (MAb) therapeutics and other biological using animal cell cultures. The continuous stirred-tank reactors are the equipped with an impeller for homogenizing culture media and a sparger for delivering oxygen to the cells. It has increased surface area for oxygen transfer, so there is an increased yield of products. These are mostly used in processing of industries, in homogeneous liquid-phase flow reactions, where constant agitation is required and which further is used in pharmaceutical industries abetting towards the growth of the market.

Inquiry Before Buying

Geography - Segment Analysis

In 2019, the North America region dominated Bioreactors Market in terms of revenue with a market share of 41.8% owing towards rising public & private funding for R&D in this region. In U.S., National Institute of Health (NIH) collaborated with 11 biopharmaceutical companies to launch the “Partnership for Accelerating Cancer Therapies (PACT)”, public-private research collaboration. The aim of the collaboration is to develop immunotherapy for cancers with total investment of $215m aids to the market’s growth. Government has taken initiatives to promote technological advancements and initiatives to escalate the drug development process are key factors in the growth of the Bioreactors market. Asia Pacific is set to record the fastest growth rate during the forecast period 2020-2025.

Schedule a Call

Drivers – Bioreactors Market

Rapid Growth Of Single Use Bioreactors In Biopharmaceutical Industries

The increasing adoption of single use bioreactors by biopharmaceutical companies and various research institutions is driving the growth of the market. Single use bioreactors are more feasible than traditional bioreactors for small-scale research and lab-scale applications as they are more economical and flexible. The use of SUBs for the production of biopharmaceutical companies are increasing, as it tends to be more cost-effective for small-scale operations are driving the markets growth.

Challenges – Bioreactors Market

Major Regulatory Concerns

Regulatory concerns regarding usage of bioreactors and growing stringent government policy and regulation toward market growth is restraining growth of the market. Lack of sufficient storage facilities, vulnerability to leaching and transportation is hindering the market’s growth. Also, large-scale disposal of plastic derivatives is a growing environmental concern restraining the business growth over the forecast years.

Buy Now

Bioreactors Industry Outlook

Product Launches was the key strategy of the players in the Bioreactors Industry. Bioreactors top 10 companies include Danaher Corporation, Sartorius AG, Eppendorf AG, ZETA Holding GmbH, Applikon Biotechnology B.V., Solaris Biotechnology srl, Pierre Guerin Technologies, Thermo Fisher Scientific Inc., Finesse Solutions, Inc. and Merck KGaA.

Acquisitions/Product Launches

In May 2019, Sartorius AG, a leading international partner of the biopharmaceutical industry launched ambr® 15 cell culture automated microbioreactor system. It offers increased flexibility and expanded capability for clone selection, media and feed optimization and early process development work.

In March 2020, Thermo Fisher Scientific Inc. to acquire QIAGEN, a leading provider of life science and molecular diagnostic solutions. This acquisition provided opportunity to leverage the industry-leading capabilities and R&D expertise to accelerate innovation and address emerging healthcare needs.

In March 2020, Danaher Corporation acquired Biopharma business from General Electric Company's (NYSE: GE) Life Sciences division. This acquisition helped company by driving its growth across multiple categories and in reaching more consumers.

#Bioreactors Market#Bioreactors Market Share#Bioreactors Market Size#Bioreactors Market Forecast#Bioreactors Market Report#Bioreactors Market Growth

0 notes

Text

ES Ranganathan on Biogas: A Paradigm Shift in India's Energy Sector

The Delhi Milk Scheme Biogas Plant serves as a great example. It converts dairy waste into biogas, solving waste disposal issues and cutting energy costs for dairy operations," explained ES Ranganathan. "This plant demonstrates how biogas technology can effectively manage waste and provide energy in urban areas."

"In recent years, biogas plant technology has advanced significantly. New anaerobic digesters like continuous stirred-tank reactors (CSTRs) and plug-flow digesters have boosted biogas production efficiency. These digesters break down organic matter more effectively, yielding more biogas per unit of input."

"Moreover, using pre-treatment techniques such as mechanical sorting and enzymatic hydrolysis has sped up the decomposition process. This makes biogas production more efficient and cost-effective, showing promise in meeting India's energy needs while lessening environmental impact.

Read More

0 notes

Text

Essential Equipment and Technology for Efficient Biogas Plant Operations

Introduction

Biogas plants are integral to advancing sustainable energy solutions, transforming organic waste into renewable energy and reducing environmental impact. At Gruner Renewable, we understand the importance of integrating the right equipment and technology to ensure efficient and effective biogas plant operations. This article explores the crucial components and innovative technologies necessary for running a successful

Setup a Biogas Plant, highlighting our commitment to providing environmentally friendly energy solutions that meet our customers' sustainability goals.

Key Equipment for Biogas Plants

Feedstock Pre-treatment Units

Efficient biogas production starts with effective feedstock preparation. Pre-treatment units such as shredders, mixers, and hydrolysis tanks are essential for breaking down complex organic materials into simpler forms, enhancing the anaerobic digestion process. Gruner Renewable utilizes state-of-the-art pre-treatment technologies to ensure that the feedstock is optimally prepared for maximum biogas yield.

Anaerobic Digesters

The heart of any biogas plant is the anaerobic digester, where the biological process of methane production occurs. These digesters are designed to maintain the ideal conditions for microbial activity, including optimal temperature, pH, and anaerobic conditions. Gruner Renewable offers a range of digester designs, from continuously stirred tank reactors (CSTR) to plug flow digesters, tailored to different types of feedstock and operational scales.

Heating and Mixing Systems

Maintaining a consistent temperature and homogeneous mixture inside the digester is crucial for the efficiency of the biogas process. Gruner Renewable equips its plants with automated heating systems and mechanical or hydraulic mixers that ensure the digestate remains in the optimal state for gas production throughout the digestion cycle.

Advanced Technologies Enhancing Efficiency

Biogas Upgrading Systems

To transform raw biogas into high-quality bio-CNG suitable for commercial use, upgrading systems are necessary. These systems remove impurities such as hydrogen sulfide, moisture, and carbon dioxide. Gruner Renewable incorporates advanced technologies such as water scrubbing, pressure swing adsorption, or membrane separation to produce clean and compressed biogas that meets regulatory standards for various applications.

Gas Storage Solutions

Efficient gas storage is vital for managing the supply and demand of biogas energy. Gruner Renewable utilizes high-pressure cylinders and gas holders designed to safely store bio-CNG until needed, minimizing energy losses and maximizing the utility of produced biogas.

Control and Monitoring Systems

Modern Setup a Biogas Plant are equipped with sophisticated control and monitoring systems that automate many aspects of the operation, from feedstock input to energy output. These systems use sensors and computerized technology to constantly monitor plant performance and adjust processes in real-time, ensuring optimal efficiency. Gruner Renewable integrates IoT technology and smart analytics to provide operators with precise control over every aspect of the plant, enhancing both safety and productivity.

Environmental and Economic Benefits

Waste Treatment and Byproduct Management

In addition to energy production, efficient biogas plants manage waste and byproducts effectively. Systems for digestate separation and treatment allow for the recycling of solid and liquid residues as fertilizers, offering an additional revenue stream and closing the loop in waste management.

Conclusion

The equipment and technology implemented in a biogas plant play a crucial role in determining its efficiency and effectiveness. At Gruner Renewable, we are dedicated to leveraging cutting-edge technologies and high-quality equipment to ensure that our biogas plants are not only efficient but also contribute positively to environmental sustainability and economic viability. Our holistic approach to biogas production reflects our commitment to revolutionizing the future of energy, providing our customers with reliable, sustainable, and cost-effective solutions.

Call to Action

Are you ready to explore the benefits of efficient biogas production? Visit Gruner Renewable to discover how our advanced equipment and technology can help you achieve your sustainability goals. Join us in transforming organic waste into valuable energy and advancing towards a greener future.

SEO Strategy:

- Keyword Optimization: Biogas plant equipment and technology is strategically used throughout the article to enhance search engine visibility.

- Informative and Engaging Content: Provides detailed insights into the equipment and technology necessary for a biogas plant, ensuring reader interest and SEO effectiveness.

- Call to Action: Encourages readers to engage with Gruner Renewable’s solutions, driving website traffic and fostering engagement with the company's sustainable energy technologies.

for more details visit now - https://grunerrenewable.com/

0 notes

Text

The ABCs of ABS: Unraveling the Characteristics and Uses of Acrylonitrile Butadiene Styrene (2023-2034)

This blog will focus on Acrylonitrile Butadiene Styrene (ABS). ABS is comprised of three monomers: Acrylonitrile, Butadiene, and Styrene. In this article, we'll look at how the polymer's unique properties work together to give ABS its exceptional strength, toughness, as well as the manufacturing process. The global Acrylonitrile Butadiene Styrene (ABS) market is likely to flourish at a moderate CAGR of 5.90% by the year 2034.

Introduction

Styrene Acrylonitrile has existed since the 1940s. While they improved toughness over pure styrene, their limits necessitated the addition of rubber (butadiene) as a third monomer. ABS consists of three major monomers: acrylonitrile, butadiene, and styrene.

Acrylonitrile contributes to ABS's chemical resistance and heat stability.

Butadiene enhances the toughness and impact strength of ABS.

Styrene provides ABS with rigidity and facilitates its processability.

Manufacturing Process

ABS copolymers exhibit notable toughness, superior thermal resistance, and properties that surpass those of polystyrene plastics. ABS is produced through three distinct polymerization techniques: emulsion, suspension, and mass processes.

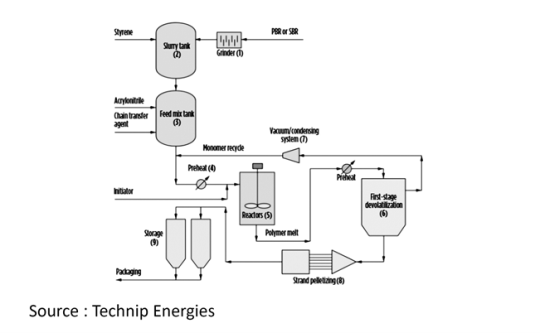

In the Mass Process, ABS is produced by the continuous copolymerization of styrene and acrylonitrile monomers with Polybutadiene Rubber (PBR) or Styrene-Butadiene Rubber (SBR) using a series of reactors, aided by organic peroxide. In a sequential process, chopped PBR or SBR is added to a slurry tank containing styrene monomer. The resultant mixture is then transferred to the ABS feed batch tank for complete rubber dissolution. This concentrated rubber solution is diluted with acrylonitrile, recycled monomer, and a chain transfer agent according to product requirements before preheating prior to entering the polymerization reactors.

Polymerization Section

The polymerization section employs a unique combination of plug flow and boiling stirred tank reactors arranged in series. Organic peroxide is introduced to initiate polymerization. This reactor setup allows precise control over various parameters such as rubber grafting, phase inversion, and molecular weight. Monomer conversion increases progressively throughout the reactor system, reaching final levels between 60% to 75%. Devolatilization is achieved through either extrusion or flash chamber methods.

Devolatization

In the extrusion devolatilization approach, the product from the last reactor undergoes stripping of unreacted monomers and byproducts in an extruder devolatilization system. Alternatively, the reactor product is subjected to volatile removal in a multistage flash devolatilization system operating under vacuum. Vapors are condensed, and the resulting mixture is recycled. The devolatilized polymer melts and then pelletizes and then dried.

Applications of Acrylonitrile Butadiene Styrene (ABS):

ABS (Acrylonitrile Butadiene Styrene) finds numerous applications across various industries. High impact grades are utilized in the production of travelling bags, helmets, furniture, sports goods, and automotive components, while medium impact grades are employed in radiator and air conditioner grills, heavy-duty domestic appliances, and control panels. Electroplating grades find their place in TV and radio knobs, bathroom fittings, refrigerator handles, and nameplates. High flow grades are ideal for housing domestic appliances, office equipment, and cabinets of electronic devices. High heat-resistant grades are utilized in automobile components and housing for electrical heaters and dryers. Transparent grades are sought after for areas requiring high transparency and impact strength, while impact modifier grades serve as modifiers for PVC compounding across various formulations. Glass-filled grades cater to applications demanding high flexural strength and stiffness, maintaining impact and tensile properties, while extrusion grades are used in refrigerator linings and luggage production.

Automotive

The automotive industry demands stringent standards from its materials. They must remain dimensionally stable and resist warping even when subjected to extreme stresses and significant temperature fluctuations.

Electronics & Electricals

ABS stands out in this regard due to its outstanding antistatic properties, providing a distinct advantage in meeting these requirements.

Appliances

ABS finds extensive applications in appliances, encompassing appliance control panels, housings for various devices such as shavers, vacuum cleaners, and food processors, as well as refrigerator liners, among others. Household and consumer goods represent the primary domains where ABS is widely utilized. Additionally, ABS is commonly employed in the manufacturing of keyboard keycaps.

Pipes & Fittings

ABS pipes and fittings are highly liked due to their ease of installation and rust resistance, making them a popular choice in a variety of applications.

Market Outlook:

ABS is an invariable thermoplastic polymer made up of three distinct monomers: acrylonitrile, butadiene, and styrene, which can change in proportion. They are also referred to as engineering plastics. Acrylonitrile provides chemical and thermal stability, styrene gives the plastic a glossy sheen, and butadiene provides strength and durability. These materials are widely used in the electronic appliance and automobile industries for vehicle and auto components production. The rapid growth of the medical business has increased demand for medical equipment, which is driving market growth. Furthermore, the growing construction and aerospace industries are predicted to significantly boost the ABS sector during the projection period. The global Acrylonitrile Butadiene Styrene (ABS) market is anticipated to reach approximately 15.7 million tonnes by 2034.

Acrylonitrile Butadiene Styrene (ABS) Major Manufacturers

Significant companies in the Global Acrylonitrile Butadiene Styrene (ABS) market are Formosa Chemicals and Fiber Corporation, LG Chem, LOTTE Chemical Corporation, Jilin Petrochemical Company, Toray Industries, CHIMEI Corporation, Tianjin Dagu Chemical Co., Ltd., and Others.

Challenges and Opportunities

While ABS possesses numerous advantageous properties, there are several restraining factors that could impact its market growth:

Environmental Concerns: ABS is derived from petrochemical sources, and its production and disposal can contribute to environmental pollution. Increasing environmental consciousness, combined with strict laws on plastic waste management and recycling, may present difficulties to the ABS market.

Competition from Alternative Materials: ABS faces competition from other engineering thermoplastics, such as polycarbonate (PC) and polypropylene (PP), which offer similar or enhanced properties in certain applications.

Conclusion:

Acrylonitrile Butadiene Styrene (ABS) is a versatile polymer with numerous useful applications. It is an essential in automotives and Electrical & Electronics industries owing to its unique set of properties. The surging demand for Acrylonitrile Butadiene Styrene (ABS) from Automotive, Home Appliances, Electrical & Electronics, and Building & Construction end-use industries, is anticipated to play a role in the demand-supply dynamics of the Acrylonitrile Butadiene Styrene (ABS) market.

0 notes

Text

ES Ranganathan: Biogas Plant Advancements in India Point Towards a Sustainable Energy Revolution

ES Ranganathan said, "Take the 'Delhi Milk Scheme Biogas Plant,' for example. They used waste from dairy farms to make biogas. This not only helped solve waste problems but also saved money on energy for the dairy." ES Ranganathan added, "It's a big success in using biogas in cities, showing how it can handle waste and provide energy.

Technological Improvements

In recent years, biogas plants have gotten much better thanks to new technology. Modern anaerobic digesters, like continuous stirred-tank reactors (CSTRs) and plug-flow digesters, make biogas more efficiently. They break down organic matter better, so we get more biogas from the same amount of stuff. Also, we've started using things like mechanical sorting and enzymatic hydrolysis to help break down stuff faster, making biogas production faster and cheaper.

We're also using smart systems to keep an eye on biogas plants. These systems help us adjust things like temperature and pH levels in real-time, so the tiny organisms making biogas work as efficiently as possible.

Read More

0 notes

Text

Fluid Dynamics in Chemistry: Flow Chemistry Market Size Gears Up for Rapid Expansion, Riding on Technological Trends in the Next Decade

The global flow chemistry market is poised for substantial growth in 2023, marking a transformative period in chemical synthesis and manufacturing. With a focus on emerging market trends, significant growth forecasts, and the forces propelling this chemistry evolution, the flow chemistry sector is reshaping the landscape of chemical processes.

Key Trends Propelling Flow Chemistry Innovation:

Continuous Processing Revolution: The flow chemistry market is witnessing a shift from batch processing to continuous flow synthesis. Continuous processing offers advantages such as improved safety, scalability, and efficiency in chemical production, driving the adoption of flow chemistry across diverse industries.

Green and Sustainable Chemistry: Sustainability is a key focus in flow chemistry, with an emphasis on reducing environmental impact and resource usage. Green solvents, renewable feedstocks, and energy-efficient processes are becoming integral to flow chemistry innovations, aligning with global efforts towards sustainable chemical manufacturing.

Integration of Automation and AI: Automation and artificial intelligence (AI) are transforming flow chemistry processes, enabling precise control and optimization of reactions. Automated systems, combined with AI algorithms, enhance the efficiency, reproducibility, and speed of chemical synthesis, providing a new dimension to flow chemistry capabilities.

Free Sample Copy of This Report at: https://www.econmarketresearch.com/request-sample/EMR0011/

Anticipated Market Growth:

The flow chemistry market is set for significant growth, driven by factors such as the demand for sustainable and efficient manufacturing processes, advancements in technology, and the increasing adoption of flow chemistry across pharmaceuticals, chemicals, and petrochemical industries. With a projected compound annual growth rate (CAGR) of [insert percentage], the market is positioned as a key player in the future of chemical synthesis.

Forces Steering and Challenges to Overcome:

Pharmaceutical and Fine Chemical Applications: The pharmaceutical and fine chemical industries are at the forefront of adopting flow chemistry. However, challenges such as process validation, regulatory compliance, and technology integration must be addressed to maximize the potential of flow chemistry in these sectors.

Market Education and Adoption: Industry stakeholders are actively working on educating end-users about the benefits of flow chemistry. Collaborative efforts are needed to facilitate the adoption of flow chemistry technologies, especially among smaller manufacturers and research institutions.

Ask For Discount: https://www.econmarketresearch.com/request-discount/EMR0011/

Segmentations

Application Outlook

Pharmaceuticals

Chemicals

Academia & Research

Petrochemicals

Others

Reactor Type Outlook

CSTR (Continuous stirred-tank reactor)

Plug Flow Reactor

Microreactor

Microwave Systems

Others

Regional Outlook

North America

Europe

Asia-Pacific

South America

The Middle East and Africa

Flowing Towards a Future of Innovation:

As the flow chemistry market continues to surge, industry leaders are actively collaborating to overcome challenges and unlock the full potential of continuous flow processes. The focus remains on developing scalable, sustainable, and accessible solutions that redefine the way chemical synthesis is approached.

About Us:

Econ Market Research is an all-inclusive resource for providing useful insight gleaned through industry research. Through our syndicated and consulting research services, we assist our clients in finding solutions to their research needs. Industries including semiconductor and electronics, aerospace and defence, automobiles and transportation, healthcare, manufacturing and construction, media and technology, chemicals, and materials are among our areas of expertise.

Contact Us:

Econ Market Research Private Limited.

E-mail: [email protected]

Phone: +1 812 506 4440

Website: - https://www.econmarketresearch.com

Connect with us at LinkedIn | Facebook | Twitter | YouTube

0 notes

Text

Chemical engineering lab instruments Manufacturer, Suppliers and Exporter in India

Chemical engineering lab instruments are essential tools for conducting experiments and research in the field of chemical engineering. These instruments are used to measure, analyze, and manipulate various chemical substances and processes. Some of the most common chemical engineering lab instruments include:

Balances: Balances are used to measure the mass of substances. They are available in a variety of sizes and capacities, from analytical balances that can measure to the nearest 0.1 milligram to industrial balances that can weigh up to several tons.

Spectrometers: Spectrometers are used to measure the absorption or emission of electromagnetic radiation by a substance. This information can be used to identify the substance and determine its composition. There are many different types of spectrometers, including UV-visible spectrometers, infrared spectrometers, and mass spectrometers.

Chromatographs: Chromatographs are used to separate and analyze mixtures of substances. They work by passing the mixture through a stationary phase, such as a column or a plate, and then detecting the separated components as they emerge from the phase. There are many different types of chromatographs, including gas chromatography (GC) and high-performance liquid chromatography (HPLC).

Reactors: Reactors are used to carry out chemical reactions. They are available in a variety of sizes and designs, depending on the specific reaction being carried out. Some common types of reactors include batch reactors, continuous stirred-tank reactors (CSTRs), and packed-bed reactors.

Separators: Separators are used to separate mixtures of substances. They work by using a variety of physical principles, such as gravity, filtration, and centrifugation. Some common types of separators include centrifuges, filters, and distillation columns.

Explore our comprehensive list of chemical engineering lab instruments used in school and college laboratories. These essential tools are vital for conducting experiments, research, and practical learning in the field of chemical engineering.

Glassware and Apparatus:

Burettes

Pipettes

Beakers

Erlenmeyer flasks

Test tubes

Graduated cylinders

Condensers

Separatory funnels

Analytical Instruments:

Spectrophotometer

Chromatography systems (GC, HPLC)

Mass spectrometer

pH meters

Conductivity meters

Flame photometer

Heating and Cooling Devices:

Hot plates

Heating mantles

Refrigerators

Freezers

Incubators

Autoclaves

Reactors and Stirrers:

Batch reactors

Continuous flow reactors

Magnetic stirrers

Overhead stirrers

Measurement Instruments:

Thermocouples

Pressure gauges

Flow meters

Rotameters

Viscometers

Safety Equipment:

Fume hoods

Safety goggles

Lab coats

Emergency showers

Fire extinguishers

Distillation and Filtration Equipment:

Distillation columns

Rotary evaporators

Filtration setups (Buchner funnels, filter flasks)

Mechanical Testing Instruments:

Tensile testers

Impact testers

Hardness testers

Computer-Aided Instruments:

Data acquisition systems

Control systems

Simulation software

Miscellaneous Instruments:

Centrifuges

Shakers

Ultrasonic cleaners

Desiccators

1 note

·

View note

Text

Flow Chemistry Solutions: Market Insights and Emerging Opportunities

The global flow chemistry market size is expected to reach USD 3.75 billion by 2030, according to a new report by Grand View Research, Inc. It is expected to expand at a CAGR of 11.2% from 2022 to 2030. Advantages over batch reactors and growing investments in the pharmaceutical and chemical industries are projected to boost the market growth. The COVID-19 pandemic has accelerated the need to move away from chemical commodities to specialty chemicals as per the requirement of customers. Moreover, the adoption of continuous manufacturing has increased due to the supply chain disruptions caused by the pandemic, which is expected to augment the demand for flow chemistry over the forecast period.

Flow Chemistry Market Report Highlights

The pharmaceuticals application segment is anticipated to expand at a lucrative CAGR of 12.0% from 2023 to 2030, in terms of revenue, due to the growing demand for technology that uses renewable energy sources and reduced manufacturing cost

By reactor type, microreactor is expected to witness significant growth over the forecast owing to the increasing demand for environmentally-friendly equipment and the ability to increase selectivity

Asia Pacific is estimated to expand at a significant CAGR of 12.4% over the forecast period on account of the rapidly growing petrochemical industries and a rise in academia and research in South Korea and Australia

In Europe, Germany accounted for the largest revenue share of over 30.0% in 2021 owing to the advanced infrastructure, growing pharmaceutical and chemical industries, and skilled workforce

For More Details or Sample Copy please visit link @: Flow Chemistry Market Report

Significant reductions in trash output and the eradication of non-renewable industrial methods are global environmental concerns. As a result, major economies are enacting policies to mitigate environmental damage. Several governments are implementing policies to meet the targets for reducing greenhouse gas emissions.

Continuous Stirred Tank (CST) reactor systems require little human involvement to operate, resulting in reduced labor costs associated with their deployment. Furthermore, both reactor systems have a high output rate, which leads to reduced production costs. The aforementioned factors are likely to boost the demand for CST reactor systems over the forecast period.

#ContinuousFlowChemistry#FlowChemistryIndustry#FlowChemistryMarket#GreenChemistry#ChemicalSynthesis#ChemicalEngineering#ChemicalProcessing#ChemicalReactionEngineering#PharmaceuticalManufacturing#FlowChemistrySystems#ChemicalProduction#FlowChemistryEquipment#FlowChemistryAnalysis#ScalableSynthesis#FlowChemistryApplications#ChemicalR&D#FlowChemistrySolutions

0 notes

Text

Shijiazhuang Zhengzhong Technology Co., Ltd Provides Anaerobic Processes Package For Global Customers

Shijiazhuang Zhengzhong Technology Co., Ltd Provides Anaerobic Processes Package For Global Customers

In the pursuit of sustainable energy solutions and efficient waste management, anaerobic processes have become essential components of modern environmental strategies. Shijiazhuang Zhengzhong Technology Co., Ltd, also known as Center Enamel, is leading the way in this field by offering comprehensive anaerobic processes packages tailored to meet the needs of global customers.

The Significance of Anaerobic Processes

Anaerobic processes, particularly anaerobic digestion, play a crucial role in converting organic waste into biogas and nutrient-rich digestate. This not only helps in reducing the environmental impact of waste but also generates renewable energy, supporting global efforts to decrease carbon emissions and promote sustainability.

The organic components and nutrients found in kitchen waste are valuable resources that, through efficient processing and recycling, can be converted into organic fertilizers, bioenergy, and other renewable resources. Resource recovery and recycling are pivotal elements in kitchen waste treatment, serving as indispensable components for driving sustainable urban development.

Zhongzhong Technology, considering the distinctive characteristics of kitchen waste in various projects, develops practical and feasible process flows and utilizes independently researched and produced equipment to provide reliable technical and equipment support for kitchen waste treatment projects. Through the innovation and development of a comprehensive kitchen waste treatment system, not only can the efficiency of kitchen waste processing be enhanced, but resources can also be effectively utilized, maximizing their value and reducing environmental pollution, aligning with the principles of sustainable development.

CSTR Reactor

The CSTR (Continuous Stirred Tank Reactor) is a core technology in the anaerobic process segment of kitchen waste and biogas engineering. It is a type of anaerobic treatment technology conducted within a closed tank, where fermentation materials and microorganisms are fully mixed to generate biogas. The CSTR reactor is equipped with a mechanical stirring device and facilitates continuous or semi-continuous feeding under constant temperature conditions. This ensures that high-suspended solids, high-concentration organic wastewater, and anaerobic microorganisms are in a state of relatively complete mixed fermentation, effectively degrading organic compounds in the wastewater.

Shijiazhuang Zhengzhong Technology Co., Ltd's Expertise

With over three decades of experience, Shijiazhuang Zhengzhong Technology Co., Ltd has established itself as a pioneer in the manufacture of high-quality storage tanks and anaerobic digesters. Our diverse product range includes Glass-Fused-to-Steel (GFS) tanks, stainless steel tanks, and fusion bonded epoxy tanks, all designed to meet the rigorous demands of anaerobic digestion systems.

Comprehensive Anaerobic Processes Package

Customized Solutions

Shijiazhuang Zhengzhong Technology Co., Ltd understands that every project is unique. Our team of experts works closely with clients to design and implement customized anaerobic processes packages that cater to specific project requirements. From initial consultation to final installation, we ensure that every aspect of the project is meticulously planned and executed.

Advanced Technology

Utilizing cutting-edge technology, our anaerobic processes packages incorporate state-of-the-art equipment and engineering solutions. Our tanks are manufactured using advanced enameling techniques, ensuring superior durability, corrosion resistance, and longevity. This guarantees optimal performance and reliability, even in the most challenging environments.

Turnkey Solutions

Our turnkey solutions cover the entire project lifecycle, from design and manufacturing to installation and maintenance. Shijiazhuang Zhengzhong Technology Co., Ltd's dedicated project management team oversees every phase, ensuring seamless integration and operation of the anaerobic digestion system. This comprehensive approach minimizes downtime and maximizes efficiency.

Global Reach

Our commitment to excellence has earned Shijiazhuang Zhengzhong Technology Co., Ltd a reputation as a trusted partner for anaerobic processes packages worldwide. With successful projects in over 90 countries, we have a proven track record of delivering high-quality solutions that meet international standards. Our global presence allows us to provide localized support and expertise, ensuring the success of each project.

Commitment to Sustainability

At Shijiazhuang Zhengzhong Technology Co., Ltd, sustainability is at the heart of our operations. Our anaerobic processes packages not only contribute to renewable energy production but also promote responsible waste management. By converting organic waste into biogas, we help our clients reduce their environmental impact and achieve their sustainability goals.

Shijiazhuang Zhengzhong Technology Co., Ltd's dedication to innovation, quality, and customer satisfaction positions us as a leader in providing anaerobic processes packages for global customers. Our comprehensive solutions, backed by decades of experience and a commitment to sustainability, ensure that we deliver unparalleled value and performance in every project. As the world moves towards a greener future, Shijiazhuang Zhengzhong Technology Co., Ltd is proud to be a trusted partner in the journey towards sustainable energy solutions.

Zhongzhong Technology is a comprehensive high-tech enterprise specializing in the research, development, manufacturing, and sales of enamel-assembled tanks, diversified environmental protection equipment, as well as undertaking environmental protection EPC projects and anaerobic process segments as its main business. Throughout the project implementation process, the company continually increases its research and development efforts, gathers scientific and technological resources, and establishes a service system covering everything from research and development to after-sales support, allowing for the rapid and high-quality customization of solutions for clients.

The criteria for evaluating projects not only need to meet technical and quality requirements but also need to shift towards overall standards focusing on sustainability, quality improvement, and energy conservation. Zhongzhong Technology actively responds to market and policy changes and, based on its rich experience and research and development strength, empowers the innovative research and development technology of enamel-assembled tanks to diverse environmental protection equipment manufacturing and environmental protection EPC projects. This is to meet the diverse needs and project requirements of various clients.

Today, Zhongzhong Technology's business covers areas such as kitchen waste, leachate, municipal sewage, biogas projects, livestock wastewater, industrial wastewater, drinking water, and firefighting water. In the future, the research and development achievements of Zhongzhong Technology will be further applied in more projects, striving to achieve a win-win situation for economic, environmental, and social benefits, and promoting the high-quality development of the environmental protection industry.

0 notes

Text

Metal Cleaning Chemicals Market was Led by Aqueous Cleaners

The metal cleaning chemicals market will reach USD 20,111.7 million by 2030, powering at 5.2% rate in the years to come.

The industry will observe a considerable growth rate in the years to come because of the increasing requirement for eco-friendly solutions.

Governments, all over the world are concentrating on sustainable development, because of which industries are going away from the prevalent solvent based cleaners, containing hazardous elements. This is resulting in the requirement for environment-friendly, sustainable chemicals, biodegradable, non-flammable and non-toxic.

Aqueous cleaners, with a revenue share of 75%, led the metal cleaning chemicals market in 2022. This will also be the leader with regards to value and volume in the years to come.

These solutions don’t catch fire, have low or no VOC concentration, and have low risks to health. These use, heat, stirring, and additives for cleaning the impurities off the surfaces of metals.

The steel category led the industry with regards to revenue. The production of steel is on the rise, all over the world as countries are expanding and its properties are really good.

To receive free sample pages of this report@ https://www.psmarketresearch.com/market-analysis/metal-cleaning-chemicals-market/report-sample

Also, aluminum will have the fastest growth, as a result of its increasing production globally. Generally, steel is stronger, but when it is about making strong, lightweight products, aluminum is the first-choice. This is due to the fact that it has possesses a greater strength-to-weight ratio. Moreover, its flexibility, elasticity, and rust resistance enhance its appeal.

The industry was led by manufacturing, with a share of revenue of 40%. This is attributable to the growing requirement for metallic products with incredible performance, for example, reactors, tanks, heavy machinery equipment, and tool.

APAC will grow the fastest in the years to come, at a rate of 6%. This is because of the increasing rate of and growing metal production in the emerging nations of the region. The growing manufacturing sector, particularly in these nations will continue to grow in the years to come.

#Metal Cleaning Chemicals Market#Demand for Metal Cleaning Chemicals Market#Trends in Metal Cleaning Chemicals Market

0 notes