#communication milling parts manufacturers

Explore tagged Tumblr posts

Photo

Top 10 Inventions of the Industrial Revolution

The British Industrial Revolution transformed life at work and at home for practically everyone. Noise, pollution, social upheaval, and repetitive jobs were the price to pay for labour-saving machines, cheap and comfortable transportation, more affordable consumer goods, better lighting and heating, and faster ways of communication.

Any shortlist of inventions is bound to be far from complete, but the following have been chosen not only for what they could do but also for how they permitted other inventions to become possible and how they transformed working life and everyday living for millions of people. The period under consideration is also important and here is taken as 1750 to 1860. With these criteria in mind, the top 10 inventions of the Industrial Revolution were:

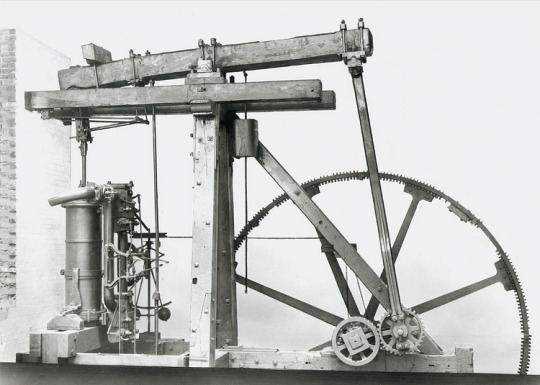

The Watt Steam Engine (1778)

The Power Loom (1785)

The Cotton Gin (1794)

Gas Street Lighting (1807)

The Electromagnet (1825)

The First Photograph (c. 1826)

Stephenson's Rocket (1829)

The Electrical Telegraph (1837)

The Steam Hammer (1839)

Mass Steel Production (1856)

The Watt Steam Engine

The steam engine, which harnessed power from the expansion of heated water, is often cited as the single most important invention of the Industrial Revolution, principally because so many other important subsequent inventions used it as their power source. The steam engine was born from the necessity to pump out flooded mine shafts and enable deeper mining. The first steam pump was invented by Thomas Savery (c. 1650-1715) in 1698. In 1712, Thomas Newcomen (1664-1729) perfected his more powerful steam pump to drain coal mines of water in Dudley in the Midlands.

To make the steam engine more useful for other purposes, it had to be made more efficient both in terms of fuel consumption and power. The Scottish instrument maker James Watt (1736-1819) and Matthew Boulton (1728-1809) kept tinkering with the workings of the steam engine until, in 1778, they had perfected a separate condenser to vastly increase the engine's efficiency. Power was also increased by the steam powering the piston down not just up (hence its name, a double-acting engine), increasing the 'horsepower', a term coined by Watt. The engine also had its power converted to a more versatile rotary motion using a flywheel. Using just one-quarter of the fuel of Newcomen's engine, Watt's engine was cheap enough to use almost anywhere. Steam engines kept on evolving, notably with the expansion steam engine, and they benefitted from ever-better tool machinery that could make stronger and better-fitting parts.

By 1800, Britain boasted over 2,500 steam engines, most of them used in mines, cotton mills, and manufacturing factories. 500 of these engines were made by the Watt and Boulton factory in Birmingham. Every walk of life was affected. Steam now powered fountains, threshing machines, sewage pumps, and printing presses. Essentially, any work that required pushing, pulling, lifting, or pressing could be made much more efficient using steam-powered machines. Steam engines were harnessed for trains and steamships, and, aptly, all these uses caused a boom in the coal mining industry, which had been the origin of the machine in the first place.

Continue reading...

33 notes

·

View notes

Text

Atlantic Station: before, after, & thoughts for the future

This is Atlantic Station (note: I've got this upside-down, with north on the bottom). It was built on a 138-acre brownfield, the former site of an Atlantic Steel facility that required major remediation.

The work involved the removal of 180,000 cubic yards of slag-contaminated soil. Steel slag is a by-product of steel manufacturing. In the absence of regulatory controls, it had been disposed of directly onto the Atlantic Steel property.

Also required was the installation of a groundwater extraction system to prevent contaminated water from running into adjacent properties or the municipal sewer system.

In 2002, this remediation work cost $25 million. The City of Atlanta created a Tax Allocation District in 1999 as part of a financing plan for the Atlantic Station project.

[Info source: Atlantic Station, Atlanta, Georgia: A Sustainable Brownfield Revitalization Best Practice, By Christopher De Sousa and Lily-Ann D’Souza. Image source: Google Earth]

There's no doubt that this was a majorly impressive undertaking.

But can we do even better for urban sustainability on this property? I see room for a BRT line through connecting to Howell Mill Rd and to MARTA rail, for instance. And how about a protected bike path?

Can we also improve the way this fits into the city's system of neighborhoods so that it feels like a natural extension? I'd like to see some truly public-owned space here with a community center, a library, and a city park.

11 notes

·

View notes

Text

HANÁCKÝ KROJ TRADITIONAL FOLK DRESS FROM CZECHOSLOVAKIA

Powerhouse Collection

Outfit, hanacky kroj (traditional folk dress), womens, cotton / embroidery / lace / silk, embroidered in part and worn by Olga Kupkova (nee Skacelova), designed and made in the Hana region of Moravia, former Czechoslovakia (Protectorate of Bohemia and Moravia), 1940

This women's hanacky kroj dating from 1940 is a well provenanced example of traditional dress from the Hana region of Moravia in Czechoslavakia. Worn and partly made by Olga Kupkova the dress includes twelve components, intricately constructed and embroidered by specialist seamstresses and needleworkers, reflecting the time, expense and variety of skills that go into creating hanacky kroj. The style and design reflect the importance placed on communicating and celebrating regional identity through dress. In addition its elaborate composition and embellishment are meant to remind the viewer that it originates from Hana, one of the most prosperous areas of Moravia, which was renowned for producing the richest and most complicated designs. The related Hanacky Kroj book explains the social significance of the hanacky kroj, the very specific conventions for manufacture and wear. This is reinforced through the inclusion of patterns for components of the outfit and embroidery, step by step instructions on how to make it and information on the fabric, threads, starches and the costs involved as well as the names and addresses of specialist makers including shoe makers, embroiderers, lace makers and seamstresses who can assist with making components of the outfit. The social and cultural importance of kroj is explained in the introduction by Dr Jan Kuhndel 'Kroj is an expensive, precious and sacred symbol of national and tribal tradition. It is a child of the Baroque era and its style, in which Czech soul found its festive days, cultural base and unqiue folk art. Every kroj is a mirror and a expression of its era, its region, and its people.' Furthermore, as records of Czechoslovakian immigration in New South Wales, the garments form part of an important historical narrative concerning the experience of refugee escape and settlement in Australia. The significance of the costume collection is further increased by its well provenanced history associated with the Skacelova/Kupkova/Slezacek family and the accompanying photographs of Olga Kupkova wearing the hanacky kroj and Olga Slezacek wearing the childs traditional dress. Glynis Jones, Curator and Sarah Crowe, intern, May 2011. References Cizkova, M. and V, Prostejove. 1940. Hanacky Kroj, Czechoslovakia. Hargreaves, B. n.d. Migrants of the Nepean Valley. NSW. Snowden, J. 1979. The Folk Dress of Europe. Mills and Boon: London, Sydney, Toronto.

26 notes

·

View notes

Text

Well, I have just been smacked in the face by the reality of time marching on...

I mentioned that I originally wrote my Donatello road trip story, Displaced close to thirty years ago, and only just recently re-edited it for AO3, right? Well, I got curious about my dad's old workplace, which was mentioned and shown in the story...

I could just make out a building nearby, and my eyes followed the brick structure's lines upward to where it gave way to a smokestack so tall that it vanished into the night sky. I got dizzy looking up, so I lowered my eyes back to the building itself, and it slowly registered in my mind that I was probably at an industrial park, and that what I was looking at was most likely the power house.

I went on to describe the inside of the place, as well as the character of Jim, who was based on my dad.

But anyway, I just found out that they have turned the old industrial park into luxury apartments.

Seriously...

Nestled between the Chicopee River and Dwight Canal, the Apartments at Ames Privilege combine the historic charm of a mill building with modern convenience for your contemporary lifestyle. Built in 1847 and listed on the National Register of Historic Places, the Ames Manufacturing Company building once produced Civil War swords and cannons. Today, after undergoing restorations and renovations, the building has been transformed into a city-center living community of 149 apartment homes that feature oversized windows, vaulted ceilings, exposed brick walls and massive wood beams. This vibrant community is centrally located just steps from Downtown Chicopee shopping & restaurants, and is minutes from Route 391, conveniently connecting you to surrounding towns and interstate highways. Experience contemporary mill living at the Apartments at Ames Privilege.

The smokestack has been repaired as a "feature", but the powerhouse is gone...

I mean, here it is back in the day...

And here it is now...

And I understand the need to update things and keep old buildings from crumbling to dust or causing harm to people if they go into a damaged structure, but seeing a part of my childhood changed in such a way just makes me sad.

This is worse than when they turned the old Rivoli Theater into a bar and my favorite (and first) comic book store into a smoke shop...

4 notes

·

View notes

Text

i'm a bit ambivalent toward FAUDA the palestinian anarchist group; i'm glad they exist tho

that said i was reading this interviews (X) with 3 of its members (with interestingly 3 really distinct vibes) and there is a moment when one of them say the following about the two state solution:

Imagine someone comes to your home and forcefully robs your home. After he sees that you are resisting and won’t leave your home, he suggests that you share your home between you both. Does this make sense to you?

so a basic metaphore with kind of a classic nationalist framing but in a my own view taking the metaphore somewhat on its own my answers to "Does this make sense to you?" is yes sometimes that's how it must be

to go back to the state framing i would describe my own preference for a one state solution as being budgetary, as a way to somewhat enmeshing the rights and guarantees in a shared constituency

in the anarchist framing the logic of ignoring the tittle deeds and having to share fairly is just taken to it's more radical end; especialy seeing how the various home robbers have already made the better part of the home their homes in fact and othen in "rights" and sometimes for a long way back and that to avoid destitution you might need to take on the role of the robber

but even when there is no rober, either fresh one or heirs to ancestral one, where you might need to take the rolle of the robber insisting on sharing, hoppefully right off the bat and not only after facing resistance; for exemple i'm reminded in this passage in Le Guin's the dispossessed:

The train Shevek was on went along in short rushes and long waits, since all provision trains took precedence over it. Then it stopped altogether for twenty hours. An overworked or underschooled dispatcher had made an error, and there had been a wreck up the line. The little town where the train stopped had no extra food in its commons or warehouses. It was not a farm community, but a mill town, manufacturing concrete and foamstone, built on the fortunate congruence of lime deposits and a navigable river. There were truck gardens, but it was a town dependent upon transport for food. If the four hundred and fifty people on the train ate, the one hundred and sixty local people would not. Ideally, they would all share, all half-eat or half-starve together. If there had been fifty, or even a hundred, people on the train, the community probably would have spared them at least a baking of bread. But four hundred and fifty? If they gave that many anything, they would be wiped out for days. And would the next provisions train come, after those days? And how much grain would be on it? They gave nothing. The travelers, having had nothing in the way of breakfast that day, thus fasted for sixty hours. They did not get a meal until the line had been cleared and their train had run on a hundred and fifty miles to a station with a refectory stocked for passengers. It was Shevek's first experience of hunger. He had fasted sometimes when he was working because he did not want to be bothered with eating, but two full meals a day had always been available: constant as sunrise and sunset. He had never even thought what it might be like to have to go without them. Nobody in his society, nobody in the world, had to go without them. While he got hungrier, while the train sat hour after hour on the siding between a scarred and dusty quarry and a shut-down mill, he had grim thoughts about the reality of hunger, and about the possible inadequacy of his society to come through a famine without losing the solidarity that was its strength. It was easy to share when there was enough, even barely enough, to go round. But when there was not enough? Then force entered in; might making right; power, and its tool, violence, and its most devoted ally, the averted eye. The passengers' resentment of the townsfolk got bitter, but it was less ominous than the behavior of the townsfolk — the way they hid behind “their” walls with “their” property, and ignored the train, never looked at it. Shevek was not the only gloomy passenger; a long conversation meandered up and down beside the stopped cars, people dropping in and out of it, arguing and agreeing, all on the same general theme that his thoughts followed. A raid on the truck gardens was seriously proposed, and bitterly debated, and might have been carried out, if the train had not hooted at last for departure.

4 notes

·

View notes

Text

1. Electrician (milling FMCG) Locations Cape Town, 7530, ZA | Job Identification: 4922 | Apply Before 02/17/2025, 11:03 AM | Job Category Supply Chain | Job Introduction:Tiger Brands, a leader in South Africa’s FMCG (Fast Moving Consumer Goods) industry, is looking for a skilled Electrician to join their Milling Division. This opportunity is perfect for someone passionate about maintaining machinery and ensuring production efficiency. If you are a qualified electrician with experience in a manufacturing environment, this role could be your ideal career move. About Tiger Brands:Tiger Brands is one of South Africa’s largest food and beverage companies, known for its iconic brands and high-quality products. The company is committed to providing consumers with nutritious and delicious food while maintaining its reputation as an employer of choice. Joining Tiger Brands means being part of a forward-thinking organization that values innovation, sustainability, and employee growth. Role Responsibility: As an Electrician in the Milling FMCG division, you will play a crucial role in ensuring the smooth operation of machinery and plant equipment. Your responsibilities will focus on optimizing production through effective maintenance and technical support. Key Responsibilities Include: - Machinery Maintenance and Safety: - Ensure machinery in the mill and packaging lines is well-maintained and safe to operate. - Conduct regular inspections and routine maintenance to avoid equipment failures. - Breakdown Reduction and Machine Availability: - Reduce breakdowns by implementing preventative maintenance strategies. - Work to increase the availability and performance of critical machines. - Technical Support and Training: - Provide hands-on technical support to resolve electrical issues. - Offer training and guidance to machine operators to ensure proper equipment use. - Preventative Maintenance Program Implementation: - Follow a structured preventative maintenance program to identify and resolve potential issues. - Ensure that all maintenance activities are documented and meet company standards. - Spare Parts Management: - Maintain a critical spares list to minimize downtime. - Update equipment registers and ensure safety gear is functional and compliant. - Documentation and Reporting: - Complete job cards, logbooks, and inspection reports accurately and on time. - Create and update electrical drawings and schedules for plant operations. - Performance Maximization: - Maximize the performance and efficiency of all machinery and electrical systems. - Work closely with the operations team to address challenges and identify improvement areas. Effective Management of Staff:While this role primarily focuses on technical responsibilities, you will also collaborate with other team members, including machine operators and maintenance staff. Your ability to communicate effectively and foster a team-oriented environment is critical for success. Effective Management of Operations:Your role directly impacts operational efficiency. By ensuring the smooth functioning of milling and packaging equipment, you will contribute to achieving production goals and maintaining quality standards. Effective Management of Business Development Function:As part of the Tiger Brands team, you may also be involved in initiatives aimed at improving processes, reducing costs, and identifying opportunities for innovation. Your technical expertise will be valuable in driving these projects forward. The Ideal Candidate: Tiger Brands seeks a highly skilled and proactive electrician who meets the following qualifications and attributes: Skills and Attributes: - Essential Qualifications: - Trade-tested, qualified electrician certification. - At least 2 years of electrical experience in a manufacturing environment. - Technical Expertise: - Hands-on experience with milling and packaging machinery is advantageous. - Familiarity with computerized maintenance management systems. - Computer Literacy: - Proficiency in using software to manage maintenance tasks and update technical documentation. - Problem-Solving Skills: - Strong ability to identify and resolve electrical issues quickly. - Analytical mindset to improve machinery performance and efficiency. - Teamwork and Communication: - Excellent interpersonal skills to work collaboratively with machine operators and other stakeholders. - Ability to provide clear instructions and support to team members. - Attention to Detail: - High level of accuracy in documentation and compliance with safety standards. - Thorough understanding of electrical schematics and equipment manuals. Why Join Tiger Brands? Tiger Brands offers a dynamic work environment where employees are empowered to grow and contribute to the company’s success. As an Electrician in the Milling FMCG division, you will benefit from: - Competitive remuneration and benefits. - Opportunities for professional development and career progression. - A supportive and inclusive workplace culture. - Exposure to cutting-edge technology and industry best practices. How to Apply: Interested candidates who meet the qualifications are encouraged to apply for this exciting opportunity at Tiger Brands. Ensure your application includes a comprehensive CV detailing your relevant experience and qualifications. Becoming an Electrician at Tiger Brands is not just a job; it’s an opportunity to join one of South Africa’s most respected FMCG companies and make a meaningful impact. If you are passionate about maintaining and improving machinery in a fast-paced environment, this role is your chance to shine. Don’t miss this opportunity to elevate your career with Tiger Brands. Apply now and take the first step towards an exciting and rewarding future in the Milling FMCG sector! 2. Engineering Manager: Breakfast Locations: Cape Town, 7405, ZA | Job Identification: 5282 | Job Category: Supply Chain | Apply Before02/17/2025, 11:05 AM | Job Introduction:Tiger Brands, South Africa’s premier FMCG (Fast-Moving Consumer Goods) company, is looking for a highly skilled and experienced Engineering Manager for its Breakfast division. This role is a pivotal leadership position with a direct impact on manufacturing performance, safety compliance, and continuous improvement initiatives. If you have a proven track record in engineering management, maintenance, and driving operational excellence, this role offers a fantastic opportunity to contribute to one of South Africa's most recognized brands. About Tiger Brands:Tiger Brands is a household name in South Africa, offering a diverse portfolio of trusted food and beverage products. The company prides itself on quality, sustainability, and innovation. As a Tiger Brands employee, you’ll join a team dedicated to making a difference in people’s lives by delivering nutritious and affordable food. Role Responsibility: As the Engineering Manager, you will oversee safety, engineering, and maintenance strategies to ensure compliance with regulations, improve equipment reliability, and maintain all operational and support elements of the factory. Your leadership will directly influence key performance indicators (KPIs) such as safety, sustainability, capacity utilization, overall equipment efficiency (OEE), and cost management. Key Responsibilities Include: - Safety and Compliance: - Serve as the GMR 2(1) Engineer, ensuring the factory complies with the OSH Act and other applicable regulations. - Lead initiatives to align factory and equipment with safety standards. - Maintenance Leadership: - Implement the Maintenance Pillar within the Manufacturing Excellence Customs and Practices (MECP). - Oversee the factory’s 5-year asset risk register to ensure long-term reliability. - Financial Management: - Develop and manage the maintenance budget to optimize costs. - Ensure financial compliance with purchasing policies. - Manage the Capex Budget, including project motivations and timely execution. - Team Leadership: - Lead the Engineering, Maintenance, and Utilities teams, focusing on coal, steam, compressed air, and water systems. - Collaborate with Production teams to address OEE losses through effective problem-solving techniques like Why-Why analysis and MDT (Machine Downtime Tracking). - Continuous Improvement: - Drive improvements in Operational Technology (OT) by automating plant and process systems. - Ensure the integrity of manufacturing systems and instrumentation. - Talent Development: - Build a career pipeline for critical maintenance positions. - Coordinate and implement training programs to upskill the engineering team. - Foster cross-skilling opportunities within the team to enhance flexibility and performance. - Performance Monitoring: - Develop engineering team goals and ensure alignment with overall business objectives. - Conduct regular reviews of team performance to identify areas for improvement. - Project Management: - Oversee the design, installation, commissioning, operation, and disposal phases of the asset lifecycle. - Ensure adherence to equipment purchasing policies to optimize capital investments. The Ideal Candidate: Tiger Brands seeks a dynamic leader with strong engineering expertise, strategic thinking, and a passion for driving operational excellence. Skills and Attributes: - Core Knowledge: - Tertiary qualification in Engineering (BTech or BSc in Electrical/Mechanical). - Government Certificate of Competence (GCC). - Proficiency in Maintenance, Utilities, and Project Management. - Experience: - 5 to 8 years of experience in engineering, maintenance, or food technology. - Demonstrated technical proficiency across the asset lifecycle, from design to end-of-life management. - FMCG industry experience is preferred. - Leadership and Teamwork: - Proven ability to lead diverse teams and drive alignment across departments. - Strong communication skills to inspire and coach team members. - Problem-Solving and Innovation: - Analytical mindset to address challenges and implement continuous improvement strategies. - Expertise in automation and process system enhancements. Why Join Tiger Brands? Tiger Brands offers more than just a job; it’s an opportunity to build a rewarding career with one of South Africa’s most trusted companies. As an Engineering Manager, you will enjoy: - A competitive salary and comprehensive benefits package. - Opportunities for professional growth and career advancement. - A supportive and inclusive work environment that values innovation and teamwork. - The chance to work with cutting-edge technology and industry-leading practices. Qualified candidates who meet the requirements are encouraged to apply for this role. Submit your application, including a detailed CV outlining your relevant experience and qualifications, through Tiger Brands' official careers portal. The Engineering Manager role at Tiger Brands is a unique opportunity to lead and make a significant impact within the FMCG industry. If you’re a results-oriented professional with a passion for engineering excellence, this position is your chance to shine. 3. Payroll Administrator ( Fixed Term Contractor) Locations Johannesburg, 1600, ZA | Job Identification5255 | Job Category Finance | Posting Date02/07/2025, 01:47 PM | About the Role:Tiger Brands is seeking a meticulous and detail-oriented Payroll Administrator to join our team on a fixed-term contract. This role is integral in ensuring accurate and timely payroll data processing while adhering to company policies, union agreements, and legislative requirements. As a Payroll Administrator, you’ll play a key role in ensuring employees are paid correctly, on time, and in line with compliance standards. About Tiger Brands:As one of South Africa’s leading FMCG companies, Tiger Brands is committed to delivering quality products and services. Our people are at the heart of what we do, and we strive to provide an inclusive work environment where employees can thrive and grow. Key Responsibilities As a Payroll Administrator, your primary duties will include: - Payroll Accuracy and Compliance: - Process payroll data with precision, ensuring alignment with company policies and legal requirements. - Verify and reconcile payroll inputs against supporting documentation. - Maintain governance frameworks and compliance standards. - Payment Processing: - Ensure all employees receive accurate and timely payments. - Process salary increases, bonuses, incentives, and leave payouts. - Calculate and process termination payments accurately. - Reporting and Auditing: - Prepare payroll reports for various stakeholders. - Support internal reporting requirements and audit processes. - Assist in the standardization and improvement of payroll systems and operations. - Records Management: - Maintain and update staff records promptly, including archiving and filing. - Ensure records comply with company policies and audit requirements. - Team Collaboration: - Work closely with the broader team to facilitate the capture and submission of payroll documentation. - Provide excellent customer service and clear communication to all stakeholders. Required Qualifications and Experience Education and Skills: - Minimum Education: Matric certificate. - Proficiency in Excel and strong financial aptitude. - Exceptional attention to detail and accuracy. - Strong teamwork and communication skills. Experience: - A minimum of 3 years of payroll and benefits experience. - Solid understanding of South African payroll legislation and reporting. - Experience with electronic document management systems. - Familiarity with Oracle/SAP Payroll and Microsoft Office. Additional Certifications: - Payroll certification is advantageous. Key Competencies: - Knowledge of the Basic Conditions of Employment Act (BCEA). - Problem-solving and ability to work under tight deadlines. - Adaptability to new systems and processes. Why Join Tiger Brands? Tiger Brands offers a collaborative work environment where your contributions directly impact our success. As part of our team, you’ll benefit from: - A competitive compensation package. - Opportunities to work with industry-leading payroll systems. - Exposure to a dynamic FMCG environment. If you meet the above requirements and are ready to make a meaningful contribution, we encourage you to apply! Submit your application via the Tiger Brands Careers Portal, including a detailed CV highlighting your experience and qualifications. This is an excellent opportunity to join Tiger Brands on a fixed-term basis and gain valuable experience within one of South Africa’s leading FMCG companies. If you’re passionate about payroll administration, compliance, and delivering exceptional service, this role is perfect for you. 4. Process Optimisation Engineer: Davita Locations Crown Mines, 2092, ZA | Job Identification5461 | Job CategorySupply Chain | Apply Before02/14/2025, 01:36 PM | Job Introduction Are you a passionate engineer or food technologist looking to make a significant impact in the manufacturing industry? Davita, a leading player in the Fast-Moving Consumer Goods (FMCG) sector, is seeking a Process Optimisation Engineer to join their team in South Africa. This role is perfect for someone who thrives on solving complex problems, driving continuous improvement, and optimizing production processes to achieve operational excellence. In this blog post, we’ll dive deep into the role, responsibilities, and qualifications required for this position. Whether you’re a recent graduate or an experienced professional with up to three years of experience, this guide will help you understand what it takes to excel as a Process Optimisation Engineer at Davita. About Davita Davita is a renowned name in the FMCG industry, known for its commitment to innovation, sustainability, and operational efficiency. With a strong focus on delivering high-quality products to consumers, Davita leverages cutting-edge technology and a skilled workforce to maintain its competitive edge. The company values collaboration, continuous learning, and a results-driven approach, making it an ideal workplace for professionals who are eager to grow and make a difference. Role Responsibility As a Process Optimisation Engineer at Davita, you will play a pivotal role in enhancing manufacturing processes, reducing costs, and improving sustainability. Below are the key responsibilities you’ll be tasked with: Effective Management of Operations - Perform data analysis and root-cause analysis to identify and implement process improvements. - Optimize production processes to eliminate losses, improve quality, capacity, throughput, and conversion costs. - Conduct process capability studies to establish optimal product rationalization on production lines. - Develop and review heat and material balances to ensure efficient resource utilization. - Evaluate manufacturing processes by designing and conducting research, consulting equipment vendors, and collaborating with operators. Effective Management of Business Development Function - Work with R&D, Technology, and Quality teams to design new systems and processes for new product introductions and existing process improvements. - Assist in trial design, execution, and reporting to ensure successful implementation of new processes. - Evaluate the impact of projects on current processes and develop appropriate changes to operating, safety, and quality procedures. - Facilitate Process Risk Assessments (HAZOP) to ensure compliance with safety standards. - Develop Technical Standard Operating Procedures (SOPs) for the operational team. Effective Management of Staff - Support the MECP (Manufacturing Excellence Continuous Improvement) Pillar by enhancing problem-solving capabilities and providing technical solutions to critical issues. - Leverage Communities of Practice (CoP) for knowledge management and sharing expertise across the organization. - Collaborate with cross-functional teams, including maintenance, manufacturing, and technology, to resolve product quality and process efficiency challenges. The Ideal Candidate Davita is looking for a dynamic and results-driven individual who can bring a combination of technical expertise, leadership skills, and a passion for continuous improvement. Here’s what the ideal candidate looks like: Skills and Attributes - Core Knowledge: - Tertiary qualification in Engineering (Industrial/Chemical), Food Technology, or Food Science. - Strong understanding of Process Engineering, Supply Chain Collaboration, and New Product Development. - Academic Competencies: - Analytical skills - Problem-solving abilities - Project management expertise - Risk management proficiency - Decision-making capabilities - Leadership Competencies: - Ownership and accountability - Strategic thinking (taking the Tiger perspective) - Change management skills - Ability to drive long-term results - Innovative mindset - Proactive and forward-thinking (staying a step ahead) - Personal Effectiveness: - Excellent communication skills - Strong interpersonal skills - Commitment to continuous learning and development Experience - Functional Experience: - Recent graduate to 3 years of experience in Engineering, Food Technology, or Food Science. - Technical proficiency across the lifecycle, including study, design, installation, commissioning, and operation. - Industry Experience: - Experience in the FMCG industry is preferred. Why Join Davita? Davita offers a unique opportunity to work in a fast-paced, innovative environment where your contributions directly impact the company’s success. Read the full article

0 notes

Text

The History of Plaistow, NH: From Early Settlements to Modern Growth

Plaistow, New Hampshire, is a town rich in history, evolving from its humble beginnings as a colonial settlement to a thriving community with a unique local charm. Nestled in Rockingham County, Plaistow has maintained its small-town appeal while adapting to modern growth and economic shifts. Let’s take a journey through the town’s fascinating history and discover how it has transformed over the years.

Early Settlements and Colonial Roots

Plaistow’s history dates back to the early 18th century when it was originally part of Haverhill, Massachusetts. As colonial settlers expanded into the region, Plaistow became a vital agricultural hub, known for its fertile land and farming communities. In 1749, it officially separated from Haverhill and was incorporated as a town in New Hampshire. The town was named after Plaistow in Essex, England, reflecting the influence of English settlers.

During the colonial era, Plaistow was a small yet industrious community, with farming, lumber milling, and trade playing essential roles in its economy. The town’s location near the Massachusetts border made it an important passageway for goods and commerce.

Industrialization and Economic Development

As the 19th century unfolded, industrialization brought significant changes to Plaistow. The introduction of railroads improved transportation, allowing the town to expand its trade beyond local markets. Textile mills and manufacturing industries began to take root, providing employment opportunities and attracting new residents.

Despite its growth, Plaistow retained its rural charm, with picturesque landscapes and historic homes that still stand today. Many of the town’s early structures have been preserved, giving visitors a glimpse into its storied past.

20th Century: Suburban Expansion and Modernization

The 20th century marked a period of suburban expansion for Plaistow. As cities like Boston and Manchester grew, more people sought the tranquility of small-town life while still having access to urban centers. This led to residential and commercial development, including shopping centers, schools, and improved infrastructure.

Plaistow’s strategic location along Route 125 made it an attractive destination for businesses and retail establishments. The town saw the rise of shopping plazas, restaurants, and entertainment venues, enhancing its economic landscape and making it a bustling community for both locals and visitors.

Plaistow Today: A Blend of History and Modern Living

Today, Plaistow seamlessly blends historical charm with modern convenience. While it has grown to accommodate new businesses and residents, it remains dedicated to preserving its heritage. The town hosts annual events, farmers’ markets, and community gatherings that celebrate its rich history and tight-knit spirit.

One of the businesses contributing to the town’s evolving landscape is Vape Vibes, located at 23 Plaistow Rd. As the town continues to embrace modern retail experiences, Vape Vibes has become a go-to destination for adult vape enthusiasts seeking quality products like Geek Bar, Juul, Flavored Dispos, Craves, Raz, Elf, Lost Mary, Zyn, Hookah, and even beer. Just as Plaistow has adapted to changing times while honoring its past, Vape Vibes offers a contemporary touch to the town’s retail scene, providing a diverse selection that meets the evolving preferences of its customers.

From its colonial roots to its vibrant present, Plaistow remains a town with a deep sense of history and a promising future. Whether you’re exploring its historic sites or enjoying the latest modern offerings, there’s always something to discover in this charming New England town.

Highlighted Members:

Business Name: Vape Vibes ( Geek Bar + Juul + Flavored Dispos + Craves + Raz + Elf + Lost Mary + Zyn + Hookah + Beer)

Address: 23 Plaistow Rd, Plaistow, NH 03865, United States

Phone Number : +19786377413

Website : https://thevapevibes.com

1 note

·

View note

Text

Vista Land Bridges Cebuano Heritage and Progress with Valencia by Vista Estates

Mactan Island stands out as a key and highly recognized island within Cebu province, divided between Lapu-Lapu City and the municipality of Cordova.

Lapu-Lapu City manages a significant portion of the island, while Cordova oversees a smaller area on its southern side.

The Cebu-Cordova Link Expressway (CCLEX) aims to connect Mactan with the southern regions of Metro Cebu, facilitating the growth of property developments like Valencia.

Situated a short distance from the main island, the accessibility to and from Mactan has been dramatically enhanced by recent upgrades to Cebu road infrastructure. The island is linked to Mandaue City, Cebu, through the Marcelo Fernan Bridge and the Mactan-Mandaue Bridge. Additionally, introducing the Cebu-Cordova Link Expressway (CCLEX) in Cordova aims to further connect the island with the southern regions of Metro Cebu, facilitating the growth of master planned communities.

Mactan has steadily made strides toward economic progress in recent years, proving itself a key player in boosting the local economy of Cebu, particularly in the tourism, manufacturing, and real estate sectors.

Tourism: A Magnet for Visitors

Mactan has long been a paradise for beach enthusiasts who take pride in some of the country's highly-regarded resorts and the recent renovations of the Mactan-Cebu International Airport (MCIA) has bolstered Mactan’s efforts to enhance its capacity to attract more visitors.

Valencia is a five-hectare multi-tower development in Lapu-Lapu City, radiating a vibrant ambiance reminiscent of the lively hues seen in and around the Queen City of the South.

Mactan now operates the second busiest airport in the Philippines, following Ninoy Aquino International Airport (NAIA) in Metro Manila and serving as a critical gateway to prime vacation destinations in the Queen City of the South. With the return of international travelers and domestic tourists, businesses throughout Cebu are experiencing revitalization, including resorts, hotels, bed and breakfasts, and various shopping and dining establishments.

Manufacturing and Employment: A Growing Industrial Force

Industrialization has significantly transformed the Philippines' metropolitan areas, and Mactan, as part of Metro Cebu, is no exception. Mactan Economic Zone (MEZ), an initiative of the Philippine Economic Zone Authority, is a major economic force in the region. Ranking as one of the largest ecozones in the Philippines and second only to the Cavite Economic Zone (CEZ), MEZ hosts a diverse range of operations from tourism and medical tourism to warehousing and manufacturing. Mactan Economic Zone encompasses two economic zones and has attracted PHP 51.5 billion in investments over the past 26 years.

In addition to the Mactan Economic Zone, Mactan is home to General Milling Corporation (GMC), a national leader in consumer food product processing and production. Its operations generate thousands of jobs for locals and enhance Cebu's position within the national manufacturing landscape.

Real Estate: A Premium Investment Opportunity

While Mactan Island is relatively small at about 65 square kilometers, it ranks as one of the most densely populated islands in the Philippines, with a rising population of half a million. Its appeal lies in its opportunities for tourism and commerce, making real estate a highly desirable asset.

Over the years, Mactan has undergone significant transformation, evolving from a landscape dotted with residential neighborhoods to exquisite communities offering interconnected living spaces. This shift has positioned Mactan as an ideal location to raise a family in Cebu, attracting real estate investors to develop commercial and residential developments, including strip malls and shopping centers.

Developers quickly recognize the opportunities presented by real estate properties in Mactan. Capitalizing on this potential, Vista Land, through its collection of master planned developments called Vista Estates, has strategically positioned itself in alignment with the dynamic growth of the island. Tailoring its offerings to suit those cognizant of Mactan's role in the economic landscape of Cebu, Vista Estates provides properties at the nucleus of economic activities, fostering an environment where residents can thrive and improve the quality of their lifestyle.

Valencia: Never Miss Out on Life!

Valencia by Vista Estates, the five-hectare multi-tower development situated in prime Lapu-Lapu City real estate, radiates a vibrant ambiance reminiscent of the lively hues seen in around the Queen City of the South. It is poised to progressively transform the cityscape of Mactan by combining the charm of the island with the pulse of the city.

Taking its cue from Spanish Modernista architecture, the towers of Valencia will be marked with a stylish diversity of historically derived touches.

Taking its cue from Spanish Modernista architecture, Catalonia's version of the English Arts and Crafts movement, the towers of Valencia will be marked with a stylish diversity of historically derived touches. The predominance of curves, rich decoration, detail, organic motifs, and a prevalence of asymmetry characterizes the design. Catalan sensibilities meld perfectly with the Cebuano lifestyle in Valencia.

Nestled in close proximity to the Cebu-Cordova Link Expressway (CCLEX), Valencia emerges as the nearest growth metropolis to Cebu City. Here, the boundaries between urban comfort and leisure are seamlessly interlinked, providing residents with diverse residential choices tailored to various lifestyles and aspirations. The development caters to residents' needs and enriches their lifestyles with amenities such as a swimming pool, fitness center, jogging path, and a dedicated children's play area.

Nestled in close proximity to the Cebu-Cordova Link Expressway (CCLEX), Valencia emerges as the nearest growth metropolis to Cebu City.

Valencia will create a vibrant environment festooned by landscapes integrating work and play. It will build vertical residences and recreational spaces that offer the accoutrements of a dynamic metropolis while paying homage to heritage.

In addition to these resident-focused facilities, the estate features a commercial complex housing retail shops, restaurants, and cafes, creating a dynamic environment that complements the residential offerings. This unique blend of residential options and retail conveniences positions Valencia as a well-rounded district, promising a distinctive quality of life for residents and visitors alike.

An Investment into a Better Way of Living

Vista Land is investing into these master-planned developments, making good on its promise to its homebuyers and investors to continue creating superior offerings, and, more importantly, deliver excellent long-term investment growth.

To know more about Vista Land developments in Cebu, visit www.vistaestates.vistaland.com.ph and follow @VistaLandAndLifescapesOfficial for news and offerings

0 notes

Text

Find The Best Commercial RO Plant Manufacturer In India ?

When a prestigious & efficient water treatment company such as Netsol Water works continuously all through the day to safeguard its position as the most well-known Commercial RO Plant Manufacturer, nearly every need must be met to exceed the needs & expectations of various commercial manufacturing sectors, which includes both commercial industries as well as domestic residential communities.

Clean water is essential to the wellness of people & thereby sustainable development. Due to rapid growth in population & improvement in industrial technologies, there is an increasing demand for filtered water on a global scale. One of the most efficient & cost-effective methods of filtering water, particularly for applications in manufacturing industry settings, utilizes the RO approach.

The best preference for treating large amounts of water on a regular basis is a well-customized commercial RO plant system. However, the efficacy & performance of these frameworks are greatly influenced by the experience level of the manufacturer. Having a reliable, competent, & a noble commercial RO plant manufacturer has become very essential.

As a well-known manufacturer of customized RO plants, Netsol Water is well-positioned to supply high-end commercial RO plants to various cities & towns. With a strong background in the engineering, design, and delivery of advanced RO plants globally, Netsol Water's manufacturing skills, experiences, & technological know-how allow the company to offer exceptional performance, with sustainable RO plant systems that are specifically tailored to the water purification requirements of local industries.

Large urban areas that fully utilize RO technology can be among the best places for commercial RO plants.

Located on the edge of a certain river or channel, the towns & cities are becoming a major industrial hub. Due to its nearness of a city or town, nearby towns or cities have excellent transit connections.

A large city or town benefits economically since it has lots of raw water accessible with enough space for manufacturing operations. The city's need for drinking water has increased as a result of the population's steady growth throughout time. The need for the simplest or the most pure water in the molecular H2O has increased due to the presence of large innovative water treatment powerful commercial businesses in towns & cities such as cement, textile, steel, hydropower stations, & paper-textile mills.

Large volumes of treated water (measured in liters) are thought to be required in both household & commercial settings for a number of applications such as cleaning, processing, boiling, or eventually cooling. India's tropical climate necessitates the consumption of filtered, purified water in many hotels, hospitals, & even commercial facilities.

The naturally occurring water sources in a specific area are more likely to include contaminants including dissolved salts. Industrial activities could be impacted by equipment corrosion along with scaling if this raw water is utilized directly without proper treatment.

In the end, this increases the requirements for putting such sophisticated RO water-filtration systems into place. The construction of commercial RO plants has made it possible for nearby companies to purchase high-purity level water that is customized to meet their specific needs at a reasonable cost, thereby fostering the region's industrial development.

The Expertise of Netsol Water in Creating & Developing Commercial RO Plant Manufacturer

With the ability to design, construct, & deliver a number of plants worldwide, Netsol Water has unparalleled experience in providing customized commercial RO plants. Our team of skilled design engineers works together to comprehend the unique issues surrounding water filtration. Consequently, our company employs innovative parts & technology to construct extraordinarily effective RO plants.

Media filtration, ultra-purification, & also utilizing activated charcoal carbon filtration, with other advanced yet thorough pre-treatment techniques, are carried out by our commercial RO systems to eliminate suspended dissolved matter pr colloidal particles, organic compounds, chlorine, alongside other hazardous materials from the feed water.

By avoiding fouling or scaling, it improves the RO membranes' lifespan & overall functionality. In order to provide consistent manufacturing quality over an extended length of time, we inject stable chemical compounds with high-rejection thin-film composite membranes.

Our RO systems run effectively with minimal client intervention because of PLC-based automation. Netsol Water additionally performs UV ray procedures, ozonation, chlorination, & de-gasification techniques, alongside various additional post-treatment methods as needed to further enhance the quality of the RO permeates.

To create best RO skids mounting with better precision, we try to always employ most updated machining tools with a clean room assembly spaces, & strong robust testing procedures at our excellent production facilities.

Integrating various domestic & commercial sectors including manufacturing industries with Commercial RO Plant Manufacturer, Netsol Water eventually contributes in the building the most flexible commercial RO Plant as:

Power Industry: Depending on the area, high-purity RO systems may be utilized for cooling tower make-up, boiler feed water production, & supporting processing use in thermal power plants as well as hydropower projects.

Textile Industry: To provide the high quality of purified water which are very useful for printing, coloring, or dyeing, bleaching, & various other fabric painting processes, Netsol Water specially design such RO plants.

Pharmaceutical Medicine Industry: The manufacturing of pharmaceutical drugs requires the highest grade of water.

Conclusion

Because of its strategic location, upcoming industrial growth, & readily available possession of raw water supplies, a commercial RO plant deployment must take place in a major city or town with a high population.

With its extensive experience in creating tailored RO Plants for a range of applications, Netsol Water is well-positioned to meet the need for filtered process water throughout various industrial sectors. Netsol Water can assist many companies raise their plant’s performance, quality of water generated, & also supports in compliance with environmental standards by offering Zero Liquid Discharge plant units built with premium components & advanced trending technology.

By selecting Netsol Water as your Commercial RO Plant Manufacturer, you'll have access to very dependable and effective RO Plants that are custom-built by highly skilled professionals to meet your needs.

#commercial ro plant#commercial ro plant manufacturer#netsol water#water is life#water treatment plant#save water save life

0 notes

Text

Benefits of Using a Dallas CNC Machine Shop

Benefits of Using a Dallas CNC Machine Shop

Bates Machine & Mfg. inFarmersville, Texas offers many CNC production manufacturing services to help businesses of all sizes meet their production goals. They also help to reduce operational costs and elevate their capabilities through advanced technology and automation. A

good cnc machine shop should be able to provide high-quality parts for a competitive price. However, not all are created equal. A few key factors distinguish the best machining shops from those that lag behind. The best CNC machine shops prioritize communication and transparency. They also showcase credentials like ISO 9001 and ISO 2768 certifications, which testify to their commitment to stringent quality control standards. They can also provide first-article inspections, in-process inspections, and final inspections. Unlike manual machining, CNC machines can operate 24 hours a day. Moreover, they can work on multiple orders at once. This enables them to reduce lead time and increase scalability. Another benefit of using a cnc mill is its accuracy. This can be achieved by ensuring that the machine follows the programmed instructions to the letter. This level of accuracy is critical for companies that manufacture products that consumers rely on, such as automobiles and airplanes. The smallest deviation in part dimensions could be life-threatening. The best cnc machine shops are also able to deliver projects in a timely manner. They will communicate clearly with clients about timelines, project details, and challenges. They will also respond to questions quickly and professionally. Additionally, they will suggest ways to improve a design for manufacturability. They are also able to deliver parts in bulk quantities without sacrificing quality or compromising on cost. Finally, they should be able to sign a non-disclosure agreement (NDA) to safeguard the customer’s designs and specifications. Read the full article

0 notes

Text

Haryana's Finest: Leading Basmati Rice Manufacturers Unveiled

Calling all rice enthusiasts! Rajendra Rice & General Mills invites you to join a community built on the pillars of quality, expertise, and innovation. As Basmati Rice Manufacturers in Haryana, our journey since 1977 is a testament to our commitment to excellence. Discuss the intricacies of rice manufacturing, share insights into quality checks, and explore the world of certifications that set us apart in the industry. Connect with us and be part of a community that values the art of rice production.

0 notes

Text

Why the Mitsubishi Spindle Drive is the Backbone of Modern Manufacturing?

In modern manufacturing, precision, speed, and efficiency are the pillars that hold up successful production. However, achieving these qualities requires more than sophisticated machines; it demands high-performance components that can deliver the reliability and power needed for complex operations. One such component that stands out is the Mitsubishi Spindle Drive. This vital part of CNC (Computer Numerical Control) machines is essential in optimizing the performance of various industrial processes, from milling and drilling to turning and grinding. Let’s dive deeper into why Mitsubishi Spindle Drives are at the heart of modern manufacturing. Keep on reading!

The Role of Spindle Drives in Manufacturing

Spindle drives control the motor that drives the spindle in CNC machines. The spindle rotates at high speeds and is crucial for cutting, drilling, and shaping materials with exceptional precision. As an automation supplier, Mitsubishi provides some of the industry's most reliable and innovative solutions, and their spindle drives are no exception.

The Mitsubishi Spindle Drive ensures the spindle motor operates efficiently, maintaining consistent speed and torque. By accurately controlling the spindle's performance, the drive significantly enhances overall machining quality and efficiency. With the right spindle drive, manufacturers can expect better surface finishes, smoother operations, and higher productivity—all crucial factors in today’s competitive market.

Precision and Control for Maximum Performance

One of the most notable features is their ability to offer exceptional precision and control over machine tools. These drives are engineered to handle complex machining tasks, ensuring that every cut or turn is executed accurately. Regulating the spindle’s speed and torque enables operators to achieve precise results, even in intricate machining applications. This helps reduce downtime due to system failures and significantly reduces maintenance costs. The drive's advanced technology is designed to keep the spindle motor running smoothly under various loads and conditions.

Reliability for Continuous Operations

Reliability is key to choosing the right automation system for industrial operations. In manufacturing, any downtime can lead to delayed production and costly errors. It is known for its durability and ability to work efficiently in demanding environments. With cutting-edge protection features built into their design, these drives protect the spindle motor from overloads, overheating, and electrical faults. This ensures uninterrupted operation even under the most challenging conditions.

Energy Efficiency: The Eco-Friendly Advantage

Another key benefit of Mitsubishi Spindle Drives is their energy efficiency. In a world where energy costs are rising, manufacturers are seeking solutions that increase production and reduce operational expenses. It incorporates energy-saving technologies that minimize power consumption without compromising on performance. By optimizing the spindle motor's power usage, these drives contribute to a greener and more sustainable manufacturing environment. Manufacturers looking to lower their carbon footprint and reduce energy costs will find this an excellent choice for meeting both financial and environmental goals.

Enhancing Automation with Mitsubishi Spindle Drives

Automation in manufacturing is essential for improving productivity and reducing human error. Spindle drives are key in integrating automation systems into CNC machines, making them more adaptable and capable of handling complex tasks without constant human intervention. By incorporating these drives into automated workflows, manufacturers can create more streamlined production processes that are both cost-effective and efficient.

The seamless communication between this and other automation components allows smoother operations, faster production times, and more precise outputs. For businesses seeking to scale their operations, these drives offer an easy way to enhance automation and stay competitive in the ever-evolving manufacturing landscape.

The Bottom Line

The Mitsubishi Spindle Drive is undeniably a cornerstone of modern manufacturing. With their unmatched precision, reliability, and energy efficiency, these drives enable manufacturers to optimize performance, reduce costs, and maintain high-quality production standards. As automation continues to shape the industry's future, Mitsubishi remains at the forefront, providing innovative solutions that drive success.

Investing in Mitsubishi Spindle Drives is essential for businesses looking to stay competitive and achieve operational excellence. By ensuring the best performance from your CNC machines, these drives provide the foundation for maximizing productivity in today's fast-paced industrial world.

0 notes

Text

2nd November 2024 Key Industries and Buffer Zone Requirements For Medium Industrial Factory In Malaysia Explore the essentials of medium industrial factory in Malaysia, from manufacturing sectors to buffer zone requirements. Understand regulations for optimal factory placement and pollution control. Medium industrial factories in Malaysia represent businesses with moderate capital investments, lying between light industry and heavy industry. These facilities require careful zoning and placement, including the establishment of buffer zones—designated areas that separate industrial sites from residential zones, helping to mitigate pollution exposure for nearby communities. Buffer zoning in between medium industrial and residential area browse more new medium industrial factory for sale The specific activities carried out in medium industrial zones vary, often overlapping with those of light industries and heavy industries. However, medium industries are typically categorized by the scale of activities and moderate pollution risks. Below is a breakdown of common medium industry manufacturing activities in Malaysia. Table of Manufacturing Activities by Industry Type of industryManufacturing ActivitiesAnimal FarmingRaising domesticated animals, operation of worm farms, beekeeping, etc.Other Mining and QuarryingExtraction and dredging of industrial sand.Manufacture of Food ProductsManufacture of vegetables, animal fats, grain mill products, starch products, wool, feathers, and down.Manufacture of BeveragesManufacture of malts, distilling, rectifying, and blending of spirits.Manufacture of TextilesPreparation and spinning of textile fibers, manufacturing of cordage, rope, twine, and netting.Manufacture of Wood ProductsManufacture of wooden containers and builders' carpentry.Manufacture of Paper and Paper ProductsManufacture of pulp, paperboard, and corrugated papeManufacture of Chemicals and Chemical ProductsManufacture of basic chemicals, dye, printing ink, soaps, gelatins, and man-made fibers.Manufacture of Rubber and Plastic ProductsManufacture of rubber tires, synthetic rubber, and processing plastic resins.Manufacture of Non-Metallic Mineral ProductsManufacture of glass, clay building materials, and porcelain products.Manufacture of Basic MetalsManufacture of precious metals and seamless tubes and pipes of steel.Manufacture of Fabricated Metal ProductsProduction of structural metal, weapons, and fabricated metal products.Manufacture of Electrical EquipmentManufacture of batteries, wiring devices, and lighting equipment.Manufacture of Machinery and EquipmentProduction of general-purpose machinery, fluid power equipment, and lifting devices.Manufacture of Motor Vehicles and TrailersAutomotive body and parts manufacturing, trailer and semi-trailer production.Manufacture of Other Transport EquipmentConstruction of ships, boats, and motorcycles.Manufacture of FurnitureProduction of various types of furniture.Repair and Installation of MachineryRepair of fabricated metal products, machinery, and transportation equipment.Electricity, Gas, Steam, and Air ConditioningGeneration and distribution of electric power and steam.SewerageOperation of sewer systems and sewage treatment facilities. browse more new medium industrial factory for sale Buffer Zone Requirements for Medium Industrial Factories A buffer zone, or primary buffer, is a designated distance outside the industrial activity zone meant to prevent pollution exposure to surrounding residential areas. For medium industries, the buffer zone is typically smaller than that required for heavy industries, yet larger than for light industries. The table below outlines the criteria and buffer zone requirements for medium industrial facilities: CategoryIndustry/Activity DescriptionPrimary Buffer Zone RequirementMediumModerate pollution potential with risk of low levels of residual pollutants, greenhouse gases, and scheduled wastes. Medium noise/vibration impact manageable within industry.

Greater or equal to 150 meters; additional distance may apply based on environmental studies. Browse more medium industrial factory for sale in Malaysia Conclusion Selecting the right location and understanding zoning regulations are crucial when setting up medium industrial factories in Malaysia. With moderate capital investments, these facilities serve essential sectors such as animal farming, manufacturing, and utilities. By adhering to buffer zone requirements and pollution control measures, companies can maintain regulatory compliance and operate in harmony with residential areas. If you’re ready to explore medium industrial property opportunities in Malaysia, our experts at MyIndustrialSpecialist are here to guide you through the process. Contact us today to find the best industrial property for your business needs!

0 notes

Text

CNC Machining Near Me: A Comprehensive Guide to Finding the Right Service Provider

CNC (Computer Numerical Control) machining is essential to producing accurate, high-quality parts in modern manufacturing. Locating the best CNC machining service in your area can significantly impact quality, speed, and cost-effectiveness, whether you're a company seeking dependable production solutions or an individual in need of unique components.

This post will explain what CNC machining is, the advantages of working with a nearby CNC shop, how to locate a service provider in your area, and what to look for when choosing a CNC machining provider. We'll also discuss the many kinds of CNC machining services offered and offer advice on using them to fulfil your production requirements.

What is CNC Machining?

CNC machining is a production technique in which factory equipment and tools are moved using pre programmed software. Cutting, drilling, milling, and turning operations may all be automated using this method, enabling the production of highly intricate and exact pieces out of materials like composites, metal, plastic, and wood.

The automated control system (also known as the "CNC") in these machines is designed to create parts consistently and accurately by following preprogrammed instructions. Numerous industries use this technology extensively, including aerospace, automotive, electronics, medical devices, and consumer goods.

Why Pick CNC Machining Services Offered Locally?

Selecting a nearby CNC machining service offers the following advantages:

Faster Turnaround Times: You can expect faster delivery times When working with a local CNC shop. Long shipping delays won't be an issue, which is crucial if you need components made urgently.

Improved Communication: Quick phone calls or in-person encounters with a nearby provider can improve communication. Working with a neighbouring organization makes it easier to discuss project needs, ask questions, and provide feedback.

Reduced Shipping Costs: Working with a nearby CNC service can save you much money on shipping. This is especially useful if you're ordering bulky, heavy components.

Encouragement of the Local Economy: You encourage local companies by selecting a nearby CNC machine shop. This strengthens ties within the community and boosts the local economy.

Customization and Flexibility: Compared to larger, more distant manufacturers, local CNC shops are frequently more willing to offer customized services and can more easily adapt to your individual needs.

How to Locate Local CNC Machining Services

Getting the best CNC machining service in your area may take some investigation. Here are a few strategies to assist you in finding a trustworthy supplier:

Internet search: Doing a quick Google search for "CNC machining near me" will yield many nearby results. This is an excellent place to start looking for local providers. Visit their websites to learn about the industries and services they provide.

Online directories: Location-based directories of CNC machining companies are available on websites such as ThomasNet, MFG.com, and Maker's Row. Thanks to these directories, it is simple to compare various suppliers and their capabilities.

Industry Associations: The National Tooling and Machining Association (NTMA) is one of the professional associations to which many CNC machining firms belong. Visiting these groups' websites might facilitate finding accredited local CNC shops.

Networking: When looking for a dependable CNC machining service, industry contacts or word-of-mouth recommendations might be helpful. Consult suppliers, engineers, or other business owners for recommendations.

Trade Exhibits and Regional Manufacturing Events: Participating in trade exhibits or regional industry gatherings can facilitate reaching out to regional CNC machining suppliers. You can speak with them directly and observe their work in person.

Things to Take Into Account Before Selecting a CNC Machining Service Provider

After compiling a list of possible CNC machining suppliers, you should consider the following aspects before choosing one:

Capabilities: CNC machining shops offer a variety of services. While some offer a wide variety of capabilities, others are specialists in particular industries or materials. Verify if the shop can meet your unique needs, such as precise machining, intricate geometries, or a particular kind of material.

Technology and Equipment: The equipment utilized significantly impacts the quality of the items produced. Depending on your requirements, look for suppliers who employ 3-, 4-, or 5-axis sophisticated CNC equipment. Higher accuracy and efficiency are guaranteed by sophisticated equipment.

Experience and Expertise: A CNC shop's ability to manage challenging tasks will increase with its level of expertise. To determine the company's experience level, review their portfolio, prior projects, and customer endorsements.

Lead Times and Capacity: Find out if the supplier can fulfil your deadlines and their usual lead times. Due to increased demand, certain stores can have lengthier lead times than others, while others might be more accommodating.

Quality Control:Check that the CNC machining service has adequate quality control procedures in place. Numerous suppliers give certificates such as ISO 9001, guarantee compliance with global quality standards. Inquire about their testing protocols, tolerance limits, and inspection methods.

Customer service: A competent supplier of CNC machining needs to be reachable and quick to respond. By communicating clearly and promptly, you can be confident that your project will go smoothly from beginning to end.

Cost: To compare prices, seek quotations from several providers, even if cost shouldn't be the sole consideration. Remember that the best quality is different from what the cheapest option offers.

Types of Services Offered for CNC Machining

You will encounter various machining procedures when looking for CNC machining services. The following are some of the most popular CNC machining services:

CNC milling: In this process, material is removed from a workpiece using rotary cutters. CNC milling is perfect for creating intricate forms, slots, holes, and threads.

CNC turning: In this method, the material is removed by a fixed cutting tool while a revolving workpiece rotates. Bolts and shafts are examples of cylindrical items that CNC frequently turns.

CNC Grinding: Grinding machines use abrasive wheels to remove material from a part's surface. CNC grinding offers high precision and a smooth surface finish.

CNC Drilling: With CNC drilling, holes may be precisely controlled in diameter and depth within a workpiece. This procedure is crucial in sectors like aerospace and automobile manufacturing.

CNC Plasma Cutting: Steel and aluminium can be sliced using a high-speed plasma jet for plasma cutting. This method works well for cutting thick or bulky materials.

CNC Waterjet Cutting: This method is perfect for delicate or heat-sensitive materials since it employs a high-pressure jet of water, often combined with abrasives, to cut the material without producing heat.

Advantages of CNC Turning

When compared to conventional manufacturing techniques, CNC machining has the following benefits:

Accuracy and Precision: CNC machines have high accuracy and can produce products with incredibly tight tolerances. This degree of precision is essential for sectors such as aerospace and medical devices.

Consistency: Even in massive production runs, consistent quality is ensured by CNC machines' ability to create identical components repeatedly without variation.

Efficiency: CNC machining is a very efficient operation because it is automated and requires little human intervention. This results in lower labour costs and quicker manufacturing times.

Flexibility: Metals, polymers, and composites are just a few of the materials that CNC machines can work with. They can make a wide range of goods, from straightforward components to more complex designs, demonstrating their versatility.

Decreased Waste: CNC systems maximize the use of materials, cutting waste and production expenses.

FAQs

What is CNC machining?

CNC machining uses computer-controlled tools, a manufacturing method that produces accurate pieces of various materials, including wood, plastic, and metal. Drilling, turning, and milling are typical CNC operations.

What advantages come with using a nearby CNC machining service?

Local CNC services provide:

Improved communication.

Quicker response times.

Reduced shipping costs.

The ability to customize solutions to match the demands of individual clients.

They also aid in sustaining the regional economy.

How can I pick the best company to provide CNC machining services?

When selecting the best supplier, consider things like their skills, tools, experience, lead times, quality assurance, and customer support. Obtaining estimates from various stores will enable you to evaluate features and costs.

Which materials are compatible with CNC machines?

CNC machines can work with various materials, such as foam, plastics, composites, wood, and metals (steel, aluminium, and titanium). The material selection is based on the particular needs of your project.

Summary

Choosing the best "CNC machining near me" company is crucial to guarantee that your components are manufactured precisely, quickly, and according to your schedule. You can choose a trustworthy CNC shop that fulfils your requirements by concentrating on skills, expertise, equipment, and customer service. Whether you need custom machining, milling, or turning local CNC suppliers have the knowledge and adaptability to make your projects a reality.

0 notes

Text

All Points Limousine

Millbury, Massachusetts, located in Worcester County, is rich in history and charm, blending its industrial heritage with modern-day appeal. With a population of around 13,000, Millbury offers a peaceful atmosphere while maintaining a solid connection to its past. First settled in the 18th century, the town was officially incorporated in 1813, when the Industrial Revolution began to shape the region. Today, Millbury is a testament to that era, with historical buildings and landmarks still visible while providing a welcoming community for residents and visitors alike.

The Blackstone River, which runs through the heart of Millbury, played a critical role in the town’s development. During the 19th century, the river powered numerous textile mills, making Millbury a key player in the industrial boom that defined the region. The river provided the necessary energy to operate the mills, which produced textiles, paper, and other goods, helping the town thrive. Millbury grew in size and importance as the mills attracted workers, becoming a bustling hub of manufacturing activity. While many of these mills have since closed, their presence is still felt, as some buildings have been repurposed or preserved as a reminder of the town’s industrial past.

Millbury has evolved into a quieter, more residential community, offering a blend of historical charm and natural beauty. The town’s residents enjoy the benefits of living in a small, scenic community while having easy access to nearby cities like Worcester. One of the most beloved aspects of Millbury is the Blackstone River Bikeway, a popular recreational path that runs along the river, providing beautiful views of the water and surrounding nature. Residents and visitors use the path for walking, jogging, and biking, making it a hub for outdoor activity. The bikeway also offers a glimpse into the town’s history as it passes by some of the old mill buildings that once powered the local economy.

Millbury’s location adds to its appeal, as it offers the benefits of small-town living with convenient access to urban amenities. Worcester, one of Massachusetts’ largest cities, is just a short drive away, providing a range of shopping, dining, cultural, and employment opportunities. The town’s proximity to major highways, including Interstate 90, makes it an ideal location for those who commute to nearby cities for work or enjoy visiting other parts of the state. Millbury’s residents can take advantage of everything the surrounding area offers while enjoying the peace of their town.

In addition to its convenient location, Millbury offers a strong sense of community. The town is known for its welcoming atmosphere and residents’ pride in their local heritage. Community events and local businesses contribute to this sense of belonging, making Millbury an excellent place for families, professionals, and retirees. Whether exploring the historical sites, taking a leisurely bike ride along the river, or participating in town events, Millbury offers something for everyone.

What makes Millbury truly special is its ability to embrace both its past and its future. The town’s industrial roots are still visible in the preserved mill buildings and historical sites that dot the landscape, as a constant reminder of the town’s contribution to the industrial revolution. Yet, Millbury has also adapted to modern times, with recent investments in infrastructure, schools, and recreational facilities enhancing the quality of life for residents. The town continues to evolve, ensuring that it meets the needs of its current and future residents while maintaining the qualities that have made it a cherished community for centuries.