#cold room panel

Explore tagged Tumblr posts

Text

#Cold room panel#Refrigeration system#Sandwich panel#Modular Cold room#Cold Room Door#Monoblock Cooling unit

0 notes

Note

Thena. A movie premiere with Gil. Very intrusive Paparazzis. For the actor au 👀

It was a barrage of flashes as soon as they were out of the car. Of course they couldn't expect otherwise. The movie was a huge hit, and with them playing leads in a studio hit again, they were bound to have press at their heels.

But this was insane. Gil wasn't sure if he'd ever been swarmed by fans and paparazzi alike in such a way. There were cameras everywhere, people holding out things for signing, screams on all sides.

Gil reached back before Thena put her feet to the red carpet. His hand closed around hers. "Don't let go."

Thena had done some modelling work over the summer, and with a few other projects she'd done coming out, she was the hottest commodity of the year. She had always been a star, but it really seemed like she couldn't take a step outside without being photographed.

And that wasn't good. It meant he had a harder time seeing her outside of work.

Gil held his hand out. Security was already on either side of them, flanking their exit and direct route into the building for the screening. He kept Thena's hand in his, tight but not enough to hurt her.

"Thena! Thena, can you sign this? Thena, we love you!"

All the voices blended together into one monstrous hivemind. Thena did her best to sign a few things. She couldn't see from all the flashes in her face, and he could tell she couldn't.

Fighting through as best he could, he eventually made it to the doorway. He looked around. A few of his security guys were with him, but Thena's weren't. And Thena wasn't either.

"What the hell?" he glared at them.

They looked affronted. They were hired for his security, after all.

But Gil growled at them, "you just left her there?!"

They had no response. Gil pushed back into the crowd, which was a hellish mass of undulating bodies at this point. Thena was surrounded on all sides. He could barely see the top of her blonde head amidst the chaos.

"Please, back up, just-" Thena was trying to reason with them, but they were pushing and shoving and deafeningly loud. There were placards and books and magazines being shoved at her from all angles. "Back up!"

Gil shoved a few people out of his way. This was beyond out of control. "She said back up!"

"Hey!" the guy most in her personal space protested to being pushed. He had some big photo of her printed on a canvas, shoving it at her for it to be signed. "What's the-"

Gil tossed the thing aside, grasping the jackass by the front of his shirt. "You don't fucking crowd her like that."

The dirt bag was easy to toss, like the trash he was. The security guys around her were trying to keep people at bay, although he didn't know how hard they were trying, since they certainly weren't fucking succeeding at anything.

He took Thena's hand in both of his, refusing to let it slip away from again. He pulled her with him, closer, keeping people away by any means necessary, if it meant kneeing, elbowing, shoulder checking.

He didn't pause at the doorway, either. Only once they were inside and the door was closed did he lean away from her at all. He glared at her security, who were shaking out their jackets. "What the fuck were you doing out there?! Because it certainly wasn't your jobs!"

"Gil," Thena put her hand on his chest.

"How the hell did anyone get that close to her?!" he bellowed at them. Although, by the second time Thena called to him his eyes were on her. He smoothed down the odd hair of hers that had gotten tousled in it all. He tilted his head. "Are you okay? You didn't get hurt, did you? Did anyone put their hands on you?"

His hands would be laid on anyone who did, was his point. But Thena shook her head, straightening herself out after the anarchy. He could see on her pale skin where people had pushed and shoved and grabbed.

Thena looked up at him as he slipped the fallen strap of her dress back onto her shoulder. Finally, she managed a small smile for him. "Thanks for the save."

He was happy to save her. But he had never considered it saving her before because there hadn't been any peril quite like that. He looked at the security again. "I'm serious, how was anyone able to just come up and get that close to her? Isn't your job to keep people away from her?"

"Look, it's crazy out there," one made a pitiful attempt at defending their poor performance. "We did what we could."

"Really?" Gil's face darkened. He put his hands on Thena's arms. He could feel her shaking. "Because I seemed to do a lot better than you guys at keeping those animals off of her, so tell me right now why I shouldn't ask each and every one of you to be replaced?"

No one had an answer to that.

He could try to beat it into their skulls how useless they were all night. But he had more important priorities. He pulled his jacket off, leaving himself in the mockneck sweater he had worn underneath. Once it was on Thena's shoulders - completely dwarfing her tiny frame - he put his hand at the small of her back.

"You'll get a reputation," she said, either chiding him or amused by him. "Acting like a beast while you're ushering me away from people."

"I think 'people' is being kind of generous in this situation," he scoffed, letting his disgust ring out loud and clear. "That's no way to behave."

Thena sighed. "It is the craziest I've seen it in some time. I may have to stop signings again, just until people can calm down. Unless the studio can arrange barricaded carpets."

They were going to work out something, Gil was certain of it. Because he wasn't going to watch Thena's bodily safety come into question like it just did. He leaned closer. "Are you sure you're okay? It was pretty scary in there."

She smiled, and he could tell she was trying to put on a brave front. But he knew he had felt her trembling when he'd touched her arm. "I admit, when they came over me like a tidal wave I didn't quite know what to do with myself. The others were there with me, but in one instant--I don't know, I lost sight of everyone."

How it was possible for her security to allow her to lose sight of them, he didn't know. But Gil swallowed that feeling. It wasn't constructive and it wasn't what Thena needed now.

"So, when I say thanks for saving me," she continued, putting her hand on his arm as they started climbing the stairs. "I mean it, now more than ever."

He put his hand over hers, letting her hold onto his arm properly while her other hand pulled her dress just enough to allow her to walk up each step. "I'll always be here to save you, Thena."

She let out a fluttery kind of laugh, although he couldn't see when she was looking away from him. "Don't say things like that."

"It's true," he protested. He could feel some of the tension leave her the further away from the screaming they got. "Those security guards may not be worth shit but I'd like to see anyone try what they tried tonight if they know I'm there."

He thought he was making her laugh; putting on a front, flexing for her like some dumb, macho tough guy. But she eyed his bicep in the half sleeve of the sweater, then looked up at him. And then she was blushing, out of nowhere.

He cleared his throat, finding himself flustered as well. Once at the top of the stairs, Thena didn't really need to hold onto him anymore. He paused, letting them catch their breath. "Are you ready?--to go in there, I mean."

She sighed, smaller than the last one, though. She nodded, her expression solidifying into more of the fearless Thena he had come to know. She looked at his jacket swaying around her like a cloak. "Won't you need this back? I'm sure your stylist will have something to say about me stealing it."

He kept imagining that creep's hands, how they had come so close to grasping her pristine ivory skin. He shook his head, helping her fan her hair out. "The oversized blazer look is a thing, and everything looks good on you."

Gil blushed again; he really had to stop saying these things to his very trusted and respected colleague.

Thena gave him a more sheepish smile as she adjusted her hold on his arm. "It's my armour, to protect me from the wilderness outside."

#Thenamesh Actors AU#an oldie but a goodie!#so this is a few things here#first that video of Joseph Quinn fixing Lupita Nyong'o's strap for her#second the videos of Angie being swamped by paparazzi just because...poor Ange#and third is the video of Tom Holland coming to Zendaya's rescue#basically Gil sees Thena get absolutely swamped and he is not here for it#not in the least#because also what is security there for if they can't actually create space for her#or do they need a dozen guys at once just for her if so make it happen#they make it to the screening#it's asked if they got through the crowds okay#Thena has a diplomatic answer while Gil says people are acting a fool#they ask about Thena's look#it's a silk gown with spaghetti straps completely swallowed by a men's blazer with the largest shoulders anyone has seen#but she's like oh I was cold Gil lent it to me isn't that sweet#meanwhile his stylist is like I swear to god just wear what I give you#and I mean Kingo is basically his stylist too since he's with Thena so much#and Kingo knew this was coming#and Thena plays it off like oh he's such a gentleman it's really sweet#meanwhile Gil is glaring at everyone on their Q&A panel so hard#of course the headlines are about a potential romance#Thena's jealous costar dares anyone to so much as look at her in a way he doesn't like#the tabloids are all WEARING EACH OTHER'S CLOTHES NOW???#Sprite is just like ugh get a room#Thena: he's just protective!#Gil: try to touch her I dare you I'll rip your arm clean off your body

7 notes

·

View notes

Text

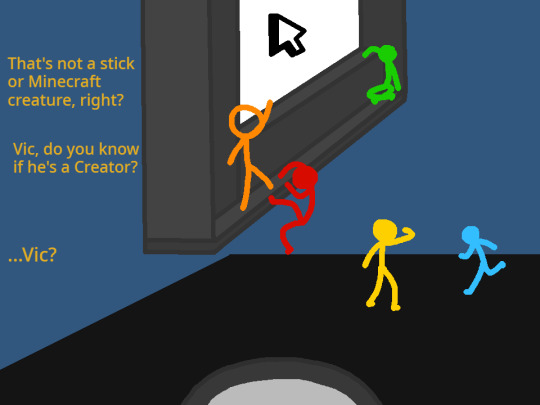

Cold Thoughts Ch 1

Welcome to my AvA comic Cold Thoughts! This should be around 14 chapters (give or take) coming out every Saturday.

For a little bit of context, this is not the first time Vic's met Alan after they died, but they tend to avoid him. Gold, however, is very excited to meet this new creature ^-^

Also this is directly connected to my prior au and headcanons so it follows all the rules of how ghosts work, including the void, ghosts affecting redstone, and most notably that only Vic can be visible (when they choose) on the computer.

First/Previous: You're here!

Next

#alan becker#animator vs animation#animation vs minecraft#cold thoughts#victim#gold#art#comic#color gang#they're technically here too#but i don't wanna list them all cause they're in one panel#blue's room was hard to draw#but i like how it turned out#btw the white border means nothing it's just to make the writing more visible when needed

158 notes

·

View notes

Text

In which Shimazaki shows up to Minegishi's apartment after his WD disappearance with nothing but a suitcase and an "I live here now." The following seasons bring way more changes than just the weather.

#shimamine#as always this is with the spirit of 'fuck the artbook -- all my homies are unbearably sad about the artbook' -_-#i wanted the last panel to be minegishis first day of work at the flower shop#idk if the timing works out since confession arc is supposed to be like two months after wd or something crazy#but then again im ignoring canon timelines anyway so adfsgf#i also love headcanons where minegishi is plant-like themself so i figured theyd hate the winter and get too cold easily#i think minegishi would get like ten times more plants#shimazaki keeps coming home to find another one sneakily added to the last available surface#they deny it and clear a new space but pretty soon that'd be taken too...#i never draw backgrounds/rooms so i was very happy it turned out decent 😅#the succulent in the last panel is a cameo of my succulent i named minegishi which proceeded to grow ridiculously fast and i now have#separated pieces into various pots and Those grow just as fast

28 notes

·

View notes

Text

Thought I'd throw up some pics of the cold frame I slapped together on my south-facing front porch.

It's mostly made from windows I scavenged this year. There's a bank of them snugged up against the front railing, there are ones on each side held in place with cinder blocks, and the one in back is resting on what I'm using for thermal mass.

It's a row of those Tidy Cats litter tubs filled 3/4 up with water and stuffed into black plastic contractor bags. The plastic bags not only help with the absorption of solar heat, but also fill in the spaces between the tubs. They're only filled 3/4 full because they're inevitably going to freeze at some point--some will crack at the bottom seam but most will make it. I do have plans to go out this weekend on a Styrofoam panel scavenging mission--you know, after people blow all their money on new tvs and stuff on black friday and throw the packaging away. Then I'll insulate the back of the thermal shelf to direct the heat all inward.

The top is just a shower door plus a small window. I can shift/lift them for harvesting and watering.

I've got two regular sized Earthboxes and two smaller in there. The smaller ones are on the ledge and the larger are on the concrete. I've got several lettuces, several spinaches, Swiss chard, and some teeny kale seedlings going. The kale is teeny because the @#@^=$_!! midnight wildlife tore apart the initial transplants when I first planted them in the boxes back in September and I had to restart from seed.

It took me a solid month to work up the energy to put this all together, but only an hour or two to construct. Thankfully, autumn seems to be on a one month delay this year except for one or two short dips below freezing. Looking forward to at least a weekly salad for as long as we don't have another "arctic blast" like we did last year.

#cold frames#they can be as simple and janky as this one and still work to extend your growing season#i'm going to try to get my hands on some more lumber this next year so i can build panels i can just snap together#but this year all the lumber went to the new chicken coop/run and rebuilding the rotting back stairs that i kept slipping and falling on#gardening#extending the growing season#lettuce#spinach#kale#swiss chard#i ran out of room or the green onions would also be out there#instead they're in a basement window

4 notes

·

View notes

Note

I’m living vicariously through you currently!!! It seems like so much fun !

You're so sweet!! I am having a BLAST out here, meeting other cosplayers has been so so fun, having that connection for a second feels incredible, and so does looking at all the merch, looking at all the vocaloid stuff and suddenly feeling very in place (as opposed to out of place lmao) with all my interests. I'm still here for a 3rd day tomorrow too 💖

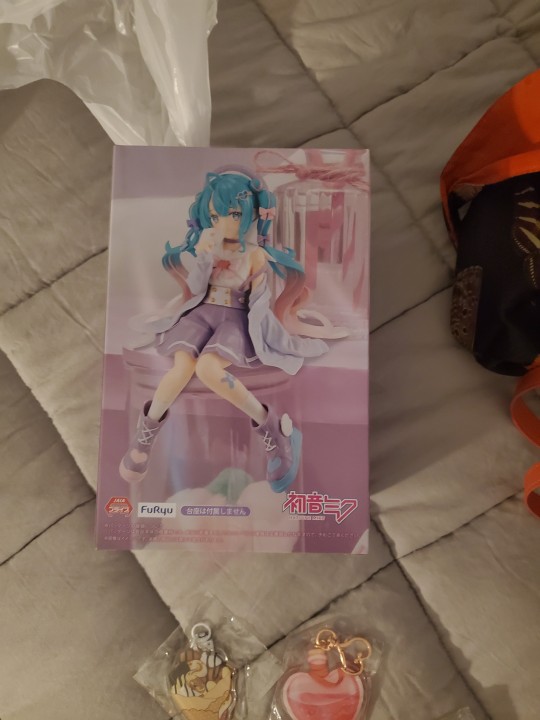

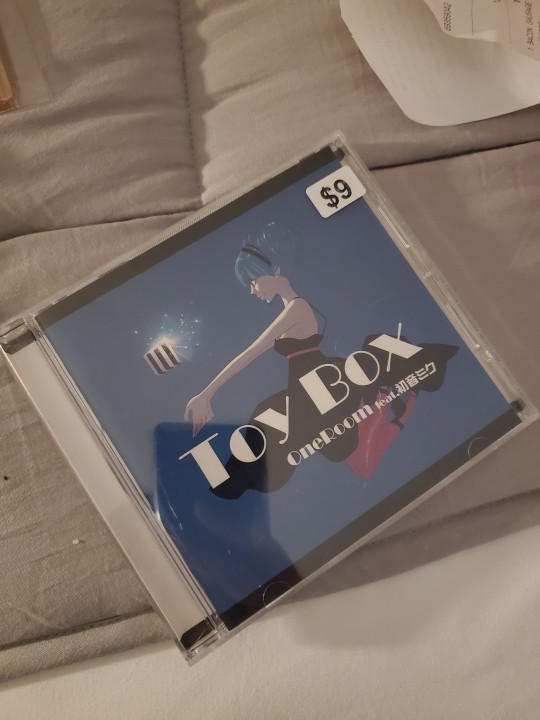

Obligatory post of some of the things I've gotten so far:

The miku album still has me REELING, 14 year old me would be losing his mind having a physical copy of a miku album, also went wild finding those pics on the bottom right, I have no idea what purpose they serve but I saw chimera ants and started grabbing 💖

I met another cosplayer dressed as the same character as me!! They gave me butterfly stickers and I put them on my con badge, I put one on my hand and that's gonna be the first sticker I put on my laptop! I still have some prepwork for my outfit tomorrow but I'm excited to go as my own character and rep bug furries bc no one talks about us 😭 the days have all been pretty long but they're all enjoyable and I'm so glad I braved driving 3 1/2 hours to get to this, I'm having so much fun and I'm glad that's so evident in how I've been talking about this 💖💖💖

#trying to not show the full extent of all the voca stuff ive been getting 😭 i like them... the loids..#actually going to a voca trivia panel rn! dropped by my hotel room to drop off my stuff + violin and all#got some prints i gotta find room for at home too 💖 honestly one of the most fun things is to just sit down by a bug traffic area#and start seeing which outfits you recognize; makes me realize i need to watch more stuff lmao#I've also been carrying around a plushie prop i made all day and i lowkey wanna carry him around to more places#I'm wrapping him in my sweater bc I'm cold and wanna bring it but it's so funny that i look like I'm swaddling him like a baby#he's so cold... i can't just let him freeze...#but yes!! ive been having a lot of fun and I'm gonna keep posting about it bc i love to share things that make me happy :)#also i dropped my phone on the con floor sometime yesterday and only got it back this morning lmao#so there's good people here too lmao!!#thank you this is such a fun ask to get 💖💖💖#asks#shai speaks

2 notes

·

View notes

Text

Modular Cold Storage Rooms – What Are Their Benefits Over Traditional?

Cold storage is a critical component for industries like food processing, pharmaceuticals, and logistics. With advancements in technology, modular cold storage rooms have emerged as a superior alternative to traditional cold storage systems. At EPACK Prefab, we specialize in delivering state-of-the-art modular cold storage solutions that cater to diverse industry needs.

What Are Modular Cold Storage Rooms?

Modular cold storage rooms are prefabricated, insulated chambers designed for temperature-controlled environments. Unlike traditional cold storage, these modular systems are built using prefabricated panels and components that allow for easy assembly, customization, and scalability.

Benefits of Modular Cold Storage Rooms Over Traditional

1. Customization and Flexibility

Modular cold storage rooms are highly customizable, offering:

Tailored dimensions to fit specific space requirements.

Adaptable temperature zones for storing different products.

Scalability, allowing easy expansion as business needs grow.

Traditional cold storage lacks this level of flexibility, making modular systems a more versatile option.

2. Faster Installation

Modular cold storage rooms are prefabricated and delivered ready for assembly. This reduces installation time significantly compared to traditional systems, which often require lengthy on-site construction.

3. Energy Efficiency

Modular systems are designed with advanced insulation materials that minimize energy loss, ensuring consistent temperature control with lower energy consumption. This translates to reduced operational costs compared to traditional cold storage solutions.

4. Cost-Effective

The prefabricated nature of modular cold storage reduces labor and material waste, making it a more cost-efficient option. Additionally, the faster installation process lowers project timelines, further reducing costs.

5. Portability

Modular cold storage rooms can be disassembled, transported, and reassembled at a new location, offering unparalleled portability. This is particularly beneficial for industries that require temporary or mobile storage solutions.

6. Superior Quality and Durability

Constructed in controlled factory environments, modular cold storage systems maintain consistent quality standards. High-quality materials such as PUF (Polyurethane Foam) panels provide excellent thermal insulation and long-lasting performance.

7. Environmentally Friendly

Modular cold storage uses sustainable materials and energy-efficient technologies, reducing its environmental footprint. These systems are also recyclable, aligning with modern sustainability goals.

8. Easy Maintenance

The modular design simplifies maintenance, as individual components can be replaced or upgraded without disrupting the entire system, unlike traditional setups.

Applications of Modular Cold Storage Rooms

Modular cold storage rooms are used across various industries, including:

Food processing and storage (fruits, vegetables, dairy, meat).

Pharmaceuticals (medicines, vaccines, medical supplies).

Logistics and warehousing.

Retail (supermarkets, cold chain transportation).

Why Choose EPACK Prefab for Modular Cold Storage?

At EPACK Prefab, we offer modular cold storage solutions tailored to your specific needs. With advanced technology, superior materials, and energy-efficient designs, we ensure optimal performance and reliability.

Conclusion

Modular cold storage rooms provide unmatched advantages over traditional systems, offering flexibility, energy efficiency, and cost-effectiveness. Whether you’re looking to optimize space, reduce energy costs, or expand your storage capabilities, modular cold storage is the future of temperature-controlled environments.

Contact EPACK Prefab today to explore how our modular cold storage solutions can benefit your business.

Read to Know - Six Reasons why Cold Storage Industry should adopt Prefabrication

#Modular Cold Storage#Prefabricated Cold Rooms#Cold Storage Solutions#Energy Efficient Storage#Cold Chain Logistics#Temperature Controlled Rooms#Sustainable Storage Systems#PUF Panels#Industrial Cold Storage#EPACK Prefab Solutions

0 notes

Text

Comprehensive Guide to Top PUF Panel Manufacturers in India

When constructing energy-efficient buildings or cold storage units, PUF panels play a critical role. Known for their superior insulation properties and durability, PUF (Polyurethane Foam) panels are becoming a preferred choice across India. Whether you're looking for panels for warehouses, industrial buildings, or cold rooms, it’s essential to choose a reliable manufacturer. This guide delves into the top PUF panel manufacturers in India, the best sandwich panel prices, and why Bnal Prefabs stands out among the competition.

What Makes PUF Panels Essential?

Energy Efficiency: PUF panels are renowned for their high thermal insulation, which helps maintain consistent temperatures inside buildings, reducing energy consumption.

Lightweight Yet Durable: These panels are lightweight, which makes them easy to install, yet they provide structural durability and soundproofing.

Versatile Applications: PUF panels are used in cold storage, prefabricated buildings, and industrial setups due to their ability to withstand varying environmental conditions.

Top PUF Panel Manufacturers in India

Here’s a look at the leading PUF panel manufacturers in the country, each known for their unique contributions to the industry:

Bnal Prefabs

Reputation for Quality: As one of the top PUF panel manufacturers in India, Bnal Prefabs is trusted for delivering high-performance panels for both industrial and commercial applications. Their products meet stringent industry standards, making them suitable for a variety of purposes.

Cost-Effective Solutions: Their pricing is competitive, offering some of the best sandwich panel prices in India. This combination of affordability and quality makes them a go-to brand.

Customizable Products: Bnal Prefabs provides tailored solutions to meet client specifications, making them ideal for specialized projects like cold storage units or prefabricated structures.

TATA BlueScope Steel

Known for its innovative steel products, TATA BlueScope also manufactures PUF panels with high insulation properties, making them ideal for industrial and commercial projects.

Kirby Building Systems

Kirby is a global leader in prefabrication and offers premium-quality PUF panels for various construction needs, particularly in industrial sectors.

EPACK Polymers

EPACK delivers PUF panels known for their durability and insulation. They are widely used in cold storage and modular building solutions.

Exploring Sandwich Panel Prices in India

The cost of sandwich panels in India depends on various factors such as thickness, size, and customization requirements. Here’s a breakdown of what to expect in terms of pricing:

Average Price Range: ₹1,500 to ₹2,500 per square meter.

Best Value: Bnal Prefabs offers one of the most competitive rates in the market, providing high-quality panels at an affordable price point. Their panels are ideal for a wide range of applications, including cold rooms, industrial buildings, and warehouses.

Choosing Bnal Prefabs ensures that you get durable panels at some of the best sandwich panel prices in India, without compromising on performance or quality.

Cold Room PUF Panel Manufacturers: Who Stands Out?

Cold storage units require panels that can maintain internal temperatures effectively. Insulation and durability are key when choosing cold room PUF panel manufacturers.

Leading Manufacturers:

Bnal Prefabs

Best for Cold Storage: Bnal Prefabs specializes in cold room PUF panels that provide excellent thermal insulation, ensuring optimal temperature regulation and energy savings. Their products are designed to meet the demands of cold storage facilities and are known for their durability and efficiency.

EPACK Polymers

Known for their reliable and durable panels, EPACK is a preferred choice for many cold room projects.

TATA BlueScope Steel

TATA BlueScope offers customized cold room panels that are known for their superior insulation and longevity.

Why Bnal Prefabs is Your Best Bet for PUF Panels

Among the many PUF panel manufacturers in India, Bnal Prefabs consistently emerges as a top choice. Here are a few reasons why they stand out:

Unmatched Quality: Bnal Prefabs uses advanced technology to ensure their PUF panels meet international quality standards. Whether for commercial or residential use, their panels are engineered for long-lasting performance.

Affordable Pricing: While many manufacturers provide high-quality products, Bnal Prefabs offers a blend of superior quality and competitive pricing, making them the best option for businesses seeking value for money.

Custom Solutions: Each project has unique needs, and Bnal Prefabs excels in delivering PUF panels customized to meet specific requirements, whether it’s cold storage, prefabricated buildings, or industrial spaces.

Nationwide Availability: With operations and distributors across India, Bnal Prefabs ensures timely delivery and service wherever you are located. If you're searching for PUF panel manufacturers near you, they’re one of the most accessible options in the country.

Sustainability: Concerned about the environment? Bnal Prefabs produces eco-friendly PUF panels that contribute to energy savings and reduce environmental impact.

Applications of PUF Panels from Bnal Prefabs

The versatility of PUF panels makes them suitable for various industries. Here’s where Bnal Prefabs’ panels excel:

Cold Storage: Their cold room panels provide exceptional thermal insulation, making them the top choice for cold storage facilities.

Warehouses & Industrial Buildings: The lightweight yet durable design of PUF panels ensures easy installation while offering strong protection against environmental factors.

Prefabricated Buildings: For modular constructions, Bnal Prefabs offers panels that are quick to assemble and cost-effective.

Conclusion: Bnal Prefabs – Leading the PUF Panel Industry in India

When it comes to PUF panel manufacturers in India, Bnal Prefabs clearly stands out for its quality, affordability, and customized solutions. Whether you need cold room PUF panels or panels for industrial projects, Bnal Prefabs is the name you can trust. They offer the best sandwich panel prices in the market, making them a cost-effective yet high-quality option for all your construction needs.

To learn more about their products and services, visit their official website and Click Here and discover how they can help bring your project to life.

#PUF panel manufacturers in India#best sandwich panel prices#cold room PUF panels#PUF panels#Bnal Prefabs

1 note

·

View note

Text

low pressure PU foaming machine india

#PU foaming machines#Polyurethane Foam Making Machine#PU High Pressure Foaming Machine#Rotary Table for thermoware production#Rotary Table for thermoware production in mumbai#Cold room panels#Cold Room PUF Panel#PUF Cold Room Panel Manufacturer#PUF Cold Room Panel Manufacturer in mumbai#PUF Cold Room Panel Manufacturer in india#cold room panels manufacturer#cold room panels manufacturer in mumbai#cold room panels manufacturer in india#clean room panels#clean room panels manufacturers#clean room panels manufacturers india#clean room panels manufacturers mumbai#PUF insulated panels#PUF insulated panels in mumbai#PUF insulated panels in india#PUF insulated doors#Manufacturer of PUF Insulated Doors#PUF insulated doors in mumbai#PUF insulated doors in india

0 notes

Text

Insulated Wall Panels and Cool Room Panels Manufacturers near Sydney

Most trusted manufacturer and supplier of cold room panels and accessories for internal and external cold store applications. Contact now for more information or visit website.

0 notes

Text

What are the advancements in cold room panel technology?

When building efficient and effective cold storage solutions, the technology behind cold room panels plays a crucial role. As the cold storage industry evolves, so do the technologies supporting it. For businesses and professionals, staying informed about the latest advancements can make a significant difference in choosing the best solutions for their needs. This blog post will explore some of the most exciting advancements in cold room panel technology, highlighting how these innovations can benefit your cold storage operations. If you're looking for cutting-edge solutions, you'll also want to know what the leading Cold Room Panels Manufacturers offer. Let's dive into the latest developments!

Enhanced Insulation Materials

One of the most significant advancements in cold room panel technology is the improvement of insulation materials. Traditional panels used materials like polystyrene (PS) or polyurethane (PU), but innovations are pushing the boundaries.

Polyisocyanurate (PIR) Panels: PIR is becoming increasingly popular due to its superior thermal insulation properties compared to conventional polyurethane panels. With a higher R-value per inch of thickness, PIR panels offer better energy efficiency and reduced operational costs. They also have improved fire resistance, which is crucial for safety and compliance with modern regulations.

Vacuum Insulated Panels (VIPs): VIPs represent the pinnacle of insulation technology. These panels contain a vacuum between two layers of material, which significantly minimizes heat transfer. While more expensive, VIPs offer superior thermal performance and are perfect for environments requiring extreme temperature control.

Aerogel Panels: Aerogel technology is another emerging option. Aerogels are among the lightest materials available and have exceptional thermal insulating properties. Though currently more niche due to cost, aerogel panels are a cutting-edge solution for high-end cold storage applications.

Sustainable and Eco-Friendly Materials

As the world increasingly focuses on sustainability, cold room panel manufacturers respond with eco-friendly options.

Recycled Content Panels: Many manufacturers are now offering panels made from recycled materials. For example, some cold room panels use recycled paper or plastics in their core materials. This not only reduces waste but also lowers the environmental impact of production.

Green Certifications: Look for cold room panels with certifications like LEED (Leadership in Energy and Environmental Design) or similar eco-labels. These certifications indicate that the products meet rigorous standards for energy efficiency, indoor environmental quality, and overall sustainability.

Low-GWP Refrigerants: In addition to sustainable panel materials, there's a shift towards using low Global Warming Potential (GWP) refrigerants in cold storage systems. Cold room panels designed to work efficiently with these refrigerants help reduce the overall environmental impact of the cold storage process.

Improved Panel Construction Techniques

Advancements in construction techniques are enhancing the durability and performance of cold room panels.

Advanced Bonding Technologies: The bonding process between the insulation core and outer skins has evolved. New adhesive technologies ensure stronger, longer-lasting bonds that resist delamination and maintain thermal performance over time.

Modular Design: Modular panel systems are becoming more prevalent. These systems allow quicker assembly and disassembly, particularly useful for temporary or reconfigurable cold storage spaces. Modular panels also offer flexibility in design, allowing for custom solutions that fit specific operational needs.

Seamless Connections: Innovations in joint design have led to the development of seamless connections that improve insulation performance. New interlocking mechanisms and gaskets prevent thermal bridging and ensure a more efficient cold storage environment.

Smart Cold Room Panels

Technology integration makes cold room panels smarter and more responsive to environmental changes.

Embedded Sensors: Modern cold room panels can be equipped with embedded sensors that monitor temperature, humidity, and other conditions in real-time. This data can be used to optimize storage conditions, predict maintenance needs, and ensure compliance with regulations.

IoT Integration: The Internet of Things (IoT) is also extending to cold room panels. IoT-enabled panels can be connected to central management systems, allowing for remote monitoring and control of cold storage environments. This technology enhances operational efficiency and helps identify issues before they become major problems.

Innovative Aesthetic and Functional Designs\

Cold room panels are not just about performance anymore—they're also about aesthetics and functionality.

Custom Finishes: Advances in manufacturing processes allow for various finishes and colours tailored to specific needs. Whether it's a clean, white surface for a pharmaceutical storage room or a rugged, industrial look for a warehouse, there are more options than ever.

Enhanced Hygienic Properties: New panel designs include features that make them easier to clean and maintain. Smooth surfaces and antimicrobial coatings help ensure that cold rooms remain hygienic, which is essential for industries dealing with food and pharmaceuticals.

Choosing the Right Cold Room Panels Manufacturers

As you explore these advancements, selecting the right Cold Room Panels Manufacturers is crucial. Leading manufacturers are adopting these new technologies and offering state-of-the-art solutions. When choosing a manufacturer, consider factors like:

Product Quality: Look for manufacturers who use high-quality materials and adhere to industry standards.

Innovation: Choose manufacturers who invest in research and development to stay at the forefront of technology.

Customer Support: Good manufacturers offer comprehensive support, including installation guidance, maintenance services, and technical assistance.

Sustainability: Opt for manufacturers committed to environmentally friendly practices and products.

Conclusion

The cold room panel technology field is advancing rapidly, driven by the need for better insulation, sustainability, and innovative features. There's a lot to be excited about, from enhanced insulation materials like PIR and VIPs to eco-friendly options and smart technologies. Understanding these advancements and partnering with top Cold Room Panels Manufacturers can lead to more efficient, cost-effective, and sustainable cold storage environments for businesses looking to invest in cold storage solutions.

As you evaluate your cold storage needs, monitor trends and seek out manufacturers who offer the latest technologies. By staying informed and choosing the right partners, you can ensure that your cold room panels meet today's demands and are prepared for the future.

0 notes

Text

How Do Cold Room Doors Manufacturers Ensure Optimal Insulation and Temperature Control?

When preserving perishable goods, be it in the food industry, pharmaceuticals, or any sector where maintaining a specific temperature is crucial, cold room doors are at the forefront of this critical task. As one of the leading Cold Room Doors Manufacturers, Isoflex takes pride in delivering top-notch products that meet the highest insulation and temperature control standards. But what goes into making a cold room door truly effective? Let's delve into the intricate process that ensures our doors are second to none.

Isoflex: Leading the Way in Cold Room Door Manufacturing

At Isoflex, we have perfected the art of manufacturing cold room doors through years of research, innovation, and a deep understanding of our customers' needs. Our doors are engineered to provide superior insulation, robust durability, and seamless operation, ensuring your cold rooms perform at their best.

Isoflex manufactures cold room doors through a meticulous process that combines cutting-edge technology with skilled craftsmanship. Here's how we ensure our doors meet the highest quality and performance standards.

Design and Engineering

Every Isoflex cold room door starts with a detailed design phase. Our engineers use advanced computer-aided design (CAD) software to create precise specifications for each door. This includes determining the optimal insulation thickness, selecting the appropriate materials, and designing the door frame and sealing mechanisms. Our design process is guided by industry standards and best practices, ensuring that each door meets rigorous performance criteria.

Material Selection

We source high-quality stainless steel, galvanized steel, and polyurethane foam from trusted suppliers. Each material undergoes stringent quality checks to ensure it meets our strength, thermal resistance, and longevity standards.

Foam Injection

This is done using state-of-the-art machinery that ensures the foam is evenly distributed and fully expanded within the panel. The foam is then allowed to cure, forming a rigid core that provides excellent thermal insulation.

Assembly

Once the insulation is in place, the door panels are assembled with the outer and inner metal surfaces. This step involves precision welding and riveting to create a seamless and robust structure. The door frames are attached, and the entire assembly is inspected for structural integrity and alignment.

Sealing and Gasket Installation

The next step involves installing high-performance gaskets around the edges of the door. These gaskets are carefully fitted to ensure a tight seal when the door is closed. We also incorporate a unique interlocking system that enhances the sealing effectiveness, preventing air leakage and maintaining the internal temperature.

Quality Control

Each Isoflex cold room door undergoes rigorous tests to ensure it meets our standards for insulation, durability, and performance. These include thermal imaging tests to detect potential insulation gaps, pressure tests to check for air leakage, and durability tests to assess the door's resistance to wear and tear.

Customization and Finishing

The final step in the manufacturing process involves customizing the door to meet our customers' specific requirements. This can include adding features such as viewing windows, automated opening systems, or heated door frames.

Why Choose Isoflex?

Choosing Isoflex as your Cold Room Doors Manufacturer means partnering with a company that prioritizes quality, innovation, and customer satisfaction.

Customized Solutions

We understand that every customer has unique needs. We offer customizable options to tailor our cold room doors to your requirements. Whether you need a particular size, colour, or special features, we can provide a solution that fits your needs.

Commitment to Quality

At Isoflex, quality is our top priority. We use only the best materials and adhere to strict manufacturing processes to ensure the highest quality of our cold room doors. Our rigorous quality control measures ensure that every door we produce meets our exacting standards.

Excellent Customer Service

We pride ourselves on providing exceptional customer service. From the initial consultation to the installation and beyond, our team is dedicated to ensuring your satisfaction. We are always available to answer your questions and provide support whenever needed.

Competitive Pricing

We offer competitive pricing without compromising on quality. Our efficient manufacturing processes and strong supplier relationships allow us to provide high-quality cold room doors at affordable prices.

Conclusion

As one of the leading Cold Room Doors Manufacturers, Isoflex is committed to providing superior products that ensure optimal insulation and temperature control. Our cold room doors are designed and manufactured with precision, using high-quality materials and advanced technology to meet the diverse needs of various industries. With a focus on quality, innovation, and customer satisfaction, Isoflex is your trusted partner for all cold room door needs. Choose Isoflex for reliable, energy-efficient, and durable cold room doors that keep your products at their best.

0 notes

Text

What Are the Latest Trends in Cold Room Panels Manufacturing?

Cold room panels are at the forefront of innovation and efficiency in the ever-evolving landscape of cold storage solutions. As a leading name in the industry, Isoflex is proud to be at the cutting edge of these advancements, ensuring that our products not only meet but exceed our clients' expectations. In this blog post, we delve into the latest trends in cold room panel manufacturing and highlight why Isoflex is the best choice among cold room panels manufacturers.

Understanding Cold Room Panels

Cold room panels are essential components in the construction of cold storage facilities. These panels provide the necessary insulation to maintain low temperatures, crucial for preserving perishable goods, pharmaceuticals, and other temperature-sensitive items. Isoflex produces high-quality cold room panels that offer superior thermal insulation, durability, and energy efficiency.

Trend 1: Enhanced Insulation Materials

One of the most significant trends in cold room panel manufacturing is the development and use of advanced insulation materials. Traditional materials like polyurethane (PU) and polystyrene (EPS) are now being supplemented or replaced by more efficient options such as polyisocyanurate (PIR) and vacuum-insulated panels (VIPs).

Polyisocyanurate (PIR): PIR offers better fire resistance and thermal performance than PU.

Vacuum Insulated Panels (VIPs): VIPs consist of a core material enclosed in a vacuum-sealed barrier, providing exceptional insulation properties.

At Isoflex, we incorporate these advanced materials into our cold room panels, ensuring that our products deliver top-tier performance in terms of insulation and safety.

Trend 2: Sustainable and Eco-Friendly Solutions

With growing environmental concerns, sustainability has become a key focus in cold room panels manufacturing. Manufacturers increasingly adopt eco-friendly practices and materials to reduce their carbon footprint and promote energy efficiency.

Isoflex is committed to sustainability. We produce our cold room panels using recyclable materials and eco-friendly manufacturing processes. Our panels are designed to reduce energy consumption, lowering our clients' greenhouse gas emissions and operational costs.

Trend 3: Smart Technology Integration

The integration of smart technology into cold room panels is revolutionizing the industry. Smart panels have sensors and IoT (Internet of Things) devices that monitor and control real-time temperature, humidity, and other environmental factors. This technology ensures optimal storage conditions, reduces energy consumption, and minimizes the risk of spoilage.

At Isoflex, we leverage the latest advancements in smart technology to offer intelligent cold room solutions. Our panels can be integrated with advanced monitoring systems that provide real-time data and alerts, helping clients maintain precise control over their storage environments.

Trend 4: Modular and Flexible Designs

Flexibility and modularity are increasingly important in designing and manufacturing cold room panels. Modular panels allow for easy and quick assembly, disassembly, and reconfiguration, providing greater adaptability to changing storage needs and facility expansions.

Isoflex's cold room panels are designed with modularity in mind. They are easy to install and can be customized to fit any space, making them ideal for a wide range of applications, from small storage rooms to large industrial cold storage facilities.

Trend 5: Enhanced Durability and Longevity

Durability is critical in cold room panels, as these structures must withstand extreme temperatures, moisture, and physical wear and tear. Recent advancements in materials and manufacturing techniques have significantly improved the durability and longevity of cold room panels.

Isoflex uses state-of-the-art materials and manufacturing processes to ensure our panels are robust and long-lasting. Our panels feature corrosion-resistant coatings and reinforced structures, providing exceptional durability and reliability even in the harshest conditions.

Why Isoflex is the Best Among Cold Room Panels Manufacturers?

At Isoflex, we pride ourselves on being at the forefront of innovation in cold room panels manufacturing. Here's why we stand out as the best choice among cold room panels manufacturers:

Superior Quality

Quality is our top priority. We use the finest materials and employ stringent quality control measures to ensure our cold room panels meet the highest performance and reliability standards. Our commitment to quality ensures that our clients receive products that deliver unmatched insulation and durability.

Customization and Flexibility

We understand that every client has unique requirements. That's why we offer various customization options for our cold room panels. Whether you need specific dimensions, insulation materials, or integrated smart technology, Isoflex can tailor our panels to meet your needs.

Sustainability

As a responsible manufacturer, we are dedicated to sustainability. Our eco-friendly manufacturing practices and energy-efficient products help reduce environmental impact and operational costs.

Innovation

Our innovative approach ensures that our clients benefit from the latest advancements in cold room panel technology.

Expert Support

We offer comprehensive support services, including installation, maintenance, and technical assistance. Our team of experts is always ready to provide guidance and support to ensure our clients get the most out of their cold room panels.

Conclusion

The world of cold room panel manufacturing is rapidly evolving, driven by advancements in materials, technology, and sustainability. As a leading name in the industry, Isoflex is committed to staying at the forefront of these trends and providing our clients with top-quality, innovative, eco-friendly cold room panels.

Whether you are looking to build a new cold storage facility or upgrade an existing one, Isoflex has the expertise, technology, and commitment to deliver the best solutions. As the best cold room panels manufacturers, we ensure that our products meet the highest performance, durability, and sustainability standards. Trust Isoflex to provide you with the cutting-edge cold storage solutions you need to stay ahead in a competitive market.

0 notes

Text

What Are the Key Factors to Consider When Choosing Clean Room Doors Manufacturers?

Maintaining a clean and contaminant-free atmosphere is crucial in highly controlled environments like laboratories, pharmaceutical production areas, and high-tech manufacturing plants. The effectiveness of these environments often hinges on the quality of their infrastructure, especially the doors. Clean room doors serve as vital barriers, preventing the entry of contaminants and maintaining the required level of cleanliness.

Therefore, selecting the rightclean room doors manufacturers is a critical decision.

At Isoflex, we pride ourselves on being the best in the industry, providing top-tier clean room doors that meet the highest quality and performance standards. In this blog, we'll delve into the essential factors to consider when choosing clean room doors manufacturers and explain why Isoflex stands out as the leading choice.

Understanding the Importance of Clean Room Doors

Clean room doors are not just simple entry points but sophisticated components designed to maintain strict environmental control. Given their critical role, it is imperative to choose manufacturers who understand these requirements and can deliver products that meet stringent standards.

Key factors-

Quality and Compliance

The primary consideration when selecting clean room doors manufacturers is the quality of their products. High-quality doors ensure long-term reliability and effective contamination control. Look for manufacturers who adhere to international standards and certifications such as ISO, GMP (Good Manufacturing Practices), and FDA guidelines. These certifications indicate that the manufacturer meets rigorous quality and safety standards.

Customization Options

Clean rooms vary significantly in their design and requirements. Hence, it is crucial to choose a manufacturer that offers customizable solutions. This includes customizing door sizes, materials, finishes, and additional features like automated operation, interlocking systems, and vision panels. Customization ensures that the doors perfectly fit the specific needs of your clean room.

Material Selection

The materials used to construct clean room doors significantly affect their performance. Common materials include stainless steel, aluminium, and high-grade plastics, each offering different benefits. For instance, stainless steel is highly durable and corrosion-resistant, making it ideal for environments with stringent hygiene requirements. Evaluate the manufacturer's material options and ensure they align with your clean room's needs.

Installation and Maintenance Services

A reliable manufacturer should supply high-quality doors and offer professional installation and maintenance services. Proper installation is crucial to ensure the doors function correctly and maintain the clean room's integrity. Additionally, regular maintenance and prompt repair services are essential to extend the lifespan of the doors and prevent any operational disruptions.

Technological Advancements

Incorporation of advanced technologies in clean room doors can enhance their functionality and user convenience. Features such as automatic sliding or swing mechanisms, touchless operation, and integration with access control systems can significantly improve efficiency and hygiene. Choose manufacturers who stay abreast of technological advancements and incorporate them into their products.

Reputation and Experience

A manufacturer's reputation and experience in the industry are strong indicators of their reliability. Research the manufacturer's history, customer reviews, and case studies to gauge their credibility and expertise. Experienced manufacturers will likely better understand clean room requirements and can provide more reliable and innovative solutions.

Cost-Effectiveness

While quality should never be compromised, it is also essential to consider the cost-effectiveness of the products. Evaluate the manufacturer's overall value, considering factors such as product quality, customization options, warranty, and after-sales service. Opt for manufacturers who provide a good balance between quality and affordability.

Why Isoflex is the Best Choice for Clean Room Doors?

At Isoflex, we excel in all the factors mentioned above, making us the industry's best clean room doors manufacturers. Here's why:

Unmatched Quality and Compliance

Isoflex is committed to delivering the highest quality clean room doors. Our products meet and exceed international standards, including ISO and GMP certifications. We use premium materials and state-of-the-art manufacturing processes to ensure that our doors provide superior performance and longevity.

Comprehensive Customization Options

That's why we offer extensive customization options. Whether you need specific door sizes, materials, finishes, or advanced features, we can tailor our products to meet your needs. Our expert team works closely with clients to design and manufacture doors perfectly fitting their clean room environments.

High-Quality Materials

Isoflex clean room doors are made from the finest materials, including stainless steel, aluminium, and high-grade plastics. These materials are selected for their durability, corrosion resistance, and ability to withstand rigorous cleaning protocols. Our doors are designed to maintain integrity and appearance even in the most demanding environments.

Professional Installation and Maintenance

We provide comprehensive installation services to ensure our clean room doors are correctly fitted and fully operational. Our team of skilled technicians has extensive experience installing clean room doors and adheres to the highest standards of workmanship. Additionally, we offer ongoing maintenance services to keep your doors in optimal condition and address any issues promptly.

Innovative Technological Features

Isoflex integrates the latest technological advancements into our clean room doors. From automatic sliding mechanisms to touchless operation and advanced access control systems, our doors are designed to enhance convenience, efficiency, and hygiene. We continuously invest in research and development to bring cutting-edge solutions to our clients.

Proven Reputation and Experience

With years of experience in the industry, Isoflex has built a solid reputation for excellence. We have completed numerous projects for leading companies in various sectors, including pharmaceuticals, biotechnology, electronics, and more. Our record of delivering high-quality products and exceptional customer service speaks for itself.

Cost-Effective Solutions

At Isoflex, we believe in providing the best value to our clients. Our clean room doors are competitively priced without compromising on quality. We offer comprehensive warranties and after-sales support to ensure our clients get the most out of their investment. With Isoflex, you get premium quality at a reasonable price.

Conclusion

Choosing the right clean room doors manufacturer is a crucial decision that can significantly impact your clean room's performance and reliability. Consider factors such as quality, customization options, material selection, installation and maintenance services, technological advancements, reputation, and cost-effectiveness to make an informed choice.

Isoflex stands out as the leading manufacturer of clean room doors, offering unparalleled quality, comprehensive customization, high-quality materials, professional installation and maintenance, innovative features, a proven reputation, and cost-effective solutions. Trust Isoflex for your cleanroom door needs and experience the difference that comes with partnering with the best in the industry.

Contact us today to learn more about our products and services and how we can help you maintain the highest cleanliness and efficiency standards in your clean room environment.

0 notes

Text

My internet goes back to the library today. It looks like the wait will be pretty short this time (maybe 2 weeks?).

In that time I hope to accomplish not much of anything. I hope to become a slug. To rest and to read a lot and maybe sort through some things in the house, but maybe not.

Time to lie fallow before the prep for the spring garden begins.

#i did drag home an adjustable wire shelving unit yesterday that will fit in the bathroom and work better for seed trays#(the bathroom is the warmest room in the house and has lots of sunlight so seed starting happens there)#i do need to rework my cold frames before Wednesday when the temperature drops--it's just been drizzling constantly here or it'd be done#i also dragged home two new free houseplants and four curtain panels#the curtains i'll use over the basement door as it's made of plywood instead of being an actual door and the curtains should help insulate#(when not in use)#also there were a lot of those cheap christmas food gifts passed along in the food waste pickup for the chickens this week#(you know like a festive mug with pkg of hot cocoa or a variety of tiny jams)#being unopened i poached them for me#so now have a tripartite tin of popcorn and pkg of flavored macarons and a block of bourbon fudge plus others#festive new year to me!#(don't worry the chickens got a massive amount of baby greens and chopped salad mixes and xmas leftovers which they greatly prefer)

1 note

·

View note

Text

Innovations in Cold Room Door Technology: What's New in the Industry

In the ever-evolving world of refrigeration, cold room door technology has seen significant advancements, driven by the need for greater energy efficiency, enhanced security, improved hygiene, and user-friendly designs. As Cold Room Doors Manufacturers continue to innovate, the industry is witnessing new products and technologies that cater to diverse needs across sectors like food storage, pharmaceuticals, and logistics. In this blog, we will explore the latest cold room door technology innovations and how they are revolutionizing the industry.

Smart Door Systems

Integrating smart systems is one of the most significant trends in cold room door technology. These systems leverage IoT (Internet of Things) for real-time monitoring and control. Smart cold room doors can now be equipped with sensors that monitor temperature, humidity, and door status. These sensors can alert operators to anomalies, ensuring that the cold room's environment remains optimal and preventing spoilage or damage to stored goods.

Moreover, smart systems can automate door operations, reducing the need for manual intervention. For instance, motion sensors can detect when someone approaches and automatically open the door, ensuring that it remains closed as much as possible to maintain temperature stability.

Energy-Efficient Solutions

Energy efficiency remains a top priority for Cold Room Doors Manufacturers. Innovations in insulation materials and door sealing technologies have significantly reduced energy consumption. High-performance insulating materials such as vacuum-insulated panels (VIPs) and advanced polyurethane foams provide superior thermal resistance, helping to maintain the desired internal temperature with minimal energy expenditure.

Developing advanced sealing mechanisms, including magnetic gaskets and multi-point locking systems, has also improved the airtightness of cold room doors. These features minimize air leakage, crucial for maintaining energy efficiency and reducing operational costs.

Hygienic Designs

Maintaining hygiene is paramount in industries such as food processing and pharmaceuticals. Recent innovations in cold room door technology have focused on creating designs that are easy to clean and resistant to microbial contamination. Stainless steel surfaces, antimicrobial coatings, and smooth, seamless door designs help prevent the accumulation of dirt and bacteria.

Furthermore, automated door operation reduces the need for physical contact, lowering the contamination risk. Hands-free operation, achieved through foot pedals or motion sensors, ensures that cold room environments remain hygienic and safe for sensitive products.

Enhanced Security Features

Security is critical for cold storage facilities, particularly those storing valuable or sensitive items. Cold room door technology innovations now include advanced security features such as biometric access control, RFID (Radio-Frequency Identification) systems, and remote monitoring capabilities.

Biometric systems, which use fingerprint or facial recognition, ensure that only authorized personnel can access the cold room. RFID systems can track who enters and exits, providing detailed logs and enhancing traceability. Remote monitoring allows managers to oversee multiple cold rooms from a central location, ensuring that security protocols are always maintained.

Improved Durability and Longevity

Durability is a key consideration for cold room doors, as they must withstand frequent use and harsh conditions. Cold Room Doors Manufacturers are now using more robust materials and construction techniques to enhance the longevity of their products. High-grade stainless steel, corrosion-resistant coatings, and reinforced door frames contribute to doors that can endure the rigours of industrial use without compromising performance.

Additionally, some manufacturers incorporate impact-resistant features to protect doors from accidental damage caused by forklifts or other machinery. These innovations not only extend the lifespan of the doors but also reduce maintenance costs and downtime.

Customizable Solutions

Every cold storage facility has unique requirements, and customizable solutions are becoming increasingly popular. Cold Room Doors Manufacturers now offer a wide range of customization options to meet specific needs. These options include size, insulation thickness, door type (hinged or sliding), and additional features like windows or pass-throughs.

Customization ensures that the cold room doors fit perfectly within the existing infrastructure and meet the facility's operational needs. It also allows businesses to optimize their storage environments for maximum efficiency and productivity.

Rapid Roll-Up Doors

Rapid roll-up doors are a game-changer for high-traffic cold storage areas. These doors are designed to open and close quickly, minimizing the time the door remains open and thus reducing temperature fluctuations. Rapid roll-up doors are ideal for facilities requiring frequent access, such as loading docks and processing areas.

These doors' fast operation is often complemented by advanced safety features, including soft-edge technology and automatic reversing mechanisms, which prevent accidents and injuries. Using durable, insulated curtain materials also ensures that energy efficiency is maintained even with the high frequency of use.

Integration with Building Management Systems (BMS)

Modern cold room doors can be integrated with Building Management Systems (BMS) for centralized control and monitoring. This integration allows for seamless temperature, humidity, and access control management across the entire facility. BMS integration provides valuable data insights, helping facility managers optimize operations, identify inefficiencies, and implement preventative maintenance strategies.

By integrating cold room doors with BMS, businesses can achieve greater operational efficiency, reduce energy consumption, and ensure compliance with regulatory standards. This holistic approach to facility management is becoming increasingly essential in the competitive landscape of cold storage.

Noise Reduction Features

Noise pollution is common in busy cold storage facilities, particularly in urban areas. Cold room door technology innovations now include noise reduction features to create a quieter working environment. Soundproofing materials and design enhancements help minimize the noise generated during door operation.

These noise reduction features are particularly beneficial in facilities where maintaining a quiet environment is crucial, such as pharmaceutical labs or food processing plants. Businesses can improve workplace conditions and enhance overall productivity by reducing noise levels.

Sustainability and Eco-Friendly Materials

Sustainability is a growing concern across all industries, and cold room door technology is no exception. Cold Room Door Manufacturers are increasingly focusing on eco-friendly materials and sustainable manufacturing practices. To reduce their environmental impact, they are adopting recyclable materials, low-VOC (volatile organic compounds) coatings, and energy-efficient production processes.

Additionally, some manufacturers are exploring using renewable energy sources for production and integrating sustainable practices throughout the supply chain. These efforts contribute to environmental conservation and align with the growing demand for sustainable products from consumers and businesses alike.

Conclusion

The cold room door industry is undergoing a significant transformation, driven by technological advancements and the evolving needs of various sectors. Innovations in smart systems, energy efficiency, hygiene, security, durability, customization, rapid roll-up doors, BMS integration, noise reduction, and sustainability are shaping the future of cold storage solutions.

As Cold Room Doors Manufacturers continue to innovate, businesses can expect more efficient, secure, and sustainable cold room environments. These advancements not only improve operational efficiency and reduce costs but also ensure the safety and quality of stored products. By staying abreast of the latest trends and technologies, businesses can make informed decisions and invest in cold room doors that meet their specific needs and future-proof their operations.

Whether you are in the food industry, pharmaceuticals, logistics, or any sector requiring reliable cold storage, the latest innovations in cold room door technology offer a range of benefits that can enhance your operations. Embracing these advancements will ensure that your cold storage facilities remain at the forefront of efficiency, safety, and sustainability.

#Clean Room Doors Manufacturers#Cold Room Panels Manufacturers#Rockwool Sandwich Panels Manufacturers

0 notes