#clean room panels

Explore tagged Tumblr posts

Text

The Evolution of Clean Room Panels: Materials, Design & Innovations

Modular Clean Room Panels revolutionize controlled environments with flexible, cost-effective solutions. These prefabricated wall systems enable quick installation, relocation, and customization as per project needs. Constructed from GI, aluminum, or stainless steel with PUF, PIR, or Rockwool insulation, they offer superior durability and contamination control for pharmaceutical, food, and chemical industries.

0 notes

Text

Unlocking the Secrets to Rapid Decluttering

Once upon a time, in a quaint town named Harmonyville, lived Clara, a spirited woman with a penchant for adventure but a perpetual struggle to keep her home in order. One day, as Clara was navigating through a maze of misplaced belongings and forgotten corners, she stumbled upon a mysterious book titled “Home Harmony: Your Guide to Order Almost Immediately.”

*Read more [ Here ]

0 notes

Text

Best Manufacturers of clean rooms for pharmaceutical industries

Pharmaceutical manufacturing is constantly ended in clean and controlled environments. Mak clean air systems supply packing materials to pharmaceutical Industries have to maintain the uppermost values in guaranteeing that the pertinent hygiene, cleanliness and microbial-free environments.

Who Needs a Cleanroom

There are a variety of reasons that a corporation may need a cleanroom. If you are manufacturing products that is easily affected by impurities in the air, then you need to go for a cleanroom. Cleanrooms are used in each and every industry where small particles can harmfully affect the manufacturing process. They also vary in size generously used in various industries

· Semiconductor manufacturing,

· Pharmaceuticals,

· Biotech

· Medical device

· Electronic Part Production

· Aerospace Industry

· Nanotechnology production

· Optics and Lens Manufacturing

· Military Applications

Types of Cleanrooms

Air Handling Units

MAK Clean Air Systems is decided to Economical, well-constructed and efficient alternative to both a large and more expensive air handling Units. These AHU are also available for indoor applications and are furnished with blowers.

Turnkey Clean Rooms

High quality Durable Turnkey Clean Rooms provides design, installation service & construction of our professional modular clean rooms throughout India. We offer complete turnkey services for our projects whether it is large and small & also serve various types of industries. Our experienced construction team impact designs through practical as well as cost-effective solutions, serviceability, constructability & energy efficiency

Clean Room HVAC System

Our reliable Clean room HVAC system has many various features that need specific care to be successful. Many industries have occupied to apply remarkable clean room panels to generate the best environment. Best Clean Room HVAC Systems requires a high standard construction and should build with walls which are airtight & have smooth internal finishes for easy.

#Clean Room HVAC System#HVAC cleaning#modular clean room manufacturers#clean room panels#clean room partitions exporters

0 notes

Text

Cleanroom Ceiling Panels – Durable, Insulated, and Customizable Solutions

Cleanroom Ceiling Panels are designed for walk-on and non-walk-on applications, ensuring superior durability and contamination control. Made from powder-coated GI, pre-painted GI, or stainless steel, these panels feature PUF, PIR, or ROCKWOOL insulation for thermal efficiency. With food-grade silicone sealing, customizable sizes, and HVAC cutouts, they offer a reliable, high-performance ceiling solution.

0 notes

Text

Global Clean Room Panels Market Research Report 2017: Radiant Insights,Inc

In this report, the global Clean Room Panels market is valued at USD XX million in 2016 and is expected to reach USD XX million by the end of 2022, growing at a CAGR of XX% between 2016 and 2022.

Download Full Research Report: https://www.radiantinsights.com/research/global-clean-room-panels-industry-2017

Geographically, this report is segmented into several key Regions, with production, consumption, revenue (million USD), market share and growth rate of Clean Room Panels in these regions, from 2012 to 2022 (forecast), covering • North America • Europe • China • Japan • Southeast Asia • India

Global Clean Room Panels market competition by top manufacturers, with production, price, revenue (value) and market share for each manufacturer; the top players including • AES Clean Technology • Pacific Panels • Metecno • Terra Universal • CGC • MRC Cleanrooms • PortaFab Corporation • American Cleanroom Systems • Fabtech Technologies International • Crane Composites

Request a Free Sample Copy of this Report: https://www.radiantinsights.com/research/global-clean-room-panels-industry-2017/request-sample

On the basis of product, this report displays the production, revenue, price, market share and growth rate of each type, primarily split into • Cleanroom Ceiling Panels • Cleanroom Window Panels • Cleanroom Wall Panels • Cleanroom Door Panels • Cleanroom Floor Panels

On the basis on the end users/applications, this report focuses on the status and outlook for major applications/end users, consumption (sales), market share and growth rate of Clean Room Panels for each application, including • Food Industry • Life Science and Medical Device Manufacturing • Optical Industry • Electronic & Semiconductor Industry • Hospitals • Research Institutes & Laboratories • Biotech & Pharmaceutical Industry • Others

See More Reports of This Category by Radiant Insights: https://www.radiantinsights.com/catalog/consumer-goods

About Radiant Insights Radiant Insights is a platform for companies looking to meet their market research and business intelligence requirements. It assist and facilitate organizations and individuals procure market research reports, helping them in the decision making process. The Organization has a comprehensive collection of reports, covering over 40 key industries and a host of micro markets. In addition to over extensive database of reports, experienced research coordinators also offer a host of ancillary services such as, research partnerships/ tie-ups and customized research solutions.

Contact Details: Michelle Thoras Corporate Sales Specialist, USA Grand View Research, Inc. 201 Spear St #1100, Suite #3036 San Francisco, CA 94105 Phone: 1-415-349-0054 Toll Free: 1-888-202-9519 Email: [email protected] Web: http://www.radiantinsights.com/

#Clean Room Panels Market#Clean Room Panels#Clean Room Panels Industry#Market Research#Marketing Research

0 notes

Text

Top Clean Room Equipment Suppliers In India

A cleanroom is a measured environment where every product are manufactured and even tested. The purposes of the clean room operations include cleansing, removal of microorganisms, removal of dust particles, anticipation of the discharge of particulates into the atmosphere, regulator of pressures and moisture etc…In partnership for many years with pharmaceutical and biotech industries, Mak clean Air system has established equipment used in clean rooms production.Mak clean Air System is a full-service manufacturer, supplier, Exporter of superior quality products to various industries like Pharmaceutical, Medical and Industrial cleanrooms. An important part of protecting a clean room set for use is Clean Room Equipment.Mak clean room equipment includes Air Shower, Laminar Flow Cabinet, HVAC, Pass Through Box, Biosafety Cabinet, Modular Operation Theatre etc…

Specifications

Type :Progressive / Non Progressive

Panel thickness :25/50/80/100 mm (Infil + Return Raisers)

Skin thickness :0.6/0.8 mm

Moc :Pre Coated GI / Powder coated / HPLC / GRP On Galvanized Sheets

Infil ( optional) :40 Kg / m of PUF,3 15 kg / m of EPS,3 80 kg / m of Rock Wool

Panel to Panel Joint :Extruded Aluminum / GI profile

#clean room panels#Clean Room HVAC System#Clean Room HVAC Equipment#clean room partitions exporters#HVAC cleaning

0 notes

Text

Clean Room Panels: A Cost-Effective and Flexible Solution

Clean room panels offer a modern, efficient, and economical alternative to traditional construction. These modular wall systems enable quick installation of prefabricated enclosures, labs, and offices while reducing engineering and labor costs. Their non-progressive design ensures easy relocation or modification, making them highly adaptable. Tailor-made to project requirements, clean room panels are available at cost-effective prices and suit industries like pharmaceuticals, food processing, and chemical manufacturing. Constructed from durable metal with options like PUF, PIR, and Rockwool insulation, these panels come in various thicknesses and finishes, ensuring optimal performance and compliance with industry standards.

0 notes

Text

What Are Modular Cleanroom Wall Panels?

Modular cleanroom wall panels are prefabricated walls designed to create controlled environments with specific cleanliness levels. These panels are constructed from materials that minimize contamination, are easy to clean, and can be customized to meet specific requirements.

Benefits of Modular Cleanroom Wall Panels

Flexibility and Customization

Modular cleanroom wall panels are highly flexible and customizable. They can be easily reconfigured, expanded, or relocated to meet changing needs, making them ideal for growing businesses and evolving projects.

Cost-Effectiveness

Compared to traditional construction methods, modular wall panels offer significant cost savings. They reduce construction time, minimize waste, and allow for precise budgeting, making them a cost-effective solution for cleanroom construction.

Ease of Installation

The installation process for modular cleanroom wall panels is straightforward and quick, reducing downtime and allowing for faster project completion. This efficiency is especially beneficial for industries where time is of the essence.

Durability and Maintenance

Modular cleanroom wall panels are designed to be durable and easy to maintain. They can withstand rigorous cleaning and disinfection processes, ensuring longevity and reliability in maintaining the desired cleanroom conditions.

0 notes

Text

What Are Clean Room Panels?

Clean room panels are specialized building materials used to construct the walls, ceilings, and sometimes floors of clean rooms. These panels are designed to maintain a controlled environment free from dust, microbes, and other contaminants.

Importance of Clean Room Panels

The importance of clean room panels cannot be overstated. They are fundamental in ensuring the cleanliness and sterility of the environment, which is critical for processes and products that are highly sensitive to contamination

Overview of Types

There are various types of clean room panels, each designed to meet specific needs and requirements. These include modular clean room panels, clean room wall panels, insulated panels, honeycomb panels, and composite panels. Let's dive deeper into each type

0 notes

Text

ADVANTAGES OF ROCKWOOL PANELS IN CLEAN ROOMS

Clean rooms are critical environments where even the smallest particles can compromise the integrity of processes, whether in pharmaceuticals, electronics, or biotechnology. The choice of materials for constructing these rooms is vital, and Rockwool panels have emerged as a leading option. But what makes these panels so special? Let's dive in and explore the advantages of Rockwool panels in clean rooms.

WHAT ARE ROCKWOOL PANELS?

Rockwool panels, also known as mineral wool panels, are made from natural stone, primarily basalt. These panels are manufactured by melting the stone and spinning it into fibers, which are then compressed into panels. The result is a material that is both robust and versatile.

KEY CHARACTERISTICS

High thermal insulation

Superior acoustic properties

Excellent fire resistance

Durability and longevity

Moisture resistancey

IMPORTANCE OF CLEAN ROOMS

Clean rooms are specially designed environments that maintain extremely low levels of particulates, such as dust, airborne organisms, or vaporized particles. They are essential in industries like pharmaceuticals, biotechnology, and electronics manufacturing, where contamination can lead to significant defects or health hazards.

STANDARDS AND REQUIREMENTS

Clean rooms must adhere to stringent standards such as ISO 14644-1, which specifies the classification of air cleanliness. Materials used in their construction must not only meet these standards but also enhance the overall functionality and safety of the environment

0 notes

Text

Rockwool Panels Manufacture in India

Rockwool panels are a crucial component in constructing energy-efficient and fire-resistant buildings. In India, these panels are manufactured with precise specifications to meet diverse industrial requirements. Here’s an in-depth look at the manufacturing details of Rockwool panels.

Key Specifications

Skin Materials:

Options: PCGI, PPGI, PPGI & SS, SS

Combinations: Any two combinations of the above materials

Structural Framework:

Material: Galvanized Iron (GI)

Sheet Thickness:

Options: 0.6 mm, 0.8 mm, 1.0 mm

Coating Thickness:

Powder Coating: 60-80 microns

Pre Coating: 30-35 microns

Insulation Types:

PUF: Density 40±2 kg/m³

PIR: Density 48±2 kg/m³

ROCKWOOL: Density 96 kg/m³ & 144 kg/m³

Sealant:

Type: Food grade silicon on both sides of the panels

Gap: Should not exceed 4 mm

Dimensions

Width: 1200 mm or as per room layout

Height: As per layout

Panel Thickness: 35 mm, 50 mm, 80 mm, 100 mm

Support System

Base Runners: Powder-coated

Panels: Self-supported with interconnecting profile

Color Options

Standard Color: RAL 9002

Custom Colors: Available from the RAL chart

Panel Types

Types: Progressive and Non-progressive

0 notes

Text

Introduction to Modular Cleanrooms

Modular cleanrooms represent a modern approach to cleanroom design and construction. Unlike conventional cleanrooms built using traditional construction methods, modular cleanrooms are prefabricated structures assembled from standardized components. This innovative approach offers numerous advantages, making modular cleanrooms a preferred choice for industries requiring controlled environments.

Flexibility and Customization

Modular Design

One of the key advantages of modular cleanrooms is their flexible design. These cleanrooms consist of interchangeable panels, allowing for easy customization to meet specific requirements. Whether it's adjusting the layout, adding new equipment, or expanding the cleanroom space, modular design offers unparalleled flexibility.

Customizable Features

Modular cleanrooms can be tailored to suit the unique needs of different industries and applications. From specialized air filtration systems to temperature and humidity controls, various features can be incorporated to optimize performance and efficiency.

0 notes

Text

Clean room wall panels are specialized building components designed to maintain strict environmental conditions. Used in industries like pharmaceuticals, biotechnology, and electronics, these panels offer superior contamination control, durability, and easy sanitation. Made from non-porous materials with sealed joints, they resist microbial growth and can endure frequent cleaning. With their sleek appearance and precision engineering, clean room wall panels ensure a hygienic and controlled environment, essential for high-stakes applications.

#Clean Room Wall Panels#clean room panels#modular clean room panels#luckydeep#rockwool panels#clean room doors#modular clean room panel#clean room manufacturers in india#modular clean room

0 notes

Text

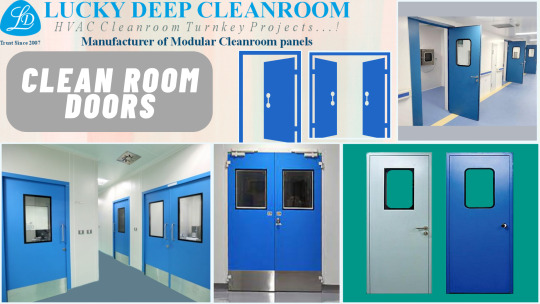

Clean room doors are crucial for places like labs, pharmaceutical factories, and semiconductor plants, where controlling contamination is a must. These doors help keep the air clean, limit who can enter, and block pollutants from getting in. They have airtight seals, smooth surfaces for easy cleaning, and systems to ensure only one door opens at a time. When picking clean room doors, you should look for durability, compliance with industry rules, and easy connections to air filtration systems.

#clean room doors#clean room panels#modular clean room panels#luckydeep#rockwool panels#modular clean room panel#clean room manufacturers in india#clean room wall panels#modular clean room

0 notes

Text

Modular clean room panels are ideal for producing sterile environments in industries such as pharmaceuticals, biotechnology, electronics, and aerospace. They are simple to install, allowing for versatile room layouts and easy expansion. They maintain a clean and sanitary environment by using smooth, contaminant-resistant surfaces. The modular architecture saves energy consumption and maintenance expenses, providing an environmentally responsible alternative. Modular cleanroom panels are available at reasonable pricing. For quick and customizable clean room setups, modular panels are the ideal option.

#clean room panels#modular clean room panels#luckydeep#rockwool panels#modular clean room panel#clean room doors#clean room manufacturers in india#clean room wall panels#modular clean room

0 notes