#cold chain warehouse market

Explore tagged Tumblr posts

Text

Cold Chain Logistics Market Size, Growth, Report & Trends Analysis- 2030

The cold chain market is rapidly evolving, driven by technological advancements, increasing demand for temperature-sensitive products, and significant investments in infrastructure. This micro blog explores the cold chain market, covering its transport and warehouse sectors, market share, growth, and prospects.

Cold Chain Market Report: Overview

The global cold chain logistics market was valued at $202.17 billion in 2020 and is projected to reach $782.27 billion by 2030, growing at a CAGR of 14.6% from 2021 to 2030. This growth is fueled by the need for reliable transport and storage solutions for temperature-sensitive goods such as pharmaceuticals, fresh produce, and frozen foods.

Cold Chain Transport Market

Cold chain transport involves the safe transportation of goods through various modes such as refrigerated trucks, railcars, cargo, and air cargo. This segment ensures that products maintain their required temperature throughout the journey, preserving their quality and safety.

Key Trends: The adoption of refrigerated transport is increasing due to the growing demand for fresh and frozen foods, particularly in emerging markets. Innovations such as temperature-controlled air cargo and IoT-based tracking systems are enhancing efficiency and reliability.

Cold Chain Warehouse Market

Cold chain warehouses are critical for storing perishable goods under controlled temperatures. These warehouses are equipped with advanced refrigeration systems to maintain the integrity of products from storage to final delivery.

Growth Drivers: The expansion of refrigerated warehouses is driven by the rise in processed food consumption and pharmaceutical needs. Investments in modern warehouse management systems and automation technologies are further boosting the efficiency and capacity of cold storage facilities.

Market Share and Analysis

The cold chain market is segmented by end-use industry, business type, and region. Key end-use industries include fruits and vegetables, bakery and confectionery, dairy and frozen desserts, meat and seafood, and pharmaceuticals. The market is also divided into warehousing and transportation segments.

Regional Insights: North America leads the market, followed by Europe, Asia-Pacific, and LAMEA. The U.S. holds the largest market share in North America, driven by stringent quality standards and significant pharmaceutical logistics. Asia-Pacific is the fastest-growing region, propelled by increasing demand for cold-stored food and pharmaceutical products.

Cold Chain Market Growth

The cold chain market is poised for significant growth, with several factors contributing to this trend:

Pharmaceutical Sector: The pharmaceutical industry’s growth, particularly with the increase in biotechnology medicines and vaccines requiring cold storage, is a major driver.

E-commerce: The rise of online grocery shopping and the need for efficient cold chain solutions for food delivery are boosting the market.

Technological Advancements: The adoption of RFID technology and IoT-based systems for real-time monitoring and management is transforming cold chain logistics.

Cold Chain Management Market

Effective cold chain management involves ensuring the integrity of temperature-sensitive goods throughout the supply chain. This includes the use of advanced technologies for monitoring and controlling temperatures, improving visibility, and enhancing efficiency.

Innovations: The integration of IoT, GPS, and cloud-based platforms allows for real-time tracking and management of cold chain logistics, ensuring the quality and safety of products.

Challenges and Opportunities

While the cold chain market offers significant growth opportunities, it also faces challenges such as high operational costs and lack of standardization. However, advancements in technology and increasing investments in infrastructure present lucrative opportunities for market players.

Key Developments

Recent developments in the cold chain market highlight its dynamic nature:

Expansion Projects: Companies like Tippmann Group and Lineage Logistics are expanding their storage capacities and investing in automated facilities to meet growing demand.

Acquisitions: Americold Logistics' acquisition of Agro Merchants Group expands its geographical reach and enhances its service offerings.

Conclusion

The cold chain market is experiencing robust growth, driven by increasing demand for temperature-sensitive goods and technological advancements. With continued investment and innovation, the market is set to expand further, offering significant opportunities for stakeholders across the supply chain.

#cold chain market report#cold chain transport market#cold chain warehouse market#cold chain market share#cold chain market analysis#cold chain market growth#cold chain transportation market#cold chain management market

0 notes

Text

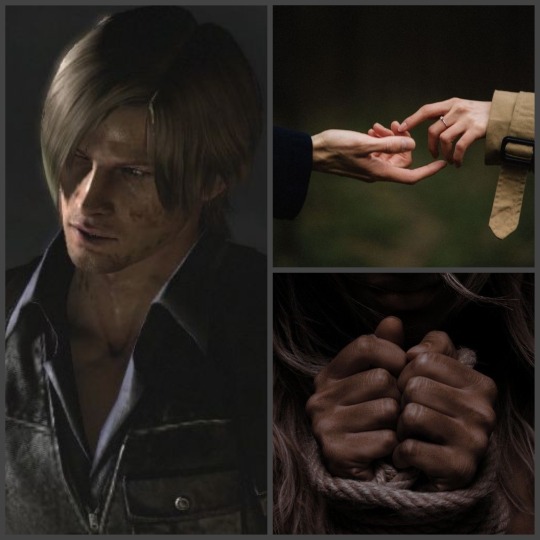

Save Her (Part One)

Leon Kennedy x Reader

Summary; Leon's fiancee has been captured by an underground black market group. He needs to save her, but once he does, he needs to prepare for her recovery.

CW; hurt/comfort, captivity, swearing, blood/bruising, mild suicidal thoughts. (lmk if I missed anything)

Three weeks. For three weeks his best friend, no, fiancée, has been missing. And after all that time stressing, all those sleepless nights, he's got a solid lead. An underground gang that sells bio-weapon prototypes. They buy blueprints off the black market and build them to sell to high bidders. With the intel Hunnigan found, they gotta be the ones who have her. The question is, why would they take her? They better not be experimenting on her. He'll have to put a bullet through every head, just like the undead he spent most of his life killing. Maybe he'll do it anyway. When he came home from work one day, he found the door broken open, many signs of a struggle, but they still got her. No ransom notes, nor blood. The anger in his eyes was strong, they can't just take her away like that. She's going to come home safe and sound. She has to.

“The location has been sent to you, but you'll need to be careful getting down. There's likely going to be some form of security, definitely cameras. Keep your head down.” Hunnigan explains as Leon, Chris, and Rebecca gear up. Leon knew he couldn't do this alone, he needed his friends. Jill is on another mission, and Claire is traveling for TerraSave. Chris wasn't going to let him do this in the state he's in. Barely a wink of sleep, very little food in his system. He had to force him to do both just so he wouldn't kill himself. He can't save her when he's passed out on the ground. “Head to the warehouse, clear the area, and find the hatch. The rest I won't be able to help much with.” She finished explaining, earning a nod from Leon.

“Got it, thank you, Ingrid.” He says softly. Ingrid gives a hint of a smile.

“I care about her too, bring her home safely.” She states, pointing at them. Leon chuckles and gives a two finger salute. The three of them are off in no time, settling into Chris’s jeep before taking off. Rebecca looks through her computer for possible access to the cameras at the warehouse.

“It doesn't seem like there are many camera's underground, just in the warehouse itself. So I'm guessing there might be some muscle down there. Judging by some old files, their number of sales on the black market have increased by 40% in the last three months.” She explains to the men. Leon's leg bounces anxiously as he listens, Chris frowning as he thinks.

“I just don't understand, what do they want with Y/n?” The muscular brunette asks. Rebecca hums and types for a couple of minutes before answering.

“My guess, using her knowledge as a biologist to build their newest experiment. Though I can’t seem to get through this inscription, so I won’t know for sure until we get there and see it for ourselves.” The professor explains.

________________

The echoes of men cheering down the hall caused a spike in her heart rate. The cold floor of the cell she’s on makes her shiver as she sits in only a dirty hospital gown and undergarments. Her hair is greasy, and knotted. She'd kill for a shower if she wasn't so weak. Y/n hugged her knees to her chest, the chains connected to her ankle making a clanking sound. Bruises and cuts litter her skin, all that fighting ended in such pain. She just wanted to be home, resting in bed with her soon to be husband. But those words from the fuckers that took her. They haunt her, every day she starts to believe them.

“He's not coming for you, doll."

“And even if he did, he won't love you.”

“You belong to us now.”

She squeezes her eyes shut as she holds her head. Tears starting to prick her eyes for the hundredth time since she's been stuck here. Leon would never leave her like that. He loves her, he promised that when he proposed. “He's just having trouble finding me.” She mutters, but still; as time goes on, hope continues to fade.

____________

The ringing of gunshots caused her to wake with a start. She can hear shouting and footsteps all around. Y/n curls up and covers her ears, too afraid to even try to see what's happening. Could be friend or foe, but it's hard to tell at this point. All those torturous nights of scaring her into talk, forcing her to do tests. She's simply too tired to move, to think. She's not even sure she wants to live anymore.

“Leon! Check all the cells! We have to get her out quickly if we're gonna blow this place.” A familiar voice called out, followed by footsteps nearing her cell. Why can't she remember that voice, and did he say Leon? As in her soon to be husband? Perhaps her mind is starting to play tricks on her. That little bit of hope left could be tricking her.

However, the footsteps get louder. A shadow of a man draws closer, and she isn't sure what to do besides try to hide herself. When the footsteps stop suddenly, she peaks her head up slightly. A tall man, fairly muscular and sandy blond hair stands in front of her cell. His eyes are a beautiful blue, but they seem dull. As he sees her, his heart stops, breath hitches. It's her, his future wife. Y/n stares at him in disbelief, this definitely has to be a trick, that man looks just like Leon.

“Y/n..” The sound of her name was breathy, but it immediately made her feel a sense of comfort. His voice, deep and smooth, it's very soothing. Though she still can't be sure that her mind isn't playing tricks. She hugs herself tighter, shaking as he approaches slowly. He kneels down in front of her, worry and sadness clear in his eyes. He frowns and slowly reaches his hand out towards her face. A whimper escapes as she tenses, which only makes him feel worse.

“It's me, baby. It's Leon.” He says softly, managing to graze his fingers along her cheek. Her eyes widen, they look almost lifeless to him. They become glossy as tears quickly begin to pour.

“You're- you're really.. here?” She asks quietly, earning a nod from the blond. The tears fall heavily down her cheeks as a loud sob racks her body. Leon quickly grabs her hands, trying not to let himself fall apart because he just can't. He has to be strong for her, he needs to get her to safety. Chris runs by and hears her cries, stopping in his tracks. He looks over and his eyes widen. He begins to step into the cell, noticing the chains. He then pulls out a set of keys that he collected from one of the guards.

“Leon, here.” He calls softly, giving him the keys. Leon looks back and smiles thankfully. “Where's Rebecca?” He asks, quickly unlocking the chains around Y/n’s ankles.

“Grabbing the files so we can figure this out. Let's go, quickly.” Chris states before rushing out. Leon looks at his fiancee and cups her cheek.

“Baby, I'm gonna get you out of here, okay? Just hold on to me.” He watches her head nod in acknowledgement before carefully lifting her up. She grabs his vest as he carries her bridal style, following where Chris went. Her glossy eyes wander around tiredly as they move. Everything feels fuzzy, the sounds of gunfire become muffled. Even Leon's voice fades in and out, but when she realizes he's talking, she looks up at him slowly. He holds her close, realizing how pale she is. When they finally find Rebecca, she goes to Y/n to check on her.

“We have to get her to a hospital. Now.” She states with a firm tone. The two nod and get what they need. Chris sets up some C4 in the computer room before they all rush out. Another group of guards enter the hallway, guns blazing. Leon takes cover, shielding her from harm, while Chris and Rebecca clear them out. Once they're all down, they run out to the warehouse and jump into the jeep. Leon looks down at his lover to see she's unconscious.

"Shit, Y/n!" He calls, trying to shake her awake, but she's out cold. He feels her neck for a pulse, luckily it's there, but faint. He shouts at Chris to hurry, and Chris detonates the bomb before speeding to the hospital.

Please be okay.

~~~~~~

A/N; Welcome to the first part of my first little series! Hope you enjoyed it, more to come soon!

#leon kennedy#leon kennedy x you#leon s kennedy x reader#leon kennedy x y/n#fanfic#resident evil#chris redfield

67 notes

·

View notes

Note

Care to share of how MC would have died if they had been the one who was kill? I have a great amount of idea in mine but I'm very, very curios of yours👀👀

Just to reaffirm: You are free to headcanon how your MC died if it had been a diff AU. This is just what my version would go.

Warning: Contains graphic violence, gore and dark themes.

Unlike how the TSR RO went down (where they were killed at their own home), MC was kidnapped and dragged out. When the ROs came home, it was an instant sense of dread and panic because the day was important to them and they even came home early for it.

So upon learning MC is missing, the ROs split up.

Maverick used his connections to check if there had been witnesses, CCTVs or anything that could provide a clue.

Rydigan went to the police and report a missing person (In the dystopian world, it's pretty useless but Rydigan had to try and plus, maybe he can see if the police officers were involved and if they were, this is of higher power).

Ittania went to the local bars and try to keep an ear out for information or any thugs that took up a job that involved kidnapping.

Enid snuck into the black markets and tried to eavesdrop any possible slavery dealings in the hope MC hasn't been sold yet.

Then one of them landed a lucky hit after a week of searching and hunted down that lead until they got to a warehouse that was abandoned long ago.

MC's corpse was in the office, brutally mutilated and horrifically scarred. The body might have been dead for a day or two, so the smell of rot was not light in the slightest. But they could see MC's body forcibly chained down to the chair, the head tilting back and mouth open. But there's slits on the side and if MC had been alive, the jaw might have the risk of falling from how broken the bones look. The arms and legs are pulled apart and there are tendrils and strings of flesh connecting still. The blood covered the floor beneath MC.

Ittania would be the first one to breakdown, crying and running for MC's body, her hands hovering MC's slited cheeks but too afraid to touch out of fear of breaking them further.

Then Enid is the next one to snap out of the shock and fury fills her, shouting that she'll kill the bastard who did this to MC.

Rydigan doesn't say a word but tears ran down his cheeks and the light in his eyes just seems to die. He ends up mumbling MC's name.

As for Maverick, he feels a cold, burning anger and he ends up being the first one to make a logical call, getting his phone out to call the needed services.

MC didn't have much of anyone - just Maverick, Rydigan, Ittania and Enid. So the funeral isn't particularly large.

But someone funded the funeral. Maverick could have sworn he hadn't paid it yet, only to learn Benefactor was the one who paid the whole thing and assigned the best funeral parlour and embalmer for MC. Ze first meet the group in said funeral, the same way Benefactor met MC in their funeral in the original timeline.

It took MC 5 or more years to achieve their revenge but for the 4 friends, it took them just a year.

48 notes

·

View notes

Text

Frequently Asked Questions: How Indian Rice Exporters Meet Global Demand

India, often referred to as the “Land of Spices,” is also a global force in rice production and export. As the world’s largest rice exporter, India plays a vital role in providing food to millions of people around the world. But how do Indian rice exporters meet such a huge global demand while maintaining quality and efficiency? In this blog, we will answer some of the most frequently asked questions on how Indian rice manufacturers and suppliers meet the ever-growing needs of the international market.

What types of rice does India export to meet global demand?

India is known for its diverse varieties of rice, which cater to different tastes and culinary preferences around the world. The country mainly exports:

Basmati Rice: Famous for its aromatic scent and long grains, Basmati rice is a favorite in the Middle Eastern, European, and North American markets.

Non-Basmati Rice: This includes varieties such as Sona Masuri, Ponni and IR64, which are widely consumed in African and Asian countries due to their affordability and versatility.

Parboiled Rice: Popular in African countries, parboiled rice undergoes a unique steaming process that retains nutrients and makes it easier to cook.

According to the Agricultural and Processed Food Products Export Development Authority (APEDA), India exported over 18 million metric tonnes of rice in 2022-2023, making it a major player in the global rice trade.

How do Indian rice exporters ensure quality and standards?

Quality assurance is a top priority for rice manufacturers. To meet international standards, exporters follow strict guidelines:

Certification: Many Indian rice suppliers are certified by global bodies such as ISO, HACCP and FDA, which ensure that their products meet safety and quality norms.

Advanced processing: State-of-the-art milling and processing units remove impurities and ensure uniformity in grain size and texture.

Quality testing: Rigorous laboratory tests are conducted to check for moisture content, broken grains, and contaminants before shipment.

For example, APEDA has mandated that all Basmati rice exports undergo DNA testing to ensure authenticity, thereby safeguarding the reputation of Indian rice in global markets.

What logistics and supply chain strategies are used for export?

Efficient logistics is crucial for timely delivery, especially in the case of perishable goods such as rice. Indian rice exporters benefit from:

Port infrastructure: Major ports such as Kandla, Mumbai, and Chennai are equipped to handle large-scale rice shipments.

Cold storage facilities: To maintain freshness, rice is stored in temperature-controlled warehouses before export.

Strategic partnerships: Collaborations with global shipping companies ensure smooth transportation to destinations around the world.

During the COVID-19 pandemic, rice suppliers showed remarkable resilience by adapting to supply chain disruptions, ensuring uninterrupted rice exports to countries in need.

How do Indian exporters keep pace with changing global demands?

The global rice market is dynamic, with changing consumer preferences and trade policies. Indian rice producers stay ahead by:

Market research: Regularly analysing trends to identify emerging markets and demand patterns.

Product diversification: Introducing organic rice, fortified rice and ready-to-cook rice products to meet the needs of health-conscious consumers.

Sustainability initiatives: Adopting eco-friendly farming practices and reducing water use to align with global sustainability goals.

For instance, there has been a surge in demand for organic rice in Europe and North America, prompting Indian exporters to increase their organic rice production.

What are the challenges faced by Indian rice exporters?

Despite their success, Indian rice suppliers face several challenges:

Climate change: Erratic weather patterns affect rice yields, making it difficult to meet demand.

Trade barriers: Some countries impose high tariffs or strict import regulations, restricting market access.

Competition: Countries such as Vietnam and Thailand are also major rice exporters, creating a competitive global market.

However, Indian exporters continue to innovate and adapt, ensuring they remain the preferred choice for rice importers across the world.

Indian rice exporters have mastered the art of balancing quality, quantity and efficiency to meet global demand. From producing diverse varieties of rice to ensuring strict quality checks and adopting sustainable practices, they have earned their reputation as reliable rice suppliers. As the demand for rice in the world grows, India's role in the global rice trade is becoming even more important.

#exporter#rice#basmati rice#food#india#healthy food#white rice#basmati rice exporter in india#parboiled#non basmati rice

1 note

·

View note

Text

Warehouse Services in India

Warehouse services play a crucial role in supply chain management, ensuring the safe storage, handling, and distribution of goods. Whether for manufacturers, e-commerce businesses, or retailers, efficient warehousing helps optimize inventory management and reduce operational costs. With the growing demand for seamless logistics, Warehouse Services in India have evolved to offer advanced solutions, including temperature-controlled storage, automation, and real-time inventory tracking.

What Are Warehouse Services?

Warehouse services involve the storage and management of goods before they are distributed to customers or retailers. These services include inventory control, order fulfillment, packaging, and transportation coordination, helping businesses streamline their supply chain operations.

Types of Warehouse Services

Public Warehousing – Shared storage facilities available to multiple businesses, offering cost-effective solutions.

Private Warehousing – Dedicated storage facilities owned or leased by a company for exclusive use.

Bonded Warehousing – Secure storage for imported goods before customs clearance, delaying duty payments until needed.

Cold Storage Warehousing – Temperature-controlled facilities for perishable items like food, pharmaceuticals, and chemicals.

Fulfillment Warehousing – Specialized storage and order processing centers for e-commerce and retail businesses.

Automated Warehousing – Facilities equipped with robotics, AI, and IoT for efficient inventory management and faster processing.

Benefits of Warehouse Services

Improved Inventory Management – Ensures accurate stock control, reducing losses due to overstocking or shortages.

Cost Efficiency – Reduces logistics costs by consolidating shipments and optimizing distribution.

Faster Order Fulfillment – Ensures quick processing and dispatch of goods, enhancing customer satisfaction.

Risk Management – Provides secure storage to protect goods from damage, theft, and environmental factors.

Scalability – Allows businesses to expand operations without immediate investments in storage infrastructure.

Challenges in Warehousing

Space & Capacity Constraints – Growing demand for storage can lead to space shortages.

High Operational Costs – Maintenance, labor, and security expenses can add up.

Inventory Loss & Damage – Poor handling or inadequate security can lead to product losses.

Regulatory Compliance – Warehouses must adhere to safety, taxation, and environmental regulations.

Supply Chain Disruptions – Delays in transportation or stock shortages can impact business efficiency.

Warehouse Services in India: A Growing Market

With the rise of e-commerce, retail expansion, and global trade, Top Warehouse Services in India have seen significant growth. Modern warehousing solutions now include smart tracking systems, automated sorting, and strategically located distribution centers to ensure fast and cost-effective deliveries. Key logistics hubs like Delhi, Mumbai, Chennai, and Bangalore have state-of-the-art warehousing facilities to support various industries.

Conclusion

Warehousing is an essential component of modern supply chains, offering businesses the ability to store, manage, and distribute goods efficiently. With advancements in technology and logistics infrastructure, Warehouse Services in India continue to evolve, providing reliable and cost-effective solutions for businesses of all sizes. Partnering with an experienced warehousing provider ensures seamless inventory management, reduced operational costs, and enhanced customer satisfaction.

0 notes

Text

Refrigerated Road Transport: Leading the Cold Chain Market

Market Size and Growth

Current Market Size: The global cold chain market size, valued at USD 228.3 billion in 2024, showcases a remarkable growth projection, anticipated to escalate to USD 372.0 billion by 2029, indicating a robust compound annual growth rate (CAGR) of 10.3% during the forecast period. The cold chain market is an essential component of global supply chains, ensuring the safe storage and transportation of temperature-sensitive products such as food, pharmaceuticals, and chemicals. As globalization continues to expand, the demand for reliable cold chain solutions has surged, making this market a critical focus for industries reliant on temperature-controlled logistics.

Unlocking Cost Efficiency: How Intermodal Transport is Revolutionizing the Cold Chain Industry

Intermodal transport has emerged as a pivotal solution in the cold chain market due to its unparalleled ability to optimize fuel costs. Cold chain logistics demands a delicate balance between temperature control and efficiency. Intermodal transport achieves this balance by seamlessly integrating multiple modes of transportation, such as trucks, trains, and ships, to deliver goods to their destination. By strategically combining different transport modes based on their strengths and cost-effectiveness, companies can minimize fuel consumption. For instance, trains are substantially more fuel-efficient than trucks over long distances, while trucks offer flexibility and accessibility for last-mile delivery. By leveraging these strengths, businesses can significantly reduce their overall fuel expenditure, thereby enhancing cost-effectiveness in the cold chain market.

Moreover, intermodal transport fosters sustainability, a growing concern in modern supply chain management. By optimizing fuel usage, companies not only cut costs but also reduce their carbon footprint. This aligns with increasingly stringent environmental regulations and consumer preferences for eco-friendly practices

Refrigerated Road Transportation Dominates Cold Chain Market Share

Refrigerated road transportation leads the refrigerated transport cold chain market due to its essential role in preserving the quality and freshness of perishable goods throughout transit. While refrigerated warehouses focus on storage, road transportation ensures consistent temperature control from the point of origin to the final destination. This is especially critical for sensitive products like fresh produce, pharmaceuticals, and certain chemicals, where even minor temperature variations can compromise their safety and quality.

Refrigerated trucks offer unmatched flexibility, allowing access to remote areas that warehouses cannot reach. Their mobility supports efficient distribution networks, cutting down on transit times and lowering inventory holding costs. Advances in refrigeration technology have also enabled precise temperature monitoring and remote management, improving product traceability and ensuring compliance with strict regulatory requirements. Moreover, refrigerated road transportation enhances supply chain efficiency by enabling just-in-time delivery, which reduces inventory spoilage and waste. Its seamless integration with other transportation modes further strengthens its position as a market leader.

Cold Chain Market Growth Drivers:

Rising Demand for Perishable Goods: The global consumption of perishable foods, such as fruits, vegetables, meat, and dairy, is driving the need for efficient cold chain solutions.

Expansion of the Pharmaceutical Industry: With the development of temperature-sensitive drugs, vaccines, and biologics, the pharmaceutical industry is a major contributor to the growth of the cold chain market.

Technological Advancements: Innovations in refrigeration technology, IoT-enabled monitoring systems, and advanced packaging materials have enhanced the efficiency and reliability of cold chain logistics.

India Set to Lead Asia Pacific Cold Chain Market Growth in the Coming Years

India stands as a significant producer and consumer of dairy products, particularly milk and curd. With a burgeoning population and a cultural inclination towards dairy consumption, the demand for efficient cold chain logistics to maintain product integrity from farm to table is imperative. As per a May 2023 report from Slurrp, India boasts a significantly higher milk consumption rate compared to the global average, with nearly half of its population (48.1%) regularly consuming milk or curd. The increasing demand for dairy products in India can be linked to its fast urbanization and improving living standards. India’s daily milk consumption stands at 427 g, well above the global average of 305 g.

To know more get PDF Copy

Moreover, India’s rapid industrialization has spurred the growth of various sectors, including pharmaceuticals, processed food, and agriculture. These industries heavily rely on cold chain solutions to preserve the quality and safety of their products. Additionally, the proliferation of Quick Service Restaurants (QSRs) and the changing dietary habits of the urban populace have fueled the demand for frozen and chilled food products. As per a report from the credit rating agency ICRA, the Indian Quick Service Restaurant (QSR) sector is projected to experience growth ranging between 20% to 25% during the fiscal year 2024.This surge in demand necessitates robust cold chain systems to ensure the seamless delivery of perishablegoods, thereby propelling the expansion of the cold chain market in India.

Top Cold Chain Companies

Americold Logistics, Inc. (US)

Lineage, Inc. (US)

NICHIREI CORPORATION (Japan)

Burris Logistics (US)

A.P. Moller – Maersk (Denmark)

Tippmann Group (US)

Coldman Logistics Pvt.Ltd. (India)

United States Cold Storage (US)

0 notes

Text

Supply Chain Improvements and Agricultural Value Chain Development

A well-functioning agricultural value chain is essential for the efficiency and sustainability of food production and distribution. Supply chain improvements play a vital role in ensuring that agricultural products reach markets in optimal condition, benefiting farmers, consumers, and all stakeholders involved. By addressing inefficiencies and enhancing coordination across the supply chain, agricultural systems can become more resilient and profitable.

Strengthening Agricultural Supply Chains

Supply chain improvements in agriculture involve reducing inefficiencies in production, storage, transportation, and market access. Many small-scale farmers face challenges such as post-harvest losses, unreliable logistics, and price volatility, which limit their ability to earn fair returns on their produce. Investments in better storage facilities, improved transportation networks, and real-time data tracking help streamline the flow of goods from farms to consumers.

Strengthening local supply chains can also reduce dependency on intermediaries, ensuring that farmers receive better prices for their produce. Cooperatives and farmer-led organisations play a key role in aggregating produce, negotiating fair trade agreements, and reducing transaction costs.

Enhancing Agricultural Value Chain Efficiency

The agricultural value chain consists of all the activities required to bring a product from production to consumption, including processing, distribution, and retailing. A well-structured agricultural value chain increases efficiency, reduces waste, and adds value to raw products, thereby improving economic returns for farmers and agribusinesses.

One key strategy for enhancing the agricultural value chain is encouraging value addition. Processing agricultural products into semi-finished or finished goods, such as turning raw grains into packaged flour or fresh fruit into dried snacks, significantly increases profitability. Developing local processing units not only boosts farmer incomes but also creates job opportunities in rural areas.

Reducing Post-Harvest Losses

Post-harvest losses remain a major issue in agricultural supply chains, often caused by inadequate storage, inefficient handling, and transportation delays. Implementing improved storage solutions, such as climate-controlled warehouses and better packaging methods, helps preserve the quality of produce and extends shelf life. Investments in cold chain infrastructure can also be critical for perishable products, ensuring they reach markets in optimal condition.

Additionally, digital technologies such as blockchain and IoT (Internet of Things) sensors can enhance traceability in agricultural supply chains. These technologies provide real-time monitoring of produce conditions, ensuring that quality is maintained throughout the distribution process.

Improving Market Access for Farmers

One of the significant barriers faced by small-scale farmers is limited access to competitive markets. Many are forced to sell their produce at low prices due to a lack of direct linkages with buyers. Digital platforms and e-commerce solutions are playing a crucial role in bridging this gap by connecting farmers with consumers, retailers, and food processors.

Government policies and private sector involvement in supply chain development can also facilitate better market access. Trade facilitation measures, transparent pricing mechanisms, and fair trade certifications contribute to a more equitable marketplace for agricultural producers.

Technology’s Role in Supply Chain and Value Chain Development

Technology is transforming agricultural supply chains by improving efficiency, transparency, and productivity. Mobile apps and digital platforms enable farmers to access weather forecasts, market trends, and financial services, reducing uncertainties in the agricultural sector.

Precision agriculture, which involves using satellite imagery and data analytics to monitor crop health and optimise input use, also contributes to supply chain improvements. By reducing waste and improving resource management, precision agriculture ensures that farming operations remain profitable and sustainable.

Policy Support for Supply Chain Improvements

Governments and development organisations play a crucial role in strengthening agricultural supply chains and value chains. Policies that promote infrastructure development, fair trade practices, and access to finance help farmers integrate into more profitable markets.

Investing in rural road networks, irrigation systems, and digital connectivity enhances the efficiency of agricultural supply chains. Public-private partnerships (PPPs) can also drive innovation in logistics and storage solutions, ultimately benefiting all stakeholders in the agricultural sector.

The Role of Organisations in Supply Chain and Value Chain Development

Several organisations work towards enhancing agricultural value chains and improving supply chain efficiency. Fuzhio is one such initiative, focusing on supporting small farmers and improving agricultural market access. Their efforts include developing innovative storage solutions, facilitating direct market linkages, and providing training on value-added processing. By addressing key challenges in the agricultural supply chain, Fuzhio helps farmers achieve better income stability and long-term sustainability. Learn more about their work at Fuzhio.

Conclusion

Supply chain improvements and agricultural value chain development are fundamental to the growth and sustainability of the agricultural sector. By reducing inefficiencies, enhancing market access, and integrating technology-driven solutions, small-scale farmers and agribusinesses can achieve greater profitability. Collaboration between governments, private enterprises, and organisations like Fuzhio is crucial in ensuring that agricultural supply chains remain resilient and capable of meeting the demands of modern food systems. Investing in these strategies will not only improve economic returns for farmers but also contribute to food security and rural development.

0 notes

Text

OAKLAND WAREHOUSE STORAGE RENTAL: COMPLETE INFORMATION FOR COMPANIES AND INDIVIDUALS

If you are looking for warehouse storage rental in Oakland, you’re not alone. As a major port city and business hub, Oakland has a growing demand for storage space. Whether you’re a business owner needing extra inventory space or an individual looking for a secure place to store your belongings, warehouse rentals in Oakland offer a range of options to suit different needs.

In this guide, we’ll cover everything you need to know about renting warehouse storage in Oakland, including types of storage available, key benefits, cost factors, and tips for finding the right space.

Why Rent a Warehouse Storage in Oakland?

1. Strategic Location

Oakland is a prime location for logistics and supply chain operations. With its proximity to major highways (I-880, I-580, I-80), the Port of Oakland, and Oakland International Airport, businesses benefit from easy access to local and international markets.

2. Flexible Storage Solutions

Warehouse rentals come in various sizes and types, from small storage units to large industrial spaces, offering flexibility based on your storage needs.

3. Cost-Effective Option

Compared to San Francisco or Silicon Valley, Oakland provides more affordable warehouse rental rates while still offering excellent access to the Bay Area.

4. Security & Safety

Most warehouse storage rentals in Oakland come with advanced security features, including 24/7 surveillance, gated access, and climate control for sensitive goods.

Types of Warehouse Storage Available in Oakland

1. Shared Warehousing

Ideal for small businesses or startups, shared warehousing allows multiple businesses to use a single warehouse space, reducing costs and increasing efficiency.

2. Private Warehousing

A dedicated storage facility rented entirely by one business, offering complete control over storage, security, and logistics.

3. Cold Storage Warehouses

Perfect for perishable goods such as food, pharmaceuticals, and flowers, these warehouses maintain a specific temperature range to keep items fresh.

4. Distribution Centers

These warehouses serve as hubs for businesses that need to distribute products quickly. They typically have loading docks and efficient logistics operations.

5. Self-Storage Warehouses

Great for individuals or businesses looking for smaller storage solutions, these spaces function similarly to personal storage units but on a larger scale.

Cost Factors for Warehouse Storage Rental in Oakland

The cost of renting a warehouse in Oakland varies based on several factors:

Size of the Warehouse: Larger spaces typically cost more.

Location: Warehouses closer to the port or major highways tend to have higher rental rates.

Lease Terms: Long-term leases may offer lower monthly rates compared to short-term or month-to-month rentals.

Amenities & Features: Climate control, security, and loading docks can add to the overall cost.

Accessibility: 24/7 access and proximity to major transport routes can influence pricing.

How to Choose the Right Warehouse Storage in Oakland

1. Assess Your Storage Needs

Determine the type and volume of goods you need to store. Are you storing large equipment, sensitive items, or products requiring temperature control?

2. Set a Budget

Factor in the rental cost along with potential additional expenses like utilities, maintenance, and security.

3. Check the Location

Choose a warehouse that is easily accessible for your suppliers, customers, or transportation network.

4. Inspect the Facility

Before signing a lease, visit the warehouse to check for:

Security measures

Cleanliness and maintenance

Structural condition

Loading and unloading facilities

5. Understand the Lease Agreement

Make sure you understand:

Rental duration

Extra costs (utilities, maintenance, insurance, etc.)

Termination policies

Top Areas in Oakland for Warehouse Rentals

Some of the best areas for warehouse rentals in Oakland include:

West Oakland: Close to the port, ideal for logistics and shipping businesses.

Jack London Square: Great for small businesses and artisan storage.

Coliseum Industrial Area: Offers larger industrial warehouses with excellent freeway access.

East Oakland: More affordable options for businesses needing extra storage space.

Conclusion

Finding the right warehouse storage rental in Oakland requires careful consideration of your needs, budget, and location. Whether you need a small self-storage unit or a large distribution center, Oakland has plenty of options to suit various business and personal storage needs.

By assessing your requirements, setting a budget, and choosing the right location, you can find the perfect warehouse storage solution for your needs in Oakland. Start your search today and take advantage of Oakland’s thriving logistics and industrial market!

Need help finding the perfect warehouse storage rental? Contact local real estate agents or use online platforms like LoopNet, Crexi, and Warehouse Exchange to explore available listings.

Original Source : https://alibabaglobalshipping.com/warehouse-storage-rental-in-oakland/

0 notes

Text

Carrollton Warehouse Space for Lease- Find the Perfect Space for Your Business

Carrollton, Texas, is a thriving hub for businesses seeking strategically located warehouse space. Whether you're a growing e-commerce company, a logistics provider, or a manufacturer in need of a distribution center, Carrollton offers a variety of warehouse leasing opportunities tailored to your needs.

Why Choose Carrollton for Your Warehouse Space?

Carrollton is an ideal location for businesses looking for Carrollton Warehouse Space for Lease due to its accessibility, infrastructure, and business-friendly environment. Situated in the heart of the Dallas-Fort Worth metroplex, Carrollton provides seamless connectivity to major highways, airports, and rail lines, making it a prime location for supply chain operations.

Key Benefits of Leasing a Warehouse in Carrollton:

Strategic Location Carrollton offers easy access to I-35E, President George Bush Turnpike, and Sam Rayburn Tollway, ensuring efficient transportation and distribution of goods.

Proximity to Major Markets The city’s central location within the DFW metroplex allows businesses to serve both local and national markets with ease.

Diverse Warehouse Options Whether you need small flex space, a distribution center, or a large industrial warehouse, Carrollton has a variety of options to meet your business requirements.

Skilled Workforce The region boasts a strong labor pool with experience in logistics, warehousing, and manufacturing, ensuring a steady supply of skilled employees.

Business-Friendly Environment Carrollton provides tax incentives, low operational costs, and a supportive local government to encourage business growth and expansion.

Types of Warehouse Spaces Available

When looking for warehouse space in Carrollton, you’ll find various types of facilities suited to different industries and needs, including:

Distribution Centers: Ideal for businesses needing large storage spaces with loading docks and easy transportation access.

Manufacturing Warehouses: Designed for production and assembly operations with built-in infrastructure for heavy equipment.

Cold Storage Warehouses: Suitable for businesses dealing with perishable goods such as food and pharmaceuticals.

Flex Spaces: A mix of office and warehouse space, perfect for startups and small businesses requiring versatile setups.

Key Features to Look for in a Warehouse

Before leasing a warehouse in Carrollton, consider the following features:

Square Footage: Ensure the space meets your storage and operational needs.

Ceiling Height: Essential for businesses utilizing tall storage racks or machinery.

Loading Dock Access: A must-have for efficient loading and unloading of goods.

Security Measures: Look for 24/7 surveillance, gated entry, and fire suppression systems.

Lease Flexibility: Choose a lease term that aligns with your business growth plans.

Find Your Ideal Warehouse Space in Carrollton Today

If you're looking for high-quality Carrollton Warehouse Space for Lease, there are numerous options available to fit your budget and business requirements. Contact a commercial real estate expert to explore listings and secure the perfect warehouse space for your company.

With Carrollton’s prime location, strong infrastructure, and diverse warehouse offerings, your business will be well-positioned for success. Start your search today and take your operations to the next level!

0 notes

Text

Future-Ready Carton Sealing Solutions: Where Innovation Meets Affordability

As global supply chains evolve in 2025, carton sealing tape manufacturers like QuickPack Tape are redefining packaging efficiency with smart, sustainable, and cost-effective solutions. Whether you’re a distributor sourcing wholesale carton sealing tape or a logistics giant needing machine-length carton sealing tape, here’s how we’re leading the revolution:

1. Material Mastery for Every Demand

Natural Rubber Carton Sealing Tape: Ideal for cold-chain logistics, our natural rubber formula ensures aggressive adhesion even in sub-zero temperatures.

Acrylic Carton Tape: A UV-resistant, eco-friendly alternative dominating the carton sealing tape suppliers market for its recyclability and clean removal.

Pressure-Sensitive Carton Sealing Tape: Engineered for automated systems, this variant reduces waste with precision application.

2. Wholesale Without Compromise

QuickPack Tape specializes in carton sealing tape wholesale, offering:

Custom Machine Length Carton Sealing Tape: Tailored to fit high-speed packaging lines (up to 5,000 meters per roll).

Cost Efficiency: Our cheap carton sealing tape range doesn’t sacrifice quality—think 50% thinner backings with 2x tensile strength.

Global Stocking Hubs: Reduce lead times with regional warehouses across North America, Europe, and Asia.

3. Price Transparency, Planet-Conscious

Navigating the carton tape price landscape can be tricky. We disrupt norms with:

Dynamic Pricing Models: Bulk discounts on pressure-sensitive carton sealing tape orders over 10,000 units.

Circular Economy Initiatives: Trade used tape cores for credits toward future purchases.

4. The Tape de Carton Advantage

Catering to bilingual markets, our tape de carton line meets Latin American and EU compliance standards, featuring:

Biodegradable adhesives.

Anti-tamper strips for secure shipments.

5. Why Partner with QuickPack Tape?

Certified Excellence: ISO 14001-certified manufacturing.

R&D-Driven: Lab-tested solutions outperforming ASTM benchmarks by 35%.

24/7 Support: Dedicated account managers for carton sealing tape suppliers and distributors.

Unlock the Future of Packaging

From natural rubber carton sealing tape for frozen goods to budget-friendly acrylic carton tape for e-commerce, QuickPack Tape merges innovation with accessibility. Explore our 2025 catalog or request a sample kit at https://quickpacktape.com/.

Pack Smarter. Pay Less. Protect More.

0 notes

Text

IMPROVING OAKLAND’S WAREHOUSE LOGISTICS WILL OPEN A PATH FOR EFFECTIVE SUPPLY CHAINS

Given Oakland’s key location and closeness to the Port of Oakland, warehouse logistics there are absolutely vital for the regional and national supply chain. Companies depending on effective logistics operations recognize the need of simplifying inventory control, warehouse, and delivery to keep a competitive edge. Why Oakland Serves As A Prime Hub For Warehouses Logistics Oakland’s logistics sector benefits from its well-developed infrastructure, including access to major highways, rail connections, and a bustling seaport. These factors make it an ideal location for businesses engaged in import-export, e-commerce, and retail distribution.

Main Benefits Of Oakland Warehouse Logistics

1 Nearby the Port of Oakland

One of the most active container ports in the United States, supporting world trade.

Faster turning around times for exports and imports.

2 Stable Transportation System

Easy access to I-80, I-880, and I-580 for seamless trucking operations.

Rail connectivity via Union Pacific and BNSF railroads.

3 Various Warehousing Solution

Conventional storage; cold storage; cross-docking systems

Scalable warehousing solutions fit companies of all kinds.

4 Technology-Driven Logistics

automation, real-time tracking, inventory control driven by artificial intelligence.

Improved running efficiency and lower expenses.

Challenges in Warehouse Logistics and How to Overcome Them

While Oakland offers numerous advantages, businesses must navigate certain challenges, such as:

Rising Operational Costs: Implementing lean logistics and automation can optimize expenses.

Regulatory Compliance: Staying updated with local and federal regulations ensures smooth operations.

Inventory Management: Leveraging data analytics and warehouse management systems (WMS) can enhance stock control.

Choosing the Right Warehouse Logistics Partner in Oakland

Selecting an experienced logistics provider ensures streamlined operations. Look for a partner that offers:

Scalable storage solutions.

Advanced inventory tracking.

Efficient last-mile delivery services.

Strong relationships with port authorities and carriers.

Conclusion

Oakland’s strategic position and robust infrastructure make it a prime location for warehouse logistics operations. Businesses that optimize their logistics strategies here can enjoy reduced costs, improved efficiency, and seamless supply chain operations. Whether you are a local business or a global enterprise, investing in warehouse logistics in Oakland can give you a significant competitive advantage in today’s fast-paced market.

Orignal source : https://portzlogistics.com/warehouse-logistics-in-oakland/

0 notes

Text

Sandwich Panel Market 2025 Size, Share, Growth, Market Supply and Demand, Company Profiles, Trends, Component & Growth with Forecast

Sandwich panels have revolutionized various industries with their versatility, durability, and efficiency. These composite structures, consisting of two face sheets bonded to a lightweight core material, offer excellent thermal insulation, soundproofing, and structural integrity. The Sandwich Panel Market has been experiencing significant growth, driven by expanding construction activities, the demand for energy-efficient solutions, and advancements in material technologies.

Sandwich Panel Market Size was valued at USD 2.32 Billion in 2024. The sandwich panel industry is projected to grow from USD 2.53 Billion in 2025 to USD 5.42 Billion by 2034, exhibiting a compound annual growth rate (CAGR) of 8.9% during the forecast period (2025 - 2034).

Growing Construction Sector: One of the primary drivers propelling the sandwich panel market is the booming construction industry. With rapid urbanization and infrastructure development worldwide, there's a heightened demand for high-performance building materials that offer both sustainability and cost-effectiveness. Sandwich panels, with their ability to enhance energy efficiency and accelerate construction timelines, have become a preferred choice for residential, commercial, and industrial projects. From residential housing to warehouses, data centers to cold storage facilities, the versatility of sandwich panels is evident across diverse construction applications.

Focus on Energy Efficiency: In an era marked by increasing environmental consciousness and stringent regulations, energy efficiency has become a paramount concern for building owners and developers. Sandwich panels, with their superior thermal insulation properties, help reduce energy consumption and carbon emissions, thereby contributing to sustainability goals. The emphasis on green building practices and energy-efficient designs is driving the adoption of sandwich panels in both new constructions and retrofit projects. Governments worldwide incentivize the use of eco-friendly building materials, further bolstering the demand for sandwich panels in the construction sector.

Technological Advancements: Continuous innovation in material science and manufacturing processes has led to the development of advanced sandwich panel solutions. Manufacturers are investing in research and development to enhance the performance characteristics of sandwich panels, including fire resistance, acoustic insulation, and structural strength. The integration of cutting-edge technologies such as nanotechnology and 3D printing is opening up new possibilities for optimizing the properties of sandwich panels while reducing production costs. Additionally, the advent of smart building technologies has spurred the demand for sandwich panels embedded with sensors and IoT capabilities for real-time monitoring and control.

Market Challenges and Opportunities: Despite the favorable growth prospects, the sandwich panel market faces certain challenges, including volatile raw material prices, regulatory complexities, and competition from alternative building materials. Moreover, the COVID-19 pandemic has disrupted supply chains and construction activities, temporarily impacting market growth. However, as economies recover and construction projects resume, the demand for sandwich panels is expected to rebound swiftly. Manufacturers can leverage this opportunity by diversifying their product offerings, expanding into emerging markets, and embracing sustainable practices to gain a competitive edge.

Future Outlook: The sandwich panel market is poised for robust expansion in the coming years, driven by factors such as urbanization, infrastructure development, and the growing emphasis on sustainability. As the construction industry evolves, sandwich panels will continue to play a pivotal role in shaping the built environment, offering innovative solutions for architects, developers, and building owners. With ongoing advancements in materials, technologies, and design capabilities, the future of the sandwich panel market looks promising, promising sustainable, efficient, and aesthetically pleasing building solutions for the world's growing population.

MRFR recognizes the following Sandwich Panel Companies - DANA Group of Companies (UAE),INVESPANEL SL (Spain),Kingspan Group (Ireland),Building Component Solutions LLC (Saudi Arabia),Nucor Corporation (U.S.),Assan Panel A.S. (Turkey),Hoesch Siegerlandwerke GmbH (Germany),ArcelorMittal S.A. (U.S.),MANNI Group (Italy),Zhong Jie Group (China),Romakowski GmbH & Co. KG (Germany),Tata Steel Limited (India),NCI Building Systems Inc. (U.S.),Multicolor Steels India Pvt Ltd. (India),Sintex (India)

Related Reports

Vacuum Insulation Panel Market - https://www.marketresearchfuture.com/reports/vacuum-insulation-panels-market-2438 Polycarbonate Panels Market - https://www.marketresearchfuture.com/reports/polycarbonate-panels-market-7851

1 note

·

View note

Text

Global Sandwich Panels Market Poised for Growth Amid Rising Demand for Energy-Efficient and Durable Construction Materials

Global Sandwich Panels Market Poised for Growth Amid Rising Demand for Energy-Efficient and Durable Construction Materials

Market Overview

The Global Sandwich Panels Market is experiencing significant growth, driven by increasing demand for lightweight, durable, and energy-efficient construction materials. Sandwich panels, which consist of insulating core materials sandwiched between two protective layers, are widely used in industrial buildings, warehouses, cold storage facilities, residential housing, and commercial structures.

The market expansion is fueled by urbanization, infrastructure development, and stringent energy efficiency regulations. Governments and private sectors worldwide are adopting sustainable construction materials that enhance thermal insulation, soundproofing, and fire resistance, positioning sandwich panels as a preferred solution for modern construction projects.

Free Sample Report:- https://www.researchallied.com/request-sample/61539-global-sandwich-panels-market

Market Insights & Trends

Growing Demand for Prefabricated and Modular Construction: The rise in off-site construction and pre-engineered buildings (PEB) is increasing the adoption of sandwich panels for quick and efficient installations.

Advancements in Insulation Materials: The use of polyurethane (PUR), polyisocyanurate (PIR), mineral wool, and expanded polystyrene (EPS) is enhancing the thermal and fire-resistant properties of sandwich panels.

Rising Adoption in Cold Storage and Logistics: The growth of the food & beverage industry, pharmaceutical cold chains, and temperature-sensitive storage solutions is driving demand for high-performance insulated sandwich panels.

Focus on Sustainable & Fire-Resistant Solutions: Manufacturers are developing eco-friendly sandwich panels with recyclable materials and improved fire safety compliance to meet regulatory standards.

Increased Investment in Smart Cities & Infrastructure: Government initiatives for green buildings, smart cities, and industrial expansion projects are boosting the use of cost-effective, energy-efficient sandwich panels.

Key Players in the Market

The Global Sandwich Panels Market is highly competitive, with major players focusing on technological innovations, enhanced insulation materials, and sustainable solutions. Leading companies include:

Kingspan Group

ArcelorMittal Construction

Isopan S.p.A.

Nucor Building Systems

Metecno Group

Tata Steel

Alubel S.p.A.

Ruukki Construction

Dana Group

Zamil Steel Holding Company

These companies are investing in high-performance, eco-friendly, and energy-efficient sandwich panel solutions to meet growing market demands.

Full Report:- https://www.researchallied.com/report/61539-global-sandwich-panels-market/

Regional Insights

North America: The United States and Canada are leading markets, driven by sustainability initiatives, green building codes, and increased adoption in cold storage applications.

Europe: Countries like Germany, France, and the UK are witnessing high demand for fire-resistant and energy-efficient sandwich panels, supported by stringent environmental regulations.

Asia-Pacific: China, India, and Japan are experiencing rapid market growth due to urbanization, rising infrastructure investments, and expansion of industrial and logistics sectors.

South America, Middle East & Africa: Growing investments in commercial buildings, cold storage facilities, and prefabricated housing solutions are fueling market expansion in these regions.

Market Outlook & Growth Prospects

The Global Sandwich Panels Market is expected to grow at a CAGR of over 6% through 2028, driven by:

Rising demand for sustainable and energy-efficient building materials

Expansion of the prefabricated and modular construction industry

Technological advancements in insulation and fire-resistant materials

Government policies promoting green buildings and smart infrastructure

Increasing need for temperature-controlled storage in food and pharmaceutical sectors

Enquire Before Buy:- https://www.researchallied.com/enquire-before/61539-global-sandwich-panels-market

Top Trending Reports

Global More Electric Aircraft Market

Nigeria Oil and Gas Upstream Activities Market

Global Industrial Plastic Bags Market

0 notes

Text

The Vital Role of Mechanical Engineering in Supply Chain Optimization

The integration of engineering machnical supply chain management has transformed industries by enhancing efficiency, reducing costs, and optimizing processes. As global supply chains become increasingly complex, the role of engineering expertise is indispensable in ensuring seamless operations. This article explores how mechanical engineering influences the supply chain, focusing on its critical contributions to logistics, production, and maintenance.

The Intersection of Mechanical Engineering and Supply Chain Management

Mechanical engineering and supply chain management might appear as distinct domains at first glance, but their overlap is undeniable. The synergy between the two ensures the design, manufacturing, and delivery of products align with market demands.

Product Design and DevelopmentMechanical engineers play a pivotal role in the design phase, ensuring that products meet quality standards and are easy to manufacture. Through Computer-Aided Design (CAD) and simulation technologies, engineers can identify potential production bottlenecks before they arise, saving time and resources.

Efficient Manufacturing ProcessesThe supply chain heavily relies on efficient production processes, which mechanical engineering innovations can enhance. Automation technologies such as robotics, conveyor systems, and advanced machining tools streamline operations, minimize downtime, and ensure high precision in manufacturing.

Material Handling and Equipment OptimizationMaterial handling is a cornerstone of supply chain management. Mechanical engineers design and maintain equipment like forklifts, conveyors, and automated guided vehicles (AGVs) to optimize the movement of goods within warehouses and factories. Proper equipment maintenance, enabled by engineering expertise, reduces delays and equipment failures.

Engineering Innovations in Logistics and Transportation

Logistics and transportation form the backbone of supply chains, and mechanical engineering significantly influences their efficiency. From designing transport vehicles to maintaining fleet systems, engineering innovations drive performance.

Vehicle Design and Fuel EfficiencyMechanical engineers contribute to designing fuel-efficient transport vehicles, ensuring the movement of goods is cost-effective and environmentally sustainable. Lightweight materials, aerodynamic designs, and hybrid power systems have revolutionized the logistics industry.

Predictive Maintenance in Fleet ManagementPredictive maintenance, powered by sensors and data analytics, ensures that transportation fleets operate at optimal capacity. Mechanical engineers develop and implement these systems to reduce breakdowns and improve delivery timelines.

Cold Chain Logistics SolutionsIn industries like pharmaceuticals and food, cold chain logistics is crucial. Mechanical engineering innovations in refrigeration systems and insulated transport containers ensure temperature-sensitive products maintain their integrity throughout the supply chain.

Sustainability and Mechanical Engineering in the Supply Chain

Sustainability is a growing priority for supply chain management, and mechanical engineering plays a crucial role in achieving eco-friendly practices.

Energy-Efficient MachineryMechanical engineers design energy-efficient machinery for manufacturing and logistics, reducing overall carbon footprints. Energy recovery systems, such as regenerative braking in conveyor belts, are examples of sustainable engineering innovations.

Waste Reduction StrategiesEngineering expertise helps identify areas where waste can be minimized. For instance, designing modular components reduces material wastage during production, while efficient equipment ensures fewer resources are consumed.

Renewable Energy IntegrationRenewable energy sources, such as solar or wind power, are being integrated into supply chain operations. Mechanical engineers develop systems that utilize these resources, such as solar-powered conveyor belts or wind-assisted transport vehicles.

Challenges and Future Trends in Mechanical Engineering for Supply Chains

While mechanical engineering has significantly advanced supply chain processes, challenges remain. These include high initial costs of advanced machinery, skill gaps in workforce training, and adapting to rapidly evolving technologies.

However, future trends show promise:

Artificial Intelligence and Machine LearningMechanical engineering will increasingly integrate AI for predictive maintenance and process optimization, enhancing supply chain resilience.

3D PrintingOn-demand manufacturing using 3D printing technology can revolutionize supply chains by reducing lead times and inventory costs.

Digital TwinsThe creation of virtual replicas of physical assets enables real-time monitoring and simulation, ensuring better decision-making across the supply chain.

Conclusion

Mechanical engineering is a driving force behind the success of modern supply chains. Its influence spans from product design and manufacturing to logistics and sustainability. By integrating advanced technologies, mechanical engineers continue to address challenges, optimize processes, and contribute to a greener future. As industries evolve, the partnership between mechanical engineering and supply chain management will remain critical in meeting global demands efficiently and sustainably.

1 note

·

View note

Text

How Rice Manufacturers Meet Global Market Demand

Rice isn’t just a staple food – it’s a global commodity that feeds more than half of the world’s population. As one of the most consumed cereals, rice plays a vital role in the diets and economies of countless countries. But have you ever wondered how rice manufacturers meet the ever-growing and diverse demands of a global market? From adapting to regional preferences to adopting sustainable practices, the rice industry has evolved significantly to stay ahead. Let’s take a look at the strategies and innovations that enable rice exporters and suppliers to meet the needs of a global audience.

Understanding varying consumer preferences across regions

The global demand for rice is not uniform. Different regions have different tastes, textures and culinary traditions, which means a one-size-fits-all approach doesn’t work for everyone. For example:

In Asia, long-grain varieties such as Basmati rice and Jasmine rice are in high demand for their aromatic qualities and soft texture.

In Latin America, medium-grain rice is preferred for its ability to absorb flavors, making it ideal for dishes like arroz con pollo.

In the Middle East, parboiled rice is popular due to its firm texture and ability to retain nutrients.

To meet these preferences, rice manufacturers invest heavily in research and development. They work closely with agricultural experts to cultivate specific rice varieties that align with regional tastes. Additionally, they ensure that their processing and packaging methods maintain the quality and authenticity of the rice, making it popular among local consumers.

Innovations in Rice Production and Processing

The rice industry has come a long way from traditional farming methods. Today, rice suppliers leverage cutting-edge technology to increase production efficiency and meet global demands. Some of the key innovations include:

Advanced milling technology: Modern milling machines remove the husk and polish the rice with precision, ensuring consistent quality and reducing waste.

Automated sorting systems: These systems use AI and machine learning to sort rice grains by size, color, and quality, ensuring that only the best grains reach the market.

Fortified rice: To address malnutrition, manufacturers are producing fortified rice enriched with essential vitamins and minerals to meet the needs of health-conscious consumers.

These advancements not only improve the quality of rice but also enable manufacturers to increase production and meet the needs of a growing global population.

Sustainability practices in modern rice manufacturing

With growing awareness about environmental issues, sustainability has become a top priority for rice exporters and manufacturers. The rice industry is adopting eco-friendly practices to reduce its carbon footprint and conserve resources. Some notable initiatives include:

Water-efficient farming: Techniques such as the System of Rice Intensification (SRI) help farmers use less water while also increasing yields.

Renewable energy: Many rice mills are using solar or wind power to power their operations, reducing dependence on fossil fuels.

Waste management: By converting rice husks into biofuels or using them as animal feed, producers are reducing waste and promoting a circular economy.

These sustainable practices not only benefit the environment, but also enhance rice suppliers reputations as responsible players in the global market.

The role of technology and logistics in meeting global demand

Meeting global market demands requires more than just efficient production – it also requires seamless logistics and distribution. Rice producers rely on technology to streamline their supply chains and ensure timely deliveries. Key strategies include:

Digital tracking systems: These systems allow producers to monitor the movement of rice from fields to warehouses and finally to consumers, ensuring transparency and quality control.

Cold storage facilities: To preserve the freshness of rice during transit, many exporters invest in state-of-the-art cold storage solutions.

Global partnerships: By collaborating with international distributors and retailers, producers can expand their reach and meet the needs of diverse markets.

These technological advancements and logistics strategies enable rice exporters to deliver high-quality rice to consumers around the world regardless of geographical barriers.

Challenges and Future Trends in the Rice Industry

While the rice industry has made significant progress, it still faces challenges such as climate change, price fluctuations, and supply chain disruptions. However, producers are adapting in the following ways:

Investing in climate-resistant rice varieties that can withstand extreme weather conditions.

Diversifying their product portfolios to include organic, gluten-free, and specialty rice varieties.

Exploring new markets in Africa and Europe, where rice consumption continues to grow.

Looking ahead, the industry is poised to grow further, driven by innovation, sustainability, and a deep understanding of consumer needs.

The global rice market is a complex and dynamic landscape, but rice manufacturers have approached the challenge with remarkable ingenuity. By understanding regional preferences, adopting technology, and prioritizing sustainability, they have successfully met the diverse demands of consumers around the world. As the industry continues to evolve, one thing is clear: rice will remain a cornerstone of global food security, thanks to the tireless efforts of rice exporters and suppliers.

1 note

·

View note

Text

3pl Companies Seattle

3pl Companies Seattle https://modernlogisticsusa.com/3pl-companies-seattle/ United States

3PL Companies Seattle: Why You Need Them, Applications, and Benefits In today’s fast-paced supply chain and logistics industry, businesses are increasingly turning to 3PL companies in Seattle to manage warehousing, distribution, and transportation. Third-party logistics (3PL) providers help businesses streamline operations, reduce costs, and improve efficiency by handling critical aspects of the supply chain. Whether you’re a small e-commerce retailer, a growing manufacturer, or a large corporation, partnering with a 3PL company can help scale your business and optimize logistics processes. This article explores why 3PL services are essential, their various applications, and the benefits of outsourcing logistics.

Why You Need 3PL Companies in Seattle Seattle is a major logistics hub, with its proximity to international ports, a strong transportation network, and a thriving economy. Businesses in the region often require efficient supply chain solutions to handle inventory, shipping, and distribution. Here are some key reasons why you may need a 3PL provider:

Efficient Warehousing and Inventory Management 3PL companies offer state-of-the-art warehousing solutions, helping businesses store and manage inventory without the need for expensive facilities.

Scalable Fulfillment Services As your business grows, so do your logistics needs. A 3PL provider allows you to scale your operations up or down based on demand without investing in additional infrastructure.

Cost Savings and Reduced Overhead Outsourcing logistics eliminates the need for investing in warehouses, trucks, and fulfillment staff, significantly reducing costs.

Faster and More Reliable Shipping Seattle is a key gateway for domestic and international shipments. A 3PL provider ensures faster shipping times by optimizing transportation routes and managing carrier relationships.

Expertise in Logistics and Compliance 3PL companies are experts in handling complex supply chain requirements, customs regulations, and freight management, ensuring smooth operations.

Focus on Core Business Operations Outsourcing logistics allows businesses to concentrate on product development, marketing, and customer service rather than managing supply chain operations.

Advanced Technology and Data Analytics 3PL providers use advanced logistics software, real-time tracking, and data analytics to improve efficiency and provide businesses with valuable insights.

Applications of 3PL Services in Seattle 3PL services cater to a wide range of industries, from e-commerce startups to large-scale manufacturers. Here are some key applications:

E-Commerce Fulfillment With the rise of online shopping, businesses require efficient order fulfillment solutions. 3PL providers manage: • Warehousing and inventory tracking • Picking, packing, and shipping • Returns processing and customer service

Retail and Wholesale Distribution For retailers and wholesalers, 3PL companies handle large-scale inventory storage, order fulfillment, and distribution to stores or customers.

Freight and Transportation Management 3PL providers arrange domestic and international freight, choosing the most cost-effective and reliable shipping methods. Services include: • Freight forwarding • LTL (Less Than Truckload) and FTL (Full Truckload) shipping • Last-mile delivery solutions

Cold Storage and Food Logistics Seattle has a strong seafood and perishable goods industry. 3PL companies offer temperature-controlled warehousing and transportation for fresh and frozen products.

Manufacturing and Industrial Logistics Manufacturers rely on 3PL companies for supply chain management, including raw material transportation, just-in-time inventory, and finished product distribution.

Cross-Docking and Transloading For businesses that import goods through Seattle’s ports, 3PL providers offer cross-docking and transloading services to move shipments quickly and reduce storage costs.

International Shipping and Customs Brokerage Seattle’s port is a major gateway for global trade. 3PL companies assist with customs clearance, import/export regulations, and international freight coordination.

Benefits of Hiring a 3PL Provider in Seattle Partnering with a 3PL provider offers numerous advantages that improve supply chain efficiency and business growth.

Reduced Costs and Increased Profitability Outsourcing logistics eliminates the need for owning warehouses, hiring staff, and managing shipping operations, leading to significant cost savings.

Faster Order Fulfillment With strategically located fulfillment centers, 3PL providers offer quicker shipping times and better customer satisfaction.

Advanced Technology and Automation Most 3PL companies use warehouse management systems (WMS), AI-driven analytics, and automated order processing to enhance accuracy and efficiency.

Risk Management and Compliance Logistics companies handle compliance with shipping regulations, tariffs, and safety standards, reducing the risk of legal issues.

Greater Flexibility and Scalability Businesses can easily adjust inventory storage and fulfillment needs based on seasonal demand without making long-term investments.

Improved Customer Satisfaction Faster deliveries, accurate order fulfillment, and better return management contribute to a superior customer experience.

Global Supply Chain Support For businesses looking to expand internationally, 3PL providers offer seamless global logistics solutions, including customs brokerage and freight forwarding.