#cnc machine tools market

Explore tagged Tumblr posts

Link

#market research future#cnc metal cutting machine tool#metal cutting machine tools#cutting machine tools market#cnc machine tools market

0 notes

Text

CNC Machine Market Size, Share & Industry Trends Growth Analysis Report by Offering (Machines, Parts & Accessories, Services), Product Type (Milling Machines, Machining Centers, Lathe Machines, Laser Machines, Drilling Machines, Grinding Machines, EDM Machines), End-User Industry & Region - Global Forecast to 2028

0 notes

Link

#market research future#cnc metal cutting machine tool#metal cutting machine tools#cutting machine tools market#cnc machine tools market

0 notes

Text

CNC Metal Cutting Machine Tools Market to Exhibit 6.7% CAGR by 2027 - Report by Market Research Future (MRFR)

CNC Metal Cutting Machine Tools Market Overview: According to a comprehensive research report by Market Research Future (MRFR), “CNC Metal Cutting Machine Tools Market Research Report, Product Type, By Application and By Region - Forecast Till 2027” the market is expected to expand at a CAGR of 6.7% from 2020 to 2027 (forecast period).

Market Analysis

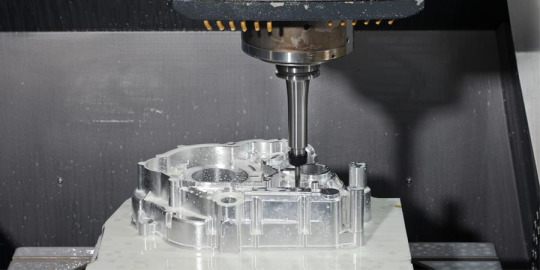

CNC metal cutting machining is a manufacturing process that uses computer software that has been pre-programmed to control the movement of factory machines and equipment. The approach is used to control a wide range of complex devices, including metal cutting, broaching, grinders, lathes, and others. These machines are frequently used in metal cutting operations to obtain the desired cutting of the metal workpiece. Metal cutting machines currently on the market include plasma cutters, laser cutting devices, and fiber cutters.

0 notes

Text

The global CNC controller market size is projected to reach USD 3.4 billion by 2026, growing at a compound annual growth rate (CAGR) of 3.6% during the forecast period.

0 notes

Text

Global top 13 companies accounted for 66% of Total Frozen Spring Roll market(qyresearch, 2021)

The table below details the Discrete Manufacturing ERP revenue and market share of major players, from 2016 to 2021. The data for 2021 is an estimate, based on the historical figures and the data we interviewed this year.

Major players in the market are identified through secondary research and their market revenues are determined through primary and secondary research. Secondary research includes the research of the annual financial reports of the top companies; while primary research includes extensive interviews of key opinion leaders and industry experts such as experienced front-line staffs, directors, CEOs and marketing executives. The percentage splits, market shares, growth rates and breakdowns of the product markets are determined through secondary sources and verified through the primary sources.

According to the new market research report “Global Discrete Manufacturing ERP Market Report 2023-2029”, published by QYResearch, the global Discrete Manufacturing ERP market size is projected to reach USD 9.78 billion by 2029, at a CAGR of 10.6% during the forecast period.

Figure. Global Frozen Spring Roll Market Size (US$ Mn), 2018-2029

Figure. Global Frozen Spring Roll Top 13 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Discrete Manufacturing ERP include Visibility, Global Shop Solutions, SYSPRO, ECi Software Solutions, abas Software AG, IFS AB, QAD Inc, Infor, abas Software AG, ECi Software Solutions, etc. In 2021, the global top five players had a share approximately 66.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

2 notes

·

View notes

Text

Integrating CNC Grinding, Gundrilling, and Steering Machines for Maximum Efficiency

When you run a workshop, your goal is to be as efficient as possible. This means making sure all your machines, like CNC grinding machines, gundrilling machines, and steering machines, work well together. This blog will guide you on how to integrate these machines to maximize workshop efficiency.

Understanding Your Machines

CNC Grinding Machine:

A CNC grinding machine uses a rotating wheel to smooth surfaces. This machine is perfect for creating precise shapes and smooth finishes on metal pieces. It’s controlled by a computer, which means it can produce parts that are consistent and of high quality.

Gundrilling Machine:

Gundrilling machines are designed to drill deep holes with a high degree of accuracy. These machines are key in industries where precision is crucial, such as in the making of molds, dies, and various engineering components.

Steering Machine:

Steering machines shape and finish steering components, ensuring they meet specific design requirements. This is critical in automotive manufacturing, where the precision of steering components can affect vehicle performance and safety.

Steps to Integrate Your Machines

Layout Planning:

Start by planning the layout of your workshop. Place machines that are part of a similar processing line close to each other. For example, materials that are first processed in a CNC grinding machine should have easy access to the gundrilling machine if the next step involves drilling.

Scheduling Software:

Use scheduling software to manage each machine's operation times. This software can help prevent bottlenecks where one machine is waiting for another to finish. It ensures that each machine starts its task at the right time, keeping the workflow smooth and continuous.

Regular Maintenance:

Keep all machines in top condition. Regular maintenance checks can prevent unexpected breakdowns that could slow down the whole production line. Each machine, from the CNC grinder to the steering machine, should have a clear maintenance schedule.

Feedback Loop:

Create a feedback loop where data from the machines' operation is regularly analyzed to find areas for improvement. For example, if the data shows that parts from the CNC grinding machine often need adjustments before gundrilling, it might be time to recalibrate the machine.

Leveraging WIDMA's Expertise

As a final point, consider partnering with technology providers like WIDMA, a renowned leader in manufacturing precision tooling solutions. WIDMA offers a range of CNC grinding machines, gundrilling machines, and other specialized equipment tailored to enhance manufacturing efficiency.

WIDMA’s machines are built with the latest technology to ensure they deliver high performance and reliability. Moreover, WIDMA provides comprehensive support and training, which can be invaluable for workshops looking to integrate new machinery or optimize existing setups.

Using WIDMA’s advanced equipment and expert services, you can achieve a streamlined workflow that maximizes productivity and reduces downtime. Their commitment to innovation and quality makes them a smart choice for any workshop serious about staying competitive in today’s fast-paced market.

Conclusion

Integrating your CNC grinding machine, gundrilling machine, and steering machine efficiently requires thoughtful planning and the use of advanced technologies. By optimizing the workflow, maintaining machines properly, and leveraging expert solutions like those from WIDMA, your workshop can achieve the high efficiency and productivity needed to succeed in the manufacturing industry.

2 notes

·

View notes

Text

Rapid Prototyping Services Revolutionizes Innovation

Rapid prototyping is a process that uses three-dimensional computer-aided design (CAD) data to quickly produce a scale replica of a physical item or assembly. The intention is to provide engineers and designers the opportunity to assess a design's shape, fit, and functionality before mass production. The procedure allows for rapid prototype, which cuts down on the development cycle's duration and expense.

Important Elements of Services for Rapid Prototyping

3D Manufacturing

3D printing is one of the most popular methods for fast prototyping. It entails the layer-by-layer deposition of material from a computer design to produce a tangible item. The versatility of materials, such as metals, ceramics, and plastics, allows for the flexible prototyping of a wide range of items.

CNC Machining: CNC machining is a type of subtractive manufacturing in which a machine tool controlled by a computer removes material from a solid block to mold it into the desired shape. Prototypes may be made with this technique using a variety of materials, including metals and polymers.

Molding by Injection

High-volume prototypes are produced by the rapid prototyping manufacturer using injection molding. The prototype is created by pouring molten material into a mold cavity, where it hardens. Larger production runs result in lower per-unit costs, notwithstanding the greater initial tooling cost.

Advantages of Services for Rapid Prototyping

Accelerated Product Development: From concept to final design, the time it takes to produce a product is greatly decreased by rapid prototyping. Businesses can gain a competitive edge by bringing items to market faster because of this speed.

Savings: When adjustments are needed, traditional prototyping techniques may be costly. Quick modifications are made possible by rapid prototyping, which lowers tooling costs and development costs overall.

Iterative Design Process: An iterative design process is supported by the capacity to swiftly create and test prototypes. Designers can quickly retest, make changes, and get feedback, which results in a better and more optimized final product.

Customization & Complexity: Using Chinese rapid prototyping services makes it feasible to produce extremely intricate and personalized designs that would be difficult or impossible to produce using conventional manufacturing techniques. In sectors including consumer electronics, healthcare, and aerospace, this capacity is very useful.

#Chinese Rapid Prototyping Services#Rapid Prototyping China#Rapid prototyping Supplier#Rapid prototyping manufacturer#Rapid Prototype

4 notes

·

View notes

Text

Woodworking tips and insights from the masters in woodworking

Are you looking for Woodworking tips from an expert in creating bespoke design and décor for businesses? Give it a shot right away to see how the outcomes turn out! Are you seeking custom-design items in Bahrain?

Then hang on, and let’s show you the top tips for woodworking in Bahrain.

Statistics say it all !

A survey of amateur and professional woodworkers conducted in New Mexico found that the highest rate of woodshop tool-related injuries was the jointer-planer at 4.9 injuries per 1000 person-hours of use.

Hammers and table saws were also frequently associated with woodshop injuries, with one-third of the reported injuries requiring professional medical care and five percent of respondents experiencing partial amputations.

Woodworking Safety Tips include

Wearing safety glasses,

Wearing appropriate clothing,

Avoiding drugs and alcohol,

disconnecting power before blade changes,

using sharp blades and bits,

checking for nails, screws, or other metal before cutting.

Check the stock for metal pieces before cutting and use a metal detector to check for metal.

Do not reach over a blade to remove cut-offs, focus on your task and avoid distractions.

Why use digital crafts from the top woodworking companies in Bahrain are trending?

In Bahrain, digital crafts allow for an infinite amount of creative expression!

We stand apart from digital creative works in Bahrain.

Art installation services in Bahrain have a well-deserved reputation.

Attractiveness to the eye is the new currency.

Because of this, Master Kraft in Bahrain ensures that

Using the services of one of the most reputable digital printing firms in Bahrain will help you take your marketing strategy to the next level and bring in additional customers.

Let us break some bubbles and tell you about the things you did not know about Masterkraft, shall we?

Why are we the best?

Anything to everything

From designing interiors to display units, we design several things.We deliver visual display services in Bahrain, thereby guaranteeing that you will receive the highest quality woodwork in Bahrain.

Top-notch professionals

In addition to highly -qualified, carpenters, vinyl applicators, painters, and other skilled and semi-skilled personnel, the company has competent project managers and site coordinators to complete diverse works on time and professionally.

The only place where you can find..

Master Krafts in Bahrain is the only place you can find CNC machines with unrivaled precision and user-friendliness. They are created for creativity, speed, and excellency with the greatest display unit cabinets in Bahrain. Because of this, people in Bahrain consider being the most advanced industrial CNC machines available.

Standing out visibilty

Your brand will have excellent visibility thanks to the Exhibition Stand Contractors in Bahrain that are provided by Master kraft. They are works of art that truly stand out in Bahrain.

Get it right away!

We have some of the most loyal customers in Bahrain as a result of our high standards of ethics and the high quality of our products.

Get original display products in Bahrain from the joinery businesses that are considered to be the best in Bahrain.

2 notes

·

View notes

Text

All you need to know about Custom Rapid Prototypes – HLH Rapid

In manufacturing, product development needs to be fast, precise, and flexible. Custom rapid prototyping helps industries quickly turn CAD designs into real products. From unique ideas to testing, these prototypes are changing how businesses innovate.

Brief Summary of Custom Rapid Prototyping

Custom rapid prototyping involves creating tailored models or components directly from a digital design file. Using techniques such as 3D printing, CNC machining, and injection molding, these prototypes are crafted to meet specific project needs, ensuring they are precise and fit for their intended purpose.

Unlike standard prototyping, custom rapid prototypes are designed with the end user’s unique requirements in mind. This personalization enables better testing, improved functionality, and faster iterations.

Key Advantages of Custom Rapid Prototyping

Speed to Market

Rapid prototyping drastically reduces lead times, enabling businesses to bring their products to market faster. Customization ensures that every iteration is closer to the final product, saving time on revisions.

Cost Efficiency

By identifying design flaws early, custom prototypes eliminate the need for costly adjustments in later production stages. Additionally, producing only what’s needed minimizes waste.

Design Flexibility

With custom prototypes, designers can test multiple variations without committing to full-scale production. This flexibility fosters innovation and creativity.

Functional Testing

Custom prototypes are not just visual models, they can be functional parts. This allows businesses to assess performance, durability, and usability in real-world conditions.

Enhanced Communication

Physical prototypes make it easier for teams, stakeholders, and clients to visualize the product, bridging the gap between concept and reality.

Popular Methods for Creating Custom Prototypes

1. 3D Printing (Additive Manufacturing)

Ideal for complex geometries and quick turnarounds, 3D printing is perfect for producing intricate designs using materials like resin, nylon, and metals.

2. CNC Machining

For high-precision prototypes with superior surface finishes, CNC machining excels. It’s commonly used for metal and plastic parts requiring tight tolerances.

3. Vacuum Casting

This process replicates prototypes using silicone molds, offering excellent detail and material options for small production runs.

4. Sheet Metal Fabrication

A great choice for creating durable and functional prototypes in industries like aerospace and automotive.

Applications of Custom Rapid Prototyping

Aerospace: Lightweight, high-strength parts for testing and assembly.

Automotive: Prototypes for components like engine parts, dashboards, and lighting systems.

Medical Devices: Custom models for surgical tools, implants, and diagnostics equipment.

Consumer Products: Iterations of gadgets, packaging, and home appliances.

Why Choose Custom Prototypes?

Custom rapid prototypes are designed specifically for your project, ensuring they meet your goals. Whether you need unique dimensions, specialized materials, or a specific functionality, custom prototypes allow for unmatched precision and personalization.

Conclusion

Custom rapid prototyping is transforming industries by making innovation faster, more efficient, and highly accurate. With advanced manufacturing methods, businesses can quickly bring their ideas to life. Whether you're creating a new product or improving an old one, custom prototypes make the process smoother and more successful.

Need custom rapid prototypes for your next product development? Contact us to learn how we can help you with your next project. Submit your CAD file here

0 notes

Text

The Growing CNC Machine Tools Market: Trends, Innovations, and Future Outlook

The CNC (Computer Numerical Control) machine tools market is experiencing significant growth, driven by the increasing demand for precision, automation, and high-quality manufacturing. CNC machine tools, which use computer programs to control machinery, have revolutionized the way industries such as automotive, aerospace, electronics, and manufacturing operate. These tools are essential for producing complex parts with exceptional accuracy and efficiency, making them indispensable in today's advanced manufacturing environments.

The CNC machine tools market size is projected to grow from USD 67.5 billion in 2023 to USD 80.4 billion by 2028, with a compound annual growth rate (CAGR) of 3.5% during the forecast period from 2023 to 2028. This growth is being driven by the increasing automation in manufacturing industries globally, as well as the need for reduced operating costs and enhanced production capabilities. The rising demand for high-precision components, especially for high-growth industries such as automotive, aerospace, and electronics, is further fueling the expansion of the CNC machine tools market.

The continuous push for efficiency, combined with the mass production of complex, high-quality parts, is making CNC machine tools an essential technology across various industrial sectors. The growing adoption of automation and the ability of CNC machines to deliver precise, repeatable results are key factors contributing to the positive market outlook. As industries strive for greater productivity and lower operational costs, the CNC machine tools market will continue to experience robust growth throughout the forecast period.

Download PDF Brochure @ https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=195192631

Key Factors Driving the CNC Machine Tools Market Growth

Several factors are contributing to the robust growth of the CNC machine tools market:

Rising Demand for Automation: As industries focus on improving efficiency, reducing labor costs, and enhancing precision, the demand for CNC machine tools has surged. Automation in manufacturing is streamlining operations, and CNC machine tools play a crucial role in this transformation.

Technological Advancements: The continuous evolution of CNC machine tools with advanced features like multi-axis capabilities, enhanced software integration, and IoT connectivity is attracting more manufacturers. These innovations not only improve the functionality of the machines but also make them more adaptable to various industries.

Precision Manufacturing Needs: As the demand for high-precision components rises, especially in sectors like aerospace and medical devices, CNC machine tools offer the precision and repeatability required to meet these stringent standards. The ability to produce complex geometries with minimal human intervention is boosting their adoption.

Growth of the Automotive and Aerospace Sectors: Both the automotive and aerospace industries are experiencing rapid growth, which is driving the need for CNC machine tools to manufacture high-quality parts efficiently. The increasing demand for electric vehicles (EVs) and aircraft components further fuels the need for precision machining.

Emerging Markets: The expansion of manufacturing activities in emerging economies, especially in Asia-Pacific, is creating new opportunities for the CNC machine tools market. Countries like China, India, and South Korea are investing heavily in industrial automation, which is expected to contribute to market growth.

Key Market Trends in CNC Machine Tools

Integration of Industry 4.0: The incorporation of Industry 4.0 technologies into CNC machine tools is enhancing their capabilities. Features such as smart sensors, predictive maintenance, and data analytics enable machines to operate more efficiently and with greater uptime. This trend is improving the overall productivity of manufacturing operations.

Customization and Flexibility: Manufacturers are increasingly looking for CNC machine tools that offer flexibility and customization. The ability to adjust machine settings based on specific production requirements is enhancing the appeal of these tools across different industries.

Green Manufacturing: As sustainability becomes a focal point, the demand for CNC machine tools that minimize waste and energy consumption is on the rise. Many manufacturers are designing more energy-efficient machines that support sustainable production practices, further contributing to the market’s growth.

Hybrid CNC Machines: The rise of hybrid CNC machine tools, which combine additive manufacturing and traditional subtractive methods, is gaining traction. These machines allow for faster and more cost-effective production processes, attracting manufacturers in various industries, including aerospace and medical device production.

Challenges in the CNC Machine Tools Market

Despite the positive growth outlook, there are challenges that could impact the CNC machine tools market:

High Initial Investment: The cost of CNC machine tools can be prohibitive for small and medium-sized enterprises (SMEs). The high capital investment required to purchase and maintain these machines can limit their accessibility for some manufacturers.

Skilled Labor Shortage: Operating and maintaining CNC machine tools requires a high level of expertise. The shortage of skilled workers in certain regions could hinder the adoption of CNC technology, slowing down market growth.

Competition from Low-Cost Manufacturers: The market for CNC machine tools is highly competitive, with numerous players offering a wide range of products. Price competition from manufacturers in low-cost regions could potentially impact the profitability of companies in the higher-end segment.

Future Outlook of the CNC Machine Tools Market

The CNC machine tools market is poised for continued expansion, driven by technological advancements and growing demand from key industries. The future of the market will likely see increased integration of automation, artificial intelligence, and machine learning, further enhancing the capabilities of CNC machine tools. As industries seek higher precision and faster production times, CNC machine tools will continue to evolve, making them even more integral to modern manufacturing.

In conclusion, the CNC machine tools market is on an upward trajectory, thanks to advancements in automation, precision, and technology. As global demand for high-quality and efficient manufacturing processes grows, CNC machine tools will remain at the heart of industrial innovation. The industry's evolution will play a pivotal role in shaping the future of manufacturing across multiple sectors, from automotive to aerospace and beyond.

By staying informed about emerging trends and leveraging new technologies, manufacturers can unlock the full potential of CNC machine tools and maintain a competitive edge in an increasingly automated world.

0 notes

Link

#market research future#multi-tasking machine tools#machine tool industry#cnc machine tools market#global machine tools market

0 notes

Text

The Basics of Machine Shop Equipment Auctions

Machine shop equipment auctions are an excellent opportunity for businesses, hobbyists, and individuals to purchase high-quality machinery at competitive prices. Understanding the basics of these auctions can help you maximize your investment and avoid potential pitfalls.

What Are Machine Shop Equipment Auctions?

Machine shop equipment auctions offer various tools, machines, and accessories used in metalworking, fabrication, and manufacturing. These auctions may be held due to business closures, upgrades to newer equipment, or liquidation of surplus inventory. Items typically available include lathes, milling machines, grinders, drill presses, CNC machines, and more.

Auctions can take place in person, online, or in a hybrid format. Online auctions have gained popularity for their convenience, allowing buyers to participate from anywhere and access a broader range of inventory.

Key Benefits of Purchasing at Auctions

Cost Savings: Equipment at auctions often sells for significantly less than its retail price, making it an affordable option for startups or expanding businesses.

Variety: Auctions provide access to diverse equipment brands and types, including hard-to-find or discontinued models.

Immediate Availability: Unlike waiting for new equipment to be manufactured or delivered, auctioned items are usually ready for pickup or shipment.

Potential for High-Quality Buys: With careful inspection, you can find well-maintained machinery that meets your needs.

Preparing for an Auction

Research the Auction: Learn about the auctioneer, the type of equipment being sold, and the terms and conditions of the event.

Set a Budget: Determine your spending limit beforehand to avoid overspending.

Inspect the Equipment: Most auctions allow for equipment previews. Assess the condition, age, and functionality of items. If you cannot attend the preview, request detailed photos or descriptions from the auctioneer.

Understand the Fees: Be aware of additional costs like buyer’s premiums, taxes, and transportation.

Tips for Bidding Successfully

Start with a Strategy: Bid competitively but avoid emotional bidding. Stick to your budget and focus on your top-priority items.

Monitor Market Prices: Familiarize yourself with the current market value of the equipment you’re interested in to ensure you're getting a good deal.

Check the Auction Format: Live and timed online auctions have different bidding dynamics. Adjust your strategy accordingly.

Common Pitfalls to Avoid

Ignoring Terms and Conditions: Overlooking payment terms, pickup deadlines, or warranty disclaimers can lead to unexpected expenses or difficulties.

Buying Without Inspection: Bidding blindly can result in purchasing faulty or incompatible equipment. Always verify the equipment’s condition.

Underestimating Logistics: Factor in transportation and rigging costs, especially for large or heavy machinery.

Closing Thoughts

Machine shop equipment auctions can be a goldmine for acquiring machinery, but success requires preparation, research, and strategic bidding. By understanding the auction process and taking the time to evaluate your options, you can secure valuable assets that enhance your operations without breaking the bank. Whether you’re a seasoned professional or a first-time buyer, the right approach ensures a worthwhile auction experience.

0 notes

Text

CNC Metal Cutting Machine Tools Market to Exhibit 6.7% CAGR by 2027 - Report by Market Research Future (MRFR)

0 notes

Text

Computer Numerical Control Machines Market

CNC Machines Market Size, Share, Trends: DMG MORI Co., Ltd. Leads

Integration of IoT and AI in CNC Machines

Market Overview:

The Computer Numerical Control (CNC) Machines Market is expected to develop at a CAGR of 6.8% from 2024 to 2031. According to estimates, the market will grow from XX USD in 2024 to YY USD by 2031. Asia-Pacific now dominates the industry, accounting for the vast majority of worldwide sales. Key factors include increased industrial automation, greater demand for precision engineering, and increased acceptance of Industry 4.0 technology. The manufacturing sector is developing, particularly in emerging markets, and driving stable expansion in the market. Factors such as increased need for mass production with shorter lead times, a greater emphasis on efficiency and precision in manufacturing processes, and the requirement for complicated component manufacture all contribute to market growth. Furthermore, the incorporation of cutting-edge technology such as artificial intelligence and machine learning into CNC machines promotes industry innovation.

DOWNLOAD FREE SAMPLE

Market Trends:

The CNC machine market is seeing a substantial shift towards the integration of Internet of Things (IoT) and artificial intelligence (AI) technologies. This transition is primarily being driven by the industry's push for smart manufacturing and the implementation of Industry 4.0 principles. IoT-enabled CNC machines provide real-time monitoring, predictive maintenance, and increased operational efficiency, whereas AI integration enables adaptive control, optimised toolpaths, and better decision-making processes. The trend of IoT and AI integration is projected to accelerate as manufacturers attempt to gain a competitive advantage through increased productivity and flexibility.

Market Segmentation:

Milling machines have established themselves as the dominant category in the CNC machine industry, owing to their versatility, precision, and broad variety of applications across several industries. These machines are capable of conducting sophisticated cutting operations on a wide range of materials, making them essential in current production processes. According to recent industry data, CNC milling machines account for about YY% of the global CNC machine market. Advances in multi-axis milling technology have reinforced the segment's market dominance, ensuring its continuous expansion and supremacy in the CNC industry.

Market Key Players:

The CNC machines market is highly competitive, with major players focusing on technological innovation and strategic alliances. Key companies such as DMG MORI Co., Ltd., Haas Automation, Inc., FANUC Corporation, Yamazaki Mazak Corporation, Okuma Corporation, Doosan Machine Tools Co., Ltd., Hyundai WIA, Makino Milling Machine Co., Ltd., GF Machining Solutions Management SA, and JTEKT Corporation dominate the market.

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes

Text

Metal Cutting Tools Market

Metal Cutting Tools Market Size, Share, Trends: Sandvik AB Leads

Growing Adoption of Additive Manufacturing in Metal Cutting Tools Production

Market Overview:

The Metal Cutting Tools Market is expected to develop at a 6.5% CAGR from 2024 to 2031. The market value is predicted to reach XX USD by 2024 and rise to YY USD by 2031.

Asia-Pacific currently dominates the market, with key data indicating high demand from the automotive and manufacturing industries. The market is rising steadily, mainly due to increased industrialisation, technological developments in cutting tools, and the growing adoption of CNC machines across a wide range of sectors.

DOWNLOAD FREE SAMPLE

Market Trends:

The metal cutting tool market is seeing a considerable shift towards the use of additive manufacturing (AM) technology in tool production. The demand for complicated geometries, customized equipment, and shorter manufacturing times has fuelled this trend. According to industry data, the usage of AM in cutting tool production has increased by 30% year on year, with some manufacturers reporting up to 40% reductions in lead times for specialized cutting tools. This tendency is especially prevalent in the aerospace and medical device production industries, where complicated and customized cutting tools are in great demand. Major cutting tool makers have reported making significant investments in AM technology, with some allocating up to 15% of their R&D expenditures to AM-related initiatives.

Market Segmentation:

The milling tools sector currently dominates the Metal Cutting Tools Market, accounting for over 35% of total market value. This supremacy is due to the versatility of milling operations in numerous production processes, as well as the ongoing technological breakthroughs in milling tool design.

Recent advancements in milling tools have reinforced this segment's position. For example, the use of improved coatings and geometries has resulted in a 25% increase in tool life and a 15% increase in cutting speeds for high-performance milling tools. These developments have been especially well-received in the aerospace industry, where a major aircraft manufacturer claimed a 30% reduction in machining time for complex titanium components utilizing the most recent milling equipment.

Market Key Players:

Sandvik AB

Kennametal Inc.

Mitsubishi Materials Corporation

Nachi-Fujikoshi Corp.

OSG Corporation

Iscar Ltd.

Contact Us:

Name: Hari Krishna

Email us: [email protected]

Website: https://aurorawaveintellects.com/

0 notes