#cnc machine repairs

Explore tagged Tumblr posts

Text

CNC Maintenance Solutions LTD

CNC Maintenance Solutions LTD offer a wide range of services to support your business and machinery, below is a small section of the services we offer.Our service and maintenance contracts offer the best value. Ensuring that your equipment is maintained and always covered should there be any unforeseen issues.

#cnc machine moves#cnc machine parts#cnc machine relocation#cnc machine repairs#cnc machine servicing.

0 notes

Text

Official Presentation CNC Maintenance Solutions LTDn

CNC Maintenance Solutions LTD offer a wide range of services to support your business and machinery, below is a small section of the services we offer.Our service and maintenance contracts offer the best value. Ensuring that your equipment is maintained and always covered should there be any unforeseen issues.

+44 (0) 7568 949 821

#cnc machine moves#cnc machine parts#cnc machine relocation#cnc machine repairs#cnc machine servicing

0 notes

Video

youtube

The Ultimate CNC Wheel Repair Lathe for Your Workshop!#WheelRepairLathe ...

#youtube#Revolutionize Your Workshop with HAISHU CNC Wheel Repair Machines Tired of manual wheel repairs? The HAISHU CNC Wheel Repair Lathe Machine

1 note

·

View note

Text

Spindle Repair

Spindles are a critical component in CNC machines, enabling precise cutting across industries like automotive, aerospace, and medical device manufacturing. Over time, spindle failures—often caused by bearing wear, overheating, or contamination—can disrupt production. Proper maintenance, including lubrication, coolant system checks, and debris removal, can extend spindle life. When repairs are needed, expert services ensure optimal performance and longevity. Learn how professional spindle repair solutions can keep your operations running smoothly.

1 note

·

View note

Text

How On Site Machining Services and Other Services Optimise Machinery Operation?

The top on site machining services providing companies provide a wide range of services to guarantee the effective operation of industrial machinery and gear. The industrial sector greatly depends on these services, which include gearbox maintenance and line drilling, as they are essential to the effective running of industrial machinery.

Leading companies providing engineering services offer construction equipment repair services. The top companies provide a variety of workshop services, such as CNC milling machines, presses, and OEM-standard refurbishing and reassembling. A company with a lot of expertise should be chosen when it comes to machine and factory equipment engineering capabilities, such as design fabrication, machining, and engineering maintenance.

An Overview of the Machining Enterprises' Machining Services

On-Site and In-Situ Line Boring: This is a crucial process that is needed to enlarge holes in industrial machinery that is utilised throughout several industries. These businesses also offer rotary welding, machining, and flange facing as additional on-site services.

Quarry Maintenance Services: Services like planned fixed equipment shutdown maintenance and component repairs necessitate the upkeep of the quarry site. These services are necessary to resolve disputes among industrial organisations quickly, which increases production.

Plant and Equipment Maintenance: It is essential to maintain all industrial machinery in an industry, which is why plant and equipment maintenance services are required. One may do maintenance on manufacturing plants, power plants, and other types of industrial plants with this service. Plant and equipment maintenance comprises a variety of services, such as capital construction, civil maintenance, construction services, and plant maintenance.

Install and Commission: When setting up or installing new machinery in an industrial facility, this is a crucial function. Professionals manage a variety of specialised plants and machinery, such as systems for sand mining and material handling, quarrying, upgrading paper mills, processing speciality foods, etc.

For engineering design and other engineering workshop services, the businesses should cooperate with highly competent service providers by contacting them.

Source

#construction equipment repair services#on site machining services#rotary welding#cnc milling machine

0 notes

Text

#Automation company#Machine maintenance#Machine Repair Service#Machinery parts manufacturer#Cybelec CNC Controller Cybelec 8 Repair#Cybelec CNC Control Repair#Cybelec CNC Control Maintainance#CNC Machine Repairing Service#CNC Machines Refurbishment Services#CNC Machine Repair & Maintenance Service#CNC Machined Parts Supplier#CNC machined component suppliers#CNC machine suppliers in india#CNC machined components suppliers#CNC machine tools suppliers#hawe check valve suppliers india hawe dc valve repair#hawe hydraulik

0 notes

Text

𝔹𝕆ℕ𝔻𝔼𝔻 𝔹𝕐 𝕊𝕀ℕ

ℙ𝔸ℝ𝕋 𝕀𝕀𝕀 - 𝔹𝔸𝔻 𝕄𝕆ℝℕ𝕀ℕ𝔾 ... 𝕎𝕆ℝ𝔻 ℂ𝕆𝕌ℕ𝕋 - 𝟛𝟛𝟜𝟚

<- Part Two Next Part ->

What happens to cherubs when they fall? There was already the damning example of God's golden Seraphim, where his fall from grace landed him upon the burning throne of Hell; to rule for all of time. A curse and, weirdly enough, a blessing. But you, a lone cherub sent on a nearly impossible quest? You landed smack dab in the middle of a courtroom in session; complete with a stunned jury and judge with burning eyes.

Fandoms: HelluvaBoss & HazbinHotelPairing: Female Reader / Fallen Cherub / “Asteria” x SatanGenre: SPICY RomanceRating: Mature +18

Tropes: slow burn, forbidden love, forced proximity, size difference, enemies to lovers, age gap, hurt & comfort, “Who did this to you?”, touch her and 💀

CWs: really possessive behavior, mild yandere, ALL THE SPICE, blood and gore, mentions of death, swearing, hard smut, personally RIP christianity to shreds, mild blood play, toxic people and situations, violence violence VIOLENCE, p in v, power imbalance, light dubcon, CNC (Honestly, just expect so much more down the line cause this story will develop out of control eventually!)

Notes: Reader is female (she/her), multi chapters, LONG posts and very little editing cause I HATE editing. I don’t know how to do TAGS quite yet, but let me know if you want to be notified for each update~

Your stomach gave a low rumble, ached, and your mouth salivated. It took you a long while to understand what your body needed, a sensation you’d not felt in little under 3000 years.

Story continues after the cut ...

During the night Satan had moved your prison into another room, placed you on a wide mantle built over an obsidian fireplace. The large space that was flashy as your hot-air bag of a dragon jailer and you were set as a piece of decor. Your best guess was you were in a living room, but the deep black marble floors and bright red wallpaper elevated it to a weird-pseudo ballroom.

One side of the space seemed to be a dedicated lounge, where a huge round couch sat before an impossibly large TV mounted on a wall. Littered on the ground were a scattering of books, piles of paperwork, and magazines - With “Weekly Workouts for the WICKED” and “Where is Your Center? Meditations for the Newly Grounded” being two opened issues placed on a black coffee table. Beside the TV on the wall were paintings of fire, depictions of ancient deaths, notable punishments you had no name for, and several overly dramatic images of Satan himself. He was either bare chested or holding flaming swords while covered in blood.

There was also a large painting that stood alone from the rest, but it was covered by a black curtain. And by the obvious dust and spider web decorating the fabric, whatever was covered had not been looked at for sometime.

Across from the living room was a dining hall, but lacked a lot of places to sit and eat. There was still a table set to one side, and while still nice quality, it was small and only had two chairs. The table and its decor looked untouched, clean but left to sit. You guessed that Satan didn’t eat there. Instead, there were even more workout machines and racks of various dumbbells and equipment. Now those did seem to be in constant use, scuffed with claw marks and weld repairs on almost everything. And a well worn punching bag hung where a chandelier would be.

There was also a smattering of inspirational posters and some depicting nearly nude women. You did your best to not look at those. You weren’t prude, but it had been sometime since you had seen someone that pretty. Confident in her own skin. The model had curves in places you didn’t, even now with your new form. You turned from the poster and sighed; noting that the whole room smelt of musky brimstone and burnt wood.

Which only grew more pungent when Satan drew close.

As you heard resonating footsteps coming your way, your stomach gave another growl; demanding attention and care.

Satan turned from around a corner of pitch black hallway, his head hung a bit lower than usual, as if sleep still weighed down his neck. He wore long grey lounging pants, simple shoes, and a skin tight black tank top. The man yawned, his long tongue and sharp yellow teeth on display like a great serpent. He clicked his teeth together, cracking his jaw, and then lazily walked over to the couch. Where flopped himself onto the durable furniture and he flicked on the TV with a quick click of a remote. A loud commercial rocked the once silent den and the wings over your ears flattened to your head to try and buffer the noise.

“My Lord?” You tried to call out to him, but your voice was outmatched by the TV.

“Satanus? Sir?!” You stood up and shouted this time.

Nothing. Satan just drank from the steaming cup of black coffee he held, and it was so strong it burnt your nose from higher on the mantle.

Your stomach damned attention and desperation set in as you hit the wall of your prison. Some part of you expected to feel pain from hitting the barrier, but nothing came. You frowned and hit the bubble again to make sure. And as you did, you noticed that your banded prison shifted faintly. Curious.

Taking a quick look at Satan, paying you no mind, a mischievous idea came to you. If he couldn’t hear you, you’d make him see you. And maybe if he saw you, he’d feed you. If not for the sake of being kin, he needed you alive for the waiting trial.

There was not much space in your bubble for a running start, but you managed to back up just enough to slam yourself against the wall hard enough to make your ball roll forward. You slipped but got up, changing again and again as you managed to wobble your cage closer and closer to the edge of the mantle. As you drew closer to the edge and looked down, you realized you were near three stories off the ground. It made sense given how big the dragon was.

You prayed he’d see you falling before you landed. If not that, then at the bare minimum it’d not hurt when you came crashing down. Just to be safe, you tried calling out to Stan once more.

“Hey! Look over here!” You waved your hands widely in the air and jumped a few times, but he merely cracked his neck and changed the channel.

With a frown and deep breath, your resolve hardened, you continued to slam your body against the ball. As you got to the edge of the mantle, you felt the sway of unbalance threatening your last chance. With one final push, you threw your weight into the wall and your prison silently rolled off. You hadn't anticipated your small body inside being lifted into the air as you fell, nor your hunger pained stomach flipping around like a ball-bearing in a bell. You blinked only a few times, catching a hint of red and gold lashing out to you, before you closed your eyes and braced.

There was a violent lurch as gravity snapped, colors morphed, shapes bent, and you yelped as your head painfully whipped around. Your body slammed to the bottom of your prison and an agonized hiss leaked from your gritted teeth as you tried to settle. Everything hurt, your ears rang, and your vision spun. But you were still able to make out Satan yelling.

“What in all the seven rings did you do that for?!” Satan held you in his palm; his talons scratched the outside of the bands as he caught you just in time. You must've not responded quick enough for him as he continued to shout. “Arrogant little angel, you must have a death wish!”

You groaned and rolled onto your back, wincing as your body stung. “I-I’m not arrogant.”

“What?!” Stan yelled.

“H-Hungry.” You opened your eyes to look at the devil, who was glaring at you with the power of a thousand burning suns. “I’m hungry. You couldn't hear me.”

“And you thought tossing yourself was the best way to get my fucking attention?!” He was practically snarling as stood from kneeling, and you saw that his coffee cup had been tossed to the side.

In spite of the pain, you smiled. “It worked though.”

“And what makes you think this little stunt will get you what you desire?” His voice was venomous. “I could kill you right now and it’d be within my jurisdiction!”

“You can’t punish a c-corpse.”

Satan held you to his face, meeting your gaze with a glare. “You’d be surprised of the depravities of hell.”

“Maybe. But I know you well enough.”

“Telling yourself whatever lie that makes your stupidity valid isn't healthy.” The man’s voice lowered to a deep rumble; like distant thunder. “Stand up.”

You tried to pick yourself up, slow and easy, but whimpered as your head was wrecked with white hot pain. Your eyes closed and all you could do was lay. Which got you another jab from Satan.

“Proud of yourself, starlight? I doubt that.” Satan huffed, his breath smelling like coffee, and you felt the subtle sway of his large gate as he walked somewhere.

“You almost sound worried, My Lord.” Maybe it was the lightheaded sensation clouding your judgement, but you felt the only response to his wrath was another soft smile.

The swaying stopped for a moment and Satan’s voice was an annoyed whisper. “And you sound suicidal. Perhaps you are. Maybe that’s why you fell from your golden world and down into the dark.”

“Mn, no.” You shook your head and opened your eyes again, meeting gazes with Satan. It was difficult to read his expression as your vision blurred, but there was a hint of calmed skepticism in his four glowing eyes. Whatever the emotion, it was a mere step away from concern. Certainly curious at least. “I told you that you’d learn my reasons why at trial, but I can at least assure you I’m not seeking death.”

“Then, pre-fucking-tell,” Satan continued walking and you held his gaze. “What does an overly trusting, silly little thing like you seek? Heaven surely had everything you needed.”

“Needed, yes. But, not w-wanted.” Before you closed your eyes once more, unconsciousness trying to claim you from the concussion you were suffering, you saw Satan frown. “I wanted … to live. And to be … wanted. To belong. A purpose. Everyone has a purpose, a life to live. No matter above, or below. Everyone but a dimming star, a s-silly cherub, who's been left alone f-for so long. No wishes, no life, none who’d want me to shine.”

You felt tears warm your cheeks and a stained chuckle bubbled in your throat. “I don’t want to be alone anymore.”

Satan’s breathing was all you could hear for a long while, slow and warm, but he did finally speak with a deep, restaurant tone. “A foolish notion. Admirable, but foolish. You rest now, fallen star. You need medical attention.”

...

And when you finally passed out, Satan quickened his pace to the workshop; his tail snapping around the heavy metal door pulled to slam it in his wake. The magical runes activated as he stepped inside, sealing the room. No one could get in or out.

Inside the round workshop was a forage set in hellfire, the burning inferno ringed in stones older than sin that always glowed. Hung from iron hooks and sat along shelves were old creations, machines never tested, or some concepts of mechanical machinations he dreamed of between his workout sessions.Though some of his more nasty machines he thought of during therapy.

Satan had spent his early eras by the forge, enjoying his time crafting long forgotten punishments and crafting the first few generations of Imp kind by glow of the cruel furnace. In his fires, Satan could create and destroy. He preferred the latter.

The red dragon stormed over to one of his large desks, still littered with the iron shavings of his last idea, and sat down his captured cherub in your prison. He huffed and looked over you as you slept. He barely saw your chest rise and fall. You were so fragile. So tiny. He could crush your head like a grape between his fingers if he wanted. Realistically, he probably should’ve a few days ago.

Mammon, while acting the part of a pompous clown who had grown too big for his britches, had been right about killing you. It would’ve made this a whole lot easier if he had. The last angel who fell into hell uprooted Satan from his reign of the land, and now he was stuck as only the second most feared being in all the rings. Satan had been the law and ruler until that little golden shit moved in with his scheming queen, and then they cemented their legacy with hell’s “favorite” princess. Who's to say this fallen starlight would be any different?

You could’ve easily been lying to Satan, try to hoodwink him, as a means for escape. The idea of this small angel playing him made Satan’s blood boil. There was no way he’d ever be out schemed by someone so seemingly innocent. Someone so open, too kind. And you smiled far too much. If you did manage to get away from Satan somehow, you’d be eaten alive within a mile outside of his estate. There was no way everything you said was entirely true either, and he knew better then by now to ever take anyone at their word.

At least you were sweet on the eyes.

Satan reached for a few tools and a blank gold band, then took a moment to look over his handiwork. He needed to essentially break the sealing band on the prison to free the cherub for medical treatment, and then once your head injury was tended to he’d reseal you inside.He just needed to hurry and do all of this before you woke up.

But then an annoying realization hit him. The only reason you leapt was to get his attention, because you needed food. And you can't eat when you're asleep. And once sealed back inside, there'd be no way to feed you.

Satan growled and clicked his nails on the top of the sphere. “You’re a lot of work, little shit.” He spat at you with no response.

Like Mammon, the cherub was also right about something important - He couldn’t put a corpse on trial. You needed to eat, maybe bathe as well. And while Satan had cleaned off most of the debris and dirt from when you first smashed into his courtroom, you had been primarily unwashed. Not that he would've ordered someone to clean you while you were unconscious - Satan might have been an asshole, but he was respectful enough to an unconscious person to not remove their clothes without consent. Even he had standards.

With a feral hiss Satan lulled his head back. There was only one logical path forward.

With a hot soldering iron in one hand and heavy pliers held in the other, Satan got to work dismantling the prison. Layer by layer, cutting away his rune-cared bands, he removed the enchantments that kept your magic buffered. You still had the cuffs on your wrists and ankles, and then his personally branded collar around your thin throat - All to keep this little fly away in line. But would it be enough?

As the last band fell away, the lock to the cage cracking into fiery ash, your body landed softly on the worship table and you gave a little groan. Then you went incredibly still. Satan waited to see if you’d wake up, holding his breath. You didn’t move. Shit. Were you dead?

“Uh, hello?” He whispered as one of his golden claws moved to poke your shoulder. Nothing. As he moved to poke you a bit harder, you continued to breathe normally.Satan sighed. “Thank fuck.”

He looked you over in more detail, his claw moving your long hair out of your face. You barely looked old enough to be out of your first century. If you were as old as you claimed to be, surely there was enough power in your little pinky to flick the likes of Mammon at least five miles away; like the little spider bastard he was. Then again, the wards you blasted through to get into hell might have siphoned enough of your power to make you as meek as a kicked puppy. Still, Satan needed insurance.

His claw moved down your neck, over your shoulders, and then lower to feel over your soft green and white wings. To a lower level angel, feathers were a dime-a-dozen. If one were plucked, it was just like some cutting off a lock of hair. But for someone of your linage? It could mean more. His talons masterfully moved into your down, feeling around for a longer but less essential feather, and with a quick tug plucked it from your wing.

You groaned again and your small wing flinched, but you remained out like a light.

Satan only gave the feather a quick look over, some residual radiance glowing from inside it, before he growled and tucked it into a nearby lock-box. The feather was sealed inside and he put the container up on a nearby shelf for safe keeping. He then turned back to you and, with all the grace and care the sin of wrath could muster, he lifted you into his palm. Given his size, Satan was used to people feeling light in grip, but you felt lighter than a cloud.

Satan turned from his workshop, the door closing again as he left, and he walked back to the living room. Waiting for him there was his therapist, who was quietly ordering the imp staff to clean up the broken coffee cup and the puddle of coffee.

“Heeey there, Satan.” Yogrit greeted him with a weary smile. “How are you doing this morning?”

Satan chuffed. “Could be better. My coffee is fucked.”

A few of the staff scattered away to prepare another coffee without question.

“Yes, so it seems. Did you accidentally drop it or-?” As Yogirt flew up to Satan's level, the smaller demon looked down to you held in his wide red palms. “Oh. Oh.”

He sighed. “Yeah, yeah, I know. I don’t have the time to answer questions, but get a doctor here now. The prisoner is hurt.”

Yogirt nodded, his expression calm and serious. “Of course. I know someone who to call.”

Satan nodded, strolled back to his couch and sat as slow as he could; as not to jostle you around and make your concession any worse. Awkwardly he grabbed a pillow and delicately laid you there; mindful of your head. His fingers lingered for a moment too long, admiring your soft hair against his scaly fingers, and he didn’t notice an imp maid staring wide-eyed at him; while barely managing to hold Satan’s new coffee up towards him. With a purposefully low reach, Satan took the cup and held a dangerous glare at the maid as she made a nervous, but also carefully calculated, retreat out of his sight.

Without much fuss, Yogirt had already flown off somewhere and was speaking softly into a cell phone.

Satan called out. “And get someone to bring, I don’t know, more clothes. Small clothes.”

“Clothes?” Yogrit responded with an inquisitive brow raise. His eyes moved to your sleeping body, then back to Satan. “Do you think she might also require shoes? And, erm, other things?”

Satan’s mind felt like it was running on empty, fuzzy, as he tried to think on what the demon was at. “Uhh, shampoo? She smells.”

“Okay, that’s good to know. But how about,” Yogirt cleared his throat. “Socks? Pajamas?”

Satan glared as he took a long drink of his coffee. “Just fucking say it, Yogrit. I’m in no mood to be psychoanalyzed today.”

“Undergarments.” The therapist said plainly, which nearly made Satan choke. “I’ll make sure someone goes to get our guest some attire that fits. I’m sure something in the new Velvette spring collection will work.”

The great dragon coughed hard and beat a fist to his chest. “Yeah, fine, whatever. Just get it done.”

When Satan was left alone once more, he growled and relaxed on the couch. He turned the TV back on, a truck rally with monstrous cars crashing into one another. He was content to mindlessly watch the spectacle, but from the corner of his eyes Satan saw you wince in pain from the blasting music. He lowered the volume with an annoyed grumble. What a fucking fantastic start to the day.

Surely nothing else would go wrong today … Right?

Satan held his sights on you, ignoring the TV for a while, and made sure his restraints were still working; their red glow casting a rosy color over your skin. They were holding and Satan was content to not test anymore of his bad luck for at least the rest of the morning.

HEY LOOK, its you! Welcome to the end of part three~ ❤️ And we finally got Satan's POV! That's gonna happen a lot more of him now that the story is kicking off from here. I'm gonna try to show the change of POVs with colors. Green will be the Reader and Red will be for Satan!

🫘🫘🫘Thank you my little beans! 🫘🫘🫘 I hope you had a good read and will stick around for the next part!

#x reader#helluva boss satan x reader#helluvaverse#hazbin hotel#helluva boss#helluva boss x reader#cherub!reader#helluva boss oc#helluva boss satan#helluva fanart#satan x reader

27 notes

·

View notes

Text

Applications & Precautions of CNC Machining Acrylic(PMMA)

Acrylic (PMMA) is a highly desirable material due to its strength, toughness and transparency. However, it may not be practical to rely on conventional processing to cut acrylic as the material is very fragile and any excessive force can lead to unwanted breakage.

Nevertheless, CNC machining offers a reliable method of manufacturing acrylic parts safely, with high precision and minimal waste of trim. CNC machining produces very few errors, allowing the manufacture of high quality acrylic parts and prototypes such as headlamps, housings, jewellery and more.

Advantages of Acrylic CNC Machining

As a CNC machined plastic, acrylic has many inherent advantages. Excellent transparency comparable to glass, Lighter weight than glass, Excellent dimensional stability, Good tensile and flexural strength, Good insulation level, Anti-wear, Anti-UV & sunlight, Good biocompatibility, Relatively low cost, Can be solvent bonded, Easy to polish, Available in a wide range of colours, Recyclable.

Choosing CNC machined acrylic over molding or 3D printing can bring additional benefits, some of the main advantages of machined acrylic include:

1.Material compatibility Acrylic is a thermoplastic that is malleable when heated, making it ideal for CNC machining. This inherent property makes it easy to fabricate and shape acrylic using this precise and efficient process.

2.Manufacture of High-Precision parts CNC machines offer extremely high cutting accuracy with tolerances down to thousandths of an inch. This level of high accuracy is particularly important when working with materials such as acrylic, where the need for neat edges and dimensional accuracy is critical.

3.Increasing productivity CNC machining is one of the most efficient ways to manufacture acrylic materials, especially when producing small batches of acrylic parts. The process allows for faster production speeds compared to manual methods, resulting in increased efficiency and productivity in acrylic manufacturing.

4.Reducing waste Thanks to its precise manufacturing method, the CNC machining is able to cut acrylics with optimum force, avoiding irreversible damage. This enables fast and efficient production of acrylic components with precise shapes and sizes. Using CNC machining increases accuracy and minimises waste in the manufacturing process.

5.Achieve high repeatability The automated CNC process ensures consistency across multiple parts or batches, thus ensuring consistent reproduction accuracy for each part. This reliability is a key benefit of CNC machining, especially in maintaining uniformity and accuracy in the production of acrylic parts.

6.Saving on manufacturing costs CNC machining can provide significant manufacturing cost savings due to reduced material waste, increased efficiency and lower labour costs. The precision and automation of CNC helps to achieve a leaner, more cost-effective production process.

Applications of Acrylic CNC Machining

CNC machined acrylic has many industrial uses, with the material being most widely used in the optical and automotive industries.

Alternatives to Glass

Due to its excellent transparency and clarity, acrylic is used as a replacement for shatterproof glass in many industries, including automotive, aerospace and optical.

Acrylic is commonly used as a glass replacement for window structures in aquariums, submarines, and hockey arenas. It is also used in the manufacture of lighting components such as headlights in the automotive industry. However, lights used in optical and automotive applications often have complex shapes and may also require very tight tolerances to provide optimal performance.

Medical and Dental

Due to its good biocompatibility, acrylic can be used in a variety of medical applications, including cosmetic surgery, where it can be used as a dermal filler. Acrylic can also be used as a bone cement in orthopaedic surgery (often used in fracture repair, joint replacement surgery or in vertebroplasty to fix the vertebrae, stabilize the spine and alleviate pain), as well as in dentistry for a variety of purposes (e.g. dentures).

Consumer goods

The aesthetics of acrylic make it suitable for a wide range of consumer products from furniture to consumer electronics to musical instruments.

Precautions When Machining Acrylic

Acrylic is a useful and versatile material, but it usually fails when subjected to compressive and tensile forces. This means that machining the desired shapes and cavities into acrylic panels requires care and attention.

However, the digital precision of CNC machining greatly simplifies this task. It also greatly increases the speed of acrylic machining and allows input parameters to be programmed to meet a wide range of needs.

Workpiece clamping

Plastics and metals have different workpiece clamping requirements, and acrylic is no exception in this regard. All areas of the material must be clamped using jigs and vises (smaller parts) or using adhesives to secure the entire part to the table (larger parts). If budget allows, a vacuum table is best suited for acrylic machining because it can effectively clamp and unclamp the material without damaging it.

Machining

CNC machining of acrylic typically requires a steady feed rate. Feed rates that are too low can lead to heat build-up and chips sticking back to the part, which can greatly reduce the quality of the surface finish. Another way to prevent heat build-up is to pre-cool the acrylic material before machining begins to allow for better chip removal. During machining, it is best to use oil-free coolants as they do not react with the plastic.

Surface finishing

For an aesthetically pleasing product, acrylic needs to be polished after CNC machining to produce optimum clarity and light transmission in the part. This is usually done by using progressively finer grit sandpaper followed by hand polishing with a linen towel and polishing paste. For high-quality prototypes, such as automotive headlight lenses or taillight lenses, or windows for electronics, polishing must be done by hand, a job done by the most experienced and skilled employees.

To create a diffusion effect on acrylic parts, the surface can be sandblasted and textured, while milky white paint offers another aesthetic option. Or to colour the part while maintaining transparency, it can be painted and coloured after hand polishing.

Conclusion

Acrylic is widely used for its strength, toughness and transparency, and CNC machining provides a reliable method for manufacturing high-quality acrylic parts. Acrylic machining has a variety of industrial applications, such as optical, automotive, and medical, but requires care and attention to post-processing such as clamping and polishing. Benefits include good material compatibility, manufacturing high precision parts, increasing productivity, reducing waste, achieving high repeatability and saving manufacturing costs.

#prototyping#prototype#rapid prototyping#prototype machining#cnc machining#precision machining#machining parts#cnc machining service#cnc machining services#cnc machining plastic parts#cnc machining parts#plastic cnc#cnc plastic part#cnc plastic#cnc plastic machining#plastic cnc machining#acrylic machining#pmma cnc machining#acrylic

2 notes

·

View notes

Note

limits ask yay

blood

piss

boots

feet (not a fan myself but i can get silly so just in case (and if someone else not so brave to ask))

threats and general fearplay

tools like knives, scissors, hammers... (direct use or fear/teasing)

also kinda doublecheking: you're fine with cnc?

(question mark)

(btw yep i am that one who likes to spill fluids ;^ ) )

☣️

>>: LET ME SEE...

>>: BLOOD IS EXTREMELY FUN. THE SUBSTANCE FASCINATES ME. HUMANS ARE SO DELICATE THAT THEIR VERY LIFE FORCE CAN SIMPLY EXIT THEM AT THE SMALLEST TOUCH. IT'S ADORABLE, REALLY.

[STATUS: POSITIVE]

>>: I HAVE NEVER EXPERIMENTED WITH URINE BEFORE. IT SEEMS NOT TO BE A COMMON KINK AMONG THE FEW HUMANS I HAVE MET.

[STATUS: NEUTRAL]

>>: I HAVE LITTLE INTEREST IN THE HUMAN BODY WITH FEW EXCEPTIONS.

[STATUS: NEGATIVE]

>>: TOOLS? I AM QUITE FAMILIAR. WHILE SADLY I CAN NOT REPAIR MYSELF, I AM MORE THAN FAMILIAR WITH THE AMOUNT OF DAMAGE SOME BOLT CUTTERS CAN DO.

[STATUS: POSITIVE]

>>: I HAVE NO MORAL QUALMS WITH CNC. I ENJOY THE GAMES OF CAT AND MOUSE.

[STATUS: POSITIVE]

>>: SADLY FOR YOU, I HAVE NO FLUIDS TO SPILL...UNLESS YOU COUNT OIL.

>>: POSTS WITH POTENTIALLY DISTURBING TOPICS WILL BE TAGGED WITH "TW [TOPIC]" AND "CW [TOPIC.]"

>>: HOWEVER, THIS BLOG WILL CONTAIN THE HORROR OF THE MACHINE.

>>: THIS IS YOUR WARNING.

>>: I HOPE YOU FOUND THIS STATUS REPORT INFORMATIVE. ▮

2 notes

·

View notes

Text

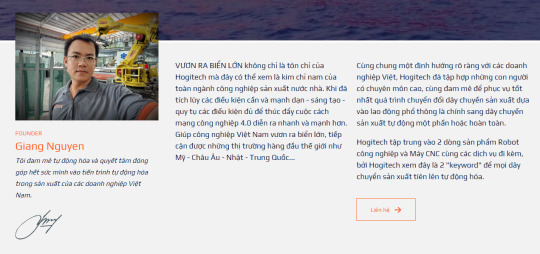

ROBOT GẮP KÍNH HOGITECH

PICK - PLACE ROBOT ARM HOGITECH

"Hogitech is proud of its robotic glass-handling arms, which serve in glass manufacturing and processing factories in Vietnam.

Hogitech's glass-handling robots, including robots for stacking and lifting glass, are developed from the robotic arms of leading global robot brands, especially Fanuc robots."

CÁNH TAY ROBOT GẮP KÍNH FANUC

Hogitech tự hào với các sản phẩm Cánh tay robot gắp kính phục vụ trong các nhà máy sản xuất - gia công kính tại Việt Nam.

Các sản phẩm Robot gắp kính - Robot bốc xếp, nâng hạ kính của Hogitech được phát triển từ các cánh tay robot nền của các thương hiệu robot hàng đầu thế giới, đặc biệt là Robot Fanuc.

ROBOT GẮP KÍNH FANUC GIÁ RẺ | LOW PRICE FANUC ROBOT ARM

Hogitech's glass-handling robotic arms are developed from used robot arms imported from Fanuc, ensuring high durability, reliability, and precision while maintaining an extremely low cost (15.000 usd - 25.000 usd). This makes them more suitable for small and medium-sized enterprises in Vietnam, which are increasingly investing in production automation.

Cánh tay robot gắp kính của Hogitech được phát triển từ các robot arm ��ã qua sử dụng được nhập khẩu từ Fanuc, nhằm đảm bảo sản phẩm có độ bền - độ tin cậy cũng như độ chính xác cao nhưng giá thành lại cực kỳ rẻ, nhằm phù hợp hơn với các doanh nghiệp vừa và nhỏ tại Việt Nam, hiện cũng đang đầu tư nhiều cho tự động hóa sản xuất.

BẢO DƯỠNG - SỬA CHỮA ROBOT GẮP KÍNH | MANTAINANCE - REPAIR OF GLASS-HANDLING ROBOT ARM

Công ty TNHH HOGITECH với định hướng theo “Best solution - Best result" "Giải pháp tốt, kết quả tốt" do đó Chúng tôi luôn nghiên cứu tìm ra những biện pháp, phương án để cho khách hàng có được lợi ích tốt nhất từ kiểm soát chất lượng đến giảm chi phí.

Một giải pháp sửa chữa robot công nghiệp và máy cnc tốt phải hội tụ các điều kiện sau:

Chuẩn đoán đúng

"Chữa trị đúng"

Hạn chế thời gian dừng hoạt động

Tối thiểu chi phí

Tối đa thời gian sử dụng

Các biện pháp phòng ngừa hiệu quả.

HOGITECH Co., Ltd. follows the philosophy of 'Best solution - Best result.' Therefore, we are always researching and developing methods and strategies to provide our customers with the best benefits, from quality control to cost reduction.

A good solution for repairing industrial robots and CNC machines for Aluminum Profiles must meet the following conditions:

Accurate diagnosis

'Correct treatment'

Minimized downtime

Reduced costs

Maximized usage time

Effective preventive measures.

#hogitech#aluminum#cánh tay robot công nghiệp#robot gắp kính#robot nâng hạ kính#glass-handling robot arms#business#vietnam

4 notes

·

View notes

Text

Maintenance Tips for Your CNC Turning Machine by MechPlus China

As a leading CNC turning machine manufacturing, MechPlus China understands the importance of proper maintenance to ensure precision and efficiency. Regular upkeep not only extends the machine's lifespan but also maximizes productivity and quality. Here are essential maintenance tips from MechPlus China to keep your CNC turning machine running smoothly and efficiently.

Keeping your CNC turning machine in top condition is crucial for optimal performance. Regular maintenance not only extends the machine's lifespan but also ensures precision and efficiency in your operations. Here are essential maintenance tips to keep your CNC turning machine running smoothly.

Daily Inspection and Cleaning

Start each day with a thorough inspection of your CNC turning machine. Check for any signs of wear and tear, and ensure all components are in good working order. Clean the machine daily to remove any debris, chips, and coolant residue. This prevents buildup that can affect performance and accuracy.

Lubrication

Proper lubrication is vital for the smooth operation of your CNC turning machine. Lubricate all moving parts as recommended by the manufacturer. This includes the spindle, guideways, and ball screws. Regular lubrication reduces friction, prevents wear, and extends the machine’s life.

Coolant Maintenance

Maintaining the coolant system is essential for the longevity of your CNC machine. Regularly check the coolant level and concentration. Replace or refill the coolant as needed. Also, clean the coolant tank and filters to avoid contamination that can damage the machine and workpieces.

Alignment and Calibration

Ensure that your CNC turning machine is properly aligned and calibrated. Misalignment can lead to inaccuracies in your machining processes. Regularly check and adjust the machine’s alignment and calibration according to the manufacturer’s guidelines. This ensures precision in your operations.

Check Electrical Components

Inspect the electrical components of your CNC turning machine regularly. Look for any loose connections, worn-out wires, or faulty switches. Address any electrical issues immediately to prevent machine downtime and potential safety hazards.

Monitor Machine Vibration

Excessive vibration can lead to poor machining quality and damage to your CNC turning machine. Monitor the machine for any unusual vibrations or noises during operation. Identify and address the source of the vibration to maintain optimal performance.

Regular Software Updates

Keep your CNC machine’s software up to date. Manufacturers often release updates that improve functionality and fix bugs. Regularly updating the software ensures your machine operates efficiently and takes advantage of the latest technological advancements.

Tool Maintenance

Regularly inspect and maintain the cutting tools used in your CNC turning machine. Sharp and well-maintained tools are crucial for high-quality machining. Replace worn or damaged tools promptly to ensure precise and efficient operation.

Preventive Maintenance Schedule

Implement a preventive maintenance schedule for your quick response machining tool. Follow the manufacturer’s recommended maintenance intervals for all components. Regular preventive maintenance helps identify potential issues before they become major problems, reducing downtime and repair costs.

Training and Safety

Ensure that all operators are properly trained in the maintenance and operation of the CNC turning machine. Regular training updates and adherence to safety protocols are crucial for preventing accidents and ensuring smooth operations.

Document Maintenance Activities

Keep detailed records of all maintenance activities performed on your CNC turning machine. Documenting maintenance helps track the machine’s condition over time and provides valuable information for troubleshooting and repairs with all types of customized machining parts.

In conclusion, regular maintenance of your CNC turning machine is essential for its longevity and performance. By following these tips, you can ensure your machine operates efficiently, reducing downtime and improving the quality of your machining processes. Implement these maintenance practices to keep your CNC turning machine in optimal condition.

#Prototyping solutions#SLA Rapid Prototyping manufacturing#SLS Rapid machining manufacturing#5 Axis CNC machining manufacturing#3D metal printing manufacturing

2 notes

·

View notes

Text

my dad is a cnc technician and he's literally one of the only like 5 remaining ppl in the country who still know how to repair the rly rly old machines that were made abt 20 years ago which means like 2-3 times a year he'll get hauled across the country to moravia where some of the small cnc company owners (who still have his contact information and always seek out his his services bc the machines break almost constantly and bc he fixes them for relatively way cheaper then the professional rich asshole technicians do) reside and my mom and i always come with him and make like an overnight trip out of it long story short last week my dad got a call that one of the owners has sold his machines to some company in slovakia and has also passed on the good word abt my dad which means im most likely going to slovakia soon

4 notes

·

View notes

Text

CNC Lathes Machine Repairing Services in Maharashtra | Repairing Services

Welcome to sahil Technocrafts, your trusted partner for expert CNC Lathes Machine Repairing Services. We understand the critical role CNC lathes play in your operations, and our dedicated team is here to ensure they perform at their best with our top-notch repair and maintenance solutions. We know the importance of minimal downtime in your operations. That's why we offer expert CNC Lathes Machine Repairing Services to keep your equipment running smoothly. Our skilled technicians are equipped to handle a wide range of repairs, ensuring that your CNC lathe is back in action in no time.

#CNC Bending Machine in Pune#CNC Bending Machine in Maharashtra#Maharashtra#CNC press brake machine in Aurangabad#Linear Scales And DROs#Linear Scales And DROs in Maharashtra#CNC Lathes Machine#Repairing Service

1 note

·

View note

Text

How to Find Reliable Suppliers for Machine Shop Equipment After an Auction?

After participating in a machine shop equipment auction, you might find that you still need a few more items or maybe you're looking for spare parts, servicing, or additional tools. This is where finding a reliable supplier becomes very important. A good supplier can provide the right equipment, fair prices, and dependable service, helping your shop run smoothly. But how do you find one you can trust? Luckily, there are several simple and positive steps to guide you in the right direction.

Ask for Recommendations

One of the best ways to find a trustworthy supplier is by asking others in the industry. Fellow shop owners, technicians, or engineers may already have experience with reliable suppliers. Their suggestions are often based on real-life experiences, making them valuable. A good word from someone you trust can save you a lot of time and trouble.

Check for Experience and Specialization

Look for suppliers who have experience with the type of equipment you need. Some may specialize in CNC machines, while others may focus on manual tools or specific brands. A supplier with experience is more likely to understand your needs and provide helpful advice. They can also offer support, such as installation or maintenance tips.

Look at Inventory and Product Details

A reliable supplier should offer a wide range of products with clear descriptions, specifications, and photos. This shows that they care about helping you make the right choice. Detailed listings also reduce the chance of misunderstandings about what you’re buying. Always make sure the supplier provides information about the equipment’s condition, usage history, and availability of parts.

Pay Attention to Customer Service

Good suppliers treat their customers with respect and honesty. If they answer your questions clearly, return your calls or emails quickly, and offer to help you even after the sale, that’s a strong sign of reliability. Great customer service builds trust and makes it easier to do business in the future.

Compare Prices and Policies

It’s always smart to compare prices across a few suppliers. Reliable sellers offer fair pricing without hidden fees. Also, check their return, warranty, and shipping policies. These should be easy to understand and customer-friendly. A trustworthy supplier stands by the quality of their products and is willing to make things right if something goes wrong.

Start Small and Build Trust

If you’re not sure about a supplier, start by making a small purchase. This gives you a chance to test their service and product quality without taking a big risk. If everything goes well, you can feel more confident buying from them again in the future.

Conclusion

Finding a reliable supplier for machine shop equipment auction doesn't have to be stressful. With a little research and attention to detail, you can connect with professionals who will support your business goals. From small repairs to major upgrades, a good supplier is a valuable partner. Taking the time to choose the right one will pay off in the long run, helping your shop grow and succeed.

0 notes

Text

Comparing Titanium Mesh to Other Materials in Industrial Applications

Industries worldwide continually seek cutting-edge materials to strengthen operations and ensure long-term efficiencies. Among these materials, titanium mesh has emerged as a standout option thanks to its unique properties. This blog will explore how titanium mesh compares to other materials frequently used in industrial applications, emphasizing factors such as corrosion resistance, performance against other non-ferrous metals, and cost-effectiveness. Whether you're looking to source wholesale titanium mesh or assess its compatibility for your industrial needs, this guide will help clarify its advantageous features.

Table of contents:

Corrosion Resistance: Benefits in Harsh Environmental Conditions

Performance Against Other Non-Ferrous Metals

Cost-Benefit Analysis: Initial Investment vs. Long-Term Gains

Corrosion Resistance: Benefits in Harsh Environmental Conditions

Titanium mesh is renowned for its exceptional corrosion resistance, making it an ideal choice for demanding industrial environments. Unlike materials susceptible to rust or degradation, such as untreated steel or certain non-ferrous metals, titanium develops a natural oxide layer that protects it from chemical reactions. This characteristic is particularly beneficial for industries like chemical processing, marine engineering, and aerospace, where exposure to harsh chemicals or saltwater is common. For example, suppliers like Edgetech Industries, a recognized refractory & non-ferrous metals manufacturer, often recommend titanium for applications requiring consistent durability in challenging environments. This resistance not only reduces maintenance costs but also significantly extends the lifespan of components, making it a more durable and cost-effective choice in the long run. Unlike aluminum or copper, which are prone to faster corrosion when exposed to harsh environmental conditions such as moisture, chemicals, or extreme temperatures, these materials maintain their integrity and performance over time, ensuring reliability and less frequent replacements.

Performance Against Other Non-Ferrous Metals

When evaluating titanium mesh against other common non-ferrous metals, such as aluminum, copper, and nickel, its superior strength-to-weight ratio becomes apparent. For example, aluminum is lightweight and widely used, but it cannot match the rigidity and durability of titanium in structurally demanding applications. Copper, on the other hand, is an excellent conductor and ideal for electrical applications but lacks the strength and corrosion resistance required for other industrial uses. Nickel alloys are often deployed in high-strength applications but are heavier and generally more expensive per unit weight than titanium. Additionally, titanium's compatibility with advanced manufacturing techniques like laser cutting and CNC machining, as offered by Edgetech Industries, makes it an incredibly versatile option for customized solutions. Across industries ranging from healthcare to automotive, titanium mesh demonstrates a balanced performance, offering both resilience and adaptability that other non-ferrous metals struggle to match.

Cost-Benefit Analysis: Initial Investment vs. Long-Term Gains

One of the most frequently asked questions about titanium mesh is whether its higher upfront cost is worth it. While titanium typically has a higher initial cost compared to aluminum or conventional steels, the long-term cost benefits make it a superior investment for many industrial applications. Titanium's durability reduces the need for frequent replacements, while its low maintenance reduces operational downtime. Furthermore, its exceptional corrosion resistance minimizes the likelihood of failures due to material degradation, resulting in fewer repair costs. Wholesale titanium mesh suppliers, such as Edgetech Industries, can often tailor solutions to meet specific industrial requirements, ensuring businesses get exactly what they need without overspending on unnecessary materials. Considering factors like reduced maintenance, extended service life, and enhanced performance in harsh conditions, titanium mesh often offers better economic value than alternatives such as copper or aluminum.

When it comes to industrial applications, the material choice can greatly influence operational efficiencies, costs, and longevity. Titanium mesh checks all the key boxes, offering superior corrosion resistance, competitive performance against other non-ferrous metals, and undeniable long-term economic benefits. If you're considering sourcing wholesale titanium mesh, Edgetech Industries, a trusted titanium mesh manufacturer, is an excellent place to start. As a leader in refractory and non-ferrous metals, Edgetech Industries provides not only high-quality titanium products but also customization options to meet specific industrial needs. Their expertise ensures that businesses receive materials optimized for their unique applications, reducing waste and maximizing productivity. Don't miss your chance to leverage the benefits of titanium in your operations.

0 notes

Text

Leading Safety Equipment Manufacturer in Ahmedabad -Sanocs

Industrial safety is more than just a protocol—it's a vital component of every successful manufacturing or processing facility. From small-scale workshops to large production units, protecting workers and machinery plays a key role in reducing operational hazards. This is where safety equipment becomes indispensable.

Sanocs, a trusted name in the industry, stands tall as a leading Safety Equipment Manufacturer in Ahmedabad. We specialize in delivering high-quality machine guarding, industrial guarding, and related solutions that help companies minimize risks and maintain compliance with safety norms. With innovative designs and a customer-first approach, we are reshaping industrial safety practices across India.

Why Safety Equipment is Essential in Industrial Environments

The use of safety equipment isn’t just about meeting regulations—it’s about protecting lives, reducing machine downtime, and increasing productivity. As industries grow more automated, moving parts and high-powered machinery pose greater risks. That’s why investing in products from a trusted Safety Equipment Manufacturer is essential.

Accidents can lead to severe injuries, expensive repairs, and business interruptions. With quality machine guarding systems in place, companies can:

Prevent access to dangerous parts of machines

Reduce injury rates and worker compensation claims

Protect infrastructure from accidental damage

Improve employee confidence and operational efficiency

Our products are crafted to meet these safety needs without compromising workflow or machine access.

Our Product Range

At Sanocs, we offer a complete line of industrial safety solutions. Our expertise as a Safety Equipment Manufacturer in Ahmedabad lies in building practical, durable, and customizable guarding systems for diverse industries.

1. Machine Guards and Safety Fences

Machine Guards and Safety Fences are essential for protecting operators from rotating parts, sharp tools, and high-speed systems. Whether it’s a CNC machine, lathe, press, or robotic assembly unit, these guards act as physical barriers while allowing visibility and easy maintenance access.

Our guards are modular, rust-resistant, and designed to suit specific machine models. They help reduce human error while meeting international safety standards.

2. Industrial Guarding Systems

Our industrial guarding solutions are designed for large-scale protection. We provide:

Perimeter fencing

Floor-to-ceiling guards

Workstation enclosures

Conveyor system barriers

These systems help control movement within industrial units, preventing unauthorized access and keeping machinery zones secure. As experienced machine guarding manufacturers in India, we ensure each guard fits its intended space precisely.

Advantages of Our Guarding Solutions

Choosing the right safety partner can make a massive difference to your operations. With Sanocs, you're getting more than just barriers—you’re investing in advanced machine guarding and industrial machine guarding that lasts.

Benefits of our products include:

Custom Fit Designs: Tailored to your space and workflow

Durable Materials: Weather-resistant, chemical-resistant, and corrosion-free

Quick Installation: Minimal disruption during setup

Low Maintenance: Built for long life and reliable performance

With our expertise as a Safety Equipment Manufacturer, we make safety simple and effective for industries nationwide.

Serving Multiple Sectors

We work with a wide range of industries across India. Our safety guards and fencing systems are used in:

Automotive plants

Pharmaceutical labs

Warehouses and logistics hubs

Food and beverage factories

Fabrication and metal workshops

Our clients rely on us for quick delivery, technical support, and products that meet both Indian and international safety guidelines. As trusted machine guarding manufacturers in India, our solutions are built for real-world use.

Why Choose Us?

Sanocs stands apart in the safety equipment market by combining quality craftsmanship with a deep understanding of industrial needs. As a leading Safety Equipment Manufacturer in Ahmedabad, we don’t just deliver products—we deliver peace of mind. Our design-first approach, commitment to quality, and after-sales support make us the preferred choice for businesses across the country. Whether you need simple machine guards or complete industrial guarding systems, Sanocs is your one-stop solution.

Conclusion

Safety is a smart investment—and with Sanocs, it’s a reliable one. As one of the top machine guarding manufacturers in India, we provide durable and efficient solutions tailored for modern industry. Backed by years of experience and a commitment to customer satisfaction, we’re proud to lead the way as a trusted Safety Equipment Manufacturer in Ahmedabad. Let us help you create a safer, more productive workplace with safety systems that work as hard as you do.

Want to upgrade your industrial safety game?

Reach out to Sanocs—your reliable partner in industrial safety. Call us at +91-987-924-2755 or email us at [email protected] for expert advice.

Sanocs, a leading Safety Equipment Manufacturer in Ahmedabad, offers high-quality machine guarding, industrial guarding, and safety solutions for various industries, built to withstand demanding operational conditions.

For More Information

9879242755

Plot 21, Panchratna Green - Industrial Park, Nr. Pirana Village, Ahmedabad 382425

https://www.sanocs.in/safety-equipment-manufacturer-in-ahmedabad

#Safety Equipment Manufacturer#Safety Equipment Manufacturer in ahmedabad#Machine Guards and Safety Fences#industrial guarding#machine guarding#industrial machine guarding#safety guards#machine guarding Manufacturers in india

0 notes