#class 150 flange

Explore tagged Tumblr posts

Text

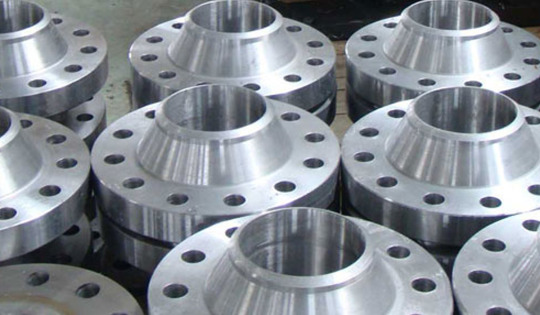

DRP GI Flange Table E-Specifications and Pricing

Understanding DRP GI Flange Table E

DRP GI Flange Table E is a specific type of galvanized iron (GI) flange used in various industrial applications. These flanges are essential components for connecting pipes, valves, and other equipment in pipelines and systems. The "DRP" in the name typically refers to a specific manufacturing process or standard, while "Table E" indicates its dimensions and specifications.

Key Specifications of DRP GI Flange Table E

Material: Galvanized Iron (GI)

Dimensions: The exact dimensions vary based on the specific Table E standard. However, they typically include the flange diameter, bolt hole diameter, bolt hole pitch, and face-to-face dimension.

Pressure Rating: DRP GI flanges are designed to withstand specific pressure ratings, ensuring their suitability for different applications.

Class: The class of the flange (e.g., 150, 300, 600) determines its pressure rating and other specifications.

Gasket Type: Flanges are typically used with gaskets to create a tight seal between the connected components. The gasket type and material will depend on the specific application and pressure requirements.

Factors Affecting Pricing

The price of a DRP GI Flange Table E can vary based on several factors:

Size and Dimensions: Larger flanges or those with more complex specifications may have higher prices.

Pressure Rating: Flanges with higher pressure ratings generally cost more.

Quantity: Purchasing in bulk can often lead to discounts.

Manufacturer: Different manufacturers may offer varying prices and quality levels.

Market Conditions: Fluctuations in the market, such as changes in material costs or demand, can affect pricing.

Finding the Best Deals

Research Manufacturers and Suppliers: Look for reputable manufacturers and suppliers in Delhi, India. Online marketplaces and industry directories can be helpful resources.

Compare Prices: Obtain quotes from multiple suppliers to compare prices and delivery times.

Negotiate: Don't hesitate to negotiate for better deals, especially when purchasing in bulk or for long-term projects.

Consider Quality: While price is important, ensure the flanges meet the required quality standards and certifications.

Check for Discounts: Inquire about any discounts or promotions offered by suppliers.

#GIFlange#FlangeTable#IndustrialSupplies#FlangeSpecifications#PipeFittings#GIProducts#Manufacturing#ConstructionMaterials#Engineering#Supplier

5 notes

·

View notes

Text

Steam Trap Supplier in Algeria

African Valve is the leading Steam Trap Supplier in Algeria. It is a critical device that is used in steam systems to remove condensate and non-condensable gasses, such as air, from the steam lines while preventing the escape of steam. Its primary function is to prevent the loss of steam while efficiently draining condensate from the system; they are essential for maintaining the efficiency and performance of steam equipment and ensuring the safe operation of steam systems.

Types of Steam Trap we supply:

Ball Float Steam Trap: These valves are used to remove condensate from steam systems, the ball lifts to open the valve, allowing condensate to drain while preventing steam loss.

Inverted Bucket Steam Trap: They uses a bucket that floats on condensate to control valve operation, when they are filled it tilts and opens the valve to discharge the condensation, and close when the bucket get empty

Bimetallic Steam Trap: When the condensate cools, the metals bend and open the valve to discharge condensate, while steam heat causes the metals to return to their original shape and close the valve

Thermodynamic Steam Trap: Use a disc and a temperature-sensitive mechanism to open and close the valve, allow concentrated gas to escape and prevent steam

Thermostatic Steam Trap: They work on temperature change, as the temperature of the condensate changes, the element expands or contracts, allowing the valve to release condensate and prevent steam.

Advantages:

Industries in Nigeria maintain their steaming system and manufacturing units with the assurance of the trusted Steam Trap Supplier in Algeria , thus ensuring smooth operation and high energy efficiency in their processes.

Efficient Condensate Removal, ensure that steam systems operate efficiently and maintain optimal heat transfer.

Energy Savings:By preventing steam leakage and reducing energy losses, they help save fuel and energy costs.

Equipment Protection: By removing condensate they protect equipment water hammer and corrosion.

Process Efficiency: Improve consistent temperature and pressure in the system, enhancing process stability and performance.

Safety Enhancement: Provide safety to the equipment and manage effective flow control

Industries:

Heating Systems

Industrial Processes

Power Generation

Steam Distribution Networks

Process Sterilization

Description:

Available materials: Cast Iron, Ductile Iron, Cast Steel (A216 WCB, WCC, LCB, LCC, WC6, WC9) Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316], A105

Size: 1/2" to 4"

Nominal Pressure: PN10 to PN250

Class: 150 to 1500

Ends: Flanged, Buttweld, Socket weld, Threaded

Visit today: https://www.africanvalve.com/product-category/steam-trap/

2 notes

·

View notes

Text

ASME B16.5 Flanges Manufacturers in UAE. We are making ANSI B16.5 Flanges, ASME B16.5 Wn Flanges, ASME B16.5 Weld Neck Flanges and ANSI B16.5 Flanges Material plausibly considering sensible expert hours in UAE and uncommon well spring of astonishing ASME B16.5 Class 150 Flanges, most very smart arrangement, cost open in Dubai, India.

Meraki Star Metals Oil & Gas Equipment Trading L.L.C. is all around acclaimed provider of ASME B16.5 Ring Joint Flanges got a handle on by Saudi Aramco. We keep up wide store of ANSI B16.5 Free Flanges, ANSI B16.5 Carbon Steel Flanges, ANSI B16.5 Diminishing Flanges, ASME B16.5 Decreasing Flanges, ASME B16.5 Slip On Flanges, ASME B16.5 Flanges Material and ASME B16.5 Blind Flanges. Meraki Star Metals Oil & Gas Equipment Trading L.L.C. stock total degree of ASME B16 5 Opening Flanges, ANSI B16.5 Expander Flanges in Stock in different sizes.

#ASME B16.5 Flanges Manufacturers in UAE#ASME B16.5 Flanges Suppliers in UAE#ASME B16.5 Flanges Stockists in UAE#ASME B16.5 Flanges Exporters in UAE

12 notes

·

View notes

Text

Incoloy 825 Flanges

Sankalp Alloys Overseas are Manufacturers, Provider, and Exporters of Incoloy 825 Flanges that is Produced using Phenomenal Unrefined parts. Incoloy 825 Flanges are Accessible in various grades and sizes, shapes. we offer these things at additional reasonable costs and these Flanges have a stunning income in the neighborhood as well as the overall market.

INCOLOY 825 ANSI B16.5 / B16.47 FLANGES SPECIFICATION :

Standard: ASTM, ASME, ANSI, JIS, DIN, BSNA 11, EN Ni 99.2, JIS NW 2200, GOST-НП-2

Dimensions: ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Designation: ASTM / ASME B 564 / SB 564

Class: Class 150, Class 300, Class 400, Class 600, Class 900, Class 1500 & Class 2500

Size: 1/2″NB TO 60″NB

Grades: Incoloy 825 (UNS N08825) Flanges, 2.4858

Pressure: DIN PN6, PN10, PN16, PN25, PN40, PN64, PN100, PN160

7 notes

·

View notes

Text

Bellow Seal Safety Valve manufacturer in USA

SVR Global is the best Bellow seal safety valve manufacturer in USA supplying superior quality valves to petrochemical industries, oil industries and chemical industries in Baltimore, Seattle and Des Moines.It's main work is to discharge extra pressure from a system when it rises above a set limit. By doing so, potential safety risks and equipment damage are reduced. The bellows is a pliable, accordion-like component of the valve. It can expand or contract to maintain a tight seal up until the predetermined pressure is attained since it is sensitive to variations in pressure.Safety valves with a bellows seal are known for being able to maintain a tight seal even at low pressure levels. This qualifies them for uses where leak protection is crucial. When maintaining a sterile or clean environment is crucial, these valves are frequently employed in the petrochemical, pharmaceutical, food processing, and aerospace industries.A bellows seal safety valve's set pressure can be changed to suit the particular needs of the application. When the system's pressure rises over this threshold, the valve opens to let the extra pressure out.It is a particular kind of safety valve used in many sectors to safeguard machinery and processes from overpressure situations is the bellows seal safety valve. These valves have a bellows-like feature that helps maintain a seal, ensuring the valve stays leak-tight until it reaches a certain set pressure.

TYPES

Spring-loaded bellow seal safety valves

Pilot-operated bellow seal safety valves

Balanced bellow seal safety valves

Bellow seal relief valves

Vacuum relief bellow seal valves

INDUSTRIES

•oil and gas industries •Petrochemical industries •Aerospace industries •Aircraft hydraulic systems •Water industries •Petroleum industries •Heating boilers

Available materials: Cast Iron and Steel (A216 WCB, WCC, LCB, LCC, WC6, WC9), Ductile Iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3, F55, F91], WCB, WC6, SS304, SS316, DUPLEX STEEL. Ends: Flanged, Buttweld, Socket weld, Threaded Class: 150 to 2500 Nominal Pressure: PN25 to PN450 Size: 1/2” to 64” https://svrglobal.net/products/balanced-bellow-seal-safety-valve/

2 notes

·

View notes

Text

Gate Valve supplier in Oman

Middleeast valve is one of the best Gate valve supplier in Oman . We supply to cities like Ibri, Sur, Muscat, and Mutrah.

A gate valve is a type of valve used to control the flow of fluids (liquids or gases) by using a gate or wedge-like disc that moves perpendicular to the flow path to either block or allow the passage of the fluid.

The main function of a gate valve is to provide a tight shutoff, effectively stopping the flow of fluid through the pipeline when the valve is fully closed, and allowing unrestricted flow when the valve is fully open. Gate valves are commonly used in applications where the fluid flow needs to be completely shut off, such as in water supply systems, oil and gas pipelines, industrial processes, and more.

Gate valves consist of several main components, including the body, gate (wedge), stem, actuator, and seats. Here's how they work:

Open Position:

In the open position, the gate (wedge) is fully retracted into the valve body, allowing the fluid to flow through the valve with minimal obstruction. The gate moves perpendicular to the direction of the fluid flow. The valve is opened by turning the valve stem (either manually using a handwheel or with an actuator) which is connected to the gate.

Closing Position:

To close the valve, the stem is turned in the opposite direction, causing the gate to move down into the flow path of the fluid. As the gate descends, it gradually restricts the flow until the valve is completely closed. The gate makes contact with the valve seats located at the bottom of the valve body, forming a tight seal that prevents any further flow.

Middleeast valve is the greatest Gate valve supplier in Oman and are known for their ability to provide a tight seal and low pressure drop when fully open. However, they might require more turns to fully open or close compared to other valve types like ball valves. It's important to use gate valves in appropriate applications and avoid using them for flow regulation where frequent adjustments are necessary.

Description:

Available materials: SS304, SS904, SS904L, SS316, Aluminium Bronze, Monel, Bronze, Brass, Duplex steel, Inconel, Incoloy, Titanium, WCB, CF8, CF8M, CF3, CF3M, WC1, WC6, WC9, Cast iron, super duplex

Size: 1/2″- 64”

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Operations: Hand Wheel Gate valve, Gear operated Gate valve, Electric actuated Gate valve and Pneumatic Actuated Gate valve

Ends: Flanged(FF,RF,RTJ), Buttweld, Socket weld, Threaded

Standards: API607, DIN, BS, ANSI, AWWA, ASME, API6D

Gate valve types:

Rising Stem Gate Valve

Non Rising Stem Gate Valve

Bellow Seal Gate Valve

Pressure Seal Gate Valve

Cryogenic Gate Valve

Forged Gate Valve

Gate valve advantages :

They have low fluid resistance.

They have superior sealing capability.

They come with a wide application range.

They have dual flow directions.

Gate valve Industries:

Textiles.

Power generation.

Refineries.

Petrochemical plants.

Shipbuilding

Chemical industry.

Paper factories.

Gate valve parts:

Hand wheel.

Stuffing Box.

Bonnet

Gasket

Stem

Flange

Disk

Body seats

Packing

Body

Visit our website: https://www.middleeastvalve.com/product-category/gate-valve/

2 notes

·

View notes

Text

Inconel 800HT Flanges

Technolloy Inc. is the Manufacturers, Suppliers, and Exporters of Incoloy 800HT flanges that are conveyed using astonishing and disturbing perspectives. Incoloy 800HT flanges are available in different grades, sizes, and shapes. These Incoloy 800HT flanges are scratched by most saw makers, who, in general, take goliath-contemplated heads for worth and standard.

INCOLOY 800/800H/800HT ANSI B16.5 / B16.47 FLANGES SPECIFICATION :

Standard : ASTM, ASME, ANSI, JIS, DIN, BSNA 11, EN Ni 99.2, JIS NW 2200, GOST-НП-2

Dimensions : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc.

Designation : ASTM / ASME B 564 / SB 564

Class : Class 150, Class 300, Class 400, Class 600, Class 900, Class 1500 & Class 2500

Size : 1/2″NB TO 60″NB

Grades : Incoloy 800 (UNS N08800) Flanges, 2.4876

Pressure : DIN PN6, PN10, PN16, PN25, PN40, PN64, PN100, PN160

For more information

Email us [email protected]

Call us :(022) 67437682

Website : https://www.technolloy.com/incoloy-alloy-800-800ht-flanges-manufacturer-exporter-supplier.html

2 notes

·

View notes

Text

Monel K500 Blind Flanges Exporters

Monel Blind Flanges are manufactured without a bore and used to blank off the ends of piping, Valves and pressure vessel openings. From the standpoint of internal pressure and bolt loading, blind flanges, particularly in the larger sizes, are the most highly stressed flange types. A Blind flange is round plate which has all of the relevant boltholes but no center hole, and because of this feature this flange is used to close off the ends of a piping systems and pressure vessel openings. It also permits easy access to the interior of a line or vessel once it has been sealed and must be reopened.

However, most of these stresses are bending types near the center, and since there is no standard inside diameter, these flanges are suitable for higher pressure temperature applications.

Monel Blind Flanges are used for testing the flow of gas or liquid through a pipeline or vessel. It helps to close the end of piping systems or vessel openings. It allows easy access to the pipeline when there is a requirement to work done inside the line. They are used in high pressure applications available in all grades, materials, size and specifications. Blind pipe flanges are typically provided with a raised face, flat face, or RTJ facing. When a raised face is necessary for blind pipe flanges, the standard height is 1/16" for blind pipe flanges under 400 ( 2.4360)#. For blind pipe flanges of 400 ( 2.4360)# and up, the standard blind pipe flange raised face height is 1/4".

B16.5 ASTM A182 Blind Flange, Fusion Bonded Epoxy Coating, EN 1092-2 PN16 Blind Flange, ASME B16.5 Dual Monel Alloy Blind Flange, ANSI B16.5 Class 150 Flat Face Blind Flange, Monel Alloy Reducing Blind Flange Stockiest.

Standards Specification:

Size : 1/2" to 48"

Specifications : ASTM A182

Rating: 150#, 300#, 600 (2.4640)#, 900#, 1500#, 2500#,

Material & Grade :

Stainless Steel :Grade: 304 (1.4301), 304L (1.4307), 304H (1.4948), 309 (1.4828), 309S, 310, 310S (1.4845) , 316 ( 1.4401), 316H, 316L( 1.4404 /1.4432) , 317, 317L (1.4438), 321 (1.4541), 321 H(1.4878), 347 (1.4550), 347H (1.4961), 904L (1.4539) Duplex Steel:Grade: 2205 (1.4507) Super Duplex Steel:Grade: 2507 (UNS S32750) (1.4410) (UNS S32750) Inconel :Grade: Inconel 600 (2.4640), Inconel 601 (2.4851), Inconel 625 (2.4856), Inconel 718(2.4668) Incoloy :Grade: Incoloy 800 (2.4958), Incoloy 800H, Incoloy 800HT Nickel :Grade: Nickel 200, Nickel 201 Titanium :Grade: Gr.1 (3.7025) , Gr.2 (3.7035) , Gr.3:(3.7055) , Gr.5(3.7164/65), Gr. 7(3.7235) , Gr. 11 (3.7225) Hastalloy :Grade: Hastalloy B2, Hastalloy B3, Hastalloy C22, Hastalloy C276, Hastalloy X.

For More Information Visit Our Website - http://www.kobsindia.in/monel-blind-flange.html Contact Us -9819523999 Email Id - [email protected]

4 notes

·

View notes

Text

Supplier of Stainless Steel Flange in Karnataka

Arisa Impex is a trusted Manufacturer, Exporter, and Supplier of Stainless Steel Flange in Karnataka. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. We offer stainless steel flanges made from top-grade materials that ensure exceptional strength and resistance to corrosion. Arisa Impex flanges are manufactured to meet international quality standards, ensuring they perform reliably in even the most challenging environments. We supply a diverse range of stainless steel flanges, including slip-on, blind, weld neck, threaded, and socket weld flanges, available in various sizes and specifications. We believe in offering premium-quality stainless steel flanges at competitive prices. Our efficient sourcing, manufacturing, and delivery processes allow us to pass on cost savings to our customers, providing excellent value for money without compromising on quality. Types of Stainless Steel Flanges Offered by Arisa Impex Weld Neck Flanges Slip-On Flanges Blind Flanges Threaded Flanges Socket Weld Flanges Why Stainless Steel Flanges are Essential for Your Business: Stainless steel flanges are critical components in piping systems, providing secure connections between pipes, valves, pumps, and other equipment. They ensure leak-proof seals, high strength, and the ability to withstand extreme temperatures, pressures, and corrosive environments. By choosing Arisa Impex, you ensure that your piping systems operate safely and efficiently, minimizing downtime and costly repairs. Specifications: Material Standards: ASTM A182 / ASME SA182 Size Range: 1/2″ (15 NB) to 48″ (1200 NB) Dimensions: ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS10, EN-1092, DIN, and other industry standards. Standard: ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges. Class / Pressure Ratings: 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64, etc. Flange Face Types: Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ). Stainless Steel Flanges Grades: 304, 304L, 304H, 310, 310S, 310H, 316, 316L, 316H, 316Ti, 317, 317L, 321, 321H, 347, 347H, 446, 904L Flanges are produced in size ranges: ½” to 40″ Applications of SS Flanges: Oil and Gas Chemical and Petrochemical Industries Water Treatment Power Generation Food and Beverage Pharmaceutical Arisa Impex is a Supplier of Stainless Steel Flange in Karnataka including locations like Bangalore, Mysore, Hubballi-Dharwad, Kalaburagi, Mangalore, Belagavi, Davanagere, Bellary, Vijayapura, Shimoga, Tumkur, Raichur, Bidar, Udupi, Hospet, Gadag-Betageri, Robertsonpet, Hassan, Bhadravati, Chitradurga, Kolar, Mandya, Chikmagalur, Gangavati, Bagalkot, Ranebennuru, Arsikere. For more information, inquiries, or to place an order, feel free to contact us today! View Product: Click here Read the full article

#Ahmedabad#ArisaImpex#blind#Exporter#Gujarat#India#internationalqualitystandards#Manufacturer#slip-on#socketweldflanges#StainlessSteelFlangeinKarnataka#StainlessSteelFlangeManufacturerinAhmedabad#StainlessSteelFlangeManufacturerinGujarat#StainlessSteelFlangeManufacturerinIndia#StainlessSteelFlanges#Supplier#SupplierofStainlessSteelFlange#SupplierofStainlessSteelFlangeinKarnataka#threaded#weldneck

0 notes

Text

Aquaflow IC CF8 Ball Valve 3 Pcs Flanged 150

Durable Aquaflow IC CF8 Ball Valve, 3 pieces, flanged, 150 class. Ideal for reliable flow control in various applications. Perfect for industrial use.

4 notes

·

View notes

Text

Slip-On Raised Face Flanges (SWRF Flanges): Your Comprehensive Guide

Slip-On Raised Face (SWRF) Flanges are a vital component in various industrial piping systems. Known for their easy installation and reliable sealing capabilities, these flanges are widely used across industries like oil and gas, chemical processing, power generation, and marine engineering. This guide delves into the features, benefits, applications, and technical considerations for SWRF flanges, providing insights to help you choose the right flange for your requirements.

What Are SWRF Flanges? Slip-On Raised Face Flanges (SWRF) are a type of pipe flange designed with a raised surface that enhances sealing when paired with a gasket. Unlike other flange types, SWRF flanges “slip” over the pipe and are welded both inside and outside for a secure, leak-proof connection. Their cost-effectiveness, ease of installation, and versatility make them one of the most popular flange types in industrial applications.

Key Features of SWRF Flanges 1. Material Options: SWRF flanges are available in various materials, including: Carbon Steel: Preferred for high-strength applications. Stainless Steel: Ideal for environments requiring corrosion resistance. Alloy Steel: Suitable for specialized, high-performance applications. 2. Dimensional Precision: SWRF flanges are designed to fulfill international standards including ASME B16.5, ANSI, and DIN. 3. This ensures compatibility with various piping systems. 4. Pressure Ratings: These flanges are designed to handle a wide range of pressure ratings, from Class 150 to Class 2500, making them suitable for diverse operational demands. 5. Sealing Efficiency: The raised face design concentrates gasket seating stress, improving sealing efficiency even under high pressure.

Applications of SWRF Flanges SWRF flanges are used in numerous industries where durability, reliability, and performance are essential: • Oil and Gas: These flanges are widely used in pipelines that transport crude oil, natural gas, and other hydrocarbons. Their ability to withstand high pressures and temperatures makes them ideal for offshore platforms and refineries. • Chemical Processing: In chemical plants, SWRF flanges provide leak-proof connections, ensuring safe handling of corrosive and hazardous materials. • Marine Engineering: Resistant to saline and harsh marine conditions, these flanges are often used in shipbuilding, offshore drilling platforms, and coastal industrial installations. • Power Generation: SWRF flanges are widely employed in power plants, where they are used in steam, gas, and water pipelines, ensuring efficient operation under high-pressure environments. • Water Treatment: In water and wastewater treatment facilities, SWRF flanges are used for their ease of installation and resistance to wear and corrosion.

Advantages of SWRF Flanges 1. Ease of Installation: The slip-on design allows the flange to be easily positioned and aligned over the pipe before welding, simplifying installation and reducing labor costs. 2. Cost-Effective: SWRF flanges are less expensive than other flange types, making them an economical choice for large-scale projects. 3. Enhanced Sealing: The raised face design ensures a tighter seal, reducing the risk of leaks in high-pressure systems. 4. Versatility: SWRF flanges can be used for a variety of industrial applications since they are compatible with a wide range of piping materials and diameters. 5. Durability: These flanges are built to last, offering exceptional resistance to wear, pressure, and temperature variations.

Technical Specifications of SWRF Flanges • Pressure Classes: Class 150, 300, 600, 900, 1500, and 2500. • Dimensions: Manufactured per ASME B16.5 or equivalent standards. • Facing Types: Raised Face (RF), Flat Face (FF), and Ring Type Joint (RTJ). • Sizes: Available in sizes ranging from ½ inch to 24 inches or more, depending on custom requirements.

How to Select the Right SWRF Flange Material Choosing the appropriate material is crucial for ensuring optimal performance and longevity. Here’s a quick guide: • Carbon Steel SWRF Flanges: Best for applications requiring high strength and low cost. Commonly used in oil and gas pipelines. • Stainless Steel SWRF Flanges: Ideal for corrosive environments, such as chemical plants and marine industries. • Alloy Steel SWRF Flanges: Suitable for high-temperature and high-pressure applications, such as power plants and refineries. Installation Guide for SWRF Flanges Proper installation of SWRF flanges is essential to ensure a leak-proof and secure connection. Follow these steps: 1. Pipe Preparation: Ensure the pipe end is clean and free from debris. 2. Flange Placement: Slip the flange over the pipe, ensuring it is positioned correctly. 3. Welding: Weld the flange to the pipe both inside and outside to provide structural stability. 4. Gasket Placement: Place the gasket on the raised face of the flange to enhance sealing. 5. Bolt Tightening: Secure the flange by tightening bolts evenly in a crisscross pattern to achieve a uniform seal.

Why Choose Anandmayee Forgings Pvt. Ltd. for SWRF Flanges? At Anandmayee Forgings Pvt. Ltd., we are committed to delivering high-quality SWRF flanges that meet the most demanding industrial requirements. Here’s why we stand out: 1. Advanced Manufacturing Facilities: Our state-of-the-art infrastructure ensures precision and adherence to international standards. 2. Custom Solutions: We offer tailored designs to meet specific project requirements, ensuring seamless integration into your systems. 3. Stringent Quality Control: Every flange undergoes rigorous testing to ensure durability, performance, and compliance with global standards. 4. Industry Expertise: With years of experience, we have earned the trust of clients across diverse industries, including oil and gas, chemical processing, and marine engineering.

Contact Us Looking for the best SWRF flange manufacturer in India? Anandmayee Forgings Pvt. Ltd. is your trusted partner for high-performance, reliable flanges. Contact us at 9315902761 or email us at [email protected] for the best estimate for flanges.

1 note

·

View note

Text

wmass flanges in Qatar

Meraki Star Metals Oil & Gas Equipment Trading L.L.C. is one of the leading Carbon Steel Flanges manufacturers India and we produce flanges in different types and material grades. The carbon steel flanges have carbon, manganese, phosphorus, sulfur, silicon, copper, nickel, chromium, molybdenum and vanadium depending on the material grade. The Carbon Steel Pipe Flange Price List varies according to the material grade as well.

The WMASS Carbon Steel Flanges have different dimensions and strengths. The tensile strength is in the range of 485MPa minimum tensile strength and 250MPa minimum yield strength. The Flange ANSI B16.5 Class 150 is a medium pressure class of the B16.5 standard flanges. The materials used for the flanges range and the pressure classes range based on the nominal bore sizes and the wall thicknesses.

The nominal bore sizes range from ½ inches to 48 inches and the classes range such as WMASS Carbon Steel Flanges Rating with different pressure ratings. There are different types of flanges that are used for different purposes. The Carbon Steel Blind Flange is used to terminate a pipe connection permanently or temporarily. The permanent connections are made with welding and the temporary ones are done with bolts and nuts. The CS Lap Joint Flange is a special type that it has a lap joint on it. The carbon steel flanges are tough and have high wear and tear resistance. Please contact us for further information on the Carbon Steel Weld Neck Flange Dimensions, prices and further information.

#WMASS Carbon Steel Flanges Manufacturers in Dubai#WMASS Carbon Steel Flanges Suppliers in Dubai#WMASS Carbon Steel Flanges Stockists in Dubai#WMASS Carbon Steel Flanges Exporters in Dubai#Carbon Steel Flanges in Oman#CS Flanges in Oman#WMASS Flanges In Oman#Mass Flanges In Oman#WMASS Stockist In Oman

2 notes

·

View notes

Text

Super Duplex S32760 Flanges Manufacturers in India

The manufacturer and supplier of Very Duplex Steel Flanges made their products in a variety of sizes and forms for the customer in response to interest. The manufacturer, stockist, and supplier of the entire stainless steel item, including this, is Sankalp Alloys Overseas. They provide everything and deliver the product while maintaining excellent quality and price as well.

Super Duplex Steel Flanges are regarded as the best in the series of steel Flanges based on their characteristics and strong points. The austenitic toughened steel is offered in Very Choice with a few components like copper, zinc, and chromium. The majority of businesses use a lot of Duplex steel products since they provide high strength when they come into touch.

There are many kinds of Flanges accessible, for example, Welding Neck Wall It is by and large utilized in low-temperature and high-pressure applications since they required the unhindered liquid stream conveyed by the line framework. Long welding Neck-They is equivalent to a weld neck just contrast in a lengthy welding neck the tightened center point (neck) is expanded and performs like an exhausting expansion. Slip-on Spine It is appended to the fittings or the line by two filet welds, one external the hole and the other one executed inside the rib. They are handily perceived by their minimal and thin shape.

Strung Rib This is attached by screwing the line into the spine rather than using a crease weld. They are typically used in small, low-temperature, low-stress applications like utility and water management. They are legally required in dangerous areas like petrol stations and industries. Since welding associations could be dangerous in this type of environment. Spine Attachment Weld To connect this type of rib to the lines, a single fillet weld is performed on the exterior of the rib. Joint-joint ribs This spine frequently uses an alloy with a stub end and a component with a level spacing. Dark Spine Due to the necessary catapulting forces and the structure pressure, these Flanges reduce outstanding mechanical forces.

A few other exceptional sorts of rib are Nipo rib, Weldo rib, Turn Rib, Elbo Rib, Lactro Rib, Growing spine, and Lessening Rib.

Specification of Super Duplex Stainless Steel S32750/S32760 Flanges

Super Duplex Stainless Steel Flanges Specification: ASTM A182 / ASME SA182 Dimension Standard : ANSI/ASME B16.5, B 16.47 Series A & B, B16.48, BS4504, BS 10, EN-1092, DIN, etc. Standard: ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges, etc. Size: 1/2" (15 NB) to 48" (1200NB) Class / Pressure : 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64 etc. Flange Face Type: Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ) DIN Flanges : DIN 2527, 2566, 2573, 2576, 2641,2642, 2655, 2656, 2627, 2628, 2629, 2631, 2632, 2633, 2634, 2635, 2636, 2637,2638, 2673. JIS Flanges : JIS B2220 5K, JIS B2220 10K, JIS B2220 16K, JIS B2220 20K BS Flanges: BS4504 PN 6, BS 4504 PN 10, BS4504 PN 16, BS4504 PN 25, BS4504 PN 40, BS 4504 PN 64, BS 4504 PN 100, BS 4504 PN 160, BS 4504 PN 250, BS 10, BS Table D, BS Table E, BS Table F, BS Table H.

11 notes

·

View notes

Text

Globe valve manufacturer in Germany

Valvesonly Europe is a Globe Valve manufacturer in Germany Globe valves are valves that move in a straight line to control media flow. They are usually used for throttling and regulating flow through the valve, but they can also be employed in on/off systems to entirely allow or restrict media.

How Globe Valve works

A globe valve is a type of valve that works by moving a disc as the closing component, providing for control over media flow in a pipeline. These valves create a globular-shaped hollow surrounding the port area, hence their name.

The operation of a globe valve requires an understanding of its moveable disc and stationary seat, which are positioned parallel to the pipe and perpendicular to the disc in a spherical body, with the seat immobile.

The valve disc moves up and down in response to the activation of the top wheel, which can be manipulated manually or using an actuator.

The globe valve is fitted for low-temperature settings, where pressure falls below the disc, and for high-temperature applications, such as steam-operated boilers, where pressure is above the disc.

How is a globe valve made?

Valvesonly Europe is a Globe Valve manufacturer in Germany are generally produced through casting methods due to their intricate design; however, for certain applications, they may also be fabricated from wrought materials. The disc and seat rings are commonly constructed from bronze, but in the case of steel globe valves intended for temperatures above 350°C, stainless steel trim is employed to prevent complications such as seizing and galling. The heat treatment of the valve's mating surfaces is crucial for achieving differential hardness values. Furthermore, alternative trim materials, including cobalt-based alloys, are also utilized. It is necessary to grind the seating surface to ensure complete bearing surface contact during the closure of the valve. In lower pressure classifications, an expanded disk locknut is used to maintain the alignment of the valve, whereas for higher pressure applications, disc guides are incorporated into the valve body.

Types of Globe Valve

Pressure Seal Globe Valve

Bellow Seal Globe Valve

Y Type Globe Valve

Angle Type Globe Valve

Forged Steel Globe Valve

Pressure Globe Valve

Industries Globe Valve

Oil and Gas

Chemical

Mining

Textile

Petroleum

Petrochemical

Pulp and Paper

Marine

Power Generation.

Features of Globe Valve

A globe valve is a device with a globe-shaped body and an interior baffle separating intake and outflow ports. The baffle, also known as the disk or plug, is connected to a stem and a hand wheel. When the wheel is turned or the actuator is activated, the stem raises or lowers the disc.

Advantages of Globe Valve

Globe valves are a reliable and efficient tool for accurately regulating flow in various fluids like water, oil, steam, and chemicals. They are also durable and dependable, with a simple design that simplifies installation, maintenance, and repair.

Applications

Globe valves are crucial in various industries like oil and gas, power generation, chemical processing, and wastewater treatment, regulating fluid flow, pipelines, power plant feedwater, chemical process flow, and water flow in water treatment facilities.

Description

Body material- Cast Iron, Cast steel [A216 WCB, WCC, LCB, LCC, WC6, WC9), Ductile Iron, Stainless Steel [SS316, SS304, SS316L, SS904L, CF8, CF8M, F304, F316, F31L, F51, F3, F55, F91]

Class- 150 – 2500; PN10 – PN 450

Size- DN 10 – DN 1200

Ends- Butt weld, Flanged, threaded, socket weld

Operations- Handwheel operated, Pneumatic actuated, Electric actuated, Gear operated

Visit us: https://www.valvesonlyeurope.com/product-category/globe-valve/

1 note

·

View note

Text

Everything You Need to Know About Stainless Steel Flange Sizes and Grades

Stainless steel flanges are essential components in piping systems used across various industries, including oil and gas, chemical processing, power generation, food processing, and construction. They are utilized to connect pipes, valves, pumps, and other equipment to ensure smooth and secure operation. Understanding stainless steel flange sizes and grades is crucial for selecting the right product that meets the requirements of your specific project. In this guide, we will explore the different aspects of stainless steel flanges, their sizes, grades, and importance, as well as insights about reliable Stainless Steel Flange Manufacturers in India like Riddhi Siddhi Metal Impex.

What are Stainless Steel Flanges?

Stainless steel flanges are mechanical fittings that join pipes and equipment in a piping system. These flanges allow for easy disassembly and maintenance of the system, as well as facilitate proper sealing. They come in a variety of types, including:

Weld Neck Flanges: Used in high-pressure systems due to their strength and durability.

Slip-On Flanges: Easy to install and cost-effective, suitable for low-pressure systems.

Socket Weld Flanges: Ideal for smaller pipes and high-pressure applications.

Blind Flanges: Used to close the ends of piping systems.

Lap Joint Flanges: Often used with stub ends for systems requiring frequent dismantling.

Each type of flange serves a specific purpose and provides different levels of strength, durability, and sealing.

Stainless Steel Flange Sizes

Flanges are available in a wide range of sizes to meet the needs of different piping systems. The size of a flange is determined by factors such as pipe diameter, pressure ratings, and application requirements. Common standards for flange sizes include ANSI/ASME, DIN, BS, and EN.

The most widely used dimensions are classified under the following:

Nominal Pipe Size (NPS): Represents the approximate inner diameter of the pipe.

Pressure Rating: Ranges from 150 PSI (Class 150) to 2500 PSI (Class 2500), depending on the system's pressure requirements.

Flange Dimensions: Includes outer diameter (OD), bolt circle diameter (BCD), thickness, and bolt hole size.

For example:

Class 150 flanges for a 2-inch pipe may have a thickness of 19.1 mm and a bolt circle diameter of 120.7 mm.

Class 600 flanges for a 4-inch pipe may have a thickness of 57.2 mm and a bolt circle diameter of 190.5 mm.

Manufacturers like Riddhi Siddhi Metal Impex, one of the leading Stainless Steel Flange Manufacturers in India, produce flanges in a variety of sizes and specifications to meet customer requirements.

Stainless Steel Flange Grades

Stainless steel flanges are available in multiple grades to suit various applications. The grade of stainless steel determines its corrosion resistance, strength, and durability. Below are some commonly used grades:

304 Stainless Steel

Offers excellent corrosion resistance and is ideal for general-purpose applications.

Suitable for food, dairy, and pharmaceutical industries.

316 Stainless Steel

Contains molybdenum, providing superior resistance to chlorides and marine environments.

Preferred for chemical and marine applications where corrosion resistance is critical.

321 Stainless Steel

Stabilized with titanium, offering high-temperature resistance.

Commonly used in heat exchangers and high-temperature environments.

347 Stainless Steel

Provides enhanced resistance to oxidation and intergranular corrosion.

Suitable for systems exposed to high temperatures and corrosive substances.

Duplex and Super Duplex Stainless Steel

Combines high strength with excellent corrosion resistance.

Used in offshore, oil and gas, and marine industries.

Reliable Stainless Steel Flange Manufacturers in India

Riddhi Siddhi Metal Impex stands as one of the most reliable Stainless Steel Flange Manufacturers in India, catering to diverse industries with precision-engineered products. With a reputation for excellence, we specialize in manufacturing and supplying a wide range of stainless steel flanges that meet international standards. Our products are highly durable, corrosion-resistant, and designed to withstand high-pressure and high-temperature conditions.

As a leading Stainless Steel Flange Supplier in India, we offer an extensive selection, including weld neck flanges, slip-on flanges, blind flanges, socket weld flanges, and threaded flanges. Each product is meticulously crafted using high-grade stainless steel to ensure superior quality and performance.

Our commitment to delivering exceptional products and services has made us a preferred choice for industries such as oil and gas, petrochemicals, power generation, and water treatment. At Riddhi Siddhi Metal Impex, customer satisfaction is our top priority, and we strive to provide tailored solutions to meet unique project requirements.

When searching for trusted SS Flange Manufacturers in India, look no further than Riddhi Siddhi Metal Impex.

For More Detail

Website: riddhisiddhimetal.com

Product: Stainless Steel Flanges Suppliers in India

Other Product: EIL Approved Pipe Fittings Suppliers in India.

#Stainless Steel Flanges Manufacturer in India#EIL Approved Flanges Manufacturers#Stainless Steel Flanges Manufacturer#Stainless Steel Flanges

0 notes

Text

Gate Valve Manufacturers in India

Speciality Valve is renowned for being one of the top Gate Valve manufacturers in India, with a global supply network.

Description:

Available materials: SS304, SS904, SS904L, SS316, Aluminium Bronze, Monel, Bronze, Brass, Duplex steel, Inconel, Incoloy, Titanium, WCB, CF8, CF8M, CF3, CF3M, WC1, WC6, WC9, Cast iron, super duplex

Size: 1/2″- 64”

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Operations: Hand Wheel, Gear operated, Electric actuated and Pneumatic Actuated

Ends: Flanged(FF,RF,RTJ), Buttweld, Socket weld, Threaded

Standards: API607, DIN, BS, ANSI, AWWA, ASME, API6D

#industrial valves#gate valve#valve#valve manufacturer#GateValve#IndustrialValves#ValveTechnology#PipelineValves#ValveAutomation#StainlessSteelValve#HighPressureValves#SmartGateValve#SustainableValves.

1 note

·

View note