#chemical reactors

Explore tagged Tumblr posts

Text

Microwave Reactor

Labotronics microwave reactor is a continuous flow thermochemical unit with the frequency range 2450 MHz±50 MHz provide precise control for critical reactions.It's frame made of non-reactive telfon to avoid unwanted reaction.Built in PID controller regulates the temperature with precision.It is equipped with glass tablewheels and H-shaped glass pipe which distributes microwave radiation throughout the reaction mixture.The stirring speed can adjust as per requirements. The interlock door switch prevents reactors from operating unless the door is securely shut.It has large screen window for observation for more visit labotronics.com

1 note

·

View note

Text

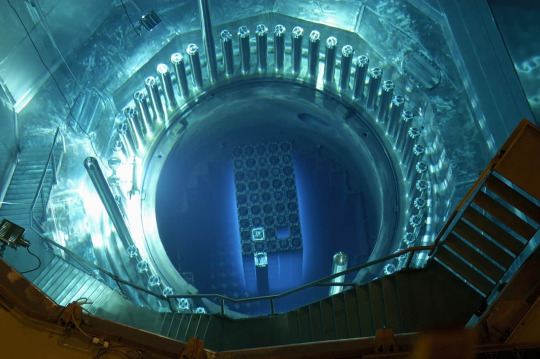

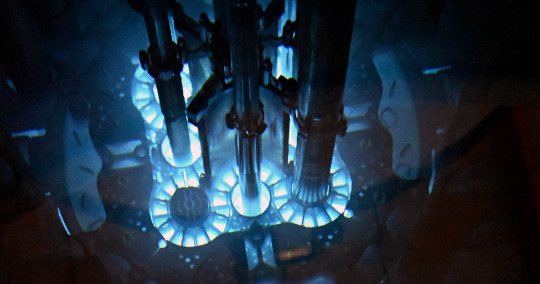

the beautiful colour of the cherenkov reaction is the closest we'll ever get to true cyberpunk

#cherenkov reaction#nuclear#nuclear power#uranium#nuclear reactor#chemical reactions#science#science posting#reactor posting#kalefaction

23 notes

·

View notes

Text

youtube

What Are the Benefits of Using the AKF-100L Double-Glazed Reactor for Advanced Chemical Reactions?

The AKF-100L Double-Glazed Reactor is a high-performance solution for chemical reactions, offering precise temperature control ranging from -120°C to 300°C. It features:

100L material capacity & 60L jacket capacity for efficient heating and cooling.

6 customizable ports for versatile experimental setups.

Stainless steel fluoropolymer-coated stirrer for reliable mixing.

5L constant pressure funnel to enhance reaction efficiency.

Optional explosion-proof control box, explosion-proof motor, and insulation sheath for added safety.

Ideal for labs that require precision and safety, the AKF-100L Reactor is perfect for a wide range of chemical and pharmaceutical applications.

Explore more: AKF-100L Double-Glazed Reactor

#Chemical Reactor#Laboratory Equipment#Double-Glazed Reactor#Chemical Engineering#Temperature Control#Explosion-Proof Equipment#Pharmaceutical Manufacturing#Lab Stirrer#Scientific Instruments#Reactors for Laboratories#Youtube

2 notes

·

View notes

Text

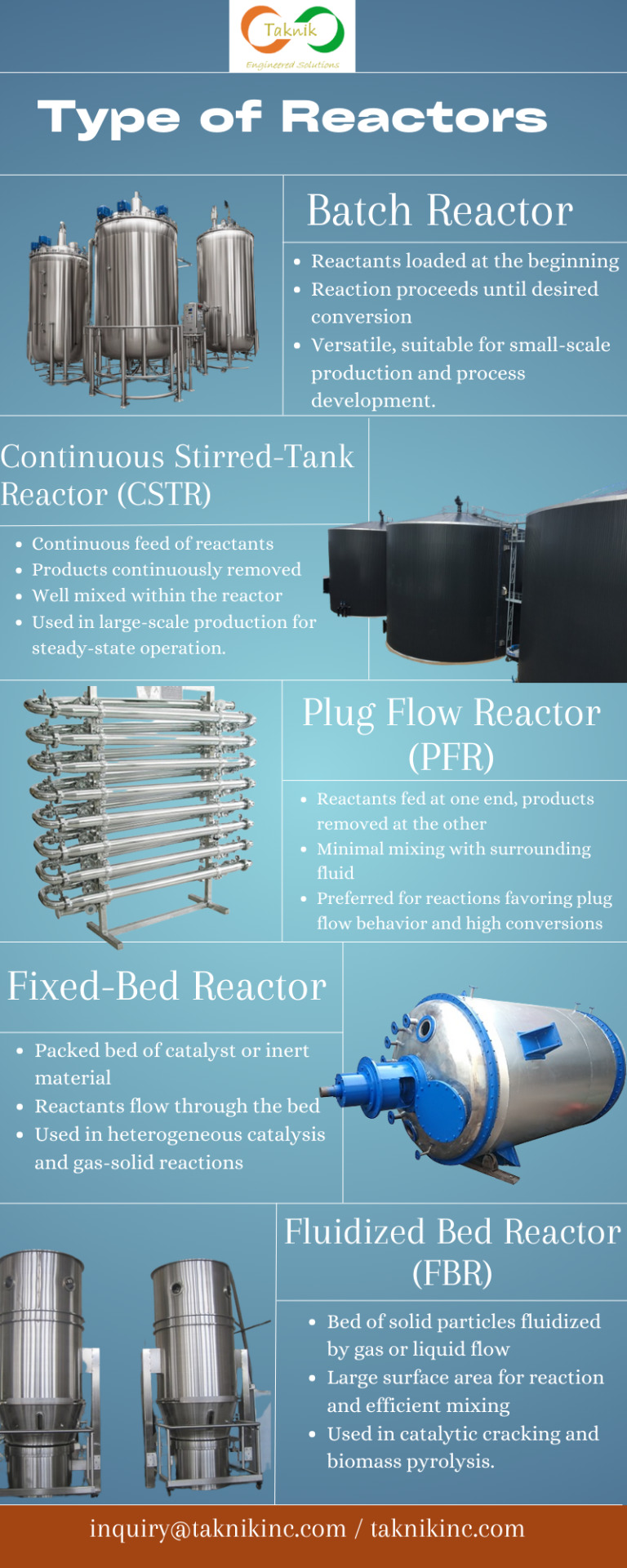

Taknik Inc is an Engineering Consultant it is a leading provider of Engineering design & Consultancy Services solution in India.

We Provide Process Equipment for the Manufacture Industries ,all kind of Matallic and non Metallic Equipment ,Reactor,HDPE Sprial Tank Blower Scrubber, Heat Exchanger, Storage Tank, Pressure Vessel etc .

for more details you can contact us

9510430147

or

email Id- [email protected]

#taknikinc#engineering#consultant#services#manufacturingindustry#manufacturer#metallic#Reactor#solutions#process#equipment#production#chemicals#tank#bharuch#gujarat

4 notes

·

View notes

Text

i understand its very very important but how they capitalize here reminds me of when im being goofy and over the top enthusiastic about stuff

edit: gathering the screenshots of me for these examples started a thing where me and sluggo (Laplace’s Angel) here read out the cesium excerpt. both of our attempts were pinned bc they were hilarious XD

these are examples of me being silly after getting out of a shower, spending a few extra mins to reply to smthn before i leave, sobbing over side profiles and old attempts at such, and a reply to a perch perkins + squillium fanart that was pinned earlier in the 🌀hyperfix-hyperfix channel. good times :3.

profile picture is a silly frame from @neon-catarina ‘s Chonny’s Inferno anination thing!! sorry for the ping 👀💧 this def doesnt relate to cj in any way lmao. my username is a playon-words of ‘chonny doll’ but idk why theres and extra L like its ‘lol.’ originally was ‘clog’ but that was odd. the chonny toothpick puppet doll thing in that animation was my favorite,,

#cesium!!!!!#caesium!!!!!!#this post is HIGHLY FLAMMABLE#this post contains a REACTIVE chemical#this post is a DANGEROUS FIRE and EXPLOSION HAZARD#nuclear reactor hyperfixation#nuclear reactor#im a large fan of cesium 137#personalposts

2 notes

·

View notes

Text

Shit like that thing I just reblogged literally terrifies me so much I'm shaking and tearing up rn. I'm weirdly drawn to art about it though like I hope that if I can expose myself to people who describe the beauty in it like that post maybe I'll get like, desensitized but instead I just end up making myself really upset

#it's not just molten metal it's also mines and chemicals and big mechanical machines and elevators and nuclear reactors#and basically any kind of heavy industry#it's like legitimately a phobia but I can't find a name for it or other people who have it

3 notes

·

View notes

Text

Why Choose PVA Glue Production Line Turnkey Project? | JCT Machinery

PVA Glue Production Process

1. Raw Material Preparation

Main Raw Materials: PVA powder, water, vinyl acetate (VAc), thickener, plasticizer, filler, preservative, etc.

PVA powder is dissolved in water in a heated stirring kettle to form a transparent viscous liquid.

2. Reaction Polymerization

In reactor, the dissolved PVA liquid is subjected to emulsion polymerization with vinyl acetate to form a stable emulsion structure.

Control the temperature, pressure, and stirring speed to ensure uniform reaction.

3. Emulsification & Thickening

Add thickeners (such as CMC, starch) and plasticizers (such as glycerin) to adjust the viscosity and fluidity of the glue.

Use a high speed disperser or emulsifier to ensure that the ingredients are fully mixed to improve the uniformity and stability of PVA glue.

4. Cooling & Filtration

After the reaction, PVA glue needs to be cooled to room temperature and filtered to remove impurities to ensure the purity of the finished product.

5. Storage & Filling

PVA glur is placed in a storage tank and packaged after being left for a period of time.

It is packaged in barrels, bottles or bags using an automatic filling machine and sealed before leaving the factory.

PVA Glue Production Line Features

✅High Degree of Automation: Optional PLC control system to improve production stability and efficiency. ✅Environmental Protection and Energy Saving: Adopts water-based formula, no solvent pollution, in line with environmental protection standards. ✅Customizable Production: It can produce PVA glue with different viscosity and solid content, suitable for a variety of industry needs. ✅High Adhesion and Low Odor: Suitable for bonding materials such as wood, paper, leather, textiles, etc.

0 notes

Text

What is a Chemical Reactor?

A chemical reactor is an enclosed capacity in which a chemical answer invoices home. In chemical engineering, it's commonly implicit to be a procedure vessel used to carry out a chemical reply, which is one of the classic unit operations in chemical process analysis. Chemical reactors are used in multiplex manufacturing processes. Though, they've certain limitations that you must keep in mind. Flow rate of reactants can be precisely skillful and the creation inclines to be of advanced quality than in batch operations. They also allow fever to be kept ceaseless added willingly.

The Advantages of Using Chemical Reactors for Manufacturing Processes

Chemical reactors are a vital part of accoutrements in legion mechanical processes, from chemical affair to food processing. These machines are designed to ease chemical answers between different outfit, creating new admixtures or altering the chattels of existing bones. The use of chemical reactors offers several advantages for mechanical employments. Chemical reactors are used in a variety of processes to change reactants into produces. They're the heart of any chemical factory. It's essential to have the right reactor for your process. The type of response, chemistry, and operating conditions determine which reactor is the elegant for you. The right choice of a reactor will help you increase the productiveness and profitability of your manufactory. You can buy chemical reactors from fat record at a competitive price.

Reactors come in different designs and sizes. There are batch, nonstop, and circle reactors. Batch reactors are the simplest and contain a demagogue. They also have jackets where serviceability can be applied to heat or cool the response mass. They're generally used to prepare chemicals and in the pharmaceutical assiduity. Nonstop and circle reactors are more advanced than batch reactors. These reactors can run as a nonstop operation, and they can control the hearthstone time. The product feature is better-quality than that of a batch reactor. They also bear lower volume to achieve the same position of conversion.

Chemical Reactors Can Help Improved Product Quality

Chemical reactors can help ameliorate the quality of products produced in artificial processes. By precisely controlling the conditions within the reactor, similar as temperature, pressure, and response time, manufacturers can insure that the asked chemical responses do with maximum effectiveness. This can lead to advanced yields, better product thickness, and smaller contaminations.

Chemical Reactors Can Enhanced Safety and effectiveness

The use of chemical reactors can also enhance safety and effectiveness in artificial processes. By containing the chemical response within a unrestricted vessel, the threat of accidents and exposure to dangerous accoutrements is reduced. The controlled terrain within the reactor can also ameliorate the effectiveness of the response, reducing the quantum of energy and raw accoutrements needed to produce the asked outgrowth.

Rahul Engineering Global Pvt.Ltd. Offers a wide range of chemical reactors for artificial operations, including batch reactors, nonstop reactors, and airman scale reactor. Their platoon of experts can help companies elect the most applicable reactor for their specific requirements, considering factors similar as response time, temperature, and pressure conditions. With Rahul Engineering Global Pvt.Ltd. high-quality outfit and support, companies can achieve bettered product quality, safety, and effectiveness in their artificial processes.

#chemicalreactor#chemical#reactor#regpl#rahulenginerring#manufacturecompanyinpune#manufacturecompanyinindia#manufacturecompanyinchakan#manufacturecompany

0 notes

Text

Explore the Key Parameters for Chemical Reactor Efficiency

Understanding the key parameters for chemical reactor efficiency is crucial to optimizing performance, safety, and productivity in industrial processes.

0 notes

Text

How to Integrate a Jacketed Glass Reactor Vessel into Your Lab’s Workflow

Modern laboratories rely on advanced equipment to enhance productivity, ensure precision, and optimize chemical processes. Among the essential tools in many labs is the jacketed glass reactor, a versatile apparatus integral to a variety of chemical process systems.

The effective integration of a jacketed glass reactor into your lab’s workflow can significantly enhance efficiency and expand experimental possibilities. In this comprehensive guide, we’ll explore the steps to achieve seamless integration, delve into different reactor jacket types, and provide insights to help you make the most of this critical piece of equipment.

Understanding the Jacketed Glass Reactor

A jacketed glass reactor is a sophisticated piece of laboratory equipment designed for chemical reactions under controlled temperature conditions. It consists of a glass vessel encased in an outer layer, or jacket, through which a heating or cooling medium circulates. This design facilitates precise thermal management, making it invaluable in research and industrial settings.

Key Features

Material Transparency: The borosilicate glass construction allows for visual monitoring of chemical reactions.

Temperature Control: The jacket accommodates fluids such as water, oil, or glycol, enabling controlled heating or cooling.

Versatility: Suitable for a variety of applications, including synthesis, mixing, distillation, and crystallization.

Why Choose a Jacketed Glass Reactor?

The jacketed glass reactor offers several advantages:

Enhanced Temperature Precision: Ideal for reactions requiring specific thermal conditions.

Scalability: Available in various sizes, from small-scale lab units to industrial-scale systems.

Chemical Resistance: Borosilicate glass resists corrosion, making it compatible with a wide range of chemicals.

Customizable Options: From reactor jacket types to stirring mechanisms, these reactors can be tailored to specific needs.

By incorporating a jacketed glass reactor into your chemical process systems, you can achieve greater control, reproducibility, and efficiency in your lab operations.

Preparing Your Lab for Integration

Before installing a jacketed glass reactor, it’s crucial to assess your lab’s layout and workflow. Follow these preparatory steps to ensure a smooth integration:

Step 1: Evaluate Space RequirementsMeasure the available space in your lab to ensure the reactor fits comfortably. Account for additional components like circulators, pumps, and control systems.

Step 2: Define Process ObjectivesIdentify the types of reactions or processes you’ll perform, such as synthesis or distillation. Determine the temperature range and pressure requirements for your applications.

Step 3: Select the Right Reactor Jacket TypeThe reactor jacket type you choose will directly impact the reactor’s performance.

Common types include:

Single Jacket: Simplest design, ideal for basic heating or cooling needs.

Double Jacket: Provides more uniform temperature control by circulating the thermal fluid between two layers.

Triple Jacket: Offers additional insulation and is suitable for extreme temperature conditions.

Installing the Jacketed Glass Reactor

Proper installation is key to ensuring optimal performance. Follow these steps to set up your jacketed glass reactor:

Step 1: Assemble the ComponentsUnpack and inspect all components, including the reactor vessel, jacket, and accessories. Secure the reactor to a sturdy stand or frame. Attach the stirring mechanism, thermocouples, and other monitoring devices.

Step 2: Connect the Thermal CirculatorSelect a compatible circulator for your chemical process systems. Ensure it meets the required temperature range and fluid capacity.

Connect the inlet and outlet ports of the reactor jacket to the circulator using high-quality tubing.

Step 3: Ensure Proper SealingCheck all joints and connections for leaks. Use appropriate sealing materials, such as PTFE gaskets, to maintain a tight seal.

Step 4: Test the SystemPerform a dry run to verify that all components are functioning correctly. Monitor temperature and pressure readings to ensure accurate operation.

Optimizing Workflow with a Jacketed Glass Reactor

Once installed, the jacketed glass reactor should integrate seamlessly into your lab’s workflow. Here’s how to maximize its efficiency:

Automate Processes

Use digital controllers to automate temperature adjustments and stirring speeds. Implement data logging systems to track reaction parameters in real time. Standardize Protocols

Develop standard operating procedures (SOPs) for common reactions. Train lab personnel on proper handling and maintenance of the reactor. Maintain Equipment Regularly

Clean the reactor and its components after each use. Schedule routine maintenance checks to prevent wear and tear. Scale Up Operations

If your experiments require larger volumes, consider scaling up to a larger jacketed glass reactor without altering the core process.

Applications of Jacketed Glass Reactors in Chemical Process Systems

The jacketed glass reactor is indispensable in various chemical process systems. Common applications include:

Synthesis and Mixing: Combine reactants under controlled temperature and agitation to achieve desired products.

Distillation: Separate components of a mixture by exploiting differences in boiling points. Use the reactor’s jacket to control reflux conditions.

Crystallization: Achieve precise temperature control to promote the formation of crystals in solution.

Extraction: Extract desired compounds from mixtures using solvents and temperature manipulation.

Troubleshooting Common Issues

Despite its robustness, the jacketed glass reactor may encounter operational challenges. Here’s how to address them: Problem: Inconsistent Temperature

Solution: Check for blockages in the thermal fluid circulation system. Ensure the circulator is operating within its specified range.

Problem: Leakage

Solution: Tighten connections and replace worn gaskets. Inspect the glass vessel for cracks or damage.

Problem: Stirring Mechanism Failure

Solution: Verify the motor’s power supply and inspect the stirrer blade for obstructions.

Conclusion

Integrating a jacketed glass reactor into your lab’s workflow is a strategic investment that enhances your lab’s capabilities in chemical process systems. By selecting the appropriate reactor jacket types, preparing your lab, and maintaining the equipment, you can achieve precise control over a wide range of chemical reactions. With proper planning and execution, the jacketed glass reactor will become a cornerstone of your laboratory, driving innovation and efficiency in your experiments.

0 notes

Text

#SS Reactors Manufacturer#GMP Reactor Manufacturer#Chemical Reactors Manufacturer#Pharma Reactor Manufacturers#Used Reactors Supplier#Pressure Vessel Manufacturer

0 notes

Text

Figure 27.23 shows a diagram of such a magnetic field and a photo of a prototype that is in operation in the USA.

"Chemistry" 2e - Blackman, A., Bottle, S., Schmid, S., Mocerino, M., Wille, U.

#book quotes#chemistry#nonfiction#textbook#tokamak#fusion reactor#plasma#chemical reactions#magnetic field#prototype#united states

1 note

·

View note

Text

Designing ,Engineering Solution , Fabrication,Expertise in mixing Technology,Manufacturing we do it all By Hexamide Agrotech Inc Mumbai

Designing, Engineering, Fabrication, and Manufacturing Excellence at Hexamide Agrotech Inc., Mumbai

At Hexamide Agrotech Inc., located in Mumbai, we take pride in offering comprehensive solutions encompassing designing, engineering, fabrication, and manufacturing services. With a legacy spanning over 25 years, we have established ourselves as leaders in the industry, delivering excellence across every aspect of our operations.

Designing and Engineering Solutions:

Our team of skilled engineers excels in providing tailored solutions to meet the unique requirements of our clients. Leveraging the latest design tools and methodologies, we conceptualize and develop innovative solutions that optimize processes and enhance efficiency.

Fabrication Expertise:

With a state-of-the-art fabrication facility equipped with cutting-edge machinery and technology, we ensure precision and quality in every component we manufacture. Our expert fabricators work tirelessly to bring our designs to life, adhering to the highest standards of craftsmanship and attention to detail.

Expertise in Mixing Technology:

Mixing technology lies at the heart of many industrial processes, and at Hexamide Agrotech, we are experts in this field. Whether it's blending powders, emulsifying liquids, or homogenizing solutions, we have the knowledge and experience to design and manufacture mixing equipment that meets the most demanding requirements.

Comprehensive Manufacturing Services:

From concept to completion, we offer end-to-end manufacturing solutions to our clients. Our manufacturing capabilities span a wide range of equipment, including reactors, blenders, distillation plants, and more. With a focus on quality, efficiency, and reliability, we ensure that every product leaving our facility meets the highest standards of performance and durability.

Why Choose Hexamide Agrotech Inc.?

Experience: With over two decades of experience, we bring a wealth of knowledge and expertise to every project we undertake.

Innovation: We are committed to staying at the forefront of technological advancements, continuously seeking out new ways to improve and innovate.

Quality: Quality is ingrained in everything we do, from the materials we use to the processes we follow, ensuring that our clients receive only the best.

Customer Focus: Our clients are at the center of everything we do. We listen to their needs, understand their challenges, and tailor our solutions to exceed their expectations.

Reliability: We understand the importance of reliability in industrial operations. That's why we go above and beyond to deliver products and services that our clients can depend on.

In conclusion, at Hexamide Agrotech Inc., we offer a complete suite of services encompassing designing, engineering, fabrication, and manufacturing, coupled with expertise in mixing technology. With a commitment to excellence and a focus on customer satisfaction, we are the trusted partner for businesses across various industries seeking reliable and innovative solutions.

0 notes

Text

With the help of high pressure reactors, manufacturing plants are able to carry out the hydrogenation of polymers for various applications.

0 notes

Text

0 notes