#cheapest metal 3d printer

Explore tagged Tumblr posts

Text

Cheapest 3D Printing Method

In the ever-evolving realm of manufacturing solutions, 3D printing has emerged as a frontrunner, democratizing production for professionals and hobbyists alike. Among the various 3D printing techniques, Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication (FFF), stands out as the most economical option. This article delves into the reasons behind FDM’s cost-effectiveness, its applications, and strategies to maximize its potential, providing a comprehensive analysis within a 500-word limit.

Tracing the Origins of Fused Deposition Modeling (FDM):

FDM, conceptualized in the late 1980s, revolutionized additive manufacturing by offering a cost-effective alternative for creating prototypes and products. Its working principle involves melting a thermoplastic filament and depositing it layer by layer to construct a 3D object, making it a popular choice for beginners.

A Comprehensive Breakdown of 3D Printing Costs:

Initial Investment: The purchase of the 3D printer constitutes a significant part of the cost, with options ranging from budget-friendly models to sophisticated versions.

Material Expenses: Raw materials, such as filaments in FDM, represent a recurring cost that varies among different 3D printing techniques.

Operational and Maintenance Charges: Regular maintenance, power, and additional accessories contribute to ongoing operational costs.

Software Investments: Depending on project complexity, users might need software tools for designing, slicing, and managing print jobs.

Post-Processing Expenditure: Post-printing steps, such as sanding or painting, contribute to the overall cost.

Diving into FDM’s Cost-Effectiveness:

Economical Entry Points: FDM offers affordable kits for hobbyists and sophisticated systems for professionals, catering to a broad audience at a lower price point.

Budget-Friendly Filaments: FDM utilizes cheaper thermoplastic filaments like PLA and ABS, allowing for cost savings without compromising quality.

Lower Maintenance Costs: FDM printers demand less frequent and less expensive maintenance, reducing the total cost of ownership.

Open-Source Software Ecosystem: FDM benefits from a vibrant open-source community, providing free or low-cost software tools, minimizing expenses.

Simplified Post-Processing: FDM prints often require minimal post-processing, avoiding the need for specialized and costly equipment.

Contrasting FDM with Other 3D Printing Methods:

Stereolithography (SLA): SLA, known for precision, uses expensive UV-curable resins, leading to higher overall costs.

Selective Laser Sintering (SLS): Specialized powders and equipment escalate costs, making SLS less suitable for budget-conscious users.

Direct Metal Laser Sintering (DMLS): Targeting industries, DMLS involves premium materials and machinery, making it costly for everyday users.

Navigating the Ideal Applications for FDM:

Rapid Prototyping: FDM is ideal for cost-effective prototyping, allowing designers to validate concepts without hefty expenses.

Educational Ventures: FDM’s affordability makes it popular in educational institutions for hands-on learning experiences at a manageable cost.

Personal Projects and Hobbies: FDM provides a budget-friendly avenue for hobbyists to explore various projects, from crafting toys to home improvement items.

Customized Manufacturing: FDM excels in manufacturing customized parts or tools at a fraction of the cost compared to traditional methods.

Acknowledging the Limitations of FDM:

Surface Finish Concerns: FDM may exhibit visible layer lines, requiring post-processing for a smoother finish in aesthetically focused projects.

Structural Constraints: Layer-by-layer construction may lead to weaker bonds between layers, posing structural concerns in specific applications.

Limited Scope for Ultra-Fine Details: Filament thickness and nozzle diameter limitations may hinder FDM’s suitability for projects demanding intricate details.

Embracing FDM in the Expansive World of 3D Printing:

In the pursuit of the Cheapest 3D printing method, FDM stands out due to its inherent cost-effectiveness. As technology advances, aligning the choice of the method with project goals becomes crucial. FDM’s rich history, diverse applications, and continuous innovations position it prominently in the 3D printing landscape, offering a balance between affordability and quality.

0 notes

Text

Technology Breakthroughs 2019

what is technology:

technology is the knowledge of techniques and processes mixed with skills and methods that enables human to apply this knowledge, technology had started by the pre-historic man when he used a very simple tools to secure his living from food and protection, then technology uses evolved from just a surviving tool to become the backbone of living that interfered in every single detail of human daily life, from the Toothpick to the space-traveling that is like a dream coming true as their rich tourists had made a space trip and its expected that it will be common and affordable trip in the upcoming years, so let’s talk about the most exciting technology breakthroughs in 2019.

Top Breakthroughs

5G Technology:

2019 is going to witness the releasing of the fifth generation of cellular mobile communication (5G) that featured with reduced latency, energy saving, cost reduction, higher system capacity, and massive device connectivity, and it’s the natural evolution of the 4G Technology that had been released on 2009 in Sweden and that was a great breakthrough in the history of mobile internet that the internet speed could reach 100 megabytes per second for high mobility mobile communication, so let’s get back to 5G technology that its speed is expected to reach 2500 MB (Megabyte) per second as peck performance, 5G mobile devices had seen a great improvement in technicality as it depend on a cell communicate by radio waves with a local antenna array and automated transceiver in the cell with low power consumption rate the antenna is connected with the telephone network through optical fiber cables or wireless backhaul connection, the devices that will equip the 5G technology is going to have 4G LTE capability as the 5G access is not available everywhere till now, the 5G is going to be used in the autonomous vehicles to support it with data about the surrounding environment in real time and nearby vehicles that could exchange their locations and intentions, the roadway is also able to deliver traffic conditions immediately ahead, which will ease the task of driving, also 5G technology is going to be compatible for laptops computers to enhance its Internet communication.

Virtual Reality (VR):

Virtual reality (VR) technology had started in the early 1950th as Morton Heling wrote about the “theater experience”, and built a prototype of Sensorama vision dubbed in 1962, this device displays engaged multiple scenes, then he developed the “Telesphere Mask”, the year 1968 had seen the releasing of the first head mounting display (HMD) system for simulation applications by Douglas Engelbart and other scientists, the 70th had seen a great leap in the virtual reality technology by interfering in many fields like medical, military and even space science as David Em was the first one to produce navigable virtual worlds in NASA laboratory, in 1979 Eric Howlett developed the Extra Perspective (LEEP) optical system which make the virtual reality helmets available today, 1991 had seen the invention of the first cubic impressive room allowing people to see their own bodies in relation to each other’s in the room, between the years 1982 and 1992 Nicole Stenger created the first real time interactive impressive movie that viewed by using a dataglove and a high resolution googles, then the new millennium comes with new update in VR technology, by the year 2001 the first pc based on cubic room had been invented, in the year 2007 google had released the street panoramic view by using 3D stereoscopic mode, 2013 had seen the start of using the virtual reality technology in smart phones by using a headset that used in virtual and augmentation of reality, the Oculus VR project had seen the light Valve Corporation, in the year 2014 Facebook had bought the Oculus VR for 2 Million dollar, and also Sony had announced the launch of the PlayStation VR project, In the year 2015 Google had announced the launch of cardboard a do-it-yourself stereoscopic viewer for smartphones, 2016 had seen a great leap in the VR technology development by many companies specially HTC which had shipped the Vive Steam VR headset as the major commercial release in this year, Sony had continued the development of the wireless headset and evolved it and released the Vive for PlayStation VR. 2019 is going to see a great leap in VR technology as Sony is working to release 3D Rubber Motion Controller for PlayStation VR, SOMNIACS company is working on Somniacs Birdly VR Flying Simulator, but this will not be the last update in the VR technology.

Artificial intelligence (AI) technology

Artificial intelligence concept had started to be known from the year 1940 by the invention of the programmable digital computer, the machine based on the abstract essence of mathematical reasoning, Dartmouth college had founded the AI research field in the year 1956, by the year 1973 the artificial inelegance had faced a new challenge from the USA and the British governments as they stopped the funding undirected research into artificial intelligence, the investors started to take the role of the governments in the funding this research but by the 80th they started to withdraw from this business because of the absence of the needed computer power (hardware), but this all had changed by the beginning of the 21 century as that the machine learning was successfully solved a lot of academic and industrial problems, the AI development in the new millennium started with the creation of the interactive toys (smart toys) in the year 2000, in the year 2004 Nasa had navigated the surface of Mars with autonomously robotic exploration rovers, in 2005 Honda released a humanoid robot that is able to walk as fast as humans and he worked as a food servant in restaurant, but the year 2005 had seen a new thinking in the AI technology by the initiation of the blue brain project that aimed to identify the structure of human brain and detect its function in disease and health, between years 2010 and 2014 the humans are being able to communicate and even speak with robots as in 2011 Apple had launched the Siri project and in year 2012 google had launched Google Now, and then the turn comes on Microsoft that released the smartphone apps the uses the natural language to answer the received questions, make recommendations and even perform actions, Artificial Intelligence (AI) Technology is going to see a great leap in 2019 as this year will see the release of:

1- Automated CCTV security cameras:

that featured by:

It could predict potential vulnerabilities, threats and menace.

Tracking missing children.

Tracking theft vehicles.

Quick action.

Identifying criminals and suspected people between the large crowd.

2-general adversarial networks (GANs):

A new concept that will be released in 2019 that will make your AI smarter as an example it could be able to distinguish between the real image or a realistic image that is created by AI technology.

3-Chatbot:

Chatbot that is also known as Smartbot, Talkbot, chatterbot, IM Bot, interactive agent, conventional interface and artificial conversational entity, the Chatbot concept is an artificial intelligence which conducts a conversation via auditory or textual methods, this technology had started in the early 20th century in the year 1960, but in the middle of the century that this technology had turned from simple conversions to powerful promotional tools for media brands and e-commerce businesses, 80% of companies are expected to be using the Chatbot by the year 2020.

3D Printing

3D printing is a number of various computer controlled processes to create a three-dimension object is made by joining and solidifying the material, 3D printing had started to enter the production industry in the early 80th particularly in 1981 when the Japanese scientist Hideo Kodama has invented two methods for fabricating three dimensional plastic models with photo hardening method, the use of 3D printing in production started with functional or aesthetical prototypes then it turned to be additive manufacturing that it can be used in manufacturing a very complex shape or geometry that is pre designed by 3D model or a CAD file, 2019 is going to see a leap in 3D printing specially in the metal 3D printing which depend on digital model that uses layer by layer material build-up approach which gives the metal a full density and high precision, the metal 3D printing technology is going to be used in manufacturing aerospace, oil & gas, automobile and marine applications, 3D printing is going to use new materials and enter the phase of mass production with high technology machines, 3D printing will see new types in 2019 by these types:

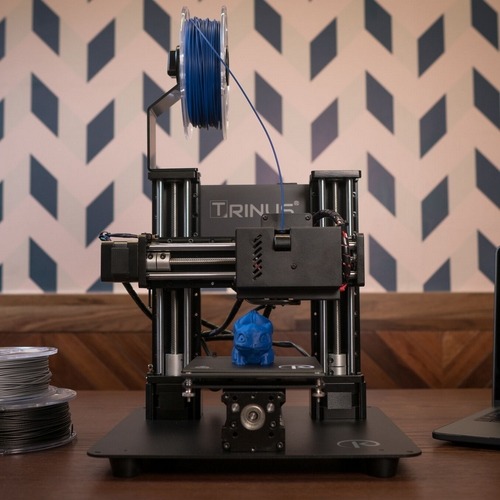

Fused Deposition Modelling (FDM): is also known as Fused Filament Fabrication which is the most commonly available and cheapest type of 3D printing.

stereolithographic (SLA): which is known as the world first 3D printing technology as its history returns to the year 1986, stereolithographic printing is Featured by using mirrors but it also had a big disadvantage that it takes too long to trace the cross-section of an object when compared to DLP.

Digital Light Processing (DLP): this type of 3D printing uses a digital light projector to flash one image for each layer at once or images of multiple flashes for larger parts, the output of this type of 3D printing is a digital image composed of square pixels resulting from rectangular blocks called Voxels.

Selective laser sintering (SLS): its creating objects by using Powder Bed Fusion technology and polymer powder, this type of 3D printing is going to be commonly used due to its low price and this type is featured by using a CO2 laser beam in scanning the object surface.

Material Jetting (MJ): this type of 3D printing has the same concept of normal inkjet printers but the difference in this printing type is that it builds multiple layers of ink upon each other until it turns to solid part, Material Jetting featured by offering objects made from multi-material printing and with full-colour.

Drop On Demand (DOD): this type of 3D printing featured by using a pair of ink Jets, one looks like a wax material and the other used for dissolvable support material, DOD printing featured by using a fly-cutter that skims the build area after the creation of each layer to ensure the commencing of this layer, this type of printing is used in casting the lost wax and suitable for other mould making applications.

Sand binder jetting: mainly this type of 3D printing depends on mixing the PMMA powder with binding liquid as an agent to produce parts colors are added to the mixture through another nozzle, binder jetting useful in production of sand cast molds and cores as they are generally made of artificial sand or (silica), this type of 3D printing is featured with its low cost and quite easily integrated into existing manufacturing of foundry process without disruption.

Metal binder jetting: this type of 3D printing is used in the fabrication of metal objects, as the metal powder is bond together using a more poly binding agent, metal binder jetting is featured by producing complex geometries objects beyond conventional manufacturing techniques, this process done on main steps of infiltration process then adding bronze is the object then we go for the sintering process, the output of this printing type had an issue of non-uniform shrinkage that is solved in the design stage.

Direct Metal Laser Sintering (DMLS): this type of 3D printing is like SLS type but the difference in that it is applied on metal objects, laser is used in fusing the metal powder at a point reaching molecular level, DMLS printing process needs a structural support as the output object is Vulnerable to distortion and wrapping due to residual stress.

Electron Beam Melting (EBM): high energy Electron beam is used in the metal fusion; EBM printing is featured with superior building speed upon any other 3D printing types because of its high energy density.

Financial

Blockchain:

Blockchain or blockchain is a growing list of records called blocks using cryptography, blockchains are resistance to modification of the data that was first described in the year 1991 but it was actually created as public transaction ledger of the cryptocurrency (bitcoin) by Satoshi Nakamoto in the year 2008, it is managed by peer to peer network collectivity adhering to a protocol for internal code communication and validating new blocks once recorded, blockchains has many types:

Public blockchains:

Public blockchains have absolutely no access restrictions, its useful as that anyone has a connection to the internet could send transactions as validator, bitcoins and Ethereum are the most known public blockchains Applications.

Private blockchains:

Private blockchains feathered with high privacy as there is no one could join the network until he had been invited by the network administrations, and even the participant and validator access is restricted, this type of blockchains is the most appropriate for companies that are interested in Blockchain technology because of the high control level, its main implement is in accounting and record keeping producer’s business.

Consortium blockchains:

Consortium blockchains are semi-decentralized as its controlling lies between the hands of many companies might control one node in the network and not just a single organization that controls the network.

Blockchains technology will see a great leap in 2019 as these types will rise:

Blockchain will work as a service (BaaS):

BaaS is a cloud-based service that allows customers to build their own Blockchain powered products and it could be including applications, smart contracts, and other Blockchain features without the need to set up or build Blockchain based infrastructure.

Hybrid Blockchain:

Hybrid Blockchain works by providing the best features and functionality of both private and public blockchains, hybrid Blockchain isn’t widely used but it is considered to be the most appropriate for banks.

Federated Blockchain:

Federated Blockchain is the natural evolution of the normal Blockchain, it looks like the private Blockchain but has more customizable outlook, federated blockchains mainly used in financial services.

Ricardian contracts:

Ricardian contracts are the start of the dependence on legal contracts that cryptographically signed and verified, Ricardian contracts provide unique solutions so that they could be understood without mediator or service for both human and computers.

Interoperability between Blockchains:

Interoperability Blockchains aims to improve information across several networks or other Blockchains networks, the cross chain services improve the daily use of Blockchains, 2019 will see an improvement in the interoperability Blockchains technology, the main applications for Interoperability Blockchains are BlockNet, Aion, WanChain, and others.

Stable Coins:

Stable coins are the side product of the cryptocurrencies, that is affected by the market condition and the stability maintained in all time, most of the stable coins are fiat-chained but they are also backed by commodity stable coins, the main applications for stable coins are everyday currency transaction and P2P payments.

Security Tokens:

Security tokens had replaced the ICOs because it is more secure and protects the investor’s rights redefines the whole investment process, by the current year 2019 investors will tend to use security tokens (STO) than (ICO).

Financial Relegation:

Financial relegation is a type of relegation or supervision, which targets financial institutions with certain requirements, guidelines and restrictions that aims to maintain integrity of the financial system, this system could be handled by government or non-government organization, financial relegation had initiated by the Dutch authorities in the early modern period on the year 1610 as short selling which means that the buyer doesn’t own the asset but he borrows it from the seller and returns it back after short time with profit, then the Financial relegation took its development way until it took the form of banks in our days, the 2010 financial crisis had affected the relegation in a positive way as regulators put a fourth substantial number of new strengthened regulations and expanded requirements, 2018 had seen a great focus on legislative agenda towards protecting the consumers and investors and encouraging financial technology innovation, 2019 is going to see big leap in the financial relegation field as Asian investors will continue their 2018 financial vision to make the trajectory of embedding global post-crisis reforms, and make the Asia-pacific outlook the trends navigating guide across the region, in Europe 2019 is expected to be the year of continuity of regulatory terms, As the first half of the year will be finalizing the legislative initiatives to complete the banking Union, strengthen the EMU, and Capital markets Union.

largest technology construction projects in 2019

London Crossrail:

London Crossrail is the world first continues growing underground system that it extends the railway system with 73 miles (117 kilometers) that links between Berkshire and Buckinghamshire this line holds the name of Elizabeth Line that will be divided into two lines, this huge project expected to cost 23 million Pound, London Crossrail had the approval to start to work on it on 2008 and it’s excepted to launch in autumn 2019.

Benban Solar Park:

Benban solar park will be the world largest photovoltaic power station than expected to generate 1650 (MVP), its located in Upper Egypt particularly in Aswan, the Benban solar park is part of Egypt’s Nubian sun project that aims to be part of generating 20% renewable power of total Egyptian needed power, this Egyptian national project is expected to start working by the end of 2019.

1 note

·

View note

Text

When Buying The Ideal 3d Color Printer, Factors To Consider

If you're looking for an outstanding 3D printer make sure that you understand the primary features first regardless of what your objective. While there are plenty of aspects to consider when buying one, you must take a look at the essential ones like price along with speed, resolution and cost. It's best not to purchase products solely because they looks appealing to your eyes. This is why you need to decide whether you want to purchase generic or brand items. These are some essential factors which are crucial when you purchase a delta 3d printer. You will get more info about metal injection molding by browsing our website.

Resolution

In terms of resolution, you must think about the kind of thing you'd like to print using the device. For example, if you would like to publish images that are detailed, with an outstanding finishing, and a high degree of precision, you will need to pick the best device. For greater levels of advice, it is recommended to go for a device that uses DLP. They're the most recommended option. Other forms, like SLA and FDM don't give you the information you want. Great things don't require refined specifications, though. Therefore, making use of the HD printer to design these types of components is a waste of resources and time.

Speed

When it comes to the printing process, the speed of the machine is the most important factor. Today is the time for speed. If it is slow you will definitely not be able to compete with the aggressive competition on the market. It is recommended to choose a model that is fast. If you're planning to print figures, a ring or another delicate piece, be sure you pick a machine with the ability to print at a reasonable rate. While it is important to produce precise effects it is also a crucial factor that must not be undervalued. In this way, users can utilize the tool quicker.

Price

While it's vital to get an 3d printing that is high-resolution and speed, price is an additional aspect that shouldn't overlook. Some sellers will advise that you choose a service plan, expensive materials, and maintenance expenses once you've paid for the machine. To save a lot of dollars, you might want to choose a device that performs many functions with the cheapest raw materials and accessories. It is therefore beneficial to look at the cost.

Shape

When you are buying 3d printing logo size is one of the key elements to be considered. This is an aspect that depends on the size of the object you want to print, is something to be considered with care. Additionally, the dimensions of the pad for printing can have a better resolution. If you are looking for this particular attribute, be aware of the technical specifications in terms of quantity and size. While buying a powerful machine will likely be expensive but it's not a great idea to reduce the price. You can also buy something of superior quality in the event that you have to put aside a few dollars.

0 notes

Text

A Brief Introduction to 3D Printers

Deciding on which 3D printer to buy could be a daunting task, particularly if you are a beginner. Therefore, you must conduct your research prior to making any decision. It is unlikely that you end up with a printer that is difficult to use or does not meet your requirements. There are a variety of 3D printers to meet different requirements and you need to figure out, what one will meet your needs. This article will help you by highlighting the most crucial elements to be considered before deciding on which 3d printed keycaps to purchase.

What are your 3D printing needs

First, understand the purpose of the printer. The cost of the printer will be contingent on your requirements.

If you intend to utilize your 3D printer for personal purposes to create decorations or for repairing household items the cheapest model is able to function. A mid-cost to low-cost printer will be optimal for you if it's being utilized for educational purposes in the classroom or similar. If you intend to make use of the printer for prototyping or production then it's worth exploring more advanced models. These printers will ensure you of higher quality and speedier printing process.

You are probably unfamiliar with the world of computers. We recommend you go with one dlp 3d printer one, as it is less expensive and more simple to use.

Price and type

There are many 3D printers in the marketplace. They can cost between 100 USD and several thousand dollars. So, it's important to consider your needs to ensure that you do not over or under invest.

There are over ten types of 3D printing, based on what material is used and how it's processed. The most popular types of 3D printers for use at home are FDM, SLS and SLA.

FDM (Fuse Deposition Modeling), is the most common type of 3D printing. It operates by heating a filament and layering it to create the model. This type of printers is mostly used by hobbyists.

SLS (Selective laser Sintering) is a process which uses lasers to melt the powder to create layers of the print. The printer is used mostly for industrial use.

SLA (Stereolithography) operates by using the principle of photo-solidification, in which chemical reactions form layers that are then hardened through UV light. This print is typically superior in quality.

Choose 3D printer quality

Consider your experience level

It is essential to be aware of this because your level of experience should correspond to the level of complexity of the technology. If you're a total novice, you should select the 3D printer with a user-friendly interface, a huge community, and easily available support. You may choose to go with an advanced model if this is your second 3d printing service near me.

Consider the total cost of your 3D printer

While the printer is a one-time purchase it is necessary to purchase filament. Also, there are the costs of maintenance and electricity. While the cost of electricity isn't significant, they can add up if the printer is often used. Be prepared to invest in this equipment in the near future.

If you choose a 3D printer using an alternative filament, such as PLA or ABS they are going to cost more. These filaments will enhance the strength of the prints. Consider if the item you are printing must be more sturdy.

Printer Features

Quality of print is a crucial quality of print is a crucial. FDM printers are among the most popular, but they produce less quality prints. After printing, prints usually need to be smoothed. While printers that use higher quality inks can be capable of producing high-quality prints, they will also be more expensive. If you'd like to learn more about this printer, you can go to pla vs abs website.

Next, you must consider your user interface. You need to ensure that it is easy to understand and use.

It is crucial to know the kind of filament your 3D printer is using and whether it is compatible with your needs. FDM printers make use of ABS and PLA filaments, which aren't recommended for food applications. Metal filament is a possibility in certain printers, however it will substantially raise printing costs.

Community and support

Figure out whether the brand you are considering is offering any kind of support, and if it is easily accessible. Are they able to provide videos for help in setting up? Are there phone lines or chat? It is likely that you will require it, particularly if are a novice. You can also benefit from existing communities on the internet. These groups, which are often Facebook forums or groups are able to provide guidance, encouragement and other valuable details.

Safety

Consider the security features of your printer when you're buying it for your children. FDM printers, for example, melt the filament and can cause burns. The majority of printers move away from the nozzle out of the printing area so you can remove your print in a safe manner. When melting filament, some printers produce smoke. It is not known whether they are harmful to your health, but it may be beneficial to be on the safer side and purchase a printer enclosure.

Retailer

Last but not last, you must consider the retailer selection. The manufacturers of 3dprinting typically offer their services through intermediaries as well as directly. You must verify the credibility of any seller before you buy. Be wary of pages offering your chosen printer for a below-average cost. Be cautious of the seller and pages you visit. There are many people out there looking to scam you online.

0 notes

Text

Consider These Factors When Searching For The Most Suitable 3d Printer

3D printing has revolutionized the manufacturing, construction , and medical industries. It is considered to be one of the best technologies available in the market right now. It's not limited to one field. It is used in a variety of other fields, including fashion engineering, jewelry arts, and engineering. With such a broad scope of applications there are plenty of choices in the market that you can choose from. To choose the most suitable option for you take into consideration a variety of factors before making a final decision.

These are the main considerations when looking for the most efficient 3D printer.

The cost

The majority of people who are looking into 3D printers for business use or to design their own models are the ones who create 3D prints.

You may be a professional 3D designer and are working with a small budget. If so, you should go for the cheapest models as they will offer you excellent features for a lesser price. If you are planning to design your own designs then you will be able to pay more since you don't need to spend money on additional options or services. The mid-priced printers have top-quality features at a low price. However, if you're an amateur DIYer who doesn't intend to make any modifications or changes in their design then you must not go for the printers that are priced at the middle as they're not flexible enough. If you have an interest to discover the latest information on metal 3d printer, you must browse around here pick3dprinter website.

The quality of the 3D printer

The top 3D printers are able to provide top-quality performance and features for an affordable price. On the other hand, if you don't wish to sacrifice quality, then look for low-cost 3D printers since they are made with lesser quality materials, however they can provide excellent performance and features.

The size of the 3D printer

The size of the 3D printer's size is also an important element you must consider when buying a machine. A larger machine will usually provide more results than a smaller one. However, you don't necessarily have to go for the largest size.

If you're planning to purchase 3d printing service for your home, it is advisable to go with a smaller size since it is more compact. However, if you are intending to use it for your office, then you must choose the bigger size as it is more effective for office use.

Technical assistance

Technical support is crucial for getting the most value out of your 3d printed products. The good thing about this is that they will offer the most current updates and assist you to get the most out of your device. If you are having issues with your printer, they will give you the assistance you require. If you do not wish to use such services, it's better to choose a different 3D printer.

Conclusion:

If you're in search of an efficient 3d printer that can give you all the above mentioned features then the E3D S5 is an excellent choice for you. It is suitable for both amateur and professional artists, since it comes with all the necessary features to help them create their work of art.

0 notes

Text

3D Printer Filament Storage – How Is It Done Properly?

If you have moisture and mold in your home, you’re more likely to have respiratory problems, allergies and weak immune system.When you know the cause of the moisture, you can take steps to limit the moisture in the air.

Likewise, humidity is a natural enemy of filaments.Some materials have no humidity problem.Others, such as PVA or nylon, are very hygroscopic and absorb water after a very short time.The wet filament sizzles and is easy to recognize during printing, and the results are terrible.Therefore, it is particularly important to store filaments spools carefully and correctly.

A comparison of dry vs wet filament. Source: Matterhackers

Why Water Damages Thermoplastics

All plastics are polymers or copolymers. you’ll see that the long molecular strands that make up them are woven together when you look at polymers or copolymers under a high-intensity microscope,That means there’s plenty of space between and around the strands.Thererfore, most polymers and copolymers are hygroscopic.Some filament materials, such as Nylon, are very sensitive to water .If they absorb only a little water, they can cause problems when printing.

How To Keep Your 3D Printer Filament Dry

Storing your filament in an airtight container with a desiccant is the easiest way to settle this issue.Filament dry boxes work well, but they can be bulky.

when it comes to airtight,most people think of plastic containers and bags.For the most part, these are good short-term solutions.

This is the cheapest way to store filament spools. Source: Paige Russell / Instructables

Nevertheless, over time, plastic containers and bags become slightly permeable.This means that the longer your printing materials stay in plastic bags, the more water they absorb, .especially when you live in a humid climate. .If you use a clear bag or box, UV light will also reduce the strength of the filament over time.

Using high-quality Mylar bags or bags made of similar materials is a better solution is to store your thermoplastic.Obviously, there is a layer of metal between two layers of plastic.

Mylar bags protect your printing material from water vapor.Source: rigid.ink

Desiccant packets keep the humidity in the containers to a minimum. Source: Amazon

This metal layer protects your printing material from any water vapor that permeates the plastic.So that your printing material produces a satisfactory result.

How You Know Your Printing Material Has Absorbed Water

Before printing, there are two simple ways to determine if your material is absorbing water.First, you can measure the diameter of the material itself.when a polymer absorbs water, it begins to grow in size.If the diameter of the filament increases by 10 percent or more, it most likely absorbs water.

Another way to determine whether a filament absorbs water is to extrude a small amount of filament before printing.We’ve all probably been there: sitting by a fire, listening to its crackle.This is because the water in the wood is changed into steam when heated.The same phenomenon occurs when you extrude thermoplastic that has absorbed water.The heat from the print end causes the water in the plastic to expand and escape.You can hear hissing or popping and also see bubbles.

How to Dry Out Filament

If your filament is wet, you must dry it out before using it to print.Why not use an oven?

Once the oven it up to temperature, place the spooled material inside.Source: Amazon

In the first place, check out the glass transition temperature for the filament that you are going to dry.You need to be sure that you keep your oven temperature below the transition temperature. In a general way , about 60-70C is just about right for most materials, except may be a bit hot for lower temp materials like PLA. Always keep in mind how hot your oven runs and only use electric ovens.

You should also be aware, even if the Glass Transition temp is very high, for a material like Nylon or Polycarbonate – the spool your filament is wound on is likely made from an ABS which will soften at lower temperatures than the filament.

How to dry PLA filament

You ought to be more careful when you dry PLA filament on account that 70C will be too hot. We recommend at the very lowest temp your oven will go around 40C. Even at this temp your PLA will soften, so drying PLA in the oven won’t always give you the results you’re after. It’s a small reminder as to the importance of keeping excellent PLA storage.

Once the oven it up to temperature, place the spooled material inside and leave it there for four to six hours. If you have a convection oven, this drying time may be shortened since the circulated air removes more moisture from the material more quickly.You can also ‘recharge’ the desiccant this way too, placing it in the oven over a low heat.

Once the time is up, remove the material from the oven, allow it to cool and place it into a water impermeable container or bag along with desiccants. Make sure that the container or bag is completely sealed.

Any material that you have oven-dried is slightly more brittle than normal.Remember,Handle the material with care.Only then can you achieve the superior results with your properly dry print material.

Source:

https://all3dp.com/2/filament-spool-8-ways-to-safely-store-your-filament/

https://rigid.ink/blogs/news/how-to-dry-your-filament?_pos=30&_sid=f8cdf3be6&_ss=r

0 notes

Text

Cheapest 3D Printing Method

In the ever-evolving realm of manufacturing solutions, 3D printing has emerged as a frontrunner, democratizing production for professionals and hobbyists alike. Among the various 3D printing techniques, Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication (FFF), stands out as the most economical option. This article delves into the reasons behind FDM’s cost-effectiveness, its applications, and strategies to maximize its potential, providing a comprehensive analysis within a 500-word limit.

Tracing the Origins of Fused Deposition Modeling (FDM):

FDM, conceptualized in the late 1980s, revolutionized additive manufacturing by offering a cost-effective alternative for creating prototypes and products. Its working principle involves melting a thermoplastic filament and depositing it layer by layer to construct a 3D object, making it a popular choice for beginners.

A Comprehensive Breakdown of 3D Printing Costs:

Initial Investment: The purchase of the 3D printer constitutes a significant part of the cost, with options ranging from budget-friendly models to sophisticated versions.

Material Expenses: Raw materials, such as filaments in FDM, represent a recurring cost that varies among different 3D printing techniques.

Operational and Maintenance Charges: Regular maintenance, power, and additional accessories contribute to ongoing operational costs.

Software Investments: Depending on project complexity, users might need software tools for designing, slicing, and managing print jobs.

Post-Processing Expenditure: Post-printing steps, such as sanding or painting, contribute to the overall cost.

Diving into FDM’s Cost-Effectiveness:

Economical Entry Points: FDM offers affordable kits for hobbyists and sophisticated systems for professionals, catering to a broad audience at a lower price point.

Budget-Friendly Filaments: FDM utilizes cheaper thermoplastic filaments like PLA and ABS, allowing for cost savings without compromising quality.

Lower Maintenance Costs: FDM printers demand less frequent and less expensive maintenance, reducing the total cost of ownership.

Open-Source Software Ecosystem: FDM benefits from a vibrant open-source community, providing free or low-cost software tools, minimizing expenses.

Simplified Post-Processing: FDM prints often require minimal post-processing, avoiding the need for specialized and costly equipment.

Contrasting FDM with Other 3D Printing Methods:

Stereolithography (SLA): SLA, known for precision, uses expensive UV-curable resins, leading to higher overall costs.

Selective Laser Sintering (SLS): Specialized powders and equipment escalate costs, making SLS less suitable for budget-conscious users.

Direct Metal Laser Sintering (DMLS): Targeting industries, DMLS involves premium materials and machinery, making it costly for everyday users.

Navigating the Ideal Applications for FDM:

Rapid Prototyping: FDM is ideal for cost-effective prototyping, allowing designers to validate concepts without hefty expenses.

Educational Ventures: FDM’s affordability makes it popular in educational institutions for hands-on learning experiences at a manageable cost.

Personal Projects and Hobbies: FDM provides a budget-friendly avenue for hobbyists to explore various projects, from crafting toys to home improvement items.

Customized Manufacturing: FDM excels in manufacturing customized parts or tools at a fraction of the cost compared to traditional methods.

Acknowledging the Limitations of FDM:

Surface Finish Concerns: FDM may exhibit visible layer lines, requiring post-processing for a smoother finish in aesthetically focused projects.

Structural Constraints: Layer-by-layer construction may lead to weaker bonds between layers, posing structural concerns in specific applications.

Limited Scope for Ultra-Fine Details: Filament thickness and nozzle diameter limitations may hinder FDM’s suitability for projects demanding intricate details.

Embracing FDM in the Expansive World of 3D Printing:

In the pursuit of the Cheapest 3D printing method, FDM stands out due to its inherent cost-effectiveness. As technology advances, aligning the choice of the method with project goals becomes crucial. FDM’s rich history, diverse applications, and continuous innovations position it prominently in the 3D printing landscape, offering a balance between affordability and quality.

0 notes

Text

Which Nerf Blasters should Choose in Nerfwar

IF you are play frequently in Nerfwar,we should play with which blaster,now we share our experience to you

Manual Operation Blaster 1. If you choose to take Nerf Retaliator blaster, then you need to change the metal small baffle, metal bolt sled, otherwise the two items must be demaged. However, it increases your cost and stuk darts in barrel when play it, and you will have to remove the stucked bullets every five minutes. 2. Choose other manual operation blasters such as Nerf N-Strike Elite Longshot CS-6, please consider the cost. 3,Nerf Prophecy, if your friends have large hand can't use it. 4, so the best choice for manual operation blasters are Nerf N-Strike Elite Strongarm Blaster, Nerf Zombie Strike Hammershot Blaster, Nerf N-Strike Elite Mega Magnus Blaster... and even Nerf N-Strike Mega Tri-Break.

Semi/Full-Auto Blaster is still the most popular. I. Exterior. 1, try to avoid 3D printers, especially the flash hider and iron sight. 2, do not have any red dot, battery life is short. 3. Use the cheapest Nerf Retaliator original buttstock.

4, use the cheapest PLA silence, in order to protect the extended inner tube, even if you use aluminum alloy tube, it will be paralyzed. Do not make a slender, protruding inner tube that will be damaged. But without extending the inner tube, the bullets fly unstability.

II. internal structure 1, semi-automatic shooting mode, bullet usually stuck in barrel. And many people don't know the situation when it happen, so continue to press, the battery is overheated and scrapped. 2, the original Worker Nef 3s lithium battery will be burnt regardless of the N-strike Elite or STF, burning a mess. 3, changed to fully automatic, putter and flywheel must be powered by two sets of electricity, otherwise burned. 4, firstly press the power supply to accelerate and then press the trigger, but for many people just as difficult to learn a car. 5, 6, don't use Worker Nef metal flywheel , it will be easy to Loose, grinding the Worker Nef Flywheel cage, sound like a silver bell.

7, don't Worker Nef metal Flywheel cage, pay attention to the cost.

8, don't use three burst mode, or six flywheels, stuck darts make you crazy 9. The Worker Nef motor selects under 3V turn-speed 11000-12000, otherwise burns. Under the 4s lipo, the coil is not hot for 30 seconds, and the battery is not hot. Under this premise, the torque is as large as possible, it's fine.

The motor must have a brand, preferably an iron back cover. Do not try cheapest motor. Motor number is like xxxx/xx, the first two numbers xx is the speed, do not try more than 30.

In summary, the most suitable choice is + Worker Nerf PLA Suppressor + Retaliator Buttstock + xsw full-auto+ two sets of batteries+ Nerf STF kit. Or Nerf N-Strike Elite Rapidstrike CS-18 Blaster whch is very troublesome to modify but the lower cost - the principle of modification is the same as above.

0 notes

Text

26 best 3D printers under $200/$300

3D printing is becoming ever more accessible - with a brand new 3D printer now costing as little as $79! We thought that we’d do a quick round up of some of the most affordable 3D printers on the market. We haven't had the chance to test all of these personally, so if you have any feedback do let us know - but check out a selection of machines under $300 below. And don’t forget to head over to MyMiniFactory to grab free 3D-printable models when you do start printing!

----------------------------------------------------------------------------------------------------

STARTT $99.99

The STARTT is a great way to start(t) with 3D printing. It is supplied as a simple kit that can be assembled in around 5 hours, enabling you to understand how a 3D printer works. Despite this model being affordably priced, the printing quality is impressive. The STARTT is compatible with any open source slicer like Cura, and is loaded with pre-sliced 3D printable designs, compliments of MyMiniFactory.

You can purchase this model here.

Check out some of STARTT’s 3D-printable designs here!

Key Statistics:

DIY kit: Yes Type: FDM Weight: 4 kg Max. build volume: 120 mm x 140 mm x 130 mm Min. layer height: 100 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: No Open source: Yes Wireless: No

----------------------------------------------------------------------------------------------------

101 Hero $79

101HERO launched on Kickstarter with the objective of being the world's most affordable 3D printer - the campaign was a great success raising more than $1M. This printer will come in 2 editions the Customer Version will be a kid-friendly edition, which allows users to print designs via an SD card. The Designer & Developer version will be more advanced, with a USB connection and open-source software compatibility.

You can pre-order this printer here.

Try out some support free prints on this one to get started, grab them here.

Key Statistics:

DIY kit: 90% pre-assembled Type: FDM Weight: 1.86 kg Max. build volume: 150 mm diameter x 100 mm height Min. layer height: 50 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: No Open source: Designer & developer version only Wireless: No

----------------------------------------------------------------------------------------------------

Tronxy X1 $187

This Chinese aluminium DIY kit is one of the cheapest 3D printers on the market. Suitable for PLA and ABS, it’s a basic model, easy to assemble and it can be recommended to beginners.

You can purchase this 3D printer here.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 3.5 kg Max. build volume: 150 mm x 150 mm x 150 mm Min. layer height: 100 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: No Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

Tronxy P802M $204

It makes use of Repetier-Host and Cura for slicing. The P802M is great value for its cost and is recommended for home use and to beginners.

You can purchase this model here.

Download free electronics 3D-printable designs here.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 8 kg Max. build volume: 220 mm x 220 mm x 240 mm Min. layer height: 50 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: Yes Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

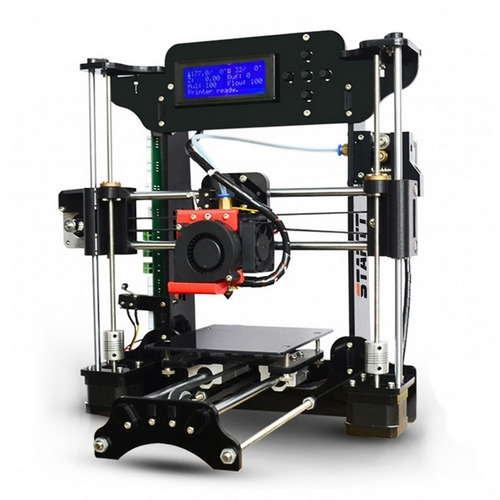

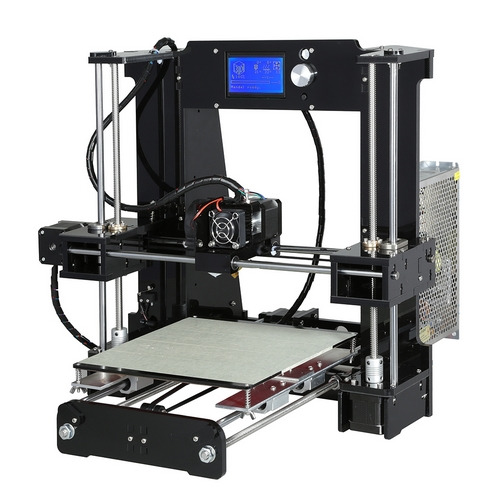

Anet A8 $170

The A8 is the cheapest model from the Chinese brand Anet. Some parts of this DIY kit can be 3D printed and changed if needed. This model is very popular which means there is a great community on the web, and lots of customisation available to kick start your 3D experience. The A8's affordable price tag makes it a favourite among consumers, but that doesn't mean that this printer isn't a 3D printing powerhouse. It boasts a large print area and very capable NEMA17 motors to navigate the print-space. The A8 comes stock with a versatile extruder and heated bed, which makes it capable of printing a diverse selection of filaments.

You can buy this 3D printer here.

And for the DIY lovers, here you can download for free thousands of 3D-printable spare parts!

Key Statistics:

DIY kit: Yes Type: FDM Weight: 8.5 kg Max. build volume: 220 mm x 220 mm x 240 mm Min. layer height: 100 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: Yes Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

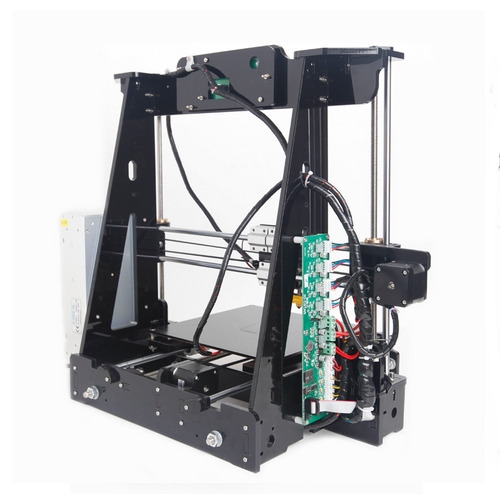

Anet A6 $198

The A6 is a bit more expensive than the A2 and A8 but has a bigger build volume.This model is a 3D printer with acrylic frame and single extruder. To maintain the garage-built feel and the handmade charms, Anet A6 3D desktop printer is also a build-it-yourself kit.

You can purchase this model here.

The build volume will enable you to print objects such as these.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 7.6 kg Max. build volume: 220 mm x 220 mm x 250 mm Min. layer height: 100 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: Yes Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

Anet A2 $203

The A2 has a build volume a bit smaller than the A6 and A8, but also a smaller minimum layer height. This 3D printer adopts the high-end configuration with stable performance, and the compact body ensures portability. It is an unassembled DIY kit, which provides you with a step-by-step guide to build the 3D printer from scratch.

You can buy this model here.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 4 kg Max. build volume: 220 mm x 220 mm x 220 mm Min. layer height: 50 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: Yes Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

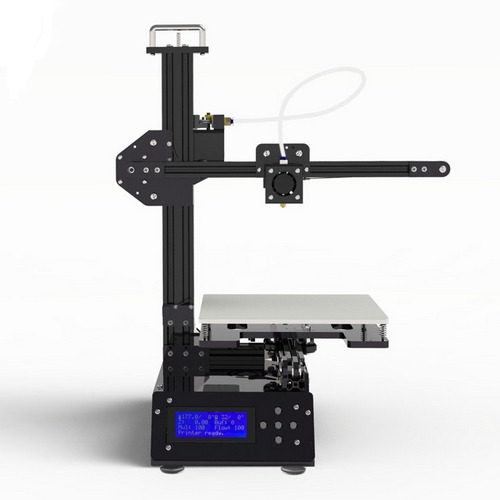

Super Helper SH105 $149

Launched by the Chinese brand Winbo, the SH105 is one of the cheapest 3D printers on the market. The SH105L is $50 more expensive than the SH105 and includes a laser head. Described as being suitable for a wide variety of applications including education, design, manufacturing, and general home and business use, the Super Helper looks to be easy to use, and its portability is a big plus.

You can purchase this 3D printer here,.

Judging by the photo this one is going to be great for planters - download some here.

Key Statistics:

DIY kit: No Type: FDM Weight: 3.6 kg Max. build volume: 105 mm x 105 mm x 155 mm Min. layer height: 40 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: No Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

Q3D OneUp 3D $199

This self-assembled 3D printer is one of the cheapest on the market for the moment, and clearly a good and honest printer for its price. For beginners, buying and building a DIY kit like this one (2-8 hours to build) is recommended to understand the ins and outs and the ups and downs of a 3D printer. With over 7,000 units out in the wild, the OneUp is the standard for entry level 3D printer kits. This model sets itself apart from other 3D printers in its class by using the finest linear motion components, including chromed, induction hardened linear shafts, dual precision ACME screws (for the Z axis) and LM8LUU linear bearings for double the rigidity over the LM8UU bearings used in most printer kits. Each of the linear motion components is tied together with a CNC laser cut melamine frame (made in the USA) which provides not only rigidity but lightweight for high-speed printing. With improved print speeds up to 100mm/s due to the lighter weight extruder and hot end, print time is apparently cut almost in half.

You can purchase this model here.

And here are some free 3D-printable designs great for first-time printers!

Key Statistics:

DIY kit: Yes Type: FDM Weight: 4 kg Max. build volume: 100 mm x 100 mm x 125 mm Min. layer height: 50 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: Optional Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

Creality CR-7 $256

The Creality CR-7 is a good machine for 3D DIY enthusiasts, and suitable for a wide range of customers. This desktop 3D printer is easy to assemble, electric-proof, anti-scald and scratch resistant. With its Ilight weight, stability, and low noise, it will provide you with a good experience of 3D printing.

You can purchase this model here.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 3.5 kg Max. build volume: 130 mm x 150 mm x 100 mm Min. layer height:100 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: No Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

Q3D TwoUp 3D $239

The TwoUp has the same specs than the OneUp except that the build volume is bigger: 175 L x 175 W x 125 H.

Buy it here.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 4 kg Max. build volume: 175 mm x 175 mm x 125 mm Min. layer height: 50 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: Optional Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

Q3D ThreeUp 3D $279

The ThreeUp has the same specs than the OneUp and the TwoUp except that the building volume is even is bigger: 175 L x 175 W x 210 H.

You can purchase it here.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 5.9 kg Max. build volume: 175 mm x 175 mm x 210 mm Min. layer height: 50 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: Optional Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

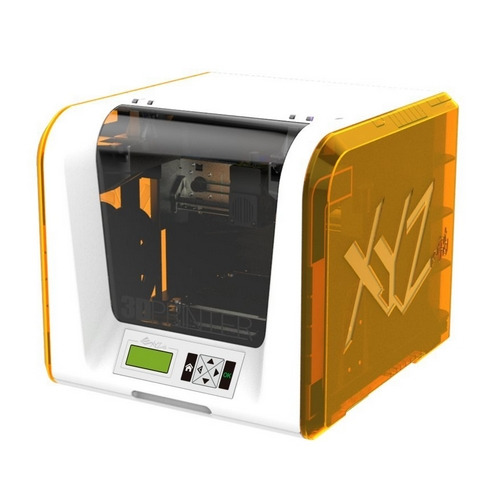

Da Vinci Junior $189.99

This 3D printer is the cheapest machine from XYZprinting, who also sell the Da Vinci miniMaker and the Da Vinci Mini. The Da Vinci Jr. has a robust build size of 5.9 x 5.9 x 5.9 inches and a resolution of 100 to 400 microns. Its design allows for the inclusion of an auto-feeding filament system, which takes the PLA filament to the extruder, and ensures that the filament is loaded properly and is ready to print. The Jr. 1.0 only prints in DEHP-free and Heavy metal-free PLA filament.

You can purchase this 3D printer here.

Key Statistics:

DIY kit: No Type: FDM Weight: 15 kg Max. build volume: 150 mm x 150 mm x150 mm Min. layer height: 100 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: No Open source: Yes Wireless: Yes

----------------------------------------------------------------------------------------------------

Da Vinci miniMaker $249.99

The Da Vinci miniMaker is a desktop 3D printer for beginners and children. Eco-friendly and easy to use, its lightweight and compact design fit easily in tight places. It has an auto-leveling bed and the auto-calibrating extruder module ensures the best possible prints. The miniMaker only prints in DEHP-free and Heavy metal-free PLA filament, ensuring that prints are safe for children and family.

You can purchase this model here.

The Da Vinci miniMaker will enable you to print very cool designs, such as toys and games downloadable here for free.

Key Statistics:

DIY kit: No Type: FDM Weight: 11.5 kg Max. build volume: 150 mm x 150 mm x150 mm Min. layer height: 100 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: No Open source: Yes Wireless: No

----------------------------------------------------------------------------------------------------

Da Vinci Mini $288.79

The Da Vinci Mini is a multifunctional 3D printer for beginners. This model is 30 percent smaller than da Vinci Jr. 1.0 and has a 5.9 inch x 5.9 inch x 5.9 inch aluminium print bed for larger and finer prints.

You can buy this model here.

Key Statistics:

DIY kit: No Type: FDM Weight: 10 kg Max. build volume: 150 mm x 150 mm x150 mm Min. layer height: 100 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: No Open source: Yes Wireless: Yes

----------------------------------------------------------------------------------------------------

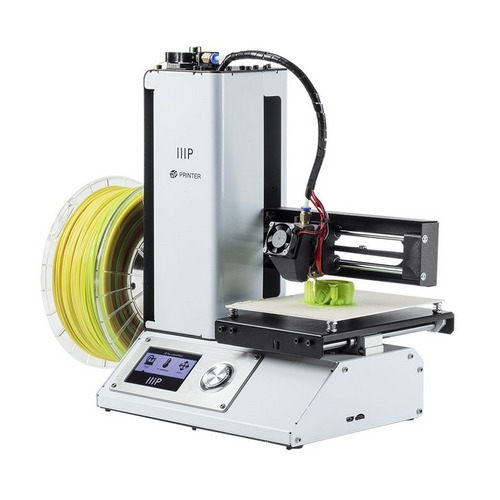

Monoprice Select Mini $199.99

The US technology company Monoprice imported the Malyan M200 from China, rebadged each unit to carry their logo and offered it for sale at the very affordable price of $199.99. Unlike most other low-cost 3D printers, this printer ships fully assembled and has already been calibrated at the factory. Sample PLA filament and a MicroSD card with preinstalled models are included so you can start printing right out of the box. Whilst there are a few defaults, the Select Mini is a good product for its price, and is a recommendable 3D printer for first-time users.

You can purchase this 3D printer here.

Key Statistics:

DIY kit: No Type: FDM Weight: 4.5 kg Max. build volume: 120 mm x 120 mm x120 mm Min. layer height: 100 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: Yes Open source: No Wireless: Yes

----------------------------------------------------------------------------------------------------

TEVO Tarantula i3 $201

The Tarantula i3 is based on the Prusa i3, a proven design with tens of thousands users all around the world. This DIY kit features automatic bed levelling (optional) and bigger bed (optional). The auto-leveling version uses a proximity sensor to detect the aluminium print bed where the normal version of the printer uses a microswitch to detect the end of travel for the Z-Axis movement (vertical limits). It is very good value for the cost and will enable you to understand how 3D printing works.

You can buy this model here.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 7.5 kg Max. build volume: 200 mm x 200 mm x 200 mm (or 200mm x 280mm x 200mm optional) Min. layer height: 50 microns Filament diameter: 1.75 mm Extruder: Dual Heated bed: Yes Open source: Yes Wireless: No

----------------------------------------------------------------------------------------------------

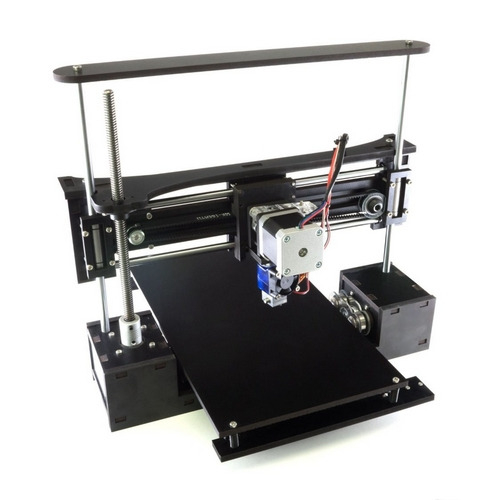

HE3D EI3 $210

This DIY 3D printer is the cheapest one from the Chinese brand HE3D. This kit has an upgraded frame using 2020 and 2040 extruded aluminium beams and 7mm reinforced acrylic supports and an upgraded ATmega2560 control board with support for up to two print heads and an intuitive LCD user interface panel. The heated 8x8x8 inch print area, 12 micron X/Y accuracy and 50-micron layer accuracy, and auto z-calibration ensure each print will achieve stunning detail and quality. The extruder’s wide temperature ranges support a variety of printer filament material including most varieties of PLA, ABS, PETG, Wood, and PVA material.

You can purchase this model here.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 8.5 kg Max. build volume: 200 mm x 200 mm x 200 mm Min. layer height: 50 microns Filament diameter: 1.75 mm Extruder: Single or dual/triple optional Heated bed: Yes Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

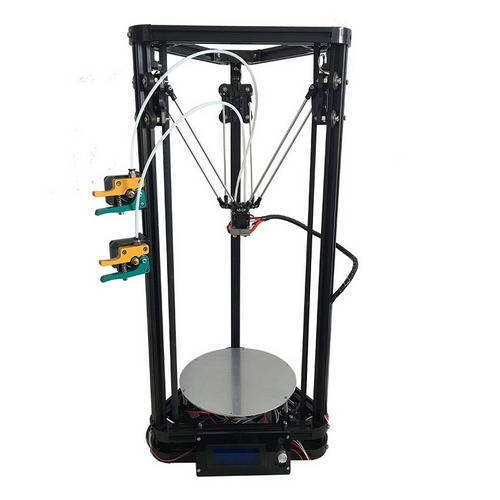

HE3D K200 $239

This DIY 3D printer, bigger than the HE3D EI3, will enable you to print objects in very good quality. The K200 breaks from the traditional limitations of Cartesian printers and offers precision and speed with a build volume over 1000 inches (11 in. diameter, 11 in. height)! The kit is built with the new enthusiast and experts in mind. With high quality 2020 aluminium extruded beams and acrylic forms the construction is simple, yet very robust. The E3D double extruder opens the possibilities to multiple print colours without having to pause, clean, and reposition. Both extruders support temperature range up to 260C to support almost all filament material including PLA, ABS, TPU, WOOD, PVA, Nylon, PVA, PP and most of their variants. The upgraded LCD interface and ATmega2560 control board with RAMPS PLUS2 and 80 step precision motors give this printer an ultra-high print quality down to 12 micron X, Y and 50-micron layer accuracy.

You can buy this 3D printer here.

Printing tall objects like these won’t be an issue anymore!

Key Statistics:

DIY kit: Yes Type: FDM Weight: 9 kg Max. build volume: 200 mm diameter x 300 mm height Min. layer height: 50 microns Filament diameter: 1.75 mm Extruder: Single or dual optional Heated bed: Optional Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

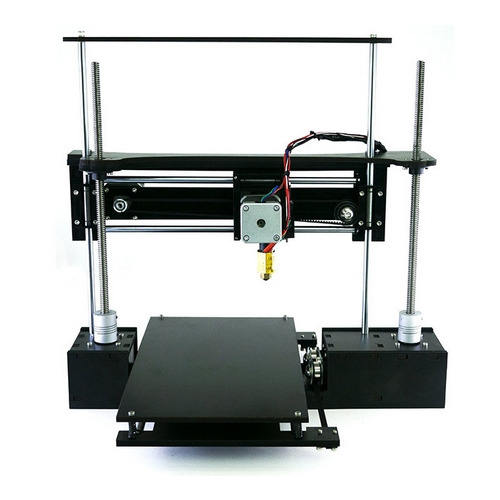

FLSUN Prusa i3 $219

This Chinese model is a good and affordable 3D printer for beginners. The metal structure is stable and provides a good printing accuracy. It has a high precision Y-axis position plate and guarantees Y-axis positioning accuracy. The printer controller is integrated motherboard, easy to connect and support DIY spread.

You can purchase this printer here.

If you feel like this will be easy to build, try printing these objects with it!

Key Statistics:

DIY kit: Yes Type: FDM Weight: 10 kg Max. build volume: 200 mm x 200 mm x 200 mm Min. layer height:100 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: Yes Open source: Yes Wireless: No

----------------------------------------------------------------------------------------------------

Heacent i3 $145

This Chinese DIY kit is an affordable 3D printer that will give you a good step-by-step learning experience. Suitable for a wide range of customers, the quality of the product is apparently very good for its price.

Purchase this 3D printer here.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 6.6 kg Max. build volume: 200 mm x 200 mm x 180 mm Min. layer height: 100 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: Yes Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

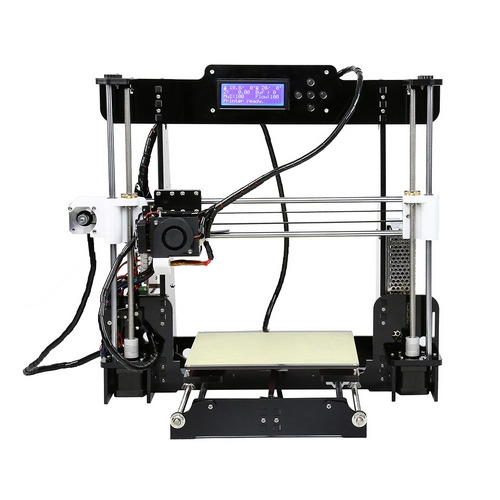

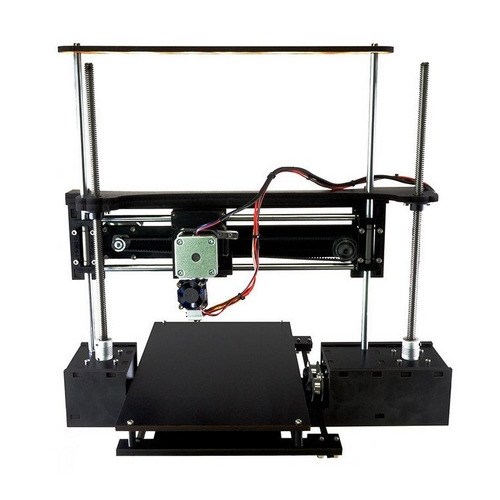

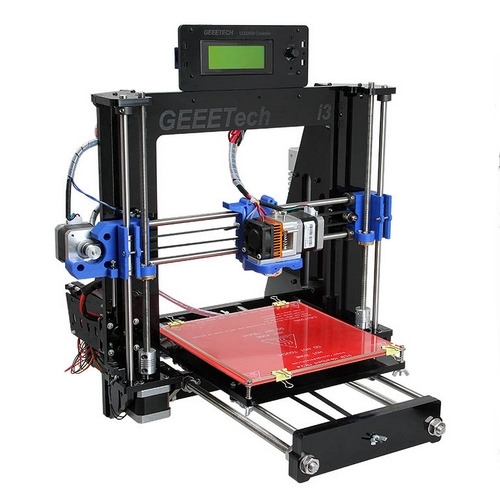

Geeetech Prusa I3 pro B $248.54

The Prusa I3 pro B is the cheapest 3D printer from Geeetech. It is based on Geeetech I3 pro, except its simple assembly, easy debugging and more stable performance, compared with the I3 pro, I3 pro B features a newly added potential for 3D printing—support 5 types of filament: ABS, PLA, Wood-Polymer, Nylon and flexible PLA., create flexible hinges, joints, shaped parts; enable you to get the most out of your 3D Printer.

You can buy this model here.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 8.5 kg Max. build volume: 200 mm x 200 mm x 180 mm Min. layer height: 100 microns Filament diameter: 1.75 mm, 3.0 mm Extruder: Single Heated bed: Yes Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

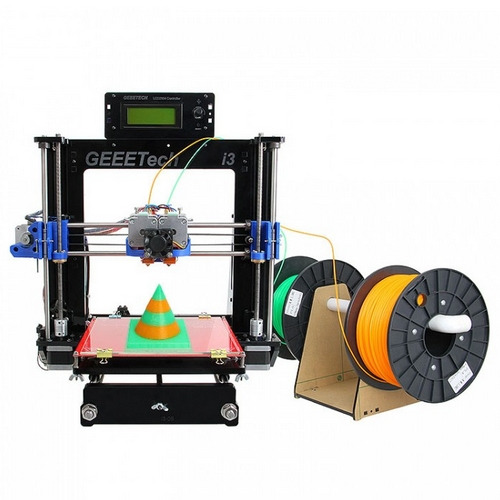

Geeetech Prusa I3 pro C $299

A little bit more expensive, the Prusa I3 pro C has the same specs than the pro B except that it has 2 extruders. You can print a single two-color object, or you can print two objects in one print job, each made from a different colour. You can also print one single-color object, as with other single-extruder 3D printers. Or you can use one extruder for infill or support. The 2 extruder motors push filament through 2 head separately, so mixing colours printing is not applicable for the moment. Geeetech I3 pro C support 5 types of filament: ABS, PLA, Wood-Polymer, Nylon and flexible PLA.

Buy this 3D printer here.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 9 kg Max. build volume: 200 mm x 200 mm x 180 mm Min. layer height: 100 microns Filament diameter: 1.75 mm, 3.0 mm Extruder: Dual Heated bed: Yes Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

Cetus 3D $299

After a successful Kickstarter campaign, Cetus 3D launched a very basic and solid printer. Quiet, small and cheap, this model can be recommended for every beginner. At 0.25, the build volume to machine volume ratio is excellent, and the light weight will enable you to take it with you everywhere. The Cetus 3D printer features cloud-based support for remote printing and notifications as well as dedicated 3D printing software.

You can purchase the Cetus 3D here.

Key Statistics:

DIY kit: No Type: FDM Weight: 3.2 kg Max. build volume: 180 mm x 180 mm x 180 mm Min. layer height: 50 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: No Open source: Yes Wireless: Yes

----------------------------------------------------------------------------------------------------

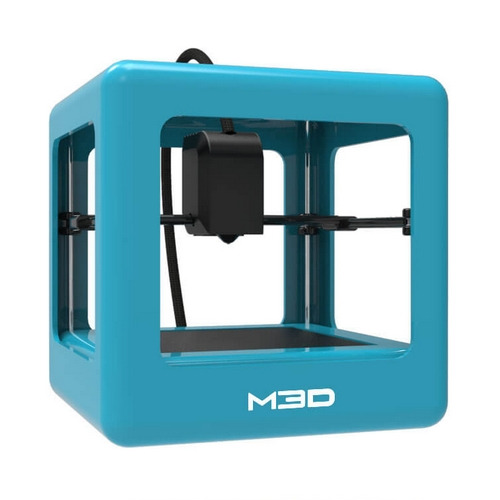

M3D Micro $299

Rated best 3D printer in class by 3D Forged & Tom's Guide, this model is the cheapest 3D printer from M3D. The Micro is the world’s first truly consumer 3D printer and is powered by "Micro Motion Technology," a series of next generation innovations, creating precision at a fraction of the cost of other 3D Printers. Sporting a compact design, cool colour choices, user-friendly software, and replaceable print beds and nozzles, it’s a great 3D printer for beginners and experts alike. The Micro comes with M3D Software for Windows operating systems. The software has an easy-to-use interface and is fully touch screen capable. The M3D Software allows you to organise the 3D models you've downloaded into an easy to view library.

You can buy this 3D printer here.

Key Statistics:

DIY kit: No Type: FDM Weight: 1 kg Max. build volume: Base:109 mm x 113 mm x 74 mm, and above the 74 mm: 91 mm x 84 mm x 42 mm Min. layer height: 50 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: No Open source: Yes Wireless: No

----------------------------------------------------------------------------------------------------

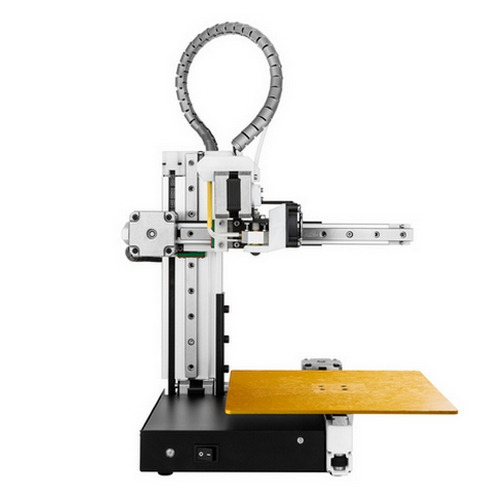

Snapmaker $299

A Kickstarter campaign has been launched to raise funds for this affordable all-metal and all-in-one 3d printer. It is easy-to-use for beginners, expandable for makers, and will enable you to do 3D printing, laser engraving and CNC carving. Designed for quick assembly, strong expandability and real affordability. Snapmaker has an innovative modular design, which enables a flat-packed and low-cost shipping, quick assembly and personalised modification. With the intuitive-to-use 3.2-inch colour touchscreen, you can conveniently control all print settings.

You can pre-order the Snapmaker here.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 4.5 kg Max. build volume: 125 mm x 125 mm x 125 mm Min. layer height: 50 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: Yes Open source: Yes Wireless: No

----------------------------------------------------------------------------------------------------

Bonus: other notable entry level 3D printers

----------------------------------------------------------------------------------------------------

Dagoma DiscoEasy200 $317

The french brand Dagoma improved its model Discovery, who became DiscoEasy. This model is based on an open source design, which makes it easy to modify. Its 3D files are accessible for free online. The Dagoma DiscoEasy200 does not provide natively a printing bed but can get one as an option. Compared to its predecessor, the DiscoEasy200 offers a new electronic card, an additional fan on the extruder and a SD card port instead of a mini SD. This 3D printer is intuitive and recommendable to the beginners.

You can purchase this model here.

And here are some cool objects designed by Dagoma that you can print with the DiscoEasy200!

Key Statistics:

DIY kit: No Type: FDM Weight: 5 kg Max. build volume: 200 mm x 200 mm x 200 mm Min. layer height: 100 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: No Open source: Yes Wireless: No

----------------------------------------------------------------------------------------------------

Kodama Trinus $379

Kodama launched a Kickstarter campaign to market the new affordable 2-in-1 Trinus 3D printer. Trinus is a professional-grade desktop 3D printer that can easily be converted into a laser engraver. The kit contains only 11 parts and can be assembled easily. You can also equip the Trinus with a heated bed and a safety enclosure. This all-metal 3D printer extrudes PLA, ABS, PC, Flex, wood and most other materials available on the market. This model is very quiet and print objects in good quality.

You can pre-order the Trinus here.

Key Statistics:

DIY kit: Yes Type: FDM Weight: 9.8 kg Max. build volume: 120 mm x 125 mm x 125 mm Min. layer height:50 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: Optional Open source: No Wireless: No

----------------------------------------------------------------------------------------------------

Honorable Mentions:

New Matter MOD-t $399

New Matter launched the MOD-t after realising an Ingiegogo campaign. This model is easy to use and has a good printing quality. The MOD-t’s beautiful clear cover and patented design makes it one of the quietest desktop 3D printers available, so it can easily live in a classroom or living room without causing disruption. The MOD-t is dependable with WiFi connectivity, a simple set-up process, and intuitive controls. If any questions arise, the New Matter Customer Support team is available for users through email, phone, and chat.The Wall Street Journal recommends the MOD-t for anybody’s “first foray into 3-D.”

You can purchase this 3D printer here.

Key Statistics:

DIY kit: No Type: FDM Weight: 5 kg Max. build volume: 150 mm x 100 mm x 125 mm Min. layer height:100 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: No Open source: Yes Wireless: No

----------------------------------------------------------------------------------------------------

Robo 3D C2 $699.99

The Robo 3D C2 is a small desktop 3D printer launched after a Kickstarter campaign. This model is more expensive but can print with great quality and efficiency. The Robo 3D C2 is a small desktop 3D printer. It has a nice and simple design, with an easy to access build platform. It is compatible with the Robo app and also adds a Wifi connectivity for a smooth user experience. The Robo 3D C2 print bed is not heated so it is not capable of 3D printing ABS.

You can buy this model here.

Key Statistics:

DIY kit: No Type: FDM Weight: 9.4 kg Max. build volume: 127 mm x 127 mm x 152.4 mm Min. layer height: 20 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: No Open source: Yes Wireless: Yes

----------------------------------------------------------------------------------------------------

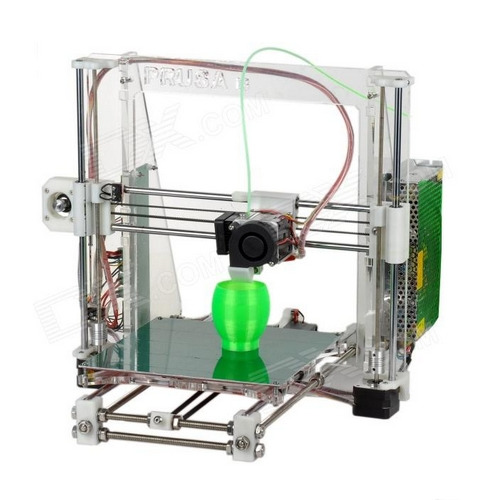

Prusa i3 MK2 kit $786

The very popular Prusa i3 from Josef Prusa is considered as the 3D printer with the best quality for its cost. It comes with a bunch of clever features and is upgradable. With tens of thousands users all around the planet, this popular model has a made a big impression on the 3D printing community since it was launched. All parts of this 3D printer are Open Source and are part of the RepRap project.

You can buy this 3D printer here,

Check out the Prusa MyMiniFactory profile here if you need spare parts!

Key Statistics:

DIY kit: Yes Type: FDM Weight: 6.5 kg Max. build volume: 250 mm x 210 mm x 200 mm Min. layer height: 50 microns Filament diameter: 1.75 mm Extruder: Single Heated bed: Yes Open source: Yes Wireless: No

1 note

·

View note

Photo

I’m like 99% sure that everyone freaking out about these is unaware that (a) even the best plastic 3D printed guns have severe durability issues since it still can’t compare to molded impact polymer or actual metal,(b) a CNC lathe can produce a firearm just as easily and with far better quality, to the point that there’s an entire cottage industry of people who have a CNC machine making upgrade parts for Glocks and AR-15s, and (c) a length of pipe and a nail can be used to make a simple firearm for waaaaay less cost and effort.

The cheapest 3D printers I’ve seen are around $200-300, not counting cost of raw materials and the metal parts that any firearm will require to be good for more than one shot (which for anything other than a single shot Liberator-style deal is going to be most of the gun, easily $300-600 depending on what you’re making) Given that you can snag a HiPoint for $200 or even a Jennings for $120, it’s not exactly cost effective, and I doubt you’re going to have criminals preferring 3D printed guns over just plain stolen or straw purchased guns anytime in this decade.

Call Pompeo

293 notes

·

View notes

Text

Creality LD-002R: Best Resin Printer Yet?

Our verdict of the Creality LD-002R: Reliable and high-quality prints, every time, in an affordable and simple to use package. Resin printers really don't get any better at this price point. 1010

The hobby market has been waiting decades for affordable high-quality 3D printers, and just like a bus, seven come along at once. The catchily named LD-002R is the latest from 3D printing experts, Creality. At under $300, it’s one of the cheapest resin printers we’ve seen yet, but it doesn’t compromise on build or print quality. In a word, it’s amazing.

LD-002R Specifications

Featuring an all-metal design with removable translucent orange UV filter cover made of thick acrylic, the LD-002R measures 8.7 x 8.7 x 16.9 inches (221 x 221 x 430mm) and weighs 15.4 pounds (7kg). The total print volume is 4.69 inches (119mm) wide x 2.56 inches (65mm) deep x 6.3 inches (160mm) height. It’s capable of printing at a layer height of 10 to 50 microns, with a 2560x1440px resolution screen, and prints at about 20-30mm per hour. Ball linear rails ensure a smooth Z-axis for stunning prints every time.

For those who work with more pungent resins, the device also features a charcoal air filter system, which should reduce the smell. Many of the more commonly used resins don’t have a noxious odor, it should be noted.

Two screws secure the resin tank on top of the UV screen. They’re easy to remove when you need to empty and clean the vat.

Also in the package, you’ll find a nice little bag of extras, including

A small metal spatula

Plastic spatula

Some resin filters

A paintbrush (I have no idea what that’s for)

2 pairs of latex gloves

USB drive

Spare FEP film

This isn’t a complete starter pack though. At the very least you’ll also need some plastic boxes to wash things in and some isopropyl alcohol. And of course, you’ll need some resin, which typically costs around $40 per liter.