#changxing refractory

Text

How to Install refractory lining

Refractory lining play an important role in steelmaking. Learn how to use refractory lining and find out additional information about Refractory lining. This article describes in detail how to install Refractory lining and informs about other related knowledge about Refractory lining, read this article to have a detailed understanding of Refractory lining.

Installing the Refractory Lining. After consulting with the refractory technician, industrial refractory installation is conducted.

Curing the Refractory Lining.

Refractory Installation Temperature Control.

Water Removal of Refractory Installation.

Drying Out Process.

A refractory lining usually comprises a safety or backup layer behind the working lining in contact with the furnace contents. The whole body is encased in a metal shell. The temperature gradients in the system and the properties of all materials must be considered.

Process of Refractory Lining Installation

1. INSTALLING THE REFRACTORY LINING

After consulting with the refractory factory, industrial refractory installation is conducted.

This process is the mixing of a certain amount of water with a fixed amount of refractory castable.

If not, the incorrect amount of water can spoil the refractory lining. Among these are lower strength, longer time to set, and more water to remove during the dry out process.

Hence, the technician must use the right amount and type of water. Refer to the refractory material datasheet for the utmost accuracy.

2. CURING THE REFRACTORY LINING

The castable refractory curing procedure is the process where the water reacts with the refractory cement. It is completed when the refractory material has hardened to its final form.

However, it is an intricate process. This is because the temperature of surroundings and castable can impact curing success.

Thus, curing needs a precise temperature range for it to work. Lower temperatures can weaken the curing. This will lead to lower permeability and longer curing time.

Comparably, higher temperatures will set the refractory product too quickly. Hence, it will affect the densification, making the refractory lining unfit for application.

3. REFRACTORY INSTALLATION TEMPERATURE CONTROL

Temperature is a major part when installing refractory. So store all refractory materials and equipment under a controlled setting.

If they are cold, you will lose precious time waiting for them to reach the desired temperature. Thus, refractory contractors put heaters surrounding the curing process depending on the ambiance.

Additionally, uncontrolled storage and mixing temperatures will disrupt further steps to refractory installation methods. Hence, causing severe spalling to the refractory lining

4. WATER REMOVAL OF REFRACTORY INSTALLATION

After installing and setting the refractory monolithic, the next step is water removal. To do this, apply heat to remove both physical water and chemical water.

Then, the water will evaporate at certain temperatures. However, the steam will cause volume expansion which can increase the internal pressure.

By applying the correct methods, the refractory lining is stronger with no risk of spalls.

5. DRYING OUT PROCESS

Lastly, conduct the drying out process for the refractory castable lining.

The dry-out process requires expertise from the right refractory engineering factory. If done improperly, the refractory lining will crack and weaken quickly. Also, the steam explosion might happen, risking the workers and the refractory project.

Therefore, discuss with your refractory technician for a dry-out plan of your plant.

Changxing Refractory Material

Types of Refractory Lining Materials

Refractories can be classified based on various different parameters in multiple ways as listed below:

Based on Chemical composition:

Acidic refractories (Silica refractories, Zirconia refractories, Aluminosilicate refractories);

Basic refractories (Magnesite refractories, Dolomite refractories, Magnesia-chrome refractories);

Neutral refractories (Carbon graphite refractories, Alumina refractories, Chromite refractories)

Method of manufacture: Dry press process, Hand molded, Fused cast, Formed, Unformed.

Fusion temperature: Normal refractories, High refractories, Super refractories.

Refractoriness: Super duty, High duty, Intermediate duty, Low duty.

Thermal conductivity:

Heat-resistant (temperatures≤ 1100 °C),

Refractory (temperatures≤ 1400 °C),

High refractory (temperatures≤ 1700 °C),

Ultra-high refractory (temperatures ≤ 2000 °C).

Purpose of Refractory Lining

Refractory lining is widely used in very high-temperature services.

Serve as a thermal barrier between the pipe/equipment wall and hot medium.

Withstand physical stresses.

Protect against corrosion and erosion.

Provide thermal insulation

Refractory Lining Materials

The common materials that are used as refractory lining materials are:

Alumina or Aluminum oxide (High Alumina bricks)

Silicon oxide

Magnesium oxide

Calcium oxide

Fire clays (Clay bricks)

Zirconia

Silicon carbide

Tungsten carbide

Boron nitride

Hafnium carbide

Molybdenum disilicide

Tantalum hafnium carbide

Corundum bricks

Plastic refractory

Refractory lining material consists of refractory aggregate, admixture, powder, binder, water, or other liquid, made of amorphous refractory products or fixed refractory products.

Induction Furnace Refractory Products

The refractory tamping process for induction furnaces is a critical step that must be performed carefully to ensure the longevity and efficiency of the furnace. Here is a step-by-step guide for tamping induction furnace refractory wall material:

Filling the floor with refractory: First step is to fill refractory carefully on the furnace floor and then leveling it. Pay attention to grounding cables.

Using bottom (floor) ramming machine: Place bottom rammer into the furnace and then start vibration with the desired duration depending on furnace size. Check leveling then remove machine after bottom refractory is tight enough.

Placing the former for wall ramming: Place the steel former into the middle of furnace. Use some tools to fix it into the position and make sure it won't move while the vibration.

Filling the refractory material into the wall: Fill refractory material space between former and furnace wall. De-air with fork tool into the layers while filling completely.

Ramming the wall refractory material: Wall rammer are placed into the former, and a level close to the bottom floor. Vibration starts and wall ramming machine starts rotating while making hits into the steel former. These hits create vibration and impact in granular refractory lining material. Wall ramming machine raised up step by step until to the surface while working and hitting.

Curing: Once the refractory material has been rammed, it must be allowed to cure. The curing time can vary depending on the specific refractory material used and furnace size.

By following these steps carefully, it is possible to create a durable and long-lasting refractory lining for an induction furnace. It is important to use high-quality refractory materials and equipment to ensure optimal results.

Article Source: How to Install refractory lining

Company name: Henan Changxing Refractory Materials Co.,Ltd

More refractory products:https://www.cxrefractories.com/en-all-refractory-products

Email:[email protected]

Website:https://www.cxrefractories.com

0 notes

Link

Refractory Material, Fire Bricks, Refractory Manufacturer, China Refractory

0 notes

Text

ムライトレンガの市場規模、シェア、開発、成長、2025年までの需要予測

Mullite Brick Marketは、業界の専門家を念頭に置いて分析され、情報に基づいたビジネス上の意思決定に必要な明確な情報を提供することで、投資収益率を最大化します。この調査は、確立された参入者と新規参入者の両方が市場のニーズ、市場規模、および競争を特定および分析するのに役立ちます。需要と供給の状況、競争のシナリオ、市場成長の課題、市場機会、主要なプレーヤーが直面する脅威について説明します。

このレポートのサンプルコピー:&nbsp ; https://axelreports.com/request-sample/77258 "

グローバルマライトブリックマーケットの競争シナリオの360度の概要は、アクセルレポートマーケットインサイトによって提示されます。これには、市場における最近の製品および技術開発に関連する膨大なデータがあります。

幅広い-これらの進歩が市場の将来の成長に与える影響の幅広い分析、これらの拡張が市場の将来の成長に与える影響の幅広い分析。調査レポートは、市場の主要な側面を説明することにより、市場を詳細に調査します。予測期間中の外挿の展開に数えられる刺激があると予測できます。

R このレポートを購入する理由:

変化する競争シナリオの分析を提供します。

ビジネスで情報に基づいた意思決定を行うために、戦略的計画手法を使用した分析データ。

Global MulliteBrickの7年間の評価を提供します

主要な主要製品セグメントの理解に役立ちます。

研究者はドライバー、拘束、傾向、機会などの市場のダイナミクスに光を当てます。

複数の利害関係者のビジネスプロファイルとともに、グローバルマライトブリックマーケットの地域分析を提供します。

Itグローバルマライトブリックの進捗に影響を与えるトレンド要因に関する膨大なデータを提供しますプレミアムレポートの概要については、ToCを入手してください@  https://axelreports.com/industry-analysis/global-mullite-brick-market/77258 市場プレーヤー別:

LONTTO GROUP

Zhengzhou Rongsheng Refractory Material

Zhengzhou Sunrise Refractory

KT Refractories

Changxing Refractory

タイプ別

焼結Mulliteブリック

溶融Mulliteブリック

用途別

ブラスト炉ホットブラストストーブ

セラミック焼結炉

石油分解システムライニング

硫黄分解炉

繊維ガラス炉A世界のMulliteBrick Marketの詳細な概要には、さまざまな業種の包括的な分析が含まれています。北米、ラテンアメリカ、アジア太平洋、アフリカ、およびヨーロッパは、いくつかの用語に基づいて調査の対象として検討されています。これにより、予測期間中に世界のムライトレンガ市場が牽引されると予想されます。この調査レポートは、市場の展望と近い将来の進捗状況をカバーしています。主要企業を調査した後、レポートは市場の成長に貢献している新規参入者に焦点を当てています。グローバルムライトブリック市場のほとんどの企業は現在、市場で新しい技術トレンドを採用しています。最後に、研究者は、成長に影響を与える長所、短所、機会、脅威を発見するためのさまざまな方法に光を当てます。世界のムライトレンガ市場。新しいレポートの実現可能性は、この調査レポートでも測定されます。このレポートの購入については、お問い合わせください:  https://axelreports.com/enquiry-before-buying/77258  目次:世界のMulliteBrick市場の概要

業界への経済的影響

メーカーによる市場競争

生産、地域別の収益(値)

生産、収益(値)、タイプ別の価格動向

アプリケーション別の市場分析

コスト分析

産業チェーン、ソーシング戦略、および下流のバイヤー

マーケティング戦略分析、ディストリビューター/トレーダー

市場効果要因分析

グローバルマライトブリック市場予測米国について:Axel Reportsには、Web上で利用可能な市場調査製品およびサービスの最も包括的なコレクションがあります。ほぼすべての主要な出版物からレポートを配信し、定期的にリストを更新して、世界の市場、企業、商品、パターンに関する専門的な洞察の世界で最も広範で最新のアーカイブにすぐにオンラインでアクセスできるようにします。連絡先:

アクセルレポート

Akansha G(ナレッジパートナー)

Office No- B 201

Pune、Maharashtra 411060

電話:US +18488639402

メール: [email protected]/

ウェブ: https:// axelreports.com/

0 notes

Text

Global Mullite Refractory Market 2019 : Worldwide Overview by Industry Size and Share, Future Trends, Growth Factors and Leading Players

Global Mullite Refractory Market 2019 by Manufacturers, Regions, Type and Application, Forecast to 2024 by MRInsights.biz covers market data concerning market, size, commercialization aspects and revenue forecast of the industry for 2019 to 2024. The report comprises various segments, end uses, regions and players on the basis of demand pattern, and future prospects associated with the Mullite Refractory market. The report presents a compressive business outlook of the market along with a summary of some of the leading market players. Key insights related to the regional spectrum and the companies that have effectively gained a commendable status in the market are highlighted in the report. The report profiles companies including LONTTO GROUP, KT Refractories, Zhengzhou Rongsheng Refractory Material, Zhengzhou Sunrise Refractory, NGK Insulators, Changxing Refractory, .

Further, the report covers the limitations and strong points of the well-known players combined with SWOT analysis. The research study then includes the major product & applications categories & segments. The market has been analyzed based on the product type, customer, application and regional segments. The competitive landscape of major companies in the market defines an important characteristic of the global Mullite Refractory market. The leading players in the market are challenging each other on the basis of the price difference and product innovation in order to mark a strong footprint in the global market. According to this report, these players will focus more on research and development to fortify their standing across the world.

DOWNLOAD FREE SAMPLE REPORT: https://www.mrinsights.biz/report-detail/221344/request-sample

Market segment by product types considering production, revenue (value), price trends: High Purity Fused Mullite, Ordinary Fused Mullite, All Natural Bauxite Concentrate Sintered Mullite, Lightly Burned Mullite

Market segment by applications considering consumption growth rate and market share: Commercial, Industrial, Others

The main regions that contribute to the Mullite Refractory market are: North America (United States, Canada and Mexico), Europe (Germany, France, UK, Russia and Italy), Asia-Pacific (China, Japan, Korea, India and Southeast Asia), South America (Brazil, Argentina, Colombia etc.), Middle East and Africa (Saudi Arabia, UAE, Egypt, Nigeria and South Africa).

After Reading The Market Report, Readers Can:

Get guidelines about various agreements, product launches, acquisitions, and R&D projects of different market players.

Outline major regions holding a significant share in the global Mullite Refractory market along with the key countries.

Explore a comparative study between leading and emerging market vendors.

An in-depth evaluation of the changing pattern of consumers across various regions.

Important trends affecting the adoption pattern in various industries.

Moreover, the report encompasses historic volume and value, current & future trends, new technological development, upstream and downstream industry chain, cost structure, company overview, strategy analysis, financial data, products and services, key developments, industry competition structure analysis, SWOT Analysis.

ACCESS FULL REPORT: https://www.mrinsights.biz/report/global-mullite-refractory-market-2019-by-manufacturers-regions-221344.html

Strategic Insights:

Partnership/acquisition, and product launch & approvals were explored as the most adopted strategy in global Mullite Refractory industry. Few of the acquisitions, partnerships, product launches and approval made by the players in the market are listed further in the report.

Customization of the Report:

This report can be customized to meet the client’s requirements. Please connect with our sales team ([email protected]), who will ensure that you get a report that suits your needs. You can also get in touch with our executives on +1-201-465-4211 to share your research requirements.

0 notes

Text

Aerated concrete as building materials and refractory binding sites

With the widespread rise of constant change and new wall materials wall materials, a super firebrick refractory temperatures up to 700 ℃ material new brick in the people's vision.

It is reported that scientific name of aerated concrete, which is equivalent to the density of solid clay bricks hollow clay brick 1 / 3,1 / 5, since the bricks of its internal model contains a lot of small independent closed porosity, the insulation capability clay 3-4 times 4-8 times that of ordinary concrete; because of its low thermal conductivity, heat transfer is slow, it can effectively resist temperatures up to 700 ℃, the level of refractory material has improved so much.

Its noise effects, and easy to handle, resistant to water penetration, economic, and environmental protection. This is a general evaluation of its people. Compared with traditional clay brick, the new refractory material can save land resources, improve the exterior insulation effect of the building, improve building energy efficiency. The main structure suitable for use in concrete exterior walls, interior partitions, senior bricks can also be applied to the seismic ring beam construction multicolored building facades or composite wall insulation can also be used for building insulation and roof insulation.

It is reported that in the country to promote the construction of a conservation-oriented society, vigorously develop energy-efficient buildings in support of the new agreement, the import bricks aerated concrete compound fertilizer in recent years has developed rapidly. According to reports, the government intends to expand the supply of bricks aerated blocks new material markets, present a variety of manufacturers are orderly conduct.

Article source:

http://www.ruizhirefractory.com/en/new/aerated-concrete-as-building-materials-and-refractory-binding-sites.html

0 notes

Link

As the Chinese New Year has passed, the 9 days holiday of Changxing Refractory is also over. If you have contacted us during this holiday, hope you were satisfied with our reply.

From February 15 Changxing Refractory is officially back and continues to solve all kinds of refractory technique questions for you. So if you have any technical problems, please do not hesitate to tell us. We are ready, and you?

1 note

·

View note

Text

How to choose right refractory castable for your needs

1.Refractory castable based on Application

Generally, the refractory material is engineered to perfection. But, it might not suit your refractory lining. Focus on the type of application of your refractory insulation. Choose suitable refractory products.

2. Choose Common Refractory Materials

Basically, everyone wants fast and cheap options, no matter the industry.

However, choosing cheap refractories ceramics will cost more in the future. So, consider buying the tried and tested refractory material regardless of price.Because refractory contractors know they are best for boiler refractory and furnaces.

3. Research Refractory Lining Trends

Although there is new refractory insulation technology, discuss with your refractory contractor first.This is because trends may seem too good to be true. Avoid asking for new types of furnace bricks for your refractory contractor to use.The engineering contractor will suggest a material that suits your refractory insulation.

4. Choose the Right Refractory Contractor

Basically, everyone thinks they are the best. But, in the end, the most experienced engineer will make the correct decision. Therefore, choose a refractoryfactory that fits your criteria. Then, they will provide refractory products and services that suit your refractory lining.

Different Refractory Castable

Things To Remember When Using Castable

Castables must always be stored in a cool and dry area.

One must ensure that the mixers and tools are free from old castable or any other material that can contaminate the product. Such contamination could affect the strength of the castable mix.

Only drinking suitable water should be used to mix castable. The temperature of the mix should be optimal as well.

Be careful while mixing castable, like castable refractory cement. Too much mixing generates heat and speeds up the setting time.

The forms should be covered with oil or grease to prevent moisture loss.

After placing the mix, the castable needs to be cured for 18 to 24 hours straight. Cover it with polyethylene sheets and spray it with cold water periodically. It will maintain the moisture of the mix and promote uniform curing at the applied area.

Silica Ramming Mass

Advantages Of Castable Refractories

Saves Time

Ease in usage

Significantly Better Structure Performance

Choosing refractory castable for the insulation process is one of the most thoughtful decisions. Their advantages and wide application seal the deal. But what is even more important is finding a reliable refractory material supplier. Welcome to contact us anytime.

Article Source: How to choose right refractory castable for your needs

Company name: Henan Changxing Refractory Materials Co.,Ltd

More refractory products:https://www.cxrefractories.com/en-all-refractory-products

Email:[email protected]

Website:https://www.cxrefractories.com

0 notes

Text

How to make magnesia brick

Magnesia Brick Manufacturing Process:

The manufacturing process of magnesia brick includes the following steps:

1. Break and smash:

Crushing is the process of processing large pieces of material into ideal particle size materials.

2. Ingredients (weighing):

The raw materials are prepared in a predetermined proportion and mixed in a strong sand mixer. The order of feeding is magnesia aggregate – carbon fiber – binder – carbon raw material.

3. Mixing:

Mix thoroughly to get perfect coating. Add mixture made in step (B) and remix the batch intensively. Now add powder Resin (item 9), then Hexamine (item 10) and mix once again.

4. Molding:

Use a molding machine to make the mixture into bricks.

5. Drying:

Use a drying oven to dry the bricks for several hours.

6. Firing:

Fire the bricks in a kiln at temperatures of 1550 to 1600 degrees Celsius.

7.Finishing:

The final step is to grind and polish the bricks to get the desired shape and size.

Types of magnesia brick:

Magnesia bricks can be divided into two categories: sintered magnesia bricks (also known as fired magnesia bricks) and chemically combined magnesia bricks (also known as unburned magnesia bricks). Magnesia bricks with high purity and firing temperature are called direct-bonded magnesia bricks due to the direct contact of periclase grains; Bricks made of fused magnesia as raw materials are called fused re-bonded magnesia bricks.

Uses of Magnesia Bricks:

Magnesia bricks are used in steelmaking furnaces, electric furnace bottom and wall, and high temperature tunnel kiln. Magnesia bricks are also used as heat storage room lattice bricks in glass kilns.

Magnesia brick is used for permanent layers in steel making converters, AOD furnaces, and more. Magnesia brick is also used to line steel ladles and Basic Oxygen Furnaces (BOFs). Magnesia bricks can be used in a variety of applications, depending on the type of brick being used. Common uses include furnaces, ladles, secondary refining vessels, and cement and glass making kilns.

Magnesia Brick for sale

The most important steps need to be considered to avoid or reduce the possibility of magnesia bricks hydration are:

1). Magnesia bricks must be transported in a container to protect the material against moisture.

2). Magnesia bricks should be stored inside storage rooms where it is dry, free of frost, ventilated, and with a temperature between 10°C and 30°C. Note that magnesia bricks storage underneath a tarpaulin cover outside is not sufficient.

3). Bricks may not be stored for more than four weeks prior to installation and preheating.

4). Lining should be protected against moisture during installation and preheating.

Article Source:How to make magnesia brick

Company name: Henan Changxing Refractory Materials Co.,Ltd

More refractory products:https://www.cxrefractories.com/en-all-refractory-products

Email:[email protected]

Website:https://www.cxrefractories.com

0 notes

Text

What are the measures to improve the purity of continuous casting steel

Purity refers to the quantity, shape and distribution of non-metallic inclusions in steel. The inclusion in steel shall be reduced to the required level according to the steel grade and product quality,

We should start from the following five aspects:

① Reduce [O] content in steel as much as possible.

② Prevent the molten steel from interacting with air.

③ Reduce the interaction between molten steel and refractory materials.

④ Reduce slag entrainment in molten steel.

⑤ The improved flow promotes the floating of inclusions in molten steel.

In terms of process operation, the following measures shall be taken:

(1) Slag free tapping: slag retaining balls are adopted for the converter and eccentric bottom tapping is adopted for the electric furnace to prevent a large amount of slag from falling into the ladle.

(2) Ladle refining: select the appropriate refining method according to the steel grade, to uniform the temperature, fine tune the composition, reduce the oxygen content, remove gas inclusions, etc.

(3) Non oxidation casting: after the molten steel is treated by ladle, the total oxygen content in the steel can be reduced from 130ppm to below 20ppm. If the injection flow from ladle to tundish is not protected or poorly protected, the total oxygen content in tundish steel will rise to the range of 60-100ppm, which will return to the level before external refining, and the effect of external refining will be wasted.

(4) Tundish metallurgy: the tundish adopts large capacity, and the addition of retaining walls and dams is an effective measure to promote the floating of inclusions. For example, for 6T tundish, the scrap rate of slab inclusion is 12%, and the inclusion is 0.82 pieces / m2; 12t tundish + retaining wall, 0 scrap inclusion in slab, 0.04 inclusions / m2.

(5) Submerged nozzle + casting mold powder: the mold powder shall be able to fully absorb inclusions. The submerged entry nozzle material, nozzle shape and insertion depth shall be favorable for the floating and separation of inclusions.

We Changxing Refractory Material Co.,LTD is professional manufacturer and supplier of refractory materials for more than 30 years. Our high quality casting powder are good sold to many countries say South Africa, Bangladesh, Indonesia, Malaysia, etc.

Article Source: improve the purity of continuous casting steel

Company name: Henan Changxing Refractory Materials Co.,Ltd

More refractory products:https://www.cxrefractories.com/en-product-solution

Email:[email protected]

Website:https://www.cxrefractories.com

0 notes

Text

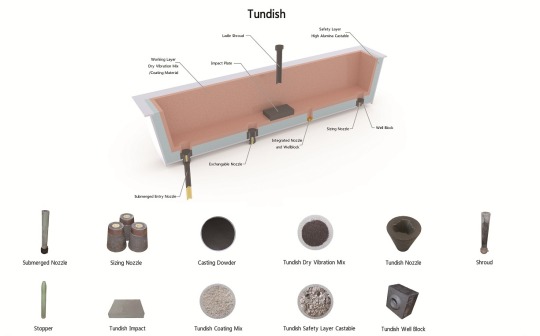

What are the prominent problems in the tundish

At present, there are many problems in the tundish used in China, especially in the tundish used for billet caster.

The specific performance is as follows:

(1) The shape of tundish cavity is unreasonable. Due to the unreasonable shape of the inner cavity, the flow of molten steel in the tundish is unreasonable and the residence time is short, which can not purify the molten steel. The distance from the drop point of the large ladle injection into the tundish to the tundish nozzle is short, or the distance from each nozzle is too different; The volume at the drop point of the ladle is too small, resulting in serious steel slag mixing and lining scouring, affecting the service life of the tundish and polluting the molten steel.

(2) The capacity of tundish is small and the depth of molten pool is shallow, so it is not suitable for high-speed caster. The molten steel stays in the tundish for a short time, which makes it difficult to purify the molten steel and remove inclusions; It is difficult to maintain constant casting speed when changing the package; During pouring, the steel slag in the tundish is agitated seriously, which makes it difficult to float the inclusions and easy to enter the mold, especially when changing the tundish.

(3) The position of tundish nozzle clogging is not properly designed, especially the nozzle on both sides is too close to the two sides, which is easy to cause unsmooth pouring of the two side nozzles.

(4) The tundish nozzle control device is too thin and unreliable, which makes it difficult to accurately control the flow of molten steel, making it difficult to stabilize the liquid level of the mold and often causing out of control accidents.

(5) The large deformation of tundish and the problems of design and manufacturing accuracy result in insufficient centering accuracy of multiple water outlets.

(6) The lifting device of tundish is ineffective, and most of them can not be lifted, which brings difficulties to the continuous casting process and causes many defects of the slab.

(7) The distance from the bottom of tundish to the upper mouth of crystallizer is improperly selected. Most of the distance is too high, which makes it difficult to align the nozzle, and also makes the nozzle too long, which increases the refractory consumption per ton of steel nozzle.

(8) Insufficient attention has been paid to the quick change technology of submerged entry nozzle.

The above tundish can only be used at low casting speed, which is not suitable for the requirements of high casting speed. Modern tundish should not only adapt to the conditions of constant speed casting at high drawing speed, high steel throughput and strength, and intense agitation in the tundish, but also play the role of purifying molten steel and removing inclusions.

The specific measures adopted include:

(1) Optimize the shape of the inner cavity of the tundish, make the liquid steel flow reasonably in the tundish, expand the volume of the large ladle at the drop point of the tundish and optimize the distance from the drop point of the large ladle to each water inlet under the condition of adapting to the high pulling speed;

(2) Tundish with large capacity deep melting bath;

(3) Prevent deformation of tundish shell;

(4) Adopt firm and reliable tundish nozzle control device;

(5) Adopt reliable tundish lifting device under load;

(6) Optimize the distance from the tundish to the upper mouth of the crystallizer.

Article Source: What are the prominent problems in the tundish

Company name: Henan Changxing Refractory Materials Co.,Ltd

More refractory products:https://www.cxrefractories.com/en-product-solution

Email:[email protected]

Website:https://www.cxrefractories.com

0 notes

Text

Technical measures for smelting clean steel

The smelting of clean steel should be based on the variety and application requirements, and the operations of hot metal pretreatment-steelmaking-refining-continuous casting should be under strict control. The main control technical countermeasures are as follows:

(1) Hot metal pretreatment. For hot metal desulfurization or three desulfurization process, the sulfur content of molten iron should be less than 0.005% or even less than 0.002%.

(2) Converter compound blowing and steelmaking end point control. Improve dephosphorization conditions, increase the end-point composition and temperature one-time hit rate, reduce the dissolved oxygen content of steel grades, and reduce the number of non-metallic inclusions in steel.

(3) Block slag and tap steel. The slag blocking method is used to tap the steel, and the thickness of the slag layer in the ladle is controlled below 50mm. It can avoid phosphorus reversion, increase the yield of alloy, and reduce oxide inclusions.

(4) Ladle slag modification. During the tapping process, a slag modifier is added to the steel stream. Reduce iron oxide and adjust ladle slag composition.

(5) Refining outside the furnace. According to the steel quality requirements, select one or more refining combinations to complete the task of molten steel refining, to achieve dehydrogenation, extremely low carbonization, extremely low vulcanization, denitrification, reduction of inclusions and inclusion shape control, etc.

(6) Protection pouring. The use of protective pouring techniques during pouring is particularly important for the production of clean steel. The ladle-tundish-crystallizer is poured with shroud argon seal protection, the tundish uses double-layer mold slag, and the crystallizer uses mold slag, etc. It has the functions of adsorbing inclusions and reducing secondary oxidation.

(7) Tundish metallurgy. Organize reasonable molten steel flow in the tundish, reasonable residence time of molten steel, and promote the floating of inclusions, etc.

(8) Crystallizer operation technology. Select the casting mold powder with suitable performance; The submerged nozzle is centered and the insertion depth is suitable; the casting speed and the liquid level are stable; The electromagnetic stirring technology of the crystallizer is used; The flow of molten steel is controlled to facilitate the floating and discharge of gas and inclusions, and improve the quality of the slab .

(9) Internal quality control of billets. Use electromagnetic stirring and light pressure technology to reduce center porosity, center segregation and shrinkage cavity. Increase the density of the slab.

(10) Straight crystallizer arc continuous casting machine and vertical curved continuous casting machine are used to facilitate the floating of inclusions.

We Changxing Refractory Material Co.,LTD is professional manufacturer and supplier of refractory materials for more than 30 years. Our high quality refractory products are good sold to many countries say South Africa, Bangladesh, Indonesia, Malaysia, etc.

Article Source:Technical measures for smelting clean steel

Company name: Henan Changxing Refractory Materials Co.,Ltd

More refractory products:https://www.cxrefractories.com/en-product-solution

Email:[email protected]

Website:https://www.cxrefractories.com

0 notes

Text

Technical description of the AOD furnace process

AOD furnace method (argon-oxygen decarbonization method) is a more advanced technology for refining stainless steel. AOD furnace method has the advantages of simple equipment, convenient operation, strong adaptability, less investment and low production cost, and is widely used.

The molten alloy of the blast furnace and the intermediate frequency furnace is injected into the AOD furnace through the ladle, and O2, Ar or N2 mixed gas is blown during smelting to decarbonize the molten steel. At the same time, reducing agent, desulfurizer, ferroalloy or coolant are added to the feeding system to adjust the composition and temperature of the molten steel, and smelting qualified stainless steel water for continuous casting machine.

The delivery and regulation of mixed gas during refining is one of the main systems of argon oxygen furnace. The gas produced by the oxygen workshop is transported into the gas storage tank near the workshop through the pipeline, and after metering, decompression, adjustment and mixing, the mixed gas is sent into the furnace through the side gun according to the flow rate and ratio required by the process.

At the beginning of smelting, oxygen is decarbonized through a double-layer water cooling oxygen blowing pipe and blown into the metal melting tank at the top furnace mouth. For refining, use the mixed gas to send into the side gun into the furnace (installed on the side of the side wall near the bottom of the furnace). When loading and discharging the steel, the furnace body leans forward at a certain Angle, and the (side) tuyere is above the steel liquid level. When blowing normally, the tuyere sinks into the deep part of the dissolution tank. The central tube of the tuyere blows into the mixed gas of oxygen and argon or nitrogen, and adjusting the ratio of oxygen and argon can reduce the partial pressure of carbon monoxide to achieve the purpose of decarbonizing and preserving chromium. The type of AOD furnace tuyere is unique, it is a gas cooled consumption tuyere. The tuyere adopts a double casing structure, the outer pipe only through argon or nitrogen to cool the tuyere, the inner tube through oxygen and nitrogen, or argon mixed gas. Both the flow rate of the central pipe and the air mask ring can be controlled in the main control room.

Using the three-way side-gun technology. It can enhance the oxygen supply strength and improve the metal material yield, and this technology can shorten the AOD smelting time. Stable and reliable control system can reduce the consumption of gas and various refractory raw materials in smelting, and obtain stable product quality.

Article Source:https://www.cxrefractories.com/en-refractory-news?article_id=1248

Company name: Henan Changxing Refractory Materials Co.,Ltd

More refractory products:https://www.cxrefractories.com/en-all-refractory-products

Email:[email protected]

Website:https://www.cxrefractories.com

0 notes

Text

Cold repair of EAF bottom ramming material

1.First, thoroughly remove the steel slag, residual steel, steel and impurities infiltrated into the cracks on the repair surface. If the refractory material is pulverized by water, it should be completely removed until the refractory brick is exposed.

2.After the slag line is replaced, place the bottom of the EAF, hoist the ramming material into the EAF, and distribute the knotted material on the repaired surface as required to form a material layer with a height of about 150mm until it is covered with the repaired surface.

3.Distribute the material evenly, and use a special air vibration fork to poke each part of the material layer from the center of the molten pool to the EAF slope.

4.Repeat the operation twice until the EAF bottom ramming material is dense. Repeat the above steps until a suitable molten pool shape is formed.

We Changxing Refractory Material Co.,LTD is professional manufacturer and supplier of refractory materials for more than 30 years. Our high quality EAF bottom ramming mass are good sold to many countries say South Africa, Bangladesh, Indonesia, Malaysia, etc. Shall any interests, welcome to contact us. Our team would make best to be your reliable partner!

Article Source:Cold repair of EAF bottom ramming material

Company name: Henan Changxing Refractory Materials Co.,Ltd

More refractory products:https://www.cxrefractories.com/en-product-solution

Email:[email protected]

Website:https://www.cxrefractories.com

0 notes

Link

1 note

·

View note

Text

Lining method of EAF bottom ramming material

Lining preparation

Clean up the permanent layer residue, dust, iron wire, plastic cloth and other foreign objects. Calculate the knot size, the actual knot thickness is equal to the required knot thickness multiplied by 1.09, and a sufficient amount of ramming material should be prepared according to the construction furnace slope and furnace bottom size requirements. After receiving the material, check whether the ramming material has debris and damp. The debris should be cleaned up. The damp material should not be used, and knotting equipment such as rammers and pneumatic picks should be prepared.

Lining method

After shoveling the material flat with a shovel, step on it with your feet to remove the air, insert the steel drill into the material and shake it repeatedly, and then use your feet to further solidify. The construction thickness of each layer of ramming material is 150~200mm. Appropriate, and then use a knotting implement to repeatedly beat it 3 times in a spiral from the periphery to the center.

The method to check the quality of knotting is usually to put a round steel with a diameter of 5mm on the ramming layer and press it down with a pressure of 10kg, and its depth does not exceed 30mm. Steel drills can be inserted forcefully during site construction, and the depth should not exceed 30mm.

The method of knotting the furnace slope is the same as that of the furnace bottom. First, use your feet firmly, and then use the knotting appliance to ram, the maximum angle between the furnace slope and the furnace bottom does not exceed 40°. Prevent rolling or collapse due to the furnace slope is too large.

Place bricks at the tapping mouth, furnace door and other places where molten steel is agitated and scour severely should be beaten vigorously and appropriately thickened to extend the service life of refractory materials in these damaged parts as much as possible.

After the ramming is finished, cover the 5~10mm thick steel plate on the ramming material to prevent the shape of the furnace bottom being damaged or the waste steel penetrates the ramming material layer when loading the scrap steel, which may cause the hidden danger of steel leakage. If steel cannot be made in time, 100~200mm thick lime is added to the iron plate to prevent the ramming material from hydrating.

We Changxing Refractory Material Co.,LTD is professional manufacturer and supplier of refractory materials for more than 30 years. Our high quality refractory products are good sold to many countries say South Africa, Bangladesh, Indonesia, Malaysia, etc.

Article Source:Lining method of EAF bottom ramming material

Company name: Henan Xinmi Changxing Refractory Materials Co.,Ltd

Email: [email protected]

Website:http://www.cxrefractories.com

1 note

·

View note

Text

Steel Flow Initiator---refractory castable---Changxing Refractory

Steel Flow Initiator

Introduction:

Steel flow initiator is a kind of ladle slid nozzle filler which is successfully developed by our company in recent years, results show that ladle castables success rate of automatic start casting can reach above 95 percent. There is no metallic inclusion in ingot surface, is a kind of ideal ladle slide nozzle filler. Steel flow initiator contains metal mixture whose weight is heavier and melting point is lower than molten steel. Before pouring we put it into upper nozzle, using it to burning and causing the molten steel within the upper nozzle will not be solidified, to achieve the purpose of automatic start casting and avoid the problem of ingot inclusions.

Content source:

http://www.yilongrefractory.com/AllProductOneServlet?id1=2&id=27

E-mail:[email protected]

0 notes