#AOD furnace process

Text

Technical description of the AOD furnace process

AOD furnace method (argon-oxygen decarbonization method) is a more advanced technology for refining stainless steel. AOD furnace method has the advantages of simple equipment, convenient operation, strong adaptability, less investment and low production cost, and is widely used.

The molten alloy of the blast furnace and the intermediate frequency furnace is injected into the AOD furnace through the ladle, and O2, Ar or N2 mixed gas is blown during smelting to decarbonize the molten steel. At the same time, reducing agent, desulfurizer, ferroalloy or coolant are added to the feeding system to adjust the composition and temperature of the molten steel, and smelting qualified stainless steel water for continuous casting machine.

The delivery and regulation of mixed gas during refining is one of the main systems of argon oxygen furnace. The gas produced by the oxygen workshop is transported into the gas storage tank near the workshop through the pipeline, and after metering, decompression, adjustment and mixing, the mixed gas is sent into the furnace through the side gun according to the flow rate and ratio required by the process.

At the beginning of smelting, oxygen is decarbonized through a double-layer water cooling oxygen blowing pipe and blown into the metal melting tank at the top furnace mouth. For refining, use the mixed gas to send into the side gun into the furnace (installed on the side of the side wall near the bottom of the furnace). When loading and discharging the steel, the furnace body leans forward at a certain Angle, and the (side) tuyere is above the steel liquid level. When blowing normally, the tuyere sinks into the deep part of the dissolution tank. The central tube of the tuyere blows into the mixed gas of oxygen and argon or nitrogen, and adjusting the ratio of oxygen and argon can reduce the partial pressure of carbon monoxide to achieve the purpose of decarbonizing and preserving chromium. The type of AOD furnace tuyere is unique, it is a gas cooled consumption tuyere. The tuyere adopts a double casing structure, the outer pipe only through argon or nitrogen to cool the tuyere, the inner tube through oxygen and nitrogen, or argon mixed gas. Both the flow rate of the central pipe and the air mask ring can be controlled in the main control room.

Using the three-way side-gun technology. It can enhance the oxygen supply strength and improve the metal material yield, and this technology can shorten the AOD smelting time. Stable and reliable control system can reduce the consumption of gas and various refractory raw materials in smelting, and obtain stable product quality.

Article Source:https://www.cxrefractories.com/en-refractory-news?article_id=1248

Company name: Henan Changxing Refractory Materials Co.,Ltd

More refractory products:https://www.cxrefractories.com/en-all-refractory-products

Email:[email protected]

Website:https://www.cxrefractories.com

0 notes

Text

Secondary Refining Furnace

The steel refining process by secondary refining furnace can be divided into two categories: primary refining, aimed at removing carbon from pig iron, and additional refining processes conducted after primary refining, collectively referred to as secondary refining. Secondary refining furnace process involves the removal of impurities and adjustment of elements. The secondary refining usually takes place in a ladle (a transport container for molten steel) and is crucial for producing high-quality steel. The primary role of secondary refining is ultimate desulfurization, the elimination of oxygen, nitrogen, hydrogen, and other impurities, as well as the final decarburization of ultra-low carbon steel.

A steel melting and secondary refining method comprising the steps of melting steel manufacture raw materials while the molten steel is subjected to oxidation and decarburization so that the oxidation and decarburization are substantially completed before melt-down; after melt-down, heating the molten steel to a temperature above a liquidus line temperature and below 50℃. in temperature increment from the liquidus line temperature, and thereafter tapping the molten steel into a primary ladle; teeming the molten steel from the primary ladle into a secondary refining furnace; allowing the molten steel to be effluent into a secondary ladle at a lower portion of the secondary refining furnace while the temperature of the molten steel is raised; and continuously performing gas bubbling in the secondary ladle in a vacuum under existence of slag simultaneously with the effluence of the molten steel into the secondary ladle.

TYPES OF SECONDARY REFINING FURNACE

In the realm of steel production, the Secondary Refining Furnace stands as a pivotal player in achieving exceptional steel purity and quality. This crucial phase of the secondary metallurgy steelmaking process encompasses various techniques aimed at fine-tuning the composition of the molten metal, eliminating impurities, and ensuring the final product meets the stringent demands of modern industries.

WHAT ARE THE FUNCTIONS OF VARIOUS SECONDARY REFINING FURNACES?

Advantages of ladle refining furnace in alloy steel secondary refining

Enhancing Steel Quality through ESR Process

Stainless steel refining: AOD and VOD furnace

Advantages of ladle refining furnace in alloy steel secondary refining

Ladle refining furnace offers strong heating functions, permits the addition of a large amount of alloys, and enables precise temperature control. The ladle secondary refining furnace also provides outstanding desulfurization by high-temperature treatment with reducing fluxes and the removal of deoxidation products. The LRF process is therefore often used for the secondary refining process of alloy steel.

THE PIVOTAL ROLE OF SECONDARY REFINING FURNACES-SHAPING MODERN STEEL EXCELLENCE

THE PIVOTAL ROLE OF SECONDARY REFINING FURNACES-SHAPING MODERN STEEL EXCELLENCE

Secondary refining aims to fine-tune the steel's properties, ensuring the secondary refining process meets the stringent requirements of various industries, including automotive, construction, aerospace, and more.

Purity Enhancement: Steel produced in primary furnaces can still contain impurities and non-metallic inclusions that might adversely affect its mechanical properties, formability, and overall quality. Secondary refining furnaces, such as ladle furnaces or vacuum degassing units, focus on reducing these impurities to enhance the steel's purity. Through secondary refining processes like desulfurization and deoxidation, excess sulfur and oxygen are removed, leading to cleaner and more refined steel.

Composition Adjustment: Steel's composition can significantly impact its performance in various applications. Secondary refining furnaces provide a controlled environment for adjusting the composition of steel by adding precise amounts of alloying elements. This secondary metallurgy steelmaking process allows steelmakers to achieve specific mechanical properties, corrosion resistance, and other characteristics required for specific applications.

Refining Quality: The secondary refining process involves precise temperature and chemical control, which aids in the removal of undesirable elements and compounds that could compromise the steel's quality. By utilizing techniques like argon or vacuum degassing, hydrogen removal, and slag foaming, steelmakers can achieve higher levels of cleanliness and homogeneity in the final product. This contributes to improved mechanical properties, surface finish, and overall quality.

FAQS ABOUT SECONDARY REFINING FURNACE

HOW DOES A SECONDARY REFINING FURNACE ENHANCE THE PURITY OF STEEL?

Secondary refining furnaces employ various processes to enhance the purity of steel. Through the flow of molten steel, these furnaces can remove excess sulfur, oxygen, and other impurities using techniques such as blowing, injection, or vacuum treatment. This treatment significantly reduces the content of non-metallic inclusions and impurities, resulting in cleaner and higher purity steel.

HOW DO SECONDARY REFINING FURNACES CONTRIBUTE TO ENVIRONMENTAL SUSTAINABILITY?

Modern secondary refining furnaces also take environmental factors into consideration. They utilize technologies such as slag recycling and waste heat utilization to reduce waste generation, energy consumption, and emissions. These measures contribute to achieving sustainable steel production and reducing the environmental impact.

HOW DO SECONDARY REFINING FURNACES ADJUST THE COMPOSITION OF STEEL TO MEET SPECIFIC REQUIREMENTS?

Secondary refining furnaces adjust the composition of steel by adding alloying elements to meet specific requirements. Steel producers can precisely control the amount of alloying elements added, thus achieving specific properties and characteristics in the steel, such as corrosion resistance, thermal conductivity, hardness, etc. This enables steel to be tailored for various application domains.

0 notes

Text

What is Stainless Steel and How is It Made?

One of the primary reasons people pick stainless steel is its benefits and physical features, the most well-known of which is its corrosion resistance, but there are many more. The fact that stainless steel is resistant to high and a low temperature implies that it may be employed in various applications and industries. While certain stainless steels keep muscular strength at high temperatures, others maintain excellent mechanical qualities at cryogenic temperatures.

The sheer strength of stainless steel is a fundamental reason for its usage, which has been demonstrated by its application in the building and construction industries. Many people like stainless steel because of its visual appeal. Stainless steel is available in various surface treatments, and its ability to be polished makes it aesthetically beautiful. Its lengthy life cycle makes it appropriate for usage in structures and differentiates it from other items by outlasting many of them.

HOW IS STAINLESS STEEL MADE?

In the later phases, the specific procedure for a grade of stainless steel will change. How a grade of steel is formed, worked, and polished dramatically impacts how it appears and performs. You must first develop the molten alloy before making a deliverable steel product. As a result, most steel grades have similar initial steps.

Melting of Raw Materials

The several stainless steel components are heated to their melting points in a furnace (usually an electric furnace for current stainless steel production applications). This procedure might take between 8 and 12 hours. Once the metal is melted, the following process in stainless steel fabrication may begin.

Removing the Carbon Content

Carbon contributes to the hardness and strength of iron. Too much carbon, on the other hand, might lead to problems like carbide precipitation during welding. Before casting molten stainless steel, calibration and carbon content reduction to the appropriate level are necessary. Foundries can manage carbon content in two methods:

The first method is through Argon Oxygen Decarburization (AOD). Injecting an argon gas combination into molten steel decreases the carbon level while preserving other critical constituents.

Vacuum Oxygen Decarburization is another procedure employed (VOD). This procedure involves transferring molten steel to another chamber where oxygen is introduced into the steel while heat is applied. A vacuum removes the vented gases from the section, further decreasing carbon concentration.

Both technologies provide precision carbon content management to ensure suitable mixing and specific properties in the finished stainless steel product.

Tuning and Stirring

The molten steel is churned to help disperse and remove specific stainless steel components from the mixture to assist in fine-tuning the quality of the final product and helping to guarantee that the stainless steel is of consistent quality and meets the criteria of end customers (like Marlin Steel).

Forming or Casting

The foundry must now build the primitive form utilized to cool and manipulate the steel once the molten steel generate. The final result will determine the precise shape and size. Typical forms include:

Blooms

Billets

Slabs

Rods

Tubes

Forms are then labeled with an identification to help monitor the batch through the different operations that will take place. The following processes will vary based on the target grade and ultimate product or function. Plates, strips, and sheets are formed from slabs. Blooms and billets are transformed into bars and cables. Steel may repeat some of these procedures depending on the grade or format requested to get the required look or properties.

The stages listed below are the most frequent.

Metal Fabrication (forming the metal)

As the stainless steel cools, it is subjected to several shaping procedures, beginning with hot rolling while the steel is still above its crystallization temperature. Hot rolling helps to form steel and is frequently used to generate billets or blooms of metal. The stainless steel may be cold rolled to produce metal blooms or billets with specified specifications.

Annealing

Most steel tempers after it is formed with controlled heating and cooling cycles. These cycles aid in steel's softening and relieving internal stress. The steel grade will determine the precise temperatures and periods involved, with heating and cooling speeds influencing the final result. Heat treatment cannot harden austenitic stainless steel. Instead, these steels harden as they function (they attain hardness during manufacture and formation). This treatment is carried out at high temperatures, often above 1000°C.

Annealing these stainless steels softens them, increases their elasticity, and improves their corrosion resistance. It does deliver heat at temperatures ranging from 1000 to 1100°.

Cutting and Shaping

Most steel tempers after it has been formed with controlled heating and cooling cycles. These cycles aid in steel's softening and relieving internal stress. The steel grade will determine the precise temperatures and periods involved, with heating and cooling speeds influencing the final result.

Finishing

Stainless steel comes in a range of finishes, from matte to mirror. Finishing is one of the final stages in the manufacturing process. Acid or sand etching, sandblasting, belt grinding, belt buffing, and belt polishing are all standard processes. The steel is now collected in its final state and prepared for shipment to the client. Rolls and coils are traditional methods for storing and shipping large amounts of stainless steel for various industrial processes.

However, the final shape depends on the type of steel used and other order-specific parameters.

QUALITY CONTROL

Marlin Steel experts do finite element evaluations on each design before finalizing a stainless steel basket or product. Marlin Steel uses top-of-the-line FEA software to maintain quality control because it offers exact simulations in minutes, saving significant time, labor, and materials compared to manual testing techniques. During this investigation, the software mimics different weight distributions on the basket at various temperatures and after exposure to certain chemicals.

The experts can discover any faults before finishing the project by assessing these impacts, assuring the customer obtains a stainless steel basket of the most excellent quality.

CONCLUSION:

Understanding the appropriate stainless steel grades and kinds for specific purposes and conditions is critical to guaranteeing long-term outcomes and cost optimization. There is a stainless steel alloy to fit your demands, whether you need something robust and corrosion-resistant for maritime settings or beautiful and simple to clean for restaurant usage.

This post was originally published here: https://www.mvikas.in/what-is-stainless-steel-and-how-is-it-made

0 notes

Text

Analysis of Indian Steel Industry & forecasting it’s Future (Demo)

Authors:

Aarush Kumar 1, Harshita Verma 2

B.Tech CSE Student, Galgotias University, Greater Noida, Uttar Pradesh, India.

B.Tech Mechanical Student, GLA University, Mathura, Uttar Pradesh, India.

Abstract

Indian Steel Development Association (ISDA) was formed in 1989 with the explicit objective of diversifying and expanding the domestic market of stainless steel. At that time, more than 90% of stainless used in the country was kitchenware but over the last two decades, stainless steel has undergone tremendous changes in perception and its increasingly growing end use

application in areas such as architecture building & construction, automotive transport, process and engineering.

The world production of stainless steel in 2012 is estimated at 35.4 million tonne. Asia has strongly emerged as both the world’s largest stainless steel producer and user. Among countries, China dominates the world production of stainless steel accounting for almost 45% share. However, India has outpaced global growth rates consistently over last 10 years with its stainless steel melt

production in 2012 reaching almost 3 million tonnes to propel the country as 4 th largest producer after China, Europe and Japan.

The potential growth of stainless steel in India is enormous, considering the fact that the per capita consumption at 1.9kg is still much lower than world average of almost 4.85kg. The per capita consumption of stainless steel has strong co-relation with per capita GDP and India is expected to more than double its per capita income over next 10 years. In addition increased urbanization, high

demographic dividends and government’s manufacturing policy seeking to enhance the share of manufacturing in GDP to 25% within a decade augurs well for the future growth of the stainless steel in India.

This research focuses on the growth story of Indian Stainless Steel industry and its market sector world and further explores on the strategy to increase the consumption domestically considering the fact that world is going through recession cycles resulting in excessive capacity especially China posing a major challenge to Indian Stainless industry.

1. Introduction

It was 100 years ago that stainless steels was first discovered, patented and produced. Over last few decades stainless steel has emerged as the fastest growing metallic material and in recent years its growth rate has even surpassed plastics as shown in Fig. 1. In sustainability, stainless steel is unmatched compared to other materials and can play an important role in sustainable development of Indian infrastructure. Such growth has only been possible due to inherent qualities of stainless steel such as its resistance against corrosion, high strength to weight ratio and its elegant appearance. Taking into account the recyclability, reuse, long life, low maintenance and product safety, the minimal emissions from the production and use of stainless steels, when compared to

any other alternative material stainless steel is a preferred choice. Also continuous development in process technology and evolution of new grades of stainless for appropriate applications along with improvement in the people’s living standard propelled this impressive growth.

2. Global Stainless Steel Scenario & Share of India

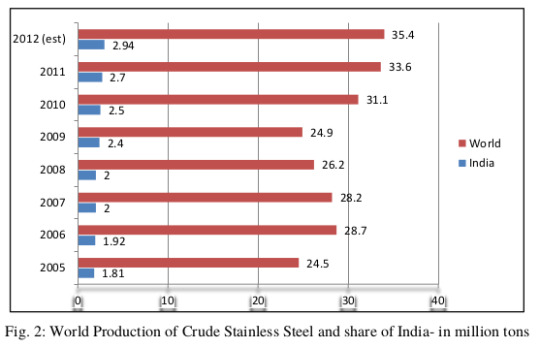

The world Crude Stainless Steel production in 2012 [1] is estimated at 35.4 million tons. The world production has grown at a CAGR of 5.2% pa over the last 10 years. Asia has strongly emerged as both the world’s largest stainless steel producer and user. Although China dominates the production of stainless steel accounting for almost 45% share of world production, India has been a part of this impressive growth with its production reaching 3 million tons in 2012 making it the 4 th largest producer after China, Europe and Japan. India has outpaced the global growth rates consistently over last several years. The average growth in India has recorded a CAGR of almost 11.5 % over the last 10 years which is more than a double the world average growth during the period. The past

world production of stainless steel and share of India is exhibited in the Fig. 2

The impact of global melt down on stainless steel consumption in the country has also been felt to some extent. While globally the impact of economic meltdown had been very severe, Indian economy by and large did not face harsh consequences of the global impact. Indian economy is mostly dependant on the overall strength of domestic demand and domestic nature of financing of

investment with exposure of exports to less than 20% of GDP. This helped it to tide over the year 2008-09 with lesser impact.

2.1 Production Status of Stainless Steel in India

At present, there are about 26 producers of stainless steel in India with EAF/IF melting and AOD/VOD facilities. These units contribute about 90 percent of the country‘s estimated 2.95 million tons melt production of Stainless Steel in 2012. The overall melt capacity of these producers is estimated at 5.8 million tons. Besides these manufacturers, there are about 20 Induction Furnace (IF) units in the country with estimated capacity of about 0.4 million ton which melt stainless steel scrap and produce pencil ingots without any refining facilities.

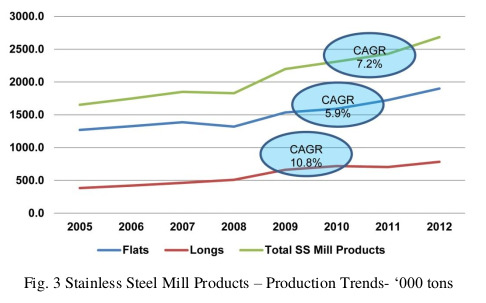

India has registered a compound annual growth rate (CAGR) of 7.2% pa in production of melt Stainless Steel in the last 7 years [2]. The overall production of Stainless Steel mill products is now estimated at 2.68 million tons. Fig. 3 Indicates the past growth rates in mill product production.

2.2 Consumption Status Of Stainless Steel In India

The major end using segments that impact the growth of Stainless steel significantly includes construction, consumer durables, transportation, Engineering goods and process machinery. The current and past macro level indicators of these end use sectors are tabulated below in Table 1. Most

of the sectors have performed below par over the last 2 years thus affecting the overall growth of stainless steel which normally grows much higher than the sectoral growth due to higher multiplier.

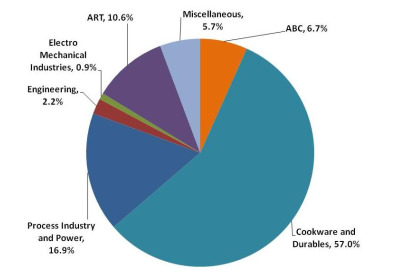

2.2.1 Consumption By End Use Sector – A Stainless Steel Grade Indicator

The main Stainless Steel consuming segments can be classified into 6 to 7 broad categories e.g.Metal products, Process and Engineering industries products; Electro mechanical and electronics;Construction, Transportation and others including medical, blades, coins etc. Out of these Metal products, Process Industries and Engineering goods etc are relatively mature applications areas

whereas areas like construction and automobile are still evolving in the country and have great future potential for growth.

The automotive, railway and transport (ART) sector is now emerging as the fastest consumption segment of Stainless steel in the country. This segment has grown the fastest 32.39% over the last 8 years propelled by large requirements from railway wagon, coaches and automotive exhausts. The Indian automobile industry has grown rapidly in the past with India emerging as a major hub

for small cars. All major international players are having their presence in India. Auto exhausts has been the major consumption segment for Stainless steel in this sector followed by disk brakes,cylinder head gaskets and exhaust manifold gaskets.

One of the new emerging segments for stainless steel consumption is the architecture, building and construction (ABC) sector. The ABC sector is mostly driven by growth in Indian real estate sector consisting of residential real estate, commercial real estate, retail space, entertainment space,hospitality projects and SEZs. All high quality construction projects like retail outlets, shopping

malls, multiplexes, Airports, Rail Metros, IT parks, Commercial Complexes, Hotels, Fast food restaurants, High Quality Residential accommodations, Hi tech town ships and showrooms etc in the country today are finding big outlet for stainless steel in different ways and product forms such as Railings, Roofings, Barriers, signages, claddings and building facades.

3. Challenges

While the country‘s future growth prospects appear to be quite bright there are certain key issues which are hindering its realisation of true potential. Some of the main issues confronting the industry are non availability of nickel in the country and its high price volatility, growing raw material prices, lack of indigenous melting scrap, increasing competition and shrinking margins in

India, Cheap imports from China etc are acting as threat to growth of Indian industry. Also the current capacity utilization of both flat and long product producers is quite low at present primarily due to large domestic capacity creation leading to surplus situation for coming few years. A large section of the market in India is price sensitive and the lack of awareness on life cycle costing

results in resistance to use Stainless Steel due to high initial cost.

4. Conclusion

From being a very insignificant player in the world market about a decade ago to become world fourth largest producer the Indian market has demonstrated a steady growth in the past years. Maintaining this positive trend will require a lot of marketing and development activities. The efforts should be made to ensure that the use of Stainless Steel in infrastructure should be made mandatory by planning commission and specified in the standards. There is a need to create

awareness among designers, specification writers about the benefits of stainless steel to reduce the level of ignorance about the material and thus, create new application areas using the life cycle cost benefits of specifying material. In the pursuit of the objective of increasing and diversifying end use of stainless steel in the country a collective effort by Indian Stainless Steel Development Association, its member companies, and downstream facilities will be helpful to realize the true potential of growth of stainless steel in the country.

Thankyou for reading!!!

0 notes

Text

India Toxic

The company was started by Mr. PRABIR SEN is 1971, on his return from Germany and England he A professional Engineer has acquired experience abroad and at home. The company had its’ operationed base in Hardwar (now in Uttarakhand) and installed 41 Pollution control systems in Bharat Heavy Elect. Ltd, Hardwar and also in Indian Drugs in Rishikesh. The company had since shifted to Kolkata, India and has bases in Delhi and Vadodara (Gujarat) and is run by Partners Mr.P. Sen and Mrs. Durba Bhattacharga, a Management Expert (M.SC + MBA). The other key PERONAL ARE :- Mr. Bhupinder singh, Elect, Engineer with 30 years experience. Mr. Sanjay Adhikary, Mech Engineer with 15 years experience.

We have installed about 280 Pollution control system, Large to small, mostly in Metallurgical industries.We are Trunkey Consulting Engineers in the field of Air Pollution Control with specialization for METALLURGICAL INDUSTRIES for the last past 42 years and we have served many distinguished and reputed clients like BHEL, SAIL, Jindal Strips, SESA GOA, KIRLOSKAR FERROUS and SIEMENS-VAL. (for VD/VOD). Greaves, Pratap steel Group, Mukand Steels, Rathi Steel Group, Maithon Alloys Gropup, Monnet Group, FACOR etc.

We conversant with any kind of Steel/Metallurgical process, viz, MBF, Converters (for Alloy/S.S), Arc Furnace, Induction Furnace, Submerged Arc Furnace, Cupola, Waste heat Recovery etc. our major achievements are listed separately and attached herewith for your kind appreciation.

Right now, we are installing system for 50 Ton AOD + 35 Ton Ind, Furnace & Secondary system in Synergy Steel, Alwar and 30 Ton AOD + 20 Ton Ind. Furnace & Secondary System in Avater Steel, Balagarh and also for a 15 Ton AOD in Mandi Govindgarh.

Overseas, we have installed 2 plants for 2 x 8 Ton I.Fs in Saudi Arab and 2 more for 2 x 12 Ton I.F + for Secondary Extraction under installation there. We have also installed 2 plants for 15 Ton I.F + for secondary in Ghana and Indian Toxic Treatment plant for 2 x 25 Ton I.F in Nigeria & 2 more for 15 Ton AOD Converters under installation there now. And we have recently commissioned a very large plant in Russian Federation country for 25 Ton I.F 25 Ton LRF & secondary system.

In SESA GOA, we have installed Skull-Dumping Station with Pollution Control & Graphite-Recovery systems, Laddle De-Sulphurisation Pollution Control, Runner Fume Control systems. We have done these for KIRLOSKAR FERROUS also. Now talks on way for Dust-control for Slag-Drying Station and we are going to install another system for (VD-VOD) under SIEMENS in SLR Metalliks, Hospet. Control for 4 PCMs.

0 notes

Text

How to make magnesia brick

Magnesia Brick Manufacturing Process:

The manufacturing process of magnesia brick includes the following steps:

1. Break and smash:

Crushing is the process of processing large pieces of material into ideal particle size materials.

2. Ingredients (weighing):

The raw materials are prepared in a predetermined proportion and mixed in a strong sand mixer. The order of feeding is magnesia aggregate – carbon fiber – binder – carbon raw material.

3. Mixing:

Mix thoroughly to get perfect coating. Add mixture made in step (B) and remix the batch intensively. Now add powder Resin (item 9), then Hexamine (item 10) and mix once again.

4. Molding:

Use a molding machine to make the mixture into bricks.

5. Drying:

Use a drying oven to dry the bricks for several hours.

6. Firing:

Fire the bricks in a kiln at temperatures of 1550 to 1600 degrees Celsius.

7.Finishing:

The final step is to grind and polish the bricks to get the desired shape and size.

Types of magnesia brick:

Magnesia bricks can be divided into two categories: sintered magnesia bricks (also known as fired magnesia bricks) and chemically combined magnesia bricks (also known as unburned magnesia bricks). Magnesia bricks with high purity and firing temperature are called direct-bonded magnesia bricks due to the direct contact of periclase grains; Bricks made of fused magnesia as raw materials are called fused re-bonded magnesia bricks.

Uses of Magnesia Bricks:

Magnesia bricks are used in steelmaking furnaces, electric furnace bottom and wall, and high temperature tunnel kiln. Magnesia bricks are also used as heat storage room lattice bricks in glass kilns.

Magnesia brick is used for permanent layers in steel making converters, AOD furnaces, and more. Magnesia brick is also used to line steel ladles and Basic Oxygen Furnaces (BOFs). Magnesia bricks can be used in a variety of applications, depending on the type of brick being used. Common uses include furnaces, ladles, secondary refining vessels, and cement and glass making kilns.

Magnesia Brick for sale

The most important steps need to be considered to avoid or reduce the possibility of magnesia bricks hydration are:

1). Magnesia bricks must be transported in a container to protect the material against moisture.

2). Magnesia bricks should be stored inside storage rooms where it is dry, free of frost, ventilated, and with a temperature between 10°C and 30°C. Note that magnesia bricks storage underneath a tarpaulin cover outside is not sufficient.

3). Bricks may not be stored for more than four weeks prior to installation and preheating.

4). Lining should be protected against moisture during installation and preheating.

Article Source:How to make magnesia brick

Company name: Henan Changxing Refractory Materials Co.,Ltd

More refractory products:https://www.cxrefractories.com/en-all-refractory-products

Email:[email protected]

Website:https://www.cxrefractories.com

0 notes

Text

Introduction and selection of burner bricks

Burner brick is a kind of refractory brick used with the burner of high temperature kiln, such as blast furnace gas burner, special burner for lime furnace kiln, shaft furnace burner, regenerative heating furnace burner, etc. The shapes are different, and the burner bricks used do not have fixed specifications and sizes, and they often need to be customized in refractory manufacturers. The use of high-aluminum steel fiber castables can meet the working conditions of most burners.

The function of the burner brick is:

1.The fuel is heated to the ignition temperature in the burner brick, so that it is easy to ignite and burn quickly.

2.Keep a certain high temperature in the burner brick to stabilize the combustion process and avoid pulsation or fuel interruption.

3.The flame shape of the organization meets the requirements of the heating process.

4.To further mix the fuel and air. Therefore, the burner brick is an indispensable high-temperature resistant material for the burner of high-temperature industrial kilns.

Because the burner parts are mostly special-shaped, the high-pressure molding and firing method is not only costly, but also has a long production cycle. The number is too small and no manufacturer is willing to do it. Therefore, the burner bricks are mostly molded by casting, which is to choose a suitable refractory castable for casting, and the finished product after curing and baking. The requirements must meet the high temperature resistance, secondly, it must have higher strength, resistance to erosion, and the mixed erosion of natural gas and air, and finally the thermal shock resistance, that is, the performance of resistance to rapid cold and heat must be good.

Wanhao is a manufacturer who is specialized in designing various kinds of furnace and making refractory products for electric furnace, ladle, tundish, blast furnace, AOD furnace, IF furnace, etc.

Article Source:Introduction and selection of burner bricks

More Refractory Products:https://www.wanhaorefractory.com/en/product.html

Website:https://www.wanhaorefractory.com/

0 notes

Text

Improvement measures for corrosion of tundish stopper

1. Strictly control the slag from the big bag

The main sources of slag components in the casting area of the tundish are ladle refining slag, tundish covering agent and molten steel inclusions floating up into the slag layer. Among them, the low silicon aluminum killed steel refining slag, which is more severely corroded by the stopper rod, is a high basicity refining slag system, and the CaO content in the slag is controlled at 55%-65%. The large ladle slag of each furnace will form a refined slag enrichment in the injection point area of the tundish. During the subcontracting process and when the pouring steel stream impacts the slag surface of the injection point area, it will cause the refined slag to enter the casting area and cause erosion of the stopper.

Therefore, it is necessary to strictly control the slagging of the big ladle, and use the automatic control of the slag detection to avoid a large amount of slagging at the end of pouring. At the same time, the tundish slagging operation should be adopted. When the large ladle is continuously pouring 5 to 7 furnaces of molten steel, the tundish level slagging operation should be carried out to control the thickness of the slag layer in the injection point area.

2. Control the superheat of the package

The liquidus line of the molten steel of XGM6-1 steel grade is 1535℃, and the superheat is controlled at 25~45℃. From the actual production process, when the average superheat of the tundish reaches 45℃ (the temperature of the tundish is 1580℃), all slag lines appear erosion off the situation. The average superheat of the tundish is reduced by 15℃, and the actual control average tundish temperature is reduced to about 1560~1565℃. The erosion of the slag line has been significantly improved, and the erosion rate of the monoblock stopper slag line can be stably controlled within 20%.

3. Optimizing the composition of the covering agent for tundish molten steel

In view of the reaction situation between the tundish slag and the stopper slag line, it is impossible to completely avoid the problem of refined slag entering the casting area and high superheat of the tundish in the actual production process. Therefore, the composition of the covering agent for the tundish molten steel is optimized for different steel grades. The temperature condition of the package increases the MgO content in the covering agent, and forms the Mg-Ca-Al-Si multi-element compound in the slag layer of the middle cladding. The melting point is above 1600℃. A protective layer is formed at the slag line of the stopper to slow down the damage of the slag. The rod body is resistant to corrosion.

The control of the MgO content in the covering agent needs to be adjusted according to the actual control range of the molten steel ladle. When the MgO content exceeds 15%, the melting point of the tundish slag will increase significantly. The slag layer in the ladle pouring area is crusted, which affects the normal stopper control.

By optimizing the composition of the tundish covering agent, a coating layer of high-melting compound mainly composed of MgO is formed at the slag line of the monoblock stopper rod, which prevents the slag-steel interface reaction from corroding the refractory material at the slag line and effectively improves the service life of the stopper.

Wanhao is a manufacturer who is specialized in designing various kinds of furnace and making refractory products for electric furnace, ladle, tundish, blast furnace, AOD furnace, IF furnace, etc.

Article Source:Main tasks of the electric furnace during the oxidation period and reduction period

More Refractory Products:https://www.wanhaorefractory.com/en/product.html

Website:https://www.wanhaorefractory.com/

0 notes

Text

Production process and damage mechanism of tundish sizing nozzle

The0 zirconium sizing nozzle is used as the key refractory material for billet continuous casting, which controls the flow of molten steel, determines the drawing speed of the billet in continuous casting, and is a necessary condition to ensure the normal operation of continuous casting. In addition to cracking, blockage and falling off of the sizing nozzle, it is also required that the diameter expansion speed should not be too fast to meet the requirements of long-term casting.

Damage to the sizing nozzle. The damage process of the oxidized sizing nozzle is a complex physical and chemical effect of its interaction with steel slag and molten steel at high temperatures.

The specific damage mechanism is divided into two categories:

(1) Physical damage: During the use of the sizing nozzle, due to the large temperature difference between before and after pouring steel (the pouring temperature of the steel is 1540C, uneven heating, a huge thermal stress is generated inside the nozzle, resulting in micro cracks in the nozzle.? The generation of slag reduces the strength and erosion resistance of the nozzle, and provides convenience for the penetration and erosion of molten steel and steel slag into the sizing nozzle.

(2) Chemical damage: ① Desolubilization of stabilizer in zirconia. The best raw material for preparing sizing nozzles is partially stabilized zirconia. In the process of casting steel, stabilizers (calcium oxide, magnesium oxide, etc.) will react with molten steel and inclusions (such as Fe, Mn, Si, etc.) in molten steel. A low melting point oxide melt is formed, which flows away with the molten steel, and the aluminum oxide solid solution is destabilized and decomposed due to the desolubilization of the stabilizer. As a result, the quantity of cubic phase aluminum oxide is reduced, and small particles of monoclinic phase are lost with molten steel. ②Infiltration and erosion of molten steel and steel slag.

Wanhao is a manufacturer who is specialized in designing various kinds of furnace and making refractory products for electric furnace, ladle, tundish, blast furnace, AOD furnace, IF furnace, etc.

Production process and damage mechanism of tundish sizing nozzle

Article Source:Production process and damage mechanism of tundish sizing nozzle

More Refractory Products:https://www.wanhaorefractory.com/en/product.html

Website:https://www.wanhaorefractory.com

0 notes

Text

Main tasks of the electric furnace during the oxidation period and reduction period

Electric furnace oxidation period

The oxidation period of electric furnace is the main process of oxidation smelting, which can remove phosphorus, gas and inclusions in steel.

When the scrap steel material is completely melted and reaches the oxidation temperature, more than 70% to 80% of phosphorus is removed and enters the oxidation period.

In order to ensure the progress of the metallurgical reaction, the oxidation starting temperature is 50-80°C higher than the melting point of the molten steel.

The main tasks during the oxidation period of the electric furnace:

Continue dephosphorization to the requirement-dephosphorization;

Decarburization to the lower limit of specification-decarburization;

Get rid of gas, get rid of inclusions-go two;

Increase the temperature of molten steel-heating up.

Electric furnace reduction period

In the traditional electric furnace smelting process, the existence of the reduction period shows the characteristics of electric furnace steelmaking. The main difference of modern electric furnace smelting process is that the reduction period is moved outside the furnace.

The main tasks during the reduction period of the electric furnace:

Deoxygenation to the requirement-deoxygenation;

Desulfurization to a certain value-desulfurization;

Adjust the composition-alloying;

Adjust the temperature-adjust the temperature.

Among them: deoxidation is the core, temperature is the condition, and slagging is the guarantee.

Wanhao is a manufacturer who is specialized in designing various kinds of furnace and making refractory products for electric furnace, ladle, tundish, blast furnace, AOD furnace, IF furnace, etc.

Article Source:Main tasks of the electric furnace during the oxidation period and reduction period

More Refractory Products:https://www.wanhaorefractory.com/en/product.html

Website:https://www.wanhaorefractory.com/

0 notes

Text

Tasks and operations during the melting period of the electric furnace

Electric furnace steelmaking uses electric energy as the main heat source and uses three-phase alternating current or direct current. An electric arc is generated directly between the charge and the electrode, and the charge is melted at a high temperature by the electric arc, and then an oxidizer, slag-forming agent, ferroalloy, etc. are added to remove inclusions. The chemical composition and temperature of the molten steel are adjusted to the specified values and then injected into the ladle. Since the 1980s, electric furnaces have developed in the direction of large-scale, ultra-high power, direct current, continuity and automation, and the world's electric furnace steelmaking production technology has developed more rapidly.

Electric furnace melting period

The melting period of the traditional smelting process accounts for 50% to 70% of the entire smelting time, and electricity consumption accounts for 70% to 80%. Therefore, the length of the melting period affects productivity and power consumption, and the operation of the melting period affects the smoothness of the oxidation period and the reduction period.

(1) The main tasks of the melting period

The massive solid charge is quickly melted and heated to the oxidation temperature;

Slagging in advance, dephosphorization at an early stage, reducing the gas inhalation and volatilization of molten steel.

(2) Operation during the melting period

Reasonable power supply, timely oxygen blowing, and slagging ahead of time.

Wanhao is a manufacturer who is specialized in designing various kinds of furnace and making refractory products for electric furnace, ladle, tundish, blast furnace, AOD furnace, IF furnace, etc.

Article Source:Tasks and operations during the melting period of the electric furnace

More Refractory Products: http://www.wanhaorefractory.com/en/product.html

Website: http://www.wanhaorefractory.com/

0 notes

Text

Problems and solutions in the use of submerged entry nozzle

After summarizing the actual operating experience, the main reasons for the problems in the use of the submerged entry nozzle and the solutions were found.

Specifically in:

1) Fracture before or during the process of pouring steel at the nozzle. The submerged entry nozzle is about 1 meter long but only fixed by the upper part, so it is mechanically damaged during transportation, hard objects collide with the nozzle during installation, unstable or falling too fast when lifting the intermediate tank, and the impact on the nozzle during the pouring process causes the root fracture. In order to prevent the nozzle from breaking, mechanical collision should be avoided as much as possible during transportation and installation, and the problem should be stopped in time, and a layer of rubber pad should be placed on the intermediate tank seat frame to make the crane take off and land smoothly.

2) The slag line is eroded too quickly. After continuous casting of 7 to 8 furnaces, the slag line of the nozzle, especially the edge of the zirconium zone, was severely corroded and even fractured. Therefore, it is necessary to improve the corrosion resistance and hot and cold strength of the zirconium zone and the transition zone; increase the length of the zirconium zone from 160mm to 210mm, and modify the relative position of the zirconium zone, so that the problem of excessive corrosion of the slag line can be solved solve.

3) Steel seepage at the junction of the separation ring and the nozzle. After continuous pouring of 7 to 8 furnaces, most of the intermediate tanks have molten steel seepage at the junction between the separating ring and the nozzle, and the pouring should be terminated in severe cases. Since the overall submerged entry nozzle is longer and the conical surface at the junction of the nozzle and the separating ring is short, the lower part of the junction cannot squeeze the fire mud tightly. After the fire mud dries, it is easy to produce gaps and reduce the fixing force of the nozzle; In addition, it contains carbon. The product cannot be well combined with the fire clay used, and the spray paint on the upper edge dries and cracks along the outer edge of the nozzle. Based on the above reasons, the original high-aluminum fire clay was changed to aluminum-chromium fire clay. The upper outer edge of the nozzle was first coated with a layer of low cement castable that is easy to combine with the nozzle, and then a layer of paint. At the same time, careful operation is basically eliminated. The problem of pouring due to steel infiltration is solved.

4) Failure of pouring opening caused by nozzle installation. In the case of normal pouring operation, the stopper cannot be opened automatically, resulting in pouring failure. This is mainly due to the cold steel at the junction of the nozzle and the stopper rod, which bonds the nozzle and the stopper rod. In response to this phenomenon, increase the length of the nozzle and require a positive tolerance when making the separation ring. The installation of the nozzle must ensure that the immersion depth and the upper edge of the nozzle are 10-15mm above the surface of the bottom working layer of the tank. The temperature of the baking tank must reach 1050~1100℃. The phenomenon of cold steel in the nozzle is fundamentally solved.

Wanhao is a manufacturer who is specialized in designing various kinds of furnace and making refractory products for electric furnace, ladle, tundish, blast furnace, AOD furnace, IF furnace, etc.

Article Source:Problems and solutions in the use of submerged entry nozzle

More Refractory Products: http://www.wanhaorefractory.com/en/product.html

Website: http://www.wanhaorefractory.com/

0 notes

Text

Advantages and disadvantages of fire clay brick

According to production process, fire clay brick is divided into machine made brick and handmade brick. According to structures, fire clay brick is divided into solid brick and hollow brick, and hollow brick can be divided into load-bearing brick and nonbearing brick. Fire clay brick is made at different shapes according to different using requirements.

Advantages of fire clay brick:

1.Fire clay brick is environmentally friendly and belongs to resource recycling bricks, so we can rest assured use fire clay brick. Fire clay bricks won’t be harmful to our health.

2.Fire clay brick has advantages of fireproof and heat insulation. Used clay brick can be used as concrete so that to save a lot of resources.

3.The price of fire clay brick is not as expensive as that of other fire bricks. Light weight brick is more expensive than fire clay brick. Besides, fire clay brick is very cheap and very durable

4. Fire clay brick has good moisture-proof function, it also has the advantages of fire insulation, heat insulation and moisture absorption.

Disadvantages of fire clay brick:

1.Clay brick is made of concrete and is much heavier than other masonry materials. It will make the whole building bear more weight, and it will increase the cost of the whole project.

2.Clay brick’s soundproof effect is poor. When outside sound spreads into clay brick, because it doesn't have a lot of air holes, it can't isolate the sound very well.

3.Clay brick’s main raw material is soil, and that will do harm to the environment. Clay brick manufacturing easily lead to the loss of soil and water. For this reason in China caly brick is being forbidden gradually.

Wanhao is a manufacturer who is specialized in designing various kinds of furnace and making refractory product for electric furnace, ladle, tundish, blast furnace, AOD furnace, IF furnace, etc.

Article Source:Advantages and disadvantages of fire clay brick

Company name :Luoyang Wanhao New Material Co., Ltd.

More Refractory Products: http://www.wanhaorefractory.com/en/product.html

Website: http://www.wanhaorefractory.com/

0 notes

Text

Cold crushing strength and high temperature crushing strength of refractory brick

Cold crushing strength

Cold crushing strength is the ultimate load per unit area of dense shaped refractory products can withstand without damage at room temperature.

The cold crushing strength of pressure-resistant refractory products has a great impact for the production, transportation and use performance, so higher cold crushing strength is better.

The high crushing strength indicates that the processed quality is good, structure is uniform, and well sintered.

High temperature crushing strength

High-temperature crushing strength is the refractory products under the specified high temperature conditions, the unit area can withstand without damage.

The high temperature crushing strength of refractory products determines the use scope, which is an important basis for the use of refractory materials.

High temperature crushing strength indexes are also meaningful to unshaped refractories, especially refractory castables and fire-resistant plastic materials. So the high temperature crushing strength is more important.

If you need refractory brick or other refractory products, welcome to contact us.Wanhao is a manufacturer who is specialized in designing?various kinds of furnace and making refractory products for electric furnace, ladle, tundish, blast furnace, AOD furnace, IF furnace, etc.

Article Source:Cold crushing strength and high temperature crushing strength of refractory brick

Company name :Luoyang Wanhao New Material Co., Ltd.

More Refractory Products: http://www.wanhaorefractory.com/en/product.html

Website: http://www.wanhaorefractory.com/

0 notes

Text

The advantages of AOD refining

1. 100% waste stainless steel, or cheap high-carbon ferrochrome and scrap carbon steel can be used as ingredients to make the chromium content in the raw materials meet the requirements of the finished product specifications, which can save most of the time when the electric furnace is used to return to the oxygen blowing process. The micro-carbon ferrochrome or metallic chromium that must be added reduces the cost of raw materials. For example, after a company in the United States adopted the AOD method, the consumption of micro-carbon ferrochromium decreased from 42.75 kg/ton in electric furnace single smelting in 1968 to 4.125 kg/ton. The consumption of silicon-chromium alloy is reduced from 10.125 kg/ton to 2.625 kg/ton, and the total chromium recovery rate reaches 98%, which is more than 10% higher than that of the electric furnace return oxygen blowing method.

2. When the double method of electric furnace and AOD furnace is used to produce stainless steel, only melting and heating are carried out in the electric furnace, so the productivity can be increased by 10-15%. The melting and heating of the electric furnace takes about 2.5-3.0 hours, and the blowing cycle of the AOD furnace is about 70-90 minutes, so two electric furnaces with one AOD furnace can achieve the best match, and the output can be increased by 40-50% compared with the single-refining of the electric furnace.

3. Compared with other secondary stainless steel refining methods, the AOD method has simple equipment and small capital investment, which is about 1/3 of the VOD method.

4. The process control is relatively simple. The vacuum oxygen blowing decarburization method needs to determine the end point through gas phase analysis, and also add a deoxidizer under vacuum, while the AOD method can dilute and decarburize in the atmosphere, and can create slag, measure temperature, and sample, which is much more convenient in comparison. In addition, compared with the electric furnace return oxygen blowing method, the AOD method is easier to smelt ultra-low carbon stainless steel, and can realize process automatic control more stably.

5. The quality of stainless steel smelted by AOD method is not inferior to electric furnace single smelting, and the gas content in the steel is slightly reduced.

We Changxing Refractory Material Co.,LTD is professional manufacturer and supplier of refractory materials for more than 30 years. Our high quality refractory products are good sold to many countries say South Africa, Bangladesh, Indonesia, Malaysia, etc. Shall any interests, welcome to contact us. Our team would make best to be your reliable partner!

Article Source:The advantages of AOD refining

Company name: Henan Xinmi Changxing Refractory Materials Co.,Ltd

Email: [email protected]

Website:http://www.cxrefractories.com

0 notes

Text

Refractory products for AOD refining furnace

The AOD furnace is an argon-oxygen blown converter for two-step steelmaking. It is an atmospheric refining furnace. Its appearance is similar to that of a converter. It is mainly used for smelting stainless steel.

The working characteristics of AOD furnace are:

1.High working temperature. In order to reduce the carbon content in steel to a very low level, the refining temperature needs to be increased to over 1700 degrees Celsius.

2.The molten steel is stirred vigorously. The spraying of a large amount of high pressure caused the molten steel to agitate violently.

3.The alkalinity of the slag changes greatly.

4.Intermittent operation.

The working process of the AOD furnace is to first blow oxygen to decarburize, then add ferrosilicon or aluminum to reduce the chromium in the slag, and then add lime for desulfurization. During the whole smelting process, the slag changed from acidic to alkaline, and the atmosphere changed from silicon oxide to reducing atmosphere. Due to the above working characteristics, refractory materials for AOD furnaces are required to have high refractoriness and high temperature strength. Good thermal shock resistance and strong slag resistance. Especially for the tuyere and the area around the tuyere, it is more necessary to use refractory materials with good corrosion resistance and peeling resistance. The refractory materials commonly used in AOD furnaces are magnesia chrome bricks, magnesia carbon bricks, and magnesia dolomite bricks. In order to form a balanced furnace lining, the upper part of the tuyere is fused and then combined with magnesia chrome bricks, the other parts are directly combined with magnesia chrome bricks, or the tuyere part uses pre-reacted magnesia chrome bricks, and the rest are magnesia dolomite bricks. The top of the furnace can be made of high-aluminum refractory castables and refractory plastics, or can be built with magnesia bricks.

Article Source:The development and function of long nozzle

Company name: Henan Xinmi Changxing Refractory Materials Co.,Ltd

Email: [email protected]

Website:http://www.cxrefractories.com

0 notes