#EAF furnace

Text

EAF Quantum Electric Arc Furnace

Primetals Technologies Limited, London, UK

a joint venture of Siemens & Mitsubishi Heavy Industries,

with equity participation by Hitachi Ltd.

image credit: Primetals

112 notes

·

View notes

Text

Excerpt from this story from Canary Media:

One of the world’s dirtiest industries is beginning to embrace cleaner methods.

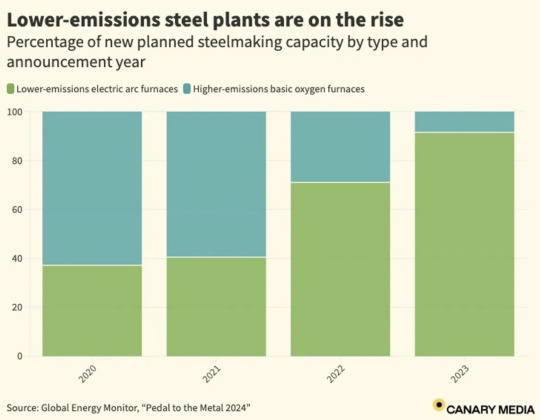

Most planned new steelmaking capacity will use lower-emissions electric arc furnace technology rather than the historically dominant but emissions-intensive basic oxygen furnaces, per a new report from the nonprofit Global Energy Monitor.

Steel is, quite literally, a pillar of our world. It props up skyscrapers, reinforces bridges, and is crucial to cars, planes, trains, and ships. It’s also incredibly dirty: As much as 11 percent of global carbon dioxide emissions come from the iron and steel industries.

The primary steelmaking process generally starts with producing iron in a superhot and extremely carbon-intensive coal-based blast furnace. The resulting iron is then typically put into a basic oxygen furnace, where it becomes steel.

But recent trends suggest that more-sustainable electric arc furnaces (EAF) are starting to replace basic oxygen furnaces, helping slash emissions. In 2023, nearly all newly announced steelmaking capacity — 93 percent — planned to use EAFs, per the Global Energy Monitor report.

As it stands, about 32 percent of global steelmaking happens in these lower-emissions electric furnaces, but that’s set to rise to more than 36 percent by the end of the decade as more EAFs come online and more oxygen furnaces retire, per the report. That growth rate nearly puts the industry on track to meet the International Energy Agency’s target for EAFs to make up 37 percent of steelmaking by 2030.

The picture is less clear for iron production, the step in the steelmaking process that is responsible for the vast majority of carbon emissions.

More than 90 percent of the world’s iron is still made in extremely dirty coal-based blast furnaces. The primary alternative to these furnaces, direct reduction iron (DRI), is beginning to gain ground. But coal-based blast furnace capacity is still being built faster than DRI capacity.

5 notes

·

View notes

Link

What is Electric Arc Furnace..? How the Billets are produced by EAF..?

A complete Process of Billet Formation from Scrap to Billets...

One of the Best Video has Information about EAF, CCM, WTP, FTP and ASP... 👇 👇 👇

Please SUBSCRIBE and LIKE the Content...

https://youtu.be/en-O6YoUF9o

#electricarcfurnace #ccm #wtp #billetformation #ftp #asp #thedailypost

4 notes

·

View notes

Text

Global Needle Coke Market, Market Size, Market Share, Key Players | BIS Research

The Global Needle Coke Market refers to the industry segment focused on the development, production, and distribution of building materials that have a reduced carbon footprint compared to traditional materials. These materials are designed to minimize greenhouse gas emissions throughout their lifecycle—from extraction, manufacturing, and transportation to use and disposal.

The global needle coke market was valued at $3.05 billion in 2023, and is expected to grow at a CAGR of 7.99% and reach $6.58 billion by 2023

Market Overview

Needle coke is a high-quality carbon material primarily used in the production of graphite electrodes, which are essential for electric arc furnaces in the steelmaking industry. Needle coke has a unique needle-like structure, high thermal conductivity, and low coefficient of thermal expansion, making it a crucial material for industries requiring strong, heat-resistant carbon.

Types of Needle Coke

Petroleum based needle coke - Derived from petroleum refining byproducts, particularly decant oil or slurry oil.

Coal based needle coke- Produced from coal tar, a byproduct of the coke-making process in steel production.

Download the TOC and get more information @ Global Needle Coke Market

Key Applications

Graphite Electrodes for steelmaking - The primary application of needle coke is in the production of graphite electrodes, which are essential in electric arc furnaces (EAF) used for steel production.

Lithium Ion Batteries - Needle coke is used to produce synthetic graphite anodes for lithium-ion batteries, a critical component in electric vehicles (EVs) and energy storage systems.

Major Key Players

Asbury Carbons

Gazpromneft

China Petroleum & Chemical Corporation

Shandong Jingyang Technology Co. Ltd

GrafTech International

Download the sample page click here@ Global Needle Coke Market

Market Demand Driver: Carbon Reduction Mandates and Environmental Standards

The needle coke market is poised for significant growth, propelled by the increasing adoption of the electric arc furnace (EAF) steelmaking process and the mounting pressure to achieve carbon neutrality targets. Sustainability considerations are reshaping the steel industry; the EAF process offers a more environmentally conscious approach compared to the traditional basic oxygen furnace (BOF) method. This shift favors needle coke, a critical material for EAF graphite electrode production

Future Outlook

The needle coke market is expected to witness sustained growth due to rising steel production through electric arc furnaces and increasing lithium-ion battery demand for electric vehicles and energy storage systems. However, environmental regulations, supply chain constraints, and price volatility will continue to shape the industry.

The market outlook is shaped by several key trends:

Rising Demand in Steelmaking

Expansion of Electric Vehicle (EV) Market

Supply Constraints

Technological Advancements

Conclusion

The global needle coke market is positioned for substantial growth, driven by increasing demand from the steel industry and the expanding electric vehicle (EV) market. As electric arc furnaces (EAF) gain traction in steel production and lithium-ion battery usage surges, the need for high-quality needle coke will rise. However, supply constraints, environmental concerns, and production challenges may create volatility in the market.

0 notes

Text

How To Select A Good Stainless Steel Round Bar Using Weight Chart

Stainless steel round bars are commonly used in the industrial sector in conditions involving high as well as low pressure work. They are either made seamless or in welded nature. The material used in manufacturing these pipes has to go through different procedures like melting, casting and hot rolling. Following is a detailed explanation of this procedure:

Melting: the stainless steel material is composed of iron, chromium, nickel, etc and it is melted in Electric Arc Furnace (EAF) for further steps.

Casting: the molten steel is then emptied into a cast to form billets or large slabs which will be used to make the round bars.

Hot rolling: this process involves passing the billets obtained in the casting process through rollers to achieve round bars. The diameter and the thickness of the bars is also decided in this stage.

After this, the bars are given cold drawing or heat treatment to provide enhanced strength or to relieve stress.

These bars are either seamless or welded. The seamless round bars are made by piercing a heated billet, thereby leaving no weak areas on the surface, while welded round bars are made by joining two ends of a steel plate by performing welding on it.

There are at least 5 different grades of stainless steel round bar namely austenitic, ferritic, martensitic, duplex and Precipitation-Hardening grades.

It becomes very hard for someone to select a good stainless steel round bar which fit into their specific preference and requirement due to availability of so many grades.

Hence following are some pointers one should remember while selecting a round bar using a weight chart:

Knowing the specification requirement:

Stainless steel round bars have a variety of grades like austenitic, ferritic, duplex, etc while contain more standard specifications like 304, 316, 310, etc, which are used in demanding environments. Hence, before selecting a material, one should know the requirements of the machinery like corrosion resistance, durability, weldability, etc. this helps in proper functioning of the machinery.

Selecting based on requirement:

One should be familiar with the conditions of the working environment, this helps in selection process regarding the material grade. many factories have extreme heat zones, high pressure work, high exposure to corrosion or low temperature zone as well. Hence because of this, there are different standard specified grades available in the market and one should carefully examine them as per the need before selecting.

Use of weight chart:

The weight chart contains very valuable information of the material related to its size, dimensions and weight.

The size of rod is an important variable as the rod should be able to cover the required area without falling short.

The dimensions are an important aspect as well because the diameter or thickness of different materials should be compatible otherwise it may lead to accident.

The weight of the material is directly proportional to its capability to handle pressure while maintaining its stability hence, one should calculate the weight requirement of the project and select the bar accordingly.

0 notes

Text

Stocks to Watch September 12, 2024: Tata Steel, Adani Ports, BPCL, and More in Focus

Stocks to Watch September 12, 2024

Indian benchmark equity indices आज सकारात्मक शुरुआत के लिए तैयार हैं, जिसे Wall Street के मजबूत overnight प्रदर्शन से प्रेरित किया गया है, जहाँ तीनों प्रमुख U.S. indices ऊंचे बंद हुए। सुबह 6:50 बजे, GIFT Nifty index 25,100 पर ट्रेड कर रहा था, जो Nifty futures के पिछले बंद स्तर से 150 पॉइंट आगे था।Global Market Overview

Asia-Pacific क्षेत्र के Markets ने गुरुवार को ऊँचाई पर शुरुआत की, जो Wall Street की सकारात्मक गति को दर्शाता है, जिसने U.S. inflation data से प्रभावित एक volatile session के बाद रैली की।Japan में, Nikkei 225 3% बढ़ा, जबकि broader Topix index 2.48% चढ़ा। South Korea का Kospi 1.2% ऊँचा खुला, जबकि small-cap Kosdaq 2.5% बढ़ा। Australia का S&P/ASX 200 0.6% बढ़ा, और Hong Kong का Hang Seng index futures 17,194 पर positive शुरुआत का संकेत दे रहा था, जो HSI के पिछले बंद 17,108.71 से ऊपर था।हालांकि, China का CSI 300 futures थोड़ी गिरावट दिखा रहा था, जो 3,181.6 पर ट्रेड कर रहा था, बुधवार के बंद स्तर 3,186.13 से थोड़ा नीचे।Overnight Gains in the U.S.

U.S. stock markets ने broad-based gains देखे, S&P 500 1.07% चढ़ा, जबकि tech-heavy Nasdaq Composite 2.17% की रैली पर रहा, और Dow Jones Industrial Average 0.31% बढ़ा। निवेशकों का रवैया सकारात्मक रहा, हालांकि inflation data के कारण session में कुछ volatility आई थी।Stocks in Focus Today- Tata Steel: कंपनी ने UK सरकार से अपने Port Talbot facility में green steel project के लिए £500 मिलियन का अनुदान हासिल किया है। यह पहल electric arc furnace (EAF) की स्थापना को फंड करेगी, जो Tata Steel को अधिक sustainable steelmaking प्रक्रियाओं की ओर ले जाएगी।

- Adani Ports and Special Economic Zone (APSEZ): APSEZ ने अपनी subsidiary DPA Container and Clean Cargo Terminal Limited (DPACCCTL) के माध्यम से Kandla के Deendayal Port में Berth No. 13 के विकास के लिए concession agreement हासिल किया है। यह multi-purpose berth, जो clean cargo और container shipments को संभालेगा, FY27 तक operational होने की उम्मीद है।

- Bharat Petroleum Corporation (BPCL): BPCL की subsidiary Urja Bharat Pte Limited (UBPL) ने Abu Dhabi में 6,162 वर्ग किलोमीटर का production concession जीता है। यह क्षेत्र conventional oil और gas resources से समृद्ध है, जो BPCL के global portfolio को और मजबूत करेगा।

- Auto Stocks: Union Cabinet ने दो नई पहलें—PM Electric Drive Revolution in Innovative Vehicle Enhancement (PM E-DRIVE) और PM-eBus Sewa-Payment Security Mechanism (PSM)—मंजूर की हैं, जिनकी कुल लागत ₹14,335 करोड़ है। इन योजनाओं का उद्देश्य electric vehicles (EVs), जिनमें buses, ambulances, और trucks शामिल हैं, के उपयोग को बढ़ावा देना है। नतीजतन, EV उत्पादन में शामिल auto manufacturing कंपनियों में निवेशकों की रुचि बढ़ने की संभावना है।

- Vedanta: Vedanta ने $900 मिलियन U.S. dollar bond issue के माध्यम से जुटाए हैं, जो 10.875% coupon rate के बावजूद oversubscribed रहा। इस राशि का उपयोग existing debt को prepay करने के लिए किया जाएगा, जो कंपनी में निवेशकों के मजबूत विश्वास को दर्शाता है।

- Route Mobile: Route Mobile के प्रमोटर Proximus Opal ने 38 लाख shares (6.03% equity) को September 12 और 13 को Offer for Sale (OFS) के माध्यम से बेचने की योजना बनाई है। OFS के लिए floor price ₹1,635 प्रति share तय किया गया है। यह offer आज non-retail investors के लिए खुला है, जबकि retail investors को कल access मिलेगा।Conclusion

देशीय और अंतर्राष्ट्रीय markets से सकारात्मक संकेतों के साथ, आज भारतीय equities के ऊँचा ट्रेड करने की उम्मीद है। Tata Steel, Adani Ports, BPCL और Vedanta जैसी कंपनियों में प्रमुख विकास और auto industry में sectoral movements को निवेशक ध्यान से देखेंगे।Also Read:Jio Financial’s Bold Step with BlackRock: Could This Be the Investment Opportunity of the Year 2024?

Read the full article

0 notes

Text

How Wire Rod Manufacturers Are Overcoming Modern-Day Obstacles?

In the complex and dynamic landscape of the steel industry, wire rod manufacturers face a myriad of modern-day challenges. These hurdles range from fluctuating raw material prices, stringent environmental regulations, technological advancements, to the ever-present demand for higher quality products. Yet, despite these obstacles, the industry is witnessing remarkable resilience and innovation as manufacturers adapt and evolve. This exploration delves into the strategies and solutions being implemented by wire rod manufacturers to navigate these challenges successfully.

Navigating Fluctuating Raw Material Prices

One of the most significant challenges wire rod manufacturers face is the volatility of raw material prices. Steel, the primary material for wire rods, often experiences price fluctuations due to changes in global supply and demand, geopolitical tensions, and trade policies. Manufacturers have responded by adopting a more agile approach to procurement and supply chain management. By diversifying their supplier base and engaging in long-term contracts with raw material providers, manufacturers can secure more stable pricing and ensure a consistent supply. Additionally, investing in forecasting tools and market analysis capabilities allows manufacturers to predict price trends and adjust their strategies accordingly.

Adhering to Stringent Environmental Regulations

Environmental sustainability has become a central concern for the steel industry. Governments worldwide are imposing stricter regulations on emissions and energy consumption, compelling wire rod manufacturers to rethink their production processes. In response, many have turned to eco-friendly technologies and practices. Electric arc furnaces (EAFs), for example, are increasingly preferred over traditional blast furnaces due to their lower carbon footprint. EAFs can melt scrap steel using electricity, significantly reducing CO2 emissions. Furthermore, manufacturers are investing in energy-efficient machinery, waste heat recovery systems, and renewable energy sources to power their operations, thus not only complying with regulations but also reducing operational costs in the long run.

Embracing Technological Innovations

Technological advancement presents both a challenge and an opportunity for wire rod manufacturers. To stay competitive, manufacturers must continuously invest in new technologies that improve efficiency, product quality, and sustainability. Automation and Industry 4.0 technologies, such as artificial intelligence (AI), the Internet of Things (IoT), and advanced data analytics, are revolutionizing manufacturing processes. These technologies enable real-time monitoring and control of production lines, predictive maintenance, and enhanced quality control. By automating routine tasks, manufacturers can reduce human error, increase productivity, and focus on innovation and quality improvement.

Meeting the Demand for Higher Quality Products

The market's demand for higher quality wire rods, with improved mechanical properties and tighter tolerances, is another challenge manufacturers must meet. This demand is particularly pronounced in industries such as automotive and construction, where the performance of wire rods can significantly impact the final product's strength and durability. Manufacturers are addressing this need by investing in research and development to refine their production processes and develop new steel alloys. Advanced rolling techniques and heat treatment processes also play a crucial role in enhancing the physical properties of wire rods, such as tensile strength, ductility, and weldability.

Building Resilience Through Strategic Partnerships

In an increasingly interconnected global market, building strong relationships with customers, suppliers, and other industry players is vital for overcoming challenges. Strategic partnerships and collaborations can provide access to new markets, technologies, and expertise. For wire rod manufacturers, working closely with customers to understand their needs and developing customized solutions can lead to more robust and long-lasting business relationships. Collaborating with research institutions and technology providers can accelerate innovation, while alliances with suppliers can secure raw material supplies and improve supply chain resilience.

Conclusion

As wire rod manufacturers navigate these complex challenges, the path forward is marked by innovation, adaptability, and strategic collaboration. By embracing new technologies, prioritizing sustainability, and fostering strong partnerships, manufacturers can secure their place in the future of the steel industry.

For businesses and projects demanding the highest quality wire rods, tailored to their specific needs, partnering with a forward-thinking manufacturer is crucial. Vital Steel Bars stands at the forefront of innovation and excellence in wire rod manufacturing. With our commitment to quality, sustainability, and customer satisfaction, we are equipped to meet the challenges of today and tomorrow.

At Vital Steel Bars, we understand the intricacies of modern-day manufacturing and the importance of overcoming these challenges to deliver superior products. Our expertise and dedication to innovation ensure that we remain a step ahead, providing our clients with wire rods that meet the highest standards of quality and performance.

If you're looking for a partner who can offer cutting-edge solutions and tailored products to navigate the complexities of modern industries, contact Vital Steel Bars. Together, we can achieve success in your projects, powered by the resilience and innovation that define our approach to wire rod manufacturing.

0 notes

Text

How Sponge Iron is Produced: From Raw Materials to Finished Product

Sponge iron, also known as Direct Reduced Iron (DRI), is a crucial material in the steelmaking process. It's an essential ingredient for producing the best quality TMT bars in India. This blog delves into the production process of sponge iron, starting from raw materials and concluding with a high-quality finished product, essential for crafting pure iron ore TMT bars in India.

1. Raw Materials: The Foundation of Sponge Iron Production

The journey of producing sponge iron begins with the careful selection of raw materials. Hematite iron ore is typically 5 to 18 millimeters and is the primary ingredient. This high-quality iron ore is rich in iron content and low in impurities, making it ideal for producing sponge iron. Non-coking coal is also used in the process, acting as both a fuel and a reducing agent.

The choice of raw materials is vital, as it directly impacts the quality of the sponge iron and the TMT bars produced. High-grade sponge iron is essential for manufacturing pure iron ore TMT bars in India, known for their exceptional strength and durability.

2. Direct Reduction Process: Transforming Ore into Iron

At the sponge iron production is the Direct Reduction Process. In this process, iron ore is subjected to high temperatures in a rotary kiln, typically ranging from 850°C to 1,500°C. The iron ore undergoes a series of chemical reactions, which gradually reduce it to metallic iron. These key reactions are:

3Fe₂O₃ + CO → 2Fe₃O₄ + CO₂

Fe₃O₄ + CO → 3FeO + CO₂

FeO + CO → Fe + CO₂

These reactions remove the oxygen from the iron ore, leaving behind high-purity sponge iron. The precision in this process ensures that the sponge iron produced is consistent in quality, with minimal impurities. This is crucial for creating the best quality TMT bars in India.

3. Cooling and Separation: Preparing Sponge Iron for Use

After the reduction process is complete, the sponge iron is cooled in a rotary cooler to prevent oxidation and preserve its quality. The cooled sponge iron is then separated from the residual coal char, ensuring a pure and consistent product.

This high-purity sponge iron is essential for producing pure iron ore TMT bars in India. The consistent quality of these TMT bars is what sets them apart, making them a preferred choice for construction projects that demand good quality and the best price.

4. From Sponge Iron to Finished Steel Products

Sponge iron is a vital raw material in steelmaking, particularly in Electric Arc Furnaces (EAFs). The high iron content and low levels of impurities ensure that the steel produced is of exceptional quality. This steel is then cast into billets and rolled into TMT bars.

For those looking for good quality and the best price, TMT bars made from pure iron ore and high-quality sponge iron offer an unbeatable combination of strength, durability, and affordability. These TMT bars are widely regarded as some of the best quality TMT bars in India, making them a top choice for construction.

The Journey of Sponge Iron to TMT Bars

The production of sponge iron is a meticulous process that begins with the selection of high-quality raw materials and ends with a finished product that is essential for making pure iron ore TMT bars in India. These TMT bars are known for their strength, consistency, and affordability, offering good quality and the best price to meet the demands of modern construction.

Understanding the transformation of sponge iron from raw materials to finished products gives insight into how some of the best quality TMT bars in India are crafted, ensuring they meet the highest standards of quality and performance.

0 notes

Text

Forging the Future: Sustainable Practices in Steel Production"

Welcome to another edition of “Steelon Call,” where we explore the cutting edge of steel technology and innovation. Today, we’re focusing on a crucial aspect of modern steel production: sustainability. As the world faces increasing environmental challenges, the steel industry is at the forefront of efforts to reduce its carbon footprint and embrace greener practices. Join us as we delve into how the steel industry is forging a path toward a more sustainable future.

1. The Environmental Challenge

Steel production is energy-intensive and traditionally associated with high carbon emissions. Conventional methods, such as the blast furnace process, rely on coke (a coal derivative) to produce steel, resulting in significant greenhouse gas emissions. With global concerns about climate change and resource depletion, there is an urgent need for the steel industry to adopt more sustainable practices.

2. Green Steel Technologies: Revolutionizing Production

Hydrogen-Based Reduction:

One of the most promising advancements in sustainable steel production is hydrogen-based reduction. This technology uses hydrogen instead of coke to reduce iron ore into steel. The process, known as Direct Reduced Iron (DRI) with hydrogen, emits water vapor instead of carbon dioxide, drastically reducing greenhouse gas emissions. Companies like SSAB and ArcelorMittal are leading the way in developing and implementing this technology, aiming to achieve near-zero emissions in their production processes.

Electric Arc Furnaces (EAFs):

Electric Arc Furnaces represent another significant shift towards greener steel production. Unlike traditional blast furnaces, EAFs use electricity to melt scrap steel, making them more energy-efficient and capable of using renewable energy sources. The EAF process produces fewer emissions and is more adaptable to integrating recycled steel, reducing the need for virgin ore and decreasing overall environmental impact.

3. Recycling and Circular Economy

Enhanced Recycling Processes:

Recycling plays a critical role in sustainable steel production. Steel is one of the most recycled materials globally, with around 90% of steel scrap being reused in production. Advances in recycling technology have improved the efficiency of scrap metal collection, sorting, and processing. By increasing the use of recycled steel, the industry can reduce the need for raw materials and lower the energy required for production.

Circular Economy Initiatives:

The concept of a circular economy is gaining traction within the steel industry. This approach focuses on minimizing waste by keeping materials in use for as long as possible. Steel producers are exploring ways to design products for easier disassembly and recycling, and developing closed-loop systems where steel products are continually reused and repurposed. Such practices not only conserve resources but also reduce the environmental impact associated with steel production.

4. Energy Efficiency and Carbon Footprint Reduction

Renewable Energy Integration:

Integrating renewable energy sources into steel production is another key strategy for reducing carbon emissions. Steelmakers are investing in wind, solar, and hydroelectric power to offset the energy used in production. By transitioning to clean energy sources, steel producers can significantly lower their carbon footprint and contribute to global sustainability goals.

Energy Efficiency Improvements:

Ongoing efforts to improve energy efficiency within steel plants include optimizing process technologies, enhancing heat recovery systems, and implementing advanced automation. These improvements help reduce energy consumption and emissions, making steel production more environmentally friendly. Innovations such as waste heat recovery systems capture and reuse excess heat from production processes, further enhancing overall energy efficiency.

5. Future Trends and Innovations

Carbon Capture and Storage (CCS):

Carbon Capture and Storage (CCS) technology is emerging as a potential solution for mitigating emissions from steel production. CCS involves capturing carbon dioxide from industrial processes and storing it underground or using it in other applications. While still in the early stages of implementation, CCS holds promise for reducing the carbon footprint of traditional steelmaking methods.

Sustainable Supply Chains:

The push towards sustainability extends beyond production to the entire steel supply chain. Steel producers are increasingly focusing on responsible sourcing of raw materials, reducing transportation emissions, and ensuring ethical practices throughout their supply chains. This holistic approach helps create a more sustainable industry overall.

Conclusion

The steel industry is undergoing a transformative shift towards sustainability, driven by innovations in production technology, recycling, energy efficiency, and supply chain management. As we forge ahead, these advancements are crucial for meeting global environmental goals and ensuring that steel remains a vital and responsible material for future generations.

At “Steelon Call,” we’re committed to keeping you informed about the latest developments in sustainable steel practices. Stay tuned as we continue to explore how the steel industry is embracing change and forging a path to a greener, more sustainable future.

1 note

·

View note

Text

Heavy Steel Recycling in Lonsdale: A Sustainable Approach to Managing Industrial Waste

Heavy steel recycling is a critical component of industrial waste management and environmental sustainability. In Lonsdale, a suburb of Adelaide known for its industrial activity, recycling heavy steel plays a vital role in reducing waste, conserving resources, and minimizing environmental impact. This blog explores the importance of heavy steel recycling, the process involved, and the benefits it offers to both the local community and the environment.

Why Heavy Steel Recycling Is Important

Heavy steel, which includes materials such as structural beams, machinery parts, and industrial equipment, is commonly used in various industrial applications. Recycling this steel is crucial for several reasons:

Resource Conservation

Steel is a valuable resource, and recycling helps conserve it. By reprocessing scrap steel, we reduce the need for new steel production, which involves extracting and processing raw iron ore. This conserves natural resources and reduces the environmental impact of mining.

Energy Efficiency

Recycling steel requires significantly less energy compared to producing new steel from raw materials. This energy savings translates into reduced greenhouse gas emissions and a smaller carbon footprint.

Waste Reduction

Recycling heavy steel helps reduce the volume of waste sent to landfills. Steel is highly durable and can be recycled repeatedly without losing its properties, making it an ideal material for recycling.

Economic Benefits

The steel recycling industry creates jobs and supports local economies. Recycling facilities in Lonsdale contribute to economic growth by processing scrap steel and supplying recycled materials to various industries.

Environmental Protection

Proper recycling of heavy steel helps prevent pollution and environmental degradation. It reduces the risk of hazardous substances contaminating soil and water, ensuring a cleaner and healthier environment.

The Heavy Steel Recycling Process

In Lonsdale, the recycling process for heavy steel involves several key steps:

Collection

Heavy steel scrap is collected from various sources, including construction sites, industrial facilities, and demolition projects. Efficient collection systems ensure that large volumes of steel are gathered for recycling.

Sorting and Preparation

Once collected, the steel scrap is sorted to remove non-metallic materials and contaminants. This step ensures that only clean, high-quality steel is processed. The scrap is then prepared for processing, which may involve cutting or shredding to reduce its size.

Shredding and Grinding

The prepared steel scrap is shredded into smaller pieces or ground into finer fragments. This step facilitates the melting process and ensures a uniform feed for the recycling furnace.

Melting

The shredded steel is melted in an electric arc furnace (EAF) or a blast furnace. The EAF is commonly used for recycling steel, as it provides a more energy-efficient and controlled environment for melting.

Refining and Alloying

The molten steel is refined to remove impurities and adjust its composition. Alloying elements may be added to produce steel with specific properties or meet industry standards.

Casting and Cooling

The refined molten steel is cast into various shapes, such as billets, blooms, or slabs. These shapes are then cooled and solidified for further processing.

Reprocessing

The cast steel is processed into finished products or components, ready for use in construction, manufacturing, or other applications. This closed-loop recycling process ensures that steel is continually reused and recycled.

0 notes

Text

The Role of Steel Manufacturers in Building a Sustainable Future

Steel is one of the most versatile and essential materials in modern construction, playing a critical role in the development of infrastructure around the world. From towering skyscrapers to bridges, railways, and homes, steel's strength, durability, and adaptability make it indispensable. As a key player in the construction industry, the manufacturer of steel has a profound impact on both the economy and the environment. This blog will explore the significance of steel manufacturing, the processes involved, and how leading manufacturers like Primegold International Limited are contributing to a sustainable future.

Understanding the Importance of Steel in Construction

Steel is celebrated for its exceptional properties, including high tensile strength, flexibility, and resistance to corrosion. These attributes make it a material of choice for a wide range of applications in construction, automotive, and industrial sectors. As urbanization and development continue to accelerate globally, the demand for high-quality steel has never been greater.

The manufacturer of steel is responsible for producing this critical material in various forms, such as TMT bars, structural steel, and sheets, which are essential for different construction purposes. TMT bars, for instance, are widely used in reinforced concrete structures due to their superior strength and ability to withstand seismic forces.

The Steel Manufacturing Process

Steel manufacturing is a complex process that involves several stages, each of which contributes to the final quality of the product. Here’s a brief overview of the process:

1. Raw Material Selection: The first step in steel manufacturing is the selection of raw materials. Iron ore, coal, and limestone are the primary materials used in the production of steel. The quality of these raw materials directly influences the properties of the final steel product.

2. Ironmaking: In this stage, iron ore is converted into molten iron in a blast furnace. The iron is then separated from impurities through a process known as smelting, where the raw materials are heated to high temperatures.

3. Steelmaking: The molten iron is then transferred to a steelmaking furnace, where it is combined with scrap steel and other alloying elements. This mixture undergoes further refinement to produce the desired grade of steel. The two primary methods of steelmaking are the Basic Oxygen Furnace (BOF) and the Electric Arc Furnace (EAF).

4. Casting: Once the steel is produced, it is cast into various shapes, such as billets, slabs, or blooms. These cast forms are then further processed to produce finished steel products like TMT bars, pipes, and sheets.

5. Rolling and Finishing: The final stage involves rolling the cast steel into the required thickness and shape. The steel is then treated to enhance its properties, such as strength and corrosion resistance, before being cut and prepared for distribution.

The Role of Steel Manufacturers in Sustainable Development

As the demand for steel continues to rise, the role of the manufacturer of steel in promoting sustainability has become increasingly important. The steel industry is traditionally energy-intensive and has a significant environmental footprint. However, leading manufacturers like Primegold International Limited are adopting innovative practices to reduce their environmental impact and contribute to a sustainable future.

1. Energy Efficiency: One of the key ways steel manufacturers are promoting sustainability is by improving energy efficiency in the production process. By investing in advanced technologies and optimizing production methods, manufacturers can reduce energy consumption and lower greenhouse gas emissions.

2. Recycling and Waste Reduction: Steel is one of the most recyclable materials, and modern steelmaking processes often incorporate a significant proportion of recycled steel. This not only conserves natural resources but also reduces the amount of waste generated by the industry. Leading manufacturers are also focusing on minimizing waste at every stage of production, from raw material sourcing to finished product distribution.

3. Sustainable Sourcing: Responsible sourcing of raw materials is another crucial aspect of sustainable steel manufacturing. By ensuring that raw materials are obtained from environmentally and socially responsible sources, manufacturers can reduce their impact on ecosystems and local communities.

4. Innovation in Product Design: Steel manufacturers are also contributing to sustainability by innovating in product design. By developing high-strength, lightweight steel products, manufacturers can reduce the amount of material required in construction, leading to lower overall resource consumption. These innovations also contribute to more energy-efficient buildings and infrastructure.

5. Commitment to Quality: Sustainable development is not just about environmental responsibility; it also involves ensuring that steel products meet the highest standards of quality and durability. High-quality steel products have a longer lifespan, reducing the need for frequent replacements and contributing to resource conservation.

The Future of Steel Manufacturing

The future of steel manufacturing lies in continued innovation and a commitment to sustainability. As global challenges such as climate change and resource depletion become more pressing, the steel industry must evolve to meet these demands. Manufacturers like Primegold International Limited are leading the way by embracing sustainable practices and setting new standards for the industry.

In conclusion, the manufacturer of steel plays a pivotal role in shaping the future of construction and infrastructure. By adopting sustainable practices, investing in innovation, and maintaining a commitment to quality, steel manufacturers can help build a more resilient and sustainable world. As we look to the future, the importance of responsible steel manufacturing will only continue to grow, making it essential for the industry to lead by example in the pursuit of sustainability.

0 notes

Text

0 notes

Text

Stainless Steel Recycling: Methods, Benefits, and Industrial Solutions

Stainless metal recycling is a important difficulty of sustainable commercial practices and environment stewardship. As industries and clients are trying to find methods to lessen waste and enhance the circular financial machine, stainless-steel recycling stands out as a key answer. Vardhaman Ferro Alloys, a leading name within the enterprise, gives whole insights into the strategies, advantages, and industrial solutions related to stainless-steel recycling. In this blog, we’ll discover how recycling stainless-steel can contribute to sustainability and financial overall performance, collectively with the placement of scrap companies and pricing within the recycling technique.

Methods of Stainless Steel Recycling

Collection and Sorting:

The first step in stainless steel recycling involves the gathering and sorting of scrap stainless steel. This scrap can come from numerous belongings, which consist of manufacturing procedures, antique home equipment, and production substances. Efficient sorting is crucial because it guarantees that the price for scrap stainless steel is separated from distinct metals and contaminants, facilitating a smoother recycling procedure.

Shredding and Size Reduction:

After sorting, the stainless-steel scrap supplier is shredded into smaller quantities. This length bargain makes it plenty less hard to deal with and method in subsequent stages. Shredding also increases the ground area of the metallic, which permits in carrying out a greater uniform softening at some stage in the recycling phase.

Melting and Refining:

The shredded stainless-steel is then melted in electric arc furnaces (EAF) or induction furnaces. The melting device entails heating the metallic to immoderate temperatures to advantage a liquid united states. During refining, impurities are removed, and alloying elements are added to accumulate the favored composition. This step is important in making sure that the recycled stainless steel meets the excellent requirements required for reuse in new products.

Casting and Forming:

Once sensitive, the molten chrome steel is cast into numerous shapes along with ingots, billets, or slabs. These solid merchandise are then in addition processed into completed items via strategies like rolling, forging, or extrusion. The resulting stainless-steel merchandise are ready for use in diverse applications, collectively with manufacturing, automobile, and customer gadgets.

Quality Control and Testing:

Recycled chrome steel undergoes rigorous terrific management and checking to make certain it meets industry requirements. This consists of checking the chemical composition, mechanical properties, and normal integrity of the metal. Quality guarantee is critical to make sure that recycled stainless steel plays comparably to virgin stainless-steel in cease-use programs.

Benefits of Stainless Steel Recycling

Environmental Impact:

Recycling stainless-steel considerably reduces the want for uncooked fabric extraction and minimizes environmental pollution. By recycling, we keep natural sources, lessen energy consumption, and decrease greenhouse gasoline emissions. Stainless metallic is inherently recyclable, making it a green preference for sustainable commercial enterprise practices.

Energy Efficiency:

The recycling technique makes use of less electricity in comparison to producing stainless-steel from raw substances. Melting scrap stainless steel requires notably an awful lot much less electricity than the producing of the latest stainless steel from ore. This cut price in power consumption results in decreased operational prices and reduced carbon footprint.

Economic Advantages:

Stainless steel recycling is economically useful because it reduces the charge of raw substances. The availability of recycled chrome steel often results in lower costs in assessment of virgin stainless-steel. For agencies, this translates into value monetary savings and superior profitability. Additionally, the recycling enterprise creates task opportunities and allows economic growth.

Resource Conservation:

Recycling allows preserving treasured natural property via reusing gift substances. Stainless metal is durable and lengthy-lasting, and recycling extends its lifecycle. This technique supports a circular economic system in which materials are continuously reused and recycled, decreasing waste and promoting sustainability.

Reduced Landfill Waste:

Recycling stainless-steel permits lessen the amount of waste sent to landfills. By diverting scrap stainless-steel from landfills, we decrease environmental impact and reduce the stress on waste manipulate structures.

Industrial Solutions and Vardhaman Ferro Alloys

Our company plays a critical feature inside the chrome steel recycling company with the aid of the use of performing as a dependable scrap issuer. Our determination to be satisfactory and sustainable ensures that we offer high-quality scrap stainless steel to numerous industries. As a major scrap dealer, we facilitate the recycling technique with the aid of offering aggressive charges for scrap stainless steel and ensuring a regular supply of recyclable material.

Key Services Offered:

Scrap Stainless Steel Supply: We offer various chrome steel scrap types appropriate for recycling, along with 304, 316, and special grades.

Competitive Pricing: Our pricing for scrap stainless-steel is aggressive and displays current marketplace conditions, offering rate for each provider and customers.

Efficient Logistics: We make sure properly timed series and shipping of stainless steel scrap, assisting easy operations and lowering downtime for recycling centers.

Conclusion

Stainless steel recycling is a crucial issue of sustainable organization practices, presenting several advantages for the surroundings and the financial machine. By know-how the techniques and benefits of recycling, organizations and clients could make knowledgeable choices that make a contribution to a more sustainable destiny. Vardhaman Ferro Alloys is dedicated to assisting the recycling industry with first-rate scrap chrome steel and aggressive pricing, riding ahead the spherical monetary device and promoting beneficial resource conservation.

0 notes

Text

Innovations in Metal Processing: A Glimpse into Tomorrow’s Techniques

The metal processing industry is on the cusp of a transformation driven by technological advancements. These innovations are not just refining existing practices but are paving the way for a future where efficiency, sustainability, and precision define manufacturing processes. Below, we explore the key innovations set to redefine metal processing.

The Advent of AI and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are revolutionizing metal processing by:

Predicting Outcomes: Analyzing vast datasets to predict machinery maintenance needs and optimize production processes.

Automating Decision-Making: Enabling real-time adjustments in manufacturing operations, thereby increasing efficiency and product quality.

Enhancing Equipment Performance: Predictive maintenance schedules minimize downtime, while ML algorithms adapt cutting speeds to ensure optimal performance.

Sustainable Manufacturing Practices

Sustainability is becoming integral to metal processing, with innovations aimed at:

Recycling: Utilizing electric arc furnaces (EAF) to recycle scrap metal, reducing reliance on virgin materials and lowering carbon emissions.

Reducing Waste: Advancements in chemical milling and waterjet cutting minimize hazardous waste and water usage.

Developing Sustainable Materials: Innovating eco-friendlier materials and coatings to ensure high-quality manufacturing that is better for the environment.

The Development of New Alloys

The creation of new alloys is key to advancing metal processing, featuring:

Stronger Materials: Computational models and high-throughput experimentation are leading to alloys that are stronger, lighter, and more corrosion-resistant.

Tailored Properties: High-entropy alloys (HEAs) offer a combination of strength, ductility, and resistance to wear and corrosion, outperforming traditional alloys.

Industry-specific Applications: Alloys designed for specific industries, enhancing safety, efficiency, and sustainability in aerospace, automotive, and construction.

The Role of 3D Printing in Metal Fabrication

3D printing is reshaping metal fabrication by:

Enabling Complex Designs: Allowing for the creation of structures that are impossible with traditional methods.

Promoting On-demand Production: Reducing inventory costs and waste with the flexibility of additive manufacturing.

Extending Product Lifecycle: Offering new possibilities for part repair and refurbishment, contributing to sustainability.

Advanced Robotics and Automation

Robotics and automation are reaching new sophistication levels in metal processing through:

Adaptable Robots: Capable of performing complex tasks with high precision alongside human workers.

Collaborative Robots (Cobots): Enhancing safety and efficiency without replacing the workforce.

Integrated Technologies: Combining advanced sensing technologies and IoT connectivity for real-time monitoring and control.

Conclusion

The path forward for metal processing is illuminated by these technological innovations, promising a future of enhanced efficiency, product quality, and environmental stewardship. For companies like Quick Metals, embracing these advancements is essential for staying competitive and contributing to a sustainable manufacturing future. As we embark on this exciting journey, the potential for transformation in metal processing is boundless, offering a glimpse into a future where innovation leads the way.

Original content: https://quickmetals.com/innovations-in-metal-processing-a-glimpse-into-tomorrows-techniques/

#Metal processing innovations#Advanced Metal Techniques#Cutting-Edge Metal Technologies#Metal Recycling Cincinnati

1 note

·

View note

Text

A516 Grade 60 Steel Plates Dealers in India

Introduction:-

Vandan Steel & Engg. co. is one of the trustworthy and prominent exporter and supplier of SA 516 GR.60 plates that are comprehensively used in a total extent of organizations on account of its unimaginable mechanical properties and features. This assessment of plates is available in a combination of sizes, shapes, structures, and points of interest recollecting the necessities of customers.

Being an assumed association, we are totally busy with giving all of our customers splendid thing not in the private country yet in various countries too. The plates are used in a wide extent of usages both in the mechanical and business region.

Product Overview:-

We, before giving these A516 GR.60 Steel plates to the customers, guarantee that all of the things are without disfigurement and offer the best execution under the specific domains of working. These plates are generally used in weight vessels as they can easily oversee high temperature and weight without getting hurt.

The steel assessment is used for moderate to cut down temperature working and is used for the formation of weldable business and present day steel weight vessels and boilers. It is on a very basic level institutionalized steel that is known for its weldability and sublime indent toughness. It is basically used in the pressurized organizations in petrochemical and oil and gas industry.

Specifications:-

Width1000mm-4500mmThickness5mm-150mmLength3000mm-18000mmSupply ConditionAs Rolled, Normalized Rolling, Furnace Normalizing, Vacuum Degassing, Simulated Post-Weld Heat Treatment or as per customer requirementImpact tested -52° CTemperingNotch toughness can be improved by quenched cooling from hot rolling or normalizing by the supplier. If such a faster cooling rate is agreed upon between purchaser and supplier then the steel is also to be tempered at 1200 F.Applications Used for weld fabrication of pressure vessels that require improved notch toughness for lower than ambient temperature service.

Benefits:-

When selecting A516 Grade 60 plates, it’s important to consider specific requirements such as temperature range, pressure conditions, and compliance with industry standards to ensure optimal performance and safety in service.

Conclusions:-

Before amassing these steel plates, there are two principal techniques done as such as to make the rough steel into high gauge and useable structure that is (BF) or basic oxygen radiator and (EAF) or an electric bend warmer. These two methods help in making high gauge of steel which can be used for making steel plates. Close by this, these plates are encircled using high gauge of rough material that is purchased from the strong market merchants. The rough material is particularly evaluated and attempted by the quality examiners that guarantee every material is of high bore and will give its best under the individual domains of working

Contact :-+91-8828813630

Mail Id- [email protected]

0 notes

Text

Steel Plate Prices Trend | Pricing | Database | News | Index | Chart

Steel Plate prices have experienced significant fluctuations over the past few years, influenced by a variety of factors that include global economic conditions, supply chain disruptions, and changes in demand from key industries. The cost of steel plates is primarily driven by the prices of raw materials like iron ore and coal, as well as energy costs, which are essential for steel production. When these input costs rise, steel manufacturers often pass the increased expenses on to their customers, leading to higher prices for steel plates. Additionally, geopolitical tensions and trade policies, such as tariffs and import restrictions, can create imbalances in supply and demand, further impacting prices.

During the early stages of the pandemic, steel production slowed significantly due to lockdowns and reduced industrial activity. This reduction in supply was met with a simultaneous decline in demand, particularly from sectors such as automotive and construction, which saw project delays and cancellations. However, as economies began to recover, the demand for steel surged, particularly driven by infrastructure projects and a rebound in manufacturing. This sudden increase in demand, coupled with the lingering effects of earlier supply disruptions, resulted in a sharp rise in steel plate prices.

Another critical factor influencing steel plate prices is the state of the global supply chain. The steel industry is heavily reliant on a complex network of suppliers and distributors. Any disruption in this chain, whether due to logistical challenges, political instability, or natural disasters, can lead to supply shortages and price volatility.

Get Real Time Prices of teel Plate: https://www.chemanalyst.com/Pricing-data/steel-plate-1439

The steel industry also faces environmental regulations and sustainability goals that impact production costs. Many countries are imposing stricter emission standards and encouraging the use of green technologies in steel manufacturing. While these measures are essential for reducing the industry's carbon footprint, they often require significant investment in new technologies and processes. These additional costs can contribute to higher steel plate prices. Companies that are proactive in adopting sustainable practices might incur higher initial costs, but they could benefit from long-term savings and regulatory incentives.

Technological advancements and innovations in steel production methods also play a role in pricing. Techniques such as electric arc furnace (EAF) production, which is more energy-efficient and environmentally friendly than traditional blast furnace methods, are becoming more prevalent. However, transitioning to new technologies requires substantial capital investment, which can initially drive up costs. Over time, these advancements are expected to lead to more stable and possibly lower prices as efficiencies are realized and production scales up.

Market speculation and financial markets can also affect steel plate prices. Commodities, including steel, are often traded on futures markets where prices can be influenced by traders' perceptions and market sentiments. When there is optimism about economic growth and industrial activity, prices can rise in anticipation of higher future demand. Conversely, fears of economic slowdown or recession can lead to price drops. Investors and speculators closely monitor indicators such as construction activity, manufacturing indices, and government infrastructure spending plans to gauge future demand for steel.

The role of major steel-producing countries cannot be overlooked when discussing steel plate prices. China, being the largest producer and consumer of steel, has a profound impact on global prices. Policies implemented by the Chinese government, such as production caps to curb pollution or efforts to balance domestic supply and demand, can have immediate and far-reaching effects on the market. Similarly, production trends in other leading steel-producing countries like India, Japan, and the United States also influence global prices. These countries' capacity to ramp up or scale down production in response to market conditions helps determine the overall supply balance.

In conclusion, the pricing of steel plates is influenced by a myriad of interconnected factors ranging from raw material costs and supply chain dynamics to technological advancements and global economic conditions. Understanding these factors provides insight into the complexities of the steel market and helps businesses and investors make informed decisions. As the world continues to navigate economic recovery and strives towards sustainable industrial practices, the steel industry will remain a critical barometer of broader economic health and a focal point for policy and investment strategies.

Get Real Time Prices of teel Plate: https://www.chemanalyst.com/Pricing-data/steel-plate-1439

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Steel Plate#Steel Plate Price#Steel Plate Prices#Steel Plate Pricing#Steel Plate News#Steel Plate Price Monitor#Steel Plate Database

0 notes