#Tundish

Text

What are the measures to improve the purity of continuous casting steel

Purity refers to the quantity, shape and distribution of non-metallic inclusions in steel. The inclusion in steel shall be reduced to the required level according to the steel grade and product quality,

We should start from the following five aspects:

① Reduce [O] content in steel as much as possible.

② Prevent the molten steel from interacting with air.

③ Reduce the interaction between molten steel and refractory materials.

④ Reduce slag entrainment in molten steel.

⑤ The improved flow promotes the floating of inclusions in molten steel.

In terms of process operation, the following measures shall be taken:

(1) Slag free tapping: slag retaining balls are adopted for the converter and eccentric bottom tapping is adopted for the electric furnace to prevent a large amount of slag from falling into the ladle.

(2) Ladle refining: select the appropriate refining method according to the steel grade, to uniform the temperature, fine tune the composition, reduce the oxygen content, remove gas inclusions, etc.

(3) Non oxidation casting: after the molten steel is treated by ladle, the total oxygen content in the steel can be reduced from 130ppm to below 20ppm. If the injection flow from ladle to tundish is not protected or poorly protected, the total oxygen content in tundish steel will rise to the range of 60-100ppm, which will return to the level before external refining, and the effect of external refining will be wasted.

(4) Tundish metallurgy: the tundish adopts large capacity, and the addition of retaining walls and dams is an effective measure to promote the floating of inclusions. For example, for 6T tundish, the scrap rate of slab inclusion is 12%, and the inclusion is 0.82 pieces / m2; 12t tundish + retaining wall, 0 scrap inclusion in slab, 0.04 inclusions / m2.

(5) Submerged nozzle + casting mold powder: the mold powder shall be able to fully absorb inclusions. The submerged entry nozzle material, nozzle shape and insertion depth shall be favorable for the floating and separation of inclusions.

We Changxing Refractory Material Co.,LTD is professional manufacturer and supplier of refractory materials for more than 30 years. Our high quality casting powder are good sold to many countries say South Africa, Bangladesh, Indonesia, Malaysia, etc.

Article Source: improve the purity of continuous casting steel

Company name: Henan Changxing Refractory Materials Co.,Ltd

More refractory products:https://www.cxrefractories.com/en-product-solution

Email:[email protected]

Website:https://www.cxrefractories.com

0 notes

Link

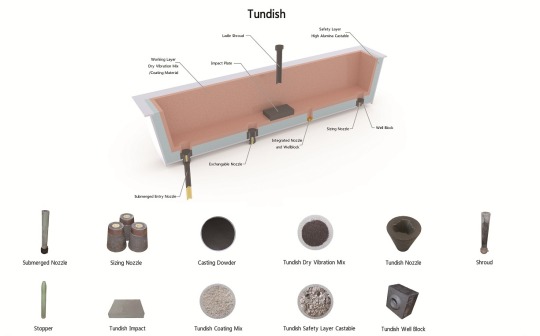

Tundish Dry Vibration Mix

Dry vibration mix for tundish refractories is made through special grinding, screening, mixing, pressurizing, drying and other processes, and is an indispensable material in the steelmaking process.

Source:

http://www.cxfirebrick.com/en/product/dry-vibration-mix.html

Email: [email protected]

0 notes

Text

no wait the best part is the tundish bit. Stephen meets an English priest trying to light a fire and says ‘use the tundish’ and the priest isn’t familiar with that word. A good young identitarian Stephen gets very excited that he knows the word but the priest doesn’t—-it must be an Irish word! and then in the journal part at the end in another throwaway line Stephen apparently looked it up and no, tundish is English, the guy just didn’t know the word. Disappointing

3 notes

·

View notes

Text

Dry Ramming Mass Market worth $3.2 billion by 2028

The report "Dry Ramming Mass Market by Type (Alumina Ramming Mass, Silica Ramming Mass, Magnesia Based Ramming Mass), Application (Foundries, Steel, Electric Arc Furnace, Blast Furnace, Non-Steel), Function, and Region - Global Forecast to 2028", is projected to reach USD 3.2 billion by 2028, at a CAGR of 6.8% from USD 2.3 billion in 2023.

The growth of the dry ramming mass market is primarily driven by global expansion of the steel industry, enhanced cost and operational efficiency coupled with ongoing technological advancements in dry ramming mass, further contributing to its expansion. Dry ramming mass is a refractory material used in the lining of induction furnaces, ladles, and other high-temperature applications. It is a mix of refractory aggregates and binders.

Download pdf-https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=252792065

“Steel by application is projected to be the largest, in terms of value, during the forecast period.”

In the steel industry, dry ramming mass plays a crucial role. It finds diverse applications in various steelmaking processes, including lining ladles for the transportation and pouring of molten steel, constructing covers for ladles to retain heat during transportation, lining tundishes for the temporary holding and distribution of molten metal during continuous casting, and providing refractory lining in reheat furnaces used to bring steel ingots or slabs to desired temperatures. Additionally, dry ramming mass is utilized in the lining of steel crucibles for smaller-scale alloy production, in pouring channels and troughs to guide molten steel from furnaces to molds, ensuring a controlled and smooth flow during casting processes. Furthermore, it contributes to the thermal stability and wear resistance of mixer furnaces employed in blending different grades of steel or alloys. The versatility of dry ramming mass makes it an integral component in enhancing the efficiency, durability, and quality of various steel manufacturing applications.

“Alumina ramming mass by type is projected to be the largest, in terms of value, during the forecast period.”

Alumina ramming mass stands out as a preferred choice in specific applications owing to its distinctive properties that confer several advantages over silica and magnesia-based ramming masses. Comprising primarily high-alumina aggregates, often exceeding 80% alumina content, it ensures excellent refractoriness and resistance to high temperatures. Notably, its commendable thermal shock resistance proves crucial in environments characterized by rapid temperature fluctuations, as commonly encountered in metal melting and casting processes. Well-suited for non-ferrous metal applications, particularly in the melting and holding of metals like aluminum and its alloys, alumina ramming mass boasts chemical inertness, preventing undesirable reactions with molten metals or slags and thereby ensuring the stability of the lining. The material's versatility extends to various non-ferrous metal melting processes, underlining its adaptability to diverse industrial applications. Further enhancing its utility, alumina ramming mass exhibits notable abrasion resistance, contributing to the longevity and durability of refractory linings within furnaces. The adaptability of alumina ramming mass to different furnace designs and operating conditions adds a layer of flexibility to its application, making it a versatile and reliable choice across a spectrum of industrial settings.

“Lining by function is projected to be the largest, in terms of value, during the forecast period.”

Refractory materials play a pivotal role in various industrial facets, primarily during the initial construction and installation of furnaces, kilns, and industrial equipment. The demand for extensive refractory linings in new facilities arises from the necessity to withstand elevated temperatures, corrosive environments, and mechanical stresses. Capitalizing on the long lifecycles of furnaces and industrial equipment, refractory linings endure for extended periods before necessitating significant repairs or replacements, fostering a continuous demand for lining materials. Industries prioritize preventive maintenance to proactively extend equipment lifespan, exemplified by regular inspections and repairs of refractory linings to avert costly downtime, ensuring efficient and safe operations. The critical role of refractory linings in preserving the integrity of industrial processes, and shielding against high temperatures, chemical reactions, and mechanical wear, maintains a consistent need for high-quality refractory materials in lining furnaces and various processing units. Their widespread applications across diverse industries such as steel, cement, glass, non-ferrous metals, and petrochemicals contribute to a substantial market for lining materials. Moreover, the construction of new facilities and the expansion of existing ones, propelled by global industrialization and development projects, propel the demand for refractory materials for lining applications. Continuous advancements in refractory technology, marked by the development of high-performance and specialized lining materials, further contribute to the sustained demand across various industries.

Sample Request- https://www.marketsandmarkets.com/requestsampleNew.asp?id=252792065

“Asia Pacific is expected to be the fastest growing market for dry ramming mass during the forecast period, in terms of value.”

The Asia Pacific region has become a focal point for the increased demand in refractory materials, particularly dry ramming mass, owing to a confluence of factors. Rapid industrialization in countries such as China, India, Japan, Thailand, Vietnam, Malaysia and Indonesia has spurred growth in steel, non-ferrous metals, and foundry industries, amplifying the need for reliable refractory solutions. China, as the world's largest steel producer, stands out as a major consumer of refractories, significantly driving the demand for dry ramming mass. The region's extensive construction and infrastructure projects, coupled with the establishment of new industrial facilities, further contribute to the escalating demand for refractory materials. Diverse manufacturing activities encompassing automotive, electronics, and heavy machinery production in the region intensify the reliance on furnaces and high-temperature equipment, necessitating steadfast refractory linings. The rise in non-ferrous metal production, including aluminum, copper, and zinc, underscores the critical role of dry ramming mass in the construction and maintenance of furnaces for these expanding industries. The energy and petrochemical sectors in countries like China and India are on the ascent, demanding refractory materials for furnaces and reactors, fostering sustained growth. Government initiatives supporting industrial growth and infrastructure development, coupled with a competitive manufacturing landscape featuring numerous refractory material suppliers, contribute to the robust market for dry ramming mass. Moreover, technological advancements in manufacturing processes enhance the quality and performance of refractory materials, driving the adoption of advanced dry ramming mass products across diverse industrial applications in the region.

Key Players

The key players in this market are Saint-Gobain (France), Dense Refractories Co., Ltd. (China), Imperial World Trade Private Limited (India), Vishva Vishal Refractory Limited (India), Refcast Corporation (India), Henan Xinmi Changxing Refractory Material Co., Ltd. (China), Casco Specialty Products, Inc. (US), Gita Refractories Private Limited (India), Shenghe Refractories (China), RHI Magnesita N.V. (Austria) etc.

0 notes

Text

Tundish Compound : Composition, Usage and Supplier

In the context of the steel production, the quality of the product and the production process itself is of high importance. This operation involves a tundish compound as one of the main parts in the process. For anyone operating in the steel industry, for example, realizing the need for the best tundish compound supplier is relatively easier. This is where Rescon India has positioned itself and can rightly claim to be the market leader at supplying the product in the country. In this write up, let us understand why Rescon India is the best source of tundish compounds that includes what tundish compounds are, composition and application of the compound.

Tundish Compound and Composition

Tundish compound is a narrow and specific material requirement, applied in the organization for steel production, particularly in the tundish- a crucial equipment in the continuous casting process. Tundish is a refining vessel that contains steel before it is poured into moulds and solidified into billets, blooms or slabs. The tundish compound also fulfill the function of protecting the tundish and the proper filtrate of molten steel in the production process. Tundish compounds are accommodated to be resistant to the severe conditions involving molten steel.

Refractory Materials: They can bear some heat and are critical for shielding the tundish from the hear of molten steel. Popular refractory materials are alumina, magnesia, and zirconia.

Binding Agents: These are used to bond the refractory materials in order to give a compound a structure. These can be of many types such as clays or organic binders.

Additives: Some additional materials are incorporated in to upgrade the tundish compound performance. These can enhance the compounds resistance to erosion, thermal shock and chemical actions on the molten steel.

Modifiers: It should be noted that the application of modifiers to the compound enables its visovereignty and the setting time to be optimised for use in the tundish.

Uses of Tundish Compound

Tundish compounds have various important functions in the process of steel production. First, they cover the outer surfaces of tundish to shield them from heat and chemical corrosion of molten steel, hence increasing the useful years of tundish without needing elaborate refurbishing. They also help in regulating the movement of molten steel, proper casting patterns, and improving the overall standard of the final products. In particular, compounds of tundish ensure heat-shielding that contributes to keeping the temperature of the steel up with less heat that could be lost. In some situations, they are applied to functions as the filler materials to eliminate the gap and defects existing in the tundish for the smooth flow of molten steel.

Why Rescon India is the Leading Supplier

1. Expertise and Experience

Rescon India has built a reputation for excellence in the steel industry through years of experience and expertise. Their deep understanding of the steelmaking process and the specific requirements of tundish compounds allows them to offer products that meet the highest standards. Their team of experts continuously researches and develops new formulations to improve the performance of their tundish compounds.

2. High-Quality Products

One of the key reasons Rescon India stands out is their commitment to quality. They use the finest raw materials and the latest technology in their manufacturing process. This ensures that their tundish compounds have the optimal composition for durability, performance, and cost-effectiveness. Their products are rigorously tested to ensure they can withstand the harsh conditions of molten steel.

3. Custom Solutions

Rescon India understands that every steel plant has unique requirements. They offer custom solutions tailored to meet the specific needs of their clients. Whether you need a tundish compound with special properties or a formulation that meets particular performance criteria, Rescon India can deliver a solution that fits your requirements.

4. Reliable Supply and Support

Timely delivery and reliable supply are crucial in the steel industry, where downtime can be costly. Rescon India has a robust supply chain and logistics system in place to ensure that their tundish compounds are delivered on time. They also offer excellent customer support, assisting clients with technical advice, troubleshooting, and any other needs related to their products.

5. Competitive Pricing

In addition to high quality, Rescon India offers competitive pricing. They understand the financial pressures in the steel industry and strive to provide cost-effective solutions without compromising on quality. Their pricing structure is designed to offer value for money, helping clients optimize their operational costs.

Research

Rescon India is all about innovation. Doing so, allows them to invest in R&D improving the tundish compounds all along. Their dedication to remaining at the forefront of industry development is what allows them to deliver products tailored towards ever-changing requirements in this sector.

7. Environmental Responsibility

All Rescon India also takes pride in keeping the environment green. Or they follow procedures that limit waste and the potential for environmental harm with their manufacturing processes. This is in line with the increasing attention to environmental concerns being placed on steel industry.

Conclusion

To sum it all up, Rescon India has emerged as one of the best and topmost tundish compound manufacturer in India owing to their proficiency, premium quality products & services for customized solutions backed by a guaranteed supply at competitive prices with an objective that caters towards innovation-driving through environmental responsibility

0 notes

Text

Acidic Ramming Mass Manufacturers And Suppliers In Rajasthan, India

Rajasthan, known for its rich mineral resources, is a hub for the production of high-quality refractory materials. Among these, acidic ramming mass stands out as a critical material used in various high-temperature applications, particularly in the steel industry. Raj Global Ramming Mass is a leading manufacturer and supplier of premium quality silica ramming mass in Rajasthan, India why Raj Global Ramming Mass is the preferred choice for many industries.

What is Acidic Ramming Mass?

Acidic ramming mass, also known as silica ramming mass, is a refractory material used primarily for lining induction furnaces. It is composed mainly of high-grade silica and is known for its excellent thermal properties and durability. The primary function of acidic ramming mass is to provide a robust and heat-resistant lining that can withstand the high temperatures and aggressive environment inside furnaces.

Key Types of Ramming Mass

1. Silica Ramming Mass: This is the most common type, made primarily from silica. It is ideal for lining induction furnaces due to its high thermal conductivity and resistance to thermal shocks.

2. Premix Ramming Mass: This variant includes a binder mixed with the silica, which helps in easy application and setting. It offers enhanced performance and a longer lining life.

Importance of Acidic Ramming Mass

1. Thermal Stability

Acidic ramming mass provides excellent thermal stability, which is crucial for maintaining the integrity of the furnace lining under extreme temperatures. This stability ensures that the furnace can operate efficiently without frequent shutdowns for repairs.

2. Enhanced Durability

The high-quality silica used in ramming mass offers superior resistance to wear and tear, extending the life of the furnace lining. This durability translates to reduced maintenance costs and improved operational efficiency.

3. Cost-Effectiveness

Using high-grade acidic ramming mass reduces the frequency of furnace relining, thereby saving costs associated with downtime and labor. It also ensures optimal furnace performance, leading to energy savings and higher productivity.

Applications of Silica Ramming Mass

Silica ramming mass is extensively used in various high-temperature applications, including:

Induction Furnaces: As the primary lining material, it provides a robust and heat-resistant barrier, ensuring efficient melting processes.

Ladle Linings: It helps maintain the temperature of molten metal during transportation and reduces contamination.

Tundishes: Used in continuous casting processes, silica ramming mass ensures smooth flow and maintains the quality of the molten metal.

Raj Global Ramming Mass: Your Trusted Partner

1. Premium Quality

Raj Global Ramming Mass is committed to delivering top-quality silica ramming mass. Our products are made from the finest raw materials, ensuring superior performance and durability. Each batch undergoes stringent quality checks to meet industry standards and exceed customer expectations.

2. Customized Solutions

We understand that every application has unique requirements. Raj Global Ramming Mass offers customized ramming mass solutions tailored to meet the specific needs of our clients. Whether you need standard silica ramming mass or premix variants, we have you covered.

3. Expert Support

Our team of experts is always available to provide technical support and guidance. From selecting the right product to installation and maintenance, Raj Global Ramming Mass ensures you get the most out of our refractory solutions.

4. Reliable Supply Chain

With a robust supply chain network, we ensure timely delivery of our products, no matter where you are located. Our efficient logistics and distribution system minimizes lead times, ensuring your operations run smoothly without interruptions.

Why Choose Raj Global Ramming Mass?

1. Industry Expertise: With years of experience in the refractory industry, Raj Global Ramming Mass has the knowledge and expertise to provide the best solutions for your needs.

2. Quality Assurance: We are dedicated to maintaining the highest standards of quality in our products. Our silica ramming mass is tested rigorously to ensure it meets the demanding requirements of high-temperature applications.

3. Customer Satisfaction: Our customer-centric approach ensures that we build lasting relationships with our clients. We prioritize customer satisfaction and strive to exceed expectations with every product we deliver.

Conclusion

Acidic ramming mass plays a vital role in the efficiency and longevity of high-temperature furnaces, particularly in the steel industry. As a leading manufacturer and supplier in Rajasthan, India, Raj Global Ramming Mass offers superior quality silica ramming mass and premix ramming mass tailored to meet the specific needs of our clients. By choosing Raj Global Ramming Mass, you are investing in reliability, durability, and exceptional performance for your industrial applications.

For more information about our products and services, or to place an order, contact Raj Global Ramming Mass today. Let us help you optimize your operations with our high-quality refractory solutions.

#acidic ramming mass#ramming mass#silica ramming mass#premix ramming mass#premixed ramming mass supplier#acidic ramming mass manufactures#ramming mass manufactures#silica ramming mass manufactures#white ramming mass manufacturer#silica ramming mass supplier

0 notes

Text

Revolutionizing High-Temperature Applications with Refshape Refractory Castables

Introduction:

In the realm of high-temperature applications, industries such as steel, petrochemical, and cement rely on advanced materials to withstand extreme conditions. Refractory castables have emerged as indispensable solutions for constructing durable linings in furnaces, kilns, and other thermal processing units. Among the innovative products making waves in this space is Refshape, a cutting-edge refractory castable brand that promises exceptional performance and longevity in the face of extreme heat.

Understanding Refractory Castables:

Refractory castables are versatile materials designed to form strong, heat-resistant linings when mixed with water and cast into shape. These linings provide crucial protection against thermal shocks, abrasion, and chemical erosion, ensuring the longevity and efficiency of high-temperature equipment.

The Unique Advantages of Refshape Refractory Castables:

High Thermal Stability:

Refshape refractory castables boast outstanding thermal stability, allowing them to maintain structural integrity even in the most demanding environments. This makes them ideal for applications where extreme heat fluctuations are common, such as in furnaces and kilns.

Exceptional Strength and Abrasion Resistance:

The unique formulation of Refshape castables results in superior strength and resistance to abrasion. This is crucial for industries where wear and tear are inevitable, ensuring a longer service life for the refractory linings.

Customized Formulations:

Refshape offers a range of formulations to cater to specific industry needs. Whether your application requires enhanced resistance to alkalis, acids, or aggressive slag, there's a Refshape castable tailored to meet your requirements.

Ease of Installation:

The castable nature of Refshape products simplifies the installation process, allowing for precise and efficient lining construction. This ease of application reduces downtime during installation and maintenance, contributing to overall operational efficiency.

Energy Efficiency:

Refshape refractory castables contribute to energy efficiency by providing excellent insulation properties. This helps in minimizing heat loss and improving the overall thermal efficiency of the high-temperature processes, translating into cost savings for the end user.

Applications of Refshape Refractory Castables:

Steel Industry:

Refshape castables find extensive use in the steel industry, particularly in the lining of ladles, tundishes, and other equipment exposed to molten metal.

Petrochemical Industry:

Refshape castables are essential in the construction and maintenance of reactors, crackers, and other high-temperature units within the petrochemical sector.

Cement Industry:

Cement kilns and rotary kilns benefit from Refshape castables, where their superior thermal stability ensures prolonged service life and reduced downtime.

Conclusion:

Refshape refractory castables have undoubtedly become a game-changer in the field of high-temperature applications. Their unique blend of thermal stability, strength, and ease of installation positions them as a reliable choice for industries seeking durability and efficiency in extreme heat environments. As technology continues to advance, Refshape remains at the forefront, pushing the boundaries of what is possible in the world of refractory materials. For those looking to enhance the performance and longevity of their high-temperature equipment, Refshape refractory castables stand as a testament to innovation and excellence.

0 notes

Text

LADLE PRE-HEATER

Preheaters are suitable for different types of gas or liquid fuels. Such as blast furnace gas, mixed gas, natural gas, propane, acetylene, etc. According to the combustion medium situation of the user, fuel parameters are provided by the user, and different forms of baking devices are designed to ensure the combustion effect.

APPLICATION

LADLE PREHEATER APPLICATION

Used for on line (off line) baking of steel (iron) ladle and continuous casting tundish, including fast or slow drying of newly built ladle and turnover ladle. Fast baking of online steel ladle or tundish. The baking temperature reaches around 1000 degrees.

CHARACTERISTICS

LADLE PREHEATER PERFORMANCE CHARACTERISTICS

The series of steel (iron) ladle baking machines produced by our factory are divided into two forms: vertical and horizontal. Vertical type is divided into online gantry type and offline flipping type, consisting of three parts: mechanical structure, ignition system, and control system.

0 notes

Text

What are the prominent problems in the tundish

At present, there are many problems in the tundish used in China, especially in the tundish used for billet caster.

The specific performance is as follows:

(1) The shape of tundish cavity is unreasonable. Due to the unreasonable shape of the inner cavity, the flow of molten steel in the tundish is unreasonable and the residence time is short, which can not purify the molten steel. The distance from the drop point of the large ladle injection into the tundish to the tundish nozzle is short, or the distance from each nozzle is too different; The volume at the drop point of the ladle is too small, resulting in serious steel slag mixing and lining scouring, affecting the service life of the tundish and polluting the molten steel.

(2) The capacity of tundish is small and the depth of molten pool is shallow, so it is not suitable for high-speed caster. The molten steel stays in the tundish for a short time, which makes it difficult to purify the molten steel and remove inclusions; It is difficult to maintain constant casting speed when changing the package; During pouring, the steel slag in the tundish is agitated seriously, which makes it difficult to float the inclusions and easy to enter the mold, especially when changing the tundish.

(3) The position of tundish nozzle clogging is not properly designed, especially the nozzle on both sides is too close to the two sides, which is easy to cause unsmooth pouring of the two side nozzles.

(4) The tundish nozzle control device is too thin and unreliable, which makes it difficult to accurately control the flow of molten steel, making it difficult to stabilize the liquid level of the mold and often causing out of control accidents.

(5) The large deformation of tundish and the problems of design and manufacturing accuracy result in insufficient centering accuracy of multiple water outlets.

(6) The lifting device of tundish is ineffective, and most of them can not be lifted, which brings difficulties to the continuous casting process and causes many defects of the slab.

(7) The distance from the bottom of tundish to the upper mouth of crystallizer is improperly selected. Most of the distance is too high, which makes it difficult to align the nozzle, and also makes the nozzle too long, which increases the refractory consumption per ton of steel nozzle.

(8) Insufficient attention has been paid to the quick change technology of submerged entry nozzle.

The above tundish can only be used at low casting speed, which is not suitable for the requirements of high casting speed. Modern tundish should not only adapt to the conditions of constant speed casting at high drawing speed, high steel throughput and strength, and intense agitation in the tundish, but also play the role of purifying molten steel and removing inclusions.

The specific measures adopted include:

(1) Optimize the shape of the inner cavity of the tundish, make the liquid steel flow reasonably in the tundish, expand the volume of the large ladle at the drop point of the tundish and optimize the distance from the drop point of the large ladle to each water inlet under the condition of adapting to the high pulling speed;

(2) Tundish with large capacity deep melting bath;

(3) Prevent deformation of tundish shell;

(4) Adopt firm and reliable tundish nozzle control device;

(5) Adopt reliable tundish lifting device under load;

(6) Optimize the distance from the tundish to the upper mouth of the crystallizer.

Article Source: What are the prominent problems in the tundish

Company name: Henan Changxing Refractory Materials Co.,Ltd

More refractory products:https://www.cxrefractories.com/en-product-solution

Email:[email protected]

Website:https://www.cxrefractories.com

0 notes

Text

Tundish Metering Nozzle

Tundish metering nozzle is composed of inner zirconia and outer high alumina, produced by reasonable size and high temperature sintering process. Tundish metering nozzle is one of the refractory materials used in billet continuous casting. It plays a role in controlling the flow of molten steel. ……

Source: http://www.cxfirebrick.com/en/product/metering-nozzle.html

View On WordPress

0 notes

Text

Holes - Slab defects

Defect name: Holes

Record No.: 1443

Type of defect (Internal/Surface): Internal, surface

Defect classification: Slab defects

Steel name: Steel

Steel composition in weight %: No data.

Note: For this study we only selected the steel charges which were cast into pipe billets Ø250mm respectively Ø270mm, using all steel grades (carbon, low-alloyed, respectively alloyed) used in making these two types of pipe billets.

The holes are cavities on the external surface or in the under-shell area of the billet at about some tenths of millimeters from the shell surface and they are presented in figure 1.

They have a diametre up to 3mm and a length (depth) that can reach 25 mm. As usually they contain CO, H2, Ar and most of all they are associated with the inclusions. In case that they are superficial and/or few, these are polished (ground). They are determined by: the insufficient deoxidation of steel (gases occurrence: hydrogen, nitrogen, oxygen), the quality and humidity of the casting powder, the quality and homogeneity of its distribution, the variation of the steel level in the mould and the humidity existence in the refractory clay work of the tundish.

Source.

1 note

·

View note

Text

T38 High Temperature

The T38 high accuracy double shear beam load cell is ideal for weighing in high temperature environments within Steel Plants and Foundries, for example ladle turret and ladle ferry scales, scrap buckets, roller tables, tundish cars, and silo/ hopper weighing systems. Read more

0 notes

Text

SAIL Bhilai Steel Plant (BSP) for achieving a record-breaking tundish sequence

Congratulations to SAIL Bhilai Steel Plant (BSP) for achieving a record-breaking tundish sequence (at SMS-2 Bloom Caster-5) of 22 heats and a casting duration of 24 hours and 35 minutes, with our specialised tundish refractories.

We are proud to be a part of this achievement and look forward to many more success stories.

0 notes

Text

Continuous Casting Machine Manufacturers: Turning Molten Metal into Usable Shapes

Have you ever wondered how metal objects, like car parts or pipes, are made with such precision and consistency? The answer lies in a fascinating process called continuous casting. Behind this process are the continuous casting machine manufacturers, the unsung heroes that enable the transformation of molten metal into various usable shapes. In this article, we'll take a journey through the world of continuous casting, breaking down the technology and its importance in a way that anyone can understand.

Understanding Continuous Casting

Imagine a river of molten metal flowing down a channel. Continuous casting is a method that takes this concept and applies it to the production of metal products. The process involves pouring liquid metal into a water-cooled mold, which then cools and solidifies the metal rapidly. The result? A solid metal shape that matches the desired product specifications.

The Role of Continuous Casting Machine Manufacturers

Continuous casting wouldn't be possible without the ingenious machines designed by continuous casting machine manufacturers. These machines consist of several components that work in harmony to create a seamless process:

Tundish: A vessel that holds the molten metal before it's poured into the mold.

Mold: The cavity into which the molten metal is poured, determining the shape of the final product.

Rollers: These help guide the solidifying metal and ensure it maintains its shape.

Water Cooling System: Essential for rapid cooling and solidification of the metal.

Cutting Mechanism: Once the metal is fully solidified, it's cut into desired lengths or shapes.

Why Continuous Casting Matters

Continuous casting has revolutionized the metal manufacturing industry in several ways:

Efficiency: Traditional methods involve casting individual pieces, which is time-consuming. Continuous casting streamlines the process, enabling faster production.

Consistency: The controlled environment of continuous casting ensures uniformity in the final products.

Reduced Waste: As the process is continuous, there's less material wasted in between casting individual pieces.

Cost-Effective: The efficiency and reduced waste translate into cost savings for manufacturers, which can potentially be passed on to consumers.

Frequently Asked Questions (FAQs)

What is continuous casting?

Continuous casting is a manufacturing process where molten metal is poured into a mold to create solid metal shapes.

Who are continuous casting machine manufacturers?

These are companies specializing in designing, building, and supplying the machines used for continuous casting.

How does continuous casting differ from traditional casting?

Traditional casting involves creating individual pieces, while continuous casting produces a continuous stream of uniform shapes.

What metals can be used in continuous casting?

A variety of metals including steel, aluminum, and copper can be processed using continuous casting.

What shapes can be produced through continuous casting?

Shapes range from simple bars and rods to more complex products like pipes and sheets.

Why is uniformity important in metal manufacturing?

Uniform products ensure consistent quality and performance in the end-use applications.

What advantages does continuous casting offer in terms of efficiency?

Continuous casting speeds up production compared to traditional methods, saving time and resources.

Is continuous casting environmentally friendly?

Yes, as it reduces waste and energy consumption compared to traditional casting.

Are there limitations to continuous casting?

Extremely intricate or customized shapes might still require other manufacturing methods.

How long does the continuous casting process take?

The process can vary depending on the metal being cast and the desired shape, but it's generally quicker than traditional methods.

What industries benefit from continuous casting?

Industries such as automotive, construction, and aerospace benefit from the consistent and cost-effective products of continuous casting.

Can small businesses adopt continuous casting?

Yes, continuous casting technology is adaptable to different scales of production.

Are there safety concerns with continuous casting?

Safety measures are in place to ensure the well-being of workers and the proper functioning of machines.

How does water cooling work in continuous casting?

Water cools the mold, solidifying the molten metal quickly and enabling its smooth progression through the process.

Can alloys be produced through continuous casting?

Yes, continuous casting can handle various alloy compositions.

Is there ongoing maintenance required for continuous casting machines?

Regular maintenance is essential to ensure the machines operate efficiently and produce quality products.

Are there any new advancements in continuous casting technology?

Advancements continue to be made in terms of machine design, automation, and energy efficiency.

What is the future of continuous casting?

The process is likely to become even more efficient, environmentally friendly, and adaptable to different materials.

Can continuous casting machines be customized?

Manufacturers often provide options for customization based on specific production needs.

Do continuous casting machines require specialized operators?

Trained operators are needed to monitor the process and address any issues that arise.

How has continuous casting contributed to sustainable manufacturing?

By reducing waste and energy consumption, continuous casting aligns with sustainable production practices.

Are there any limitations to the size of products produced by continuous casting?

The size is somewhat constrained by the machinery and mold design.

What is the significance of the tundish in continuous casting?

The tundish regulates the flow of molten metal into the mold, ensuring a continuous and controlled process.

Can continuous casting create finished products?

While it produces basic shapes, additional processes might be required to create fully finished products.

What other industries could benefit from a continuous manufacturing approach?

Industries like plastics and ceramics could explore similar continuous manufacturing methods for enhanced efficiency.

Conclusion

Continuous casting machine manufacturers play a pivotal role in shaping the metal manufacturing industry. Their innovative machines and technology bring efficiency, consistency, and cost-effectiveness to the production of a wide range of metal products. As the industry continues to evolve, continuous casting is likely to remain at the forefront of modern manufacturing practices, driving progress and innovation for years to come.

0 notes