#ceramic proppant market

Explore tagged Tumblr posts

Text

Ceramic Proppant Prices: Trend | Pricing | News | Price | Database

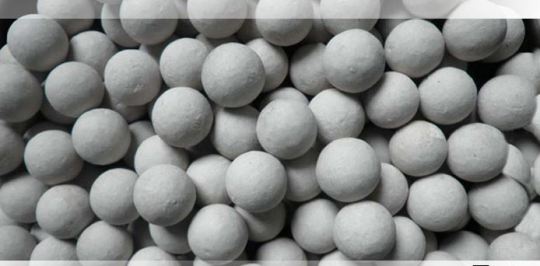

Ceramic Proppant are essential materials used in hydraulic fracturing, commonly known as fracking, to enhance the extraction of oil and gas from underground reservoirs. These proppants are made from high-strength ceramic materials that resist crushing under extreme pressure and are designed to keep fractures in the rock formation open, allowing oil or gas to flow freely. The ceramic proppant market has seen significant growth in recent years due to the increasing demand for oil and gas, particularly from shale plays. As a result, the prices of ceramic proppants have fluctuated in response to various factors, including raw material costs, technological advancements, and the supply and demand dynamics within the energy industry.

The price of ceramic proppants is influenced by several key factors, with raw materials being one of the primary determinants. Ceramic proppants are typically made from bauxite, kaolin, and other mineral-based materials. These raw materials have seen price fluctuations due to changes in global supply and demand, mining regulations, and geopolitical events. For instance, bauxite, the primary raw material for ceramic proppants, has been subject to price volatility due to changes in mining activity in countries like China, Australia, and Brazil. The cost of kaolin, another significant material, has also experienced fluctuations, driven by changes in demand from various industries, including ceramics and paper.

Get Real time Prices for Ceramic Proppant: https://www.chemanalyst.com/Pricing-data/ceramic-proppant-1576

In addition to raw material costs, the manufacturing process of ceramic proppants plays a crucial role in determining their price. Ceramic proppants are produced through a high-temperature sintering process, which involves heating the raw materials to a temperature where they melt and form small, spherical pellets. The energy-intensive nature of this process can impact the cost of production, particularly in regions where energy prices are high. Technological advancements in manufacturing processes have led to the development of more efficient methods for producing ceramic proppants, which could potentially reduce production costs and, in turn, impact the overall pricing of these materials.

The supply and demand dynamics of the oil and gas industry also significantly affect the price of ceramic proppants. When oil and gas prices are high, there is typically an increase in exploration and production activity, leading to a higher demand for proppants. Conversely, when oil and gas prices decline, exploration and production activities may slow down, leading to a decrease in demand for proppants. This cyclical nature of the oil and gas industry means that ceramic proppant prices are often highly sensitive to fluctuations in commodity prices. For example, during periods of high oil prices, the demand for hydraulic fracturing services increases, which in turn boosts the demand for ceramic proppants, driving up their prices. However, when oil prices drop, the demand for proppants may decrease, causing prices to soften.

Geopolitical factors can also influence ceramic proppant prices. Trade tensions, sanctions, and changes in government policies can impact the global supply chain for raw materials and finished proppants. For example, trade disputes between major ceramic proppant-producing countries like China and the United States can result in tariffs or restrictions on the import and export of these materials. Such disruptions in the supply chain can lead to shortages or price hikes for ceramic proppants in certain regions. Additionally, government regulations related to the oil and gas industry, such as stricter environmental standards or changes in hydraulic fracturing regulations, can affect the demand for ceramic proppants and, consequently, their prices.

The development of alternative proppant technologies is another factor that can influence ceramic proppant prices. While ceramic proppants are known for their high strength and durability, they are also more expensive than other types of proppants, such as sand. As a result, some oil and gas companies are exploring the use of alternative proppants that offer similar performance at a lower cost. If these alternative technologies gain traction in the market, they could put downward pressure on ceramic proppant prices. However, the high performance and reliability of ceramic proppants continue to make them a preferred choice for many operators, particularly in deep and ultra-deep wells where the risk of crushing is higher.

The competitive landscape of the ceramic proppant market also plays a role in determining pricing trends. Several large multinational companies dominate the market, and these companies typically have the resources and economies of scale to offer ceramic proppants at competitive prices. However, smaller, regional manufacturers may provide lower-cost alternatives, contributing to price fluctuations within the market. Additionally, the level of competition can affect the pricing strategies of manufacturers, as companies may adjust their prices based on market conditions and the actions of competitors.

In recent years, the global ceramic proppant market has seen increasing consolidation, with mergers and acquisitions taking place between major players in the industry. These strategic moves are aimed at expanding production capabilities, improving market reach, and achieving cost efficiencies. As a result, the consolidation trend may impact the competitive landscape and pricing dynamics in the future, as larger companies are able to leverage their resources to maintain competitive pricing.

In conclusion, the ceramic proppant market is influenced by a complex set of factors, including raw material costs, manufacturing processes, supply and demand dynamics in the oil and gas industry, geopolitical factors, and the competitive landscape. While ceramic proppants are a premium product in terms of strength and performance, their prices are subject to fluctuations based on the broader economic and energy market conditions. As the demand for hydraulic fracturing services continues to rise in response to growing global energy needs, the ceramic proppant market is expected to remain a key component of the oil and gas industry, with price trends being closely tied to the ebb and flow of global commodity prices and technological advancements.

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Ceramic Proppant#Ceramic Proppant Prices#Ceramic Proppant Price Trend#Ceramic Proppant News#Ceramic Proppant Monitor#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research

0 notes

Text

Latin America Silica Sand Market Outlook and Forecast 2025-2032

Silica sand, also known as industrial sand, is a high-purity form of quartz sand that undergoes processing to meet specific industrial and manufacturing requirements. It consists primarily of silicon dioxide (SiO₂), with purity levels exceeding 95% in most commercial applications. The sand is categorized based on its grain size, impurity levels, and intended use.

Silica sand is a crucial raw material in industries such as glass manufacturing, construction, foundry applications, hydraulic fracturing (oil & gas), filtration, and ceramics. The demand for silica sand in Latin America has increased significantly due to the expansion of construction activities, growth in the glass industry, and rising industrialization across major economies such as Brazil and Mexico.

Download a Free Sample Report PDF @ https://www.24chemicalresearch.com/download-sample/286438/latin-america-silica-s-market-2025-2032-201

Market Size

The Latin America Silica Sand Market was valued at US$ 845 million in 2024 and is expected to reach US$ 1.12 billion by 2030, growing at a CAGR of 4.8% during the forecast period from 2024 to 2030.

Key Market Trends and Statistics:

Historical Growth: The market has grown steadily over the past decade due to increasing demand in construction, glass production, and foundry applications.

Projected Demand: The demand for high-purity silica sand is projected to rise with the expansion of the solar panel manufacturing sector, which requires ultra-clear glass made from superior-grade silica sand.

Production Growth: Leading silica sand producers in Latin America, including Brazil, Mexico, and Chile, are investing in advanced mining technologies to enhance production efficiency.

End-Use Distribution:

Glass Manufacturing: 35%

Construction: 28%

Foundry Applications: 22%

Oil & Gas (Hydraulic Fracturing): 15%

Quality Segmentation:

High-grade (>99% SiO₂): 42%

Medium-grade (98-99% SiO₂): 35%

Standard-grade (<98% SiO₂): 23%

Market Dynamics

Drivers

Rising Demand for Glass Manufacturing

The expansion of automotive, construction, and solar energy industries has driven the demand for high-quality silica sand for glass production.

Latin America's glass manufacturing industry is expected to grow at a CAGR of 5.2% through 2030.

Infrastructure Development & Urbanization

Countries like Brazil, Mexico, and Argentina are witnessing rapid urbanization, leading to increased demand for cement, concrete, and silica-based construction materials.

Growing Oil & Gas Exploration

The hydraulic fracturing (fracking) industry in Argentina and Mexico is fueling demand for proppant-grade silica sand.

Restraints

Environmental Regulations & Mining Restrictions

Strict regulations on sand mining activities due to environmental concerns may limit production capabilities.

Governments are enforcing sustainable mining practices to protect natural water bodies and ecosystems.

High Transportation Costs

Transporting bulk silica sand across long distances increases logistics costs, impacting profitability.

Opportunities

Sustainable Mining Practices

Companies investing in eco-friendly mining technologies and water-efficient processing methods have a competitive advantage.

Expansion of High-Purity Silica Market

Electronic-grade silica sand used in semiconductors and solar panels is gaining traction.

Challenges

Supply Chain Disruptions

Geopolitical tensions and trade policies can disrupt the export and import of silica sand.

Fluctuations in Raw Material Prices

Variability in the cost of extraction, processing, and transportation impacts overall pricing.

Regional Analysis

Brazil

Largest producer of silica sand in the region.

Major players are investing in new silica mines and advanced processing plants.

Growing construction and solar energy sector fueling silica demand.

Mexico

Strong export market for silica sand, particularly to the United States.

Increased usage in glass and filtration industries.

Chile

Foundry industry and ceramic manufacturing are the key drivers of silica sand consumption.

Government incentives to boost mining activities.

Other Countries

Argentina, Colombia, Peru, and Venezuela contribute to the market with localized mining operations and niche industry applications.

Competitor Analysis

Major Players in the Latin America Silica Sand Market

Sibelco – Leading supplier with a strong presence in Brazil and Mexico.

Canteras Industriales – Focuses on high-purity silica sand production.

Arena Silícea Dorada – Key supplier in Argentina.

Emisiles C.A – Specialized in foundry-grade silica sand.

Saint-Gobain – Major player in the glass and construction sector.

Industrias Extractivas de México, S.A. de C.V. – Large-scale mining operations in Mexico.

Mineração Jundu Ltda – Major silica sand producer in Brazil.

Grupo Arenas y Gravas Silicas – Key regional player in filtration-grade silica sand.

Arena Sílice de Veracruz – Mexican supplier with a strong export market.

Market Segmentation (by Application)

1. Construction

Used in concrete, cement, and road construction.

2. Glass Manufacturing

High-purity silica sand is essential for flat glass, container glass, and specialty glass.

3. Filtration

Used in water treatment plants for removing contaminants.

4. Foundry

Foundry-grade silica sand is used for molding and core-making in metal casting.

5. Ceramics & Refractories

Essential for tiles, sanitaryware, and high-temperature-resistant materials.

Market Segmentation (by Type)

Less than 40 mesh – Used in construction applications.

40-70 mesh – Preferred for glass manufacturing and filtration.

More than 70 mesh – Used in high-purity applications like semiconductors.

Key Company Profiles

Sibelco

Canteras Industriales

Arena Silícea Dorada

Emisiles C.A

Saint-Gobain

Industrias Extractivas de México, S.A. de C.V.

Mineração Jundu Ltda

Grupo Arenas y Gravas Silicas

Arena Sílice de Veracruz

Geographic Segmentation

Brazil

Mexico

Argentina

Chile

Colombia

Peru

Venezuela

FAQ

What is the current market size of the Latin America Silica Sand Market?

➣ The market was valued at US$ 845 million in 2024 and is expected to grow to US$ 1.12 billion by 2030 at a CAGR of 4.8%.

Which are the key companies operating in the Latin America Silica Sand Market?

➣ Major companies include Sibelco, Saint-Gobain, Mineração Jundu Ltda, and Industrias Extractivas de México.

What are the key growth drivers in the Latin America Silica Sand Market?

➣ The main growth drivers are increased demand from the glass industry, urbanization, and rising hydraulic fracturing activities.

Which regions dominate the Latin America Silica Sand Market?

➣ Brazil, Mexico, and Chile are the top producers.

What are the emerging trends in the Latin America Silica Sand Market?

Eco-friendly mining practices

Expansion in high-purity silica for semiconductors

Increased use in renewable energy applications

Competitor Analysis

The report also provides analysis of leading market participants including:

Key companies Silica Sand revenues in Latin America market, 2019-2024 (Estimated), ($ millions)

Key companies Silica Sand revenues share in Latin America market, 2023 (%)

Key companies Silica Sand sales in Latin America market, 2019-2024 (Estimated),

Key companies Silica Sand sales share in Latin America market, 2023 (%)

Key Points of this Report:

The depth industry chain includes analysis value chain analysis, porter five forces model analysis and cost structure analysis

The report covers Latin America and country-wise market of Silica Sand

It describes present situation, historical background and future forecast

Comprehensive data showing Silica Sand capacities, production, consumption, trade statistics, and prices in the recent years are provided

The report indicates a wealth of information on Silica Sand manufacturers

Silica Sand forecast for next five years, including market volumes and prices is also provided

Raw Material Supply and Downstream Consumer Information is also included

Any other user's requirements which is feasible for us

Reasons to Purchase this Report:

Analyzing the outlook of the market with the recent trends and SWOT analysis

Market dynamics scenario, along with growth opportunities of the market in the years to come

Market segmentation analysis including qualitative and quantitative research incorporating the impact of economic and non-economic aspects

Regional and country level analysis integrating the demand and supply forces that are influencing the growth of the market.

Market value (USD Million) and volume (Units Million) data for each segment and sub-segment

Distribution Channel sales Analysis by Value

Competitive landscape involving the market share of major players, along with the new projects and strategies adopted by players in the past five years

Comprehensive company profiles covering the product offerings, key financial information, recent developments, SWOT analysis, and strategies employed by the major market players

1-year analyst support, along with the data support in excel format.

Download a Free Sample Report PDF @ https://www.24chemicalresearch.com/download-sample/286438/latin-america-silica-s-market-2025-2032-201

0 notes

Text

0 notes

Text

0 notes

Text

Global Oilfield Stimulation Market: Trends, Analysis, and Growth Opportunities

Oilfield Stimulation Chemicals: An Overview

What are Stimulation Chemicals? Stimulation chemicals are compounds used in oil and gas well operations to maximize productivity from reservoirs. These chemicals are used during processes like hydraulic fracturing, acidizing, and matrix stimulation treatments which help stimulate reservoir flow. Some common stimulation chemicals and their functions include: Proppants - Materials like sand or ceramic beads that are pumped into fractures created through hydraulic fracturing or acidizing to prop them open once pumping pressure is removed. This allows oil and gas to more easily flow through the induced fractures and pores to the wellbore. Acids - Various acids are used to dissolve minerals in the formation like calcite or dolomite, widening existing pores and fractures. Hydrochloric acid and other acids help increase near-wellbore permeability and conductivity. Biocides - Biocides are chemicals that kill bacteria in fracture fluids which can impede flow. They prevent bacteria from colonizing in the produced fluids and degrading the formation. Common biocides used include glutaraldehyde and polymaleic acid. Friction Reducers - Polyacrylamide polymers and other friction reducers are added to fracture fluid slurries to reduce friction pressures during pumping. They allow fluids to carry higher proppant concentrations farther through wellbores and created cracks. Corrosion Inhibitors - Chemicals like isopropanolamine help form a protective film or coating inside the wellbore and production equipment to prevent corrosion. This inhibition is important to maximize asset life and production uptime. Gellants - Chemicals that increase the viscosity of fracture fluids through crosslinking. Viscosified fluids can suspend more proppant per gallon of fluid pumped to maximize proppant placement deep inside fractures. Common gellants are guar gum and cellulose derivatives. Breakers - Used to decrease the viscosity of fracturing fluids after the job is complete so they can be recovered from the formation. Breakers enzymatically or hydrolytically degrade gelling chemistry allowing fluid flowback. What is Hydraulic Fracturing? Hydraulic fracturing, or fracking, is a stimulation treatment employing high-pressure fluid to induce cracks in underground formations. Water, proppant, and additives are pumped downhole at pressures exceeding the fracture gradient of the rock. This creates cracks radiating away from the wellbore, providing channels for oil and gas to flow more easily. Fracturing fluid is mostly water but contains chemicals like acids, biocides, friction reducers, crosslinkers, and proppant. Pumped at pressures as high as 15,000 psi, it generates cracks up to 1000 feet long. Proppant like sand props the fractures open against reservoir pressures once pumping stops. This creates a conductive network for hydrocarbons to travel through, boosting production rates. How are Acids Used in oilfield stimulation chemicals? Acidizing refers to injection of acidic fluids into the formation to increase porosity and permeability near the wellbore. Various acids are tailored for different rock mineralogies: - Hydrochloric acid dissolves calcite and dolomite, common minerals in carbonate reservoirs. It is the most widely used acid for this purpose. - Hydrofluoric acid is more effective for dissolving siliceous materials like quartz and feldspar in sandstone reservoirs. - Acetic, formic, and other organic acids are sometimes used as alternatives or mixtures with HCl to control reaction rates. During an acidizing treatment, acid is pumped downhole and allowed to contact the formation for a set injection time. As it reacts with minerals, it widens natural and induced fractures as well as dissolving pore-filling deposits. This enhances conductivity and injectivity around the wellbore.

0 notes

Text

Oilfield Stimulation Chemicals Market: A Comprehensive Analysis of Corrosion Inhibitors for Well Integrity

Introduction Oilfield stimulation involves the use of various chemicals to enhance oil and gas recovery from hydrocarbon reservoirs. These stimulation chemicals play a vital role in increasing well productivity by improving fluid flow within the reservoir formation. The need for oilfield stimulation arises due to the presence of low permeability reservoirs with complex drainage patterns that require artificial means to increase hydrocarbon flow rates. From acidizing to hydraulic fracturing, stimulation treatments have helped maximize recovery and optimize well performance in both onshore and offshore fields. Hydraulic Fracturing- A Key Stimulation Technique Hydraulic fracturing is one of the most widely used stimulation methods for unconventional reservoirs like tight sands and shale. It involves injecting fluids like water, mixed with proppants like sand, ceramics or plastics into deep underground wells at high pressures to fracture the hydrocarbon-bearing formation. These induced fractures provide conductive channels through which oil and gas can flow more freely from the reservoir to the wellbore. A variety of chemicals including friction reducers, gel stabilizers, surfactants, biocides and scale inhibitors are blended into hydraulic fracturing fluids to create fractures and maintain them open. These additives help in transporting proppants, controlling fluid viscosity and minimizing formation damage post-treatment. Fracture geometry and conductivity can be optimized using tailored fracture fluid chemistries which enhance long-term flowback and production enhancement. Chemical Usage in Matrix Acidizing Oil-wet formations with low permeability often require acidizing treatments to connect movable oil to the wellbore through the formation matrix. Commonly used acids like hydrochloric acid and hydrofluoric acid dissolve carbonates and other minerals, improving near-wellbore conductivity. However, acid penetration needs to be controlled to prevent excessive etching or wormholing. Buffers like zinc and ammonium salts are used to control acid reaction kinetics and etch patterns. Chelating agents remove acid insoluble precipitation to minimize formation damage during cleanup. Surfactants and mutual solvents also improve acid-rock interaction and cleaning efficiency. Proper chemical evaluation helps determine the ideal formulation for optimum acid placement and zonal coverage in carbonate reservoirs. Conformance Control using Gels and Polymers Excessive water production is a major issue affecting well and reservoir performance. Polymer gels are effective for controlling fluid conformance and diverting production to targeted zones. Smart gels like pH-sensitive crosslinked systems gel under reservoir conditions, plugging high permeability thief zones while allowing access to oil-bearing layers. Similarly, preformed particle gels effectively block uncontrolled water channels. Digitalization Boosts Stimulation Effectiveness Advances in digital instrumentation, remote sensing, big data analytics and simulation are being leveraged to optimize completion design and chemical selection. Downhole sensor arrays provide real-time diagnostics on fluid placement, fracture width profiles and reaction kinetics for closed loop operations. This helps calibrate treatment variables instantaneously and enhance economic value. Geomechanics coupled with fluid-rock interaction modeling aids job design based on local lithology and in-situ stresses. Production logging tool analytics coupled with chemical flowback signatures characterize conductivity, fluid recovery and completion quality. Digital twin approaches integrate field measurements with simulations for history matching and predictive operations. Overall, digitalization helps maximize benefits from oilfield stimulation chemicals investments by ensuring safer, cleaner and more efficient well treatments.

#Oilfield Stimulation Chemicals Market#Oilfield Stimulation Chemicals Market Trends#Oilfield Stimulation Chemicals Market Growth

0 notes

Text

0 notes

Text

Ceramic Proppant Prices | Pricing | Trend | News | Database | Chart | Forecast

Ceramic Proppant Prices are an essential material used primarily in hydraulic fracturing, also known as fracking, in the oil and gas industry. These proppants are engineered to keep fractures open in subterranean rock formations, allowing oil and gas to flow more freely to the surface. Over the years, ceramic proppant prices have fluctuated due to various market dynamics, including changes in crude oil prices, supply and demand imbalances, and advancements in fracking technologies. Understanding these factors is crucial for industry stakeholders, including oil and gas companies, suppliers, and investors, who are all impacted by the cost of these materials.

One of the primary drivers of ceramic proppant prices is the price of crude oil. When oil prices are high, there is usually an increase in fracking activity, leading to a surge in demand for proppants. This heightened demand typically results in upward pressure on ceramic proppant prices. Conversely, when oil prices decline, fracking operations tend to slow down, reducing the need for proppants and consequently driving down their prices. This direct relationship between crude oil prices and ceramic proppant demand means that proppant suppliers must carefully monitor the global oil market to anticipate price changes.

Get Real Time Prices for Ceramic Proppant: https://www.chemanalyst.com/Pricing-data/ceramic-proppant-1576

Another factor influencing ceramic proppant prices is the supply chain, particularly the availability of raw materials used in their production. Ceramic proppants are made from high-quality bauxite, kaolin, and other clay minerals that must undergo extensive processing, including calcining and sintering at high temperatures. The cost of these raw materials can vary depending on geographical location, mining regulations, and transportation logistics. When there are disruptions in the supply of these materials, such as mining restrictions or increased transportation costs, the prices of ceramic proppants tend to rise. Moreover, suppliers often face higher production costs due to energy consumption during manufacturing, which further adds to the final price of the product.

Technological advancements in hydraulic fracturing also play a significant role in shaping ceramic proppant prices. As the fracking industry has evolved, companies have developed more efficient drilling techniques, which, in some cases, reduce the amount of proppant required per well. This reduction in demand for ceramic proppants can result in price decreases as suppliers compete to maintain their market share. However, as drilling techniques become more sophisticated, there is also a growing need for higher-quality proppants that can withstand extreme pressure and temperatures in deeper wells. These premium proppants, which offer better conductivity and durability, are often more expensive than standard ceramic proppants, leading to price differentiation within the market.

Global economic conditions also have a significant impact on ceramic proppant prices. For example, during periods of economic downturn, energy consumption tends to decrease, leading to lower demand for oil and gas. As a result, the demand for ceramic proppants also declines, putting downward pressure on prices. On the other hand, during times of economic growth, industrial activity and energy consumption increase, driving up the need for oil and gas production, and by extension, ceramic proppants. Therefore, suppliers and buyers must keep a close eye on macroeconomic trends to forecast potential price fluctuations in the proppant market.

Competition within the proppant industry also affects pricing dynamics. Ceramic proppants face competition from alternative materials such as resin-coated proppants and frac sand, which are often less expensive. Frac sand, in particular, is a cheaper alternative that has gained popularity due to its availability and lower production costs. However, ceramic proppants typically offer better performance in certain well conditions, such as high-pressure or high-temperature environments. The competition between these different types of proppants forces ceramic proppant manufacturers to continuously optimize their production processes to remain competitive on price while maintaining product quality. As a result, prices can vary depending on the specific applications and performance requirements of the fracking operation.

Geopolitical factors also play a role in determining ceramic proppant prices. Many of the raw materials required for producing ceramic proppants are sourced from specific regions, such as China and Brazil, which are major producers of bauxite. Any political instability, trade restrictions, or tariff changes in these regions can disrupt the supply chain, leading to increased production costs and higher prices for ceramic proppants. Additionally, the global energy market is highly influenced by geopolitical events, such as conflicts in oil-producing regions or changes in energy policies by major governments, which can affect the demand for fracking and, consequently, the demand for proppants.

Environmental regulations and sustainability concerns are increasingly influencing the cost structure of ceramic proppant production. Governments and regulatory bodies are imposing stricter environmental standards on mining operations and manufacturing processes, which can lead to higher compliance costs for proppant producers. These costs are often passed on to consumers in the form of higher prices. Moreover, as the industry shifts toward more sustainable practices, there is growing interest in developing eco-friendly proppants, which could command a premium price in the market. While this trend is still in its early stages, it has the potential to reshape the pricing landscape for ceramic proppants in the future.

In summary, ceramic proppant prices are influenced by a complex interplay of factors, including crude oil prices, supply chain dynamics, technological advancements, global economic conditions, competition from alternative proppants, geopolitical events, and environmental regulations. As the oil and gas industry continues to evolve, the market for ceramic proppants will likely experience ongoing fluctuations in pricing. Industry stakeholders must remain agile and informed to navigate these changes effectively, ensuring they can optimize their operations and minimize costs while maintaining access to high-quality proppants. By staying ahead of market trends and understanding the factors that drive ceramic proppant prices, companies can better position themselves for success in the ever-changing energy landscape.

Get Real Time Prices for Ceramic Proppant: https://www.chemanalyst.com/Pricing-data/ceramic-proppant-1576

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Ceramic Proppant#Ceramic Proppant Prices#Ceramic Proppant Price Trend#Ceramic Proppant News#Ceramic Proppant Monitor

0 notes

Text

Proppants Market : A Study of the Current Status and Future Prospects

Report Overview

Polaris Market Research announces the release of a new report Proppants Market by Share, Size, Trends, Future Growth, and Demand Analysis 2032 Keyword. The research report conducts an in-depth market study to provide a comprehensive analysis of the current state and future potential of the Proppants Market. It covers several aspects, including industry size, key players, growth drivers, key opportunities, and challenges. Besides, market segmentation, competitive landscape, and regional analysis are detailed in the report.

The research study aims to assist stakeholders, investors, and businesses in making more informed decisions and formulating effective strategies to stay ahead of the curve. In addition, the impact of technological advancements, changing consumer preferences, and rising demand for innovative services on the market is covered. The report is a must-read for anyone currently involved or interested in the industry.

Request Our Free Sample Report for Proppants Market Insights and Emerging Trends @ https://www.polarismarketresearch.com/industry-analysis/proppants-market/request-for-sample

According to the research report published by Polaris Market Research, the Global Proppants Market Size Is Expected To Reach USD 13.23 Billion By 2028., at a CAGR of 8.6% during the forecast period.

Competitive Landscape

The research study analyzes the current competitive environment of the market by providing information regarding Proppants Market key players. The competitive landscape section covers several aspects of industry players, including their sales volume, market share, price, and gross margin. Additionally, important information about strategic developments such as mergers, acquisitions, and collaborations is provided in the report.

Major Key Players

Atlas Sand Company

Badger Mining Corporation

Carbo Ceramics Inc.

Compagnie de Saint-Gobain S.A.

Covia Holdings LLC

Fores Engineering

Hexion Inc.

Hi-Crush Inc.

JSC Borovichi Refractories Plant

Mineração Curimbaba Ltda

Momentive Performance Materials

Preferred Proppants LLC

Schlumberger Limited

U.S. Silica Holdings Inc.

Unimin Corporation LLC

Xinmi Wanli Industry Development Co. Ltd

Yixing Orient Petroleum Proppant Co. Ltd.

Make an Enquiry before Buying: https://www.polarismarketresearch.com/industry-analysis/proppants-market/inquire-before-buying

Growth Drivers

Key trends: The report identifies and analyzes the key trends and drivers that are shaping the growth trajectory of the Proppants Market.

Technological advancements: Advances in technology and their overall impact on the industry have been covered in the report.

Regulatory landscape: The research study provides an in-depth examination of the regulatory environment to help stakeholders seize opportunities and mitigate potential challenges.

Buy this Premium Research Report: https://www.polarismarketresearch.com/buy/908/2

Segmental Analysis

The Proppants Market segmentation is primarily based on type, application, end use, and region. A comprehensive analysis of each of these segments is detailed in the report. Besides, the study sheds light on all the major sub-segments in the market. That way, stakeholders can better understand the needs of their customers and align their business strategies accordingly.

Regional Overview

The study offers additional insight into the regional market distribution, covering industry trends, revenue sources, and potential opportunities. Also, it offers predictions for revenue growth at regional, national, and global levels. Other important factors like pricing, production capacity, supply and demand ratios, and projected Proppants Market sales are detailed in the report.

The Geographical Analysis Covers Following Key Regions:

North America (United States, Canada, and Mexico)

Europe (Germany, France, United Kingdom, Russia, Italy, and the Rest of Europe)

Asia-Pacific (China, Japan, Korea, India, Southeast Asia, and Australia)

South America (Brazil, Argentina, Colombia, and the rest of South America)

The Middle East and Africa (Saudi Arabia, United Arab Emirates, Egypt, South Africa, and the Rest of the Middle East and Africa)

Key Highlights of the Report

A descriptive analysis of the demand-supply gap and forecast in the global market.

Bottom-up and top-down approaches for regional analysis.

Covers a SWOT analysis of key players and the overall Proppants Market.

Includes both primary and secondary research methods to provide a thorough market understanding.

Porter’s Five Forces model provides an in-depth examination of industry vendors, substitutes, and competition among industry players.

Provides a detailed picture of the market by including value chain analysis.

The Report Answers Questions Such As

What is the current size and projected value for the market?

What are the key factors driving the Proppants Market demand?

Which is the leading segment in the industry?

What are the potential attractive investment opportunities in the market?

At what CAGR is the market projected to grow over the forecast period?

Where will strategic developments take the Proppants Market in the short to long term?

Read More Trending Report of "Polaris Market Research Exclusive": https://www.polarismarketresearch.com/industry-analysis/proppants-market

About Us

Polaris Market Research is a worldwide market research and consulting organization. We give unmatched nature of offering to our customers present all around the globe across industry verticals. Polaris Market Research has expertise in giving deep-dive market insight along with market intelligence to our customers spread crosswise over various undertakings. We at Polaris are obliged to serve our different client base present over the enterprises of medicinal services, healthcare, innovation, next-gen technologies, semiconductors, chemicals, automotive, and aerospace & defense, among different ventures, present globally.

Contact Us:

Polaris Market Research

Email: [email protected]

Ph: +1-929 297-9727

0 notes

Text

0 notes

Text

0 notes

Text

Your Source for Quartz Granules: Trusted Supplier

In the realm of industrial minerals, quartz granules play a pivotal role in a wide array of applications, ranging from construction and manufacturing to electronics and cosmetics. Pratibha Refractory Minerals stands as a prominent and trusted name as Supplier of Quartz Granules in the industry, known for its superior quality quartz granules and unwavering commitment to customer satisfaction has not only harnessed the potential of these quartz granules but has elevated itself to the status of a trailblazing supplier.

Quartz Granules: An Overview

Quartz granules, composed primarily of silicon dioxide (SiO2), are a form of crystalline silica. They are obtained from naturally occurring quartz crystals through a meticulous process of mining, crushing, and purification. What makes quartz granules highly sought after in various industries is their exceptional hardness, chemical resistance, and thermal stability.

The Versatile Applications of Quartz Granules

Construction Industry: Quartz granules, due to their hardness and durability, are used as key components in construction materials like concrete, mortars, and grouts. They enhance the mechanical properties and longevity of these materials, making them essential for building foundations, roadways, and structures.

Manufacturing Sector: In manufacturing, quartz granules find application in the production of ceramics, glass, and silicon wafers. Their ability to withstand high temperatures and their electrical insulating properties make them indispensable for manufacturing processes.

Electronics and Semiconductors: Quartz granules are an integral part of the electronics industry, where they are used in the production of quartz crystals, resonators, and oscillators. These components are crucial for precise timekeeping and frequency control in electronic devices.

Cosmetics and Pharmaceuticals: The cosmetic and pharmaceutical industries utilize quartz granules for exfoliating scrubs and skincare products. The fine texture of quartz granules helps gently remove dead skin cells, promoting smoother and healthier-looking skin.

Paints and Coatings: Quartz granules are added to paints, coatings, and adhesives to enhance their texture, durability, and resistance to wear and tear. They provide aesthetic appeal and protect surfaces from harsh environmental conditions.

Oil and Gas Sector: Quartz granules are used in the exploration and production of oil and gas. They are employed as proppants in hydraulic fracturing processes, helping to keep fractures open and allowing for the efficient extraction of hydrocarbons.

Pratibha Refractory Minerals: A Trusted Supplier

Pratibha Refractory has firmly established itself as a reliable supplier of high-quality quartz granules to industries worldwide. With a commitment to excellence and a customer-centric approach, the company has garnered a strong reputation in the market.

1. Quality Assurance: We place paramount importance on the quality of our products. We source quartz granules from reputable mines and employ rigorous testing procedures to ensure that the granules meet stringent quality standards.

2. Technological Expertise: We leverage advanced mining and processing technologies to extract and refine quartz granules. This ensures that the granules possess optimal purity, particle size distribution, and other essential properties.

3. Customized Solutions: We understand that different industries have varying requirements. As a result, we offer tailored solutions, providing quartz granules in different sizes and specifications to meet the unique needs of each application.

4. Sustainability: We are committed to sustainable practices throughout its operations. We adhere to responsible mining practices and environmental regulations, minimizing our ecological footprint.

5. Global Reach: Our extensive distribution network enables us to serve clients across the globe. This global reach, coupled with efficient logistics, ensures timely delivery of products to customers.

Quartz granules, with their exceptional properties and versatility, are indispensable in numerous industries, driving innovation and development. Pratibha Refractory Minerals' unwavering dedication to providing top-quality quartz granules has positioned it as a leading supplier in the market. As industries continue to evolve and demand for high-performance materials increases, we remain poised to meet the diverse needs of our clients, contributing to the advancement of various sectors and the global economy at large. Partner with Excellence: Are you seeking a reliable supplier for your quartz granule needs? Look no further. Partner with Pratibha Refractory Minerals and experience the difference of uncompromising quality, tailored solutions, and global reach. Contact Us to discuss your requirements and embark on a journey of industrial success together.

0 notes

Text

Sudarshan Group: Delivering Excellence as a Leading Quartz Grains Manufacturer

Introduction

Quartz, a durable and versatile mineral, finds extensive use in various industries due to its exceptional properties. As a prominent Quartz Grains Manufacturer, Sudarshan Group has established itself as a trusted name in the market. With a strong commitment to quality, innovation, and customer satisfaction, Sudarshan Group delivers high-grade quartz grains that cater to the diverse needs of industries such as construction, electronics, and more.

Understanding Quartz Grains and their Applications

Quartz grains, also known as silica grains, are small fragments of quartz crystal with a consistent size and shape. They are widely utilized in different industrial applications due to their unique characteristics and suitability for various processes. Here are some key applications of quartz grains:

1. Construction Industry:

Quartz grains are essential in the construction industry as a key ingredient in manufacturing materials such as concrete, mortar, and artificial stone. Their hardness, resistance to weathering, and high silica content make them ideal for enhancing the strength and durability of construction materials.

2. Electronics and Semiconductor Industry:

The electronics and semiconductor industry heavily relies on quartz grains for their purity, high-temperature resistance, and excellent electrical properties. Quartz grains are utilized in the production of quartz crystal oscillators, quartz resonators, and semiconductor chips.

3. Glass and Ceramics:

Quartz grains play a vital role in the manufacturing of glass and ceramics. Due to our high silica content and low thermal expansion, we help achieve transparency, strength, and resistance to heat and chemical corrosion in glass products. In ceramics, quartz grains enhance the mechanical properties and contribute to the desired texture and appearance.

4. Oil and Gas Industry:

Quartz grains are employed in the oil and gas industry as proppants in hydraulic fracturing operations. Their high crush resistance, uniformity, and permeability make them effective in maintaining fractures in rock formations, allowing the efficient extraction of oil and gas.

Sudarshan Group: Delivering Excellence in Quartz Grain Manufacturing

Sudarshan Group has emerged as a leading manufacturer of quartz grains, delivering superior-quality products to meet the growing demands of various industries. Here's why Sudarshan Group stands out in the market:

1. State-of-the-Art Manufacturing Facilities:

Sudarshan Group possesses advanced manufacturing facilities equipped with cutting-edge technology. These facilities enable precise processing and grading of quartz grains, ensuring consistent quality and adherence to customer specifications.

2. Stringent Quality Control:

The company follows rigorous quality control measures at every stage of the manufacturing process. Sudarshan Group's dedicated quality assurance team conducts thorough testing and analysis to ensure that their quartz grains meet the highest industry standards for purity, size distribution, and other relevant parameters.

3. Customized Solutions:

Sudarshan Group understands that different industries have unique requirements. We offer customized quartz grain solutions tailored to specific applications. Our team of experts works closely with customers to understand their needs, recommend suitable grades, and optimize the performance of quartz grains in their processes.

4. Research and Development:

Sudarshan Group invests in ongoing research and development to stay at the forefront of quartz grain technology. Our dedicated team of researchers and scientists continuously explores innovative manufacturing processes, product enhancements, and applications to meet the evolving needs of industries.

Conclusion

As a leading manufacturer of quartz grains, Sudarshan Group has earned a reputation for delivering excellence in quality, innovation, and customer satisfaction. Our state-of-the-art manufacturing facilities, stringent quality control measures, customized solutions, and commitment to sustainability make them the preferred choice for industries seeking reliable quartz grain suppliers. By choosing Sudarshan Group, you can be confident in receiving high-grade quartz grains that meet your specific requirements and contribute to the success of your business.

0 notes