#Proppant Market

Explore tagged Tumblr posts

Text

Proppant Market Industry Leaders Size & Share Outlook & New Revenue Pockets

The proppants market is estimated to be USD 7.8 billion in 2020 and is projected to reach USD 12.1 billion by 2025, at a CAGR of 9.1% during the forecast period. The proppants market between 2020 and 2025 will be drive by The improvements in fracturing technology and new drilling techniques, increasing proppants conssumption per well, innovation in proppants technologies and the growing natural gas demand to ensure energy security.

Download PDF Brochure at https://www.marketsandmarkets.com/pdfdownloadNew.asp?id=802

Frac sand is a naturally occurring proppant made from high purity sandstone. Frac sand has a round shape and is homogeneous in nature. There are three types of frac sand: Northern White Sand, Brown Sand, and In-Basin Sand. The increased demand for frac sand and resincoated proppants, along with the low-cost and abundant availability of frac sand with increasing new well drilling, is expected to drive the overall proppants market.

The domestic demand for natural gas will increase in major APAC economies due to the development of shale gas in the region. The extraction of shale gas is likely to enhance the region’s energy security by allowing the countries to become less dependent on external sources. However, the development of shale gas is at the initial stage. Countries are extracting shale gas using advanced technology from their shale gas reserves, majorly driven by China and this trend makes APAC the fastest growing proppants market during the forecast period.

Request For FREE Sample of Report at https://www.marketsandmarkets.com/requestsampleNew.asp?id=802

The unprescedented demand shock in the oil industry in 2020 led to historic oil price drop as governments around the world closed down businesses and imposed restriction on travelling. This impacted the demand of proppants in 2020 and the market declined by 27% in terms of volume . The impact of reduced economic activities around the world created oversupply of oil in the international market and the oil price war between Saudi Arabia and Russia plunged the oil price dramatically.

0 notes

Text

The Global Proppant Market is expected to grow at a CAGR of around 7% during the forecasted period from 2022-2028F.

0 notes

Text

#global#Proppant Market#Proppant Market size#Proppant Market share#Proppant Market growth#Proppant Market forecast

0 notes

Text

Proppant Market Size Projected to Garner Significant Revenues By 2018 – 2027

Proppant Market will multiply at an impressive CAGR of 9% by 2027 & Top Key Players Superior Silica Sands LLC, Hi-Crush Partners LP, Fairmount Santrol Holdings Inc., Minerao Curimbaba Ltd., Fores Ltd., JSC Borovichi Refractories Plant, S. Silica Holdings Inc., Saint-Gobain Proppant Inc., Carbo Ceramics Inc., Badger Mining Corporation

According to a recently published report by Research Nester on “Proppant Market: Global Demand Analysis & Opportunity Outlook 2027” delivers detailed overview of the proppant market in terms of market segmentation by product type, by application, and by region.

Further, for the in-depth analysis, the report encompasses the industry growth drivers, restraints, supply and demand risk, market attractiveness, BPS analysis and Porter’s five force model.

Based on product-type, the segment is divided into sand, resin coated & ceramic; by application into shale gas, tight gas, coal-bed methane, and others. The proppant market is anticipated to record a CAGR of around 9% over the forecast period i.e. 2019-2027.

The increasing application of proppant majorly in shale gas is one the key factors for driving the growth of the market across U.S. The growing demand for oil and gas as a form of energy is encouraging the drilling activities in different countries such as Saudi Arabia, UAE. Additionally, the ease of availability of sand at low cost is propelling its growth in the product type segment cross the globe. According to BP Stats, the oil production has seen considerable growth in North America and Middle East in 2018 and 2019, which is anticipated to foster the growth of the proppant demand during the forecast period.

Get Sample PDF Brochure: @ https://www.researchnester.com/sample-request-849

Based on region, proppant market is segmented into five major regions including North America, Europe, Asia Pacific, Latin America and Middle East & Africa region. North America market is expected to showcase a dominating growth followed by the market in Asia Pacific. This growth can be attributed to increasing number of well drilling and matured wells in these regions. Additionally, Europe is also predicted to attain a considerable growth in the market owing to the high demand of proppant for extraction processes.

Application in Oil and Gas Extraction

Application of the proppant during oil and gas drilling out of hydraulic fractures are highly productive due to its properties of being resistant, high strength and conductivity. The rising drilling activities and growing projects in developing regions fostered by high oil demand across the globe is anticipated to foster the market growth of proppant at a high pace during the forecast period. Additionally, the rising shale gas excavation process in UAE and U.S. is anticipated to bolster the demand for proppant in the market of these countries.

However, contamination of underground water due to application of proppant during extraction is hampering the environment. Additionally, the rising health issues and lack of drinking water due to pollution occurring during the extraction by proppant is a key restraint to the growth of the market over the forecast period.

This report also provides the existing competitive scenario of some of the key players of the proppant market which includes company profiling of Superior Silica Sands LLC, Hi-Crush Partners LP, Fairmount Santrol Holdings Inc., Minerao Curimbaba Ltd., Fores Ltd., JSC Borovichi Refractories Plant, S. Silica Holdings Inc., Saint-Gobain Proppant Inc., Carbo Ceramics Inc., Badger Mining Corporation and other prominent players. The profiling enfolds key information of the companies which encompasses business overview, products and services, key financials and recent news and developments. On the whole, the report depicts detailed overview of the proppant market that will help industry consultants, equipment manufacturers, existing players searching for expansion opportunities, new players searching possibilities and other stakeholders to align their market centric strategies according to the ongoing and expected trends in the future.

Download Sample of This Strategic Report: @ https://www.researchnester.com/sample-request-849

About Research Nester

Research Nester is a leading service provider for strategic market research and consulting. We aim to provide unbiased, unparalleled market insights and industry analysis to help industries, conglomerates and executives to take wise decisions for their future marketing strategy, expansion and investment etc. We believe every business can expand to its new horizon, provided a right guidance at a right time is available through strategic minds. Our out of box thinking helps our clients to take wise decision so as to avoid future uncertainties.

Contact for more Info: AJ Daniel Email: [email protected] U.S. Phone: +1 646 586 9123 U.K. Phone: +44 203 608 5919

0 notes

Text

Unlocking the Potential of the Proppant Market: Trends, Opportunities, and Challenges Ahead

With the surge in fracturing activities, on account of the discovery of new reservoirs of shale gas, the requirement for frac sand, which is a proppant, is rising sharply. As per the Railroad Commission of Texas (RRC), the number of wells that were completed during January–March 2017 was 1,925 and this number will rise to 2,712 during January-March 2018. This subsequently increased the…

View On WordPress

#Proppant Market#Proppant Market Growth#Proppant Market Outlook#Proppant Market Research Report#Proppant Market Share#Proppant Market Size#Proppant Market Trends

0 notes

Text

Fracking Revolution: Examining the Global Proppant Market and Its Key Role in the Oil and Gas Industry's Success

With the surge in fracturing activities, on account of the discovery of new reservoirs of shale gas, the requirement for frac sand, which is a proppant, is rising sharply. As per the Railroad Commission of Texas (RRC), the number of wells that were completed during January–March 2017 was 1,925 and this number will rise to 2,712 during January-March 2018. This subsequently increased the requirement for frac sand. According to various reports, the demand for the material is predicted to rise from 45 million tons in 2016 to 110 million tons in 2018.

This material is needed to break the pores in the reservoir for creating a vent, which will allow the shale gas to flow up to the surface. As frac sand is cheaper than other proppants, it is widely used all over the world. Besides this factor, the development of environment friendly and non-phenolic resin-coated materials is also creating lucrative growth opportunities for the players operating in the proppant market. As the phenolic-based resin-coated material causes various environmental issues such as the contamination of water, many companies like the Dow Chemical Company and Preferred Sands are developing non-phenolic resin-coated materials, which are highly eco-friendly.

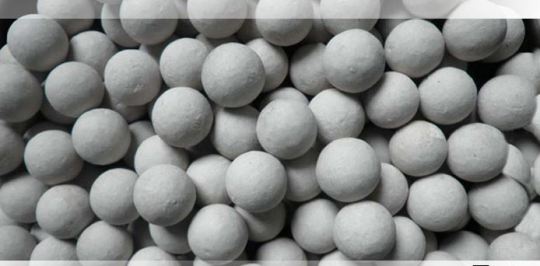

There are mainly three types of proppants used across the world—resin-coated, sand, and ceramic. The ceramic proppants are further classified into high-density, medium-density, and low-density variants. Out of the three types of proppants, the demand for the sand materials was found to be the highest in 2017. This was because of their lower cost than the other variants. Moreover, these materials are extensively used by exploration and production (E&P) organizations in fracturing processes.

Browse Full Report Proppant Market Growth Drivers Impact Analysis

#Proppant Market#Proppant Market Size#Proppant Market Share#Proppant Market Trends#Proppant Market Growth#Proppant Market Outlook#Proppant Market Research Report

0 notes

Text

Ceramic Proppant Prices: Trend | Pricing | News | Price | Database

Ceramic Proppant are essential materials used in hydraulic fracturing, commonly known as fracking, to enhance the extraction of oil and gas from underground reservoirs. These proppants are made from high-strength ceramic materials that resist crushing under extreme pressure and are designed to keep fractures in the rock formation open, allowing oil or gas to flow freely. The ceramic proppant market has seen significant growth in recent years due to the increasing demand for oil and gas, particularly from shale plays. As a result, the prices of ceramic proppants have fluctuated in response to various factors, including raw material costs, technological advancements, and the supply and demand dynamics within the energy industry.

The price of ceramic proppants is influenced by several key factors, with raw materials being one of the primary determinants. Ceramic proppants are typically made from bauxite, kaolin, and other mineral-based materials. These raw materials have seen price fluctuations due to changes in global supply and demand, mining regulations, and geopolitical events. For instance, bauxite, the primary raw material for ceramic proppants, has been subject to price volatility due to changes in mining activity in countries like China, Australia, and Brazil. The cost of kaolin, another significant material, has also experienced fluctuations, driven by changes in demand from various industries, including ceramics and paper.

Get Real time Prices for Ceramic Proppant: https://www.chemanalyst.com/Pricing-data/ceramic-proppant-1576

In addition to raw material costs, the manufacturing process of ceramic proppants plays a crucial role in determining their price. Ceramic proppants are produced through a high-temperature sintering process, which involves heating the raw materials to a temperature where they melt and form small, spherical pellets. The energy-intensive nature of this process can impact the cost of production, particularly in regions where energy prices are high. Technological advancements in manufacturing processes have led to the development of more efficient methods for producing ceramic proppants, which could potentially reduce production costs and, in turn, impact the overall pricing of these materials.

The supply and demand dynamics of the oil and gas industry also significantly affect the price of ceramic proppants. When oil and gas prices are high, there is typically an increase in exploration and production activity, leading to a higher demand for proppants. Conversely, when oil and gas prices decline, exploration and production activities may slow down, leading to a decrease in demand for proppants. This cyclical nature of the oil and gas industry means that ceramic proppant prices are often highly sensitive to fluctuations in commodity prices. For example, during periods of high oil prices, the demand for hydraulic fracturing services increases, which in turn boosts the demand for ceramic proppants, driving up their prices. However, when oil prices drop, the demand for proppants may decrease, causing prices to soften.

Geopolitical factors can also influence ceramic proppant prices. Trade tensions, sanctions, and changes in government policies can impact the global supply chain for raw materials and finished proppants. For example, trade disputes between major ceramic proppant-producing countries like China and the United States can result in tariffs or restrictions on the import and export of these materials. Such disruptions in the supply chain can lead to shortages or price hikes for ceramic proppants in certain regions. Additionally, government regulations related to the oil and gas industry, such as stricter environmental standards or changes in hydraulic fracturing regulations, can affect the demand for ceramic proppants and, consequently, their prices.

The development of alternative proppant technologies is another factor that can influence ceramic proppant prices. While ceramic proppants are known for their high strength and durability, they are also more expensive than other types of proppants, such as sand. As a result, some oil and gas companies are exploring the use of alternative proppants that offer similar performance at a lower cost. If these alternative technologies gain traction in the market, they could put downward pressure on ceramic proppant prices. However, the high performance and reliability of ceramic proppants continue to make them a preferred choice for many operators, particularly in deep and ultra-deep wells where the risk of crushing is higher.

The competitive landscape of the ceramic proppant market also plays a role in determining pricing trends. Several large multinational companies dominate the market, and these companies typically have the resources and economies of scale to offer ceramic proppants at competitive prices. However, smaller, regional manufacturers may provide lower-cost alternatives, contributing to price fluctuations within the market. Additionally, the level of competition can affect the pricing strategies of manufacturers, as companies may adjust their prices based on market conditions and the actions of competitors.

In recent years, the global ceramic proppant market has seen increasing consolidation, with mergers and acquisitions taking place between major players in the industry. These strategic moves are aimed at expanding production capabilities, improving market reach, and achieving cost efficiencies. As a result, the consolidation trend may impact the competitive landscape and pricing dynamics in the future, as larger companies are able to leverage their resources to maintain competitive pricing.

In conclusion, the ceramic proppant market is influenced by a complex set of factors, including raw material costs, manufacturing processes, supply and demand dynamics in the oil and gas industry, geopolitical factors, and the competitive landscape. While ceramic proppants are a premium product in terms of strength and performance, their prices are subject to fluctuations based on the broader economic and energy market conditions. As the demand for hydraulic fracturing services continues to rise in response to growing global energy needs, the ceramic proppant market is expected to remain a key component of the oil and gas industry, with price trends being closely tied to the ebb and flow of global commodity prices and technological advancements.

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Ceramic Proppant#Ceramic Proppant Prices#Ceramic Proppant Price Trend#Ceramic Proppant News#Ceramic Proppant Monitor#india#united kingdom#united states#germany#business#research#chemicals#Technology#Market Research

0 notes

Text

https://linkewire.com/2025/01/28/proppants-market-valued-at-13-23-billion-by-2028-cagr-8-6/

0 notes

Text

Latin America Silica Sand Market Outlook and Forecast 2025-2032

Silica sand, also known as industrial sand, is a high-purity form of quartz sand that undergoes processing to meet specific industrial and manufacturing requirements. It consists primarily of silicon dioxide (SiO₂), with purity levels exceeding 95% in most commercial applications. The sand is categorized based on its grain size, impurity levels, and intended use.

Silica sand is a crucial raw material in industries such as glass manufacturing, construction, foundry applications, hydraulic fracturing (oil & gas), filtration, and ceramics. The demand for silica sand in Latin America has increased significantly due to the expansion of construction activities, growth in the glass industry, and rising industrialization across major economies such as Brazil and Mexico.

Download a Free Sample Report PDF @ https://www.24chemicalresearch.com/download-sample/286438/latin-america-silica-s-market-2025-2032-201

Market Size

The Latin America Silica Sand Market was valued at US$ 845 million in 2024 and is expected to reach US$ 1.12 billion by 2030, growing at a CAGR of 4.8% during the forecast period from 2024 to 2030.

Key Market Trends and Statistics:

Historical Growth: The market has grown steadily over the past decade due to increasing demand in construction, glass production, and foundry applications.

Projected Demand: The demand for high-purity silica sand is projected to rise with the expansion of the solar panel manufacturing sector, which requires ultra-clear glass made from superior-grade silica sand.

Production Growth: Leading silica sand producers in Latin America, including Brazil, Mexico, and Chile, are investing in advanced mining technologies to enhance production efficiency.

End-Use Distribution:

Glass Manufacturing: 35%

Construction: 28%

Foundry Applications: 22%

Oil & Gas (Hydraulic Fracturing): 15%

Quality Segmentation:

High-grade (>99% SiO₂): 42%

Medium-grade (98-99% SiO₂): 35%

Standard-grade (<98% SiO₂): 23%

Market Dynamics

Drivers

Rising Demand for Glass Manufacturing

The expansion of automotive, construction, and solar energy industries has driven the demand for high-quality silica sand for glass production.

Latin America's glass manufacturing industry is expected to grow at a CAGR of 5.2% through 2030.

Infrastructure Development & Urbanization

Countries like Brazil, Mexico, and Argentina are witnessing rapid urbanization, leading to increased demand for cement, concrete, and silica-based construction materials.

Growing Oil & Gas Exploration

The hydraulic fracturing (fracking) industry in Argentina and Mexico is fueling demand for proppant-grade silica sand.

Restraints

Environmental Regulations & Mining Restrictions

Strict regulations on sand mining activities due to environmental concerns may limit production capabilities.

Governments are enforcing sustainable mining practices to protect natural water bodies and ecosystems.

High Transportation Costs

Transporting bulk silica sand across long distances increases logistics costs, impacting profitability.

Opportunities

Sustainable Mining Practices

Companies investing in eco-friendly mining technologies and water-efficient processing methods have a competitive advantage.

Expansion of High-Purity Silica Market

Electronic-grade silica sand used in semiconductors and solar panels is gaining traction.

Challenges

Supply Chain Disruptions

Geopolitical tensions and trade policies can disrupt the export and import of silica sand.

Fluctuations in Raw Material Prices

Variability in the cost of extraction, processing, and transportation impacts overall pricing.

Regional Analysis

Brazil

Largest producer of silica sand in the region.

Major players are investing in new silica mines and advanced processing plants.

Growing construction and solar energy sector fueling silica demand.

Mexico

Strong export market for silica sand, particularly to the United States.

Increased usage in glass and filtration industries.

Chile

Foundry industry and ceramic manufacturing are the key drivers of silica sand consumption.

Government incentives to boost mining activities.

Other Countries

Argentina, Colombia, Peru, and Venezuela contribute to the market with localized mining operations and niche industry applications.

Competitor Analysis

Major Players in the Latin America Silica Sand Market

Sibelco – Leading supplier with a strong presence in Brazil and Mexico.

Canteras Industriales – Focuses on high-purity silica sand production.

Arena Silícea Dorada – Key supplier in Argentina.

Emisiles C.A – Specialized in foundry-grade silica sand.

Saint-Gobain – Major player in the glass and construction sector.

Industrias Extractivas de México, S.A. de C.V. – Large-scale mining operations in Mexico.

Mineração Jundu Ltda – Major silica sand producer in Brazil.

Grupo Arenas y Gravas Silicas – Key regional player in filtration-grade silica sand.

Arena Sílice de Veracruz – Mexican supplier with a strong export market.

Market Segmentation (by Application)

1. Construction

Used in concrete, cement, and road construction.

2. Glass Manufacturing

High-purity silica sand is essential for flat glass, container glass, and specialty glass.

3. Filtration

Used in water treatment plants for removing contaminants.

4. Foundry

Foundry-grade silica sand is used for molding and core-making in metal casting.

5. Ceramics & Refractories

Essential for tiles, sanitaryware, and high-temperature-resistant materials.

Market Segmentation (by Type)

Less than 40 mesh – Used in construction applications.

40-70 mesh – Preferred for glass manufacturing and filtration.

More than 70 mesh – Used in high-purity applications like semiconductors.

Key Company Profiles

Sibelco

Canteras Industriales

Arena Silícea Dorada

Emisiles C.A

Saint-Gobain

Industrias Extractivas de México, S.A. de C.V.

Mineração Jundu Ltda

Grupo Arenas y Gravas Silicas

Arena Sílice de Veracruz

Geographic Segmentation

Brazil

Mexico

Argentina

Chile

Colombia

Peru

Venezuela

FAQ

What is the current market size of the Latin America Silica Sand Market?

➣ The market was valued at US$ 845 million in 2024 and is expected to grow to US$ 1.12 billion by 2030 at a CAGR of 4.8%.

Which are the key companies operating in the Latin America Silica Sand Market?

➣ Major companies include Sibelco, Saint-Gobain, Mineração Jundu Ltda, and Industrias Extractivas de México.

What are the key growth drivers in the Latin America Silica Sand Market?

➣ The main growth drivers are increased demand from the glass industry, urbanization, and rising hydraulic fracturing activities.

Which regions dominate the Latin America Silica Sand Market?

➣ Brazil, Mexico, and Chile are the top producers.

What are the emerging trends in the Latin America Silica Sand Market?

Eco-friendly mining practices

Expansion in high-purity silica for semiconductors

Increased use in renewable energy applications

Competitor Analysis

The report also provides analysis of leading market participants including:

Key companies Silica Sand revenues in Latin America market, 2019-2024 (Estimated), ($ millions)

Key companies Silica Sand revenues share in Latin America market, 2023 (%)

Key companies Silica Sand sales in Latin America market, 2019-2024 (Estimated),

Key companies Silica Sand sales share in Latin America market, 2023 (%)

Key Points of this Report:

The depth industry chain includes analysis value chain analysis, porter five forces model analysis and cost structure analysis

The report covers Latin America and country-wise market of Silica Sand

It describes present situation, historical background and future forecast

Comprehensive data showing Silica Sand capacities, production, consumption, trade statistics, and prices in the recent years are provided

The report indicates a wealth of information on Silica Sand manufacturers

Silica Sand forecast for next five years, including market volumes and prices is also provided

Raw Material Supply and Downstream Consumer Information is also included

Any other user's requirements which is feasible for us

Reasons to Purchase this Report:

Analyzing the outlook of the market with the recent trends and SWOT analysis

Market dynamics scenario, along with growth opportunities of the market in the years to come

Market segmentation analysis including qualitative and quantitative research incorporating the impact of economic and non-economic aspects

Regional and country level analysis integrating the demand and supply forces that are influencing the growth of the market.

Market value (USD Million) and volume (Units Million) data for each segment and sub-segment

Distribution Channel sales Analysis by Value

Competitive landscape involving the market share of major players, along with the new projects and strategies adopted by players in the past five years

Comprehensive company profiles covering the product offerings, key financial information, recent developments, SWOT analysis, and strategies employed by the major market players

1-year analyst support, along with the data support in excel format.

Download a Free Sample Report PDF @ https://www.24chemicalresearch.com/download-sample/286438/latin-america-silica-s-market-2025-2032-201

0 notes

Text

0 notes

Text

0 notes

Text

Revolutionizing Oil Production: How Modern Technologies Maximize Well Efficiency

In today's competitive energy market, oil producers are under increasing pressure to maximize output while minimizing operational costs. With technological advancements reshaping the landscape, modern drilling and extraction methods have revolutionized oil well efficiency. These innovations not only extend the productive lifespan of wells but also ensure more sustainable and cost-effective operations. This article explores the cutting-edge techniques employed to boost oil well efficiency and drive greater profitability in the energy sector.

Horizontal Drilling: Accessing Hard-to-Reach Reserves

Traditional vertical drilling limits access to certain oil reservoirs, especially those trapped in thin or unconventional layers. Horizontal drilling, however, allows the drill to curve and move horizontally through the oil-rich layer, exposing more surface area to extraction. This technique enables operators to reach reserves that would otherwise remain untapped, significantly increasing production. Horizontal drilling is especially effective in shale formations, where hydrocarbons are dispersed across broad, thin strata.

By drilling multiple horizontal wells from a single platform, companies can also reduce their operations' environmental footprint and optimize production from a limited land area.

Hydraulic Fracturing: Unlocking Unconventional Reservoirs

Hydraulic fracturing, or "fracking," involves injecting high-pressure fluid into rock formations to create fractures. These fractures release trapped oil and gas, making extraction more accessible and more efficient. Fracking has been instrumental in unlocking unconventional reservoirs, including shale and tight sands, where oil would otherwise be inaccessible using traditional methods.

Technological advancements in fracking fluids and proppants (particles used to keep fractures open) have improved efficiency and reduced water consumption, making the process more sustainable. Fracking has also allowed producers to revive old wells by stimulating reservoirs, bringing new life to previously declining operations.

Enhanced Oil Recovery (EOR): Extending Well Lifespans

Enhanced Oil Recovery (EOR) refers to techniques that increase the amount of oil extracted from a reservoir beyond what is achievable through primary and secondary recovery methods. There are three main types of EOR:

Thermal Injection: This involves heating the reservoir, usually with steam, to reduce oil viscosity and improve flow.

Gas Injection: Gases such as carbon dioxide or nitrogen are used to increase reservoir pressure and push more oil to the surface.

Chemical Injection: Injects polymers or surfactants into the reservoir to reduce surface tension and enhance flow.

These methods allow operators to recover up to 60% of the reservoir's total oil, compared to 20–30% through traditional extraction techniques. EOR plays a critical role in extending the productive life of wells and maximizing their yield.

Real-Time Monitoring and Data Analytics

The integration of data analytics and real-time monitoring has become a game-changer in oil well management. Sensors placed throughout wells and pipelines collect data on pressure, temperature, and flow rates. This data is then analyzed using machine learning algorithms to predict equipment failures, optimize production schedules, and detect inefficiencies.

Smart oilfields powered by the Internet of Things (IoT) enable remote monitoring and control, reducing the need for on-site personnel. By identifying potential issues early, operators can perform predictive maintenance, minimizing downtime and enhancing overall efficiency.

Drill Automation and Robotics

Automation has entered the oil and gas sector, with robotic drilling systems improving precision and safety. Automated rigs can operate continuously with minimal human intervention, leading to faster drilling and fewer delays. Additionally, robotic systems handle repetitive tasks, reducing the risk of injury to workers and improving overall operational efficiency.

Companies are also exploring the use of artificial intelligence (AI) to optimize drilling operations, guiding the drill bit in real time to avoid obstacles and maximize reservoir contact. Automation reduces costs by lowering labor requirements and minimizing errors, making it a valuable tool in the quest for more efficient oil production.

Multiphase Pumping: Improving Fluid Handling

In traditional wells, oil, gas, and water are typically separated at the wellhead, requiring different pipelines and processing systems. Multiphase pumping technology simplifies this process by allowing the simultaneous transport of oil, gas, and water through a single pipeline.

This innovation minimizes equipment needs, reduces energy consumption, and lowers operational costs. Multiphase pumps are also used in offshore platforms, where space constraints make traditional separation systems impractical. By streamlining fluid handling, these pumps enhance efficiency and reduce environmental impact.

Sustainability Through Energy Efficiency

Modern oil extraction techniques are increasingly focused on sustainability and minimizing environmental impact. Companies are adopting energy-efficient equipment and practices to lower emissions and reduce waste. For instance, many operators now recycle produced water from wells, cutting freshwater usage.

Additionally, the use of renewable energy sources, such as solar or wind, to power remote facilities is gaining popularity. Combining sustainable practices with advanced extraction techniques ensures that oil production remains viable while meeting environmental standards.

A New Era in Oil Production

The energy sector is undergoing a profound transformation, with modern techniques pushing the boundaries of oil well efficiency. Horizontal drilling, hydraulic fracturing, and Enhanced Oil Recovery unlock more oil from reservoirs while automation, real-time data, and advanced pumping technologies streamline operations. As the industry embraces these innovations, oil companies are better positioned to meet growing energy demands while ensuring cost-effectiveness and sustainability. The future of oil production lies in continuously refining these technologies to maximize output and minimize environmental impact, ushering in a new era of more intelligent and more responsible oil extraction.

0 notes