#cement silo manufacturer

Explore tagged Tumblr posts

Text

Boosting Construction Efficiency with the Right Cement Silo

What is Concrete Batching Plant?

A Concrete Batching Plant is a facility where various ingredients such as cement, water, sand, aggregates (like gravel or crushed stone), and sometimes additives are mixed together to produce concrete. These plants ensure a consistent, high-quality mix by accurately weighing and blending the materials according to specific recipes, which is crucial for achieving the desired strength and durability of the concrete.

Cement Silo

In construction, efficiency is paramount. From project timelines to material handling, every element must work seamlessly to meet deadlines and budgets. One often-overlooked tool that significantly impacts efficiency is the cement silo. Choosing the right cement silo can streamline operations, reduce costs, and ensure quality control for concrete-based projects. This guide will cover how the right cement silo can enhance efficiency and what factors to consider when selecting one.

Understanding the Role of a Cement Silo

A cement silo is a storage solution specifically designed for cement and other fine, dry materials like fly ash or lime. It keeps these materials safe from moisture and contamination, which is essential for maintaining their quality. Cement silos can be found in various forms—stationary or portable, large or small—each suited to specific construction needs. By having cement readily available on-site, crews can mix concrete consistently and quickly, avoiding delays associated with transporting materials from distant storage locations.

Benefits of Using the Right Cement Silo

Using the right cement silo can make a significant difference in construction efficiency. Here’s how:

Optimized Material Handling

Cement silos provide efficient storage, allowing for a seamless flow of material when needed. With built-in systems like pneumatic or screw conveyors, cement can be transferred directly to mixers without manual handling, reducing labor requirements and minimizing material waste.

Cost Savings

Bulk storage in a silo eliminates the need for frequent deliveries and reduces reliance on bagged cement, which can be costly and environmentally taxing. By buying in bulk, companies can also negotiate better prices, reducing overall project costs.

Quality Control

Keeping cement in a well-sealed silo prevents exposure to moisture, which can compromise the material’s effectiveness. A silo ensures that cement is kept dry and ready for use, improving concrete quality and durability, which is crucial for the longevity of any structure.

Reduced Downtime

Having cement readily accessible in a silo minimizes downtime associated with reordering or transporting material. This is especially beneficial on large construction sites where concrete is needed continuously.

Environmental Benefits

Reducing the use of bagged cement decreases plastic waste and packaging materials. Additionally, the controlled handling of cement in a silo minimizes dust and material loss, promoting a cleaner work environment.

Types of Cement Silos and Choosing the Right One

There are several types of cement silos, each suited for different operational needs. Here’s a breakdown of the most common types:

Horizontal Cement Silos

These silos have a low profile, making them easy to transport and set up on-site. They’re ideal for sites with height restrictions and offer convenient access for loading and maintenance.

Vertical Cement Silos

Vertical silos, typically larger than horizontal ones, have a smaller footprint and can store a greater volume of cement. They’re suited for large projects where storage capacity is a priority, and they often come with advanced features like remote level monitoring.

Mobile or Portable Cement Silos

Mobile silos are designed for projects where mobility is essential. These silos are easy to transport and set up, making them perfect for temporary sites or projects requiring flexibility.

Stationary Cement Silos

Stationary silos are ideal for long-term projects or permanent batching plants. With higher capacities and customizability, they provide stable storage and are equipped with advanced loading systems to keep material accessible.

When choosing a cement silo, consider the following factors:

Project Scale and Duration: Large-scale projects benefit from high-capacity, stationary silos, while short-term or mobile projects may require portable options.

Space Availability: Assess your site for height and space restrictions. Horizontal silos are suitable for compact areas, while vertical silos save ground space.

Material Handling Needs: Look for silos with integrated conveyors or pneumatic systems if you need fast and efficient material transfer.

Climate and Weather Conditions: Ensure the silo is durable enough to withstand your local weather, as exposure to moisture and extreme temperatures can impact cement quality.

Best Practices for Cement Silo Maintenance

To maintain efficiency, it’s essential to keep the cement silo in good working condition. Here are some tips:

Regular Cleaning: Cement silos can experience build-up, which reduces capacity and can cause blockages. Schedule regular cleanings to maintain efficient material flow.

Inspect Safety Valves and Filters: Over time, pressure and vacuum relief valves and filters may wear out. Inspect these regularly to prevent accidents and ensure a dust-free environment.

Check for Moisture Control: Ensure seals and gaskets are tight to keep moisture out. Moisture can compromise cement quality, so maintain a dry environment within the silo.

Level Monitoring: Use level indicators to monitor the cement levels and avoid material shortages. Some advanced silos come with remote monitoring features to make this easier.

How Cement Silos Contribute to Sustainable Construction

The use of cement silos aligns well with sustainable construction practices. Bulk storage reduces the need for single-use packaging, while efficient handling systems cut down on dust and emissions from bagged cement. Some silos are designed to be energy-efficient, with low-energy consumption motors or advanced insulation, further supporting environmentally-friendly operations.

Conclusion

Choosing the right cement silo is essential for optimizing construction efficiency. From reducing material waste to improving workflow and controlling costs, the right silo can make a big difference in the success of a project. By selecting a silo that matches your project’s scale, location, and storage needs, you can ensure reliable, high-quality concrete supply that keeps your project running smoothly and sustainably.

#Tags:cement silo#cement silo capacity#cement silo Gujarat#cement silo Manufacturer#cement silo manufacturer and supplier#cement silo manufacturering#concrete batching plant

0 notes

Video

youtube

9855597851 | Mini Concrete Transit Mixer Tractor operated | Manufacturer...

Navya Engineers & Equipments is a prominent manufacturer & exporter of Automatic Concrete Batching Plants, Cement Silos & Tractor operated Concrete Transit Mixer.

#youtube#tractor transit mixers#mini transit mixers#mini concrete transit mixers#tractor transit mixer manufacturers#4cum capacity transit mixer#concrete batching plants manufacturer#mobile concrete batching plants#cement silo manufacturer#construction equipment manufacturing company#navya equipments

0 notes

Text

1 note

·

View note

Text

Fly Ash Silos: Sustainable Solutions for Modern Construction Needs

In modern construction, sustainability has emerged as a crucial aspect of project planning and execution. Among the innovations driving this change, fly ash silos play a pivotal role. These storage solutions not only improve operational efficiency but also contribute to eco-friendly construction practices. If you’re looking to invest in reliable fly ash storage systems, understanding their features and benefits can help you make informed decisions.

What is a fly ash silo?

A fly ash silo is a specialized structure designed to store and manage fly ash, which is a product of coal combustion in power plants. Thanks to advances in construction technology, these silos are now an integral part of products such as cement production and concrete mix production.

Fly ash silos come in a variety of styles, including Radimix welded silos and modular structures, designed to meet industrial needs. Their system offers greater storage capacity for fly ash and less environmental impact.

Why choose a fly ash silo?

Efficient storage:

Fly ash silos are designed to control the bulk density of most products, providing efficient fly ash storage for large operations.

Environmentally friendly solutions:

By collecting and recycling fly ash, these silos reduce environmental waste and encourage sustainable production.

Durability and reliability:

Leading manufacturers build cylons from rugged materials, ensuring their durability and reliability in extreme conditions.

Key Features of Fly Ash Storage Silos

High Capacity: Designed to efficiently collect significant amounts of fly ash.

Flexible Design: Manufacturers of large fly ash silos offer options to suit specific project needs.

Integrated silo feeding system: Improved feed system simplifies fly ash transfer, reducing processing time.

Miscellaneous Uses: Suitable for storing cement, fly ash, and other building materials.

Choosing the Right Fly Ash Silo Manufacturer

When choosing a manufacturer of fly ash cement silos, it is important to examine their experience and range of products. For celebrities:

High quality fly ash silos for sale

Customizable designs to suit fly ash storage requirements.

Comprehensive solutions, including cement storage silos and integrated systems.

Applications of Fly Ash Silos in Construction

Cement Production: Fly ash silos are widely used for blending and storing fly ash with cement, ensuring consistent quality.

Ready-Mix Concrete Plants: The readymix welded silo design is ideal for batching plants, enabling efficient material handling.

Eco-Friendly Construction: Storing and reusing fly ash helps reduce the carbon footprint of construction projects.

Fly Ash Silos: Sustainability at Its Core

With the construction industry shifting towards greener practices, fly ash storage silos have become a cornerstone of sustainability. By reducing waste and proper storage, these silos not only improve efficiency but also contribute to a cleaner environment.

Why Choose RCMPL for Fly Ash Silos?

At RCMPL, we specialize in the construction of state-of-the-art fly ash storage silos. Whether you are looking for a high capacity fly ash silo or a robust silo feeding system, we have the expertise to provide a customized solution.

Our offerings include:

High capacity fly ash silos for sale

Strong cement storage silos

Easy integrated internal control systems

Explore our full range of solutions at RCMPL and discover how we can enhance your manufacturing process.

Conclusion

Investing in a quality fly ash silo is a step towards sustainable and efficient production. With state-of-the-art solutions and innovative features, this storage system meets the growing demands of modern manufacturing. Whether you’re an entrepreneur or business owner, ensuring reliable fly ash storage is essential to being productive and environmentally responsible.

Ready to take the next step? Contact us at RCMPL and explore our fly ash silos today!

#fly ash silo#fly ash storage#fly ash silo manufacturer#Fly Ash Storage Silo#Fly Ash Storage Silo Capacity#Manufacturer of Fly Ash Cement Silo#Fly Ash Silos For Sale

0 notes

Text

Top 10 Cement Silo Dust Collector Manufacturer

Key Features:

High-Efficiency Filtration: The dust collector utilizes high-quality filtration media and advanced filtration technology to capture even the finest dust particles, ensuring compliance with stringent environmental regulations.

Robust Construction: Built with durable materials and a robust design, the dust collector is capable of withstanding harsh industrial environments and prolonged operation, minimizing maintenance downtime.

Modular Design: The modular design of the dust collector allows for easy installation and scalability, catering to varying cement silo sizes and production capacities.

Optimized Airflow: The system is engineered to maintain optimal airflow within the cement silo, preventing dust buildup and maintaining efficient material flow.

Advanced Control System: Equipped with an intelligent control system, operators can monitor and adjust key parameters such as airflow rate, pressure drop, and filter status for optimal performance and energy efficiency.

Easy Maintenance: Designed for ease of maintenance, the dust collector features accessible filter elements and serviceable components, reducing downtime and maintenance costs.

Compliance and Safety: Ventilair prioritizes safety and regulatory compliance, ensuring that the dust collector meets or exceeds industry standards for dust emissions control and workplace safety.

Applications:

Cement manufacturing plants Concrete production facilities Construction sites Industrial warehouses and storage facilities

Benefits:

Minimizes dust emissions for a cleaner and safer work environment Protects equipment from dust contamination, extending operational life Reduces maintenance costs and downtime Enhances overall productivity and operational efficiency

If you want to know more about our Cement Silo Dust Collector Manufacturer how they are useful for your work , please contact us today . Our team is always here to help and find best solutions for your specific needs.

Visit: https://www.ventilair.in/cement-silo-dust-collector/

Address: №11/7, Mile Stone, Mathura Road, Faridabad — 121003, Haryana, India

#cement#silo#dust#collection#manuifacturer#clean#air#vent#run#natural#nature#silo apple tv#air handling unit manufacturers#air washer system#cleanair#blower#industry#anushka sharma#dust collector#silouette#siloedit#juliette nichols#friday night lights#ilovehotactresses#the mummy returns#don draper#factory#silo series

1 note

·

View note

Text

Grain Bulkers Manufacturer | Bitumen Distributor Manufacturer | Storage Silos Manufacturer

Established in the UAE in 1997, Qasioon has emerged as a pioneering force in the fabrication of trailers and storage tanks within the GCC. Over the years, our dedicated team has honed their skills and accumulated extensive experience in crafting superior-quality trailers and storage tanks. Committed to excellence, we prioritize the highest standards of quality assurance. Embracing cutting-edge technology and innovative techniques, we ensure that our products not only meet but exceed stringent safety standards.

Our commitment to customer satisfaction goes beyond the ordinary. We specialize in custom fabrication services, tailoring our solutions to the unique requirements of our clients. This personalized approach has allowed us to forge lasting relationships with our customers.

Having earned a commendable reputation in the fiercely competitive domestic market, Qasioon set its sights on expansion. We ventured into the broader landscape of the GCC region, extending our operations to encompass countries such as Oman, and Yemen, and even reaching into the African continent. This strategic move is a testament to our unwavering dedication to delivering top-notch products and services beyond borders, solidifying our position as a trusted name in the industry. As we continue to grow and evolve, Qasioon remains at the forefront of the trailers and storage tank manufacturer, driven by a commitment to quality, innovation, and customer satisfaction.

Grain Bulkers Manufacturer

Bitumen Distributor Manufacturer

Low Bed Trailer Manufacturer

Mobile Fuel Station Manufacturer

Storage Silos Manufacturer

Cement Bulk Tanker UAE

0 notes

Text

Building a Stronger Infrastructure - Awadh RMC

Building is the foundation of any city's growth, and good concrete is the foundation of every strong structure or long-lasting road. Ready-Mix Concrete (RMC) has completely transformed the construction sector by offering consistent, dependable, and effective concrete solutions. RMC guarantees quality and saves time in infrastructure development, business complexes, and residential projects.

Uttar Pradesh's capital, Lucknow, is seeing a boom in building. There is a greater need than ever for high-quality RMC in large-scale infrastructure projects and contemporary residential complexes. Selecting the best RMC plant in Lucknow is essential to guarantee the durability and strength of your project.

What do we do?

At Awadh RMC, We manufacture top quality Ready mix concrete for the construction of high-rise buildings, roads, bridges, & complex construction. We have certified engineers to manufacture strong ready-mix concrete & we have various testing labs to ensure the strength of concrete.

Benefits of Ready Mix Concrete Over Traditional Mixing Methods:

Consistency: RMC facilities produce consistent quality by maintaining precise proportions with the use of automated technology.

Time-saving: By removing the requirement for on-site mixing, ready-made concrete expedites the building process.

Decreased Waste: Accurate measurements guarantee that little raw resources are wasted.

Environmentally friendly: RMC manufacturing reduces noise and dust pollution.

Key Components of an RMC Plant:

The batching unit makes sure that the materials are measured precisely.

Mixing Unit: A strong mixer is used to combine the ingredients for concrete.

Raw materials like aggregates and cement are kept in storage silos.

Control System: Automatic systems that keep an eye on the whole operation.

Concrete is delivered to the construction site by specialized trucks called transit mixers.

RMC Plant in Lucknow

Lucknow is becoming a significant center for building and infrastructural development. With new commercial, industrial, and residential projects underway, the city's skyline is changing quickly. In recent years, there has been a notable increase in the demand for superior Ready-mix concrete.

Urbanization: As the population grows, so does the need for homes and businesses.

Infrastructure Development: Reliable solid solutions are needed for projects like flyovers, highways, and metro expansions.

Accessibility: The transportation of RMC and the delivery of raw materials are made easier by Lucknow's connections with neighboring cities.

Examples of RMC Usage in Lucknow:

construction of contemporary residential structures.

construction of shopping centers and commercial complexes.

Roads, bridges, and public utilities are examples of infrastructure projects.

Best RMC Plant in Lucknow

Not every RMC plant is made equally. Selecting the top RMC plant in Lucknow is crucial to the success of your project. Here are some things to think about:

1. Concrete Quality: To create reliable and long-lasting concrete, a top-notch RMC facility employs sophisticated equipment and stringent quality control procedures. Seek out facilities that have earned certifications such as ISO 9001, which attest to their compliance with quality standards.

2. On-time Delivery: Construction projects frequently have strict timelines. In order to produce concrete on schedule and guarantee continuous project progress, a reputable RMC facility needs have effective logistics.

3. Cost-Effectiveness: Affordability is important, but so is quality. The top RMC facilities provide affordable prices without sacrificing quality.

4. Customer Service: A trustworthy RMC provider will have excellent customer service. They must to answer your questions promptly and be prepared to meet the demands of a particular job.

How the Best RMC Plants Ensure Quality:

utilizing premium raw materials.

Concrete batches are routinely tested for durability and strength.

competent engineers and technicians managing the manufacturing process.

Top RMC Manufacturers in Lucknow

Awadh RMC is the best RMC plant in Lucknow. And, We are the leading manufacturers of top-quality ready-mix concrete. Why we are different from others?

1. Advanced Technology: To guarantee accuracy and productivity in production, top RMC

manufacturers employ automated methods and cutting-edge gear.

2. Skilled Teams: Skilled engineers and technicians are essential to upholding quality standards and fulfilling project-specific specifications.

3. Sustainable Practices: Leading producers place a high priority on environmentally friendly procedures including wastewater recycling and lowering carbon emissions during manufacturing.

Standards & Certifications: Seek out producers who hold certifications such as BIS (Bureau of Indian Standards) and ISO 14001 (environmental management). A dedication to sustainability and quality is demonstrated by these certifications.

Tips for Selecting the Right Manufacturer:

Examine prior customer reviews and testimonials.

Visit the plant to look at its equipment and procedures.

Examine the offers and quotes from several manufacturers.

Chose Awadh RMC for All types of construction projects?

There are various benefits to collaborating with regional RMC manufacturers:

1. Quicker Delivery: Fresh concrete can be delivered swiftly by nearby plants while maintaining its quality and workability.

2. Cost Savings: Local RMC is less expensive than vendors from farther away due to lower transportation costs.

3. Recognizing Local Needs: Local producers are able to customize their goods in accordance with the city's development problems, which include soil conditions and climate.

4. Supporting Local Businesses: You may boost the local economy and encourage the creation of jobs in the area by selecting RMC plants that are located nearby.

Conclusion

The Ready-Mix Concrete's efficiency, quality, and dependability have made it an essential component of contemporary building. High-quality RMC is essential to the booming construction sector in Lucknow in order to meet its expanding demands. Selecting the appropriate RMC

0 notes

Text

Galvanized Steel Silos: Durable and Efficient Storage Solutions

Galvanized Steel Silos: Durable and Efficient Storage Solutions

As a global leader in bolted storage tank manufacturing, Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) offers high-quality galvanized steel silos tailored to meet the diverse storage needs of agricultural, industrial, and commercial sectors. Designed with durability, efficiency, and cost-effectiveness in mind, our galvanized steel silos provide a reliable solution for the safe and long-term storage of bulk materials.

What Are Galvanized Steel Silos?

Galvanized steel silos are storage structures made from high-grade steel coated with a layer of zinc for enhanced corrosion resistance. This protective coating ensures that the silos can withstand harsh environmental conditions, making them suitable for both indoor and outdoor applications.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Key Features of Center Enamel’s Galvanized Steel Silos

Corrosion Resistance

The galvanized coating protects the steel from rust and corrosion, ensuring long-term performance even in humid or saline environments.

Robust Construction

Our silos are constructed using high-strength steel sheets and precision engineering techniques, providing exceptional structural integrity.

Customizable Design

Center Enamel offers galvanized silos in various capacities, diameters, and heights to accommodate specific storage requirements, ranging from a few tons to thousands of tons.

Ease of Installation

The modular design of our silos enables quick and efficient on-site assembly, reducing construction time and labor costs.

Versatile Applications

Suitable for storing grains, seeds, feed, cement, biomass, and other bulk materials, our silos cater to a wide range of industries.

Cost-Effective Solution

With minimal maintenance requirements and a long service life, galvanized steel silos are an economically sound investment.

Applications of Galvanized Steel Silos

Our galvanized silos serve diverse industries, including:

Agriculture: Grain, seed, and feed storage.

Food and Beverage: Raw material storage for processing.

Construction: Storage of cement, sand, and aggregates.

Biomass Energy: Secure storage of wood chips, pellets, and other biomass materials.

Advantages of Center Enamel’s Galvanized Steel Silos

Enhanced Safety and Quality

The seamless design and airtight sealing ensure the safe storage of materials, preventing contamination and spoilage.

High Capacity and Efficiency

Our silos are designed for maximum storage capacity while optimizing space utilization.

Global Standards Compliance

Center Enamel’s galvanized silos meet international quality and safety standards, ensuring superior performance and reliability.

Sustainability Focus

Galvanized steel is a recyclable material, making our silos an eco-friendly choice for environmentally conscious businesses.

Proven Track Record in Global Projects

Center Enamel’s galvanized steel silos have been successfully implemented in numerous projects across more than 100 countries, including agricultural grain storage projects in Africa, cement storage in Asia, and feed storage facilities in North America.

Why Choose Center Enamel?

Expertise: Over three decades of experience in storage tank and silo manufacturing.

Innovation: Advanced technology and continuous R&D ensure cutting-edge solutions.

Global Reach: A trusted partner in storage solutions for clients worldwide.

Customer-Centric Approach: Tailored solutions and exceptional after-sales support.

Center Enamel: Your Partner in Storage Solutions

As a leading manufacturer of galvanized steel silos, Center Enamel is committed to delivering high-quality products that enhance storage efficiency and protect your valuable materials. Whether you are storing grains, feed, or industrial raw materials, our silos provide the durability and reliability you need for seamless operations.

Contact us today to learn more about our galvanized steel silos and how we can support your storage needs with innovative and sustainable solutions.

0 notes

Video

youtube

High Quality Cement Silo Manufacturer/Fabricant de silos à ciment de hau...

0 notes

Text

Top Features to Look for in a Ready Mix Concrete Batching Plant

Choosing the right ready mix concrete batching plant is critical for ensuring the quality and efficiency of construction projects. With numerous options available, identifying key features that align with project requirements is essential. Partnering with trusted construction equipment manufacturers can make all the difference in finding a solution that meets your needs. Below, we explore the top features to look for in a ready mix concrete batching plant.

Capacity and Output

The capacity of a batching plant determines its suitability for different project scales. Whether it’s a small residential project or a large-scale infrastructure development, selecting a plant with an output capacity that matches your needs is essential to maintain efficiency and prevent delays.

Accuracy and Consistency in Mix

Consistency is paramount in ready-mix concrete production. Look for a batching plant that offers high precision in ingredient measurement, ensuring uniform quality in every batch. Advanced weighing systems and accurate mixing mechanisms can help achieve this.

Automation and Control Systems

Automation in batching plants simplifies operations and enhances productivity. Automated systems reduce manual intervention, minimize errors, and improve overall efficiency. Key features include programmable logic controllers (PLCs) and user-friendly interfaces.

Features of Modern Control Systems

Modern control systems bring sophistication to batching plants. Features such as real-time monitoring, remote control, and data logging enable operators to maintain optimal plant performance. Integration with IoT technologies is an added advantage for enhanced operational control.

Material Handling and Storage

Efficient material handling and storage systems ensure seamless operations. Features like separate compartments for aggregates, cement silos with proper ventilation, and advanced conveyors contribute to better management of materials and reduce wastage.

Energy Efficiency

Energy-efficient designs not only reduce operational costs but also contribute to environmental sustainability. Look for plants equipped with energy-saving components such as variable frequency drives (VFDs) and optimized power consumption systems.

Mobility and Flexibility

For projects requiring frequent site changes, mobile ready-mix concrete batching plants are ideal. Their compact designs, easy assembly, and disassembly processes offer unmatched flexibility.

Durability and Maintenance

Investing in a durable batching plant minimizes downtime and ensures long-term performance. Features like corrosion-resistant materials, robust construction, and easy-to-access components for maintenance enhance the lifespan of the equipment.

Compliance with Environmental Regulations

With stringent environmental standards, it’s crucial to choose a batching plant that adheres to regulations. Dust collectors, water recycling systems, and noise-reduction features are essential for minimizing the environmental impact.

Safety Features

Safety should never be compromised. Modern batching plants come with features like emergency stop buttons, enclosed moving parts, and warning alarms to ensure operator safety and prevent accidents.

Cost-Effectiveness

Balancing quality with cost-effectiveness is key when selecting a batching plant. Assess the total cost of ownership, including initial investment, operational costs, and maintenance expenses, to make an informed decision.

Contact a Reliable Construction Equipment Manufacturer

Partnering with a trusted construction equipment manufacturer is essential for ensuring quality and after-sales support. Reliable manufacturers provide tailored solutions, training, and maintenance services to help you maximize the efficiency of your ready-mix concrete batching plant.

Read More: Top Features of a Ready Mix Concrete Batching Plant

By considering these features, you can choose the perfect batching plant that enhances productivity, ensures consistency, and delivers long-term value for your projects.

0 notes

Text

Boosting Construction Efficiency with the Right Cement Silo

What is Concrete Batching Plant?

A Concrete Batching Plant is a facility where various ingredients such as cement, water, sand, aggregates (like gravel or crushed stone), and sometimes additives are mixed together to produce concrete. These plants ensure a consistent, high-quality mix by accurately weighing and blending the materials according to specific recipes, which is crucial for achieving the desired strength and durability of the concrete.

Cement Silo

In construction, efficiency is paramount. From project timelines to material handling, every element must work seamlessly to meet deadlines and budgets. One often-overlooked tool that significantly impacts efficiency is the cement silo. Choosing the right cement silo can streamline operations, reduce costs, and ensure quality control for concrete-based projects. This guide will cover how the right cement silo can enhance efficiency and what factors to consider when selecting one.

Understanding the Role of a Cement Silo

A cement silo is a storage solution specifically designed for cement and other fine, dry materials like fly ash or lime. It keeps these materials safe from moisture and contamination, which is essential for maintaining their quality. Cement silos can be found in various forms—stationary or portable, large or small—each suited to specific construction needs. By having cement readily available on-site, crews can mix concrete consistently and quickly, avoiding delays associated with transporting materials from distant storage locations.

Benefits of Using the Right Cement Silo

Using the right cement silo can make a significant difference in construction efficiency. Here’s how:

Optimized Material Handling

Cement silos provide efficient storage, allowing for a seamless flow of material when needed. With built-in systems like pneumatic or screw conveyors, cement can be transferred directly to mixers without manual handling, reducing labor requirements and minimizing material waste.

Cost Savings

Bulk storage in a silo eliminates the need for frequent deliveries and reduces reliance on bagged cement, which can be costly and environmentally taxing. By buying in bulk, companies can also negotiate better prices, reducing overall project costs.

Quality Control

Keeping cement in a well-sealed silo prevents exposure to moisture, which can compromise the material’s effectiveness. A silo ensures that cement is kept dry and ready for use, improving concrete quality and durability, which is crucial for the longevity of any structure.

Reduced Downtime

Having cement readily accessible in a silo minimizes downtime associated with reordering or transporting material. This is especially beneficial on large construction sites where concrete is needed continuously.

Environmental Benefits

Reducing the use of bagged cement decreases plastic waste and packaging materials. Additionally, the controlled handling of cement in a silo minimizes dust and material loss, promoting a cleaner work environment.

Types of Cement Silos and Choosing the Right One

There are several types of cement silos, each suited for different operational needs. Here’s a breakdown of the most common types:

Horizontal Cement Silos

These silos have a low profile, making them easy to transport and set up on-site. They’re ideal for sites with height restrictions and offer convenient access for loading and maintenance.

Vertical Cement Silos

Vertical silos, typically larger than horizontal ones, have a smaller footprint and can store a greater volume of cement. They’re suited for large projects where storage capacity is a priority, and they often come with advanced features like remote level monitoring.

Mobile or Portable Cement Silos

Mobile silos are designed for projects where mobility is essential. These silos are easy to transport and set up, making them perfect for temporary sites or projects requiring flexibility.

Stationary Cement Silos

Stationary silos are ideal for long-term projects or permanent batching plants. With higher capacities and customizability, they provide stable storage and are equipped with advanced loading systems to keep material accessible.

When choosing a cement silo, consider the following factors:

Project Scale and Duration: Large-scale projects benefit from high-capacity, stationary silos, while short-term or mobile projects may require portable options.

Space Availability: Assess your site for height and space restrictions. Horizontal silos are suitable for compact areas, while vertical silos save ground space.

Material Handling Needs: Look for silos with integrated conveyors or pneumatic systems if you need fast and efficient material transfer.

Climate and Weather Conditions: Ensure the silo is durable enough to withstand your local weather, as exposure to moisture and extreme temperatures can impact cement quality.

Best Practices for Cement Silo Maintenance

To maintain efficiency, it’s essential to keep the cement silo in good working condition. Here are some tips:

Regular Cleaning: Cement silos can experience build-up, which reduces capacity and can cause blockages. Schedule regular cleanings to maintain efficient material flow.

Inspect Safety Valves and Filters: Over time, pressure and vacuum relief valves and filters may wear out. Inspect these regularly to prevent accidents and ensure a dust-free environment.

Check for Moisture Control: Ensure seals and gaskets are tight to keep moisture out. Moisture can compromise cement quality, so maintain a dry environment within the silo.

Level Monitoring: Use level indicators to monitor the cement levels and avoid material shortages. Some advanced silos come with remote monitoring features to make this easier.

How Cement Silos Contribute to Sustainable Construction

The use of cement silos aligns well with sustainable construction practices. Bulk storage reduces the need for single-use packaging, while efficient handling systems cut down on dust and emissions from bagged cement. Some silos are designed to be energy-efficient, with low-energy consumption motors or advanced insulation, further supporting environmentally-friendly operations.

Conclusion

Choosing the right cement silo is essential for optimizing construction efficiency. From reducing material waste to improving workflow and controlling costs, the right silo can make a big difference in the success of a project. By selecting a silo that matches your project’s scale, location, and storage needs, you can ensure reliable, high-quality concrete supply that keeps your project running smoothly and sustainably.

#cement silo#cement silo capacity#cement silo Gujarat#cement silo Manufacturer#cement silo manufacturer and supplier#cement silo manufacturering#concrete batching plant

0 notes

Text

Compact Bin Concrete Batching Plants is used to produce concrete at sites where space is a constraint for installation of Inline Feeder Plants. Generally Compact Concrete plants are installed where space is limited for both installation of plant & execution of construction projects. Compact Concrete plants are designed & fabricated having material storage bins, belt conveyor arrangement & Mixer unit on a single frame. This design reduce the overall size of inline concrete plants to a compact concrete plant. Compact Concrete plants are also Automatic in operations just like inline concrete plants. Though it has reduced bin, storage capacity is lesser as compared to inline bin concrete plants but there are more benefits of installing a compact concrete batching plant at construction sites mentioned below:

A) Requirement of Lesser space for Installation : Compact Concrete batching plants requires 10 meter & 2.5 meter space for installation.

B) Availablity with All types of Mixer units : Compact concrete batching plants are having versatility with all types of mixer like reversible drum, pan mixer or Twin Shaft mixer.

C) Wide Range of Capacity : Coompact concrete batching plants are available in wide range of capacity having 20M³/Hr , 30M³/Hr , 45M³/Hr & 60M³/H.

D) Power Consumption : Compact Concrete batching plants consume lesser power. Electric Power Consumption required for a Compact batching plant is 82KVA.

Navya Engineers & Equipments is a leading & prominent manufacturing company of Automatic Concrete Batching Plants, Tractor Transit Mixers & Silos for Cement & Fly Ash. For more Product details Visit www.navyaindia.in or Call us at +919855597851.

#concrete batching plant#tractor transit mixer manufacturers#automatic concrete plants#compact concrete batching plants#manufacturers of tractor transit mixers#tractor transit mixer#automatic concrete batching plants#mini concrete transit mixer#stationary concrete batching plant#cement silo manufacturers

0 notes

Text

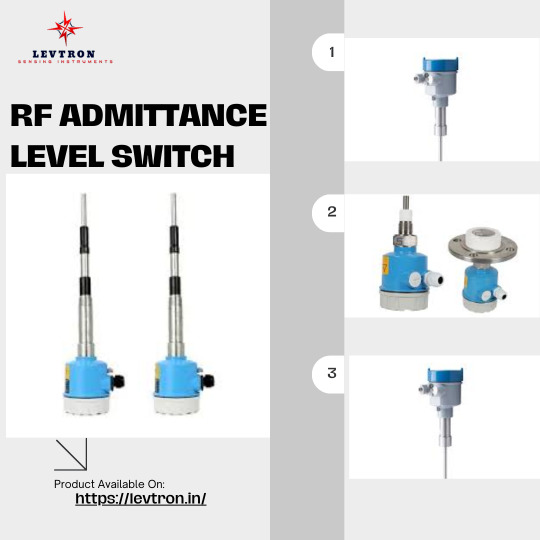

Rotating Paddle Level Switch – The Reliable Solution for Level Monitoring

In industries where the storage and movement of bulk solids are essential, having an efficient level detection system is critical to ensure operational accuracy and safety. Among the advanced level measurement devices available today, the Rotating Paddle Level Switch stands out as a highly reliable and versatile solution. Levtron Instruments Pvt. Ltd., a leading manufacturer of level switches, specializes in designing and delivering high-quality rotating paddle level switches for various industrial applications.

What Is a Rotating Paddle Level Switch?

A Rotating Paddle Level Switch is a mechanical device used to detect the presence or absence of bulk solids, such as grains, powders, or granules, in storage silos, hoppers, and tanks. The device features a motor-driven paddle that rotates freely when the material is not present. When the material comes into contact with the paddle, the rotation stops, triggering a signal to alert the operator or control system.

Levtron Instruments Pvt. Ltd. offers robust and reliable rotating paddle level switches designed for long-lasting performance in demanding industrial environments.

Why Choose a Rotating Paddle Level Switch?

High Reliability in Solid MaterialsA Rotating Paddle Level Switch is perfect for monitoring solids like sand, grain, cement, or plastic pellets. Its reliable mechanism ensures precise detection without interruptions.

Cost-Effective SolutionThese switches are budget-friendly and require minimal maintenance, making them an economical choice for level measurement.

Versatile ApplicationsFrom food processing plants to cement factories, rotating paddle level switches are adaptable to various industries.

Durable and Sturdy DesignLevtron Instruments Pvt. Ltd. ensures its rotating paddle level switches are built with high-quality materials, guaranteeing durability in harsh operating conditions.

Rotating Paddle Level Switch vs. RF Admittance Level Switch

While the Rotating Paddle Level Switch is highly effective for bulk solids, the RF Admittance level switch is an advanced solution for liquid and slurry level measurement. RF Admittance level switches work on capacitance-based technology and are ideal for applications where temperature and pressure conditions are extreme.

Levtron Instruments Pvt. Ltd. manufactures both Rotating Paddle Level Switches and RF Admittance level switches, helping industries find the right solution for their specific needs.

Key Features of Rotating Paddle Level Switches by Levtron Instruments Pvt. Ltd.

Adjustable Sensitivity These devices allow easy adjustments to suit the density of the material being monitored.

Compact and Simple Design Installation and operation are straightforward, making them suitable for diverse industrial setups.

Long Service Life Levtron Instruments Pvt. Ltd.’s rotating paddle level switches are designed for longevity, reducing replacement costs and downtime.

Fail-Safe Mechanism Equipped with fail-safe features, these devices provide accurate alerts, even in power failure scenarios.

Applications of Rotating Paddle Level Switches

Grain Storage FacilitiesAccurate level monitoring of grains like wheat, rice, or corn.

Chemical IndustryReliable detection of powdered chemicals and granules.

Cement PlantsMonitoring cement or other construction materials in hoppers and silos.

Levtron Instruments Pvt. Ltd. has extensive experience in delivering rotating paddle-level switches to industries with diverse needs, ensuring efficiency and reliability in every application.

Why Levtron Instruments Pvt. Ltd.?

Levtron Instruments Pvt. Ltd. is a trusted name in the level measurement industry. As a prominent manufacturer of Rotating Paddle Level Switches, the company provides:

Tailor-made solutions for specific industry needs.

High-quality products designed for challenging environments.

Expert support and consultation for level measurement devices.

A comprehensive range of solutions, including RF Admittance level switches.

With Levtron Instruments Pvt. Ltd., industries can achieve better operational efficiency, safety, and reliability in level monitoring systems.

Conclusion

The Rotating Paddle Level Switch is an excellent solution for industries handling bulk solids. With its robust design and dependable performance, this device ensures accurate level monitoring and prevents material overflows or shortages. Levtron Instruments Pvt. Ltd. takes pride in offering superior rotating paddle level switches and advanced RF Admittance level switches, catering to industries worldwide.

Choose Levtron Instruments Pvt. Ltd. as your trusted partner for level measurement solutions. Contact them today to explore their comprehensive range of products, including the highly reliable Rotating Paddle Level Switch!

0 notes

Text

Maximizing Efficiency with Cement Storage Silos in Construction Projects

In the fast-paced construction world, efficiency and resource management play an important role in delivering successful projects. One solution that has revolutionized material handling and storage is the Cement Storage Silo. These stable storage facilities are essential for bulk storage applications such as cement and fly ash, to ensure optimal operation of the project.

Let’s explore how Cement Silos can maximize efficiency in construction projects while highlighting the role of manufacturers like RCMPL.

The Role of Cement Storage Silos in Construction

Cement storage silos provide a reliable, systematic and efficient way of storing and managing cement. It is designed to handle more material, reduce waste, and lower operating costs. Whether vertical, horizontal or portable, cement silos have become an essential part of modern construction.

Types of Cement Storage Silos

Vertical cement silos

These silos are a popular choice for space-constrained projects, storing cement directly and making land use more efficient.

Horizontal Cement Silo

Ideal for portability and flexibility, horizontal silos are easy to transport and install on various project sites.

Radimix welded silos

These silos are designed for mixed plants, facilitating the storage and supply of cement and fly ash.

bulk storage silos

Designed for massive storage, these silos are ideal for long-term projects that require large amounts of storage.

Benefits of Using Cement Storage Silos

Efficient Material Handling

With a well-designed Silo Feeding System, materials can be easily loaded, stored, and retrieved, saving time and labor.

cost reduction

Multiple storage units eliminate the need for repeated shipments, reducing logistics costs.

Environmentally Friendly

By limiting material spillage and contamination, Cement and Fly Ash Silos contribute to eco-friendly construction practices.

Enhanced Safety

Properly designed Silo Containers ensure safe handling and storage, minimizing risks associated with material management.

Why Choose a Reliable Manufacturer of Cement Silos?

Choosing the right cement storage silo manufacturer is essential to ensure high performance and longevity. A reputable cement silo manufacturer like RCMPL offers a wide range of products, e.g.

300 ton storage silos

RMX Cement Silo

Bee ash silos

Their expertise ensures that each product is tailored to the specific needs of the business.

Applications of Cement Silos in Construction

Cement Storage Silos are widely used in:

Ready-mix concrete plants

Infrastructure projects

High-rise buildings

Large-scale industrial projects

From handling raw materials to ensuring on-site efficiency, Cement Silos streamline the construction process.

Tips on maintaining cement storage silos

To ensure long-term efficiency and durability of your Cement Storage Silos, follow these maintenance tips:

Regular cleaning

Clean silos periodically to prevent buildup, which can disrupt smooth operations.

Check for wear and tear

Check for any cracks, dents, or damage to the silo housing and address it immediately.

Monitor the Silo Feeding System

Make sure the feed is working properly to avoid blockages or uneven flow.

Perform Routine Calibration

Regular testing of weighing and feeding equipment ensures accuracy and efficiency.

Innovations in Cement Silo Technology

The construction industry is booming, as are cement silos. Modern developments include:

Automated silo feeding system

These systems simplify resource management, reduce manual labor, and increase efficiency.

Modular silos

The modular design facilitates assembly and disassembly, allowing flexibility in temporary construction sites.

Smart silo monitoring

IoT-enabled silos provide real-time data on material levels, temperature, and usage, aiding in better inventory management.

Why RCMPL for Cement Storage Solutions?

At RCMPL, we are proud to be a leading cement silos manufacturer offering innovative and sustainable solutions to meet the requirements of the project. Our silo feeding systems and horizontal cement silos are designed to maximize efficiency, reduce waste and increase project sustainability.

Explore our wide range of cement and fly ash silos, including Vertical Cement Silos and Radimix Welded Silos, to find the perfect storage solution for your construction project.

conclusion

Storing cement to supplement your construction project is a wise investment. This versatile warehouse increases productivity, reduces costs and encourages sustainable practices. Whether you need a 300 Ton Storage Silo, Fly Ash Silo, or Horizontal Cement Silo, trust RCMPL to deliver exceptional quality and efficiency.

Visit RCMPL today to find out more about our range of Cement Storage Solutions and how they can improve your next construction project!

#Cement Storage Silos#Cement Silo#Manufacturer of Cement Silo#Horizontal Cement Silo#Cement And Fly Ash Silo#Cement Storage Silo Manufacturer#Manufacturer of Cement Silos

0 notes

Text

Key Considerations for Star Discharge Valve Selection

The star discharge valve is an unloading device designed for discharge points that operate under negative pressure. It conveys materials using a rotating rotor. This design provides a sealing effect that prevents air from being drawn in during pneumatic conveying, ensuring normal discharge.

Features of Star Discharge Valve

Compact Structure and Attractive Design: The design is user-friendly and convenient.

Smooth Operation and Low Noise: It operates quietly, enhancing user comfort.

Superior High-Temperature and Lubrication Performance: The bearings and gearboxes are positioned away from the housing, improving performance under high temperatures.

Custom Design: We can create designs tailored to your specific requirements.

Lubrication Maintenance: Each valve is filled with special lubricants before leaving the factory. Regular checks for lubrication are recommended.

Star discharge valves are commonly used in pneumatic conveying systems. They supply materials uniformly and continuously to the conveying pipe. This ensures stability for gases and solids within the pneumatic transport system. Additionally, they isolate pressure in the valve's upper and lower sections, achieving a locking effect. Therefore, the star discharge valve is essential for pneumatic conveying systems.

Applications of Star Discharge Valve

Star discharge valves serve as unloading devices in material collection systems, particularly for silos. They rank among the most advanced unloading devices available today. These valves are commonly used in dust removal systems and are especially suitable for dust and small particle materials. Industries such as environmental protection, metallurgy, chemicals, food, cement, road construction, and drying equipment favor star discharge valves for various projects.

Selection Guide for Star Discharge Valves

Choosing the right star discharge valve involves several key steps:

1. Define the Usage Location

Determine if the valve will be used indoors or outdoors. This choice influences protective measures.

2. Determine the Purpose of Use

Clarify if the valve will discharge materials in a metered, full-volume, or air-locking manner. This helps select the appropriate model.

3. Specify the Material Flow Rate

Understand the valve's hourly flow rate. Specify whether the discharge is metered or variable to select the right capacity.

4. Define the Conveying Method

Classify the type of conveying: pneumatic or gravity flow. Clarifying this helps in selecting the correct valve.

5. Understand the Conveyed Material

Know the material characteristics and the pressure difference between the inlet and outlet flanges of the blower. This knowledge aids in determining the valve's material and structure.

6. Analyze Material Properties

Consider properties like material name, particle size, true density, bulk density, temperature, repose angle, moisture content, and viscosity. These factors will influence the valve's selection and configuration.

7. Consider Special Requirements

If you need an acceleration chamber or exhaust chamber, specify the models required. Also, consider the manufacturer of the reducer motor and the protection level.

8. Material Selection

Different materials have specific requirements. For example, food processing and pharmaceutical industries often require stainless steel star discharge valves due to their corrosion resistance and durability at high temperatures.

9. Safety Performance

Ensure safety and ease of operation by selecting reliable brands and models known for stability.

By following these steps, you can effectively choose a star discharge valve that meets your needs, ensuring stable operation and high performance in your production process.

Conclusion

In summary, selecting the right star discharge valve is crucial for efficient operation in your material handling systems. If you seek high-quality valves, Darko offers a range of reliable options tailored to your needs. For any inquiries or to discuss your specific requirements, please contact us. We are here to help!

0 notes