#cement brands in India

Explore tagged Tumblr posts

Text

Top 10 Cement Companies in India: Building the Nation's Future

India's cement industry plays a crucial role in building the nation's infrastructure and boosting its economy. As urbanization and industrialization continue to surge, the demand for high-quality cement has never been higher. Choosing the right cement brand is essential for ensuring the longevity and strength of any construction project. In this article, we’ll explore the top 10 cement companies in India, including the factors that set them apart and their contributions to the construction industry.

1. Kamdhenu Cement

Rounding out the list is Kamdhenu Cement, one of the fastest-growing cement brands in India. Known for its high-quality raw materials, which are meticulously tested by lab-tested, highly qualified professionals, Kamdhenu Cement offers a range of products designed to meet the needs of modern construction. With a focus on innovation, quality, and customer satisfaction, Kamdhenu Cement is quickly becoming a preferred choice for builders across the country.

2. Ambuja Cement

Ambuja Cement is another giant in the Indian cement industry, recognized for its superior quality and consistent performance. The company is known for its innovative approach to production, with a focus on reducing its carbon footprint. Ambuja’s products are trusted for their strength and durability, making them a popular choice among builders and contractors.

3. ACC Limited

ACC Limited is one of the oldest cement companies in India, with a legacy of over eight decades. The company has a strong reputation for producing high-quality cement and is a pioneer in the use of advanced technologies in cement manufacturing. ACC’s commitment to sustainability and innovation has cemented its position as one of the top 10 cement companies in India.

4. Shree Cement

Shree Cement is a rapidly growing cement manufacturer with a strong presence in northern and eastern India. Known for its efficient production processes and high-quality products, Shree Cement has gained the trust of consumers and professionals alike. The company’s focus on energy efficiency and sustainable practices has earned it accolades in the industry.

5. Dalmia Bharat Cement

Dalmia Bharat Cement is a prominent player in the Indian cement industry, known for its innovative products and sustainable practices. The company offers a wide range of cement types, including Portland cement, blended cement, and specialty cements for various applications. Dalmia Bharat Cement’s commitment to quality and customer satisfaction has made it a top choice for many construction projects.

6. Birla Corporation Limited

Birla Corporation Limited, part of the MP Birla Group, is a leading manufacturer of cement in India. The company’s products are known for their superior quality and consistent performance. Birla Corporation offers a range of cement types, including Portland cement, and has a strong presence in the central and eastern regions of the country.

7. Ramco Cement

Ramco Cement is a well-known name in the southern and eastern parts of India. The company is recognized for its innovative approach to cement production, focusing on sustainability and energy efficiency. Ramco Cement’s products are trusted for their high quality and are widely used in residential, commercial, and infrastructure projects.

8. JK Cement

JK Cement is a leading cement manufacturer with a strong presence in northern and western India. The company is known for its high-quality white cement, which is widely used in decorative and architectural applications. JK Cement’s commitment to innovation and customer satisfaction has made it a top contender in the Indian cement market.

9. India Cements

India Cements is a major player in the southern region, known for its high-quality products and strong brand presence. The company offers a range of cement types, including Portland cement, and is committed to sustainability and environmental responsibility. India Cements’ products are trusted by builders and contractors for their strength and durability.

10. UltraTech Cement

As the largest cement producer in India, UltraTech Cement dominates the market with an extensive portfolio of products. Known for its commitment to sustainability, UltraTech offers a wide range of cements, including Portland cement, white cement, and specialized products for specific applications. With a strong distribution network, UltraTech Cement is a reliable choice for projects of any scale.

Conclusion

Choosing the right cement brand is critical for the success of any construction project. The top 10 cement companies in India, including Kamdhenu Cement, have set the standard for quality, innovation, and sustainability in the industry. Whether you’re building a residential home, a commercial complex, or an infrastructure project, these companies offer the reliability and performance you need to ensure your construction stands the test of time.

When selecting a cement brand, consider factors such as the type of cement required for your project, the reputation of the manufacturer, and the availability of the product in your region. By choosing a brand from the top 10 cement companies in India, you can be confident that you’re investing in the future of your construction, ensuring strength, durability, and peace of mind.

Final Thoughts

Kamdhenu Cement, with its commitment to quality and customer satisfaction, is not just a top player in the cement industry but a brand that represents the future of construction in India. With continuous innovation and a focus on sustainability, Kamdhenu Cement is poised to contribute significantly to building a stronger, more resilient nation.

#best cement#top 10 cement company in India#cement product manufacturer#portland cement#cement supplier#cement manufacturing company#kamdhenu cement price#best cement for house construction#cement brand#top 5 cement in india#no 1 cement in india#top ten cement in india#top ten cement company in india#rmc concrete#cement manufacturer#opc cement#ready mix concrete plant#rmc plants#cement brands in india

0 notes

Text

cement

Top Cement Company in India

JK Lakshmi has been a pioneer cement company in the cement industry. JK Lakshmi Cement is a name synonymous with quality and strength. Our cement manufacturing technology ensures that the final product adheres to the latest and globally established standards of quality and performance making us a top cement manufacturing company in India. Currently, our cement factory manufactures a wide range of cement products and provides other value added solutions that help enhance various construction projects.

#cement#cement price#cement company#cement manufacturer#cement bag price#cement factory#best cement for house#best cement for house construction#best quality cement in india#cement brands in india

1 note

·

View note

Text

Best Cement Companies in India - Nagarjuna Cement

Nagarjuna Cement is the largest cement company in India and one of the world's most prestigious cement producers. A list of the Indian largest cement companies ranked by Revenue and Market Share.

Nagarjuna Cement offers the quality PPC, OPC and IRS grade cement for House and roof construction.

For more details please visit the website.

https://www.nagarjunacement.com

0 notes

Text

cement brands and Cement factory in India: IBEF

Several cement brands in India are well-known for their quality and reliability. These include Ambuja Cement, UltraTech, Shree Cement, ACC, and Dalmia Bharat, among others. Many of these companies have multiple cement factories across India to cater to the growing demand for cement in various regions. Some of the major players in the industry have also invested in newer technologies and sustainable practices to reduce their environmental impact and increase efficiency in their cement factories. To get more information on Cement factory in India, visit the India Brand Equity Foundation website.

#cementproduction#cementsector#cementcompaniesinindia#CementCompanies#topcementcompaniesinindia#cement brands in India#Cement factory in India#cement production

1 note

·

View note

Text

MasterCoat - Best Wall Putty Manufacturer in Ahmedabad

MasterCoat, established in Ahmedabad, India since 1997, stands as a premier wall putty manufacturer.

With an illustrious history of quality and innovation, they've consistently delivered premium wall putty solutions.

MasterCoat's commitment to excellence, advanced production techniques, and a diverse range of products have earned them a reputation as the best in the industry.

Trusted by professionals and homeowners alike, MasterCoat continues to set the benchmark for wall putty, ensuring flawless finishes and lasting aesthetics for every surface.

#putty#manufacturing#interior design#interior#interiors#distemper#exterior design#reverend putty#primer#stephanie putty#mastercoat#best wall putty manufacturers in ahmedabad#best wall putty brand in india#best wall putty in gujarat#white cement based wall putty

3 notes

·

View notes

Text

#best safety shoes in india#best safety shoes brands in india#branded safety shoes#construction safety shoes#safety shoes manufacturer#safety shoes company#mining safety shoes#waterproof safety shoes in india#top safety shoes brands in india#cement work shoes

0 notes

Text

Transform Your Tiling Projects with CAPA FLEX!

Experience unparalleled precision and reliability with CAPA FLEX, our advanced tile adhesive solution. Featuring a unique gel-like texture, CAPA FLEX offers effortless application and superior adhesion on a wide range of surfaces, including vitrified tiles, natural stones, and large format tiles.

Say goodbye to worries about tile slippage or uneven surfaces – CAPA FLEX ensures a flawless finish, every time. Whether you're tackling residential renovations or commercial installations, trust CAPA FLEX to elevate your tiling projects to new heights of excellence.

Join the countless professionals who rely on CAPA FLEX for its unmatched performance and versatility. Step up your tiling game with CAPA FLEX today!

To know more about tile gel adhesive manufacturers and tile adhesives for vitrified tiles visit: https://capaindia.in/product/capa-flex/

#tile adhesive companies in india#tile adhesive manufacturers#top building materials companies in india#top tile adhesive brands in india#high strength flooring mortars#tile adhesives for vitrified tiles#tile adhesives for fixing natural stones#block jointing mortar manufacturers in india#best tile adhesive in india#floor repairs mortars in india#tile gel adhesive manufacturers#Flooring mortar#Tile and stone adhesive#Industrial Grouts#floor repairs mortars#epoxy grouts#Powder grouts#Ready mix plaster manufacturers#Machine sprayable plaster#Thin joint mortars#Thin joint mortars for AAC blocks#Waterproofing mortar#Waterproofing system#cement based tile adhesive#tileadhesive#tile adhesives for semi vitrified and ceramic tiles#tile adhesive for large format tiles#high strength cementitious tile grout

0 notes

Text

#one of the best cement companies in India#opc 43#opc cement#opc cement price#opc cement brands in india#ordinary portland cement#opc and ppc cement#best cement#cement products

1 note

·

View note

Text

सकरनी मैगज़ीन डिजिटल 2023 का आनंद लें, साथ ही जानिए कंपनी का नए साल का नया विज़न - Sakarni

#best wall putty in india#best wall putty manufacturers in india#gold touch wall putty#best white cement#best white cement brand in delhi#emulsion

0 notes

Text

WOODBINE Offers High-Quality Grounded Calcium Carbonate Powder, CaCO3

#IndustrialMinerals #GroundedCalciumCarbonate #WoodbineGCC #NewDelhi #Rajasthan #CalciumCarbonate

Attention industries! Looking for top-quality Grounded Calcium Carbonate Powder for your industry needs? Look no further! DHANSRI INFRAX PRIVATE LIMITED presents WOODBINE brand of GCC (Grounded Calcium Carbonate – CaCO3), your ultimate solution for various applications. Our extensive range of Grounded Calcium Carbonate Powder, with a formula of CaCO3, caters to diverse industries including cement, paint, glass, soap & detergent, ceramics, rubber, cosmetics, and more.

Available in micron sizes ranging from (2/5/8/10/15/20) and grades including (Super/2nd Super/Normal). WOODBINE GCC meets the stringent requirements of industrial manufacturers Like cement, paint, glass, soap & detergent, footwear, ceramics, paper & pulp, rubber, tyre, cosmetics, toothpaste, PVC wire & pipe, fertilizers, and putty manufacturers. Whether you're in any part of Entire India Tier 1, Tier 2, Tier 3 with in City Limit or with a manufacturing plant in Outer Area (Industrial Clusters), our Indian manufacturing facility based at Rajasthan, India, ensures high-quality alternatives to imported CaCO3. Search DHANSRI INFRAX Private Limited, Industries can rely on us for bulk purchases, with packaging options of 50 kg and 1000 kg HDPE woven laminated bags, ensuring convenient handling and transportation. With a brightness range of 92-98%, WOODBINE GCC guarantees superior performance in your products.

For B2B, B2C, and B2BD2C needs, DHANSRI INFRAX PRIVATE LIMITED stands as your trusted partner. Contact us now to elevate your industry standards with WOODBINE Grounded Calcium Carbonate Powder, a superior option for B2B, B2C, and B2BD2C buyers, suppliers, dealers, importers, exporters, and wholesalers.

2 notes

·

View notes

Text

Inside the World of Cement Manufacturing: What Sets Leading Companies Apart

Cement is the backbone of construction, an essential material that gives structures their strength and durability. As a leading cement manufacturing company in India, Kamdhenu Cement understands the intricate processes and standards that contribute to producing top-quality cement. In this blog, we’ll dive into the key aspects that define a successful cement manufacturing company and what sets Kamdhenu Cement apart in this competitive industry.

The Role of a Cement Manufacturing Company

A cement manufacturing company plays a crucial role in the construction industry. From producing the raw material that forms the basis of concrete to ensuring that the end product meets high standards, these companies are integral to building infrastructure, homes, and commercial spaces. The quality of cement directly impacts the safety, longevity, and performance of constructed structures. Kamdhenu Cement exemplifies this role by adhering to stringent quality controls and innovative manufacturing practices.

Key Processes in Cement Manufacturing

Understanding how cement is made is essential for appreciating the quality of the final product. Here’s a brief overview of the primary processes involved in cement manufacturing:

Raw Material Extraction: The process begins with the extraction of raw materials such as limestone, clay, and gypsum. These materials are carefully selected and tested to ensure they meet quality standards.

Crushing and Grinding: Once extracted, the raw materials are crushed and ground into a fine powder. This step is crucial for achieving the desired chemical composition and particle size for optimal cement production.

Homogenization: The ground raw materials are mixed in precise proportions to achieve a uniform blend. This mixture, known as raw meal, is essential for consistent quality in the final product.

Kiln Heating: The raw meal is then heated in a rotary kiln to temperatures exceeding 1400°C. This process, known as calcination, transforms the raw meal into clinker—a key component of cement.

Grinding and Blending: The clinker is cooled and ground with gypsum to produce cement. This final grinding process ensures that the cement achieves the necessary fineness and performance characteristics.

Quality Testing: Throughout the manufacturing process, the cement undergoes rigorous testing to ensure it meets industry standards. This includes checking its strength, fineness, and chemical composition.

What Sets a Leading Cement Manufacturing Company Apart

In a competitive market, several factors distinguish the best cement manufacturing companies from the rest:

Quality Control: Leading cement manufacturers, like Kamdhenu Cement, implement strict quality control measures at every stage of production. This includes testing raw materials, monitoring the manufacturing process, and inspecting the final product to ensure it meets high standards.

Innovation and Technology: The use of advanced technology and innovative practices enhances the efficiency and quality of cement production. Kamdhenu Cement invests in cutting-edge technology to optimize production processes and improve product performance.

Sustainability Practices: Sustainable manufacturing practices are becoming increasingly important. Top cement manufacturers focus on reducing their environmental impact through energy-efficient processes, waste management, and the use of alternative fuels and materials.

Customer Focus: A commitment to meeting customer needs and delivering reliable products is crucial. Leading companies maintain strong relationships with their customers, providing support and tailored solutions to meet specific project requirements.

Kamdhenu Cement’s Commitment to Excellence

Kamdhenu Cement stands out as a leading cement manufacturing company due to its unwavering commitment to quality and innovation. Here’s what makes Kamdhenu Cement a top choice in the industry:

Rigorous Testing: Every batch of Kamdhenu Cement is subjected to extensive lab testing to ensure it meets the highest quality standards. This includes examining the raw materials and the final product for consistency and performance.

Advanced Manufacturing Facilities: Kamdhenu Cement utilizes state-of-the-art manufacturing facilities that incorporate the latest technology. This ensures efficient production processes and high-quality outputs.

Expertise and Experience: With years of experience in the industry, Kamdhenu Cement’s team of highly qualified professionals brings expertise and knowledge to every aspect of cement production. Their skills contribute to the brand’s reputation for excellence.

Sustainability Initiatives: Kamdhenu Cement is dedicated to sustainability, implementing practices that minimize environmental impact. This includes energy-efficient processes, responsible waste management, and efforts to reduce the carbon footprint.

The Impact of Choosing a Leading Cement Manufacturing Company

Selecting a reputable cement manufacturing company like Kamdhenu Cement has significant benefits for construction projects:

Enhanced Quality: High-quality cement ensures the strength and durability of structures, reducing the risk of future issues and ensuring long-term performance.

Reliability: A leading company provides consistent product quality, minimizing variations and ensuring reliable results for every project.

Support and Expertise: Top manufacturers offer expert advice and support, helping customers choose the right products and solutions for their specific needs.

Sustainability: By choosing a company with strong sustainability practices, customers contribute to environmentally responsible construction practices.

Conclusion

The role of a cement manufacturing company extends far beyond simply producing a construction material. It involves a commitment to quality, innovation, and sustainability. Kamdhenu Cement exemplifies these attributes, offering high-quality products backed by rigorous testing, advanced technology, and a focus on environmental responsibility. By choosing Kamdhenu Cement, you invest in a brand that not only delivers superior performance but also supports the future of sustainable construction.

#cement supplier#cement manufacturer#Top Cement#cement manufacturing plant#cement product manufacturer#best cement#cement manufacturing company#top 10 cement company in India#cement brands in india

0 notes

Text

Best cement manufacturer

JK Lakshmi Cement is the best OPC and PPC cement brand in India for house construction. Book & order your cement online. We have the best quality cement in India. Know the price of the cement bags here

#cement#cement price#cement company#cement manufacturer#cement bag price#cement factory#best cement for house#best cement for house construction#best quality cement in india#cement brands in india

1 note

·

View note

Text

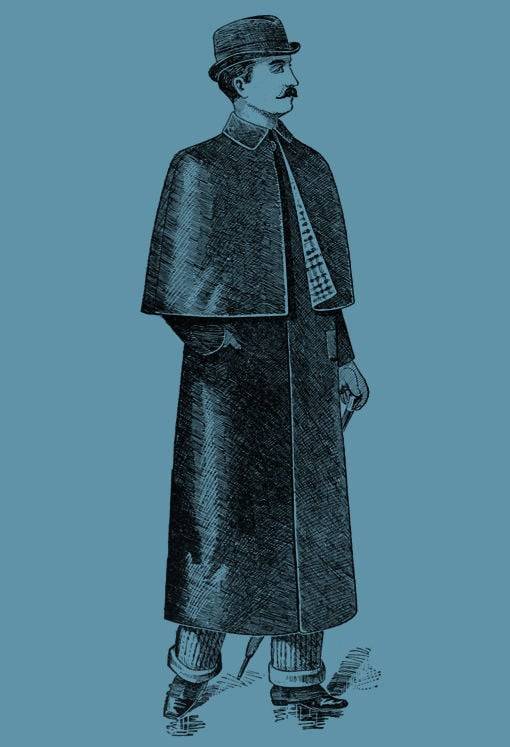

On June 17th 1823 Charles Macintosh patented the waterproof cloth he was using to make raincoats.

While he was trying to find uses for the waste products of gasworks, Charle discovered that coal-tar naphtha dissolved india rubber. He took wool cloth and painted one side with the dissolved rubber preparation and placed another layer of wool cloth on top.

This created the first practical waterproof fabric, but the fabric was not perfect. It was easy to puncture when it was seamed, the natural oil in wool caused the rubber cement to deteriorate. In cold weather the fabric became stiffer and in hot weather the fabric became sticky. When vulcanized rubber was invented in 1839, Macintosh's fabrics improved since the new rubber could withstand temperature changes.

Of course just because you patent something it does not mean you actually were the first to invent it, controversy has followed the invention of the telephone since Alexander Graham Bell patented it, other inventions were questioned, the tyre, the television and the bicycle, all connected to Scotland and all have earlier versions that were thought of, or made beforehand, the “Mac” is no different.

James Syme, a surgeon and chemist based in Edinburgh, had discovered a derivative of coal tar (naphtha) could dissolve rubber and published his findings in Thomson's Annals of Philosophy five years before Macintosh came up with his idea.

It was the same process used by Macintosh following his own chemistry experiments with waste from Glasgow’s coal-gas works, and it has been claimed that the inventor had read Syme’s work before developing it for his own uses.

While Syme, uninterested in commercial matters, failed to patent his valuable discovery and continued to build a noteworthy career in surgery, Macintosh stamped his name on the idea in 1823, had Syme done so you might be calling the coats Symes.....it doesn’t have the same ring does it? Syme’s paper had not detailed the crucial sandwich-type construction employed by Macintosh, although this too was not completely new.

Spanish scientists previously used the method to make leak-proof containers for mercury, and renowned British balloonist Charles Green made a balloon envelope that applied the same principle in 1821.

French scientists also made balloons gas-tight and impermeable by impregnating fabric with rubber dissolved in turpentine and the use of rubber to waterproof fabric dates back to the Aztecs, who used natural latex.

But what made Macintosh’s invention revolutionary was its ease of manufacture and wear, seeing him swiftly launching into the production of cloth to be converted into coats and other garments by tailors in Glasgow.

Some of you might have picked up on the different spelling of the names in the first two paragraphs? Others will now be scrolling back to see what I mean! Well when As news of his invention spread, the repeated misspelling of the inventor’s name is thought to have popularised the description of the resulting coat as a “Mackintosh” – a name that has stuck to the present day.

Macintosh was elected as a fellow of the Royal Society for his contributions to chemistry and enjoyed considerable success before his death in 1843, aged 76.

First sold in 1824, his coat remains on the market in numerous forms across the world, it is now primarily a luxury brand still bearing its inventor’s name, even though it is spelled wrong!

6 notes

·

View notes

Text

The top cement companies in India are those that have established themselves as leaders in the industry through their quality products, innovative technology, and strong market presence. These companies have a proven track record of delivering superior cement products to construction companies, builders, and infrastructure development projects across the country. They have also invested heavily in research and development to constantly improve their products and meet the evolving needs of their customers. Some of the top cement companies in India include Ultratech Cement, ACC Limited, and Ambuja Cements.

#cementsector#cementproduction#cementcompaniesinindia#CementCompanies#topcementcompaniesinindia#ement brands in India#Cement factory in India

1 note

·

View note

Text

Navigating the Varied Realm of Wall Putty: A Comprehensive Guide to Types and Utilizations

Wall putty, a fundamental ingredient for achieving impeccably smooth and enduring finishes on both interior and exterior surfaces, is available in an array of formulations designed to suit distinct purposes.

This blog will delve into the intricate universe of wall putty, uncovering its diverse categories, applications, and advantageous characteristics.

Also Read: Master Coat – Best Wall Putty Brand in India

Conventional Wall Putty: Serving as a versatile choice, conventional wall putty finds its niche on interior surfaces. Its application is effortless, effectively concealing minor fissures and imperfections. It acts as an essential foundation for paints, elevating adhesion and ensuring a uniform coat.

White Cement-Based Putty: Engineered for achieving a refined and luminous veneer, white cement-based putty encompasses white cement and polymer additives. This variant is particularly well-suited for interior walls, as it repels moisture while providing an optimal canvas for paints. Its usage extends to decorative finishes as well.

Acrylic Wall Putty: Renowned for its pliability, acrylic wall putty stands as a fitting choice for both interior and exterior surfaces. It exhibits the ability to withstand slight shifts without succumbing to fractures and boasts elevated water resistance. It is notably effective in spaces characterized by high humidity, such as bathrooms and kitchens.

Gypsum-Based Putty: Crafted from gypsum powder and enriching additives, gypsum-based putty is favored for its lightweight constitution and superlative smoothness. Its common application encompasses ceilings and drywalls. However, it's essential to acknowledge that its water-soluble nature renders it unsuitable for wet areas.

Polymer-Modified Cement Putty: This category marries cement with polymers, augmenting its adhesive characteristics and pliancy. It is an excellent contender for exterior walls that contend with fluctuating weather conditions, as it showcases resilience against fissures and water infiltration.

Fast-Setting Putty: Engineered for expedited drying, fast-setting putties abbreviate the waiting period between successive layers. These variants prove particularly advantageous for projects constrained by tight timelines. Nevertheless, their successful application hinges on prompt and efficient execution.

High-Performance Putty: High-performance putties present advanced attributes like heightened adhesion, crack resistance, and even protection against mold formation. They are optimal choices for high-traffic zones, commercial establishments, and locales susceptible to dampness.

Applications:

Conventional and white cement-based putties excel at leveling surfaces and establishing a seamless undercoat.

Acrylic putties find their forte in areas marked by humidity concerns, thanks to their adeptness at repelling water.

Gypsum-based putties shine in the creation of intricate ceiling designs.

Polymer-modified putties emerge as prime contenders for exterior surfaces that confront diverse weather variations.

Benefits:

Amplified paint adhesion and finish quality.

Skillful concealment of cracks and imperfections.

Prolonged longevity of paint applications.

Heightened aesthetic appeal of walls and ceilings.

Endurance against water and longevity.

Conclusion: The realm of wall putty is a multi-faceted one, with each variant catering to distinct requisites. Whether the goal is to achieve a flawlessly curated interior or a weather-enduring exterior, the choice of wall putty wields a significant influence on the ultimate result. Gaining insight into the classifications, applications, and benefits empowers informed decisions and paves the way for attaining superlative surface finishes.

Looking For Best Wall Putty Brand in India? Visit MasterCoat- #1 Wall Putty Brand Based in Ahmedabad, India since 1997.

#distemper#exterior design#interior#interior design#interiors#manufacturing#primer#putty#reverend putty#stephanie putty#mastercoat#best wall putty manufacturer in ahmedabad#best wall putty brand in india

2 notes

·

View notes