#carbon steel api storage tanks

Explore tagged Tumblr posts

Text

Discover how AFCO Steel revolutionizes storage with advanced steel tank manufacturing. Offering water storage tanks, carbon steel API storage tanks, and more.

#steel tank manufacturers#used steel tanks for sale near me#water storage tanks#carbon steel api storage tanks#steel water tank manufacturers#metal storage tanks#storage tank manufacturer

0 notes

Text

Industrial Vessels in Different Industries

Industrial vessels are integral to numerous industries, providing crucial functions that enhance productivity, safety, and efficiency.

1. Pharmaceutical Industry

In the pharmaceutical sector, industrial vessels must adhere to stringent regulatory standards to ensure product quality and safety. Stainless steel is a common material for these vessels, as it resists corrosion and can withstand sterilization processes. Pharmaceutical-grade vessels include mixing tanks for compounding ingredients, reactor vessels for synthesizing active pharmaceutical ingredients (APIs), and storage tanks for purified water. Cleanability is a top priority, with vessels often equipped with CIP (Clean-in-Place) systems to maintain sterile conditions. By maintaining high standards of hygiene and precision, industrial vessels in this industry contribute to the safe production of medicines and other healthcare products.

2. Chemical Industry

The chemical industry heavily relies on industrial vessels for storing and processing volatile or hazardous substances. Reactor vessels enable controlled chemical reactions, while separation vessels play a role in refining raw materials. Materials like carbon steel and stainless steel are preferred due to their durability and resistance to chemicals. Tanks with advanced coatings are often used to handle corrosive chemicals, enhancing the lifespan of the equipment. Safety features, such as pressure-relief valves and fire-resistant designs, are crucial in this industry to prevent accidents and ensure compliance with safety regulations.

3. Food and Beverage Industry

Industrial vessels are essential in the food and beverage sector, where they are used to mix, process, and store ingredients under sanitary conditions. Stainless steel vessels are commonly employed, as they resist corrosion, are easy to clean, and do not react with food-grade ingredients. Mixing vessels help ensure uniformity in products like sauces, dairy, and beverages, while storage tanks are used to maintain the freshness of ingredients such as oils, syrups, and flavorings. Temperature-controlled tanks are often employed to keep perishable items fresh. Industrial vessels in this industry meet regulatory standards to maintain product quality and prevent contamination.

4. Oil and Gas Industry

Industrial vessels in the oil and gas sector must be robust and capable of withstanding harsh conditions. Storage tanks are essential for holding crude oil, refined fuels, and other hydrocarbons, while separation vessels are used in refining processes to separate oil, water, and gas. Spherical and cylindrical tanks are typical in this sector, with materials such as carbon steel and alloys used to handle high pressures and temperatures. Corrosion resistance and fire safety are critical in these vessels, as the materials stored are often flammable and subject to regulatory oversight. Industrial vessels in this industry are engineered to ensure safe handling and storage, protecting both personnel and the environment.

5. Water Treatment and Wastewater Management

In water treatment facilities, industrial vessels are used to store and process water at various stages of treatment. Stainless steel and fiberglass-reinforced plastic (FRP) are common materials, as they resist corrosion from chemicals used in purification processes. Storage tanks hold raw water, while mixing vessels add treatment chemicals. Clarifiers and sedimentation tanks remove solids, while holding tanks store treated water before distribution. Industrial vessels in this industry contribute to efficient water management, ensuring that clean, potable water is available for communities and industries.

Key Considerations for Selecting Industrial Vessels

When selecting industrial vessels, several factors are considered to ensure safety, compatibility, and efficiency.

Material Compatibility: Vessels must be made of materials compatible with the substances they will contain. For example, stainless steel is ideal for pharmaceutical and food applications, while FRP works well in water treatment.

Capacity and Size: Determining the right size and capacity is essential for optimizing production processes. Larger operations may require custom-sized vessels, while small-scale processes may benefit from compact designs.

Pressure and Temperature Resistance: High-pressure applications require reinforced vessels, while those exposed to varying temperatures must be designed to prevent structural damage. In chemical industries, vessels may be lined or coated to withstand corrosive environments.

Safety and Compliance: Industries dealing with hazardous or flammable substances must follow strict safety regulations. Pressure-relief valves, explosion-proof designs, and automated monitoring systems are often implemented to meet regulatory standards and protect workers.

Maintenance and Cleaning Requirements: Some applications, like pharmaceuticals and food processing, require frequent cleaning. CIP (Clean-in-Place) systems are integrated to allow for thorough cleaning without disassembling the vessel, ensuring hygiene and minimizing downtime.

Conclusion

Industrial vessels serve as the backbone of multiple industries, enabling efficient, safe, and compliant operations. Each industry relies on specialized vessels, tailored to meet specific needs while adhering to safety and regulatory standards. With innovations in materials and design, these vessels continue to evolve, offering increased durability, efficiency, and environmental sustainability.

#Industrial Vessels#storage vessels#inudstrial storage vessles#storage tanks#water treatment#chemical#cosmetic#food and beverage#paper and pulp industry#pharmaceutical water treatment#water solution#swjalprocess

0 notes

Text

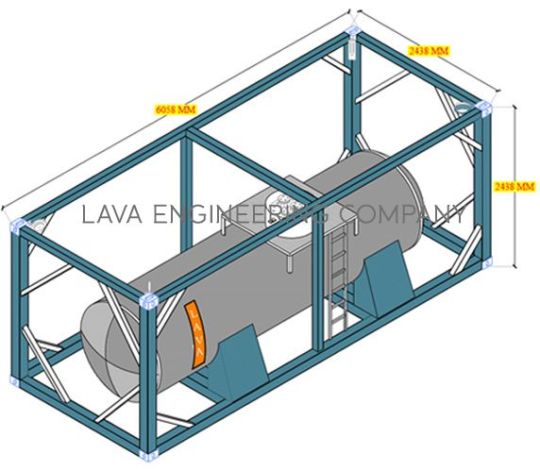

ISO TANK CONTAINER SPECIALIST

ISO TANK CONTAINER LAVA Engineering Company designs and builds UN portable ISO tank containers with ASME VIII / ISO668 design standards for storage and transport of all edible Liquids, chemicals, Oils and Gases. LAVA ISO Tank Containers conforms to the International Maritime Organization Standards (IMO) which allows LAVA Containers to be used for imports/exports in for countries like INDIA, Middle East, AFRICA, USA, CANADA, EUROPE,US and other parts of the world through Sea, Rail and Road transport.

KNOW MORE

Some Of Our Approved Model ISO Tank Containers

T1 ISO tank container for Wine / Juices and Light liquids T3 ISO tank container for Petrol, Diesel, Jet Fuel, Crude Oil (ATF), Bitumen T4 ISO tank container for Edible / Non Edible Oils T11 ISO tank container for Non hazardous chemicals T14 ISO tank container For Hazardous Chemicals and Acids like HCL / Caustic / sulfuric acid/ Ferric Chloride) with Rubber lining / FRP lining Inner / PE lining T20 ISO tank container for Bromine T50 ISO tank container for LPG / Ammonia Gas / Propane SWAP Tank container for cargo above 28,000 Litres to 35,000 Litres We have the facility and experts in the design and fabrication of DV Box Container and Tank containers to serve the worldwide Food industries, Chemical Industry, Oil Drilling & exploration companies, Oil field Equipment service companies, Pharmaceutical companies, Nuclear and Defense Industries. We apply the same precision and engineering excellence throughout the whole of our extensive range of Containers with International design standards of ASME / ISO/ API /DNV.

T1 ISO TANK CONTAINER LAVA Engineering manufactures UN portable T1 – ISO Tank Containers in exclusivity for Juice and Wine manufacturers as per ISO 668 design code.

KNOW MORE

T1 – UN Portable ISO Tank Container Technical Specification

Size–20ft / 40ft ISO tank container Capacity–26,000 Litres / 44,000 Litres Design Code–ASME VIII, EN 12972 ,ISO 668 MOC–Carbon Steel / Stainless Steel Gross Weight–34,000 Kgs Temperature–-40 to 65 deg C Operating Pressure–1.74 Bar Test Pressure–2.90 Bar

T3 ISO TANK CONTAINER LAVA Engineering manufactures UN portable T3 ISO Tank Containers & Airport storage tanks for Diesel, Jet Fuel (ATF) as per IS 7667 standards.

KNOW MORE

T3 – UN Portable ISO Tank Container Technical Specification

Size–10ft / 20ft / 40ft ISO tank container Capacity–8000 Litres, 24,000 Litres, 44,000 Litres Design Code–ASME VIII, EN 12972 ,ISO 668 MOC–Carbon Steel / Stainless Steel Gross Weight–34,000 Kgs Temperature–- 40 to 65 deg C Operating Pressure–1.74 Bar Test Pressure–2.90 Bar

T4 ISO TANK CONTAINER LAVA Engineering is a UN portable T4 ISO Tank Container manufacturers India. These tanks are for food grade liquids and edible and inedible Oils. Specific customer Design requirement for food grade liquid handling are also undertaken to suit individual industries.

KNOW MORE

T4 – UN Portable ISO Tank Container Technical Specification

Size–10ft / 20ft / 40ft ISO tank container Capacity–8000 Litres, 24,000 Litres, 44,000 Litres Design Code–ASME VIII, EN 12972 ,ISO 668 MOC–Carbon Steel / Stainless Steel Gross Weight–34,000 Kgs Temperature–- 40 to 65 deg C Operating Pressure–1.74 BarTest Pressure–2.90 Bar

T11 ISO TANK CONTAINER LAVA Engineering is the only Indian company to have Prototype approved and fully certified UN T11 ISO Tanks for storage and transport of Non Hazardous chemicals in any country in the world for Road, Rail and Marine operations. LAVA T11 ISO tanks are Type tested as per ISO 1496 /3 and are certified by authorized classification body with ASME, IMDG, CSC, TIR, ADR/ RID, US DOT, TC, UIC and CFR 49.

KNOW MORE

T11 – UN Portable ISO Tank Container Technical Specification

Size–10ft / 20ft / 40ft ISO tank container Capacity–8000 Litres, 24,000 Litres, 44,000 Litres Design Code–ASME VIII, ISO 668 MOC–CS / SS Gross Weight–30,000 Kgs Temperature–+65 deg C Operating Pressure–4 Bar Test Pressure–6 Bar

T14 ISO TANK CONTAINER LAVA Engineering is the only T14 HCL ISO Tank Container manufacturer in India to have Prototype approved and fully certified UN T14 ISO Tank Container for storage and transport of Hazardous chemicals in any country in the world for Road, Rail and Marine operations. LAVA T14 ISO tank containers are Type tested as per ISO 1496 /3 and are certified by authorized classification body with ASME, IMDG, CSC, TIR, ADR/ RID, US DOT, TC, UIC and CFR 49.

KNOW MORE

LAVA T14 tanks are made of Carbon Steel or Stainless Steel with Rubber lining / FRP lining / PE lining inners for storage and transport of Hazardous Chemicals like Hydrochloric Acid (HCL), Caustic Soda, Sulfuric Acid, Ferric Chloride etc. As an ISO Tank Containers Manufacturer India, Lava Engineering supplies T14 ISO Tank containers, which are tested as per ISO 1496 /3 and are prominent with customers in Gulf and Middle East countries like UAE, Iran, Oman, Saudi Arabia, Qatar, Kuwait, Bahrain and Asian countries like Singapore, Malaysia and Vietnam and North American countries like US and Mexico and European countries like Greece, France, Poland and Netherlands.

T14 – UN Portable ISO Tank Container Technical Specification

Size-20ft ISO tank containerCapacity-20 M3Design Code-ASME VIII, EN 12972 ,ISO 668Lining-Rubber Lining / FRP lining / PE liningGross Weight-30,000 KgsTemperature-+65 deg COperating Pressure-4 BarTest Pressure-6 Bar

T22 ISO TANK CONTAINER T22 – ISO Tank Container Technical Specification

KNOW MORE

Lava engineering company manufacturing ISO tank container for bromine liquid (UN no. 1744) storage & transport with all required international certification like ASME SEC VIII DIV -I, ISO (T22), IMDG-T22,CSC,RID/ADR,US DOT – CFR,TIR,TC,UIC

The ISO tank container liner with Lead lining inner suitable for storage of bromine liquid.

Offshore Chemical tanks Norway

T50 ISO TANK CONTAINER LAVA Engineering manufacture T50 - ISO tank containers and Gas storage tanks for LPG Propane, and other gaseous liquids. We supply LPG storage bullets and LPG transport trailers with CCOE / PESO for Indian operations of Road & Rail and with IMDG & ADR certifications for overseas customers.

KNOW MORE

T50 – UN Portable ISO Tank Container Technical Specification

Size-20ft ISO tank containerL / W / H-6058 X 2438 X 2591 mmCapacity-24,000 LitresDesign Code-ASME VIII, ISO 668Gross Weight-30,000 KgsTemperature-- 40 to +60 deg COperating Pressure-22 BarDesign Pressure-25 Bar

SWAP TANK LAVA Engineering Company also manufactures SWAP tank containers for customers interested to carry Bulk cargo with capacity of 30,000 to 35,000 Litres

KNOW MORE

The frame Dimension varies from 7150 – 7820L X 2550W X 2670H mm depending on the capacity requirement of the customer

The SWAP tank container is ideal for Storage and Road transport application in Gulf and Middle East countries like UAE, Iran, Oman, Saudi Arabia, Qatar, Kuwait, Bahrain and Asian countries like Singapore, Malaysia and Vietnam and North American countries like US and Mexico and European countries like Greece, France, Poland and Netherlands and African countries where the road restrictions are minimal

The SWAP tank container comes with UN classification of T1, T4 and T11 Containers. Special modifications are also provided for T14 containers for Rubber or PE lined inner for Acid chemicals.

The SWAP tank can be customized as specialty containers as per client requirements and shall carry certifications of ASME, IMDG and ISO for specific chemicals.

0 notes

Text

Why are API 5l Gr X 65 pipes suppliers critical for material selection and production?

Pipes of different measures are essential components of any oil and gas operations. They are needed for transportation to wellheads or storage tanks. Natural gas also moves from pipes to the processing plant. As a basic component, it is the key to successful and safe operations. Dealing with the right pipe suppliers is critical for large-scale solutions.

Yash Impex is a professional company which caters to the demands of the oil & gas industry’s piping needs. For over 50 years we have been making pipes which find their way into the O & G functions. As API 5l Gr X 65 pipes suppliers, our manufacturing units offer high-quality products.

Types of pipes used in the O&G processes

Seamless steel pipes are the core of several processing units due to resistance to high pressure. They are easy to transport as they are light in weight. We are API 5l Gr X 52 pipes suppliers for clients based in other countries. The other kinds are PVC, galvanized steel, copper, and ductile iron pipes.

Steel is combined with other materials to alter its characteristics to suit the processes. The other materials used include carbon, molybdenum, or nickel. When chromium is added the pipes withstand CO2, Hydrogen sulfide or extreme temperatures. All high-pressure fluid transportation depends on the specific piping system for best results.

Pipe grades we supply

API 5l Gr X 65

It is best for onshore and offshore processes. It is also referred to as ISO 3183 L450 pipe. It has a minimum yield strength of 65000 Ksi or 450 Mpa. It has a high grade making it essential for fluid transfer and a premium product from our manufacturing unit.

API 5l Gr X 52

It offers a minimum yield strength of 52 Ksi (360 Mpa). It’s a medium grade in API 5L and ISO 3183 specifications. They come in different sizes and shapes. We offer them as:

Rolled

Normalized form

Tempered and quenched

Sour service

Thermomechanical rolled or formed

API 5l Gr X 60

This is yet another crucial component for fluid transfer in extreme conditions. It is also called as a L415 pipe, which has a yield strength minimum in 415 Mpa (60,200 psi). Our manufacturing unit makes it seamless (hot rolled and cold rolled), and welded for the required purposes. It is used for onshore and offshore functions.

If you are looking for more productive operations, we could offer some exciting solutions. We use the best quality steel for your needs. Our sourcing team puts efforts to get the right prices for the raw materials so the deal is cost-effective for your company. As we focus on material selection your team can pay attention to the production capabilities.

Yash Impex tries to improve the performance of its product line with trending market technology. This is why we continue to be the leading supplier of pipes and fittings in different industries. We look forward to your enquiry to offer the best solutions. Our credentials are already established in the world market, especially in the oil and gas industry.

0 notes

Text

Advanced Expertise Technology Leaders in Fluoropolymer Coating, Lining, and Pharma Machinery

Advanced Expertise Technology Pvt. Ltd. (ADVETPL) is a leading manufacturer and supplier of pharmaceutical machinery and Fluoropolymer Coating. We are the leaders in designing and manufacturing machinery related to the supply of Fluoropolymer Lining and coating which is utilized in the manufacturing of Active Pharmaceutical Ingredient, Medications, Food and food products, synthesized chemicals, fine chemicals, petrochemical and for treatment of surface and ore.

We provide different types of coating like HALAR, PVDF, ETFE, PFA,PP and PTFE. These coatings prepare the material against factors like abrasion and corrosion. Our coatings can be applied on various materials of processing appliances such as Tanks, Receivers, Agitated Nutshe filters, Centrifuge Machines, Agitators, Heat exchangers, Strainers, Rotary Vacuum cone dryers, Valves, etc.

Our team constantly works to deliver the best quality products and services. We believe that accuracy and quality are the most important factors that are needed to be delivered to our customers. Our clients are spread around the world, ranging from small-scale industries to MNCs.

We are the sole competitors in the market, who provide a comprehensive solution to customer queries, with our committed and skilled service crew being available on sites in Vizag, Chennai, Mumbai, Gujarat, and Hyderabad. We also provide services to existing machinery recoating, lining, and centrifuge.

Using advanced technology, high-end tools, exceptional quality management system, we work towards providing our customers with products of the highest quality which give optimum performance with cost-effectiveness.

The ultimate goal of our company is complete profitability and satisfaction for our customers.

Workshop and Plan Details

The Fluoropolymer coating industry workshop of our company is one of the largest in India with its area spread across 28,000 Sq.ft.

We offer Electro conductive and Anti-static coating for HALAR, PFA, and ETFE. Our processes are designed in a manner that offers no harm to people and plants, and our coating is also compatible with food.

Our groups of companies are spread out all over India, they are India glass-lined equipment, Porima Technology Pvt.Ltd., Synovatic India Machinery Pvt Ltd., Leborn Technomach, and last but not the least Advanced Expertise Controlling System. Together we work to meet the International standards and design, market, and manufacture products of premium quality with high performance to our clients.

Our products come in a wide variety.

Filter Equipment - Filters are used to separate the solid molecules from liquid or gas. Either the filtrate or the solid particles removed may be the desired product. We are a leading supplier of different varieties of a filter.

Our products include, Centrifuge filters used in pharmaceutical, fine chemical, dye intermediates, and chemical industry. Sparkler filters are used in biotech, bulk drugs, food distilleries, and API industries, a candle filter is used where polishing and low moisture cake filtration is required. Pressure Nutsche filter these handle variety of flow rated and work on the principle of pressure and volume, a Cartridge filter is used in beverage, alcohol, solvent, chemical and cosmetics industry. Basket filter is used for separating contamination from fluids

Drying Equipment - Removes moisture from the material, making it safe for storage and processing. We provide a variety of drying equipment, Vacuum Tray dryers are used in the herbal, chemical, food products, and healthcare industries. Air tray dryers are used in the automobile and chemical industry, and Rotary cone vacuum dryer food and pharmacy industry.

Heavy Engineering-We design and build large units of machinery according to regulated codes and standards. Our product range includes receivers, heat exchangers, pressure vessels, and reactor storage tanks.

We provide different types of Fluoropolymer Coating and Lining Service

The most notable and highly acclaimed work of our company is Fluoropolymer Coating. These coatings are used diligently in different environments. The most prominent attribute of these coating are, that they are heat-proof, non-stick , and resistant to corrosion and chemicals.

Few listed advantages of PTFE, HALAR, ETFE, and PFA coating and lining services.

It can be cleaned effortlessly.

Does not require care and keep-up.

Safe to operate on hazardous substances.

We are a leading brand in India for Fluoropolymer Coating and Lining. Our coating products , PVDF, HALAR (ECTFE), ETFE, PP, and PFA are used in machinery for Pesticide, API, Cryogenics Corrosion, BULK Drug, Fluorine, and Bromine Handling, Pharmaceutical, Fine Chemical, Chemical, Inorganic Chemical, Surface treatments, Petrochemical, Powder Industry, Paper Industry, Bio Diesel Industry, etc.

HALAR Antistatic Coating (ECTFE Coating)

Industries in which resistance and protection from corrosion and high temperature are required Ethylene chlorotrifluoroethylene coating is applied. ECTFE coating provides high resistance from chemicals and elevated temperature conditions. These are most suited for appliances with a full vacuum.

PFA Coating (Perfluoroalkoxy Alkane Coating)

Perfluoroalkoxy Alkane coating provides extensive protection in adverse environments involving chemicals at high temperatures, from inorganic oxidizers and bases, strong mineral acids, inorganic and organic compounds, mechanical and thermal stress. PFA coatings have similar characteristics to PTFE. These coatings are applied on stainless steel and carbon steel varying temperature surrounding.

ETFE and PTFE Coating

Ethylene tetrafluoroethylene coating is highly robust and resistant to chafing. It provides high corrosion resistance, protection from radiation, and wear over a varied range of temperatures, also because of its high melting point, it prevents the emission of harmful gases when burnt. ETFE coating is known for its adaptability and rare features. This coating is used in the petrochemical and chemical industries.

PTFE coating is a thin layer of film and very durable. It is generally known as Teflon. It is highly resistant to water and can work in extreme weather conditions. Polytetrafluoroethylene coating is commonly used to apply Non-stick coating for cookware and pans. Teflon Coating is non-reactive, chafing resistant, thus it is used in lining pipes and containers where corrosive and reactive chemicals are used.

PP Coating (Polypropylene Coating)

Polypropylene coating is used for storing hydrochloric, hydrofluoric, and sulfuric acids, caustics, corrosives, etc. It belongs to the group of partially crystallized and non-polar. Polyolefins. It is a thermoplastic polymer also known as a polyprotein.

PVDF Coating (Polyvinylidene Fluoride Coating)

Polyvinylidene Fluoride coating is used in places that require robustness, purity, resistance to acids, solvents, and bases. These coatings can melt easily due to their low melting point. It is light in weight and cost-effective in comparison to other fluoropolymers. PVDF coating is widely used in the semiconductor, defense, and medical industries. It is used in the manufacturing of appliances like pipes, valves, tubes, sensors, etc.

Peek Coating

Fluoropolymer contains molecules of fluorine and carbon. Peek coating demand is high in industrial coatings because they provide low friction, corrosion, chemical, water, and abrasion resistance.

Our company goal is to manufacture reliable, durable, and cost-effective products. We try to reach the highest standard while manufacturing our products to satisfy our customer base. We work towards the overall profitability of our clients, and we constantly grow ourselves to work with changing and emerging technologies to fulfill our customer needs.

0 notes

Text

Top 10 Best Backpacking Camping Stoves in 2019

It is difficult to find someone that genuinely dislikes camping. Camping is a popular activity especially for the ones that are looking to get away from the rush and noise of the city. As long as the company is great, and all the necessary essentials are packed, it is difficult to not have a great time. Packing sandwiches can work but nothing beats a hot meal prepared while camping in the middle of nature.

Since there are so many different camping stoves to choose from, we had to trim down the list and pick just 10 models. Practicality and a compact form factor have been the most important aspects that rendered some camping stoves more appealing than others. Most of them are quite inexpensive and they usually run on propane. With these things said, let us have a quick look at our list of the top 10 best backpacking camping stoves.

Best Backpacking Camping Stoves in 2019

# Preview Product Price 1

Bisgear 12pcs Camping Cookware Stove Canister Stand Tripod Folding Spork Wine Opener Carabiner Set… $29.99 View on Amazon 2

Jetboil Flash Camping Stove Cooking System, Carbon $99.95 View on Amazon 3

MSR PocketRocket 2 Ultralight Backpacking, Camping, and Travel Stove $44.95 View on Amazon 4

Fire-Maple Feast 1.5L Camping Cookwear Pot FMC-K2, Pot Support & Propane/Butane Canister Stand, Jet… $46.95 View on Amazon 5

Etekcity Ultralight Portable Outdoor Backpacking Camping Stove with Piezo Ignition (2pack), Survival… $22.99 View on Amazon 6

AOTU Portable Camping Gas Stove Backpacking Stove 110g Stable Support Wind-Resistance Camp Stove for… $6.77 View on Amazon 7

Coleman Gas Stove | Portable Bottletop Propane Camp Stove with Adjustable Burner from $30.50 View on Amazon 8

Camping Gas Stove Burner Backpacking Stove Portable Backpack Cooking Camp Stove with Igniter Hiking… $19.99 View on Amazon 9

ENKEEO 3000W Windproof Camping Stove Foldable Backpacking Stoves Ultralight Portable Gas Cooker with… $19.99 View on Amazon 10

Odoland Camping Cookware Stove Carabiner Canister Stand Tripod and Stainless Steel Cup, Tank… $27.99 View on Amazon

Last update on 2019-08-08 / Affiliate links / Price / Images from Amazon Product Advertising API

Table of Contents

10. Housweety Lightweight Camping and Backpacking Stove

Check price on Amazon

Housweety is a small brand that makes several practical products. Their backpacking stove is a great choice for the ones that like spending time out in nature. It is a compact stove that was designed to be very easy to pack.

The model has a small burner with supporting arms that can be folded so that the stove takes even less storage space. It is large enough for regular frying pans and pots and has threading so that nothing slips off the stove.

To use the burner, a regular butane or propane tank can be used. It is just screwed on top. It might not seem all that stable with a pot on, but it can be secured with rocks. The stove includes a small carrying pouch for easier transportation.

We recommend this because:

Very small and compact

Works with all regular propane and butane tanks

Includes a carrying pouch

Inexpensive but sturdy

9. Terra Hiker Camping Gas stove

Check price on Amazon

Terra Hiker camping gas stove is a great companion for the ones that love spending time out and away from the city. It is a very compact stove that is very easy to pack and just as easy to use. According to the manufacturers, it can boil 1 liter of water in just 2 minutes.

The stove has folding arms so that it takes as little storage space as possible. It is mostly made from aluminum and steel making it quite durable and resistant to corrosion. Despite being so small and just 9.8 oz. in weight, it can support large cookware as large as 18 liters.

To improve practicality, the stands are serrated thus preventing a pan or pot from slipping. The stove comes with a short hose and works with most propane and butane tanks.

We recommend this because:

Folding design becomes very compact

Serrated stands for improved stability

Short hose with a flame adjusting knob

Lightweight but sturdy

8. OUTAD Windproof Foldable Camping Stove

Check price on Amazon

OUTAD folding camping stove is quite similar to the rest of the models that were picked for our list but it has one extra feature that simply adds even more utility to it. The stove comes with a special design that protects the burner from the wind.

As expected, the stove has folding stands and legs which reduce its size so that it is easier to pack. The stand is serrated which prevents a pot or pan from slipping. The legs provide decent stability and can handle even large pots.

As far as practicality goes, the stove is very small and compact. It has a small reinforced hose that can be connected to a propane tank and a small know to adjust the burner. It can withstand high temperatures and can bring to a boil 1 liter of water in less than 3 minutes.

We recommend this because:

High-quality lindal valve tank connection

Folding design for easy transportation

Includes a carrying case

360-degree wind deflector

7. Lixada Pocket Camping Stove

Check price on Amazon

Lixada pocket camping stove is exactly what the name of the product states. It is a small stove that can even fit inside a pocket. Because of its folding design, the stove becomes extremely small and is extremely lightweight.

The stove has folding supports. When folded it becomes so small that it can fit inside a small pocket. The stand is serrated which prevents the pots and pans from slipping. They are also large enough to work with regular cookware.

To use the stove, a regular butane gas tank can be used. It offers about 2700 watts of cooking power and can boil a liter of water in less than 3 minutes. The stove is also quite inexpensive and fairly well built.

We recommend this because:

Very compact and lightweight

Serrated stand to prevent the cookware from slipping

2700 watts of cooking power, heat 1 liter of water in less than 3 minutes

Works with regular butane and propane gas

6. MSR PocketRocket 2 Ultralight Camping Stove

Check price on Amazon

MSR PocketRocket 2 camping stove is one of the more expensive stoves in our list but despite this aspect, it is well worth the money. It can be classified as a pocket stove because of itits compact size and how easy it is to use.

The stove has a folding design. Its stands that hold the pan are serrated so that it keeps the pan securely in place. It also has a small metal wall placed on the burner which protects it from the wind so that it does not extinguish.

In terms of construction, the burner is made entirely out of metal and feels quite sturdy. It needs to be screwed on directly onto the propane tank and has a small knob that can be used to control the burner.

We recommend this because:

Very compact and lightweight

Burner protected against wind

Easy to install onto a propane or butane tank

Serrated stand for large pots and pans

5. MSR WhisperLite Portable Camping and Backpacking Stove

Check price on Amazon

The MSR WhisperLite is one of the larger stoves that were picked for our list. It has a different design that makes it a bit larger even when disassembled. However, because it is a bit larger, it feels more stable especially when used directly on the ground.

To improve its practicality, MSR made the stove with a short flexible hose that can be connected to most propane or butane gas tanks. It also has a small nozzle to control the burner and make it easier to prepare any kind of meal.

Since it is going to be used outdoors, the stove also has raised side walls which protect the burner from the wind. Cleaning the stove is very easy and comes with a lifetime warranty offered by the manufacturers.

We recommend this because:

Lifetime warranty included

Raised side walls around the burner to protect it from wind

Flexible Hose

Very easy to clean

4. Coleman Powerpack Propane Stove

Check price on Amazon

Coleman Powerpack propane stove is quite large for a camping model but it is still usable. It can be packed in a large backpack but what recommends it the most is how easy it is to cook on. Being large makes it usable with pans as large as 12 inches in diameter.

The stove has a cooking power of 7,500 BTU which makes it just as good as a regular stove. The burner is very easy to adjust and offers very precise temperature control. Cleaning the stove is fairly simple since it has a chrome-plated grate.

Because of how it is designed, the burner uses less fuel while cooking when compared to other stoves. It is quite sturdy and durable and it works even in the most extreme conditions.

We recommend this because:

Easy to clean

Powerful, 7,500 BTU cooking power

Precise temperature control

Works even with large 12-inch pans

3. Coleman Sportster II Dual Fuel Burner Stove

Check price on Amazon

Coleman offers several high-quality products and their Sportster II burner stove is one of the most appreciated ones especially for camping. It is a compact stove that was made to be very easy to use and practical.

The stove works with regular propane tanks and all it takes it to just screw it on. It does not have any kind of folding mechanism to make it smaller but it is small as is. The stove works with 6-inch pans and pots which is more than suitable for camping.

To make it work in all weather conditions, the stove has 4 cross-shaped walls that work as stands for the pan and block wind thus protecting the burner. Cooking power is about 10,000 BTUs and temperature can be controlled using a small knob mounted at the base.

We recommend this because:

10,000 BTU cooking power

Works in all weather conditions

Quite compact and practical

Wind baffles to protect the burner

2. Coleman Bottle Top Propane Stove

Check price on Amazon

The Coleman Bottle Top propane stove is a great choice for the ones that go camping often and like to pack light. Its reduced size and simple design make it work in all weather conditions even on a windy day.

What makes it stand out when compared to other stoves is the wind baffles on the burner. They block the wind and prevent the burner from going out. Also, the stands are large enough to hold pans that are 8 inches wide.

In terms of power, the burner offers about 10,000 BTU. That is more than enough to cook any type of food. The temperature control will help cook food better while the stove itself is quite easy to clean.

We recommend this because:

High efficiency, burns less fuel

Wind baffles to protect the burner

10,000 BTU cooking power

High precision temperature control knob

1. Etekcity Ultralight Portable Outdoor Backpacking Camping Stove

Check price on Amazon

Etekcity portable camping stove is the ideal choice for campers. It is extremely compact and very practical. It folds in such a way that it can even fit inside a pocket. Also, it is quite inexpensive and well builds.

The stove has a very minimalistic design and needs to be screwed on directly onto a butane or propane tank. It has serrated stands to prevent the pan from slipping and a small knob at the base that can be used to adjust the temperature.

As far as construction goes, the stove is made mostly out of stainless steel and aluminum. Because of its compact size, the stove is also lightweight. The manufacturers also included a small carrying pouch to make it easier to pack.

We recommend this because:

Very compact fits inside a pocket

Comes with a carrying pouch

Serrated stand to prevent the pan from slipping

High precision control valve

Things to keep in mind when looking for the best backpacking camping stoves

Camping stoves come in many different shapes and sizes. There are a lot of models to choose from and it can be a bit confusing especially when comparing several of them. Also, there are a lot of brands that offer the exact same camping stove but with a different branding.

In order to spend money on something practical that will actually prove useful on a camping trip, it is important to have a few things in mind. If one camping stove may prove to be ideal for someone, others may find it unsuitable for them. Here are the main things to take into account.

Folding design. The vast majority of backpacking camping stoves has a folding design. This type of stoves is made to be as compact as possible so that they fit even inside a pocket. Larger models may be a bit more difficult to pack but they offer a higher cooking power and work with larger pots and pans.

Wind baffles. Not all stoves have wind baffles and not everyone may need them. Their main utility is to protect the burner against the wind. The design of the wind protectors may be different from one model to another.

Cooking power. The cooking power of a stove can vary a bit depending on its size and how it is designed. Not all manufacturers state how powerful the burner is but as a general rule, at least 7,500 BTUs is required in order to be able to cook food properly.

Conclusion

There are a lot of camping stoves available to choose from. The main idea that gave birth to these compact stoves is practicality. They need to be easy to pack, lightweight and provide a reliable means of cooking food.

Backpacking camping stoves are essential especially when spending time in nature and away from the city. Packing some sandwiches may seem a bit more practical but it is difficult to replace a hot, freshly cooked meal. It is the proper way to enjoy camping and without a stove, it might as well be called a picnic.

0 notes

Text

Global Cryogenic Storage Tanks Vessels Market to Register Stable Expansion During 2017-2025

Cryogenic Storage Tanks Market: Introduction

As the name suggests, cryogenic storage tanks are vacuum flasks used for storing cryogens, such as liquid helium or liquid nitrogen, which have a boiling point lower than room temperature. These storage dewars (named after James Dewars) are available in several shapes, such as a flask with loose fittings, an open bucket or a special pressuring tank. They are designed to keep heat away from the liquid contained in the inner vessel. With the help of vaporizers, the liquid is converted into a gaseous state, such as in the case of liquid nitrogen. A pressure control manifold controls the pressure at which the gas is fed to the process.

Cryogens present several safety hazards and hence, storage vessels are designed to minimize the associated risks. For instance, these vessels are well covered with API Standard 653 (2014). The increasing demand for LNG, nitrogen, oxygen, argon and other low temperature gases from end use industries (food, pharmaceutical, metal treating and many others) is surging the demand for cryogenic storage tanks and is expected to continue doing so over the forecast period.

Cryogenic Storage Tanks Market: Dynamics

Increasing demand for cryogenics in laborites & chemical plants is spurring the demand for cryogenic storage tanks. Also, the rising demand for carbon dioxide and liquid nitrogen in the transportation of frozen foods is driving the demand for the cryogenic storage tanks market. Similarly, in countries, such as Japan, Oman, China, Qatar and many others, the demand for LNG is growing, which is supporting the demand for the cryogenic storage tanks market. However, the high cost of these systems will hamper the growth of cryogenic storage tanks market.

Request For Report Sample@ https://www.persistencemarketresearch.com/samples/21778

Cryogenic Storage Tanks Market: Trend/ Regional Outlook

During 1954, steels were used in competition with stainless steel, other austenitic alloys, and aluminum for LNG storage. In fact, stainless steel were used or building smaller storage tanks. However, large containment vessels are usually welded from 9%-nickel steel because of expense considerations. Globally, this technology is accepted all the world and improvement in design will give provide manufacturers to increase their sales. Also, rapid industrialization and rise in scope of these in healthcare, food and beverage & refrigeration industries will the opportunistic market for the manufacturers. Collaboration and mergers & acquisitions coupled with backward integration will helps companies/ manufacturers to expand their market share and better reach to customers. Also, the companies constantly involved in expanding their product portfolio and offering for the customers.

Asia-Pacific is likely to dominate the global demand for cryogenic storage tanks over the forecast period. This can be attributed to the fact that large scale development in LNG infrastructure, especially in Japan, India and Indonesia will support for the demand for cryogenic storage tanks. Europe and North America will also be prominent regions over the forecast period due to the increasing demand from end use industries, such as food and pharmaceutical. Latin America and Middle East & Africa (MEA) will account for less than a 15% share in the overall market, owing to a smaller population and fewer industries.

Cryogenic Storage Tanks Market: Segmentation

On the basis of end use, the cryogenic storage tanks market can be segmented into:

Food freeing

De flashing plastic or rubber

Preserve biological sample

Metal Treating

Pulverization

Others

On the basis of product type, the cryogenic storage tanks market can be segmented into:

LNG

LPG

Nitrogen

Oxygen

Argon

Others

On the basis of material, the cryogenic storage tanks market can be segmented into:

Stainless Steel

Aluminum

Austenitic Alloys

Others

On the basis of application, the cryogenic storage tanks market can be segmented into:

Storage

Transportation

Request For Report Table of Content (TOC): https://www.persistencemarketresearch.com/toc/21778

Cryogenic Storage Tanks Market: Market Participants

Examples of some of the market participants identified in the cryogenic storage tanks market across the globe are:

Inox India Private Limited

Cryofab Inc.

Linde AG

Chart Industries

VRV SPA

Suretank Group Ltd.

Saint Gobain (ISOVER)

Eden Cryogenics LLC

FNF Gas Technology Products Private Ltd.

Cryoquip Australia

Gardner Cryogenics

Worthington Industries

Cryogas Equipment Private Ltd.

Fiba Technologies

Know More About Report@ https://www.persistencemarketresearch.com/market-research/cryogenic-storage-tanks-vessels-market.asp

0 notes

Photo

Fire Water Tank China Fire Protection Storage Tank Supplier Offers Q235B Alloy Steel Fire Water Tank, API 650, Fixed Roof, Welded, Vertical, Max 100,000 Gallon Plus. Name: Fire Protection Tank. Sheel Material: Q235-B. Earthing Lug Material: Stainless Steel 304 (SS304). Roof Material: Q235-B. Compression Ring Material: Q235-B. Bottom Plate Material: Q235-B. Standard: API 650, GB 50341. Media: Water. Working Temperature(In/Out): 25℃. Design Temperature: 4℃ to 80℃. Volume: 400 m3/Approx. 105,669 Gallon. Design Pressure: -490 PaG to 20,000 PaG. website: http://www.dfctank.com/fire-water-tank-carbon-steel-q235b-api-650-100000-gal.html

0 notes

Text

Новости сайта #ENGINEERING - 工程

New Post has been published on http://engineer.city/thermomechanical-tank-technology/

Thermomechanical tank technology

Highlighting the advantages of TMCP steel plates for the construction of storage tanks

There have been more than four decades of experience in the successful application of thermo-mechanically hot rolled heavy plates in the fields of offshore oil and gas platforms, offshore wind power, shipbuilding, steel construction and most popularly, for the construction of large diameter oil and gas pipelines based on the API standards.

Considering the construction of pressure vessels and storage tanks, there is a contrary situation. In spite of the evident advantages of thermo-mechanical controlled processing (TMCP) steels, their usage in this sector is rather uncommon.

For pressure vessels comprising heads, where a new quality heat treatment after processing becomes mandatory or for pressure vessels with high wall thicknesses, which need a considerable post weld heat treatment (PWHT), there are clear arguments against these steels.

But regarding the fabrication of large storage tanks for hydrocarbon products and ammonia, the application of thermo-mechanically rolled steels offers considerable technical and economic benefit for the manufacturer as well as the end user. This benefit increases if these steels are applied in sour service conditions, where the risk of hydrogen induced cracking (HIC) is present.

As the pressure vessel industry is highly regulated, it is very important that the use of TMCP steels is permitted by the applying codes. Consequently, Dillinger experts reviewed the globally established construction codes such as ASME BPVC, API 620, EN13445, EN14620 and so on, (Table 1) with the result, that all of them allow the application of thermo-mechanically rolled steels up to about 40mm in thickness.

The basics TMCP steels

Steels made by TMCP are not only characterised by high strength and excellent toughness, but also by outstanding weldability.

Conventionally it has been impossible to obtain these characteristics simultaneously and one had to be chosen at the expense of the other. With regard to normalised steels, higher strength could only be achieved by increasing the content of alloying elements, which in turn has a negative impact on the weldability. The situation is different with TMCP steels. They achieve their strength properties by a combination of a process-optimised, very lean chemistry (Table 2) and a special rolling technique (Fig. 1), resulting in a unique, fine grained microstructure compared to normalised steels (Fig. 2).

Strength levels and alloying content

The relationship between achievable strength levels and required alloying contents is clearly shown in Fig. 3.

The content of alloying elements is described by the carbon equivalent. It can be seen that it is possible to achieve the same strength level with a considerable reduction in alloying elements for TMCP compared to normalised steels. This is based on the Hall-Petch relationship, which provides an improvement of strength and also toughness if the grain size of a microstructure gets reduced.

The combination of a fine-grained microstructure and a very lean chemical analysis, which is typical for TMCP steels, leads to several advantages when it comes to further processing of the plates.

Subsequently the advantages for different production steps are illustrated.

Advantages of TMCP plates during fabrication

The first step during fabrication of storage tanks is the cutting and weld edge preparation of the delivered plates. Due to their lean chemical analysis, TMCP steels show only a very low susceptibility to hardness increase. This means there is no need for any preheating before the thermal cutting process.

The second step during fabrication of storage tanks is the bending of the shell plates. Like all other production steps (especially welding), bending shifts the impact transition temperature of the material to higher temperatures. This is equivalent to a reduction of the material’s toughness. TMCP plates offer a significantly higher toughness level than normalised steels (Fig. 4).

The advantage for the fabricator is a safer production process arising from the higher toughness reserves and lower susceptibility to brittle fracture.

The welding advantage

The most challenging process during the fabrication of storage tanks is the welding of the bended shell segments. Generally this production step consists of three separate processes, which are preheating, welding and PWHT.

For normalised material it is usually mandatory to carry out a preheating to avoid excessive hardening and cold cracking after welding. Regarding the European codes EN1011-2 gives the following formula to calculate the necessary preheating temperature (See Formula 1).

Tp=697∙CET+160∙tanhd/35+62∙���HD〗^0,35+(53∙CET-32)Q-328

Tp: Preheating temperature [°C]

CET: Carbon equivalent [%] (CET=C+((Mn+Mo))/10+((Cr+Cu))/20+Ni/40)

d: plate thickness [mm]

HD: Hydrogen content [ml/100g]

Q: Heat input [kJ/mm]

The advantage of TMCP steels becomes clear when the formula is plotted into a diagram for different steels (Fig. 5).

The diagram shows that a thermo-mechanically rolled steel with a yield strength of 355 MPa, such as SA841-A-1 or P355ML2 (which are equivalent to normalised SA516-70 or SA537-1) can be easily welded with no preheating up to 40mm plate thickness, while the normalised grades would need a preheating in the range of 60-100°C.

Furthermore, a TMCP steel with a yield strength of 420 MPa, such as SA841-B-2 or P420ML2, which are equivalent to quenched and tempered SA537-2, might also be welded with no preheating up to 40mm plate thickness, if the hydrogen and heat input are carefully controlled.

The benefit for the fabricator is that no preheating before welding becomes necessary, which results in a faster fabrication, less energy consumption and lower costs. This advantage of TMCP in comparison to normalised steels arises from their lean chemistry, which is represented by the CET value in the given equation.

Referring to the ASME BPVC, the same advantage of TMCP steels regarding preheating is included.

Based on table 6.8 of ASME BPVC VIII Div. 2 for P-No.1, Group 1, 2, 3 steels, which are normalised steels, a PWHT plate thicknesses between 32mm and 38mm becomes mandatory, unless a preheating of 95°C has been applied. For the TMCP grades SA841-A-1 and SA841-B-2 this preheating is not necessary, if their carbon equivalent according to S77 of ASTM A841 does not exceed 0.40 %.

Concerning the welding process itself, there are two main requirements relating to the plate material that have to be fulfilled.

On the one hand, the impact values in the heat-affected zone have to exceed the required values from the codes. On the other hand, the hardness values have to stay under a defined value.

Due to their lower contents of carbon, alloying and microalloying elements, TMCP plates show superior toughness even with high heat inputs and reduced hardness values in the heat affected zones compared to normalized steels (Figure 6 and Figure 7).

Subsequently TMCP steels offer an increased working range for the welding process, resulting in an increased safety to fulfil the requirements of the code, especially due to the fact that storage tanks are fabricated on site and not in a workshop.

One disadvantage of TMCP steels is their limited resistance against PWHT with holding temperatures above 600°C. However, for most storage tanks no PWHT is required by the codes and if required the codes offer lower temperatures with longer holding times. In general the best idea is to agree about the parameters of PWHT with the steel supplier at the time of the inquiry.

TMCP steels in sour service

Even if the stored gas or liquid causes the risk of sour service-related HIC, the application of TMCP plates has advantages. For normalised plates a stress relieving of the plate or a PWHT of the whole vessel even under 38mm is necessary to achieve HIC resistance, verified in accordance with NACE TM 0284. For TMCP plates this additional heat treatment is not required.

Tailor-made solution

After investigating a large number of plate enquiries, studying the requirements of different construction codes and having in mind the benefits of TMCP steels, Dillinger developed a tailor-made TMCP steel branded Di-Tank for the construction of storage tanks.

Di-Tank is available with 355 MPa and 415 MPa yield strength in accordance to different construction codes, offering improved toughness properties and a very low carbon equivalent compared to grades listed in Table 1. Di-Tank 355 is also available with improved resistance to hydrogen induced cracking, offering a CLR ≤ 10 %, CTR ≤ 3 % and CSR ≤ 1 %, verified in accordance with NACE TM 0284.

In summary

TMCP plates offer various advantages compared to equivalent normalised plates and are furthermore in accordance with the construction codes for storage tanks.

During recent years some projects using TMCP steels have been realised, achieving overall cost savings of approximately 10%.

The fact that TMCP steels are uncommon for the application of storage tanks derives from the experience-based approach by the specification writers regarding the selection of materials.

Looking at the worldwide growing energy demand and the need for storage along the whole oil and gas value chain, there will be many future opportunities to profit from the use of thermo-mechanically rolled heavy plates.

Dr Peter Flüß, Joerg Maffert and Philipp Schirra are with Dillinger.

Tags:

dillinger

Thermomechanical tanks

thermo-mechanical controlled processing steels

TMCP

Images:

Categories:

Oil and Gas Engineer

Production/Processing

Source: engineerlive.com

0 notes

Link

CSA Z 662 Reference publications and definitions

June 13, 2020

P.Eng.

Meena Rezkallah

2.1 Reference publications There is a commentary available for this Clause. This Standard refers to the following publications, and where such reference is made, it shall be to the edition listed below, unless the user finds it more appropriate to use newer or amended editions of such publications. CSA Group A3000-13 Cementitious materials compendium A3001-13 Cementitious materials for use in concrete A3002-13 Masonry and mortar cement B51-14 Boiler, Pressure Vessel, and Pressure Piping Code B137 Series-13 Thermoplastic pressure piping compendium B149.1-10 Natural Gas and Propane Installation Code B149.2-10 Propane Storage and Handling Code C22.1-15 Canadian Electrical Code, Part I CAN/CSA-C22.3 No. 4-13 Control of electrochemical corrosion of underground metallic structures CAN/CSA-C22.3 No. 6-13 Principles and practices of electrical coordination between pipelines and electric supply lines PLUS 663-04 Land use planning for pipelines: A guideline for local authorities, developers, and pipeline operators S408-1981-11 Guidelines for the development of limit states design standards CAN/CSA-S471-04 (withdrawn) General requirements, design criteria, the environment, and loads

W48-14 Filler metals and allied materials for metal arc welding W59-13 Welded steel construction (metal arc welding) W178.2-14 Certification of welding inspectors Z245.1-14 Steel pipe Z245.6-06 (R2011) Coiled aluminum line pipe and accessories Z245.11-13 Steel fittings Z245.12-13 Steel flanges Z245.15-13 Steel valves Z245.20 Series-14 Plant-applied external coatings for steel pipe Z245.20-14 Plant-applied external fusion bond epoxy coating for steel pipe Z245.21-14 Plant-applied external polyethylene coating for steel pipe Z245.22-14 Plant-applied external polyurethane foam insulation coating for steel pipe Z245.30-14 Field-applied external coatings for steel pipeline systems Z246.1-13 Security management for petroleum and natural gas industry systems Z276-15 Liquefied natural gas (LNG) — Production, storage, and handling Z341 Series-14 Storage of hydrocarbons in underground formations CAN/CSA-Z731-03 (R2014) Emergency preparedness and response

CAN/CSA-ISO 9001-08 (R2014) Quality management systems — Requirements CAN/CSA-ISO 31000-10 Risk management — Principles and guidelines AGA (American Gas Association) B109.1-2000 (R2008) Diaphragm-Type Gas Displacement Meters (Under 500 Cubic Feet per Hour Capacity) (Catalogue # XQ0008) API (American Petroleum Institute) 5L-2012 (SPEC) Specification for Line Pipe 5LCP-2006 (R2013) (SPEC) Coiled Line Pipe 6D-2014 (SPEC) Specification for Pipeline and Piping Valves 15HR-2001 (R2010) (SPEC) High Pressure Fiberglass Line Pipe 15LE-2008 (R2013) (SPEC) Polyethylene (PE) Line Pipe 15S-2006 (R2013) (RP) Qualification of Spoolable Reinforced Plastic Line Pipe 17J-2014 (SPEC) Specification for Unbonded Flexible Pipe 17K-2005 (R2010) (SPEC) Specification for Bonded Flexible Pipe 510-20146 (STD) Pressure Vessel Inspection Code: In-Service Inspection, Rating, Repair, and Alteration 572-2009 (RP) Inspection Practices for Pressure Vessels 576-2009 (RP) Inspection of Pressure-relieving Devices 599-2013 (STD) Metal Plug Valves-Flanged, Threaded and Welding Ends 600-2009 (STD) Steel Gate Valves-Flanged and Butt-welding Ends, Bolted Bonnets

602-2009 (STD) Steel Gate, Globe and Check Valves for Sizes DN 100 and Smaller for the Petroleum and Natural Gas Industries 608-2012 (STD) Metal Ball Valves-Flanged, Threaded and Welding Ends 609-2009 (STD) Butterfly Valves: Double-flanged, Lug- and Wafer-type 610-2010 (STD) Centrifugal Pumps for Petroleum, Petrochemical and Natural Gas Industries 617-2002 (R2009) (STD) Axial and Centrifugal Compressors and Expander-compressors for Petroleum, Chemical and Gas Industry Services 618-2007 (STD) Reciprocating Compressors for Petroleum, Chemical and Gas Industry Services 650-2013 (STD) Welded Tanks for Oil Storage 651-2007 (RP) Cathodic Protection of Aboveground Petroleum Storage Tanks 652-2005 (RP) Linings of Aboveground Petroleum Storage Tank Bottoms 653-2009 (STD) Tank Inspection, Repair, Alteration, and Reconstruction 1604-1996 (R2010) (RP) Closure of Underground Petroleum Storage Tanks 2015-2014 (STD) Requirements for Safe Entry and Cleaning of Petroleum Storage Tanks 2028-2002 (R2010) (RP) Flame Arresters in Piping Systems 2350-2012 (STD) Overfill Protection for Storage Tanks in Petroleum Facilities 2610-2005 (R2010) (STD) Design, Construction, Operation, Maintenance, and Inspection of Terminal & Tank Facilities Q1-2013 (SPEC) Specification for Quality Management System Requirements for Manufacturing Organizations for the Petroleum and Natural Gas Industry

ASME (The American Society of Mechanical Engineers) B1.1-2003 (R2008) Unified Inch Screw Threads, (UN and UNR Thread Form) B1.20.1-2013 Pipe Threads, General Purpose, Inch B16.1-2010 Gray Iron Pipe Flanges and Flanged Fittings: Classes 25, 125, and 250 B16.5-2013 Pipe Flanges and Flanged Fittings: NPS 1/2 through NPS 24 Metric/Inch Standard B16.9-2012 Factory-Made Wrought Buttwelding Fittings B16.11-2011 Forged Fittings, Socket-Welding and Threaded B16.20-2012 Metallic Gaskets for Pipe Flanges: Ring Joint, Spiral Wound, and Jacketed B16.21-2011 Nonmetallic Flat Gaskets for Pipe Flanges B16.24-2011 Cast Copper Alloy Pipe Flanges and Flanged Fittings: Classes 150, 300, 600, 900, 1500 and 2500 B16.33-2009 Manually Operated Metallic Gas Valves for Use in Gas Piping Systems up to 175 psi (Sizes NPS ½ through NPS2) B16.34-2013 Valves Flanged, Threaded and Welding End B16.36-2009 Orifice Flanges B16.40-2013 Manually Operated Thermoplastic Gas Shutoffs and Valves in Gas Distribution Systems B16.47-2011 Large Diameter Steel Flanges: NPS 26 through NPS 60 Metric/Inch Standard B16.48-2010 Line Blanks B16.49-2012 Factory-Made, Wrought Steel, Buttwelding Induction Bends for Transportation and Distribution Systems

B18.2.1-2012 Square, Hex, Heavy Hex, and Askew Head Bolts and Hex, Heavy Hex, Hex Flange, Lobed Head, and Lag Screws (Inch Series) B18.2.2-2010 Nuts for General Applications: Machine Screw Nuts, Hex, Square, Hex Flange, and Coupling Nuts (Inch Series) B31G-2012 Manual for Determining the Remaining Strength of Corroded Pipelines B31.3-2012 Process Piping B31.8-2012 Gas Transmission and Distribution Piping Systems B31.8S-2012 Managing System Integrity of Gas Pipelines B36.19M-2004 (R2010) Stainless Steel Pipe Boiler and Pressure Vessel Code, 2013: Section II: Materials Section V: Nondestructive Examination Section VIII: Pressure Vessels — Division 1 Section VIII: Pressure Vessels — Division 2 — Alternative Rules Section IX: Welding and Brazing Qualifications PCC-2-2015 Repair of Pressure Equipment and Piping ASTM International (American Society for Testing and Materials) A53/A53M-12 Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-Coated, Welded and Seamless A105/A105M-13 Standard Specification for Carbon Steel Forgings for Piping Applications A106/A106M-14 Standard Specification for Seamless Carbon Steel Pipe for High-Temperature Service A126-04 (R2014) Standard Specification for Gray Iron Castings for Valves, Flanges, and Pipe Fittings

A193/A193M-14 Standard Specification for Alloy-Steel and Stainless Steel Bolting for High Temperature or High Pressure Service and Other Special Purpose Applications A194/A194M-14 Standard Specification for Carbon and Alloy Steel Nuts for Bolts for High-Pressure or High-Temperature Service, or Both A216/A216M-14 Standard Specification for Steel Castings, Carbon, Suitable for Fusion Welding, for High-Temperature Service A234/A234M-13e1 Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service A268/A268M-10 Standard Specification for Seamless and Welded Ferritic and Martensitic Stainless Steel Tubing for General Service A269-14e1 Standard Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service A307-12 Standard Specification for Carbon Steel Bolts, Studs, and Threaded Rod 60 000 PSI Tensile Strength A320/A320M-14 Standard Specification for Alloy/Steel Bolting Materials for Low-Temperature Service A333/A333M-13 Standard Specification for Seamless and Welded Steel Pipe for Low-Temperature Service and Other Applications with Required Notch Toughness A350/A350M-13 Standard Specification for Carbon and Low-Alloy Steel Forgings, Requiring Notch Toughness Testing for Piping Components A352/A352M-06 (2012) Standard Specification for Steel Castings, Ferritic and Martensitic, for Pressure-Containing Parts, Suitable for Low-Temperature Service A354-11 Standard Specification for Quenched and Tempered Alloy Steel Bolts, Studs, and Other Externally Threaded Fasteners A381-96 (2012) Standard Specification for Metal-Arc-Welded Steel Pipe for Use with High-Pressure Transmission Systems

A395/A395M-99 (2014) Standard Specification for Ferritic Ductile Iron Pressure-Retaining Castings for Use at Elevated Temperatures A420/A420M-13 Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Low-Temperature Service A563/A563M-07 Standard Specification for Carbon and Alloy Steel Nuts A694/A694M-13 Standard Specification for Carbon and Alloy Steel Forgings for Pipe Flanges, Fittings, Valves, and Parts for High-Pressure Transmission Service A707/A707M-13 Standard Specification for Forged Carbon and Alloy Steel Flanges for Low-Temperature Service A789/A789M-10a Standard Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service A860/A860M-13 Standard Specification for Wrought High-Strength Ferritic Steel Butt-Welding Fittings A984/A984M-03 (withdrawn) Standard Specification for Steel Line Pipe, Black, Plain-End, Electric-Resistance-Welded A1005/A1005M-00 (2010) Standard Specification for Steel Line Pipe, Black, Plain End, Longitudinal and Helical Seam, Double Submerged-Arc Welded A1024/A1024M-02 (2012) Standard Specification for Steel Line Pipe, Black, Plain-End, Seamless A1037/A1037M-05 (2012) Standard Specification for Steel Line Pipe, Black, Furnace-Butt-Welded B43-14 Standard Specification for Seamless Red Brass Pipe, Standard Sizes B75/B75M-11 Standard Specification for Seamless Copper Tube B88-09 Standard Specification for Seamless Copper Water Tube B241/B241M-12e1 Standard Specification for Aluminum and Aluminum-Alloy Seamless Pipe and Seamless Extruded Tube

B361-08 Standard Specification for Factory-Made Wrought Aluminum and Aluminum-Alloy Welding Fittings D257-14 Standard Test Methods for DC Resistance or Conductance of Insulating Materials D323-08(2014) Standard Test Method for Vapor Pressure of Petroleum Products (Reid Method) D570-98(2010)e1 Standard Test Method for Water Absorption of Plastics D1000-10 Standard Test Methods for Pressure-Sensitive Adhesive-Coated Tapes Used for Electrical and Electronic Applications D1002-10 Standard Test Method for Apparent Shear Strength of Single-Lap-Joint Adhesively Bonded Metal Specimens by Tension Loading (Metal-to-Metal) D1525-09 Standard Test Method for Vicat Softening Temperature of Plastics D1653-13 Standard Test Methods for Water Vapor Transmission of Organic Coating Films D1693-13 Standard Test Method for Environmental Stress-Cracking of Ethylene Plastics D2240-05 (2010) Standard Test Method for Rubber Property — Durometer Hardness D2290-12 Standard Test Method for Apparent Hoop Tensile Strength of Plastic or Reinforced Plastic Pipe D2343-09 Standard Test Method for Tensile Properties of Glass Fiber Strands, Yarns, and Rovings Used in Reinforced Plastics D2412-11 Standard Test Method for Determination of External Loading Characteristics of Plastic Pipe by Parallel- Plate Loading D2584-11 Standard Test Method for Ignition Loss of Cured Reinforced Resins D2837-2013 (E2014) Standard Test Method for Obtaining Hydrostatic Design Basis for Thermoplastic Pipe Materials or Pressure Design Basis for Thermoplastic Pipe Products

D2992-12 Standard Practice for Obtaining Hydrostatic or Pressure Design Basis for “Fiberglass” (Glass-Fiber- Reinforced Thermosetting-Resin) Pipe and Fittings D3261-2012 (E2014) Standard Specification for Butt Heat Fusion Polyethylene (PE) Plastic Fittings for Polyethylene (PE) Plastic Pipe and Tubing D3350-14 Standard Specification for Polyethylene Plastics Pipe and Fittings Materials D3839-14 Standard Guide for Underground Installation of “Fiberglass” (Glass-Fiber Reinforced Thermosetting- Resin) Pipe D3895-07 Standard Test Method for Oxidative-Induction Time of Polyolefins by Differential Scanning Calorimetry D4060-10 Standard Test Method for Abrasion Resistance of Organic Coatings by the Taber Abraser D4541-09e1 Standard Test Method for Pull-Off Strength of Coatings Using Portable Adhesion Testers D5064-07 (2012) Standard Practice for Conducting a Patch Test to Assess Coating Compatibility D5084-10 Standard Test Methods for Measurement of Hydraulic Conductivity of Saturated Porous Materials Using a Flexible Wall Permeameter E18-14 rev 4 Standard Test Methods for Rockwell Hardness of Metallic Materials E21-09 Standard Test Methods for Elevated Temperature Tension Tests of Metallic Materials E23-12c Standard Test Methods for Notched Bar Impact Testing of Metallic Materials E29-13 Standard Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications E114-10 Standard Practice for Ultrasonic Pulse-Echo Straight-Beam Contact Testing E384-11 (E2012) Standard Test Method for Knoop and Vickers Hardness of Materials

E747-04 (2010) Standard Practice for Design, Manufacture and Material Grouping Classification of Wire Image Quality Indicators (IQI) Used for Radiology E1025-11 Standard Practice for Design, Manufacture, and Material Grouping Classification of Hole-Type Image Quality Indicators (IQI) Used for Radiology E1820-13 Standard Test Method for Measurement of Fracture Toughness E1901-13 Standard Guide for Detection and Evaluation of Discontinuities by Contact Pulse-Echo Straight-Beam Ultrasonic Methods F1290-08 (withdrawn) Standard Practice for Electrofusion Joining Polyolefin Pipe and Fittings F1973-2013 (E2013) Standard Specification for Factory Assembled Anodeless Risers and Transition Fittings in Polyethylene (PE) and Polyamide II (PAII) and Polyamide 12 (PA12) Fuel Gas Distribution Systems F2206-11 (R2014) Standard Specification for Fabricated Fittings of Butt-Fused Polyethylene (PE) F2620-13 Standard Practice for Heat Fusion Joining of Polyethylene Pipe and Fittings F2634-10 Standard Test Method for Laboratory Testing of Polyethylene (PE) Butt Fusion Joints Using Tensile- Impact Method G8-96 (2010) Standard Test Methods for Cathodic Disbonding of Pipeline Coatings G9-07(2013)e1 Standard Test Method for Water Penetration into Pipeline Coatings G10-10 Standard Test Method for Specific Bendability of Pipeline Coatings G11-04(2012) Standard Test Method for Effects of Outdoor Weathering on Pipeline Coatings G14-04 (2010)e1 Standard Test Method for Impact Resistance of Pipeline Coatings (Falling Weight Test) G17-07(2013) Standard Test Method for Penetration Resistance of Pipeline Coatings (Blunt Rod)

G18-07(2013) Standard Test Method for Joints, Fittings, and Patches in Coated Pipelines G19-88 (withdrawn) Standard Test Method for Disbonding Characteristics of Pipeline Coatings by Direct Soil Burial G20-10 Standard Test Method for Chemical Resistance of Pipeline Coatings G21-13 Standard Practice for Determining Resistance of Synthetic Polymeric Materials to Fungi G42-11 Standard Test Method for Cathodic Disbonding of Pipeline Coatings Subjected to Elevated Temperatures G55-07 (2013) Standard Test Method for Evaluating Pipeline Coating Patch Materials G80-88 (withdrawn) Standard Test Method for Specific Cathodic Disbonding of Pipeline Coatings G154-12a Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Nonmetallic Materials UOP163-10 Hydrogen Sulfide and Mercaptan Sulfur in Liquid Hydrocarbons by Potentiometric Titration AWS (American Welding Society) A5.32/A5.32M-11 Welding Consumables — Gases and Gas Mixtures for Fusion Welding and Allied Processes D3.6M-10 Underwater Welding Code AWWA (American Water Works Association) C205-12 Cement-Mortar Protective Lining and Coating for Steel Water Pipe — 4 In. (100 mm) and Larger – Shop Applied BSI (British Standards Institution) BS EN 253:2013 District heating pipes. Preinsulated bonded pipe systems for directly buried hot water networks. Pipe assembly of steel service pipe, polyurethane thermal insulation and outer casing of polyethylene BS EN 489:2009 District heating pipes. Preinsulated bonded pipe systems for directly buried hot water networks. Joint assembly for steel service pipes, polyurethane thermal insulation and outer casing of polyethylene

BS 7910:2013 Guide to methods for assessing the acceptability of flaws in metallic structures PD 6493:1991 (withdrawn) Guidance on methods for assessing the acceptability of flaws in fusion welded structures CAPP (Canadian Association of Petroleum Producers) 2004-0022 Planning Horizontal Directional Drilling for Pipeline Construction 2009-0009 Best Management Practice — Use of Reinforced Composite Pipe (Non-Metallic Pipelines) 2009-0010 Mitigation of Internal Corrosion in Oilfield Water Pipelines 2009-0011 Mitigation of External Corrosion on Buried Pipeline Systems 2009-0012 Mitigation of Internal Corrosion in Oil Effluent Pipeline Systems 2009-0013 Mitigation of Internal Corrosion in Sour Gas Gathering Systems 2009-0014 Mitigation of Internal Corrosion in Sweet Gas Gathering Systems CCME (Canadian Council of Ministers of the Environment) PN 1180 Environmental Guidelines for Controlling Emissions of Volatile Organic Compounds from Aboveground Storage Tanks CEPA (Canadian Energy Pipeline Association) Stress Corrosion Cracking Recommended Practices, 2nd ed. (December 2007) Facilities Integrity Management Program (FIMP) Recommended Practices, 1st ed. (May 2013) Development of a Pipeline Surface Loading Screening Process & Assessment of Surface Load Dispersing Methods (Final Report No. 05-44R1) (October 2009) CGA (Canadian Gas Association) OCC-1-2013 Recommended Practice for the Control of External Corrosion on Buried or Submerged Metallic Piping Systems CGA (Common Ground Alliance) Best Practices, Version 10.0 (March 2012)

CGSB (Canadian General Standards Board) CAN/CGSB-48.9712-2014/ISO 9712:2012 Non-destructive Testing — Qualification and certification of NDT personnel DIN (Deutsches Institut für Normung e.V.) 30672-2000 Tape and shrinkable materials for the corrosion protection of buried or underwater pipelines without cathodic protection for use at operating temperatures up to 50 °C DNV (Det Norske Veritas) DNV-OS-F101-2013 Submarine Pipeline Systems DNV-RP-F101-2010 Corroded Pipelines DNV-RP-J202-2010 Design and Operation of CO2 Pipelines DOT (US Government, Department of Transportation) DTRS56-02-D-70036 (2005) Derivation of Potential Impact Radius Formulae for Vapor Cloud Dispersion Subject to 49 CFR 192 ESI (Electricity Supply Industry) 98-2-1979 (withdrawn) Ultrasonic Probes: Medium Frequency, Miniature Shear Wave, Angle Probes Government of USA US Code of Federal Regulations, Title 33, Chapter I, Part 154, Appendix A, “Guidelines for Detonation Flame Arresters” (referenced as 33 CFR 154, Appendix A) US Code of Federal Regulations, Title 49, Part 192, Transportation of Natural and Other Gas by Pipeline: Minimum Federal Safety Standards (referenced as 49 CFR 192) IGEM (Institution of Gas Engineers & Managers) IGEM/TD/1 Steel pipelines and associated installations for high pressure gas transmission, ed. 5 The INGAA Foundation Guidelines for Parallel Construction of Pipelines, December 2008 ISO (International Organization for Standardization) 2566-1:1984 (R2010) Steel — Conversion of elongation values — Part 1: Carbon and low alloy steels 3183:2012 Petroleum and natural gas industries — Steel pipe for pipeline transportation systems

3898:2013 Bases for design of structures – Names and symbols of physical quantities and generic quantities 5579:2013 Non-destructive testing — Radiographic testing of metallic materials using film and X- or gamma rays — Basic rules 9080:2012 Plastics piping and ducting systems — Determination of the long-term hydrostatic strength of thermoplastics materials in pipe form by extrapolation 12162:2009 Thermoplastics materials for pipes and fittings for pressure-applications — Classification, designation and design coefficient 12176-1:2012 Plastic pipes and fittings — Equipment for fusion joining polyethylene systems — Part 1: Butt fusion 12176-2:2008 Plastic pipes and fittings — Equipment for fusion joining polyethylene systems — Part 2: Electrofusion 12176-3:2011 Plastic pipes and fittings — Equipment for fusion joining polyethylene systems — Part 3: Operator’s badge 12176-4:2003 Plastic pipes and fittings — Equipment for fusion joining polyethylene systems — Part 4: Traceability coding 13953-2001 Polyethylene (PE) pipes and fittings — Determination of the tensile strength and failure mode of test pieces from a butt-fused joint 14175:2008 Welding consumables — Gases and gas mixtures for fusion welding and allied processes 14555:14 Welding — Arc stud welding of metallic materials 15156-2:2009 Petroleum and natural gas industries — Materials for use in H2S-containing environments in oil and gas production — Part 2: Cracking-resistant carbon and low-alloy steels, and the use of cast irons 15156-3:2009 Petroleum and natural gas industries — Materials for use in H2S-containing environments in oil and gas production — Part 3: Cracking-resistant CRAs (corrosion-resistant alloys) and other alloys 15653:2010 Metallic materials — Method of test for the determination of quasistatic fracture toughness of welds

16708:2006 Petroleum and natural gas industries — Pipeline transportation systems — Reliability-based limit state methods 19232-1:2013 Non-destructive testing — Image quality of radiographs — Part 1: Determination of the image quality value using wire-type image quality indicators ISO TR 19480:2005 Polyethylene pipes and fittings for the supply of gaseous fuels or water — Training and assessment of fusion operators ISO/TS 24817:2006 Petroleum, petrochemical and natural gas industries — Composite repairs for pipework — Qualification and design, installation, testing and inspection MSS (Manufacturers Standardization Society) SP-6-2012 Standard Finishes for Contact Faces of Pipe Flanges and Connecting-End Flanges of Valves and Fittings ANSI/MSS-SP-25-2013 Standard Marking System for Valves, Fittings, Flanges and Unions SP-75-2014 Specification for High-Test, Wrought, Butt Welding Fittings SP-79-2011 Socket Welding Reducer Inserts (Includes Errata Amended 7/8/2012) SP-83-2014 Class 3000 Steel Pipe Unions, Socket-Welding and Threaded SP-95-2014 Swage(d) Nipples and Bull Plugs SP-97-2012 Integrally Reinforced Forged Branch Outlet Fittings — Socket Welding, Threaded and Buttwelding Ends NACE International ANSI/NACE MR0175/ISO 15156-2-2009 Petroleum and natural gas industries — Materials for use in H2S-containing environments in oil and gas production — Part 2: Cracking-resistant carbon and low-alloy steels, and the use of cast irons Note: Including circular 1-2011 and circular 2-2014. ANSI/NACE MR0175/ISO 15156-3-2009 Petroleum and natural gas industries — Materials for use in H2S-containing environments in oil and gas production — Part 3: Cracking-resistant CRAs (corrosion-resistant alloys) and other alloys Note: Including circular 1-2011, circular 2-2014, circular 3-2013, circular 4-2014.