#calcined mica

Explore tagged Tumblr posts

Text

It is really really really really really interesting to read these old chemistry guides with a knowledge of geology. By functionally ignoring the words and focusing on the reactions that are happening, you can piece together the real minerals despite the translators' struggles for the right word.

Like here, "Zungufr" is clearly "red ????". The translators (there were two translations before this one) likely didn't have a knowledge of mineralogy. From the rest of the text, I'm fairly certain Copper acetate is either Copper Acetate or Copper Nitrate, to be added with (NH)4Cl and Malachite (Hydrated Copper Carbonate). However, the end result via the translator is Cinnabar - which is a theoretically reasonable guess. Natural cinnabar is red, and so is arsenic sulfide. However, there's literally no As or Hg in this equation, which means that the result is the red Copper Oxide mineral, CuO. Cuprite.

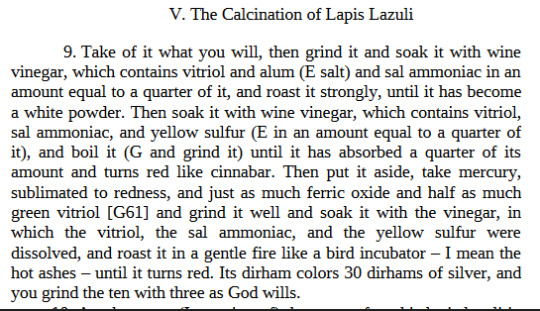

Likewise, you have "The Calcination of Lapis Lazuli", which I thought was interesting in the first place, because in the beginning of the text, Al-Razi describes all the reagents. (21) The translator decided to stick with Lapis Lazuli, although seemingly aware that Azurite and Lapis Lazuli are not even close to the same mineral.

However, when you look at the minerals in 21, something doesn't add up. I was already suspicious of the Lapis Lazuli description, but something was clearly wrong in 21. Neither Lapis nor Hematite have copper, or are "oily/vitreous" minerals. Plus, they already described "Iron Oxides" above this point. Which makes it much more likely that "Lapis Lazuli" actually means Azurite, and Hematite is actually describing Sphalerite, (Zn,Fe)S, and Al-Razi prefers the Fe-rich Sphalerite.

This was also supported by his description of several "zinc ore" minerals, but I couldn't find a good description of sphalerite among them. Then I realized that what Al-Razi was really describing were different variations of Zinc Oxides, and separating out Zinc Sulfides.

Talc does NOT glitter. And there's no reason to differentiate "sea-talc" and "mountain-talc". But there would be if you knew there were Fe-Micas and Mg-Micas! (Or even just the straight Al-Mica.)

But to be clear, this is not the fault of the translators!! The fact they got close enough I can recognize the errors and described the mineral well enough I can recognize these reactions are a blessing in and of itself.

#archeometallurgy#archeochemistry#mineralogy#I'm having so much fun. I've been reading all day and it's killing me but I'm so excited. And this is important!!!#'so and so described X mineral in 1549' No they fucking didn't. I just read how to amalgum Au out of arsenopyrite from 900AD!!!#They might've called it yellow marcasite but they knew what they were doing.#Anyway I still haven't gotten to the part with Copper Smelting which is theoretically the only part I care about. xDDD#Hey did you know Cyprus was exporting sulfuric acid from Roman-era AMD??????#It's just a pity that some people will look at that Lapis reaction and think that Al-Razi didn't know what he was talking about.#No he DEFINITELY did.

2 notes

·

View notes

Text

Calcined Mica Powder| 20 Nano

Achieve dazzling, natural shimmer with our ultra-fine 20 20-nano calcined Mica Powder! This silky, weightless powder offers superior adhesion and oil control for long-lasting, flawless makeup. Made from natural mica, it's gentle on the skin and delivers a spectrum of stunning reflective colors.

Mica's magic goes beyond makeup! This versatile powder adds shimmer to art projects, crafts (think pen turning & scrapbooking!), and even industrial applications.

For more information: https://20nano.com/mica/#products

0 notes

Text

Calcined Mica Powder for Industrial & Cosmetic Use - 20Microns Nano

20 Nano understands the requirements of the business and hence provides solutions that are realistic and based on the use. If you are in the industry where there is a need to procure Calcined Mica Powder, you can contact us and get your requirement fulfilled. Please send us your condition, and our team will assist you further. For More Information Visit: https://20nano.com/mica/

0 notes

Text

What Are the Benefits of Diatomaceous Earth?

Introduction

Diatomaceous Earth, or Diatomite or Kieselguhr in German, is a chalky sedimentary rock made from the skeletal material of aquatic plants called Diatoms. Each particle has a structure that resembles a snowflake, rods and cones, and a honeycomb. It also has holes in it. When examined under a microscope, the particles resemble broken glass when they are crushed into a fine powder. Because of its extensive industrial knowledge, Seema Minerals & Metals offers natural and calcined diatomaceous earth, diatomite, and kieselguhr powder at the best prices. It is also one of the diatomite manufacturers in India. Due to its structure and properties, it is utilized extensively in industries, agriculture, and animal feed.

Uses of Diatomaceous earth:

There are numerous applications for diatomaceous earth. Diatomaceous Earth is used to make calcium silicate boards, fireproof safes and cabinets, brake liners, mold release in latex products, mold release in auto parts spun pipes, mold release in animal feeds as a carrier and directly used, aquaculture, coil coating paints, oil well drilling, in an oil refinery, as an anti-caking agent in fertilizers and animal feed, for grain storage, paper manufacturing, filtration of edible oil, pharmaceutical drugs, chemicals, and as a catalyst in the We process

Agriculture

In the nursery, DE can be used to control various bugs and irritations. It can be utilized, for instance, to eradicate slugs and snails from vegetable gardens. Additionally, mites, aphids, and whiteflies, which can harm plants, are eliminated by diatomaceous earth. If you're looking for Calcined Diatomaceous Earth in India, Diatomite Kieselguhr Manufacturers in India, and diatomite manufacturers, Seema Mineral is the company to deal with. The protective coating of DE Silicon Fertilizer Granules shields the surface from chemicals, gasoline, wind, water, and other elements. As a result, paint and other products that are subjected to chemical reactions and weathering can be used as coating materials.

Benefits of diatomaceous earth

Diatomaceous earth has been adapted to almost all industrial filtration applications, including the processing of oils, alcoholic and non-alcoholic beverages, antibiotics, solvents, and chemicals. In the past, it was primarily used as a filter to clarify sugar and syrups. A second major application is as a filler or extender in numerous products, including paper, paint, brick, tile, ceramics, linoleum, plastic, soap, and detergent.

Conclusions

The fossilized remains of diatoms, which are small aquatic organisms, are what make up diatomaceous earth. Natural silica is the material used to construct their skeletons. Diatoms accumulated in the sediment of rivers, streams, lakes, and oceans for a considerable amount of time. These areas are used to extract silica deposits at the moment. Silica is very common in nature and accounts for 26% of the weight of the earth's crust. Sand, emerald, quartz, feldspar, mica, clay, asbestos, and glass are all examples of various forms of silica. Silicon, a silica component, does not naturally exist in its pure form. Silicon dioxide is typically produced when it reacts with oxygen and water. On the other hand, it might contain very little crystalline silicon dioxide.

1 note

·

View note

Link

Devidayal Chemicals is one of the leading manufacturers of Calcined Mica Powder in Mumbai, in India

Keeping in mind the ever-evolving requirements of our clients, we are devoted towards offering an optimum quality range of Calcined Mica Powder. Our Calcined Mica is of High quality, High Lustre and high whiteness.

#Calcined Mica Powder Manufacturers In India#calcined mica powder#calcined mica#Mica Powder suppliers

0 notes

Text

What’s the difference between Bone China and porcelain?

What’s the difference between Bone China and porcelain?

Chapter one-The Raw Material

Because Bone China is a kind of porcelain, the raw materials used are almost similar.With one key difference—Bone China actually contains real bones (cow bone ash, usually). This special ingredient makes Bone China thinner and smoother than regular porcelain, giving it a creamy, white color and opaqueness.

Clay: The specific composition of clay is typically determined by where it is extracted. Regardless of where it is obtained, clay will frequently have very similar characteristics. All clays, for example, vitrify only at high temperatures. The sole exception is when the addition of certain materials reduces the vitrification threshold. Furthermore, burned clays have a refractory contribution to the completed product.

Feldspar: Feldspar is primarily made up of flint and aluminum silicate. Flint is hard quartz that is used as a flux in a porcelain composition. Changes can be utilized to lower the temperature at which liquid glass is produced, typically around 1000 to 1300oC.

Silica: Silica is a chemical molecule produced by the interaction of silicon and oxygen gas, two of the most common elements on the planet. It occurs naturally in three forms: amorphous, crystalline, and impure, as seen in quartz, sand, and opal, respectively.

China stone: China stone is a partly kaolinized, feldspar-rich type of granite that contains no iron and is used in the manufacturing of bone China (see later). Its mineral makeup includes mica, quartz, and feldspar, and it is frequently found in conjunction with kaolin. The resemblance of China stone to Petuntse, which is used to produce hard-paste porcelain, is likely why it became a significant component of bone China.

Kaolin: Kaolin is a clay mineral that is white and produced by the weathering of other aluminosilicate minerals. It is utilized in the majority of contemporary ceramics.

Bone ash: Bone ash is calcined, crushed, and finely powdered animal bones used in Bone China production. Typical bone ash comprises roughly 56% calcium oxide, 42% phosphorus pentoxide, and the remainder water. The calcination process takes place at a temperature of about 1,000 °C.

5 notes

·

View notes

Text

Abhraka Bhasma | Abhrak Bhasm | Calcined | Mica | Mica ash | Oxidized Mica | Biotite Calx | Abhrakacalx #jayherbs

Message us on WhatsApp..

+91-8309989127

#herb #ayurvadic #unani #jayherbs #Jadibuti #raw #rawherbs #chemicals #Thymol #menthol #ayurveda #ayurvedic #guggal #Loban #poojaitems #hawan #cinnaber #arsenic #unani #liquidmercury #telangana #tamilnadu #kerala #India #andhrapradesh #jayjadibutiwala #8309989127 #herbdealer #jayjain

0 notes

Text

MANMANTHABHRA RASA

Text Ref.: Rasendrasarasangraha-Rasayanvajikaranadhikara.

Caution: To be taken under medical supervision only.

Ingredients: Each tablet of 250 mg. contains

Kajjali (Black sulphide of mercury), Abhraka bhasma (Calcined mica)-45.52 mg. (each

of the above ingredients), Karpur (Camphor)-7.27 mg., Vang bhasma (Calcined

satannum), Lauh bhasma (Calcined iron)-22.75 mg. (each of the above ingredients),

Tamra bhasma (Calcined copper)-11.37 mg., Vidhara beej (Argyreia speciosa),

Vidharikand (Pueraria tuberosa), Shatavari (Asparagus recemosus), Talamkhana

(Asteracantha longifolia), Bala (Sida cordifolia), Ati bala (Abutilon indicum), Jaiphala

(Myristica fragrans), Javitri (Myristica fragrans), Lavang (Syzygium aromaticum),

Bhang beej (Cannabis sativus), Shavet rall (Shorea robusta), Ajwain (Trachyspermum

ammi)-7.27 mg (each of the above ingredients).

Indications:Acts as an aphrodisiac & rejuvenator. Useful in impotency,

premature ejaculation, errectile dysfunction, helps in the process of

spermatogenesis, increases quality and quantity of semen, helps to retain

vigour and vitality. Checks premature greying and falling of hair & wrinkling of

skin before time.

Dosage: 1 to 2 tablets to be taken twice in a day with water, milk, or as directed

by the physician.

PURNA CHANDRA RASA

Rasendrasarasangraha-Rasayanvajikaranadhikara.

Caution: To be taken under medical supervision only.

Ingredients: Each tablet of 250 mg. contains

Rasa sindoora (Red sulphide of mercury), Abhraka bhamsa (Calcined mica),

Lauh bhasma (Calcined iron), Shudh Shiljit (Pure asphaltum), Vidang (Embelia

ribes), Swarn makshik bhasma (Calcined chalco pyrite)-41.60 mg. (each of

the above ingredients), Go ghrit, Honey—Q.S. (for mardana).

Indications: Acts as aphrodisiac, rejuvenator & retentive. Useful to

increase vigour & vitality, improves quality & quantity of semen, helps in the

formation of new blood in the body & enhances sexual desire and power.

Dosage: 1 to 2 tablets to be taken twice in a day with water, milk or as

directed by the physician.

SHIVA GUTIKA

Chakradatta-Rasayanadhikara.

Caution: To be taken under medical supervision only.

Ingredients: Each tablet of 300 mg. contains

Shudh Shilajit (Pure asphaltum)-101.20 mg., Harad (Terminalia Chebula), Bahera (Terminalia bellerica), Amla

(Emblica officinalis), Brihati (Solanum indicum), Laghukantakari (Solanum xanthocarpum), Shalparni

(Desmodium gangatium), Prishanparni (Uraria picta), Bilav chhal (Aegle Marmelos), Gambhari (Gmelina arborea),

Patha (Cissampelos pareira), Agnimantha (Premna integrifolia), Patala (Stereospermum suavealens), Gokshuru

(Tribulus terrestris), Giloye (Tinospora cordifolia), Khadir chhal (Acacia catechu), Patolpatra (Trichosanthes

dioica), Mulethi (Glycyrrhiza glabra), Cow's urine, Cow's milk, Kakoli (Lilium polyphyllum), Kshir kakoli (Fritillaria

royalei), Meda (Polygonatum cirrhifolium), MahaMeda (Polygonatum cirrhifolium), Ridhi (Habenaria intermedia),

Vridhi (Habenaria intermedia), Jivak (Microstylis muscifera), Rishbhak (Microstylis muscifera), Kshir vidhari (),

Shatavari (Asparagus racemosus), Munnaka (Vitis vinifera), Jatamansi (Nardostachys jatamansi), Gorakhmundi

(), Shavet jirak (Cuminum cyminum), Krishan jirak (Carum bulbocastanum), Sarivan (Desmodium gangeticum),

Pithvan (Uraria picta), Rasana (Pluchea lanceolata), Pushkarmool (Inula racemosa), Chitrakmool (Plumbago

zeylanicum), Dantimool (Baliospermum montanum), Gajpippali (Scindaspus indicus), Indra yava (Kurchi seeds),

Chavya (Piper chaba), Mustak (Cyperus rotundus), Kutaki (Picrorrhiza kurroa), Kakrashringi (Pistacia

integerrhima), Patha (Cissampelos preira)-2.60 mg. (each of the above ingredients), Pippali (Piper longum),

Shunthi (Zingiber officinalis), Kutaki (Picrorrhiza kurroa), Kakarashringi (Pistacia integerrhima), Marich (Piper

nigrum)-6.30 mg. (each of the above ingredients), Vidharikand (Pueraria tuberosa)-3.10 mg.,, Talispatra (Abies

webbiana)12.60 mg., Mishri (Sugar candy)-6.30 mg., Go Ghrit-12.60 mg., Vanshlochan (Bambusa arundinacea),

Tejpatra (Cinnamum inners), Dalchini (Cinnamum zeylanicum), Sukshmaila (Elettaria cardamum), Nagkeshar

(Mesua ferrea)-1.60 mg. (each of the above ingredients).

Indications: Useful aphrodisiac, can be used in all types of diabetes, rheumatism, tuberculosis,

polyuria, dysuria, piles, fistula, anorexia, dyspepsia, impaired digestion, enlargement of liver and

spleen, anaemia, jaundice, burning micturition, all types of fever, cough, asthma, abdominal

disorders, premature ejaculation, erectile dysfunction, insanity, hysteria and various gynecological

disorders.

Dosage: 1 to 2 tablets to be taken twice in a day with water, milk or as directed by the physician.

DHATRI LAUH

Bhaishajyaratanavali-Shoolarogadhikara.

Caution: To be taken under medical supervision only.

Ingredients: Each 125mg. contains

Amla (Emblica officinalis), Shunthi (Zingiber officinalis), Kali

marich (Piper nigrum), Pippali (Piper longum), Haridra (Curcuma

longa), Lauh bhasm (Calcined iron)-20.83 mg. (each of the

above ingredients)

Indiacations: Useful in Hyperacidity, Anaemia, Jaundice, Pain,

diseases of the eyes, Premature greying and falling of hair .

Dosage: 250 to 500 mg. to be taken twice in a day with honey,

Goghrita or sugar candy or as directed by the physician

PANCHAMRIT PARPATI

sendrasarasangraha-grahanirogadhikara.

Caution: To be taken under medical supervision only.

Ingredients: Each 125 mg. contains

Kajjali (Black sulphide of mercury)-64.50 mg., Shudh gandhaka

(Purified sulphur)-32.25 mg., Lauh bhasma (Calcined iron)-16.12 mg.,

Abhrak bhasma (Calcined mica)-8.06 mg., Tamra bhasma (Calcined

copper)-4.03 mg

Indications: Malabsorption Syndrome, Piles, Nausea, Diarrhoea, fever,

dyspepsia, Phthisis, Epistaxis, premature greying & falling of hair,

disorders of eyes, impaired digestion & deficiency of semen.

Dosage: 125 mg. to 250 mg. to be taken twice in a day with honey,

butter, ghee, Roasted jirak (Cuminum cyminum) or as directed by the

physician

0 notes

Text

Classical Vajikarana formulation Review

Vajikarana (aphrodisiac therapy) mainly deals with the promotion of sexual health, healthy progeny, and treatment of male sexual disorders such as premature ejaculation, erectile dysfunction, and infertility. The formulations described in Ayurveda generally contain ingredients of herbal, herbo-mineral, metal, or animal in origin.

Musali or Shweta (White) Musali is a potent herbal drug primarily utilized for Vajikaran therapy and indicated in the management of male infertility. Until date, no published information is presented in compiled form on the classical formulations of Musali with their dose and indications. Therefore, in this study, an attempt has been made to compile different formulations of Musali indicated for Vajikarana therapy.

so here is the classical review on vajikaran. go to Maxx Ayurveda website for more information and find solution about your sexual problems.

This study aims to gather information on various formulations of Musali primarily utilized for Vajikarana therapy. Critical review of various formulations of Shweta Musali is compiled from seven Ayurvedic texts, and the therapeutic efficacy of Musali is discussed on the basis of available data. Vajikarana formulations of Musali were discovered after Samhita period. In the present review, 51 formulations of Shweta Musali are found, which are mainly indicated for Vajikarana. In the formulations of Musali, ingredients such as Godugdha (cow’s milk), Goghrita (cows clarified butter), Khanda sharkara (sugar), Madhu (honey), Ashwagandha (Withania somnifera L.), Shatavari (Asperagus racemosus Wild.), Vidarikanda (Pueraria tuberosa), Abhrak, Bhasma (calcined mica), and Rasasindoor (red oxide of mercury) augment the Vajikarana potential of Musali and also help to prevent other complications.

On the basis of the reviewed research, it is concluded that Musali-containing formulations claimed significant aphrodisiac and spermatogenic properties, and present review will be helpful for research and pharmaceutical standardization purpose of Vajikarana formulations of Shweta Musali.

0 notes

Text

kaolin processing plant Processing line for kaolin

Introduction of main processing technology of kaolin: Kaolin processing technology generally includes beneficiation purification, ultra-fine crushing, calcination and surface modification. The original kaolin ore contains kaolinite minerals as the main components, and there are small amounts of montmorillonite, illite, diaspore, quartz, feldspar, mica and iron minerals (limonite, hematite, diamond) Iron ore, pyrite, etc.), titanium oxides (ilmenite, rutile, etc.), organic matter (plant fiber, organic peat, coal) and other impurities. As a mineral filler application, it must be beneficiated and purified. The processing technology of kaolin depends on the type of ore. Different beneficiation and purification processes are adopted for soft kaolin, sandy kaolin and hard kaolin (kaolinite). Dry and wet separation are the two main processes of the kaolin beneficiation process. The dry separation process is used to process kaolin ore with high whiteness and low grit content. It is easy to operate and saves costs. The raw kaolin ore is crushed in a crusher, and then the kaolin concentrate can be obtained by grinding in a Raymond mill. Wet kaolin beneficiation process is used to process complex kaolin ore. Wet beneficiation process uses high gradient magnetic separation, foam flotation and selective flocculant to make full use of kaolin mineral resources. Main production process of kaolin: 1.pounding The raw ore is added with water and dispersant according to the set concentration requirements, and is made into pulp in a mixer or a tamping machine. The purpose of pulping is to disperse kaolin and separate it from sandy minerals and plant impurities in order to prepare a slurry of suitable concentration for the next process. 2. Spiral classifier to remove coarse sand The raw particles of kaolin clay such as quartz, feldspar, mica and other impurities have coarser particle sizes, generally larger than 325 mesh, while the particles of kaolin have finer particle sizes, mainly concentrated in -2μm. A spiral classifier can remove most of the quartz and feldspar coarse sand. 3. Sorting of hydrocyclone The hydrocyclone is used for separation. The operation is to remove kaolin fine sand (fine-grained quartz, feldspar and other impurities). Generally, hydrocyclones with different diameters such as Ø75, Ø50, and Ø25 are used for multiple sorting. 4. Classification of horizontal spiral centrifuge The horizontal spiral centrifuge is used for classification, and the process parameters (such as separation factor) can be adjusted according to different materials to keep the product quality stable. At present, domestic kaolin beneficiation also adopts hydrocyclone for selective classification, but due to the influence of flow and pressure changes, the product quality is difficult to stabilize at -2μm accounting for more than 90%, and the classification efficiency is not as good as horizontal spiral centrifugal classifiers. 5. Magnetic separation In order to obtain high-quality or high-quality kaolin, in most cases, strong magnetic separation or high gradient magnetic separation, chemical bleaching, even flotation and selective flocculation are required. The dyed mineral impurities in kaolin, such as limonite, hematite, siderite, pyrite, anatase, rutile, etc., have weak magnetic properties, so the kaolinite after sand removal can be further used strong magnetic separator or high gradient The magnetic separator performs magnetic separation. Since most of the iron and titanium minerals in kaolin are embedded with finer particle size, the removal rate of strong magnetic separation is generally not high. Therefore, most of the industries currently use high gradient magnetic separators for magnetic separation of kaolin. In addition, superconducting magnetic separators with better performance have also been used for the magnetic separation and iron removal of kaolin. This magnetic separator not only further improves the strength of the magnetic field, but also obtains high-quality high-quality kaolin and reduces energy consumption. If the whiteness index of kaolin after magnetic separation still cannot meet the requirements of high-quality kaolin, chemical bleaching is generally adopted. The special magnetic separator for washing kaolin is a wet strong magnetic separator. The magnetic strength is up to 16000GS. It can remove the regenerated iron in the kaolin during the kaolin grinding process to improve the whiteness. And other weak magnetic substances. 6. Chemical bleaching The chemical bleaching of kaolin is often related to the use performance of kaolin and the impurities contained. The main impurities affecting the use performance of kaolin are iron minerals, titanium minerals and organic matter. Commonly used chemical bleaching includes reduction method, oxidation method, oxidation-reduction combined bleaching method, acid leaching treatment method, etc. 7. Pressure filter process Using high-pressure slurry feeding to improve productivity, ensure product moisture is less than 32 to 35%, save energy consumption and improve working environment. 8. Drying process Powerful drying can be used. Kaolin powder specifications: The specifications of kaolin powder include 100 mesh, 200 mesh, 325 mesh, 800 mesh, 1200 mesh, 2000 mesh, 2500 mesh, 3000 mesh, etc. What kind of equipment is needed to process kaolin ore? It is mainly to determine the finished product according to the use The fineness range belongs to coarse crushing or fine crushing. The equipment used for coarse crushing between 50~325mm is Raymond grinding equipment or ultrafine ring roller mill. The fine crushing is divided into 325~2500 mesh. The equipment is micro-powder grinding equipment such as kaolin powder ultra-fine vertical mill, which can determine which production line is used according to the fineness of the finished product. Regardless of the coarse crushing production line or fine crushing production line, the entire production line includes the crusher and the milling process. For the powder processing of attapulgite, it can be used directly because of its small size. Read the full article

0 notes

Text

300+ TOP BUILDING MATERIALS and CONSTRUCTION Objective Questions and Answers

Building Materials and Construction Multiple Choice Questions :-

1. Gypsum is a a) mechanically formed sedimentary rock b) igneous rock c) chemically precipitated sedimentary rock d) metamorphic rock Ans: c 2. Which of the following sedimentary rocks changes into quartzite by metamorphic action ? a) sand stone b) lime stone c) shale d) gypsum Ans: a 3. Which of the following represents a metamorphic rock? i) slate ii) shale iii) quartzite The correct answer is a) only (iii) b) both (i) and (iii) c) both (ii) and (iii) d) all (i), (ii) and (iii) Ans: b 4. Quartitze is a a) silicious rock b) argillaceous rock c) calcareous rock d) aqueous rock Ans: a 5. Which of the following is a mineral ? a) basalt b) granite c) quartz d) syenite Ans: c 6. Slate is formed by metamorphic action on a) shale b) lime stone c) sand stone d) granite Ans: a 7. Sandstone is a i) sedimentary rock ii) aqueous rock iii) silicious rock The correct answer is a) only (i) b) both (i) and (ii) c) both (i) and (iii) d) all (i), (ii) and (iii) Ans: d 8. Which of the following is a rock ? a) quartz b) mica c) gypsum d) none of the above Ans: c 9. Based on the following rocks and minerals, select the correct statement, quartz, shale, basalt, granite, marble, gypsum, mica a) basalt and marble are the only metamorphic rocks b) there is no sedimentary rock c) granite is the only igneous rock d) quartz and mica are minerals Ans: d 10. A heavy stone is suitable for a) arches b) rubble masonry c) roads d) retaining walls Ans: d 11. The stone suitable for rubble masonry should be. a) hard b) tough c) heavy d) light Ans: a 12. Which of the following metamorphic rocks has the most weather resisting characteristics? a) marble b) quartzite c) slate d) lime stone Ans: b 13. A good building stone should not absorb water more than a) 5% b) 10% c) 15% d) 20% Ans: a 14. Which of the following has more fire resisting characteristics ? a) marble b) lime stone c) compact sand stone d) granite Ans: c 15. Jumper is a tool used for a) testing of stones b) quarrying of stones c) dressing of stones d) none of the above Ans: b 16. The important test to be conducted on a stone used in docks and harbors is- a) hardness test b) work ability test c) weight test d) toughness test Ans: c 17. The predominant constituent which is responsible for strength in granite is a) quartz b) feldspar c) mica d) none of the above Ans: a 18. Granite is not suitable for ordinary building purpose because a) it can not be polished b) it is not a fire proof material c) it is costly d) it has less crushing strength Ans: c 19. Which of the following stone is best suited for construction of piers and abutments of a railway bridge ? a) granite b) sand stone c) lime stone d) quartzite Ans: a 20. The preparation of surface of stone to obtain plain edges or to obtain stones of required size and shape is known as a) quarrying of stones b) blasting of stones c) seasoning of stones d) dressing of stones Ans: d 21. Crushing strength of a good building stone should be more than a) 50 MPa b) 100 MPa c) 150 MPa d) 200 MPa Ans: b 22. Specific gravity for most of the building stones lies between a) 1.5 to 2.0 b) 2.0 to 2.5 c) 2.5 to 3.0 d) 3.0 to 3.5 Ans: c 23. Spalling hammer is used for a) driving wooden headed chisels b) rough dressing of stones c) carving of stones d) breaking small projection of stones Ans: b 24. Cross cut saw is used for a) cutting soft stones b) cutting hard stones c) cutting large blocks of stones d) dressing stones Ans: b 25. Sapwood consists of a) innermost annular rings around the pith b) portion of timber between heartwood and cambium layer c) thin layers below the bark d) thin fibre which extends from the pith outwards and holds the annular rings together Ans: b 26. Which of the following trees yields hard wood ? a) deodar b) chir c) shishum d) pine Ans: c 27. The radial splits which are wider on the outside of the log and narrower towards the pith are known as a) heart shakes b) cupshakes c) starshakes d) rindgalls Ans: c 28. In which of the following pairs both trees yield soft wood? a) deodar and shishum b) chir and sal c) sal and teak d) chir and deodar Ans: d 29. Which of the following timbers is suitable for making sports goods ? a) mulberry b) mahogany c) sal d) deodar Ans: a 30. Assertion A : Shishum is used for decorative woodwork. Reason R : Shishum can be polished to an excellent finish. Select your answer according to the coding system given below : a) Both A and R are true and R is the correct explanation of A b) Both A and R are true but R is not the correct explanation of A c) A is true but R is false d) A is false but R is true Ans: a 31. The disease of dry rot in timber is caused by a) lack of ventilation b) alternate wet and dry conditions c) complete submergence in water d) none of the above Ans: a 32. Plywood has the advantage of' a) greater tensile strength in longer direction b) greater tensile strength in shorter direction c) same tensile strength in all directions d) none of the above Ans: c 33. In which of the following directions, the strength of timber is maximum ? a) parallel to grains b) 45° to grains c) perpendicular to grains d) same in all directions Ans: a 34. The moisture content in a well seasoned timber is a) 4% to 6% b) 10% to 12% c) 15% to 20% d) 100% Ans: b 35. The trunk of tree left after cutting all the branches is known as a) log b) batten c) plank d) baulk Ans: a 36. The age of a tree can be known by examining a) cambium layer b) annular rings c) medullary rays d) heart wood Ans: b 37. Plywood is made by bonding together thin layers of wood in such a way that the angle between grains of any layer to grains of adjacent layers is a) 0° b) 30° c) 45° d) 90° Ans: d 38. The plywood a) has good strength along the panel only b) can be spilt in the plane of the panel c) has greater impact resistance to blows than ordinary wood d) cannot be bent more easily than ordinary wood of same thickness Ans: c 39. The practical limit of moisture content achieved in air drying of timber is a) 5% b) 15% c) 25% d) 35% Ans: b 40. First class timber has an average life of a) less than one year b) 1 to 5 years c) 5 to 10 years d) more than 10 years Ans: d 41. A first class brick when immersed in cold water for 24 hours should not absorb water more than a) 15% b) 20% c) 22% d) 25% Ans: b 42. Crushing strength of a first class brick should not be less than a) 3.5 N/mm2 b) 7.0 N/mm2 c) 10.5 N/mm2 d) 14.0 N/mm2 Ans: c 43. The main function of alumina in brick earth is a) to impart plasticity b) to make the brick durable c) to prevent shrinkage d) to make the brick impermeable Ans: a 44. The percentage of alumina in a good brick earth lies between a) 5 to 10% b) 20 to 30% c) 50 to 60% d) 70 to 80% Ans: b 45. Excess of alumina in brick earth makes the brick a) impermeable b) brittle and weak c) to lose cohesion d) to crack and warp on drying Ans: d 46. The nominal size of the modular brick is a) 190 mm x 90mmx 80 mm b) 190 mm x 190 mm x 90 mm c) 200 mm x 100 mm x 100 mm d) 200 mm x 200 mm x 100 mm Ans: c 47. Percentage of silica in a good brick earth lies between a) 5 to 10% b) 20 to 30% c) 50 to 60% d) 70 to 80% Ans: c 48. Excess of silica in brick earth results in a) cracking and warping of bricks b) loss of cohesion c) enhancing the impermeability of bricks d) none of the above Ans: b 49. Which of the following ingredients of the brick earth enables the brick to retain its shape ? a) alumina b) silica c) iron d) magnesia Ans: b 50. Which of the following pairs gives a correct combination of the useful and harmful constituents respectively of a good brick earth ? a) lime stone and alumina b) silica and alkalies c) alumina and iron d) alkalies and magnesium Ans: b 51. The process of mixing clay, water and other ingredients to make brick is known as a) kneading b) moulding c) pugging d) drying Ans: a 52. Advantage of a clamp compared to a kiln for burning bricks is that a) it takes less time for burning b) it gives more output of first class bricks c) it has less initial cost d) it is suitable when bricks are required in large numbers Ans: c 53. The internal size of mould used in brick preparation is a) equal to the size of a fully burnt brick b) smaller than the size of a fully burnt brick c) greater than the size of a fully burnt brick d) none of the above Ans: c 54. Pug mill is used for a) preparation of clay b) moulding of clay c) drying of bricks d) burning of bricks Ans: a 55. Which of the following bricks are used for lining of furnaces ? a) overburnt bricks b) underburnt bricks c) refractory bricks d) first class bricks Ans: c 56. The frog of the brick in a brick masonry is generally kept on a) bottom face b) top face c) shorter side d) longer side Ans: b 57. Number of bricks required for one cubic metre of brick masonry is a) 400 b) 450 c) 500 d) 550 Ans: c 58. Glazing is used to make earthenware a) hard b) soft c) porous d) impervious Ans: d 59. Quick lime is a) calcium carbonate b) calcium oxide c) calcium hydroxide d) none of the above Ans: b 60. Quick lime is i) slow in setting ii) rapid in slacking iii) good in strength The correct answer is a) only (i) b) only (ii) c) both (i) and (ii) d) both (ii) and (iii) Ans: c 61. Assertion A : Pure lime takes a long time to develop adequate strength. Reason R : Pure lime has slow hardening characteristics. Select your answer according to the coding system given below : a) Both A and R are true and R is correct explanation of A. b) Both A and R are true and R is not a correct explanation of A. c) A is true but R is false. d) A is false but R is true. Ans: a 62. Hydraulic lime is obtained by a) burning of lime stone b) burning of kankar c) adding water to quick lime d) calcination of pure clay Ans: b 63. The main constituent which imparts hydraulicity to hydraulic lime is a) calcium oxide b) silica c) clay d) water Ans: c 64. Study the following statements. i) Hydraulic lime is suitable for white washing, ii) Fat lime is suitable for whitewashing, iii) Hydraulic lime is suitable for making mortar, iv) Fat lime is suitable for making mortar. The correct answer is a) (i) and (iv) b) (ii) and (iii) c) (i) and (ii) d) (iii) and (iv) Ans: b 65. The main ingredients of Portland cement are a) lime and silica b) lime and alumina c) silica and alumina d) lime and iron Ans: a 66. The constituent of cement which is responsible for all the undesirable properties of cement is a) dicalcium silicate b) tricalcium silicate c) tricalcium aluminate d) tetra calcium alumino ferrite Ans: c 67. Le Chatelier's device is used for determining the a) setting time of cement b) soundness of cement c) tensile strength of cement d) compressive strength of cement Ans: b 68. The main constituent of cement which is responsible for initial setting of cement is a) dicalcium silicate b) tricalcium silicate c) tricalcium aluminate d) all of the above Ans: c 69. The initial setting time for ordinary Portland cement as per IS specifications should not be less than a) 10 minutes b) 30 minutes c) 60 minutes d) 600 minutes Ans: b 70. As per IS specifications, the maximum final setting time for ordinary Portland cement should be a) 30 minutes b) 1 hour c) 6 hours d) 10 hours Ans: d 71. For testing compressive strength of cement, the size of cube used is a) 50 mm b) 70.6 mm c) 100 mm d) 150 mm Ans: a 72. The normal consistency of ordinary Portland cement is about a) 10% b) 20% c) 30% d) 40% Ans: c 73. Early attainment of strength in rapid hardening cement is mainly due to a) gypsum b) finer grinding c) tricalcium silicate d) tricalcium aluminate Ans: b 74. After storage, the strength of cement a) decreases b) increases c) remains same d) may increase or decrease Ans: a 75. According to IS specifications, the compressive strength of ordinary portland cement after three days should not be less than a) 7 MPa b) 11.5 MPa c) 16 MPa d) 21 MPa Ans: c Building Materials and Construction Objective Type Questions :: 76. Addition of pozzolana to ordinary Portland cement increases a) bleeding b) shrinkage c) permeability d) heat of hydration Ans: b 77. Gypsum consists of a) H2S and C02 b) CaS04 and H20 c) Lime and H20 d) C02 and calcium Ans: b 78. For testing compressive and tensile strength of cement, the cement mortar is made by mixing cement and standard sand in the proportions of a) 1:2 b) 1:3 c) 1:4 d) 1:6 Ans: b 79. The slump recommended for mass concrete is about a) 25 mm to 50 mm b) 50 mm to 100 mm c) 100 mm to 125 mm d) 125 mm to 150 mm Ans: a 80. With increase in moisture content, the bulking of sand a) increases b) decreases c) first increases to a certain maximum value and then decreases d) first decreases to a certain minimum value and then increases Ans: c 81. Which of the following cements is suitable for use in massive concrete structures such as large dams ? a) ordinary Portland cement b) low heat cement c) rapid hardening cement d) sulphate resisting cement Ans: b 82. Proper amount of entrained air in concrete results in i) better workability ii) better resistance to freezing and thawing iii) lesser workability iv) less resistance to freezing and thawing The correct answer is a) (i) and (ii) b) (i)and(iv) c) (ii) and (iii) d) (iii) and (iv) Ans: a 83. The most common admixture which is used to accelerate the initial set of concrete is a) gypsum b) calcium chloride c) calcium carbonate d) none of the above Ans: b 84. The maximum quantity of calcium chloride used as an accelerator in cement in percentage by weight of cement is a) 1 b) 2 c) 3 d) 4 Ans: b 85. The basic purpose of a retarder in concrete is a) to increase the initial setting time of cement paste in concrete b) to decrease the initial setting time of cement paste in concrete c) to render the concrete more water tight d) to improve the workability of concrete mix Ans: a 86. Which of the following cements contains maximum percentage of dicalcium silicate? a) ordinary Portland cement b) low heat cement c) rapid hardening cement d) sulphate resisting cement Ans: b 87. The most commonly used retarder in cement is a) gypsum b) calcium chloride c) calcium carbonate d) none of the above Ans: a 88. Three basic raw materials which are needed in large quantities for production of steel are a) iron ore, coal and sulphur b) iron ore, carbon and sulphur c) iron ore, coal and lime stone d) iron ore, carbon and lime stone Ans: c 89. Compared to mild steel, cast iron has i) high compressive strength ii) high tensile strength iii) low compressive strength iv) low tensile strength The correct answer is a) (i) and (ii) b) (ii) and (iii) c) (iii) and (iv) d) (i)and(iv) Ans: d 90. Which of the following gradients exerts maximum influence on properties of steel? a) iron b) carbon c) manganese d) sulphur Ans: b 91. Which of the following is the purest form of iron ? a) cast iron b) wrought iron c) mild steel d) high carbon steel Ans: b 92. The ultimate tensile strength of structural mild steel is about a) 160N/mm2 b) 260N/mm2 c) 420 N/mm2 d) 520 N/mm2 Ans: c 93. Percentage of carbon content in mild steel is a) less than 0.25 b) between 0.25 and 0.7 c) between 0.7 and 1.5 d) greater than 1.5 Ans: a 94. Which of the following stresses is used for identifying the quality of structural steel ? a) ultimate stress b) yield stress c) proof stress d) none of the above Ans: b 95. The ratio of the thickness of web to that of flange of steel rolled structural beams and channels is a) less than 1 b) equal to 1 c) greater than 1 d) less than 1 in beams but greater than 1 in channels Ans: a 96. Paints with white lead base are suitable for painting of a) wood work b) iron work c) both wood work and iron work d) none of the above Ans: a 97. Assertion A : Paints with white lead base are not recommended for painting of iron works. Reason R : Paints with white lead base do not check rusting of iron. Select your answer according to the coding system given below : a) Both A and R are true and, R is the correct explanation of A. b) Both A and R are true but R is not the correct explanation of A c) A is true but R is false d) A is false but R is true Ans: a 98. The amount of water used for one kg of distemper is a) 0.2 liter b) 0.4 liter c) 0.6 liter d) 0.8 liter Ans: c 99. The vehicle used in case of enamel paints is usually a) linseed oil b) water c) varnish d) none of the above Ans: c 100. Assertion A : Normally turpentine oil is recommended as thinner for indoor painting. Reason R : Turpentine oil is costlier than other thinners. Select your answer according to the coding system given below : a) Both A and R are true and R is the correct explanation of A. b) Both A and R are true but R is not the correct explanation of A. c) A is true but R is false. d) A is false but R is true. Ans: b 101. In brick masonry the bond produced by laying alternate headers and stretchers in each course is known as a) English bond b) double flemish bond c) zigzag bond d) single flemish bond Ans: b 102. The stretcher bond in brick masonry can be used only when the thickness of wall is a) 90 mm b) 180 mm c) 190 mm d) 280 mm Ans: a 103. The pressure acting on the stones in stone masonry construction should be a) along the direction of bedding planes b) at 45° to the direction of bedding planes c) at 60° to the direction of bedding planes d) perpendicular to the direction of bedding planes Ans: d 104. Which of the following should be used for hearting of thicker walls ? a) headers b) stretchers c) brick bats d) queen closer Ans: a 105. A queen closer is a a) brick laid with its length parallel to the face or direction of wall b) brick laid with its breadth parallel to the face or direction of wall c) brick having the same length and depth as the other bricks but half the breadth d) brick with half the width at one end and full width at the other Ans: c 106. Minimum thickness of wall where single flemish bond can be used is a) half brick thick b) one brick thick c) one and a half bricks thick d) two bricks thick Ans: c 107. The most important tool in brick laying for lifting and spreading mortar and for forming joints is a) trowel b) square c) bolster d) scutch Ans: a 108. Expansion Joints in masonry walls are provided in wall lengths usater than a) 10 m b) 20 m c) 30 m d) 40 m Ans: d 109. The type of bond provided in brick masonry for carrying heavy loads is a) single flemish bond b) double flemish bond c) English bond d) zigzag bond Ans: c 110. A mortar joint in masonry which is normal to the face of wall is known as a) bed joint b) wall joint c) cross joint d) bonded joint Ans: c 111. The slenderness ratio for masonry walls should not be more than a) 10 by 20 c) 30 d) 40 Ans: b 112. The proportions of lime and sand in the mortar normally used in brick construction are a) 1:2 b) 1:4 c) 1:6 d) 1:8 Ans: a 113. Number of vertical joints in a stretcher course is x times the number of joints in the header course, where x is equal to a) 1/2 b) 1 c) 2 d) 1/4 Ans: a 114. As compared to stretcher course, the thickness of joints in header course should be a) less b) more c) equal d) equal or more Ans: a 115. As compared to English bond, double flemish bond is a) stronger b) more compact c) costly d) none of the above Ans: b 116. Single flemish bond consists of a) double flemish bond facing and Eng-lish bond backing in each course b) English bond facing and double flemish bond backing in each course c) stretcher bond facing and double flemish bond backing in each course d) double flemish bond facing and header bond backing in each course Ans: a 117. The differential settlement in case of foundations on sandv soils should not exceed a) 25 mm b) 40 mm c) 65 mm d) 100 mm Ans: a 118. In case of foundations on black cotton soils, the most suitable method to increase the bearing capacity of soils is to a) increase the depth of foundation b) drain the soil c) compact the soil d) replace the poor soil Ans: d 119. The type of footing which is used to transmit heavy loads through steel columns is a) raft foundation b) grillage foundation c) well foundation d) isolated footing Ans: b 120. The maximum total settlement for isolated foundations on clayey soils should be limited to a) 25 mm b) 40 mm c) 65 mm d) 100 mm Ans: c 121. The type of pile which is driven at an inclination to resist inclined forces is known as a) friction pile b) sheet pile c) batter pile d) anchor pile Ans: c 122. The minimum depth of foundation in clayey soils is a) 0.5 m b) 0.7 m c) 0.9 m d) 1.2 m Ans: c 123. The maximum total settlement for raft foundation on clayey soils should be limited to a) 25 mm b) 25 to 40 mm c) 40 to 65 mm d) 65 to 100 mm Ans: d 124. The bearing capacity of a water logged soil can be improved by a) compacting the soil b) draining the soil c) increasing the depth of foundation d) grouting Ans: b 125. The type of flooring suitable for use in churches, theatres, public libraries and other places where noiseless floor covering is desired is a) cork flooring b) glass flooring c) wooden flooring d) linoleum flooring Ans: a 126. The vertical distance between the springing line and highest point of the innercurve of an arch is known as a) intrados b) rise c) spandril d) extrados Ans: b 127. Depth or height of the arch is the a) perpendicular distance between intra-dos and extrados b) vertical distance between springing line and intrados c) perpendicular distance between springing line and extrados d) none of the above Ans: a 128. The triangular space formed between the extrados and the horizontal line drawn through the crown of an arch is known as a) haunch b) spandril c) voussoirs d) skewbacks Ans: b 129. The lintels are preferred to arches because a) arches require more headroom to span the openings like doors, windows etc. b) arches require strong abutments to withstand arch thrust c) arches are difficult in construction d) all of the above Ans: d 130. In the construction of arches, sand box method is used for a) centring b) actual laying of arch work c) striking of centring d) none of the above Ans: c 131. The type of arch generally constructed over a wooden lintel or over a flat arch for the purpose of carrying the load of the wall above is a) segmental arch b) pointed arch c) relieving arch d) flat arch Ans: c 132. The type of joint commonly used at the junction of a principal rafter and tie beam in timber trussess is a) mortise and tennon joint b) oblique mortise and tennon joint c) butt joint d) mitred joint Ans: b 133. The type of roof suitable in plains where rainfall is meagre and temperature is high is a) pitched and sloping roof b) flat roof c) shell roof d) none of the above Ans: b 134. Pitched and sloping roofs are suitable for a) coastal regions b) plain regions c) covering large areas d) all of the above Ans: a 135. The type of roof which slopes in two directions with a break in the slope on each side is known as a) gable roof b) hip roof c) gambrel roof d) mansard roof Ans: c 136. Mansard roof is a roof which slopes in a) two directions without break in the slope on each side b) two directions with break in the slope on each side c) four directions without break in the slope on each side d) four directions with break in the slope on each side Ans: d 137. The horizontal timber piece provided at the apex of a roof truss which supports the common rafter is called a) ridge board b) hip rafter c) eaves board d) valley rafter Ans: a 138. The lower edge of the pitched roof, from where the rain water of the roof surface drops down, is known as a) hip b) gable c) ridge d) eaves Ans: d 139. Higher pitch of the roof i) results in stronger roof ii) results in weaker roof iii) requires more covering material iv) requires less covering material The correct answer is a) (i) and (iii) b) (i) and (iv) c) (ii) and (iii) d) (ii) and (iv) Ans: a 140. Couple close roof is suitable for maximum span of a) 2.5 m b) 3.5 m c) 4.5 m d) 5.5 m Ans: c 141. In a colar beam roof a) there is no horizontal tie beam b) there is a horizontal tie at the feet of rafters only c) there is a horizontal tie at almost the middle of rafters only d) there are two horizontal ties, one at the feet and other at the middle of the rafters Ans: c 142. The function of king post in a king post roof truss is a) to support the frame work of the roof b) to receive the ends of principal rafter c) to prevent the walls from spreading outward d) to prevent the tie beam from sagging at its centre Ans: d 143. The function of cleats in a roof truss is a) to support the common rafter b) to support purlins c) to prevent the purlins from tilting d) all of the above Ans: c 144. The term string is used for a) the underside of a stair b) outer projecting edge of a tread c) a sloping member which supports the steps in a stair d) a vertical member between two treads Ans: c 145. The vertical posts placed at the top and bottom ends of a flight supporting the hand rail are known as a) balusters b) newal posts c) balustrades d) railings Ans: b 146. The maximum number of steps in a flight should generally be restricted to a) 10 b) 12 c) 15 d) no limit Ans: b 147. The number of steps in a flight generally should not be less than a) 2 b) 3 c) 5 d) no limit Ans: b 148. Sum of tread and rise must lie between a) 300 to 350 mm b) 400 to 450 mm c) 500 to 550 mm d) 600 to 650 mm Ans: b 149. Minimum width of landing should be a) equal to width of stairs b) half the width of stairs c) twice the width of stairs d) one fourth the width of stairs Ans: a 150. In any good staircase, the maximum and minimum pitch respectively should be a) 90° and 0° b) 75° and 30° c) 60° and 10° d) 40° and 25° Ans: d BUILDING MATERIALS and CONSTRUCTION Questions Answers pdf free download :: Read the full article

0 notes

Text

China Clay Market to See Incredible Growth During 2025

China clay, also known as kaolin, is a loose, dense, fine, flaky, earthy aggregate mineral in white color found in the earth’s crust. Kaolin is the name derived from its raw material called kaolinite, a clay mineral. Presence of impurities affects the color of china clay, which becomes reddish, brownish or bluish. This impacts the commercial value of the product. Its commercial utility is influenced by its properties that include purity, brightness, glossiness, viscosity, and abrasiveness. China clay is available in the form of deposits formed by chemical weathering of aluminum silicate minerals such as feldspar through a complex sequence of events. China clay deposits are classified into primary and secondary deposits. Primary china clay originates from weathering of rocks containing high concentrations of feldspathic minerals and is found in the place where the deposition occurs. Secondary china clay is subsequently settled in another place by being carried along by water currents with other minerals such as quartz and mica.

Read Report Overview @

https://www.transparencymarketresearch.com/china-clay-market.html

The global china clay market can be segmented based on type, form, and application. Based on form, the china clay market can be divided into powder, lumps, and granules. In terms of type, the market can be segregated into calcined, hydrous, and other grades. Calcined China clay is a thermally processed product exposed to ultra-high temperature to produce minerals such as mullite, spinel, and cristobalite. Hydrous china clay is a processed product containing kaolin minerals with structural water or hydroxide component. China clay is used in different applications such as paper, packaging, plastic, paints & coatings, building & construction, rubber, ceramic, pharmaceutical, petroleum, and others. It acts as filler in the paper industry, as raw material in ceramic, and as pigment & brightener in plastic, paints, and rubber industries. It is employed in the rubber industry for stiffening and reinforcing properties.

China clay is used in the ceramic industry in a wide range of products such as dinnerware, sanitary ware, and pottery products. China clay substantially increases the strength of plastic. It improves ink holdout and preserves the gloss of ink when used as pigment in inks. It is also used in catalysts, which are employed in catalytic cracking of petroleum. China clay is a good source of alumina and silica that increases the whiteness of cement and also helps in providing additional strength to cement. The global building & construction industry has been expanding at a significant pace; however, the usage of china clay in the industry is low.

Request to view Sample Report:

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=38687

Paper and ceramic industries dominate the global china clay market in terms of application. This trend is expected to continue during the forecast period. Asia Pacific dominates the global china clay market in terms of demand. It is followed by Europe, North America, Latin America, and Middle East & Africa. The market in Asia Pacific is anticipated to expand at a fast-paced CAGR driven by the growth in the paper and ceramic industries in the region during the forecast period. North American offers lucrative opportunities for the china clay market, as it is used in catalytic cracking of petroleum. Major companies operating in the global china clay market include BASF S.E, KaMin & CADAM, Thiele Kaolin Company, Quarzwerke GmbH, EICL Ltd., Imerys S.A., Ashapura China Clay Company, and Uma Group of Kaolin.

0 notes

Text

China Clay Market to Reap Excessive Revenues by 2025

China clay, also known as kaolin, is a loose, dense, fine, flaky, earthy aggregate mineral in white color found in the earth’s crust. Kaolin is the name derived from its raw material called kaolinite, a clay mineral. Presence of impurities affects the color of china clay, which becomes reddish, brownish or bluish. This impacts the commercial value of the product. Its commercial utility is influenced by its properties that include purity, brightness, glossiness, viscosity, and abrasiveness. China clay is available in the form of deposits formed by chemical weathering of aluminum silicate minerals such as feldspar through a complex sequence of events. China clay deposits are classified into primary and secondary deposits. Primary china clay originates from weathering of rocks containing high concentrations of feldspathic minerals and is found in the place where the deposition occurs. Secondary china clay is subsequently settled in another place by being carried along by water currents with other minerals such as quartz and mica.

View Report Preview:

https://www.transparencymarketresearch.com/china-clay-market.html

The global china clay market can be segmented based on type, form, and application. Based on form, the china clay market can be divided into powder, lumps, and granules. In terms of type, the market can be segregated into calcined, hydrous, and other grades. Calcined China clay is a thermally processed product exposed to ultra-high temperature to produce minerals such as mullite, spinel, and cristobalite. Hydrous china clay is a processed product containing kaolin minerals with structural water or hydroxide component. China clay is used in different applications such as paper, packaging, plastic, paints & coatings, building & construction, rubber, ceramic, pharmaceutical, petroleum, and others. It acts as filler in the paper industry, as raw material in ceramic, and as pigment & brightener in plastic, paints, and rubber industries. It is employed in the rubber industry for stiffening and reinforcing properties. China clay is used in the ceramic industry in a wide range of products such as dinnerware, sanitary ware, and pottery products. China clay substantially increases the strength of plastic. It improves ink holdout and preserves the gloss of ink when used as pigment in inks. It is also used in catalysts, which are employed in catalytic cracking of petroleum. China clay is a good source of alumina and silica that increases the whiteness of cement and also helps in providing additional strength to cement. The global building & construction industry has been expanding at a significant pace; however, the usage of china clay in the industry is low.

Paper and ceramic industries dominate the global china clay market in terms of application. This trend is expected to continue during the forecast period. Asia Pacific dominates the global china clay market in terms of demand. It is followed by Europe, North America, Latin America, and Middle East & Africa. The market in Asia Pacific is anticipated to expand at a fast-paced CAGR driven by the growth in the paper and ceramic industries in the region during the forecast period. North American offers lucrative opportunities for the china clay market, as it is used in catalytic cracking of petroleum. Major companies operating in the global china clay market include BASF S.E, KaMin & CADAM, Thiele Kaolin Company, Quarzwerke GmbH, EICL Ltd., Imerys S.A., Ashapura China Clay Company, and Uma Group of Kaolin.

Request to view Sample Report:

https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=38687

The report offers a comprehensive evaluation of the market. It does so via in-depth qualitative insights, historical data, and verifiable projections about market size. The projections featured in the report have been derived using proven research methodologies and assumptions. By doing so, the research report serves as a repository of analysis and information for every facet of the market, including but not limited to: Regional markets, technology, types, and applications.

0 notes

Link

Devidayal Chemicals is one of the leading Calcined Mica Powder Manufacturers and suppliers in Mumbai, India. The best quality of Calcined Mica Powder is provided by us to customers with a reasonable price tag.

#mica powder suppliers#calcined mica powder manufacturers in Mumbai#calcined mica powder manufacturers in india

0 notes

Text

China Clay Market by Top Manufacturers with Production, Price, Revenue 2025

China clay, also known as kaolin, is a loose, dense, fine, flaky, earthy aggregate mineral in white color found in the earth’s crust. Kaolin is the name derived from its raw material called kaolinite, a clay mineral. Presence of impurities affects the color of china clay, which becomes reddish, brownish or bluish. This impacts the commercial value of the product. Its commercial utility is influenced by its properties that include purity, brightness, glossiness, viscosity, and abrasiveness. China clay is available in the form of deposits formed by chemical weathering of aluminum silicate minerals such as feldspar through a complex sequence of events. China clay deposits are classified into primary and secondary deposits. Primary china clay originates from weathering of rocks containing high concentrations of feldspathic minerals and is found in the place where the deposition occurs. Secondary china clay is subsequently settled in another place by being carried along by water currents with other minerals such as quartz and mica.

Request Report Brochure @ https://www.transparencymarketresearch.com/sample/sample.php?flag=B&rep_id=38687

The global china clay market can be segmented based on type, form, and application. Based on form, the china clay market can be divided into powder, lumps, and granules. In terms of type, the market can be segregated into calcined, hydrous, and other grades. Calcined China clay is a thermally processed product exposed to ultra-high temperature to produce minerals such as mullite, spinel, and cristobalite. Hydrous china clay is a processed product containing kaolin minerals with structural water or hydroxide component. China clay is used in different applications such as paper, packaging, plastic, paints & coatings, building & construction, rubber, ceramic, pharmaceutical, petroleum, and others.

It acts as filler in the paper industry, as raw material in ceramic, and as pigment & brightener in plastic, paints, and rubber industries. It is employed in the rubber industry for stiffening and reinforcing properties. China clay is used in the ceramic industry in a wide range of products such as dinnerware, sanitary ware, and pottery products. China clay substantially increases the strength of plastic. It improves ink holdout and preserves the gloss of ink when used as pigment in inks. It is also used in catalysts, which are employed in catalytic cracking of petroleum. China clay is a good source of alumina and silica that increases the whiteness of cement and also helps in providing additional strength to cement. The global building & construction industry has been expanding at a significant pace; however, the usage of china clay in the industry is low.

Read Report Overview @ https://www.transparencymarketresearch.com/china-clay-market.html

Paper and ceramic industries dominate the global china clay market in terms of application. This trend is expected to continue during the forecast period. Asia Pacific dominates the global china clay market in terms of demand. It is followed by Europe, North America, Latin America, and Middle East & Africa. The market in Asia Pacific is anticipated to expand at a fast-paced CAGR driven by the growth in the paper and ceramic industries in the region during the forecast period. North American offers lucrative opportunities for the china clay market, as it is used in catalytic cracking of petroleum. Major companies operating in the global china clay market include BASF S.E, KaMin & CADAM, Thiele Kaolin Company, Quarzwerke GmbH, EICL Ltd., Imerys S.A., Ashapura China Clay Company, and Uma Group of Kaolin.

About Us

Transparency Market Research (TMR) is a global market intelligence company providing business information reports and services. The company’s exclusive blend of quantitative forecasting and trend analysis provides forward-looking insight for thousands of decision makers. TMR’s experienced team of analysts, researchers, and consultants use proprietary data sources and various tools and techniques to gather and analyze information.

TMR’s data repository is continuously updated and revised by a team of research experts so that it always reflects the latest trends and information. With extensive research and analysis capabilities, Transparency Market Research employs rigorous primary and secondary research techniques to develop distinctive data sets and research material for business reports.

Contact

Transparency Market Research

State Tower,

90 State Street,

Suite 700,

Albany NY – 12207

United States

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Email: [email protected]

Website: http://www.transparencymarketresearch.com

0 notes

Text

How much is the superfine grinding mill for processing

In the kaolin processing production, high efficiency and green kaolin superfine grinding mill price need to be determined according to customers detail powder making request, Fujian Fengli customer-centric philosophy, specializing in the manufacturing of high capacity and high efficiency kaolin ultrafine grinding equipment, and provide professional and integrated processing selection program for your powder making project.

1. Application status of kaolin

Naturally produced kaolin ores can be classified into three types: hard (coal) kaolin, soft kaolin and sandy kaolin according to their quality (physical and chemical properties), plasticity and sand content (quartz, feldspar, mica and other mineral particle size >50 micron). In general, domestic kaolin (kaolinite) is more suitable for the development of calcined kaolin, mainly used in all kinds of filler. Calcined kaolin is also used in papermaking because of its high whiteness, and it is more expensive to produce high grade copper plate. But the calcined soil mainly used to increases the whiteness, it is generally not used alone, and the amount of the soil in the paper is less than that of the water washing soil.

2. Ultrafine grinding mill used for processing kaolin

Ultrafine mill is focused on ultra fine powder grinder of kaolin, limestone, calcite and other fields, Fujian Fengli is professional ultrafine grinding mill manufacturer, kaolin superfine grinding machine is the main equipment manufactured by Fengli which accumulated many years of experience, can produce high quality finished product of 200-2500 mesh, with integration of milling, impacting and other comprehensive mechanical crushing performance, the equipment is called as energy-saving environmental protection equipment under long-term market practice and client authentication, it is also the economic utility ultrafine powder processing equipment for customers.Fujian Fengli can tailor for each customer a detail selection program combined with the specific processing information of customers, and promote the healthy development of kaolin processing project.

Fujian Fengli kaolin ultrafine grinding mill: ACM ultrafine grinding mill

[Maximum size of feed]: ≤10mm

[Production capacity]: 0.5-6.5t/h

[Finished Fineness]: 200-2500mesh

[Features]: 1.Built-in separation mechanism-preventing over-grinding. 2.Able to produce uniform granules of required sizes by adjusting the speed of the stage-separation wheel(s) or by adjusting the strength of the blower(s). 3.Powerful blowing and strong self-cooling capability, suitable for grinding heat-sensitive materials. 4.Different grinding accessories/devices are used according to the hardness of the material being ground; different types of materials (alloyed carbon steel, stainless steel, ceramics etc) are available for the Machine's inner linings and product extracting system, meeting the needs of different industries. 5.Both manual and programmable auto-controlled machines available.

[Focus areas]: Focus on magnesite, manganese ore, gypsum, calcite, barite, fluorite, marble and other Mohs hardness below 7 and humidity less than 6% non-metallic mineral ultra-fine processing and AC foaming agent, carbon black, sulfur and other chemical material grinding, the equipment with a number of countries patented technology, performance reached the national leading level.

#grinder#grinding mill#grinding plant#Grinding Machine#grinder machine#crusher#stone crusher#Crushing equipment#stone crusher machine#pulverizer#stone pulverizer#mining equipment#mining machinery

0 notes