#bulk battery manufacturer

Explore tagged Tumblr posts

Text

The Role of Sternum Saws in Modern Cardiac Surgery: Mercury HC

Modern cardiac surgery relies heavily on precision tools, and one of the most critical instruments is the sternum saw. As one of the leading sternum saw manufacturers & suppliers in India, Mercury Healthcare has revolutionized the market with its advanced, reliable, and high-quality sternum saws. This blog explores the pivotal role of sternum saws in cardiac surgery and highlights why Mercury HC stands out in this essential field.

Importance of Sternum Saws in Cardiac Surgery

Cardiac surgeries often require access to the heart and thoracic cavity, necessitating a median sternotomy. This procedure involves a vertical incision along the sternum (breastbone), which is then divided to provide surgeons with the necessary access. The precision and efficiency of this procedure depend significantly on the quality of the sternum saw used.

Types of Sternum Saws

There are various types of sternum saws, including manual, electric, and battery-operated versions. Each type offers unique benefits and is suited to different surgical scenarios. Mercury HC specializes in both electric and battery-operated sternum saws, providing surgeons with versatile options to meet their specific needs.

Mercury HC: Leaders in Sternum Saw Manufacturing

Advanced Technology

Mercury HC is at the forefront of innovation in surgical instruments. As a top sternum saw electric exporter from India, the company utilizes cutting-edge technology to design and manufacture sternum saws that meet the highest standards of precision and safety. Their electric sternum saws are known for their efficiency, reliability, and ease of use.

Quality and Reliability

When you buy electrical sternum saw in bulk at wholesale price from Mercury HC, you are assured of receiving products that have undergone rigorous quality control processes. Mercury HC’s commitment to quality is unwavering, ensuring that every sternum saw performs flawlessly in critical surgical environments.

Features of Mercury HC Sternum Saws

Precision Cutting

Mercury HC’s sternum saws are engineered for precision. The blades are designed to make clean, accurate cuts, minimizing tissue damage and promoting faster patient recovery. This precision is crucial in cardiac surgeries where even the slightest error can have significant consequences.

Battery-Operated Convenience

Among the cardiac surgery equipments, Mercury HC's battery operated sternum saw stands out for its portability and convenience. These saws are especially useful in settings where access to electrical outlets may be limited, or mobility is essential. They provide consistent power and performance, ensuring that surgeons can focus on the procedure without worrying about equipment limitations.

Ergonomic Design

Mercury HC places a strong emphasis on the ergonomic design of their sternum saws. The instruments are lightweight and easy to handle, reducing fatigue for surgeons during long procedures. The intuitive design also enhances control, allowing for more precise and efficient operations.

Bulk Purchasing Benefits

For hospitals and medical facilities looking to equip their surgical suites, purchasing in bulk can be highly cost-effective. Mercury HC offers attractive wholesale prices, making it feasible for healthcare providers to buy electrical sternum saw in bulk at wholesale price without compromising on quality. This approach not only ensures a steady supply of essential equipment but also helps manage budgets more effectively.

Commitment to Customer Satisfaction

Mercury HC's reputation as one of the leading sternum saw manufacturers & suppliers in India is built on a foundation of exceptional customer service. The company works closely with medical professionals to understand their needs and deliver tailored solutions. This customer-centric approach ensures that each client receives the best possible products and support.

Conclusion

In the realm of modern cardiac surgery, the importance of high-quality sternum saws cannot be overstated. Mercury Healthcare has established itself as a premier provider of these essential tools, offering advanced, reliable, and ergonomically designed sternum saws. As a sternum saw electric exporter from India, Mercury HC combines technological innovation with a commitment to quality, making them the preferred choice for surgeons worldwide.

For healthcare facilities looking to enhance their surgical capabilities, Mercury HC provides the ideal solution. By offering cardiac surgery equipments like the battery operated sternum saw, and ensuring that each product meets stringent quality standards, Mercury HC supports the critical work of cardiac surgeons. For those needing reliable, high-performance sternum saws, buying from Mercury HC ensures access to some of the best tools in the industry.

#Sternum Saw Manufacturers & Suppliers in India#Sternum Saw Electric Exporter from India#Sternum Saw - Sternal Saw Latest Price#Buy Electrical Sternum Saw in bulk at wholesale price#Cardiac Surgery Equipments - Battery Operated Sternum Saw#Sternum Saw (for trauma operation)#Sternum Saw at Best Price from Manufacturers#Top Sternum Saw Manufacturers in India#Best Sternum Saw Manufacturers & Suppliers in India

0 notes

Text

This is a Tesla model Y battery. It takes up all of the space under the passenger compartment of the car. To manufacture it you need:

--12 tons of rock for Lithium (can also be extracted from sea water) -- 5 tons of cobalt minerals (Most cobalt is made as a byproduct of processing copper and nickel ores. It is the most difficult and expensive material to obtain for a battery.) -- 3 tons nickel ore -- 12 tons of copper ore You must move 250 tons of soil to obtain: -- 26.5 pounds of Lithium -- 30 pounds of nickel -- 48.5 pounds of manganese -- 15 pounds of cobalt

To manufacture the battery also requires: -- 441 pounds of aluminum, steel and/or plastic -- 112 pounds of graphite

The Caterpillar 994A is used to move the earth to obtain the minerals needed for this battery. The Caterpillar consumes 264 gallons of diesel in 12 hours.

The bulk of necessary minerals for manufacturing the batteries come from China or Africa. Much of the labor in Africa is done by children. When you buy an electric car, China profits most.

The 2021 Tesla Model Y OEM battery (the cheapest Tesla battery) is currently for sale on the Internet for $4,999 not including shipping or installation. The battery weighs 1,000 pounds (you can imagine the shipping cost). The cost of Tesla batteries are: Model 3 -- $14,000+ (Car MSRP $38,990) Model Y -- $5,000–$5,500 (Car MSRP $47,740) Model S -- $13,000–$20,000 (Car MSRP $74,990) Model X -- $13,000+ (Car MSRP $79,990)

It takes 7 years for an electric car to reach net-zero CO2. The life expectancy of the battery is 10 years (average). Only in the last 3 years do you start to reduce your carbon footprint, but then the batteries must be replaced and you lose all gains made.

And finally, my new friend, Michael, made some excellent points: I forgot to mention the amount of energy required to process the raw materials and the amount of energy used to haul these batteries to the U.S. sometimes back and forth a couple of times.

But by all means, get an electric car. Just don't sell me on how awesome you are for the environment. Or for human rights.

Credit: @Hanna Roth

350 notes

·

View notes

Text

This is a Tesla model Y battery. It takes up all of the space under the passenger compartment of the car.

To manufacture it you need:

--12 tons of rock for Lithium (can also be

extracted from sea water)

-- 5 tons of cobalt minerals (Most cobalt is made

as a byproduct of the processing of copper

and nickel ores. It is the most difficult material

to obtain for a battery and the most

expensive.)

-- 3 tons nickel ore

-- 12 tons of copper ore

You must move 250 tons of soil to obtain:

-- 26.5 pounds of Lithium

-- 30 pounds of nickel

-- 48.5 pounds of manganese

-- 15 pounds of cobalt

To manufacture the battery also requires:

-- 441 pounds of aluminum, steel and/or plastic

-- 112 pounds of graphite

The Caterpillar 994A is used for the earthmoving to obtain the essential minerals. It consumes 264 gallons of diesel in 12 hours.

Finally you get a “zero emissions” car.

Presently, the bulk of the necessary minerals for manufacturing the batteries come from China or Africa. Much of the labor for getting the minerals in Africa is done by children! If we buy electric cars, it's China who profits most!

BTW, this 2021 Tesla Model Y OEM battery (the cheapest Tesla battery) is currently for sale on the Internet for $4,999 not including shipping or installation. The battery weighs 1,000 pounds (you can imagine the shipping cost). The cost of Tesla batteries is:

Model 3 -- $14,000+ (Car MSRP $38,990)

Model Y -- $5,000–$5,500 (Car MSRP $47,740)

Model S -- $13,000–$20,000 (Car MSRP $74,990)

Model X -- $13,000+ (Car MSRP $79,990)

It takes SEVEN years for an electric car to reach net-zero CO2. The life expectancy of the batteries is 10 years (average). Only in the last three years do you begin to reduce your carbon footprint. Then the batteries have to be replaced and you lose all the gains you made in those three years.

The truth is far better than the fiction we are all being told !

#truth#common sense#msm is the enemy#green movement lies#green energy lies#green energy hoax#green hoax#green agenda#government subsidized lies

12 notes

·

View notes

Text

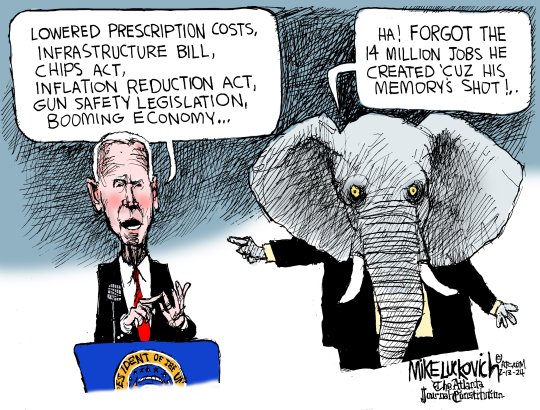

Mike Luckovich

* * * *

LETTERS FROM AN AMERICAN

May 8, 2024

HEATHER COX RICHARDSON

MAY 09, 2024

Today, in Racine, Wisconsin, President Joe Biden announced that Microsoft is investing $3.3 billion dollars to build a new data center that will help operate one of the most powerful artificial intelligence systems in the world. It is expected to create 2,300 union construction jobs and employ 2,000 permanent workers.

Microsoft has also partnered with Gateway Technical College to train and certify 200 students a year to fill new jobs in data and information technology. In addition, Microsoft is working with nearby high schools to train students for future jobs.

Speaking at Gateway Technical College’s Racine campus, Biden contrasted today’s investment with that made by Trump about the same site in 2018. In that year, Trump went to Wisconsin for the “groundbreaking” of a high-tech campus he claimed would be the “eighth wonder of the world.”

Under Republican governor Scott Walker, Wisconsin legislators approved a $3 billion subsidy and tax incentive package—ten times larger than any similar previous package in the state—to lure the Taiwan-based Foxconn electronics company. Once built, a new $10 billion campus that would focus on building large liquid-crystal display screens would bring 13,000 jobs to the area, they promised.

Foxconn built a number of buildings, but the larger plan never materialized, even after taxpayers had been locked into contracts worth hundreds of millions of dollars for upgrading roads, sewer system, electricity, and so on. When voters elected Democrat Tony Evers as governor in 2022, he dropped the tax incentives from $3 billion to $80 million, which depended on the hiring of only 1,454 workers, reflecting the corporation’s current plans. Foxconn dropped its capital investment from $10 billion to $672.8 million.

In November 2023, Microsoft announced it was buying some of the Foxconn properties in Wisconsin.

Today, Biden noted that rather than bringing jobs to Racine, Trump’s policies meant the city lost 1,000 manufacturing jobs during his term. Wisconsin as a whole lost 83,500. “Racine was once a manufacturing boomtown,” Biden recalled, “all the way through the 1960s, powering companies—invented and manufacturing Windex…portable vacuum cleaners, and so much more, and powered by middle-class jobs.

“And then came trickle-down economics [which] cut taxes for the very wealthy and biggest corporations…. We shipped American jobs overseas because labor was cheaper. We slashed public investment in education and innovation. And the result: We hollowed out the middle class. My predecessor and his administration doubled down on that failed trickle-down economics, along with the [trail] of broken promises.”

“But that’s not on my watch,” Biden said. “We’re determined to turn it around.” He noted that thanks to the Democrats’ policies, in the past three years, Racine has added nearly 4,000 jobs—hitting a record low unemployment rate—and Wisconsin as a whole has gained 178,000 new jobs.

The Bipartisan Infrastructure Law, the CHIPS and Science Act, and the Inflation Reduction Act have fueled “a historic boom in rebuilding our roads and bridges, developing and deploying clean energy, [and] revitalizing American manufacturing,” he said. That investment has attracted $866 billion in private-sector investment across the country, creating hundreds of thousands of jobs “building new semiconductor factories, electric vehicles and battery factories…here in America.”

The Biden administration has been scrupulous about making sure that money from the funds appropriated to rebuild the nation’s infrastructure and manufacturing base has gone to Republican-dominated districts; indeed, Republican-dominated states have gotten the bulk of those investments. “President Biden promised to be the president of all Americans—whether you voted for him or not. And that’s what this agenda is delivering,” White House deputy chief of staff Natalie Quillian told Matt Egan of CNN in February.

But there is, perhaps, a deeper national strategy behind that investment. Political philosophers studying the rise of authoritarianism note that strongmen rise by appealing to a population that has been dispossessed economically or otherwise. By bringing jobs back to those regions that have lost them over the past several decades and promising “the great comeback story all across…the entire country,” as he did today, Biden is striking at that sense of alienation.

“When folks see a new factory being built here in Wisconsin, people going to work making a really good wage in their hometowns, I hope they feel the pride that I feel,” Biden said. “Pride in their hometowns making a comeback. Pride in knowing we can get big things done in America still.”

That approach might be gaining traction. Last Friday, when Trump warned the audience of Fox 2 Detroit television that President’s Biden’s policies would cost jobs in Michigan, local host Roop Raj provided a “reality check,” noting that Michigan gained 24,000 jobs between January 2021, when Biden took office, and May 2023.

At Gateway Technical College, Biden thanked Wisconsin governor Tony Evers and Racine mayor Cory Mason, both Democrats, as well as Microsoft president Brad Smith and AFL-CIO president Liz Schuler.

The picture of Wisconsin state officials working with business and labor leaders, at a public college established in 1911, was an image straight from the Progressive Era, when the state was the birthplace of the so-called Wisconsin Idea. In the earliest years of the twentieth century, when the country reeled under industrial monopolies and labor strikes, Wisconsin governor Robert “Fighting Bob” La Follette and his colleagues advanced the idea that professors, lawmakers, and officials should work together to provide technical expertise to enable the state to mediate a fair relationship between workers and employers.

In his introduction to the 1912 book explaining the Wisconsin Idea, former president Theodore Roosevelt, a Republican, explained that the Wisconsin Idea turned the ideas of reformers into a workable plan, then set out to put those ideas into practice. Roosevelt approvingly quoted economist Simon Patten, who maintained that the world had adequate resources to feed, clothe, and educate everyone, if only people cared to achieve that end. Quoting Patten, Roosevelt wrote: “The real idealist is a pragmatist and an economist. He demands measurable results and reaches them by means made available by economic efficiency. Only in this way is social progress possible.”

Reformers must be able to envision a better future, Roosevelt wrote, but they must also find a way to turn those ideals into reality. That involved careful study and hard work to develop the machinery to achieve their ends.

Roosevelt compared people engaged in progressive reform to “that greatest of all democratic reformers, Abraham Lincoln.” Like Lincoln, he wrote, reformers “will be assailed on the one side by the reactionary, and on the other by that type of bubble reformer who is only anxious to go to extremes, and who always gets angry when he is asked what practical results he can show.” “[T]he true reformer,” Roosevelt wrote, “must study hard and work patiently.”

“It is no easy matter actually to insure, instead of merely talking about, a measurable equality of opportunity for all men,” Roosevelt wrote. “It is no easy matter to make this Republic genuinely an industrial as well as a political democracy. It is no easy matter to secure justice for those who in the past have not received it, and at the same time to see that no injustice is meted out to others in the process. It is no easy matter to keep the balance level and make it evident that we have set our faces like flint against seeing this government turned into either government by a plutocracy, or government by a mob. It is no easy matter to give the public their proper control over corporations and big business, and yet to prevent abuse of that control.”

“All through the Union we need to learn the Wisconsin lesson,” Roosevelt wrote in 1912.

“We’re the United States of America,” President Biden said today, “And there’s nothing beyond our capacity when we work together.”

LETTERS FROM AN AMERICAN

HEATHER COX RICHARDSON

#Letters From An American#Heather Cox Richardson#Biden Administration#election 2024#infrastructure#jobs#economic reality

7 notes

·

View notes

Text

For those of you thinking of buying an electric car to save the planet just read this.

This is a Tesla model Y battery.

It takes up all of the space under the passenger compartment of the car.

To manufacture it you need:

--12 tons of rock for Lithium (can be extracted from sea water)

-- 5 tons of cobalt minerals (Most cobalt is made as a byproduct of

the processing of copper and nickel ores. It is the most difficult

material to obtain for a battery and the most expensive.)

-- 3 tons nickel ore

-- 12 tons of copper ore

You must move 250 tons of soil to obtain:

-- 26.5 pounds of Lithium

-- 30 pounds of nickel

-- 48.5 pounds of manganese

-- 15 pounds of cobalt

To manufacture the battery also requires:

-- 441 pounds of aluminum, steel and/or plastic

-- 112 pounds of graphite

The Caterpillar 994A is used for the earthmoving to obtain the essential minerals. It consumes 264 gallons of diesel in 12 hours.

Finally you get a “zero emissions” car.

Presently, the bulk of the necessary minerals for manufacturing the batteries come from China or Africa. Much of the labor for getting the minerals in Africa is done by children! If we buy electric cars, it's China who profits most!

BTW, this 2021 Tesla Model Y OEM battery (the cheapest Tesla battery) is currently for sale on the Internet for $4,999 not including shipping or installation. The battery weighs 1,000 pounds (you can imagine the shipping cost). The cost to replace Tesla batteries is in $US

Model 3 -- $14,000+ (Car MSRP $38,990)

Model Y -- $5,000–$5,500 (Car MSRP $47,740)

Model S -- $13,000–$20,000 (Car MSRP $74,990)

Model X -- $13,000+ (Car MSRP $79,990)

It takes SEVEN years for an electric car to reach net-zero CO2. The life expectancy of the batteries is 10 years (average). Only in the last three years do you begin to reduce your carbon footprint. Then the batteries have to be replaced and you lose all the gains you made in those three years.

Let that sink in.

3 notes

·

View notes

Text

This is a Tesla model Y battery. It takes up all of the space under the passenger compartment of the car.

To manufacture it you need:

--12 tons of rock for Lithium (can also be extracted from sea water)

-- 5 tons of cobalt minerals (Most cobalt is made as a byproduct of the processing of copper and nickel ores. It is the most difficult material to obtain for a battery and the most expensive.)

-- 3 tons nickel ore

-- 12 tons of copper ore

You must move 250 tons of soil to obtain:

-- 26.5 pounds of Lithium

-- 30 pounds of nickel

-- 48.5 pounds of manganese

-- 15 pounds of cobalt

To manufacture the battery also requires:

-- 441 pounds of aluminum, steel and/or plastic

-- 112 pounds of graphite

The Caterpillar 994A is used for the earth-moving to obtain the essential minerals. It consumes 264 gallons of diesel in 12 hours.

Finally you get a “zero emissions” car.

Presently, the bulk of the necessary minerals for manufacturing the batteries come from China or Africa. Much of the labor for getting the minerals in Africa is done by children! If we buy electric cars, it's China who profits most!

BTW, this 2021 Tesla Model Y OEM battery (the cheapest Tesla battery) is currently for sale on the Internet for $4,999 not including shipping or installation. The battery weighs 1,000 pounds (you can imagine the shipping cost). The cost of Tesla batteries is:

Model 3 -- $14,000+ (Car MSRP $38,990)

Model Y -- $5,000–$5,500 (Car MSRP $47,740)

Model S -- $13,000–$20,000 (Car MSRP $74,990)

Model X -- $13,000+ (Car MSRP $79,990)

It takes SEVEN years for an electric car to reach net-zero CO2. The life expectancy of the batteries is 10 years (average). Only in the last three years do you begin to reduce your carbon footprint. Then the batteries have to be replaced and you lose all the gains you made in those three years.

.

Tell me again, why THIS approach is supposed to be better for the ecosystem? It's amazing how the facts just don't measure up to ignorance and stupidity...

4 notes

·

View notes

Photo

Researchers report technique to fabricate nanosheets in one minute

A research group led by Professor Minoru Osada (he, him) and postdoctoral researcher Yue Shi (she, her) at the Institute for Future Materials and Systems (IMaSS), Nagoya University in Japan, has developed a new technology to fabricate nanosheets, thin films of two-dimensional materials a couple of nanometers thick, in about one minute.

This technology enables the formation of high-quality, large nanosheet films with a single click without the need for specialized knowledge or technology. Their findings are expected to contribute to developing the industrial manufacturing process for various types of nanosheet devices. The study was published in ACS Applied Materials & Interfaces.

Nanosheets have a thickness that is measured in nanometers. Nanometers are so thin that the sheets cannot be seen from the side with the naked eye. They have potential uses in several different fields, including electronics, catalysis, energy storage, and biomedicine. Those made from graphene and inorganic nanosheets are being tested for use in a range of devices, from solar cells to sensors and batteries, because they have electrical, transparency, and heat-resistance functions different from those of conventional bulk materials.

Read more.

#Materials Science#Science#Nanotechnology#Thin flims#2D materials#Materials processing#Nagoya University

14 notes

·

View notes

Text

What Are the Most Common Uses of Curved Lithium Batteries?

Curved lithium batteries have become increasingly important due to their flexibility and space efficiency, which are highly sought after in modern technology.

These batteries allow for sleek, compact designs, making them ideal for various devices, from smartphones to electric vehicles (EVs).

Ufine Battery, a leading lithium battery manufacturer, is leading the way in providing customized solutions for curved lithium batteries.

Though not the largest company, Ufine stands out by specializing in tailored battery solutions for various applications. They offer multiple batteries, including lithium-ion, 18650, lithium iron phosphate, ultra-thin, high-temperature, low-temperature, and high-rate batteries.

Ufine also provides OEM and ODM services, allowing even small orders, starting from just one piece. With quick customer service, fast shipping, and a one-year warranty, Ufine is a reliable partner for businesses needing high-quality, customized batteries.

What Are Curved Lithium Batteries?

Curved lithium batteries are a specialized type of lithium-ion battery designed to bend and fit into non-traditional shapes. Unlike standard flat batteries, these can be contoured to the specific shape required by the device, providing flexibility and space optimization.

This makes them ideal for applications where traditional, flat batteries would be too bulky or impractical. Curved lithium batteries offer the same power and efficiency as regular lithium-ion batteries, but they also have the added benefit of being adaptable to unique designs.

The Role of Curved Lithium Batteries in Consumer Electronics

One of the most common uses of curved lithium batteries is in consumer electronics. Devices like smartphones, tablets, and smartwatches are increasingly incorporating these batteries due to their ability to fit into slim and compact designs. The curved shape helps manufacturers save space, leading to sleeker designs and improved device ergonomics.

For instance, smartphones with curved edges are not only aesthetically appealing but also require a battery design that can fit the contours of the device. Curved lithium batteries make this possible, ensuring that devices maintain a thin profile while still providing sufficient power to meet user demands.

Curved Lithium Batteries in Wearable Technology

Wearable technology is another industry where curved lithium batteries are essential. Devices like smartwatches, fitness trackers, and health monitoring devices require batteries that can be both small and flexible enough to conform to the shape of the device. The ability to integrate curved lithium batteries into wearables allows for longer battery life without adding bulk, making the devices more comfortable to wear.

As wearables evolve, the demand for customized battery solutions that fit specific designs will increase. Curved lithium batteries are poised to meet these demands, offering flexibility without sacrificing performance.

The Use of Curved Lithium Batteries in Electric Vehicles (EVs)

Electric vehicles (EVs) are one of the most innovative industries benefiting from curved lithium batteries. While most EV batteries are flat, curved lithium batteries have started to play a role in providing more efficient energy storage solutions. These batteries are particularly useful in applications where space is limited or when the design needs to conform to certain contours, like in the battery management systems or smaller EV models.

Curved lithium batteries help optimize space within EVs, allowing manufacturers to fit more batteries into compact areas while maintaining a high energy output. This is critical in enhancing the range and performance of electric vehicles.

The Impact of Curved Lithium Batteries in Medical Devices

Medical devices often require specialized batteries that are both compact and reliable. Curved lithium batteries are commonly used in devices like hearing aids, implantable medical devices, and portable diagnostic equipment. The flexibility of these batteries allows manufacturers to create small and lightweight devices without compromising on power.

In addition, many medical devices need batteries that can withstand long periods of use without recharging. Curved lithium batteries offer excellent energy density, which is crucial in meeting the power needs of medical devices that are used frequently or continuously.

Curved Lithium Batteries in Smart Home Devices

As smart home technology becomes more ubiquitous, curved lithium batteries have found their place in various devices. From smart thermostats to motion detectors and wireless cameras, these batteries help ensure that devices are long-lasting and efficient. The flexibility of curved lithium batteries allows them to be integrated into compact spaces, which is often a requirement in modern home automation systems.

The rise of IoT (Internet of Things) devices has also fueled the need for smaller, more powerful batteries. Curved lithium batteries meet this demand, offering high energy output while occupying less space.

The Role of Curved Lithium Batteries in Drones

Drones are another area where curved lithium batteries are essential. Drones require lightweight yet powerful batteries to keep them in the air for extended periods. Curved batteries are ideal for these applications because they can be designed to fit into the specific form factor of the drone, ensuring a compact and balanced design.

Moreover, drones that need to operate in tight or unusual spaces, such as search and rescue operations or delivery systems, can benefit from the flexibility of curved lithium batteries. They offer a high-energy output while taking up minimal space, which is vital for the drone's performance.

Advantages of Curved Lithium Batteries

Space Efficiency: One of the most significant benefits of curved lithium batteries is their ability to fit into smaller, more irregularly shaped spaces.

Design Flexibility: Manufacturers can design products with more freedom, knowing they can integrate these batteries without compromising the aesthetic or functionality.

Lightweight and Durable: Curved lithium batteries are lighter than traditional batteries, making them ideal for portable and wearable technology.

Longer Battery Life: With more energy-dense components, these batteries offer better performance, allowing devices to operate longer on a single charge.

Future Trends in Curved Lithium Battery Usage

As technology continues to advance, the demand for curved lithium batteries is expected to grow. Innovations in areas such as flexible electronics, foldable smartphones, and advanced medical devices will likely drive the need for batteries that can fit more complex shapes and sizes.

In addition, as industries push for more environmentally friendly solutions, solid-state batteries and other advanced lithium-ion technologies may emerge in the curved battery market. This could lead to safer, more efficient curved batteries with even better performance and energy density.

FAQs

What are the main advantages of curved lithium batteries?

Curved lithium batteries offer space efficiency, design flexibility, and long-lasting power, making them ideal for compact devices, wearables, and electric vehicles.

How do curved lithium batteries work?

Curved lithium batteries are designed with flexible components, allowing them to bend and conform to non-standard shapes while maintaining their performance and energy output.

Are curved lithium batteries safe to use?

Yes, curved lithium batteries are safe to use when manufactured to high standards. They are equipped with protective circuits to prevent overheating and short-circuiting, just like traditional lithium-ion batteries.

What industries use curved lithium batteries?

Curved lithium batteries are used in a variety of industries, including consumer electronics, wearable technology, electric vehicles, medical devices, and smart home devices.

Can curved lithium batteries be recycled?

Yes, curved lithium batteries can be recycled like traditional lithium-ion batteries. Proper recycling procedures are essential to ensure safe disposal and environmental protection.

Conclusion

Curved lithium batteries are revolutionizing the design and functionality of modern technology. From smartphones and wearables to electric vehicles and medical devices, these batteries provide the flexibility and space efficiency needed for innovative products. With companies like Ufine Battery offering customized battery solutions, the future of curved lithium batteries looks incredibly promising. Whether designing the next generation of wearable technology or building electric vehicles, curved lithium batteries offer a robust, adaptable solution to meet the evolving needs of modern industries.

0 notes

Text

DC vs. AC Cooling Fans: The Ultimate Guide to Choosing the Right Option

When selecting cooling fans for your equipment, the choice between DC and AC models is critical. These two types differ significantly in design, performance, cost efficiency, and safety features. Below, we break down everything you need to make an informed decision.

Key Differences Between DC and AC Fans

1.1 How They Work DC fans use compact motors, allowing higher RPM (rotations per minute) in smaller sizes. AC fans rely on bulkier motors with lower RPM, making DC models the clear winner for airflow efficiency in tight spaces.

1.2 Performance Comparison At identical RPMs, DC fans deliver 30-50% greater airflow than AC counterparts. This makes DC ideal for high-heat scenarios like gaming PCs, servers, or industrial machinery requiring robust thermal management.

1.3 Space-Saving Design DC fans' compact build enables seamless integration into space-constrained devices—think laptops, medical equipment, or IoT systems.

Cost Analysis: Short-Term vs. Long-Term Savings

2.1 Upfront Costs DC fans typically cost 20-30% less than AC models due to simpler construction—a budget-friendly choice for startups or small-scale projects.

2.2 Bulk Purchasing Benefits Large-volume buyers see amplified savings with DC fans. Enterprises can slash long-term operational costs by 15-25% through optimized DC fan solutions.

Safety First: Protection Mechanisms

3.1 Circuit Protection Types

Shock-Resistant Chips: Survives reversed polarity but risks overheating. Monitor operating temperatures closely.

Unprotected Chips: Fails instantly if wired incorrectly, posing fire/smoke hazards.

3.2 Pro Safety Tip Opt for polarized connectors (e.g., 4-pin terminal blocks) to prevent miswiring accidents.

Buying Checklist: What Matters Most

4.1 High Airflow Needs Choose DC fans for heat-intensive applications like data centers or EV battery systems.

4.2 Safety Certifications Prioritize fans with UL/CE certifications and built-in surge/overload protection.

4.3 Trusted Brands Reputable manufacturers like Cooltron stand out with: ✅ Higher airflow & pressure ratings ✅ Whisper-quiet operation (as low as 15 dB) ✅ Custom solutions for industries like healthcare, 5G networks, and smart appliances

Why Cooltron Delivers Peace of Mind

5.1 Rigorous Quality Control Every fan undergoes 12+ performance tests, including 72-hour endurance trials and IP68 waterproof validation.

5.2 Lifetime Support Get 24/7 technical assistance and industry-leading warranties.

Final Verdict DC fans dominate in compact, high-performance scenarios, while AC suits basic low-cost needs. For mission-critical applications, prioritize safety-certified DC models from proven brands.

Struggling with thermal management? Discover Cooltron’s tailored cooling solutions at https://www.cooltron.com/ – where innovation meets reliability.

0 notes

Text

Thionyl Chloride Market Tactics: Key Strategies, Trends, and Growth Opportunities Worldwide

Thionyl chloride (SOCl₂) is a crucial chemical reagent widely used in pharmaceuticals, agrochemicals, dyes, and lithium battery electrolytes. With its increasing demand across multiple industries, businesses are adopting innovative market tactics to gain a competitive edge. This article explores key strategies employed by players in the thionyl chloride market, along with trends, challenges, and growth opportunities.

Market Overview

The global thionyl chloride market is experiencing steady growth due to its extensive applications in chemical synthesis and industrial manufacturing. Companies operating in this sector focus on optimizing production processes, securing supply chains, and adopting sustainable practices to stay ahead.

Key Market Tactics

1. Strategic Partnerships and Collaborations

Industry leaders are forming alliances with raw material suppliers, research institutions, and distribution networks to enhance production efficiency and market penetration. Collaborations enable businesses to access advanced technologies and reduce production costs.

2. Expansion into Emerging Markets

The demand for thionyl chloride is rising in developing economies due to rapid industrialization and increasing pharmaceutical manufacturing. Companies are expanding their presence in regions such as Asia-Pacific, Latin America, and the Middle East to tap into new revenue streams.

3. Product Innovation and Differentiation

R&D investments are crucial for developing high-purity and environmentally friendly variants of thionyl chloride. Manufacturers are focusing on low-emission production methods to comply with stringent environmental regulations and enhance product appeal.

4. Pricing Strategies and Cost Optimization

Competitive pricing strategies, bulk production, and cost-effective supply chain management are essential for maintaining profitability. Companies aim to optimize logistics, reduce raw material costs, and implement automation to enhance operational efficiency.

5. Sustainable Manufacturing Practices

Environmental concerns are pushing manufacturers toward sustainable production methods, such as waste recycling and energy-efficient processes. Regulatory compliance and corporate sustainability initiatives are becoming major factors influencing purchasing decisions.

Challenges in the Thionyl Chloride Market

Despite its growth potential, the thionyl chloride market faces several challenges:

Stringent Environmental Regulations: The production and handling of thionyl chloride require compliance with safety and environmental norms, which increases operational costs.

Raw Material Price Volatility: Fluctuations in the cost of raw materials impact profitability and create supply chain disruptions.

Health and Safety Concerns: Thionyl chloride is a hazardous chemical, necessitating strict safety protocols for storage, handling, and transportation.

Future Opportunities

Technological Advancements: Innovations in synthesis and purification processes will improve efficiency and sustainability.

Growing Demand in Lithium Batteries: The expansion of the electric vehicle (EV) industry is boosting the need for lithium battery electrolytes, where thionyl chloride plays a crucial role.

Increased Adoption in Pharmaceuticals: The pharmaceutical sector’s rising demand for active ingredient synthesis presents new market opportunities.

Conclusion

The thionyl chloride market is evolving rapidly, driven by industrial growth, technological advancements, and sustainability initiatives. Companies leveraging strategic partnerships, market expansion, product innovation, and cost optimization will gain a competitive advantage. Despite challenges, the market holds significant growth potential, especially in emerging economies and high-tech industries.

0 notes

Text

Yamaha OEM Spare Parts: Genuine Quality from Smart Parts Exports

Yamaha motorcycles and scooters are known for their durability, performance, and reliability. To maintain the efficiency of your Yamaha vehicle, it's essential to use Yamaha OEM spare parts. At Smart Parts Exports, we ensure that our customers get genuine Yamaha spare parts at competitive wholesale prices.

Why Choose Yamaha OEM Spare Parts?

OEM (Original Equipment Manufacturer) parts are designed to meet the exact specifications of your Yamaha vehicle. Unlike aftermarket parts, Yamaha OEM spare parts guarantee compatibility, reliability, and longevity, ensuring a seamless riding experience.

The Importance of Genuine Yamaha Spare Parts

Using genuine spare parts helps maintain the performance of your Yamaha bike or scooter. Non-OEM parts may compromise safety, fuel efficiency, and overall durability. Yamaha OEM parts are crafted with high-quality materials and tested rigorously for optimal performance.

Wide Range of Yamaha OEM Spare Parts

Smart Parts Exports offers a comprehensive range of Yamaha OEM spare parts, including:

Engine components (pistons, cylinder heads, camshafts)

Electrical parts (batteries, ignition switches, alternators)

Brake and clutch systems (brake pads, clutch plates, master cylinders)

Suspension and body parts (shock absorbers, fairings, fenders)

Filters and lubrication systems (oil filters, fuel filters, air filters)

Why Buy Yamaha OEM Spare Parts from Smart Parts Exports?

At Smart Parts Exports, we prioritize authenticity and quality. We are a trusted global distributor of all brand spare parts and specialize in supplying genuine Yamaha spare parts at wholesale prices.

Benefits of Buying from Smart Parts Exports

100% Genuine OEM Parts – We source directly from Yamaha manufacturers.

Wholesale Pricing – Affordable bulk purchases for distributors and retailers.

Worldwide Shipping – Reliable and fast global delivery services.

Expert Customer Support – Dedicated assistance for all your spare part needs.

Ensuring the Longevity of Your Yamaha Bike

Regular maintenance using Yamaha OEM spare parts significantly extends the life of your vehicle. Replacing worn-out components with genuine Yamaha parts ensures smoother performance and prevents costly repairs in the future.

Avoid Counterfeit Yamaha, Spare Parts

Counterfeit and substandard parts flood the market, often leading to mechanical failures. At Smart Parts Exports, we guarantee authentic Yamaha OEM spare parts, ensuring the highest level of performance and safety.

How to Identify Genuine Yamaha OEM Spare Parts?

Look for the following signs when purchasing Yamaha spare parts:

Yamaha logo and part number on packaging

High-quality material and precise finishing

Hologram or QR code verification for authenticity

Purchase from authorized distributors like Smart Parts Exports

Bulk Purchasing for Yamaha Spare Parts

Whether you are a retailer, distributor, or workshop owner, Smart Parts Exports provides bulk purchasing options at wholesale rates. We cater to businesses worldwide, ensuring a smooth supply chain for Yamaha parts.

The Role of Yamaha OEM Spare Parts in Performance Enhancement

Every component in a Yamaha bike is designed to work harmoniously. Replacing parts with OEM Yamaha spares ensures that the engine, transmission, and braking system function optimally, enhancing overall performance.

Yamaha Motorcycle Accessories and Customization

Apart from essential spare parts, Smart Parts Exports also offers Yamaha accessories, such as:

Performance exhausts

Custom seats and grips

Protective covers and crash guards

Lighting and electrical add-ons

Easy Ordering Process at Smart Parts Exports

Ordering Yamaha OEM spare parts from Smart Parts Exports is simple and hassle-free. Customers can:

Browse our catalog for Yamaha spare parts.

Request a quote for bulk orders.

Get expert guidance from our team.

Receive doorstep delivery anywhere in the world.

Trusted Supplier for Yamaha OEM Spare Parts

With years of experience in the automotive spare parts industry, Smart Parts Exports has built a reputation as a trusted supplier of Yamaha OEM spare parts. Our commitment to quality and customer satisfaction sets us apart.

Contact Smart Parts Exports for Yamaha Spare Parts

If you need genuine Yamaha OEM spare parts, Smart Parts Exports is your go-to supplier. Contact us today for wholesale pricing and worldwide shipping.

0 notes

Text

Platform Weighing Scale in Bharuch – Alexandra Scale Co. For industries that require accurate and durable weighing solutions, Alexandra Scale Co. is a trusted name in Platform Weighing Scales in Bharuch. Designed for industrial, commercial, and warehouse applications, our platform scales ensure high-precision weight measurement for manufacturing, logistics, chemical, and pharmaceutical industries.

Why Choose Our Platform Weighing Scales? ✔ Rugged & Durable Design – Built with heavy-duty steel or stainless steel platforms, ensuring long life and resistance to corrosion. ✔ Advanced Load Cells – Our weighing scales provide stable and accurate readings for various industrial applications. ✔ Multiple Weight Capacities – Available in capacities ranging from 100kg to 5000kg, meeting the needs of light and heavy industries. ✔ Digital Display & User-Friendly Interface – Bright LED/LCD indicators offer clear visibility, even in harsh industrial environments. ✔ Power Backup & Efficiency – Operates on both mains and battery, ensuring uninterrupted weighing operations. ✔ Customization Options – We offer custom-built platform scales as per business requirements.

Industries We Serve in Bharuch: 🔹 Chemical & Pharmaceutical Units – Accurate measurement of raw materials and finished products. 🔹 Manufacturing & Warehousing – Precision weighing for goods and material handling. 🔹 Retail & Distribution – Efficient weight management in wholesale and bulk trade operations.

At Alexandra Scale Co., we deliver high-quality, certified, and reliable platform weighing scales with excellent after-sales service, calibration, and maintenance support. Whether for small-scale businesses or large industries, our platform scales in Bharuch are built for accuracy and efficiency.

🔹 Choose Alexandra Scale Co. – Trusted Weighing Solutions for Every Industry! 🔹

0 notes

Text

Top Tubular Battery Manufacturers in India

🔋 Top Tubular Battery Manufacturers in India – ARM Power Leads the Way! 🇮🇳

Looking for high-performance tall tubular batteries? ARM Power is a trusted name in the industry, delivering:

✅ Longer Backup & Lifespan ✅ Deep Discharge Recovery ✅ Low Maintenance & High Efficiency ✅ Reliable for Solar & Inverter Applications

Power up your home, office, or industry with ARM Power Tubular Batteries – Built for Indian conditions! 🌞⚡

📞 Contact us today for dealership & bulk orders! 📍 Available across India & UAE 🏢 Afghanistan, Dubai , Lebanon, Syria , Turkey and Nigeria 👉 Contact us today for more info and a free quote! 🎯 https://armpower.in/en/blogs/post/top-tubular-battery-manufacturers-in-india/ 📞 Contact us now +91 72173 33585 for a free consultation and find out how easy it is to go solar.

#ARMPower #TubularBattery #PowerBackup #EnergySolutions #MadeInIndia #SolarBattery

0 notes

Text

How Alligator Automations Helps in Reducing Manual Labour Through Technology

Automation has become a core driver of productivity, shifting from a futuristic idea to an essential part of modern industry. Tasks once handled manually, especially repetitive ones, are now managed by intelligent machines, revolutionizing manufacturing, packing, and distribution processes. Alligator Automations is a leader in this shift, delivering cutting-edge solutions that streamline industrial workflows. Imagine a busy factory floor: products moving on conveyors, robots assembling intricate devices, and a synchronized packaging system—all showcasing automation’s potential. This vision of seamless collaboration between humans and machines has now become a reality due to companies like Alligator Automations.

From Humble Beginnings to Industry Leaders

Founded in 2008, Alligator Automations started with competition-based robotics and has evolved into a major player in end-of-line packaging automation. Committed to driving innovation, we provide automated solutions to diverse sectors like automotive, food and beverage, FMCG, agriculture and many more, positioning ourselves as a leader in industrial transformation.

How Alligator Automations Reduces Manual Labour in Key Areas

Advanced Palletizing Systems: Handling heavy palletizing loads manually is labour-intensive and risky. Alligator Automations’ robotic palletizers streamline this process, reducing worker strain and injuries while adapting to varied product shapes and weights. With robotic precision, companies can achieve high palletizing efficiency with minimal labour.

Automated Sorting & Product Handling: Our advanced systems use vision recognition to automate sorting, a valuable feature for industries like food and beverage, chemical, retail and many more, which demand high precision and hygiene. Automation enhances sorting accuracy, reduces manual input, and improves operational speed.

Bulk Material Bagging Solutions: For sectors like agriculture and construction, Alligator’s automated bagging systems manage bulk materials quickly and efficiently, reducing contamination, spillage, and wastage. This enhances productivity and safety on bagging lines, thus reducing manual labour through technology.

Improved Safety & Cost Savings: Automation reduces repetitive tasks and heavy lifting, lowering workplace injuries and labour costs. Alligator’s robotics improve safety and meet industry standards, making the work environment secure and efficient.

Data-Driven Production Insights: Alligator Automations’ IoT-enabled systems track real-time productivity, helping businesses optimize operations and asset maintenance. This AI-driven monitoring minimizes human oversight, ensuring seamless and efficient process control.

Applications Across Industries

Alligator Automations’ solutions cater to diverse industries, from FMCG and food production to warehousing, agriculture to automotive and many more. These automation solutions address unique pain points and labour-intensive tasks in each sector, allowing companies to scale their operations efficiently. For example:

Food & Beverages: Automation solutions like automatic bagging, secondary packaging, and intralogistic conveyor systems ensure compliance with food safety and quality standards.

Cement: Transitioning to automated packaging increases precision and operational speed.

Chemicals & Fertilizers: Safe handling systems reduce risks associated with hazardous materials.

Tyre Industries: Specialized systems streamline tyre manufacturing and handling.

Petrochemical, FMCG, Agro Commodities, Appliances, Automobile, E-commerce, Oil & Paints, Papers & Battery, and Seed industries benefit from enhanced packaging, palletizing, and intralogistics solutions tailored for high efficiency, safety, and reliability in each application.

Embrace Future-Ready Production with Alligator Automations

As labour shortages and operational costs rise, adopting automation becomes not just beneficial but essential. Alligator Automations empowers industries to enhance productivity, safety, and precision. By transitioning to automated systems, companies can significantly cut down on manual labour, streamline processes, and gain a competitive edge in today’s technology-driven market.

For an in-depth assessment and solution tailored to your production line, reach out to Alligator Automations today and explore the future of intelligent, labour-free automation.

#alligator automations#bagging machine#agatha harkness#packaging machine manufacturer#automatic conveyor systems

0 notes

Text

The Ultimate Guide to Buying Nissan Spare Parts Online

The Smart Buyer’s Guide to Nissan Spare Parts Online

Nissan vehicles are known for their reliability, durability, and performance. However, like any other car, they require regular maintenance and occasional replacements to keep them running smoothly. Buying Nissan spare parts online can be a convenient and cost-effective way to ensure your vehicle stays in top condition. In this guide, we’ll explore the benefits of purchasing Nissan spare parts online, what to look for when shopping, and tips to get the best deals.

Why Buy Nissan Spare Parts Online?

Convenience: Shopping for Nissan spare parts online allows you to browse a vast selection from the comfort of your home without the hassle of visiting multiple stores.

Cost-Effective: Online platforms often offer competitive prices, discounts, and promotions that are not available at brick-and-mortar stores.

Authenticity Assurance: Reputable online stores provide genuine OEM (Original Equipment Manufacturer) parts, ensuring the highest quality and compatibility with your vehicle.

Wide Selection: Online marketplaces provide access to a broader range of spare parts, including hard-to-find components for older Nissan models.

Customer Reviews & Ratings: Buying online lets you check customer feedback and ratings to ensure you’re purchasing reliable and high-quality parts.

How to Find the Right Nissan Spare Parts Online

Know Your Vehicle Details: Ensure you have your car’s model, year, and VIN (Vehicle Identification Number) to find the correct parts.

Choose Reputable Sellers: Always buy from trusted online stores, such as authorized Nissan dealers, certified auto parts suppliers, and reputable marketplaces like Bp Auto Spares India and Partsmith.

Check Product Descriptions: Read product descriptions carefully to confirm compatibility and quality.

Compare Prices: Don’t settle for the first price you see. Compare costs across different platforms to get the best deal.

Look for Warranties & Return Policies: Ensure the seller offers warranties and easy return options in case of incorrect or defective parts.

Top Nissan Spare Parts to Buy Online

Brake Pads & Rotors: Essential for maintaining your Nissan’s braking system.

Engine Components: Such as spark plugs, filters, and belts for optimal engine performance.

Suspension & Steering Parts: Ensure smooth and safe handling with quality control arms, bushings, and tie rods.

Lighting & Electrical Parts: Headlights, taillights, and battery components for enhanced visibility and functionality.

Body & Exterior Parts: Replacement bumpers, mirrors, and fenders to maintain your vehicle’s appearance.

Tips for Getting the Best Deals on Nissan Spare Parts Online

Sign Up for Alerts: Subscribe to newsletters from auto parts websites to get notifications on discounts and promotions.

Use Discount Codes & Coupons: Many online stores offer promo codes that can help you save money.

Buy in Bulk: If you need multiple parts, purchasing in bulk can often lower the overall cost.

Check Seasonal Sales: Look out for Black Friday, Cyber Monday, and end-of-season sales for significant discounts.

Conclusion

Buying Nissan spare parts online is an excellent way to maintain your vehicle without breaking the bank. By following the tips and recommendations in this guide, you can ensure that you get high-quality, genuine parts at the best prices. Whether you need essential replacements or performance upgrades, the online marketplace offers endless options to keep your Nissan running smoothly for years to come.

0 notes