#briquette machine manufacturer

Explore tagged Tumblr posts

Text

Explore Innovative Briquetting Solutions with Jay Khodiyar

Looking for reliable briquetting machines? Jay Khodiyar offers advanced briquette machinery, helping industries reduce waste and generate green energy. Visit us to learn more about our cutting-edge technology.

0 notes

Text

LEHRA Fuel: Leading Rotary Drum Dryer Manufacturer in India

LEHRA Fuel, based in India, stands out as a prominent manufacturer of Rotary Drum Dryers, renowned for their cutting-edge technology and efficient performance. With a strong focus on innovation and customer satisfaction, LEHRA Fuel has established itself as a leader in the industry.

Expertise and Innovation: LEHRA Fuel's Rotary Drum Dryers are crafted with precision, incorporating the latest advancements in drying technology. Their team of skilled engineers and technicians ensures that each dryer is manufactured to meet international standards of quality and reliability. The company's innovative approach to design and engineering has resulted in highly efficient and energy-saving dryers.

Customized Solutions: One of the key strengths of LEHRA Fuel is their ability to provide customized solutions tailored to meet specific requirements. Whether it's agricultural products, minerals, biomass, or any other material that needs drying, LEHRA Fuel's Rotary Drum Dryers are designed to handle a wide range of materials efficiently.

Quality Assurance: LEHRA Fuel places great emphasis on quality assurance. Each Rotary Drum Dryer undergoes rigorous testing to ensure flawless performance before it reaches the customer. The company's commitment to quality has earned them a stellar reputation in the market.

Environmental Responsibility: Apart from delivering high-quality dryers, LEHRA Fuel is also dedicated to environmental sustainability. Their dryers are designed to minimize environmental impact by optimizing energy usage and reducing emissions. This eco-friendly approach aligns with global efforts towards a greener future.

Customer Support: LEHRA Fuel's dedication to customer satisfaction doesn’t end with the sale. Their excellent customer support ensures that clients receive timely assistance, be it for installation, maintenance, or troubleshooting. This proactive approach to customer service has fostered strong, long-lasting relationships with clients across India and beyond.

Conclusion: As a leading Rotary Drum Dryer manufacturer in India, LEHRA Fuel stands at the forefront of innovation, quality, and customer service. Their commitment to excellence and environmental responsibility makes them a preferred choice for businesses seeking reliable drying solutions. Choosing LEHRA Fuel ensures not just a dryer, but a partnership built on trust, quality, and innovation.

Call: +91 991 520 0537

Visit Our Website: www.lehrafuel.com/specification/rotary-drum-dryer/

#lehrafuel#rotary drum dryer manufacturers#rotary drum dryer price#rotary drum dryer working principle#rotary dryer manufacturers#rotary dryer manufacturers in india

#rotary drum dryer manufacturers#rotary drum dryer working principle#rotary dryer manufacturers#rotary drum dryer price#rotary dryer manufacturers in india#lehra fuel#briquette machine manufacturer#briquetting machine manufacturer

0 notes

Text

Briquette Machine Manufacturer and Briquetting Machine | Lehra Fuel In the realm of sustainable energy solutions, Lehra Fuel stands as a beacon of innovation and excellence. As a prominent briquette machine manufacturer, the company has carved a remarkable niche for itself by providing state-of-the-art machinery that transforms biomass waste into valuable fuel briquettes. With an unwavering commitment to environmental preservation and resource optimization, Lehra Fuel has become a driving force in the transition towards cleaner energy alternatives. https://lehrafuel.com/

1 note

·

View note

Text

How to Start a Charcoal Business: Complete Guide & Profit Tips

🌟 Turn your business dreams into reality with our step-by-step guide on starting a charcoal manufacturing business! 💼🔥 Don't miss out on this profitable and eco-friendly venture.Follow us for more business hacks and tips! 🚀✨ #Charcoal #Businessideas

Charcoal is created by burning wood or other organic materials in a low-oxygen environment, a process known as pyrolysis. In recent years, there has been a growing demand for charcoal due to its versatile applications in various sectors such as cooking, metallurgy, and pharmaceuticals. India, blessed with abundant forestry resources, offers a lucrative opportunity for entrepreneurs and investors…

#activated charcoal business#charcoal#charcoal briquettes#charcoal briquettes production#charcoal business#charcoal business idea#charcoal business plan#charcoal making machine#charcoal manufacturing business#charcoal press machine#coco charcoal business#coconut shell charcoal#coconut shell charcoal business#how to make charcoal business#how to make charcoal soap for business#how to start a charcoal manufacturing business

0 notes

Text

LS Screw Conveyor: Efficient Material Handling Solution

The LS screw conveyor is widely used for material transport. The name "LS" stands for "screw" and "horizontal" transport. This equipment comes in various diameters, including 100, 160, 200, 250, 315, 400, 500, 630, 800, 1000, and 1250 mm. The maximum length of a single unit can reach 35 meters (30 meters for LS1000 and LS1250). It operates effectively in temperatures ranging from -20℃ to 50℃ and can transport materials at angles less than 20° and temperatures not exceeding 200℃.

Advantages

Simple Structure: The design is compact, and the cross-section is small, leading to lower manufacturing costs.

High Flexibility: It allows for intermediate loading and unloading at multiple locations.

Safe Operation: The design ensures ease of use and safety.

Good Sealing: The cover design effectively isolates materials from the outside, preventing leaks.

Disadvantages

High Power Consumption: Moving materials requires overcoming friction between materials and the casing or screw.

Material Crushing: The screw action may crush materials during transport.

Severe Wear: The screw and casing wear out easily over time.

Due to these pros and cons, the LS screw conveyor suits various powdery, granular, and small block materials, such as coal powder, flour, cement, sand, grains, briquettes, and stones. However, it is not suitable for perishable, sticky, or easily clumping materials since they may stick to the screw and cause operational issues.

Additionally, the effective flow cross-section is small, making it unsuitable for large block materials. To ensure normal operation, maintain a uniform feed to avoid material blockages and overloads.

Installation Requirements

The installation of the screw conveyor must meet the following technical conditions to ensure proper operation:

Foundation Requirements: Complete the foundation at least 20 days before installation for stability.

Parts Inventory: Check all components before installation to ensure nothing is missing and clean them.

Symmetrical Installation: Align the casing and end frames symmetrically in the vertical plane.

Horizontal Alignment: Keep the centerline of the casing consistent in the horizontal plane.

Smooth Connections: Ensure there are no significant height differences at the joint surfaces of adjacent casings.

Stable Base: Secure the base after installation and tighten the corner bolts.

Bearing Support: Ensure the intermediate suspension bearing supports the connecting shaft properly to avoid bending or suspension.

Tight Connections: Tighten all connection screws to a reliable degree.

Lubrication Check: Check the oil level after installation to ensure it is sufficient.

No-Load Testing: Conduct at least 4 hours of no-load testing after installation to observe smooth operation and check for leaks, overheating, or looseness.

Address any issues immediately to ensure proper function.

Operation and Maintenance

The LS screw conveyor transports powdery and small block materials. It often operates in harsh environments, making proper operation and maintenance essential:

Uniform Feeding: Ensure consistent feeding to prevent material blockage and overload. Start Without Material: Start the machine when empty, then add materials.

Stopping Conditions: Only stop the machine after all materials are transported.

Avoid Large Blocks: Prevent hard, large materials from entering to avoid damaging the screw.

Regular Inspections: Check the operational status regularly and ensure all fasteners are secure.

Connection Checks: Pay special attention to bolts connecting the screw pipe flange and the shaft; address any issues promptly.

Safe Operation: Do not remove the cover during operation for safety.

Regular Lubrication: Ensure all moving parts receive regular lubrication.

Daily Maintenance

Perform maintenance at the start of each shift, taking about 10 minutes.

After 720 hours of operation, conduct a primary maintenance check, taking 4 hours.

After 2400 hours of operation, conduct a secondary maintenance check, taking 16 hours.

Use lubricants with the same properties as substitutes. Regularly clean the equipment to ensure the cleanliness of the drive mechanism and other components.

Conclusion

The LS screw conveyor is an efficient material handling device. With proper installation, operation, and maintenance, it can maximize performance and ensure long-term stable operation. For more information or inquiries, please contact us. We are ready to provide you with professional support and services.

0 notes

Text

Burning Bright Bio Briquettes Manufacturers - Shubh Shree Bricks

Shubh Shree Bricks is also known as Bio Briquettes Manufacturers, are an eco-friendly alternative to traditional fossil fuels. These compacted blocks of materials are produced using various agricultural and forestry residues, such as sawdust, agricultural waste, and wood chips. It is play a crucial role in converting these renewable resources into clean and efficient energy sources.

Densification Technologies:It is a leading of machines and equipment. Their state-of-the-art briquetting technology enables the conversion of residues into high-density briquettes with consistent quality and performance. We are offers a wide range of briquetting solutions tailored to meet the specific needs of different industries and applications.

RUF Briquetting Systems:It is a global leader in biomass briquetting technology, offering innovative solutions for biomass waste recycling and energy generation. Their machines are known for their reliability, efficiency, and durability, enabling customers to produce high-quality from various feedstocks. We are used in industries such as agriculture, forestry, and energy production.

C.F. Nielsen: It is a Danish company specialized in the development and manufacture of briquetting solutions and waste materials. We are designed to process a wide range of feedstocks, including straw, rice husks, and paper waste, into compact and energy-dense briquettes. It is technology offers efficient conversion of residues into valuable energy resources, contributing to environmental sustainability and resource conservation.

Briquette Master Indonesia: It is a leading producer of specializing in the manufacture of premium-quality briquettes from sustainable biomass sources. The company's state-of-the-art production facilities and stringent quality control measures ensure consistent product quality and performance. Briquette Master Indonesia's bio briquettes are widely used for heating, cooking, and industrial applications, providing an environmentally friendly alternative to fossil fuels Bio Briquettes Suppliers.

Address : Jaipur:- Pn. 8, Ganesh Vihar-b, T.n. Mishra Marg, Nirman Nagar, Jaipur, 302019

Phone No : +91 9799998880

Email Id : [email protected]

Url : https://www.biomass.co.in/manufacturers/bio-briquettes.html

#Mustard Briquettes Manufacturers#Sawdust Briquettes Manufacturers#Sawdust Pellet Manufacturers#6mm Pellet Manufacturers#Pellet Burner Manufacturers#Non Torrefied Pellets Manufacturers

0 notes

Text

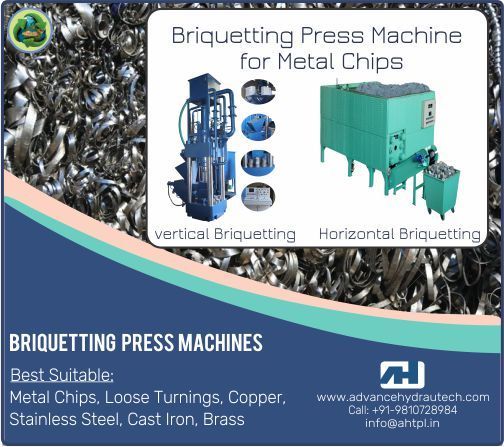

Aluminium Chips Briquetting Machine, Automatic Horizontal Metal Chip Briquetting Press

Our Metal Chip Briquetting machine is designed to turn fine or loose particles and residues into hard, dense briquettes or pucks. The briquetting machines manufacture by Advance Hydrau-Tech is the ideal solution for getting high-quality briquettes from a variety of metals such as steel, aluminium, cast iron, brass, copper, etc. We have vertical and horizontal briquetting machines compacts the metal dust or chips into highly dense and dry briquettes. We are India’s largest manufacturer of scrap processing machines dealing with wide range of recycling machines. Our scrap baler, shear, metal shredder, briquetting, paper baler, automatic balers are widely used and most reliable machines in recycling industries.

youtube

0 notes

Text

Trade deficit improves by 47% in April-September 2023, reaching $39.91 Billion

India's economic landscape showcased notable shifts in trade dynamics for September 2023, with overall exports estimated at $63.84 billion, representing a slight downturn of -1.20% compared to the same period in 2022. Meanwhile, overall imports stood at $68.75 billion, reflecting a more pronounced decrease of -13.67% from September 2022. In terms of merchandise trade, September 2023 witnessed merchandise exports totaling $34.47 billion, a minor dip from $35.39 billion in September 2022. Concurrently, merchandise imports for the same month reached $53.84 billion, notably lower than the $63.37 billion recorded in the previous year. For the period spanning April to September 2023, merchandise exports amounted to $211.40 billion, down from $231.73 billion during April-September 2022. Correspondingly, merchandise imports for the same period were $326.98 billion, compared to $372.56 billion in the prior year. The merchandise trade deficit for April-September 2023 was estimated at $115.58 billion, down from $140.83 billion in April-September 2022. Non-petroleum and non-gems & jewellery exports showed resilience, rising to $24.78 billion in September 2023, surpassing the $24.33 billion recorded in September 2022. Meanwhile, non-petroleum, non-gems & jewellery imports for September 2023 were at $33.58 billion, a decrease from the $38.25 billion in September 2022. From April to September 2023, non-petroleum and non-gems & jewellery exports reached $153.89 billion, compared to $160.25 billion in the prior year. Imports for the same period were recorded at $209.65 billion, down from $224.89 billion in April-September 2022. The services sector presented a mixed picture, with services exports valued at $29.37 billion in September 2023, up from $29.22 billion in September 2022. In contrast, services imports for September 2023 stood at $14.91 billion, a decrease from $16.27 billion in the same month of the previous year. For the April-September 2023 period, services exports reached $164.89 billion, compared to $156.07 billion in the same period of 2022. Meanwhile, services imports for April-September 2023 were $89.22 billion, down from $90.58 billion in the prior year. This contributed to a services trade surplus of $75.67 billion for April-September 2023, compared to $65.49 billion during the same period in 2022. In September 2023, merchandise exports showed varied growth patterns. Notably, 12 of the 30 key sectors exhibited positive growth, including Iron Ore (8054.78%), Oil Meals (72.66%), Ceramic Products & Glassware (50.49%), Cotton Yarn/Fabs./Made-Ups, Handloom Products Etc. (27.39%), Meat, Dairy & Poultry Products (19.4%), Cereal Preparations & Miscellaneous Processed Items (17.65%), Tobacco (9.18%), Drugs & Pharmaceuticals (9.01%), Oil Seeds (8.77%), Carpet (7.51%), Engineering Goods (6.79%), and Marine Products (4.66%). Electronic goods exports saw notable growth, registering a 27.62% increase, with exports amounting to $13.11 billion during April-September 2023, compared to $10.27 billion during April-September 2022. Merchandise imports, on the other hand, encountered a mixed trajectory, with 20 out of 30 key sectors experiencing negative growth in September 2023. These sectors included Silver (-89.94%), Cotton Raw & Waste (-87.68%), Fertilisers, Crude & Manufactured (-61.89%), Sulphur & Unroasted Iron Pyrites (-56.96%), Transport Equipment (-53.15%), Coal, Coke & Briquettes, Etc. (-33.39%), Vegetable Oil (-24.11%), Project Goods (-23.53%), Pearls, Precious & Semi-Precious Stones (-22.49%), Newsprint (-22.4%), Leather & Leather Products (-21.72%), Petroleum, Crude & Products (-20.32%), Wood & Wood Products (-14.71%), Organic & Inorganic Chemicals (-12.89%), Chemical Material & Products (-12.04%), Textile Yarn Fabric, Made-Up Articles (-8.29%), Metaliferrous Ores & Other Minerals (-4.44%), Iron & Steel (-3.25%), Machine Tools (-1.6%), and Pulp And Waste Paper (-0.83%). The period from April to September 2023 saw 13 of the 30 key sectors in merchandise exports exhibiting positive growth, including Iron Ore (128.04%), Oil Meals (41.16%), Electronic Goods (27.62%), Oil Seeds (23.47%), Ceramic Products & Glassware (20.25%), Fruits & Vegetables (10.67%), Tobacco (7.6%), Drugs & Pharmaceuticals (5.02%), Coffee (3.43%), Cereal Preparations & Miscellaneous Processed Items (1.89%), Cotton Yarn/Fabs./Made-Ups, Handloom Products Etc. (1.83%), Spices (1.35%), and Cashew (0.31%). In the merchandise import category, 17 of the 30 key sectors experienced negative growth during April-September 2023, as compared to the same period in 2022. These sectors included Silver (-88.58%), Cotton Raw & Waste (-62.9%), Sulphur & Unroasted Iron Pyrites (-48.62%), Coal, Coke & Briquettes, Etc. (-36.72%), Fertilisers, Crude & Manufactured (-36.25%), Pearls, Precious & Semi-Precious Stones (-25.88%), Organic & Inorganic Chemicals (-25.38%), Vegetable Oil (-23.33%), Petroleum, Crude & Products (-22.81%), Textile Yarn Fabric, Made-Up Articles (-19.62%), Leather & Leather Products (-15.14%), Wood & Wood Products (-12.99%), Fruits & Vegetables (-8.19%), Transport Equipment (-7.7%), Metaliferrous Ores & Other Minerals (-6.76%), Artificial Resins, Plastic Materials, Etc. (-6.37%), and Newsprint (-1.39%). Notably, silver imports registered a significant decrease of 89.94%, falling from $1.06 billion in September 2022 to $0.11 billion in September 2023. Looking ahead, services exports are projected to continue their positive growth trend, with an estimated 5.65% increase during April-September 2023 over the same period in 2022. Overall, India's trade deficit has shown substantial improvement for April-September 2023. Overall trade deficit for April-September 2023* is estimated at USD 39.91 Billion as compared to the deficit of USD 75.34 Billion during April-September 2022, registering a decline of (-) 47.03 percent. Read the full article

0 notes

Text

The Charcoal Briquette Machine's Path to Cleaner Energy

In the realm of sustainable energy solutions, the charcoal briquette machine has emerged as a game-changer, enabling the efficient conversion of biomass materials into valuable charcoal briquettes. This innovative technology holds significant promise for reducing waste, curbing deforestation, and providing an eco-friendly alternative to traditional fuels. At the heart of this transformation is the expertise of briquette manufacturers, who harness the potential of the charcoal briquette machine to drive positive environmental and economic change.

The Charcoal Briquette Machine

The charcoal briquette machine is a specialized piece of equipment designed to convert various forms of biomass, such as wood chips, sawdust, agricultural residues, and even municipal waste, into compact charcoal briquettes. This machine applies pressure and heat to the biomass materials, causing lignin, a natural binding agent present in the biomass, to bind the particles together, forming dense and uniform briquettes.

Advantages of Charcoal Briquettes

1.Sustainable Fuel Source

Charcoal briquettes offer a renewable and sustainable alternative to conventional charcoal and fossil fuels. By utilizing biomass waste, they reduce the demand for non-renewable resources and contribute to responsible resource management.

2.Reduced Greenhouse Gas Emissions

When compared to traditional charcoal production methods, which often involve open burning, the use of a charcoal briquette machine results in significantly lower greenhouse gas emissions. This leads to a reduction in carbon dioxide and other harmful pollutants.

3.Waste Utilization

The machine enables the utilization of various types of biomass waste that would otherwise be discarded or left to decompose, contributing to waste reduction and cleaner environments.

4.Energy Efficiency

The uniform size and density of charcoal briquettes ensure consistent combustion and higher energy efficiency compared to irregularly shaped and less dense biomass materials.

5.Local Economic Growth

The production of charcoal briquettes can stimulate local economies by creating job opportunities in material collection, processing, machine operation, and distribution.

The Role of Briquette Manufacturers

Briquette manufacturers are at the forefront of harnessing the potential of charcoal briquette machines to produce high-quality and eco-friendly fuel. Their expertise and contributions are paramount in this process:

1.Technical Mastery

Briquette manufacturers possess in-depth knowledge of charcoal briquette machine operation, optimizing settings and parameters to achieve efficient production and high-quality briquettes.

2.Material Selection and Preparation

Manufacturers carefully select and prepare biomass materials, ensuring the optimal blend of feedstock for the charcoal briquette machine. This attention to detail influences briquette quality and performance.

3.Quality Assurance

Manufacturers implement rigorous quality control measures to maintain consistent briquette density, size, and combustion characteristics. This ensures that the end product meets the expectations of consumers and industries.

4.Innovation and Research

Manufacturers continually explore innovative binder materials, processing techniques, and machine enhancements to improve the efficiency and environmental impact of the charcoal briquette production process.

5.Market Expansion

Manufacturers play a vital role in raising awareness about the benefits of charcoal briquettes, expanding market reach, and driving demand for this sustainable fuel source.

Conclusion

The charcoal briquette machine stands as a beacon of innovation and progress in the quest for sustainable energy solutions. Its ability to transform biomass waste into valuable charcoal briquettes has far-reaching implications for waste reduction, deforestation mitigation, and climate change mitigation. Briquette manufacturers, with their technical expertise, commitment to quality, and dedication to sustainability, play an instrumental role in realizing the full potential of this technology. As charcoal briquette machines continue to evolve and gain prominence, they hold the power to reshape the energy landscape and drive us towards a greener, more sustainable future, guided by the ingenuity and determination of briquette manufacturers.

0 notes

Text

What Is a Charcoal Making Machine and How Will It Work?

A charcoal making machine uses pyrolyzing technique to turn biomass waste matter into charcoal. The charcoal-making process requires an oxygen-free atmosphere and extremely high temperature. This machine needs raw materials like biomass, including palm shell, sugarcane bagasse, peanut shell, olive shell, sawdust, coconut shell, rice husk, bamboo, and wood, sorted MSW, and sewage sludge. The charcoal produced finds its way into the agricultural, iron, ceramic, and steel industry. Thousands of people in rural areas likewise use charcoal as fuel in order to cook food.

So how exactly does charcoal making machine work?

This charcoal manufacturing plant is made up of two crucial parts: transmission mechanism and briquetting device. The motor's output shaft connects on the reducer's input shaft. However, the speed reducer's output shaft remains close to the main driving chain wheel. This enables the little passive sprocket to connect using the briquetting device's input shaft.

The charcoal-making process has two parts: first involving pressing biomass wood materials into small briquettes. And second, charring the biomass briquettes in a charring kiln.

Step 1

A hammer mill or wood crusher crushes the raw materials into powder or 3 to 5mm pieces. It may help them burn evenly in the next step.

Step Two

A dryer dries the crushed raw materials to make sure they hardly contain any moisture. However, different raw materials could have different moisture requirements. It's best to speak to the equipment manufacturer or talk with specialists prior to the first batch.

Step Three

Next, use the briquetting machine to transform the raw materials into stick briquettes. The biomass briquette's surface gets carbonized throughout the briquetting process. Make sure you retain the high temperature and pressure throughout this step. The inside parts don't get carbonized completely throughout the briquetting process. That's the reasons people call stick briquettes as biomass briquettes.

Step 4

Within the penultimate stage, the biomass charcoal briquettes get carbonized to be final charcoal briquettes. The charcoal making machine features a charcoal kiln that assists to accomplish this transition. Many factories work with a carbonization furnace, but the machine features a similar setting in a tiny space.

The charcoal kiln carbonizes the biomass briquettes thoroughly even though the furnace carbonizes the crushed biomass raw materials. This means you may use the equipment to carbonize raw materials, even while making a wood charcoal briquette line. The carbonization furnace setting chars the last charcoal so it will be ready to be used.

Step 5

The finished charcoal briquettes experience an extensive packing process. You will observe them used in different industries as soon as they appear as finished briquettes.

Features of charcoal making machine

Here are a few features to be aware of before buying a charcoal producing machine:

Low operating cost and high thermal efficiency.

High calorific worth of the gas.

Pollution-free charcoal making system.

Use of cheap raw materials.

Continuous working pattern.

This particular machine can produce a great deal of finished charcoal briquettes daily. You could buy a device in accordance with the amount of charcoal you have to produce daily.

0 notes

Text

What's the matter with the finished product of the ball briquette machine?

The briquette machine equipment can obtain high-quality and environmentally friendly new briquette products by pressing raw materials such as coal powder, coal slime, and cinders. The size of the briquette pellets produced by the briquette machine equipment can be determined and changed in combustion characteristics, and the properties are stable. , which is superior to natural lump coal. At the same time, the porosity of processed briquette pellets is significantly larger than that of natural lump coal, and the gas permeability is better during combustion, so the combustion efficiency is higher. According to the needs of combustion and environmental protection, Adding sulfur-fixing agent and other auxiliary materials in the pressing production of the ball press, not only the combustion performance is improved compared with the raw coal after the pressing, but the smoke and dust emission is also significantly reduced, achieving the effect of environmental protection.

Users who buy the ball briquette machine know that its core part is the forming roller. Today, let’s analyze the phenomenon that the finished product of the ball press machine is not easy to demould:

1. The moisture of the raw material pressed by the ball briquette machine does not reach the standard, and the humidity is too high, which will easily cause material blockage and difficult demoulding. Solution: Control the moisture content to between 8% and 13%. Natural drying or mechanical drying can be used.

2. Does the material enter the ball press machine evenly? If the material is not evenly fed, of course it is not easy to demould. The solution is to use an automatic feeder to feed evenly.

3. The ball socket of the ball pressing machine is too small. The size of the ball socket of the ball pressing machine is also related to the ball output rate of the ball pressing machine. If the ball socket is too small, it is not easy to demould. The solution is that the ball socket is larger than 3 cm.

4. The speed of the ball pressing machine should not be too low. The speed of the ball pressing machine should be between 10-20 revolutions.

5. The quality of the forming roller of the briquette machine is also very important. It is the core part of the entire machine and the premise to ensure smooth briquette production.

When choosing ball press equipment, users should start from their own working performance, aim at solving actual needs, choose the best, and choose the right manufacturer to choose the right price.

If you want to know about more briquette machine informations, you can visit our website: https://www.sinogomine.com/Briquette-Pressing-Machinery/

0 notes

Text

Explore the eco-friendly world of Jay Khodiyar Biomass Briquetting Plant in India. Our advanced technology transforms agricultural and forestry waste into high-quality briquettes, promoting sustainability and profitability. Dive into the benefits and setup processes of our innovative briquetting solutions and join the green revolution today!

#Biomass Briquetting Plant#Eco-Friendly Fuel Alternatives#Agricultural Waste Recycling#Biomass Briquetting Technology#Sustainable Biofuel Production#Biomass Energy Equipment#Biomass to Briquettes Process#Waste to Energy Systems#Briquetting Plant Manufacturer#Biomass Pellet Machine#Biomass Briquetting Benefits#Cost-Effective Heating Solutions#Green Energy Briquettes#Biomass Briquetting Press

0 notes

Text

Your Trusted Briquetting Machine Manufacturer - Lehra Fuel

In the quest for sustainable energy solutions, the role of a Briquetting Machine Manufacturer cannot be understated. These machines are instrumental in converting various waste materials into eco-friendly briquettes, providing an efficient and environmentally responsible alternative to traditional fossil fuels. Among the industry leaders, Lehra Fuel stands out as a name synonymous with innovation, reliability, and commitment to a greener future.

Pioneers in Briquetting Machine Manufacturer

Lehra Fuel is a renowned name in the field of briquetting machine manufacturing. With over two decades of experience, the company has earned its reputation through a combination of cutting-edge technology and a deep commitment to sustainability. Here’s why Lehra Fuel is the preferred choice for businesses and organizations looking for briquetting solutions:

1. State-of-the-Art Technology: Lehra Fuel takes pride in its modern manufacturing facilities equipped with the latest technology. This ensures that their briquetting machines are not only efficient but also highly durable, delivering consistent performance over time. 2. Customization: Recognizing that different materials require specific processing, Lehra Fuel offers a range of briquetting machines tailored to meet various needs. Whether it’s agricultural residues, wood waste, or any other biomass material, they have a solution to suit your requirements. 3. Sustainability: Lehra Fuel’s briquetting machines play a pivotal role in reducing waste and minimizing the carbon footprint. By transforming waste materials into briquettes, these machines contribute to a cleaner environment while providing a valuable source of energy. 4. Energy Efficiency: Lehra Fuel’s briquetting machines are designed to maximize energy efficiency. They ensure minimal energy consumption while delivering high-quality briquettes, making them a cost-effective and eco-friendly choice. 5. Robust Customer Support: Beyond the sale of machines, Lehra Fuel offers exceptional customer support. Their team of experts is readily available to provide guidance, technical assistance, and maintenance services, ensuring that your investment continues to perform optimally. 6. International Presence: Lehra Fuel’s commitment to sustainable energy has transcended borders. They export their briquetting machines worldwide, making a positive impact on a global scale. 7. Innovative Solutions: In an ever-evolving industry, Lehra Fuel keeps pace with innovation. They continually refine their briquetting machines, incorporating the latest advancements to stay at the forefront of the industry.

Conclusion

As the world grapples with environmental challenges, the role of a reliable Briquetting Machine Manufacturer like Lehra Fuel becomes increasingly important. Their commitment to sustainability, technological prowess, and customer-centric approach make them a trusted partner in the journey towards a greener and more sustainable future. Whether you’re in agriculture, forestry, or any industry generating biomass waste, Lehra Fuel’s briquetting machines can help you reduce waste, save on energy costs, and contribute to a cleaner planet. Choose Lehra Fuel and join the movement towards a more sustainable and eco-friendly energy solution.

Call: +91 991 520 0537

#Briquette Machine Manufacturer#Briquetting Machine Manufacturer#Briquetting Machine#Briquette Machine#BRIQUETTING#Biomass Briquetting#LehraFuel

0 notes

Text

Coco peat manufacturing involves a multi-step production process that begins with the collection and harvesting of coconut husks. These husks are then processed through a series of machines that remove the long fibers, leaving behind the coco peat material. ~ The coco peat is then washed and screened to remove any impurities and graded based on its texture and quality. It is then dried under controlled conditions to ensure that it retains its high moisture retention capacity. ~ Once dried, the coco peat is compressed into various shapes and sizes using specialized machines. These compressed blocks or briquettes are then packaged and prepared for shipping to various markets around the world. ~ Throughout the entire production process, strict quality control measures are implemented to ensure that the final product meets the highest standards of quality and consistency. From start to finish, the manufacturing of coco peat requires careful attention to detail and a commitment to sustainability and environmental responsibility. ~ Contact Us :- WhatsApp : +91 8838166448 (or) https://wa.me/918838166448 Website : www.coastalcoirs.com Mail : [email protected]

#coco coir#coir pith#coco peat#pith blocks#growing soil#garden soil#compost#soilless#production process#manufacturer#importers#exporter#supplier#business#garden supplies#horticulture#hydroponics#hydroponics supplies

0 notes

Text

How to Start Biomass Briquettes Business

Biomass briquettes are solid biofuels made from compressed organic matter like agricultural, forestry, or industrial waste. In recent years, the demand for alternative energy sources has surged globally, with a growing emphasis on sustainable and eco-friendly solutions. So, biomass briquettes, have emerged as a promising substitute for traditional fuels like coal and wood. Biomass briquettes are…

View On WordPress

#biomass briquette machine#biomass briquette plant#biomass briquettes#biomass briquettes business#biomass briquettes business in india#biomass briquettes business plan#biomass briquettes manufacturing business#biomass briquettes production process#how to start biomass briquettes business#new business idea#sawdust briquette machine#small business ideas#start biomass briquettes business

0 notes

Text

Fine Crusher Sand Making Machine factory

Fine Crusher Sand Making Machine factory Our Factory Zhengzhou Hengxing Heavy Equipment Co.锛孡td is a joint stock corporation integrating with research, manufacture and sale which targeted at the large and medium sized series of heavy equipments. Our main products are stone crushing machines, sand making machine ,ball mill machine ,mineral ore dressing machines, rotary dryer,rotary kiln, AAC block making machine,coal briquetting machine,which were widely used in mineral processing and construction industry. Our company is located at the National High-Tech Development Zone in Zhengzhou city, Henan province. Since the establishment of our company, a passel of scientific elites has been gathered with our modernized management system and accurate product positioning. Our company has set up the computer information-based management with production, CAD and CAPP on production research and processing design. Besides, our company has been equipped with powerful machines and equipments for machining, forging, rivet welding, carburization heat processing. With the long term cooperative relationship to the research institutes at home and abroad, we have introduced advanced technology, processing and detecting equipment for the development of the new products and promotion of our workmanship. We adhere "survive on high quality, develope by good credit" as the guideline of our company on the market development and consumer service. We have got good social reputation, economic benefits and the approval of the ISO9001-2000 Certificate of Registration, Our products have marketed very well at home and abroad markets and got a very high appraisement from our clients. Our Product Stone crushers Ball mill Sand making &sand washing machine Ore beneficiation equipment Rotary dryer &rotary kiln Coal briquette equipment AAC Block Making Machine Product Application Mining, Water conservancy, quarry plant, coal briquetting, building Our Certificate ISO锛孋E Production Equipment Vertical Lathe Boring Machine Milling machine Gear processing machine Our Service 鈼哖re-Sales Service 1. Inquiry and consulting support. 2. Pre-sale service:Freely provide project designing, process designing, choosing suitable equipment for you. 3. View our Factory.Field trips to sell products. 鈼哋n-sale Service: develop appropriate equipment solutions for users 鈼咥fter-Sales Service 1. After acceptance of the equipment, we will draft the construction program and detailed process, and complete the export process 2. After-sales service: We sent engineer to the scene to guide installation, debugging and training operators.Fine Crusher Sand Making Machine factory website:http://www.crushers-china.net/

0 notes